Bringing Light into the Dark—Overview of Environmental Impacts of Carbon Fiber Production and Potential Levers for Reduction

Abstract

:1. Introduction and Motivation

2. Overview of the Applied Methods

- The general process of CF manufacturing;

- The quantitative mass and energy flows of CF production;

- The influence of the energy sources in CF production;

- The environmental impacts of CF manufacturing;

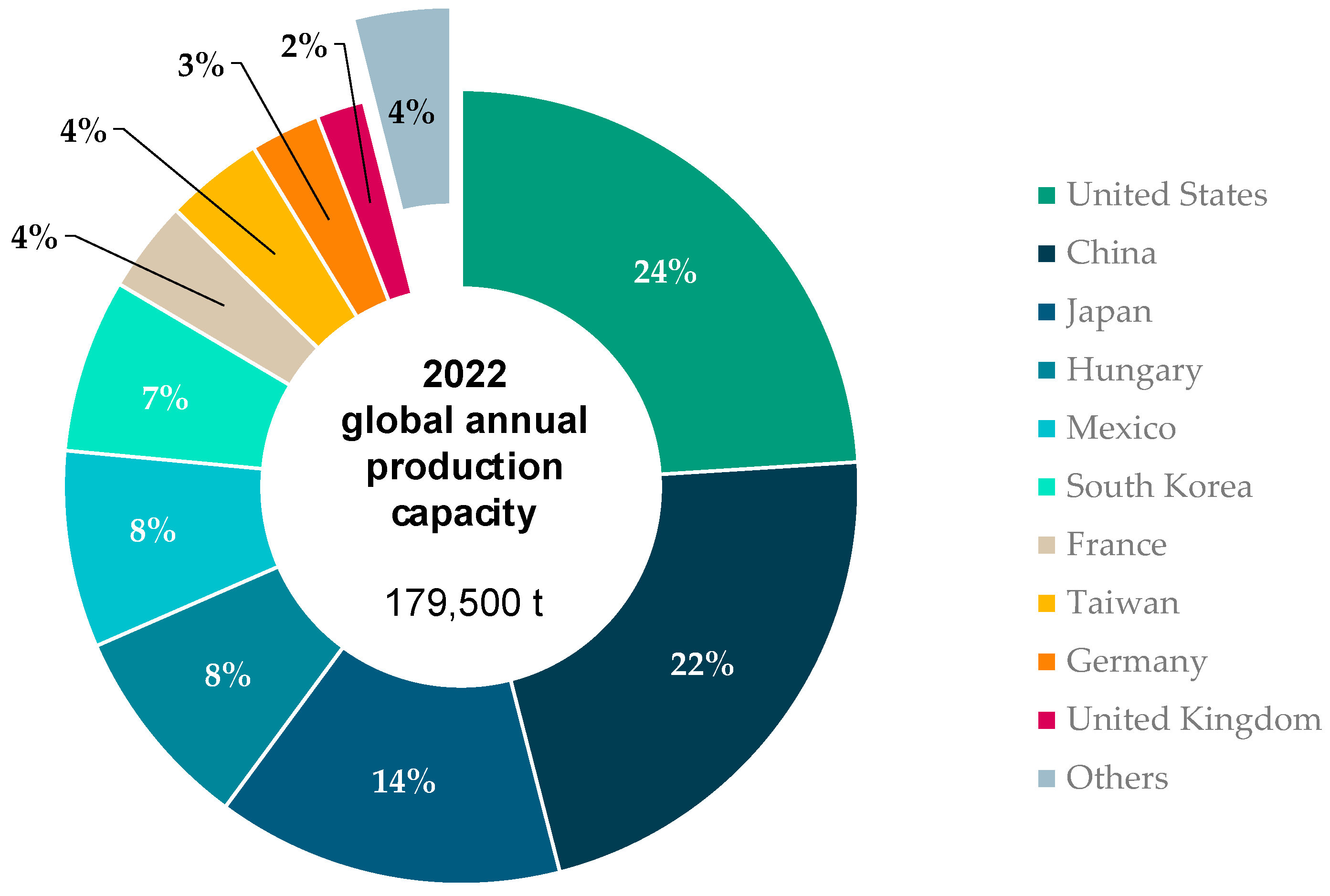

- The most relevant countries for the production of CF;

- The identification of relevant levers to reduce overall environmental impacts of CF.

