1. Introduction

The deep drawing process, a widely used manufacturing technique in industries ranging from the automotive to consumer goods, involves the transformation of flat sheet metal into three-dimensional shapes through the application of mechanical force [

1]. Key factors influencing the success of deep drawing include the geometry of the parts involved, material properties such as hardness and surface finish, lubrication, blank holder force, and process parameters such as the draw ratio and strain distribution [

2].

Manufacturing deep drawing dies via conventional methods entails significant costs, primarily attributed to materials, labour, and machining processes. The largest portion of the cost is often associated with the materials required for constructing the die, which typically consists of high-strength tool steels or other specialised materials capable of withstanding the high pressures and repetitive stresses involved in the deep drawing process [

3,

4]. Additionally, skilled labour is necessary for the design, machining, and assembly of the die components, contributing to the overall manufacturing cost [

5].

The economies of scale associated with mass production allow the upfront costs of die manufacturing to be spread across a large number of parts, resulting in a lower per-unit cost [

3,

4,

5,

6]. This cost efficiency is particularly advantageous for industries that require large quantities of identical or similar parts, such as automotive or appliance manufacturing [

4].

Furthermore, the lifespan of a deep drawing die is a critical factor in assessing its cost-effectiveness. With proper maintenance and periodic refurbishment, deep drawing dies can last for a significant number of production cycles, ranging from tens of thousands to hundreds of thousands of parts [

2], depending on factors such as material selection, die design, and operating conditions.

Conventionally, the manufacturing of stamping devices is performed using metal, and through a multitude of possible operations, processed materials, and variations in the thickness of the blank, it has led to the development of a wide range of specialised alloys to keep up with mechanical demands [

6]. So, choosing the right material becomes a significant aspect, especially in the current industry context, where the cost of production tends to be minimised [

7].

However, while deep drawing dies offer significant cost advantages for high-volume production scenarios, their efficiency diminishes for low-batch or bespoke production runs [

3,

4,

5]. In such cases, the upfront costs associated with die manufacturing may outweigh the benefits of mass production economics. The high initial investment in die design and fabrication becomes less financially viable when spread across a limited number of parts, resulting in a higher per-unit cost for each component produced. Furthermore, the extended lifespan of deep drawing dies may pose a challenge in low-batch production scenarios. The fixed costs of die maintenance, storage, and refurbishment remain constant regardless of the production volume, leading to a higher cost per part for smaller production runs. Additionally, the lead time associated with die manufacturing and setup further exacerbates the financial inefficiencies of low-batch production. The time and resources required for die design, machining, and validation may lead to prolonged production cycles and increased production costs for small quantities of parts. As a result, the cost-effectiveness of deep drawing dies diminishes for low-batch or bespoke production scenarios, where the economies of scale associated with mass production cannot be fully realised.

In recent years, the Additive Manufacturing (AM) industry has undergone significant advancement, driven by forecasts of reduced production costs and manufacturing times, as well as the proliferation of available materials for processing. This convergence of factors has opened doors for the widespread implementation of AM technology across various fields. Consequently, the exploration of integrating AM technology into sheet metal-processing industries has emerged as a novel alternative, garnering increasing attention for its potential applications.

The exploration of stamping dies fabricated by means of the AM concept has garnered attention from multiple researchers in recent times, with the preliminary findings showing promising results [

8].

Attempts to manufacture a metal die made through the Selective Laser Sintering (SLS) and Sheet Lamination methods have concluded that this, although possible, is not justified by the production and post-processing costs [

9,

10].

Researchers in the field have turned their attention to Material Extrusion (MEX) as a manufacturing process for stamping devices due to its widespread use and accessibility. Attempts have been made to obtain embossing or bending devices using different polymers, with results that vary depending on the thickness of the processed sheet metal or the metal from which it was made.

Grigoraș et al. [

11] highlighted the advantages of using AM to produce polymer dies, noting the reduced production costs and shorter manufacturing times compared to traditional metal dies. Specifically, they investigated stretch forming using dies with components 3D printed from polylactic acid (PLA). The experiments utilised six punches, varying in radius from 180 mm to 1080 mm in increments of 180 mm, to stretch aluminium 2024-T0 sheet metal strips, a material commonly used for aircraft skins. Besides evaluating the shape of the resulting parts, the study also examines other process parameters such as punch force, part radius, and deviation from circularity.

Giorleo et al. [

12] explore the advantages of using AM to produce punches for the deep drawing process. The study analyses various process parameters, including the punch fillet radius, blank material, drawing ratio, and drawing depth, to determine the optimal conditions for deep drawing using MEX-produced punches. The findings indicate that the best results were achieved when drawing aluminium blanks with a drawing ratio of 1.8.

Building on this work, Alan et al. [

13] investigated the use of AM technology for producing stretch forming tools used in the low-volume production of double-curvature panels, particularly in the architectural cladding and aerospace sectors. The study demonstrates the feasibility of creating a large tool by assembling smaller, printed hollow sections using FDM technology. Additionally, the research includes a comparison of the springback and surface strains between experimental trials and forming process simulations modelled in PAMSTAMP. It is particularly notable that the anticlastic tooling solution produced with 3D printing exhibited significantly lower springback, attributed to the interaction of longitudinal and transverse residual stresses.

Further studies by Madhura et al. [

14] examined the viability of using AM polymer composite tooling in the automotive industry. The study employs both experimental and numerical methods to assess the performance of glass fibre-reinforced polycarbonate (GF-PC) AM polymer tooling for stamping 1.5 mm thick HSS 590 steel sheets. The experimental phase involved conducting sheet metal stamping tests with GF-PC tooling, and evaluating its performance based on tool deformation and the accuracy of the stamped parts. Complementing the experiments, finite element simulations of the stamping process were performed, accurately replicating the observed tool deformations by incorporating anisotropic material models. These simulations also proved effective in optimising the process parameters to achieve the desired final part geometry. The findings indicate that GF-PC AM polymer composite tooling is well-suited for low-volume production.

Similarly, Nakamura et al. [

15] investigated the feasibility of using plastic tools, created via MEX, in sheet metal forming processes. Both aluminium and steel sheets were subjected to V-bending and deep drawing using these plastic tools. The study found that the dimensional accuracy of sheets bent with plastic tools was inferior to that achieved with steel tools, primarily due to the lower stiffness of the plastic. This accuracy further declined with an increase in the flow stress of the sheet material. To address this issue, the stiffness of the plastic tools was enhanced by reinforcing them with steel bars, resulting in the improved dimensional accuracy of the bent sheets. Additionally, modifications to the tool shapes effectively corrected for both the springback of the sheets and the elastic deformation of the plastic tools. The research also explored the deep drawability of a cylindrical cup using a plastic die, demonstrating the practical applications and potential adjustments required for plastic tooling in metal forming processes.

