Enhanced Crystallization of Sustainable Polylactic Acid Composites Incorporating Recycled Industrial Cement

Abstract

1. Introduction

2. Experiments

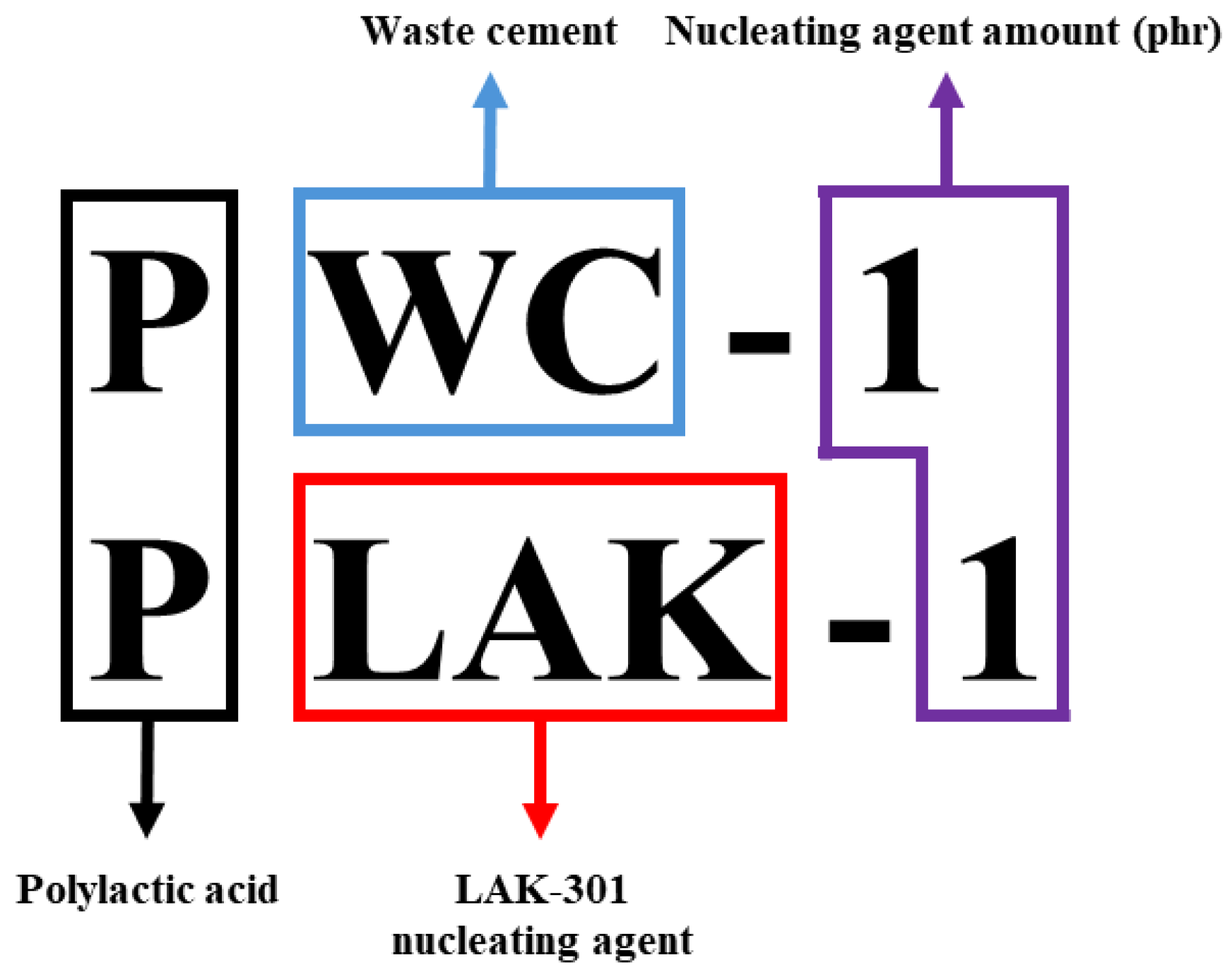

2.1. Materials

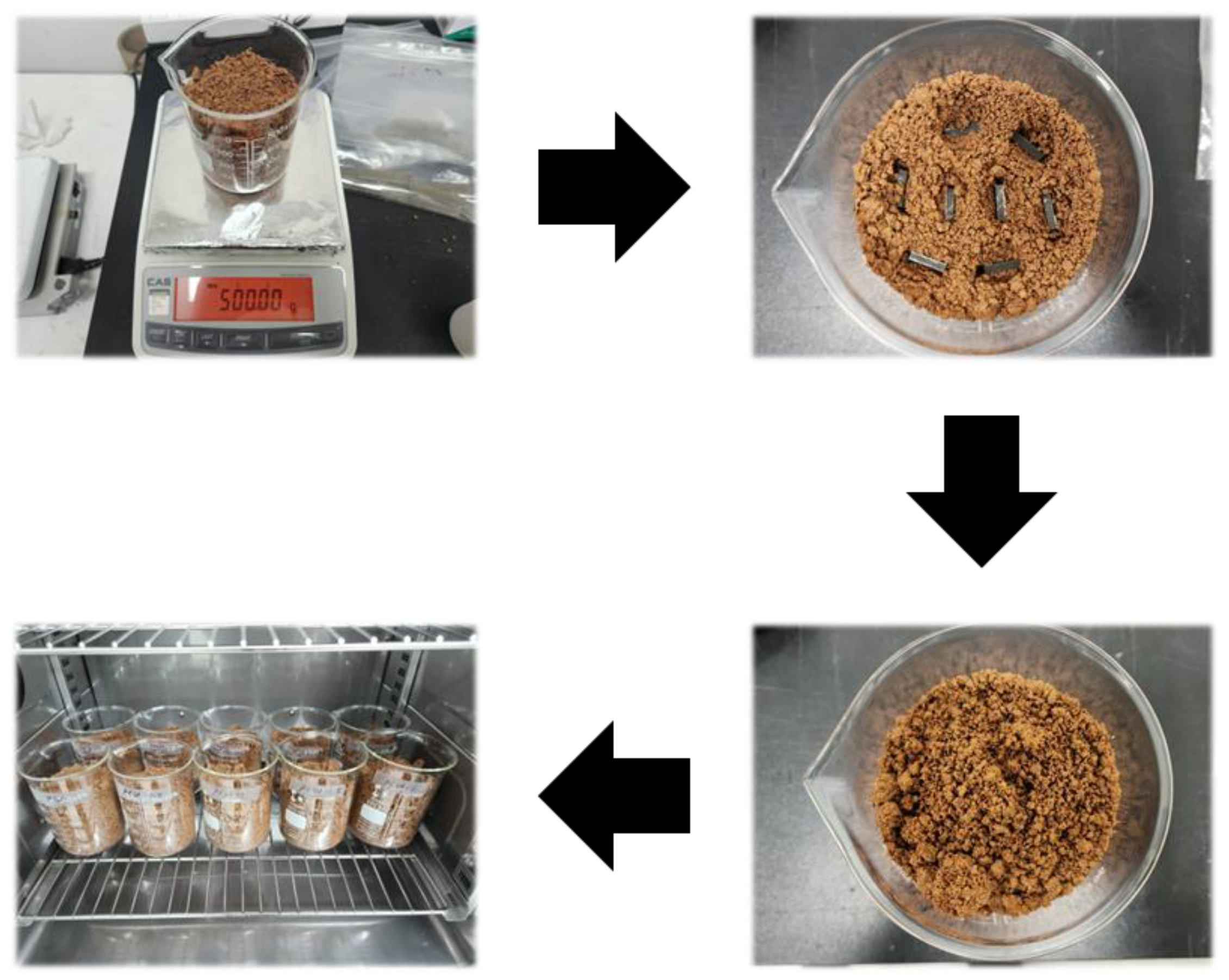