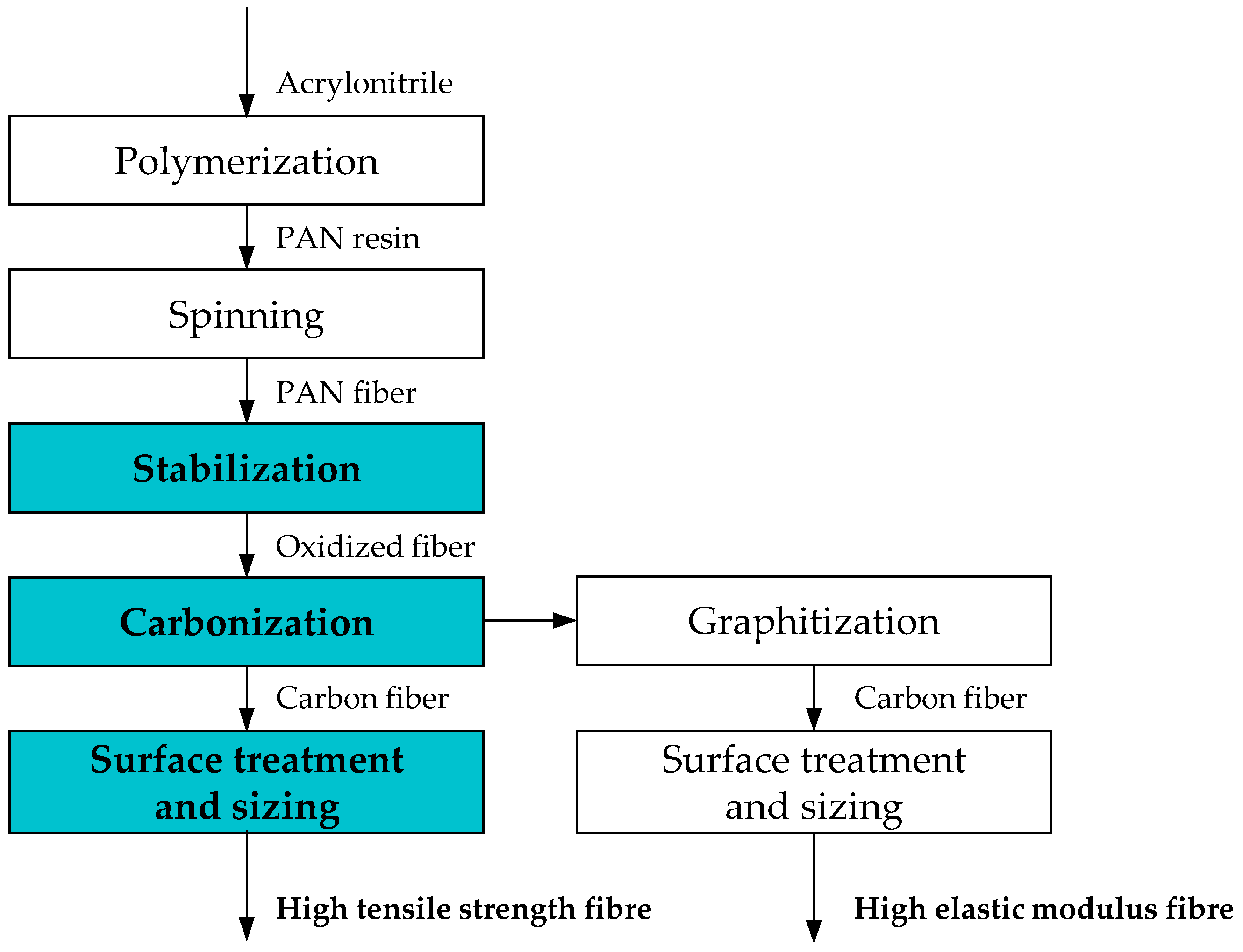

3. Description and Analysis of CF Production

3.1. Manufacturing Process

3.1.1. Stabilization

3.1.2. Carbonization

3.1.3. Surface Treatment and Sizing

3.1.4. Supplementary Processes for Exhaust Gas Treatment

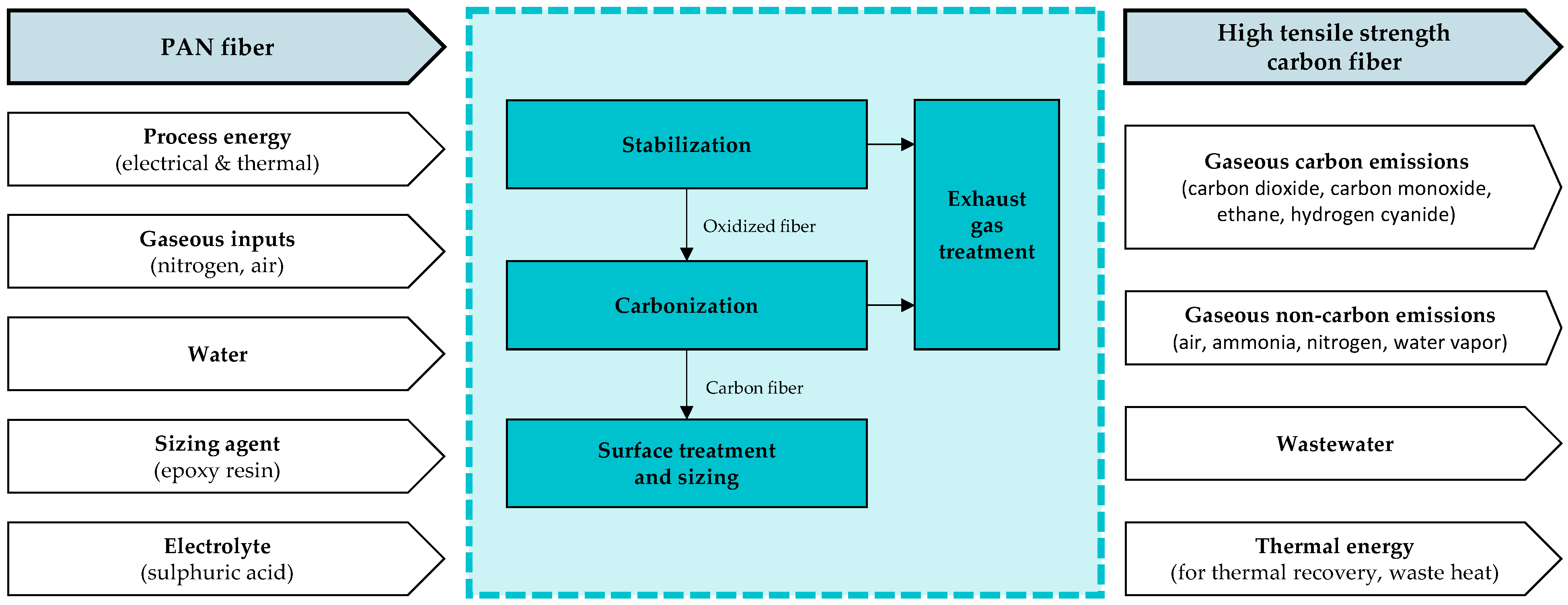

3.2. Quantification of Relevant Process Flows

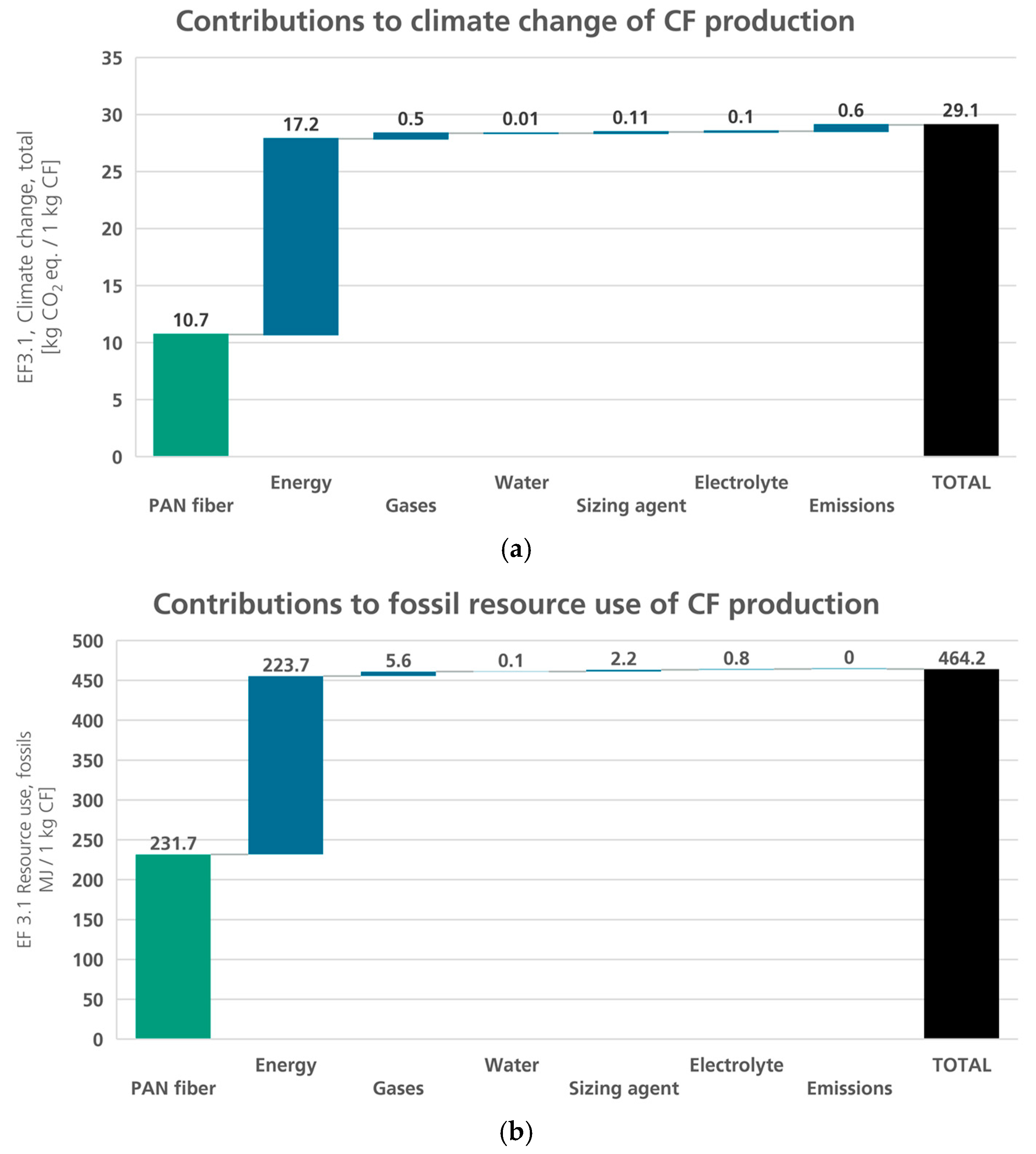

4. Initial Hotspot Assessment

5. Investigated Variants and Scenarios

- Energy source precursor

- Energy source CF production

- Technologically optimized process (−50% energy demand)