In a related study, Nakamura et al. [

16] examined the application of plastic punches and dies, produced via the MEX process, for the V-bending of sheet metals. The research highlights the advantages of plastic tools in terms of a lower production time and cost compared to traditional steel tools, despite the significantly lower yield stress and Young’s modulus of plastic. The study examines the dimensional accuracy of bent sheets produced using these plastic tools. To enhance the accuracy, a combination of a steel punch and a plastic die was tested. The findings reveal that while the plastic tools experience substantial elastic deformation during the forming process, the springback effect is nearly identical to that observed with steel tools. This suggests that plastic tools, despite their limitations, are effective for bending sheet metals.

Additionally, Geuke et al. [

17] explored the evolution from the traditional subtractive manufacturing of dies for sheet metal forming to the emerging field of AM for tooling applications. Their research evaluates the deformation and wear characteristics of an optimised AM tool during a drawing operation using a low batch size of automotive-grade sheet material. Comparative analyses are conducted between the performance of the bio-based polymer AM tool, a solid AM die approach, and a conventionally manufactured tool. This investigation underscores the potential of AM in achieving sustainable, cost-effective tooling solutions tailored for product individualisation and small batch series production, thereby contributing to advancements in manufacturing efficiency and economic viability.

Furthermore, Tondini et al. [

18] investigated the viability of additively manufactured polymer tools for metal forming applications, particularly in scenarios involving small production volumes. The study begins by detailing the materials, printing strategies, and accuracy considerations for these tools. The experimental evaluations focus on the V-bending and groove pressing of 1 mm aluminium sheets using the printed tools.

In V-bending, the tools exhibit an evolving surface topography during the initial strokes, stabilising after approximately five cycles. Geometrical accuracy is assessed through parameters such as springback angle and bend radius, with the findings highlighting the influence of elastic deflection in the tools and the impact of punch nose radius variation. The study underscores the role of the printing strategy, particularly in managing the ratio between the tool radius and the thickness of the printed solid shell relative to the less dense bulk part.

Groove pressing experiments illustrate how groove heights and angular changes due to springback affect part accuracy, emphasising the importance of tool corrections to achieve closer conformity to the nominal values. Throughout the research, repeatability is a key consideration, demonstrating the potential for iterative adjustments in tool design to enhance formed part precision.

In agreement with these results, Giorleo et al. [

19] showed the application of rapid tooling in forming processes, focusing on plastic punches designed for industrial-scale applications. The study addresses the challenge of adapting Additive Manufacturing to produce tools suitable for small- to medium-sized batch production. Specifically, the research investigates the performance of plastic punches in a deep drawing process using AISI 304 blanks to manufacture cups.

Both experimental and numerical analyses are employed to evaluate the quality of the cups and the behaviour of the plastic punches. The key findings indicate that larger punch dimensions correlate with the improved geometric precision of the cups, achieving high fidelity to the drawing depth (99%), cup precision on the fillet radius (98%), and a minimal roundness error (0.53%). These results highlight the potential of plastic punches manufactured through rapid tooling for enhancing the accuracy and reliability of forming operations in industrial settings.

In agreement with these results, Günther et al. [

20] focused on the application of additively manufactured functional elements within deep drawing tools. Their study introduces the initial concept of these tools and details the experimental test series conducted to validate their performance. This includes an analysis of how these tools enhance the production feasibility of deep drawn parts under conditions of small batch production, aiming to bridge the gap between traditional tooling costs and the flexibility required in modern automotive manufacturing.

Although some studies have shown that, in certain circumstances, the process is not feasible, the general outcomes of processes utilising polymer-based devices and methods demonstrate the efficacy of this method in terms of both financial considerations and manufacturing duration. Despite these advancements, challenges remain in optimising the design for improving the resulting parts’ tolerances. According to Ismail et al. [

21], further research is needed to address issues related to a dimensional accuracy that deteriorates significantly due to the squeezing of MEX layers after repeated stamping cycles. This gap in the literature underscores the need for continued investigation into polymer materials and their application in die manufacturing. This paper aims to demonstrate theoretically the feasibility of using polymer-based additively manufactured stamping devices instead of traditional metal ones for small batches of products and the influence of different polymers on the dimensional precision of the part products made by them. The authors are using a preliminary finite element model in order to prove such a feasibility from a theoretical point of view.

3. Result

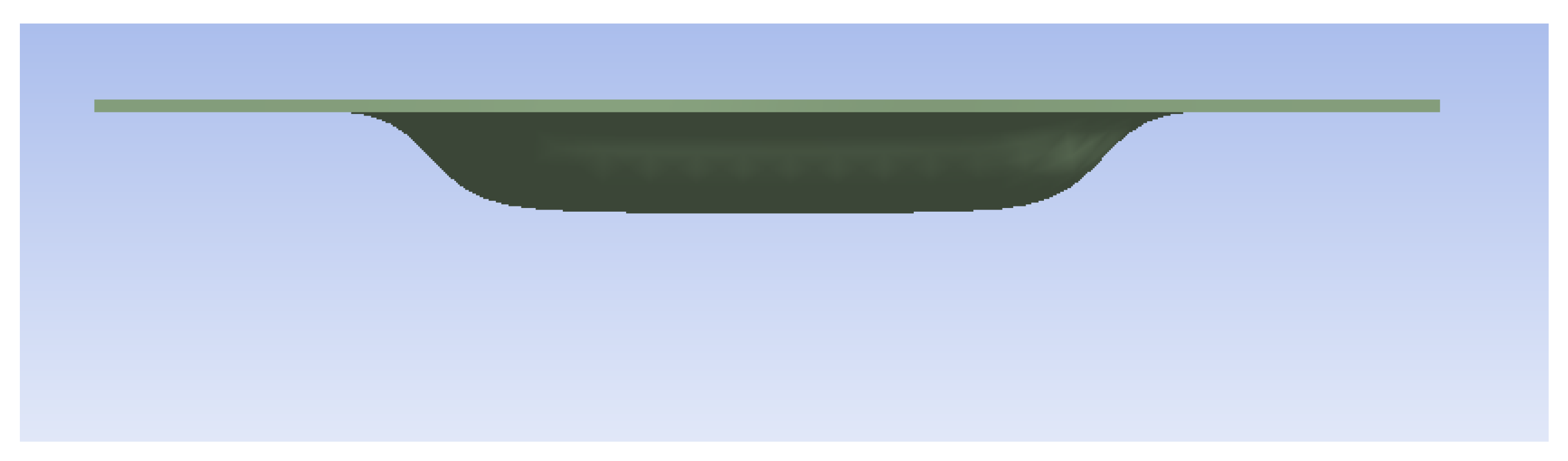

Several simulations were carried out, where five devices made of different materials were tested, performing a deep drawing process on four metal sheets of different thicknesses. In total, 20 simulations were completed, and their results were centralised and then compared.