2.2. Specimen Process

2.3. Thermal Analysis of PWC

2.4. Analysis of PWC Crystallites

2.5. Moisture Drying Test of PWC

2.6. Mechanical Analysis of PWC

2.7. Biodegradation of PWC

3. Results and Discussion

3.1. Crystallite Properties with DSC

3.2. Crystallinity Properties with XRD

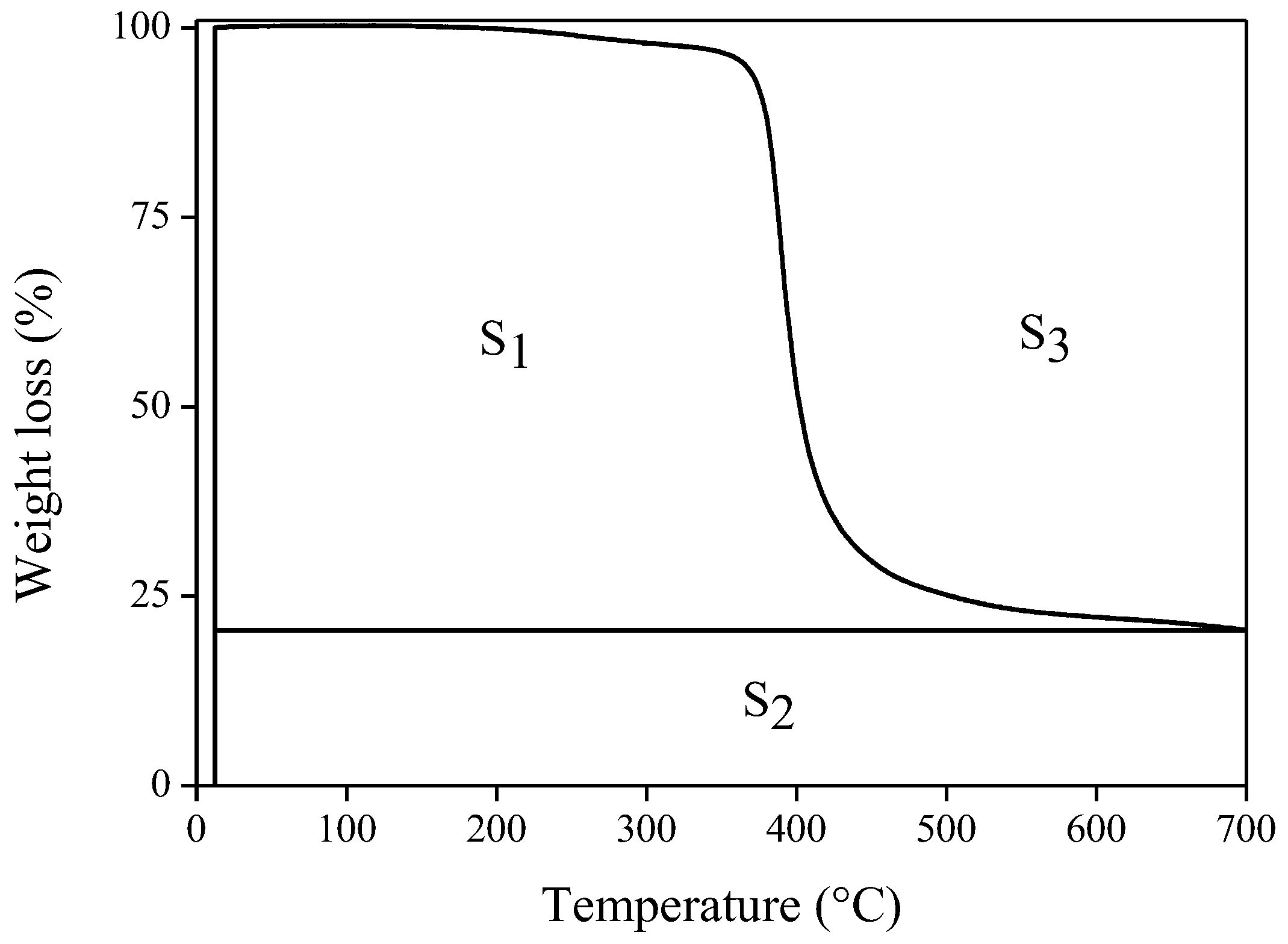

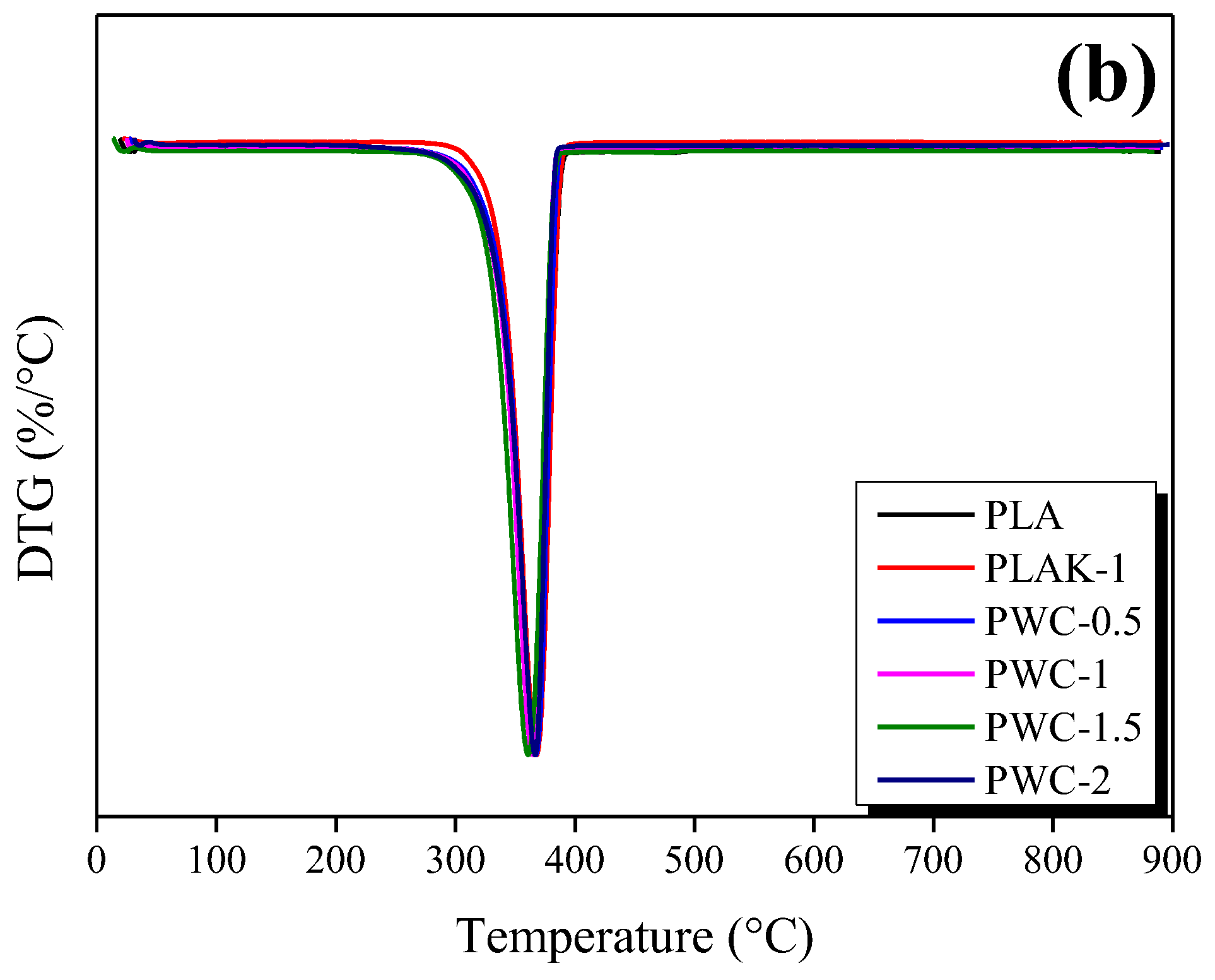

3.3. Thermal Stability with TGA

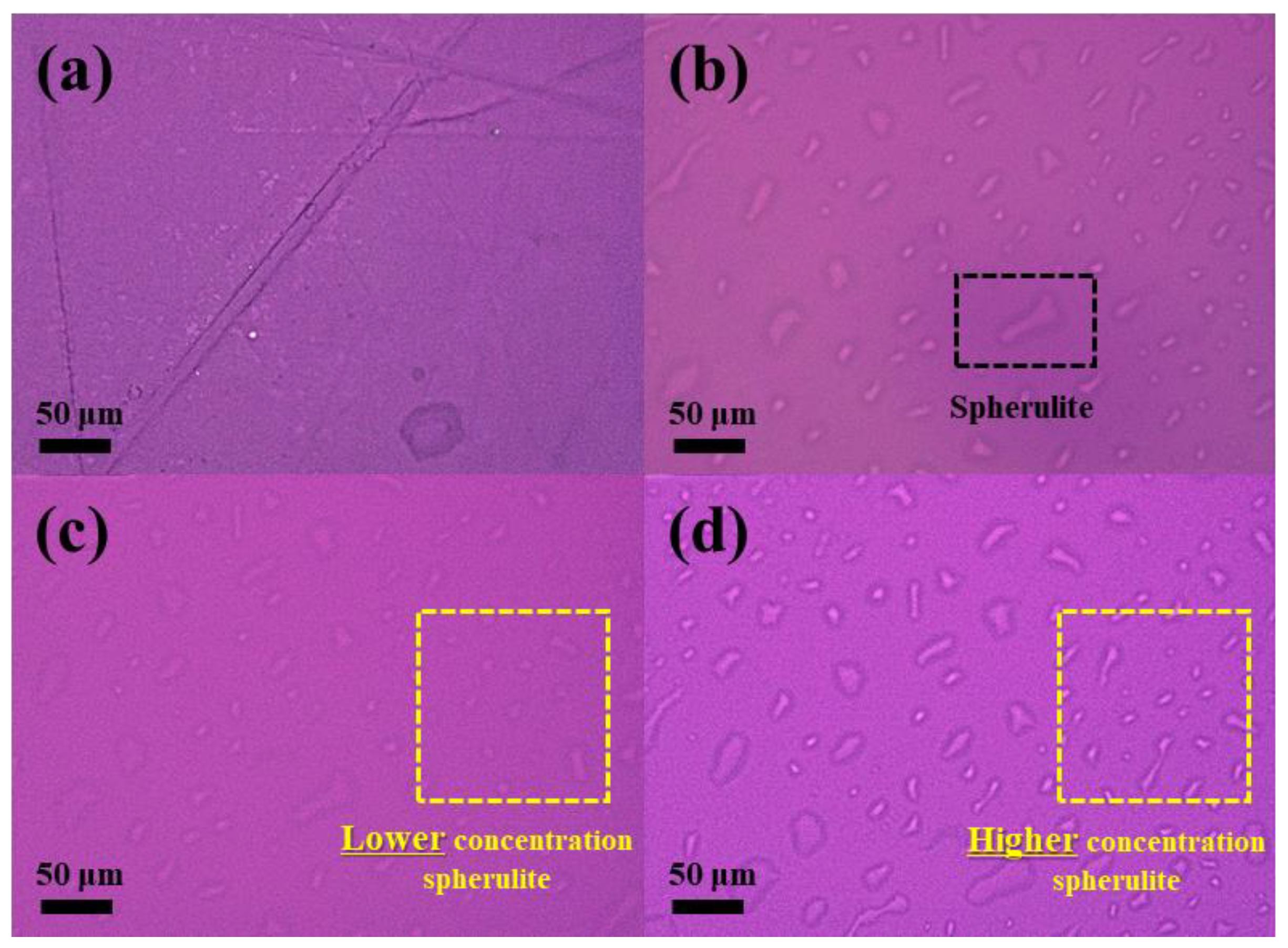

3.4. Spherulite and Lamellar Structure Analysis