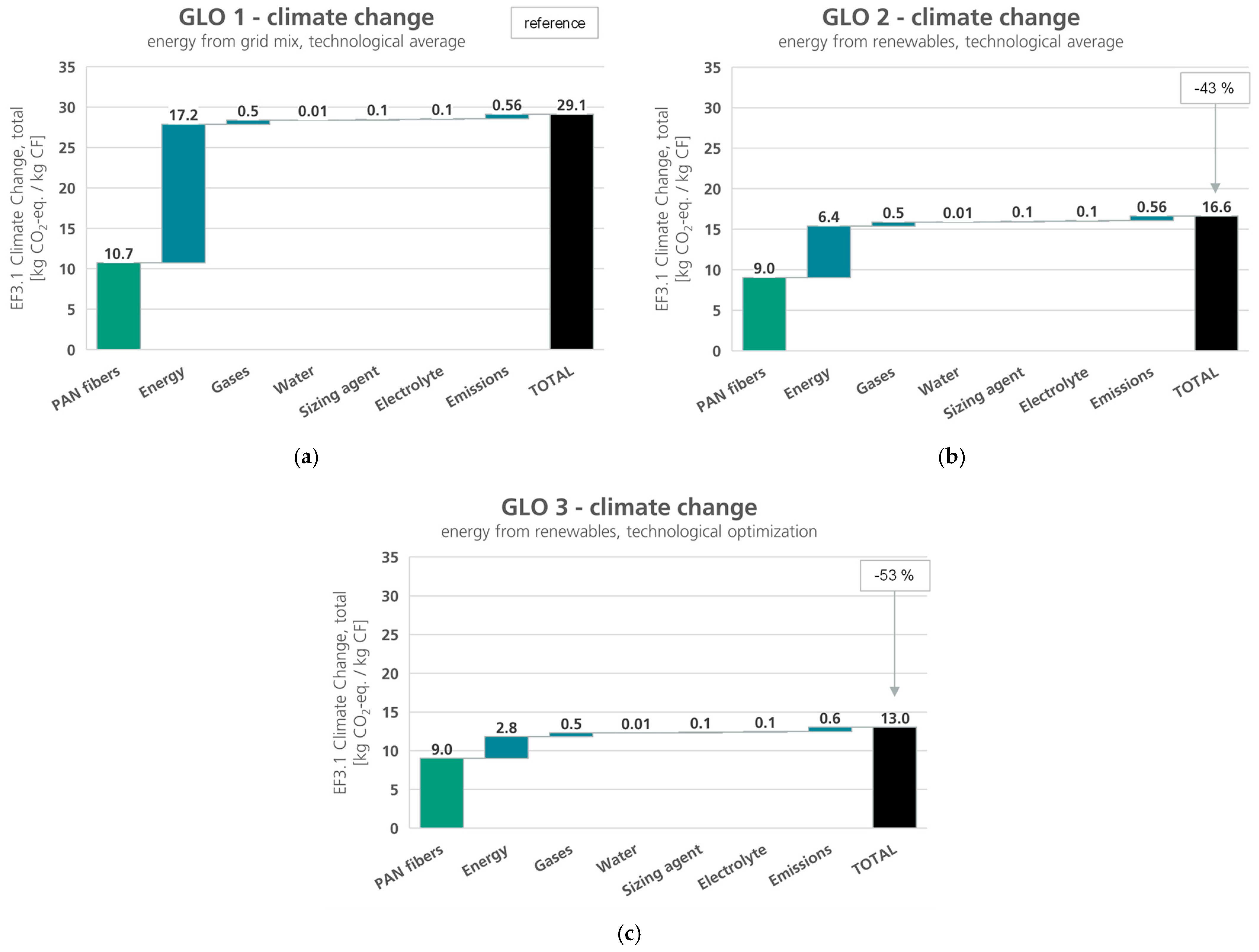

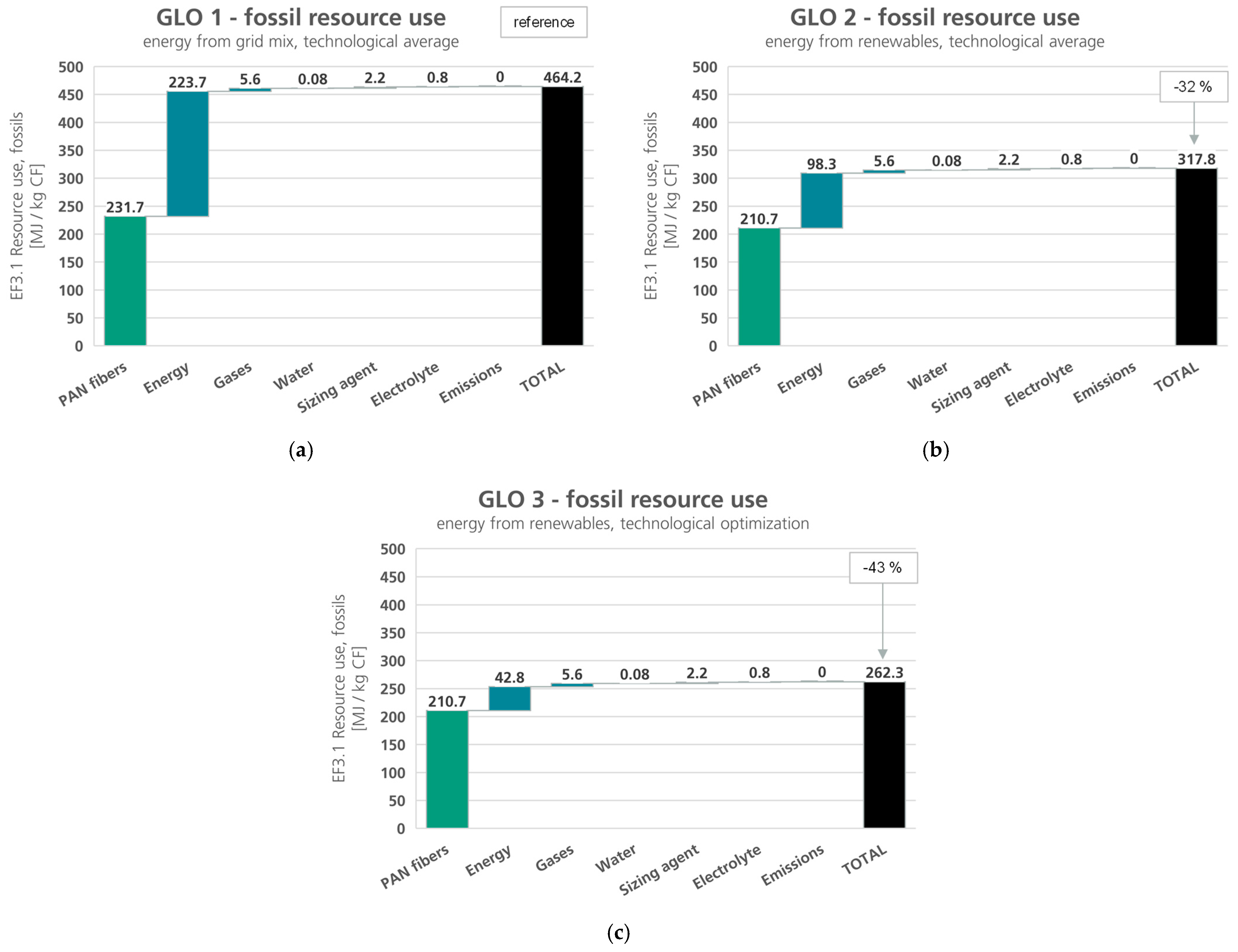

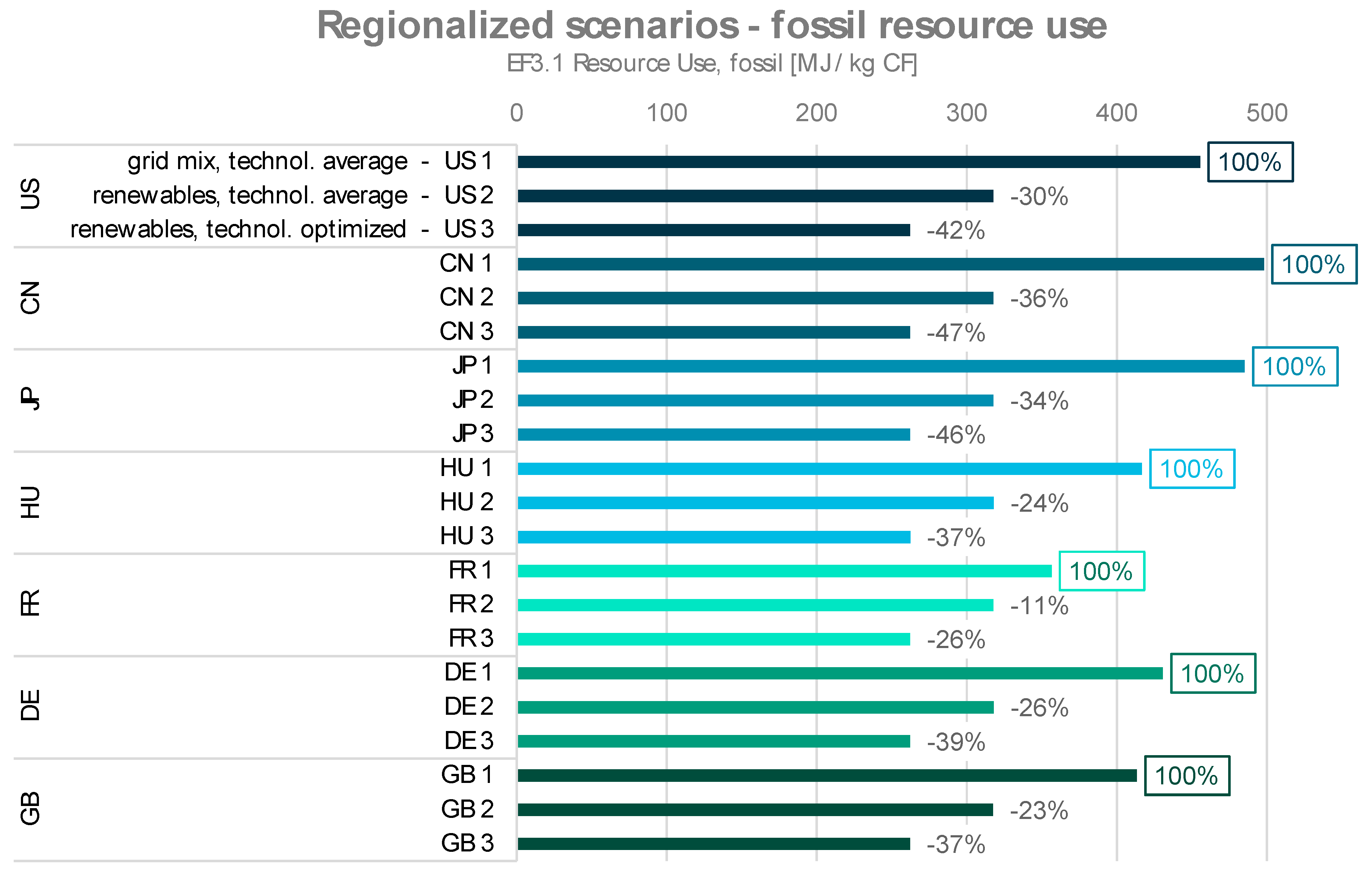

6. Results of the Investigated Scenarios

7. Discussion of the Results

- Location-specific electricity grid profiles;

- The use of renewable energy sources for production;

- Accounting for new research results like technology-optimized processes in fiber production, resulting in a more efficient energy consumption.

8. Conclusions and Recommendations

- A scrutinized life cycle inventory (LCI) for the cradle-to-gate production of high-tenacity carbon fibers of average technical quality has been presented, which was approved by an industrial advisory board. The LCI also proved valid against various authors in the literature review. This baseline enables other researchers in the future to model CF production themselves, e.g., for the evaluation of additional impact categories or regional scopes, or for plant-specific assessments.

- Building on the transparent LCI, an approved and consistent life cycle impact assessment (LCIA) following the ISO 14040 series was produced for a global “standard fiber” (cradle-to-gate) based on global market shares and technological averages for production. A substantial proportion of the overall impacts regarding climate change, total and resource use, fossil (acc. to EF3.1) result from the direct energy consumption in CF production (59% of climate change and 48% of the resource use, respectively), as well as from the manufacturing of PAN fibers as the standard precursor material (37 and 50%).