Using the results provided by total deformation, the resulting part dimension can be established.

The determination of the critical dimensions of the parts was carried out on the models in the STL format of the resulting part. Thus, the connection radii were measured, along with the angle of incidence of the part wall (see

Figure 6). The dimensions thus measured were compared with the table General Tolerances to DIN ISO 2768-mk [

25] to determine the influence of the material of the device on the tolerances of the parts.

According to ISO 2768-mk [

25], each dimension without tolerance values is assigned a set of general tolerances depending on the desired precision. Thus, the general tolerances for linear and angular dimensions that are classified in four accuracy categories—f (fine), m (medium), c (coarse), and v (very coarse)—were collected for the dimensions of interest (

Table 4,

Table 5 and

Table 6). This was done to have a reference regarding the tolerances offered by the dies made of different polymers.

The desired length of the W dimension is 10 mm, and this represents the height of the part. A negative deviation from this translates into the insufficient compression resistance of the stamping die.

The desired size of the X dimension is 3 mm and that of the Y dimension is 2 mm + the sheet thickness. These are the connecting radii of the part, and a positive deviation from this translates into a high elasticity coefficient of the material of the stamping die.

The Z dimension should be as close as possible to the value of a right angle (90°), and its increase represents the weak resistance of the device to the compression forces involved in the processing of the material.

Coarse deviations can be noticed in the case of parts resulting from devices made of polymers by comparison with those made from classic devices (

Table 7). However, these linear deviations are small and can be corrected during the design process of the device. Angular deviations are more significant, PLA and PET being the materials that most satisfy these conditions.

As in the case of the 0.25 mm plate processing devices, coarse deviations for linear dimensions can also be observed here (

Table 8). Also, for angular dimensions, the devices made of PLA and PET showed the best behaviour.

A thickness of 0.75 mm for the processed sheet raises problems for the devices made of ABS and Nylon (

Table 9), because the tolerances offered are no longer found in the ISO standard, and the resulting parts may be classified as non-compliant. In the case of devices made of PLA and PET, the tolerances offered tend to become very coarse.

A thickness of 1 mm pushes the resistance of devices made of ABS and Nylon to their limit (

Table 10), the resulting parts being categorically non-compliant with the proposed requirements (

Figure 7). Also, devices made of PLA and PET make parts deemed as inappropriate; the only device capable of making compliant parts is the one made of steel (

Figure 8).

Differences can be observed between the parts obtained on conventionally made devices and the parts obtained on devices made of polymers.

Thus, an initial comparison is made (

Table 11), where the biggest differences are highlighted between the results obtained by means of polymer devices compared to those made conventionally.

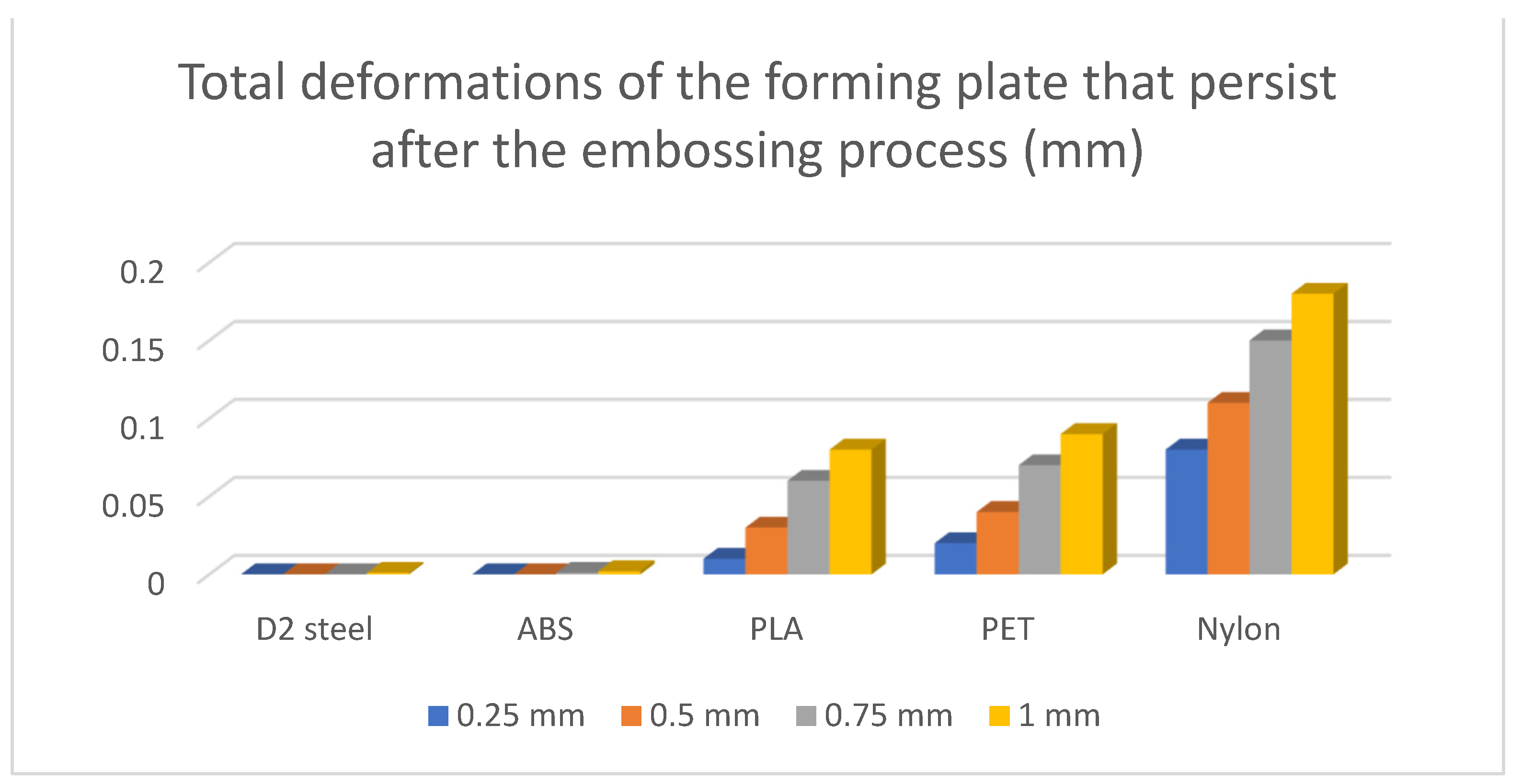

Using the results provided by total deformation, the impact of the displacements on different parts of the die during and after the deep drawing process can be determined.