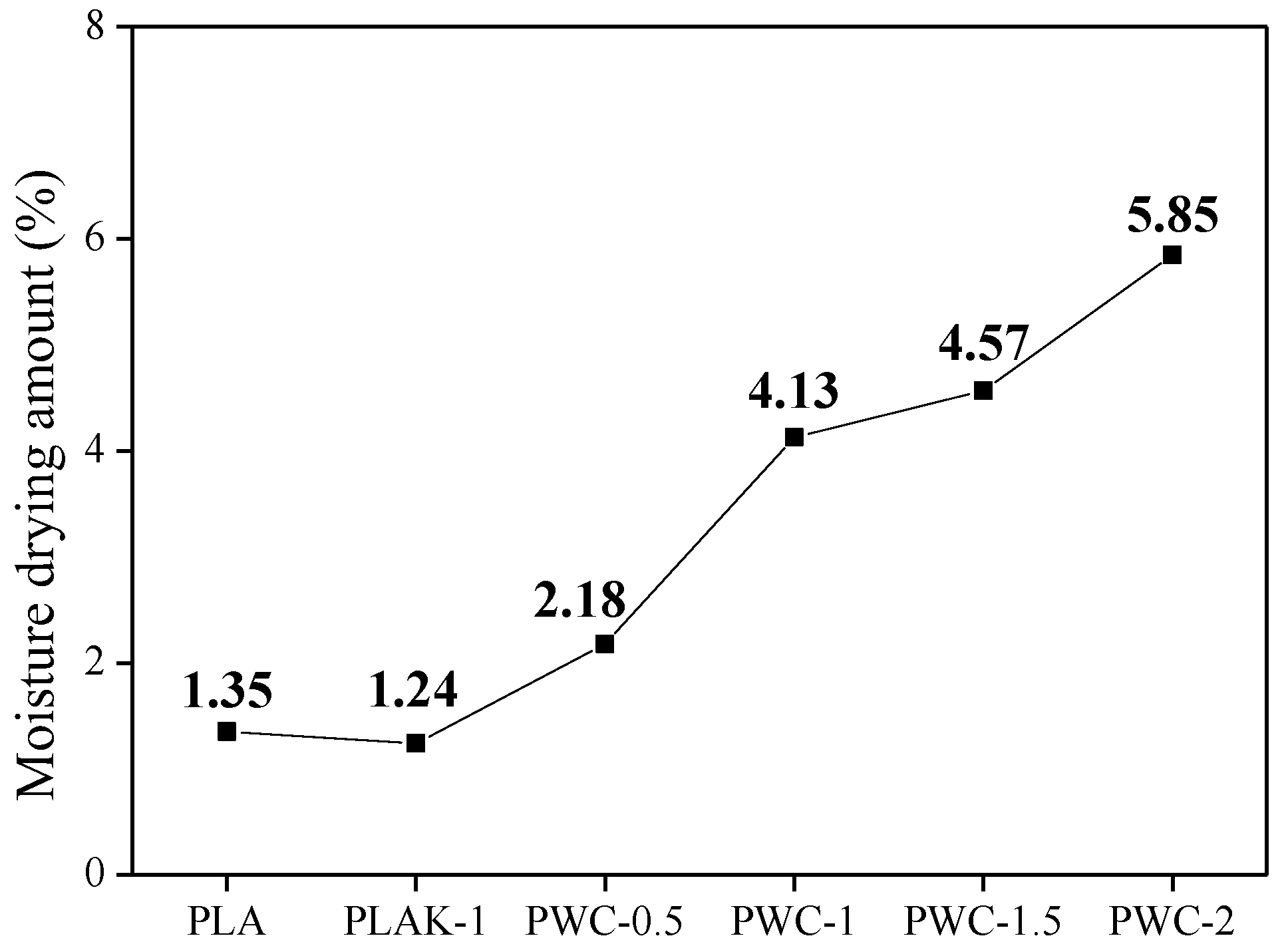

3.5. Drying Properties

3.6. Mechanical Properties

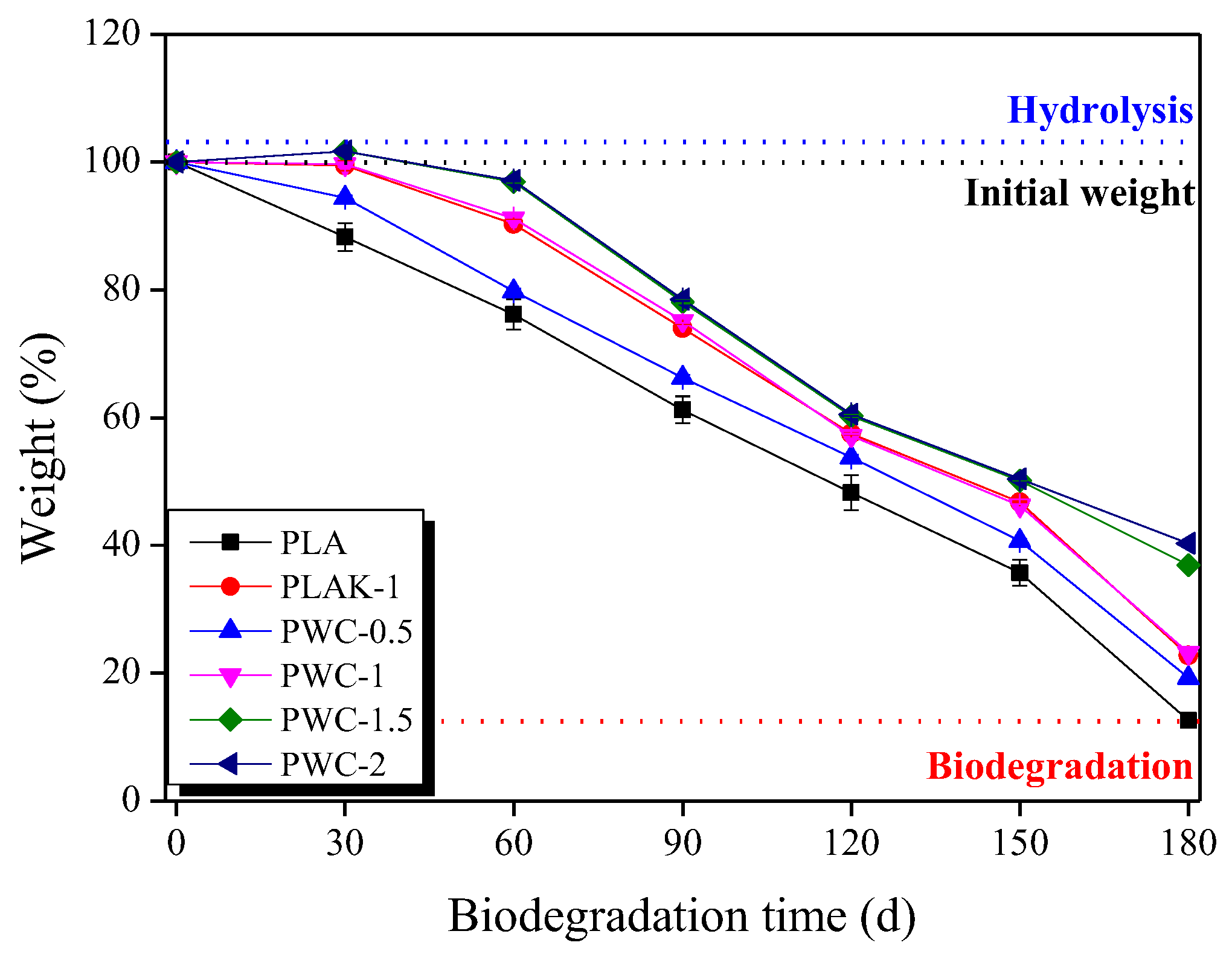

3.7. Biodegradation Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alfonso, M.B.; Arias, A.H.; Menéndez, M.C.; Ronda, A.C.; Harte, A.; Piccolo, M.C.; Marcovecchio, J.E. Assessing threats, regulations, and strategies to abate plastic pollution in LAC beaches during COVID-19 pandemic. Ocean Coast. Manag. 2021, 208, 105613. [Google Scholar] [CrossRef] [PubMed]