- Lastly, different scenarios have been evaluated to create insights into potential levers for reducing environmental impacts. To this end, the energy source (for PAN fibers and for CF production), as well as a different plant condition (technological average vs. technological optimization) were considered. These variations were applied to the global CF market mix, as well as seven highly relevant supplier countries of CFs. Depending on the scenario and impact category, the environmental impacts of CF production could be reduced by between 11 and 62% at different geographical locations. The deviation between the results and reduction potentials highlights the dependency of the results on the scenario’s specific system boundaries and the investigated setup.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Background Data for Emission Modelling

| Constituents [wt.%] | ||||

|---|---|---|---|---|

| C | N | H | O | |

| PAN fiber | 68 | 26 | 6 | - |

| Stabilized PAN fiber | 65 | 12 | 5 | 8 |

| Carbonized PAN fiber (<500 °C) | 67 | 19 | 11 | 3 |

| Carbonized PAN fiber (<700 °C) | 72 | 18 | 7 | 2 |

| PAN-based carbon fiber (~1500 °C) | >95 | 4.5 | 0.3 | 0.2 |

| Literature Source | Required Amount of PAN Fiber for the Production of 1 kg of CF [kg] | Corresponding Loss of PAN Fiber during Production Process [wt.%] |

|---|---|---|

| [83] | ~2 | ~50% ** |

| [2,54] | 1.82 ** | 45% * |

| [62] based on [84] | 2 to 2.2 ** | 50 to 55% * |

| [70] based on [85] | 1.82 to 2 ** | 45 to 50% * |

| Supplementary data for [24] | 1.75 | 43% ** |

| [26] based on [54] | 1.82 | 45% ** |

| [40] | 1.695 | 41% ** |

| [1] | 2.08 ** | 52% * |

| [3] | 1.82 to 2 ** | 45 to 50% * |

| [77] based on [54] | 1.82 | 45% ** |

| [86] | 1.67 to 2 ** | 40 to 50% * |

| Source | HCN | NH3 | NOX | H2O | CO | CO2 | H2 | N2 | VOCs | HCs (C2H4, C2H6) | CH4 | Other |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [3] | X | X | X | X | ||||||||