The remaining deformations in the forming plate will be translated as deviations from the desired shape of the next processed part—implicitly, the capacity of reusing the device a second time.

The results provided by equivalent stress underline the capacity of the devices to withstand the process, depending on the material from which they are manufactured and the loads to which they are subjected. In FEA, equivalent stress, often referred to as von Mises stress, is a scalar value used to predict the yielding of materials under complex loading conditions. It is derived from the stress state at a point and provides a single value that reflects the combined effect of all the individual stress components (normal and shear stresses) acting on the material. This measure is crucial in assessing whether the parts manufactured of different materials will yield or fail when subjected to the applied loads. If the equivalent stress at any point in the part exceeds the material’s yield strength, yielding is expected to occur at that point. This indicates potential failure or permanent deformation.

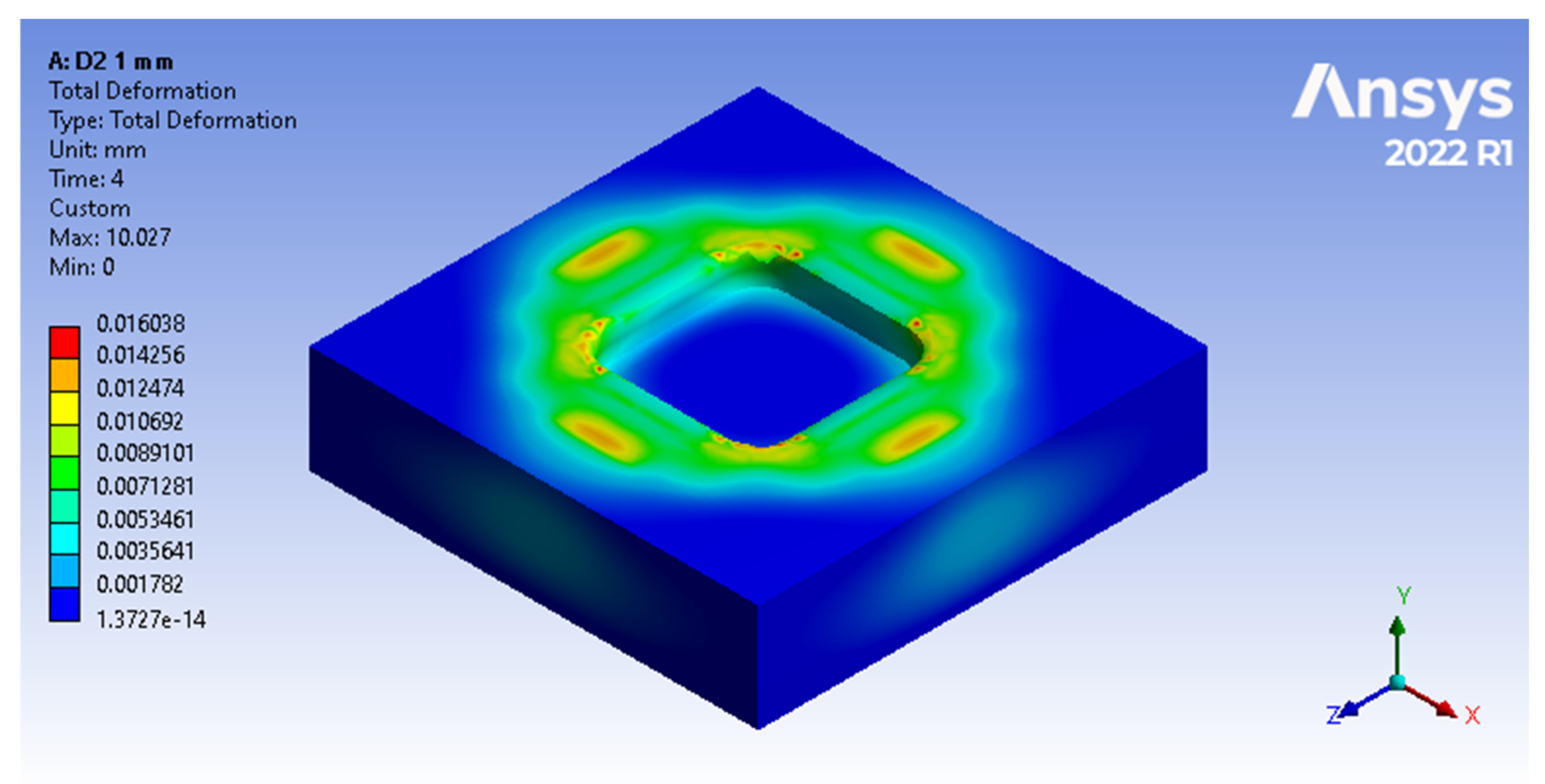

For the results captured through total deformations (

Figure 9 and

Figure 10), the material displacements in the device are showcased by a colour gradient, where the largest material displacements are indicated with a red colour and the unaffected areas are indicated in blue.