- Benson, N.U.; Bassey, D.E.; Palanisami, T. COVID pollution: Impact of COVID-19 pandemic on global plastic waste footprint. Heliyon 2021, 7, e06343. [Google Scholar] [CrossRef] [PubMed]

- Patrício, S.A.L.; Prata, J.C.; Duarte, A.C.; Barcelò, D.; Rocha-Santos, T. An urgent call to think globally and act locally on landfill disposable plastics under and after covid-19 pandemic: Pollution prevention and technological (Bio) remediation solutions. Chem. Eng. J. 2021, 426, 131201. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Xu, S.; Liu, B.; Wang, H.; Qiao, F.; Ren, X.; Wei, Q. PLA bioplastic production: From monomer to the polymer. Eur. Polym. J. 2023, 193, 112076. [Google Scholar] [CrossRef]

- Panda, A.K.; Singh, R.K.; Mishra, D.K. Thermolysis of waste plastics to liquid fuel: A suitable method for plastic waste management and manufacture of value added products—A world prospective. Renew. Sustain. Energy Rev. 2023, 14, 233–248. [Google Scholar] [CrossRef]

- Das, K.P.; Sharma, D.; Saha, S.; Satapathy, B.K. From outbreak of COVID-19 to launching of vaccination drive: Invigorating single-use plastics, mitigation strategies, and way forward. Environ. Sci. Pollut. Res. 2021, 28, 55811–55845. [Google Scholar] [CrossRef]

- Chek, M.F.; Kim, S.Y.; Mori, T.; Tan, H.T.; Sudesh, K.; Hakoshima, T. Asymmetric Open-Closed Dimer Mechanism of Polyhydroxyalkanoate Synthase PhaC. IScience 2020, 23, 101084. [Google Scholar] [CrossRef]

- Lendvai, L.; Omastova, M.; Patnaik, A.; Dogossy, G.; Singh, T. Valorization of Waste Wood Flour and Rice Husk in Poly(Lactic Acid)-Based Hybrid Biocomposites. J. Polym. Environ. 2023, 31, 541–551. [Google Scholar] [CrossRef]

- Yetis, F.; Liu, X.; Sampson, W.W.; Gong, R.H. Biodegradation of Composites of Polylactic Acid and Microfibrillated Lignocellulose. J. Polym. Environ. 2023, 31, 698–708. [Google Scholar] [CrossRef]

- Boonluksiri, Y.; Prapagdee, B.; Sombatsompop, N. Promotion of polylactic acid biodegradation by a combined addition of PLA-degrading bacterium and nitrogen source under submerged and soil burial conditions. Polym. Degrad. Stab. 2021, 188, 109562. [Google Scholar] [CrossRef]

- Borrowman, C.K.; Johnston, P.; Adhikari, R.; Saito, K.; Patti, A.F. Environmental degradation and efficacy of a sprayable, biodegradable polymeric mulch. Polym. Degrad. Stab. 2020, 175, 109126. [Google Scholar] [CrossRef]

- de Andrade, M.F.C.; Souza, P.M.S.; Cavalett, O.; Morales, A.R. Life Cycle Assessment of Poly(Lactic Acid) (PLA): Comparison Between Chemical Recycling, Mechanical Recycling and Composting. J. Polym. Environ. 2016, 24, 372–384. [Google Scholar] [CrossRef]

- Sundar, N.; Kumar, S.A.; Pavithra, A.; Ghosh, S. Studies on Semi-crystalline Poly Lactic Acid (PLA) as a Hydrophobic Coating Material on Kraft Paper for Imparting Barrier Properties in Coated Abrasive Applications. Prog. Org. Coat. 2020, 145, 105682. [Google Scholar] [CrossRef]

- Wang, F.; Lin, P.; Jiang, W.; Hu, X. Tailoring the crystallization and melting behavior of 3D protein-polymer biocomposite materials: A study of pressure-induced silk fibroin/poly(L-lactic acid) foams. Eur. Polym. J. 2023, 195, 112199. [Google Scholar] [CrossRef]

- Rivero, S.; Lecot, J.; Pinotti, A. Impregnation of kraft paper support with polylactic acid multilayers. Adv. Mater. Lett. 2017, 8, 741–751. [Google Scholar] [CrossRef]

- Can, A.; Tomak, E.D.; Ermeydan, M.A.; Aykanat, O. Synergic effect of basalt/wood fiber reinforced polylactic acid hybrid biocomposites against fungal decay. Eur. Polym. J. 2023, 195, 112246. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, L.; Wang, H.; Cheng, C.; Yin, X.; Zhu, Z. Fabrication of a flame retardant, strong mechanical toughness and antimicrobial polylactic acid by chitosan Schiff base/ammonium polyphosphate. Polym. Degrad. Stab. 2023, 216, 110492. [Google Scholar] [CrossRef]

- Cisneros-López, E.O.; Pal, A.K.; Rodriguez, A.U.; Wu, F.; Misra, M.; Mielewski, D.F.; Kiziltas, A.; Mohanty, A.K. Recycled poly(lactic acid)–based 3D printed sustainable biocomposites: A comparative study with injection molding. Mater. Today Sustain. 2020, 7–8, 100027. [Google Scholar] [CrossRef]

- Lee, C.H.; Sapuan, S.M.; Ilyas, R.A.; Lee, S.H.; Khalina, A. Chapter 5—Development and Processing of PLA, PHA, and Other Biopolymers. In Advanced Processing, Properties, and Applications of Starch and Other Bio-Based Polymers, 1st ed.; Al-Oqla, F.M., Sapuan, S.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 47–63. [Google Scholar] [CrossRef]