| [51] | X | X | X | X | X | X | X | |||||

| [54] | X | X | X | X | X | X | X | X | ||||

| [86] based on [87] | X | X | X | X | X | X | X | X |

| Emission | Mass | Emission Path | |

|---|---|---|---|

| Sulfuric acid | H2SO4 | 0.0199 kg/kg CF | water |

| Ethane | C2H6 | 0.0000101 kg/kg CF | air |

| Ammonia | NH3 | 0.00116 kg/kg CF | air |

| Hydrogen cyanide | HCN | 0.0157 kg/kg CF | air |

| Carbon monoxide | CO | 0.00324 kg/kg CF | air |

| Carbon dioxide | CO2 | 1.013 kg/kg CF | air |

| Emission | During Stabilization | During Carbonization | |

|---|---|---|---|

| Ammonia | NH3 | 95 to 99 wt.% | 95 to 99 wt.% |

| Hydrogen cyanide | HCN | 95 to 99 wt.% | 95 to 99 wt.% |

| Ethane | C2H6 | - | 95 to 99 wt.% |

| Ethene | C2H4 | - | 100 wt.% |

| Carbon monoxide | CO | 95 to 99 wt.% | 95 to 99 wt.% |

| Methane | CH4 | - | 100 wt.% |

| Hydrogen | H2 | - | 100 wt.% |

| Combustion of ammonia | ||

| ≈ −1399.6 kJ/mol | (A1) | |

| ≈ −1170.8 kJ/mol | (A2) | |

| ≈ −1532.0 kJ/mol | (A3) | |

| Combustion of hydrogen cyanide | ||

| ≈ −2556.2 kJ/mol | (A4) | |

| ≈ −2327.4 kJ/mol | (A5) | |

| ≈ −2688.6 kJ/mol | (A6) | |

| Combustion of ethane | ||

| ≈ −3124.0 kJ/mol | (A7) | |

| Combustion of ethene | ||

| ≈ −1412.0 kJ/mol | (A8) | |

| Combustion of methane | ||

| ≈ −816.0 kJ/mol | (A9) | |

| Combustion of carbon monoxide | ||

| ≈ −566.4 kJ/mol | (A10) | |

| Combustion of hydrogen | ||

| ≈ −572.0 kJ/mol | (A11) | |

References

- Das, S. Life cycle assessment of carbon fiber-reinforced polymer composites. Int. J. Life Cycle Assess. 2011, 16, 268–282. [Google Scholar] [CrossRef]

- Griffing, E.; Vozzola, E.; Overcash, M. Life cycle inventory data for carbon fiber and epoxy systems and use in environmentally optimized designs. In Proceedings of the LCA XIV, San Francisco, CA, USA, 6–8 October 2014. [Google Scholar]

- Fitzer, E.; Foley, A.; Frohs, W.; Hauke, T.; Heine, M.; Jäger, H.; Sitter, S. Fibers, 15. Carbon Fibers. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley: Hoboken, NJ, USA, 2000. [Google Scholar] [CrossRef]

- Sauer, M.; Schüppel, D. Marktbericht 2022—Der Globale Markt für Carbonfasern und Carbon. Composites: Marktentwicklungen, Trends, Ausblicke und Herausforderungen. Langfassung für Mitglieder des CU; Composites United e.V.: Berlin, Germany, 2023. [Google Scholar]

- Kelly, G. Joining of Carbon Fibre Reinforced Plastics for Automotive Applications. Ph.D. Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2004. [Google Scholar]

- SGL Carbon. Mechanical Engineering. Available online: https://www.sglcarbon.com/en/markets-solutions/applications/mechanical-engineering/ (accessed on 16 August 2023).

- SGL Carbon. Sports Equipment. Available online: https://www.sglcarbon.com/en/markets-solutions/applications/sports-equipment/ (accessed on 16 August 2023).

- Zoltek. Sporting Goods Applications. Available online: http://zoltek.com/applications/sporting-goods (accessed on 16 August 2023).

- International Renewable Energy Agency. Accelerating Hydrogen Deployment in the G7: Recommendations for the Hydrogen Action Pact; IRENA: Abu Dhabi, United Arab Emirate, 2022; ISBN 978-92-9260-479-0. [Google Scholar]

- Nachtane, M.; Tarfaoui, M.; Abichou, M.A.; Vetcher, A.; Rouway, M.; Aâmir, A.; Mouadili, H.; Laaouidi, H.; Naanani, H. An Overview of the Recent Advances in Composite Materials and Artificial Intelligence for Hydrogen Storage Vessels Design. J. Compos. Sci. 2023, 7, 119. [Google Scholar] [CrossRef]

- Lieboldt, M.; Tietze, M.; Schladitz, F. C3-Projekt—Erfolgreiche Partnerschaft für Innovation im Bauwesen. Bauingenieur 2018, 93, 265–273. [Google Scholar] [CrossRef]

- Schmohl, A.; Adamow, K.; Martens, N.; Breuer, K. Zum Potenzial von Kohlenstofffaserverbundwerkstoffen in Bauanwendungen. Bauphysik 2014, 36, 11–19. [Google Scholar] [CrossRef]

- Ad-Media GmbH. Innovativ mit Carbon: Beton-Fassadenplatten mit 3D-Gitter-Bewehrung aus Carbonfasern in der Schweiz. In opusC—Planen & Gestalten mit Beton; Ad-Media Verlag: Köln, Germany, 2013; pp. 48–50. [Google Scholar]

- Sbahieh, S.; Mckay, G.; Al-Ghamdi, S.G. A comparative life cycle assessment of fiber-reinforced polymers as a sustainable reinforcement option in concrete beams. Front. Built Environ. 2023, 9, 1194121. [Google Scholar] [CrossRef]

- Cai, J.Y.; McDonnell, J.; Brackley, C.; O’Brien, L.; Church, J.S.; Millington, K.; Smith, S.; Phair-Sorensen, N. Polyacrylonitrile-based precursors and carbon fibers derived from advanced RAFT technology and conventional methods—The 1st comparative study. Mater. Today Commun. 2016, 9, 22–29. [Google Scholar] [CrossRef]

- Faneca, G.; Segura, I.; Torrents, J.M.; Aguado, A. Development of conductive cementitious materials using recycled carbon fibres. Cem. Concr. Compos. 2018, 92, 135–144. [Google Scholar] [CrossRef]

- Früchtl, M.; Holland, M.; Hieronymus, A. Biological Transformation along the Product Life Cycle Considering Ecological Sustainability, Costs and Performance by using Graph-based Design Language. Procedia CIRP 2022, 112, 531–536. [Google Scholar] [CrossRef]

- Hohmann, A.; Albrecht, S.; Lindner, J.P.; Wehner, D.; Kugler, M.; Prenzel, T. Recommendations for Resource Efficient and Environmentally Responsible Manufacturing of CFRP Products: Results of the Research Study MAI Enviro 2.0; Carbon Composites e.V.: Augsburg, Germany, 2018; ISBN 978-3-9818900-0-6. [Google Scholar]

- Höhne, C.-C.; Blaess, P.; Ilinzeer, S.; Griesbaum, P. New approach for electric vehicle composite battery housings: Electromagnetic shielding and flame retardancy of PUR/UP-based sheet moulding compound. Compos. Part A Appl. Sci. Manuf. 2023, 167, 107404. [Google Scholar] [CrossRef]

- Khalil, Y.F. Eco-efficient lightweight carbon-fiber reinforced polymer for environmentally greener commercial aviation industry. Sustain. Prod. Consum. 2017, 12, 16–26. [Google Scholar] [CrossRef]