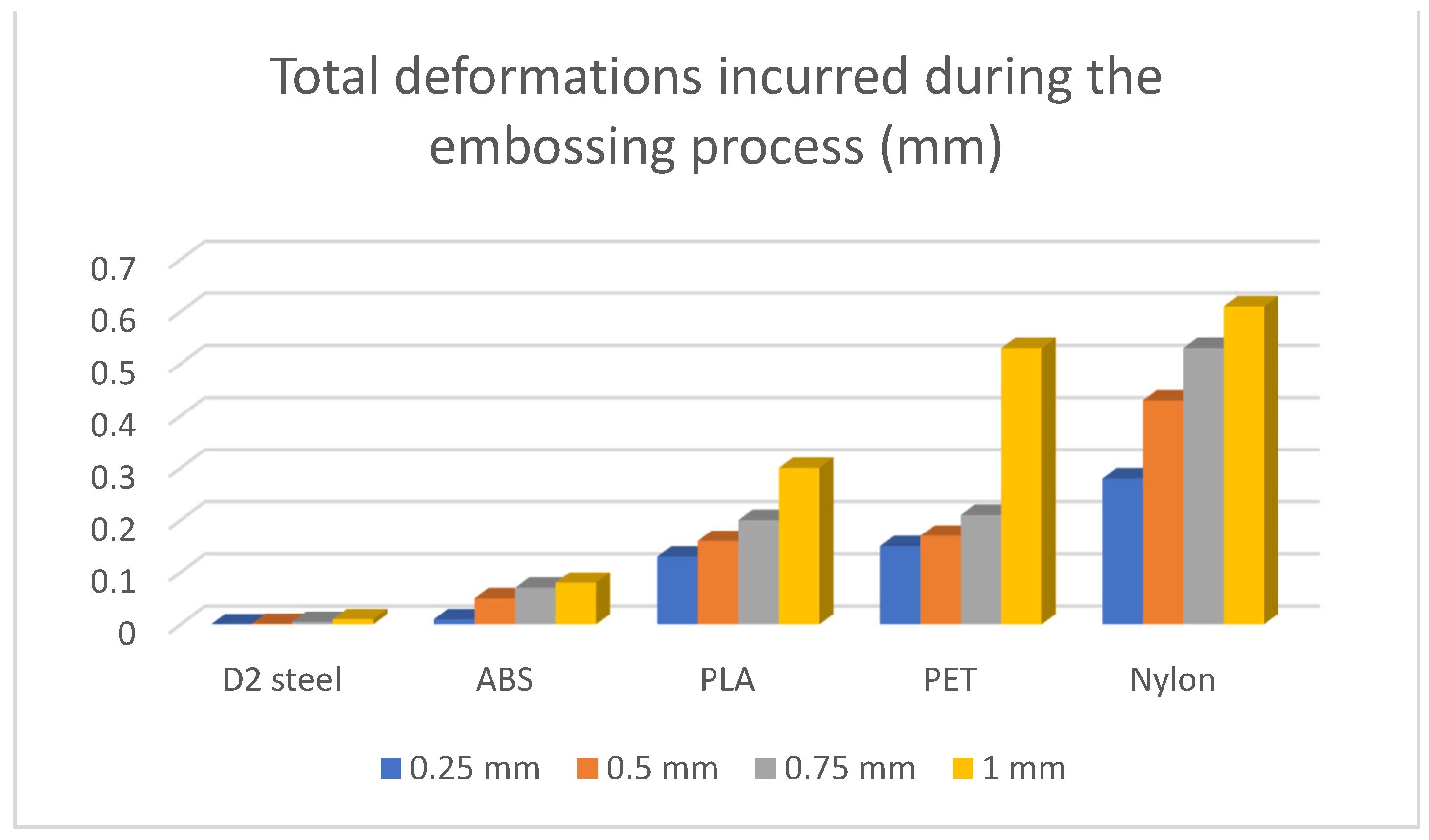

The results of the simulations are summarised (

Table 12 and

Table 13,

Figure 11 and

Figure 12) in the form of the highest indicated value based on the type of material and the thickness of the processed sheet.

In

Figure 9, it can be observed how the tension concentrates at the radii of the forming plate, and how this is the most affected area. For a similar analysis between devices made of different materials, the measuring area is chosen as the straight area between them, as that determines the gauge dimensions of the part. It is also worth mentioning that the results highlight the propagation of stresses along and in the depth of the plate.

A series of events can be observed such as that the devices made of steel show an insignificant deformability in the process of embossing metal sheets. It is also possible to observe the good behaviour of the devices made by MEX, results that allow one to use such devices in the embossing process.

These deformations are imprinted on the part, and they influence deviations from its imposed external dimension.

The result of the analysis shows which are the most affected areas of the forming plate (

Figure 10) by compression following the embossing process.

The return to the initial shape of devices made of ABS presents a similar characteristic to that of devices made conventionally. A similarity of the behaviour is also observed between the devices made of PLA and PET, while the devices made of Nylon show the weakest characteristic of returning to the initial shape.

These deformations are imprinted to the next part that will be processed on it. With these results, we can determine the mechanical characteristics of the devices, such as their ability to process a larger number of parts or their life cycle.

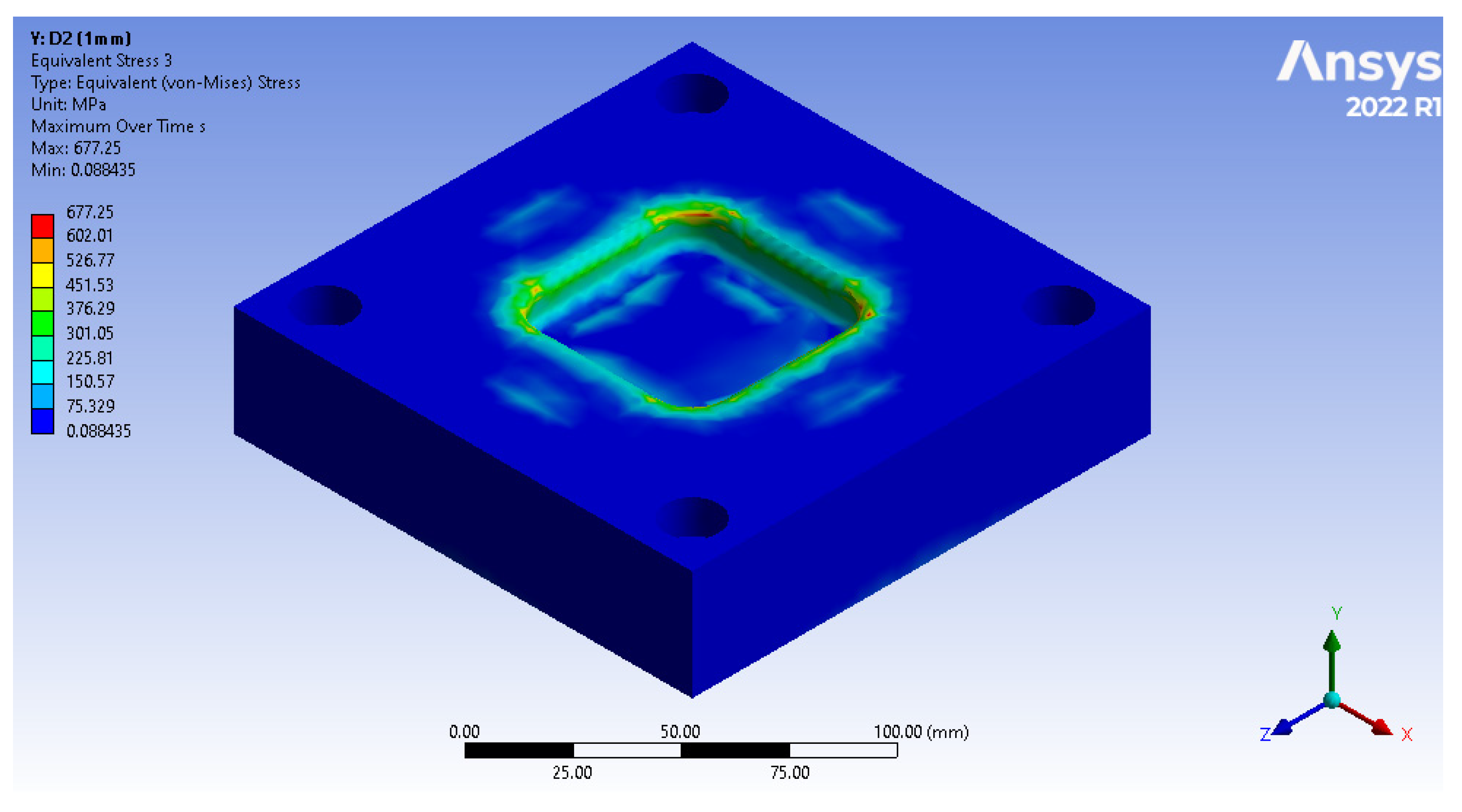

For the results captured through equivalent stress (

Figure 13), the highest stress of one of the principal directions for each element is illustrated through a chromatic spectrum, where blue represents the areas that store the lowest stress. The stress increases progressively, altering the colour gradually, depending on its intensity. The red colour marks the areas where the greatest concentration of forces is found, as well as the areas most susceptible to failure due to mechanical forces.