- Reddy, M.M.; Vivekanandhan, S.; Misra, M.; Bhatia, S.K.; Mohanty, A.K. Biobased plastics and bionanocomposites: Current status and future opportunities. Prog. Polym. Sci. 2013, 38, 1653–1689. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, S.; Han, S.; Yu, K.; Wang, L. Regulating cell morphology of poly(lactic acid) foams from microcellular to nanocellular by crystal nucleating agent. Polym. Degrad. Stab. 2022, 204, 110117. [Google Scholar] [CrossRef]

- Elsawy, M.A.; Fekry, M.; Sayed, A.M.; Maziad, N.A.; Saad, G.R. Physico-chemical Characteristics of Biodegradable Poly(lactic acid) and Poly(lactic acid)/Chitosan Nano-Composites Under the Influence of Gamma Irradiation. J. Polym. Environ. 2023, 31, 2705–2714. [Google Scholar] [CrossRef]

- Maureira, J.; Olate-Moya, F.; Bastías, R.; Farias, S.; Alvarez, R.; Rosales-Cuello, N.; Palza, H. Multifunctional poly(3-hydroxybutyrate) composites with MoS2 for food packaging applications. Eur. Polym. J. 2023, 188, 111914. [Google Scholar] [CrossRef]

- Yu, W.; Wang, X.; Ferraris, E.; Zhang, J. Melt crystallization of PLA/Talc in fused filament fabrication. Mater. Des. 2019, 182, 108013. [Google Scholar] [CrossRef]

- Li, H.; Huneault, M.A. Effect of nucleation and plasticization on the crystallization of poly(lactic acid). Polymer 2007, 48, 6855–6866. [Google Scholar] [CrossRef]

- Feijoo, J.L.; Cabedo, L.; Gimenez, E.; Lagaron, J.M.; Saura, J.J. Development of amorphous PLA-montmorillonite nanocomposites. J. Mater. Sci. 2005, 40, 1785–1788. [Google Scholar] [CrossRef]

- Picard, E.; Espuche, E.; Fulchiron, R. Effect of an organo-modified montmorillonite on PLA crystallization and gas barrier properties. Appl. Clay Sci. 2011, 53, 58–65. [Google Scholar] [CrossRef]

- Piekarska, K.; Piorkowska, E.; Bojda, J. The influence of matrix crystallinity, filler grain size and modification on properties of PLA/calcium carbonate composites. Polym. Test 2017, 62, 203–209. [Google Scholar] [CrossRef]

- Aliotta, L.; Cinelli, P.; Coltelli, M.B.; Lazzeri, A. Rigid filler toughening in PLA-Calcium Carbonate composites: Effect of particle surface treatment and matrix plasticization. Eur. Polym. J. 2019, 113, 78–88. [Google Scholar] [CrossRef]

- Chow, W.S.; Leu, Y.Y.; Ishak, Z.A.M. Mechanical, Thermal and Morphological Properties of Injection Molded Poly(lactic acid)/Calcium Carbonate Nanocomposites. Period Polytech. Mech. Eng. 2016, 60, 15–20. [Google Scholar] [CrossRef]

- Kumar, V.; Dev, A.; Gupta, A.P. Studies of poly(lactic acid) based calcium carbonate nanocomposites. Compos. B Eng. 2014, 56, 184–188. [Google Scholar] [CrossRef]

- Yang, K.; Wang, H.; Liu, Z. Evaluation on mechanical properties of high-performance biocomposite bridge deck structure: A review. Polym. Compos. 2021, 42, 6265–6297. [Google Scholar] [CrossRef]

- Song, J.; Li, Y.; Xu, W.; Liu, H.; Lu, Y. Inexpensive and non-fluorinated superhydrophobic concrete coating for anti-icing and anti-corrosion. J. Colloid Interface Sci. 2019, 541, 86–92. [Google Scholar] [CrossRef]

- Ju, Y.; Shen, T.; Wang, D. Bonding behavior between reactive powder concrete and normal strength concrete. Constr. Build. Mater. 2020, 242, 118024. [Google Scholar] [CrossRef]

- Su, N.; Lou, L.; Amirkhanian, A.; Amirkhanian, S.N.; Xiao, F. Assessment of effective patching material for concrete bridge deck—A review. Constr. Build. Mater. 2021, 293, 123520. [Google Scholar] [CrossRef]

- Bertino, G.; Kisser, J.; Zeilinger, J.; Langergraber, G.; Fischer, T.; Österreicher, D. Fundamentals of Building Deconstruction as a Circular Economy Strategy for the Reuse of Construction Materials. Appl. Sci. 2021, 11, 939. [Google Scholar] [CrossRef]

- Singh, S.N.; Rao, D.N. Growth of wheat plants exposed to cement dust pollution. Water Air Soil Pollut. 1980, 14, 241–249. [Google Scholar] [CrossRef]

- Shah, K.; An, N.; Ma, W.; Ara, G.; Ali, K.; Kamanova, S.; Zuo, X.; Han, M.; Ren, X.; Xing, L. Chronic cement dust load induce novel damages in foliage and buds of Malus domestica. Sci. Rep. 2020, 10, 12186. [Google Scholar] [CrossRef]

- ASTM Standard D790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM Standard D256; Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. ASTM International: West Conshohocken, PA, USA, 2010.