- Kim, K.-W.; Lee, H.-M.; An, J.-H.; Chung, D.-C.; An, K.-H.; Kim, B.-J. Recycling and characterization of carbon fibers from carbon fiber reinforced epoxy matrix composites by a novel super-heated-steam method. J. Environ. Manag. 2017, 203, 872–879. [Google Scholar] [CrossRef] [PubMed]

- La Rosa, A.D.; Banatao, D.R.; Pastine, S.J.; Latteri, A.; Cicala, G. Recycling treatment of carbon fibre/epoxy composites: Materials recovery and characterization and environmental impacts through life cycle assessment. Compos. Part B Eng. 2016, 104, 17–25. [Google Scholar] [CrossRef]

- Li, X.; Bai, R.; McKechnie, J. Environmental and financial performance of mechanical recycling of carbon fibre reinforced polymers and comparison with conventional disposal routes. J. Clean. Prod. 2016, 127, 451–460. [Google Scholar] [CrossRef]

- Meng, F.; McKechnie, J.; Turner, T.A.; Pickering, S.J. Energy and environmental assessment and reuse of fluidised bed recycled carbon fibres. Compos. Part A Appl. Sci. Manuf. 2017, 100, 206–214. [Google Scholar] [CrossRef]

- Newcomb, B.A. Processing, structure, and properties of carbon fibers. Compos. Part A Appl. Sci. Manuf. 2016, 91, 262–282. [Google Scholar] [CrossRef]

- Nunes, A.O.; Viana, L.R.; Guineheuc, P.-M.; da Silva Moris, V.A.; de Paiva, J.M.F.; Barna, R.; Soudais, Y. Life cycle assessment of a steam thermolysis process to recover carbon fibers from carbon fiber-reinforced polymer waste. Int. J. Life Cycle Assess. 2017, 23, 1825–1838. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Progress. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Strauß, S.; Senz, A.; Ellinger, J. Comparison of the Processing of Epoxy Resins in Pultrusion with Open Bath Impregnation and Closed-Injection Pultrusion. J. Compos. Sci. 2019, 3, 87. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, M.; Li, J.; Yu, J.; Sun, S.; Ge, S.; Guo, X.; Xie, F.; Jiang, B.; Wujcik, E.K.; et al. Silver nanoparticles/graphene oxide decorated carbon fiber synergistic reinforcement in epoxy-based composites. Polymer 2017, 131, 263–271. [Google Scholar] [CrossRef]

- Wetjen, D. Wechselwirkung von Carbonfasern, Schlichte und Epoxidbasierter Polymerer Matrix in Carbonfaserverstärkten Kunststoffen. Ph.D. Thesis, University Augsburg, Augsburg, Germany, 2016. [Google Scholar]

- Yusof, N.; Ismail, A.F. Post spinning and pyrolysis processes of polyacrylonitrile (PAN)-based carbon fiber and activated carbon fiber: A review. J. Anal. Appl. Pyrolysis 2012, 93, 1–13. [Google Scholar] [CrossRef]

- Huang, X. Fabrication and Properties of Carbon Fibers. Materials 2009, 2, 2369–2403. [Google Scholar] [CrossRef]

- Audi, A.G. Life Cycle Assessment: Audi Looks One Step Ahead. 2011. Available online: https://www.audi.com/content/dam/com/EN/corporate-responsibility/product/audi_a6_life_cycle_assessment.pdf (accessed on 24 August 2018).

- Greisel, M.; Horn, S. MAI Polymer—Zentrum für Faser-Matrix-Anbindung: Anwendungsangepasste Thermoplastische Matrix/Schlichte-Systeme; Abschlussbericht FKZ 03MAI11A; Universität Augsburg: Augsburg, Germany, 2016. [Google Scholar]

- Brockhaus, R.; Alles, W.; Luckner, R. Flugregelung, 3., neu Bearbeitete Auflage; Springer: Berlin/Heidelberg, Germany, 2011; ISBN 9783642014420. [Google Scholar]

- Tober, G.; Schiller, D. NDT in Aerospace—State of Art. In Proceedings of the 15th World: Conference on Non-Destructive Testing, Rome, Italy, 15–20 October 2000. [Google Scholar]

- Rommel, S.; Geiger, R.; Schneider, R.; Baumann, M.; Brandstetter, P.; Held, M.; Albrecht, S.; Creutzenberg, O.; Dasenbrock, C. Leichtbau in Mobilität und Fertigung: Ökologische Aspekte; e-mobil BW GmbH—Landesagentur für Elektromobilität und Brennstoffzellentechnologie Baden-Württemberg: Stuttgart, Germany, 2012. [Google Scholar]

- Duflou, J.R.; Deng, Y.; van Acker, K.; Dewulf, W. Do fiber-reinforced polymer composites provide environmentally benign alternatives?: A life-cycle-assessment-based study. MRS Bull. 2012, 37, 374–382. [Google Scholar] [CrossRef]

- Hohmann, A.; Albrecht, S.; Lindner, J.P.; Voringer, B.; Wehner, D.; Drechsler, K.; Leistner, P. Resource efficiency and environmental impact of fiber reinforced plastic processing technologies. Prod. Eng. Res. Dev. 2018, 12, 405–417. [Google Scholar] [CrossRef]

- Duflou, J.R.; de Moor, J.; Verpoest, I.; Dewulf, W. Environmental impact analysis of composite use in car manufacturing. CIRP Ann. 2009, 58, 9–12. [Google Scholar] [CrossRef]

- United States Department of Energy. Bandwidth Study on Energy Use and Potential Energy Saving Opportunities in U.S. Carbon Fiber Reinforced Polymer Manufacturing (DOE/EE-1662); United States Department of Energy: Washington, DC, USA, 2017.

- Shimanoe, H.; Ko, S.; Jeon, Y.-P.; Nakabayashi, K.; Miyawaki, J.; Yoon, A.S.-H. Shortening Stabilization Time Using Pressurized Air Flow in Manufacturing Mesophase Pitch-Based Carbon Fiber. Polymers 2019, 11, 1911. [Google Scholar] [CrossRef] [PubMed]

- Groetsch, T.; Creighton, C.; Varley, R.; Kaluza, A.; Dér, A.; Cerdas, F.; Herrmann, C. A modular LCA/LCC-modelling concept for evaluating material and process innovations in carbon fibre manufacturing. Procedia CIRP 2021, 98, 529–534. [Google Scholar] [CrossRef]

- European Commission—Joint Research Centre—Institute for Environment and Sustainability. International Reference Life Cycle Data System (ILCD) Handbook—General guide for Life Cycle Assessment—Detailed guidance. First Edition March 2010. EUR 24708 EN; Publications Office of the European Union: Luxembourg, 2010. [Google Scholar] [CrossRef]

- ISO 14040:2006/Amd 1:2020; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044:2006/Amd 2:2020; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Sphera Solutions GmbH. LCA for Experts Software System and Database for Life Cycle Engineering. Software Version 10.7.1.28. Database Version Professional + Extension CUP 2023.1; Sphera Solutions GmbH: Leinfelden-Echterdingen, Germany, 2023. [Google Scholar]

- European Union—European Platform on LCA. Developer Environmental Footprint (EF). EF Reference Package 3.1. Available online: https://eplca.jrc.ec.europa.eu/LCDN/developerEF.xhtml (accessed on 28 July 2023).

- Frank, E.; Hermanutz, F.; Buchmeiser, M.R. Carbon Fibers: Precursors, Manufacturing, and Properties. Macromol. Mater. Eng. 2012, 297, 493–501. [Google Scholar] [CrossRef]

- JCMA. Manufactualing Process of Carbonfiber. Available online: http://www.carbonfiber.gr.jp/english/material/manufacture.html (accessed on 16 August 2023).