The details regarding the mechanical properties of the materials (

Table 14) were taken from the Ansys Workbench database, and they will be compared with the nominal values obtained during the analysis.

Following the preliminary results (

Table 15), the devices made of PLA, PET, and Nylon present an equivalent stress that exceeds the tensile yield stress; however, those areas are found in a narrow area of the device. This can translate into irreparable deformations of certain areas at the corners of the device. This phenomenon is predictable and occurs at the first embossing of the device, the following cycles not affecting the condition of the die in a significant way [

15,

20].

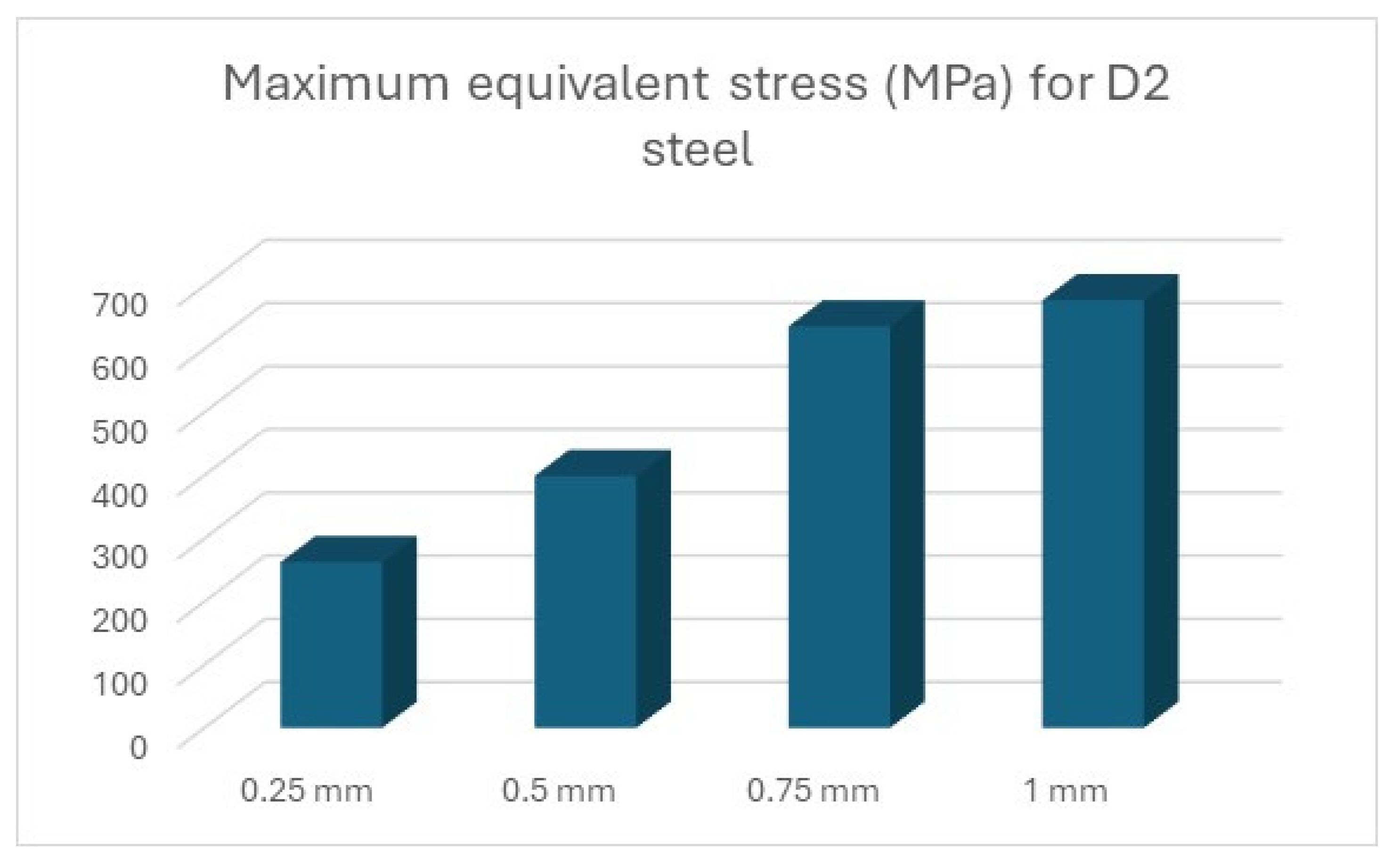

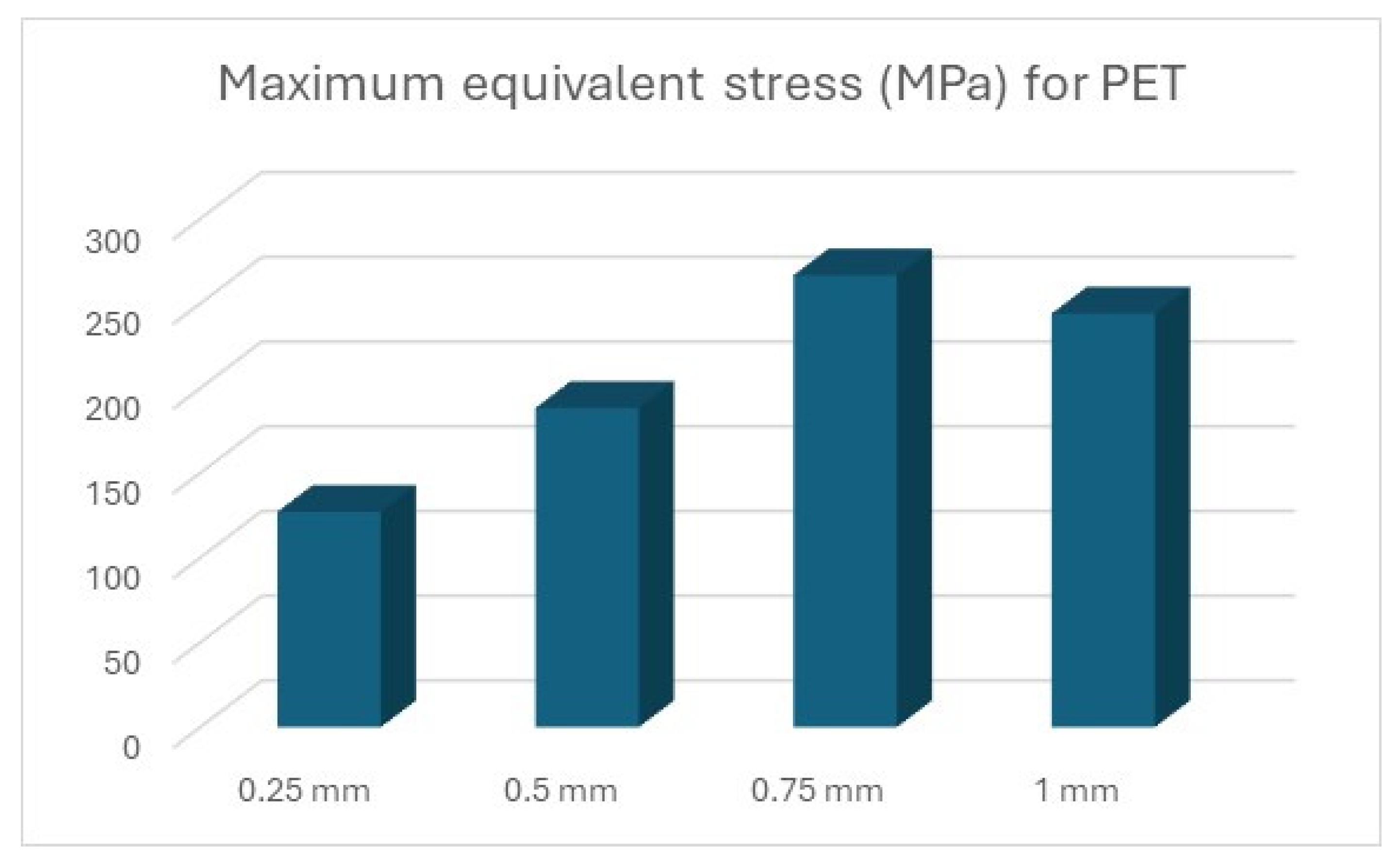

Thus, the graphic representation of the maximum equivalent stress for the devices was completed, where the equivalent stress that appears in the forming plate during the processing of sheets of different thicknesses can be observed and compared to the stress that can be seen in the forming plate made of steel (