- Harris, A.M.; Lee, E.C. Improving mechanical performance of injection molded PLA by controlling crystallinity. J. Appl. Polym. Sci. 2007, 107, 2246–2255. [Google Scholar] [CrossRef]

- Fehri, S.; Cinelli, P.; Coltelli, M.B.; Anguillesi, I.; Lazzeri, A. Thermal Properties of Plasticized Poly (Lactic Acid) (PLA) Containing Nucleating Agent. Int. J. Chem. Eng. 2016, 7, 85–88. [Google Scholar] [CrossRef]

- Doyle, C.D. Estimating Thermal Stability of Experimental Polymers by Empirical Thermogravimetric Analysis. J. Am. Chem. Soc. 1961, 33, 77–79. [Google Scholar] [CrossRef]

- Kim, D.K.; Kim, K.W.; Han, W.; Kwac, L.K.; Kim, B.J. Studies on Cure Kinetics and Thermal Stability of Epoxy/Nylon 6 Blend. Appl. Chem. Eng. 2015, 26, 538–542. [Google Scholar] [CrossRef]

- Lee, Y.M.; Kim, K.W.; Kim, B.J. Thermal and Mechanical Characterization of Epoxy/Polyimide Blends via Postcuring Process. Polymers 2023, 15, 1072. [Google Scholar] [CrossRef] [PubMed]

- Ren, Z.; Dong, L.; Yang, Y. Dynamic mechanical and thermal properties of plasticized poly(lactic acid). J. Appl. Polym. Sci. 2006, 101, 1583–1590. [Google Scholar] [CrossRef]

- Qian, S.; Sheng, K.; Yao, W.; Yu, H. Poly(lactic acid) biocomposites reinforced with ultrafine bamboo-char: Morphology, mechanical, thermal, and water absorption properties. J. Appl. Polym. Sci. 2016, 133, 43425. [Google Scholar] [CrossRef]

- Fukushima, K.; Tabuani, D.; Abbate, C.; Arena, M.; Ferreri, L. Effect of sepiolite on the biodegradation of poly(lactic acid) and polycaprolactone. Polym. Degrad. Stab. 2010, 95, 2049–2056. [Google Scholar] [CrossRef]

- Aliotta, L.; Sciara, L.M.; Cinelli, P.; Canesi, I.; Lazzeri, A. Improvement of the PLA Crystallinity and Heat Distortion Temperature Optimizing the Content of Nucleating Agents and the Injection Molding Cycle Time. Polymers 2022, 14, 977. [Google Scholar] [CrossRef]

| Nomenclature | PLA (g 1) | Waste Cement (phr 2; g 1) | LAK−301 (phr 2; g 1) |

|---|---|---|---|

| PLA | 250 | - | - |

| PLAK−1 | - | 1; 2.50 | |

| PWC−0.5 | 250 | 0.5; 1.25 | - |

| PWC−1 | 1; 2.50 | - | |

| PWC−1.5 | 1.5; 3.75 | - | |

| PWC−2 | 2; 5.00 | - |

| Sample | 1st Tm (°C) | 2nd Tm (°C) | ΔHm (J/g) | 1st Tcc (°C) | 2nd Tcc (°C) | Xc (%) |

|---|---|---|---|---|---|---|

| PLA | 152.67/157.81 | 150.96/156.11 | 23.15/22.78 | 115.17 | 115.94 | 24.73/24.34 |

| PLAK−1 | 151.69/155.11 | 151.70/155.03 | 25.49/29.16 | 117.08 | 116.35 | 27.23/31.15 |

| PWC−0.5 | 151.69/155.53 | 150.15/155.34 | 26.64/30.64 | 116.32 | 113.61 | 28.46/32.74 |

| PWC−1 | 154.53 | 150.11/156.21 | 29.71/30.68 | 124.22 | 113.71 | 31.74/32.78 |

| PWC−1.5 | 151.85 | 150.20/156.89 | 30.78/29.22 | 117.72 | 112.92 | 33.88/31.22 |

| PWC−2 | 154.33 | 153.68 | 31.01/31.91 | 125.45 | 125.74 | 33.13/34.09 |

| Sample | 1 IDT (°C) | 2 Tmax (°C) | 3 A*·K* | 4 IPDT (°C) |

|---|---|---|---|---|

| PLA | 320.34 | 372.08 | 0.4149 | 375.33 |

| PLAK−1 | 330.22 | 367.62 | 0.4007 | 371.37 |

| PWC−0.5 | 323.72 | 370.41 | 0.4007 | 373.96 |

| PWC−1 | 325.53 | 372.08 | 0.4149 | 380.52 |

| PWC−1.5 | 321.17 | 370.41 | 0.4010 | 371.68 |

| PWC−2 | 315.53 | 366.81 | 0.4109 | 387.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, Y.-M.; Kim, K.-W.; Yang, J.-Y.; Kim, B.-J. Enhanced Crystallization of Sustainable Polylactic Acid Composites Incorporating Recycled Industrial Cement. Polymers 2024, 16, 1666. https://doi.org/10.3390/polym16121666

Lee Y-M, Kim K-W, Yang J-Y, Kim B-J. Enhanced Crystallization of Sustainable Polylactic Acid Composites Incorporating Recycled Industrial Cement. Polymers. 2024; 16(12):1666. https://doi.org/10.3390/polym16121666

Chicago/Turabian StyleLee, Yong-Min, Kwan-Woo Kim, Jae-Yeon Yang, and Byung-Joo Kim. 2024. "Enhanced Crystallization of Sustainable Polylactic Acid Composites Incorporating Recycled Industrial Cement" Polymers 16, no. 12: 1666. https://doi.org/10.3390/polym16121666

APA StyleLee, Y.-M., Kim, K.-W., Yang, J.-Y., & Kim, B.-J. (2024). Enhanced Crystallization of Sustainable Polylactic Acid Composites Incorporating Recycled Industrial Cement. Polymers, 16(12), 1666. https://doi.org/10.3390/polym16121666