- Zoltek. How is Carbon Fiber Made? Available online: http://zoltek.com/carbon-fiber/how-is-carbon-fiber-made/ (accessed on 31 July 2023).

- Eisenmann. Carbon Fiber: Material of the Future. ETS-B-002a-en-0316; Eisenmann: Bovenden, Germany, 2016. [Google Scholar]

- Liu, L. Leightweight Materials: Carbon Fiber. Available online: http://www.eisenmann-china.com/en/products-and-services/?SId=3&PId=155 (accessed on 20 September 2018).

- Griffing, E.; Overcash, M. Carbon Fiber HS from PAN [UIDCarbFibHS]: Contents of Factory Gate to Factory Gate Life Cycle Inventory Summary; Updated Version 10/04/2010; 1999-Present, Chemical Life Cycle Database; Environmental Clarity: Washington, DC, USA, 2010. [Google Scholar]

- Morgan, P. Carbon Fibers and Their Composites, 1st ed.; CRC Press/Taylor & Francis Group: Boca Raton, FL, USA, 2005; ISBN 9781420028744. [Google Scholar]

- Park, S.-J. Carbon Fibers, 2nd ed.; Springer Nature: Singapore, 2018; ISBN 978-981-13-0537-5. [Google Scholar]

- Zhang, C.; Liu, J.; Guo, S.; Xiao, S.; Shen, Z.; Xu, L. Comparison of microwave and conventional heating methods for oxidative stabilization of polyacrylonitrile fibers at different holding time and heating rate. Ceram. Int. 2018, 44, 14377–14385. [Google Scholar] [CrossRef]

- Park, S.; Kil, H.-S.; Choi, D.; Song, S.-K.; Lee, S. Rapid stabilization of polyacrylonitrile fibers achieved by plasma-assisted thermal treatment on electron-beam irradiated fibers. J. Ind. Eng. Chem. 2019, 69, 449–454. [Google Scholar] [CrossRef]

- Khayyam, H.; Naebe, M.; Milani, A.S.; Fakhrhoseini, S.M.; Date, A.; Shabani, B.; Atkiss, S.; Ramakrishna, S.; Fox, B.; Jazar, R.N. Improving energy efficiency of carbon fiber manufacturing through waste heat recovery: A circular economy approach with machine learning. Energy 2021, 225, 120113. [Google Scholar] [CrossRef]

- Heine, M. Carbon Fibers—Manufacturing and Optimisation Potential. In Proceedings of the Conference: Aachen Reinforced! 2022, Aachen, Germany, 17–19 October 2022. [Google Scholar]

- Hohmann, A. Ökobilanzielle Untersuchung von Herstellungsverfahren für CFK-Strukturen zur Identifikation von Optimierungspotentialen—Systematische Methodik zur Abschätzung der Umweltwirkungen von Fertigungsprozessketten. Ph.D. Thesis, Technische Universität München (TUM), Munich, Germany, 2019. [Google Scholar]

- Stiller, H. Material Intensity of Advanced Composite Materials: Results of a Study for the Verbundwerkstofflabor Bremen e.V.; Wuppertal Papers No. 90; Wuppertal Institut für Klima, Umwelt, Energie gGmbH: Wuppertal, Germany, 1999. [Google Scholar]

- The Japan Carbon Fiber Manufacturers Association. Overview of LCI Data for Carbon Fiber. Available online: https://www.carbonfiber.gr.jp/english/tech/pdf/lci2022_en.pdf (accessed on 8 December 2023).

- 24 Chemical Research. Global Polyacrylonitrile (PAN) Market Research Report; 24 Chemical Research: Pune, India, 2023. [Google Scholar]

- International Energy Agency. Japan—Countries & Regions—IEA. Available online: https://www.iea.org/countries/japan (accessed on 8 December 2023).

- International Energy Agency. World Energy Outlook 2023. Available online: https://www.iea.org/reports/world-energy-outlook-2023 (accessed on 8 December 2023).

- Hohmann, A. Nachhaltige Verbundwerkstoffe für Hochleistungsanwendungen—Abschätzung der Umweltwirkungen und möglicher Reduktionspotentiale. In Proceedings of the Technologietag Leichtbau—Global Lightweight Summit, Stuttgart, Germany, 9–10 November 2021. [Google Scholar]

- Wehner, D.; Prenzel, T.; Betten, T.; Briem, A.-K.; Hong, S.H.; Ilg, R. The Sustainability Data Science Life Cycle for automating multi-purpose LCA workflows for the analysis of large product portfolios. E3S Web Conf. 2022, 349, 11003. [Google Scholar] [CrossRef]

- Prenzel, T.M.; Shevelov, A.; Wehner, D. Detecting environmental hotspots in extensive portfolios through LCA and data science: A use-case perspective. E3S Web Conf. 2022, 349, 11001. [Google Scholar] [CrossRef]

- DeVegt, O.M.; Haije, W.G. Comparative Environmental Life Cycle Assessment of Composite Materials; ECN Report ECN-I--97-050; Netherlands Energy Research Foundation (ECN): Petten, The Netherlands, 1997. [Google Scholar]

- Gehr, M. LCA benefits of rCF. In Proceedings of the Composite Recycling & LCA Conference, Stuttgart, Germany, 9 March 2017. [Google Scholar]

- Howarth, J.; Mareddy, S.S.; Mativenga, P.T. Energy intensity and environmental analysis of mechanical recycling of carbon fibre composite. J. Clean. Prod. 2014, 81, 46–50. [Google Scholar] [CrossRef]

- JCMA. Lifecycle Assessment of Aircraft, Automobil & Windmill: JCMA’s Assessment Model. Available online: https://www.carbonfiber.gr.jp/english/tech/pdf/lca.pdf (accessed on 12 December 2023).

- Life Cycle Assessment Society of Japan. JLCA News Letter; JLCA News English Edition No. 8; 2009; Available online: http://lca-forum.org/english/pdf/08.pdf (accessed on 16 August 2023).

- Manis, F.; Betz, T.; Wölling, J.; Drechsler, K. Bewertung der mechanischen und ökologischen Aspekte des thermischen Recyclings von Faserverbundwerkstoffen. In 4. Symposium Rohstoffeffizienz und Rohstoffinnovationen; Fraunhofer Verlag: Stuttgart, Germany, 2016. [Google Scholar]

- Matsuhisa, Y. Quantification of CO2 Reduction Effect through Carbon Fiber Usage: Importance of Life Cycle Assessment (LCA). Life Cycle Assess. Soc. Jpn. 2009, 9, 27–33. [Google Scholar]

- Schmidt, J.H.; Watson, J. Eco Island Ferry: Comparative LCA of Island Ferry with Carbon Fibre Composite Based and Steel Based Structures. 2.-0 LCA Consultants: Aalborg, Denmark, 2013. Available online: https://www.eco-island.dk/pdf/Eco_E_Ferry_LCA_20130418(JS).pdf (accessed on 12 December 2023).

- Schmidt, J.H. Plastberegner.dk—LCA Tool for Plastics Converters in Denmark: Documentation of the Tool and Database. Aalborg, Denmark, 2012. Available online: https://lca-net.com/files/Plastindustrien_LCAreport_20121008.pdf (accessed on 12 December 2023).