Figure 14).

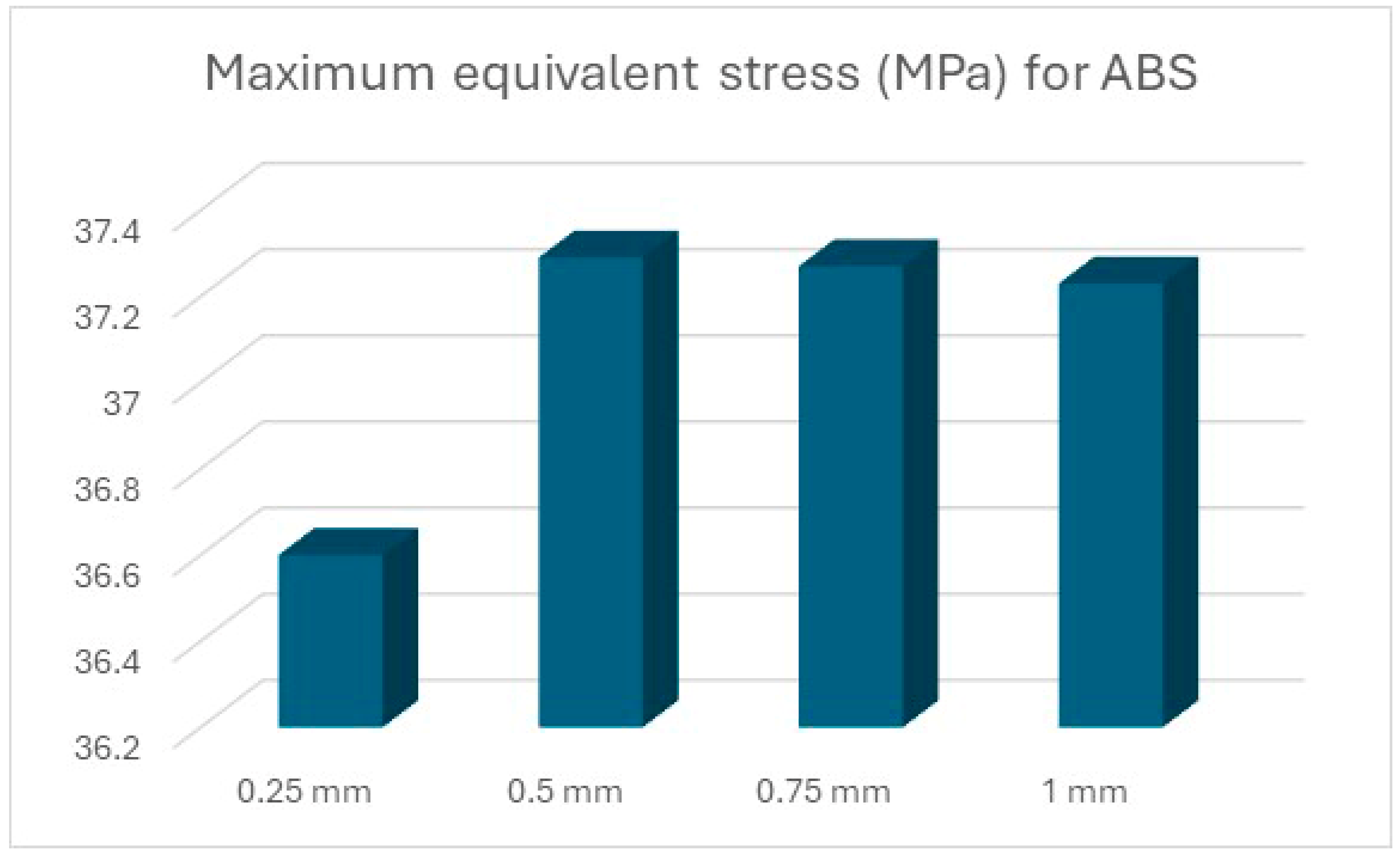

In the case of the devices made through the AM process, the lowest stress area can be found in the parts made of ABS (

Figure 15). This material showed a limit behaviour even for thin sheet metalprocessing applications, with a stress value close to the stress limit. The stress varies slowly in respect to the shell thickness. For this material, a bilinear hardening model was employed. Bilinear isotropic hardening is a material model which allows the progressive expansion of the elastic limit. The yield strength increases as plastic deformations occur [

26]. Another problem with ABS is that the material is time-dependent, both in elasticity and plasticity [

27]. Although ABS proved to have the best behaviour regarding the handling of equivalent stress, further investigations are required for the acceptance of this material as punch or die parts.

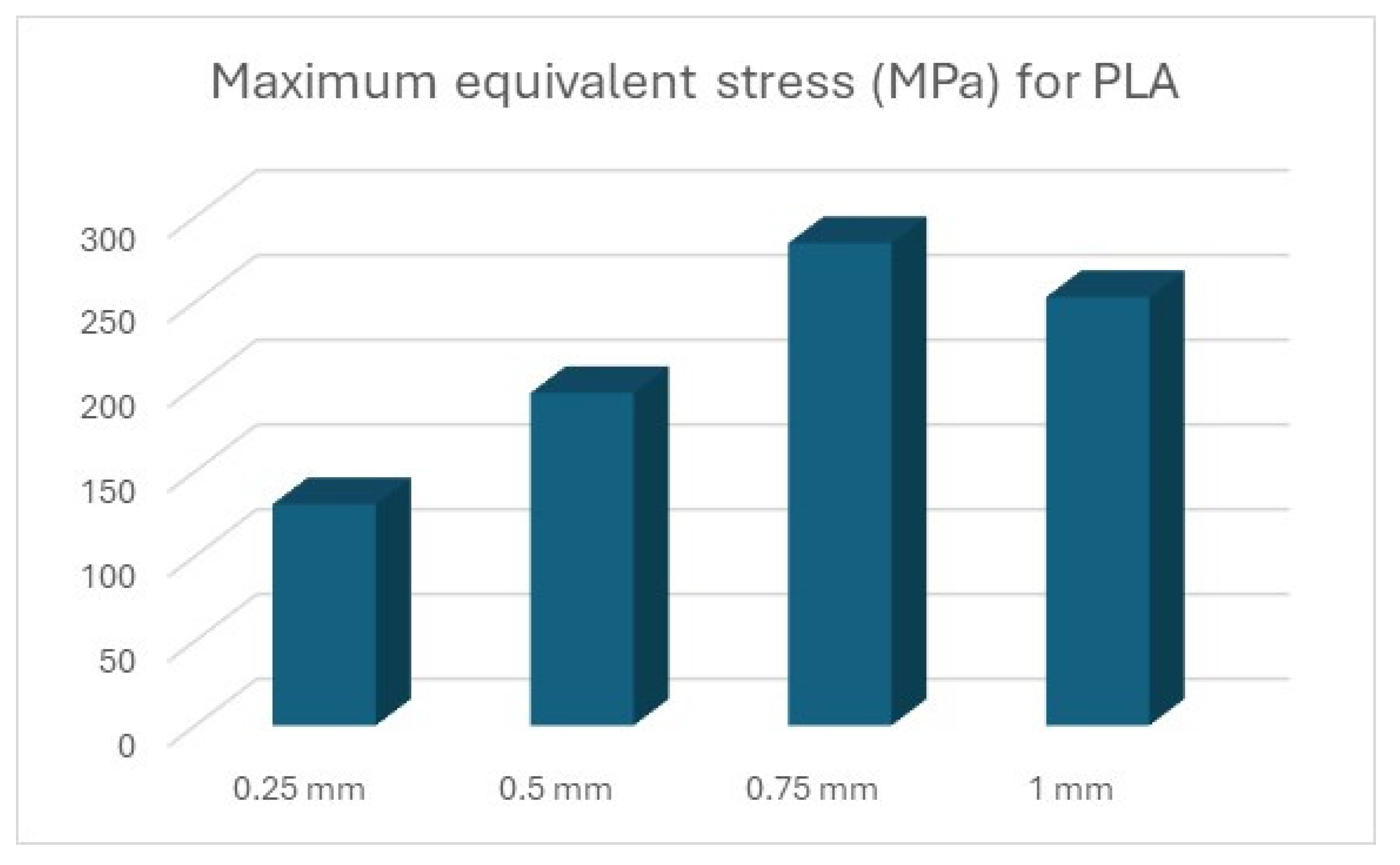

In the case of PLA (

Figure 16), PET (

Figure 17), and Nylon (

Figure 18), exceeding the values for tensile ultimate strength can be observed, meaning permanent changes in the shape of the device. However, these areas are limited to the radius on which the metal sheet is drawn, not being present in its entire structure.

The results provided by the total deformations analysis are accompanied by the equivalent stress analysis, providing a complete picture of the behaviour of polymers in the embossing process of metal sheets.

4. Discussion

These results highlight the effectiveness and potential of polymeric die sets in deep drawing applications, specifically focusing on materials like PLA and PET. The results indicate that these materials demonstrate superior wear resistance and minimal deformation, which is attributed to their higher tensile strength and impact resistance compared to Nylon and ABS. Notably, the study found that PLA and PET had acceptable differences in part production when compared to conventional dies, especially with thin sheets. For instance, the deviations observed were 0.3 mm for 0.25 mm sheets and 0.15 mm for 0.5 mm sheets.

Further analysis showed that devices made from PLA and PET exhibited areas exceeding maximum equivalent stress values, particularly in the radii regions during the embossing process. This aligns with previous findings by Nakamura et al. [

15] and Günther et al. [

20], suggesting that subsequent embossing processes would result in minimal deformation, indicating the potential for iterative tool design improvements. On the other hand, Nylon devices performed adequately for thinner sheets (0.25 mm)—not as effectively as PLA and PET, yet better than ABS.

ABS, however, demonstrated significant limitations due to its flexural strength properties, resulting in poor shape definition on metal sheets and substantial deviations in rays, ranging from 4.22 degrees for 0.25 mm thick sheets to 45 degrees for 1 mm sheets. This suggests ABS’s limited applicability for precise deep drawing operations but highlights the potential for its use in less demanding applications or where flexibility and recovery are critical.

In summary, while polymeric materials like PLA and PET show promise for deep drawing applications, offering a balance of strength, wear resistance, and manufacturability, further research and optimisation are required to enhance their dimensional accuracy and application scope. This study underscores the necessity for continued investigation into the materials’ properties and their practical implications in die manufacturing to fully leverage their potential in industrial settings. This study can be continued by streamlining the process, using a range of special materials, or improving mechanical characteristics by inserting standardised objects (screws, metal bars) or non-standardised ones (plates made of other materials, or elements specially designed for their respective case) into the forming plates in order to minimise the deformations occurring within the process, to enhance the precision of parts and to increase the lifetime of devices.