- Song, Y.S.; Youn, J.R.; Gutowski, T.G. Life cycle energy analysis of fiber-reinforced composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1257–1265. [Google Scholar] [CrossRef]

- Suzuki, T.; Takahashi, J. LCA of lightweight vehicles by using CFRP for mass-produced vehicles. In Proceedings of the Fifteenth International Conference on Composite Materials, Durban, South Africa, 27 June–1 July 2005. [Google Scholar]

- Witik, R.A.; Payet, J.; Michaud, V.; Ludwig, C.; Månson, J.-A.E. Assessing the life cycle costs and environmental performance of lightweight materials in automobile applications. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1694–1709. [Google Scholar] [CrossRef]

- Witik, R.A.; Teuscher, R.; Michaud, V.; Ludwig, C.; Månson, J.-A.E. Carbon fibre reinforced composite waste: An environmental assessment of recycling, energy recovery and landfilling. Compos. Part A Appl. Sci. Manuf. 2013, 49, 89–99. [Google Scholar] [CrossRef]

- Achternbosch, M.; Bräutigam, K.-R.; Kupsch, C.; Reßler, B.; Sardemann, G. Analyse der Umweltauswirkungen bei der Herstellung, dem Einsatz und der Entsorgung von CFK-bzw; Aluminiumrumpfkomponenten. Wissenschaftliche Berichte FZKA 6879; Institut für Technikfolgenabschätzung und Systemanalyse, Forschungszentrum Karlsruhe GmbH: Karlsruhe, Germany, 2003. [Google Scholar]

- Blumberg, H. Fibers for composites—Status quo and trends. Chem. Fibers Int. 1997, 47, 36–41. [Google Scholar]

- Lee, S.M.; Jonas, T.; DiSalvo, G. Beneficial energy and environmental impact of composite materials. An unexpected bonus. SAMPE J. 1991, 27, 19–25. [Google Scholar]

- Minus, M.L.; Kumar, S. The processing, properties, and structure of carbon fibers. JOM 2005, 57, 52–58. [Google Scholar] [CrossRef]

- Fiedler, A.K.; Fitzer, E.; Rozploch, F. PAN Pyrolysis studied by Gas- and ESR Analyses. In Proceedings of the 11th Biennial Conference, Gatlinburg, TN, USA, 4–8 June 1973. [Google Scholar]

- Beckmann, M. Beschreibung Unterschiedlicher Techniken und Deren Entwicklungspotentiale zur Minderung von Stickstoffoxiden im Abgas von Abfallverbrennungsanlagen und Ersatzbrennstoff-Kraftwerken hinsichtlich Leistungsfähigkeit, Kosten und Energieverbrauch. Dessau-Roßlau, 2011. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/461/publikationen/4196.pdf (accessed on 12 December 2023).

- Linstrom, P. NIST Chemistry WebBook, NIST Standard Reference Database 69: Last Update to Data: 2023. Available online: https://webbook.nist.gov/chemistry/ (accessed on 8 December 2023).

| Flow | Amount | Unit | |

|---|---|---|---|

| Input | Polyacrylonitrile (PAN) fiber | 1.95 | [kg/kg CF] |

| Air | 9.6 | [kg/kg CF] | |

| Nitrogen [N2] | 10.0 | [kg/kg CF] | |

| Electrolyte [Ammonium bicarbonate] | 0.03 | [kg/kg CF] | |

| Sizing agent [Epoxy resin] | 0.02 | [kg/kg CF] | |

| Water [H2O] | 5.5 | [kg/kg CF] | |

| Process energy (electric and thermal) | 170 | [MJ/kg CF] | |

| Output | Carbon fiber | 1.00 | [kg] |

| Gaseous carbon emissions [HCN, C2H6, CO2, CO] | 0.6 | [kg/kg CF] | |

| Gaseous non-carbon emissions [exhaust air, N2, NH3, H2O (g)] | 20.0 | [kg/kg CF] | |

| Wastewater | 5.5 | [kg/kg CF] | |

| Recovered thermal energy | 11.2 | [MJ/kg CF] | |

| Waste heat | 8.32 | [MJ/kg CF] |

| Variant | Scenario | Energy Source Precursor Production | Energy Source CF Production | Technologically Optimized Process (−50% Energy Demand) |

|---|---|---|---|---|

| Global | GLO 1 | Grid mix (JP) | Grid mix (GLO) | No |

| GLO 2 | Hydropower (JP) | Hydropower (GLO) | No | |

| GLO 3 | Hydropower (JP) | Hydropower (GLO) | Yes | |

| US | US 1 | Grid mix (JP) | Grid mix (US) | No |

| US 2 | Hydropower (JP) | Hydropower (US) | No | |

| US 3 | Hydropower (JP) | Hydropower (US) | Yes | |

| Japan | JP 1 | Grid mix (JP) | Grid mix (JP) | No |

| JP 2 | Hydropower (JP) | Hydropower (JP) | No | |

| JP 3 | Hydropower (JP) | Hydropower (JP) | Yes | |

| China | CN 1 | Grid mix (JP) | Grid mix (CN) | No |

| CN 2 | Hydropower (JP) | Hydropower (CN) | No | |

| CN 3 | Hydropower (JP) | Hydropower (CN) | Yes | |

| Hungary | HU 1 | Grid mix (JP) | Grid mix (HU) | No |

| HU 2 | Hydropower (JP) | Hydropower (HU) | No | |

| HU 3 | Hydropower (JP) | Hydropower (HU) | Yes | |

| Germany | DE 1 | Grid mix (JP) | Grid mix (DE) | No |

| DE 2 | Hydropower (JP) | Hydropower (DE) | No | |

| DE 3 | Hydropower (JP) | Hydropower (DE) | Yes | |

| France | FR 1 | Grid mix (JP) | Grid mix (FR) | No |

| FR 2 | Hydropower (JP) | Hydropower (FR) | No | |

| FR 3 | Hydropower (JP) | Hydropower (FR) | Yes | |

| GB | GB 1 | Grid mix (JP) | Grid mix (GB) | No |

| GB 2 | Hydropower (JP) | Hydropower (GB) | No | |

| GB 3 | Hydropower (JP) | Hydropower (GB) | Yes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prenzel, T.M.; Hohmann, A.; Prescher, T.; Angerer, K.; Wehner, D.; Ilg, R.; von Reden, T.; Drechsler, K.; Albrecht, S. Bringing Light into the Dark—Overview of Environmental Impacts of Carbon Fiber Production and Potential Levers for Reduction. Polymers 2024, 16, 12. https://doi.org/10.3390/polym16010012

Prenzel TM, Hohmann A, Prescher T, Angerer K, Wehner D, Ilg R, von Reden T, Drechsler K, Albrecht S. Bringing Light into the Dark—Overview of Environmental Impacts of Carbon Fiber Production and Potential Levers for Reduction. Polymers. 2024; 16(1):12. https://doi.org/10.3390/polym16010012

Chicago/Turabian StylePrenzel, Tobias Manuel, Andrea Hohmann, Tim Prescher, Kerstin Angerer, Daniel Wehner, Robert Ilg, Tjark von Reden, Klaus Drechsler, and Stefan Albrecht. 2024. "Bringing Light into the Dark—Overview of Environmental Impacts of Carbon Fiber Production and Potential Levers for Reduction" Polymers 16, no. 1: 12. https://doi.org/10.3390/polym16010012

APA StylePrenzel, T. M., Hohmann, A., Prescher, T., Angerer, K., Wehner, D., Ilg, R., von Reden, T., Drechsler, K., & Albrecht, S. (2024). Bringing Light into the Dark—Overview of Environmental Impacts of Carbon Fiber Production and Potential Levers for Reduction. Polymers, 16(1), 12. https://doi.org/10.3390/polym16010012