New Approach for Processing Recycled Carbon Staple Fiber Yarns into Unidirectionally Reinforced Recycled Carbon Staple Fiber Tape

Abstract

:1. Introduction

2. Materials and Methods

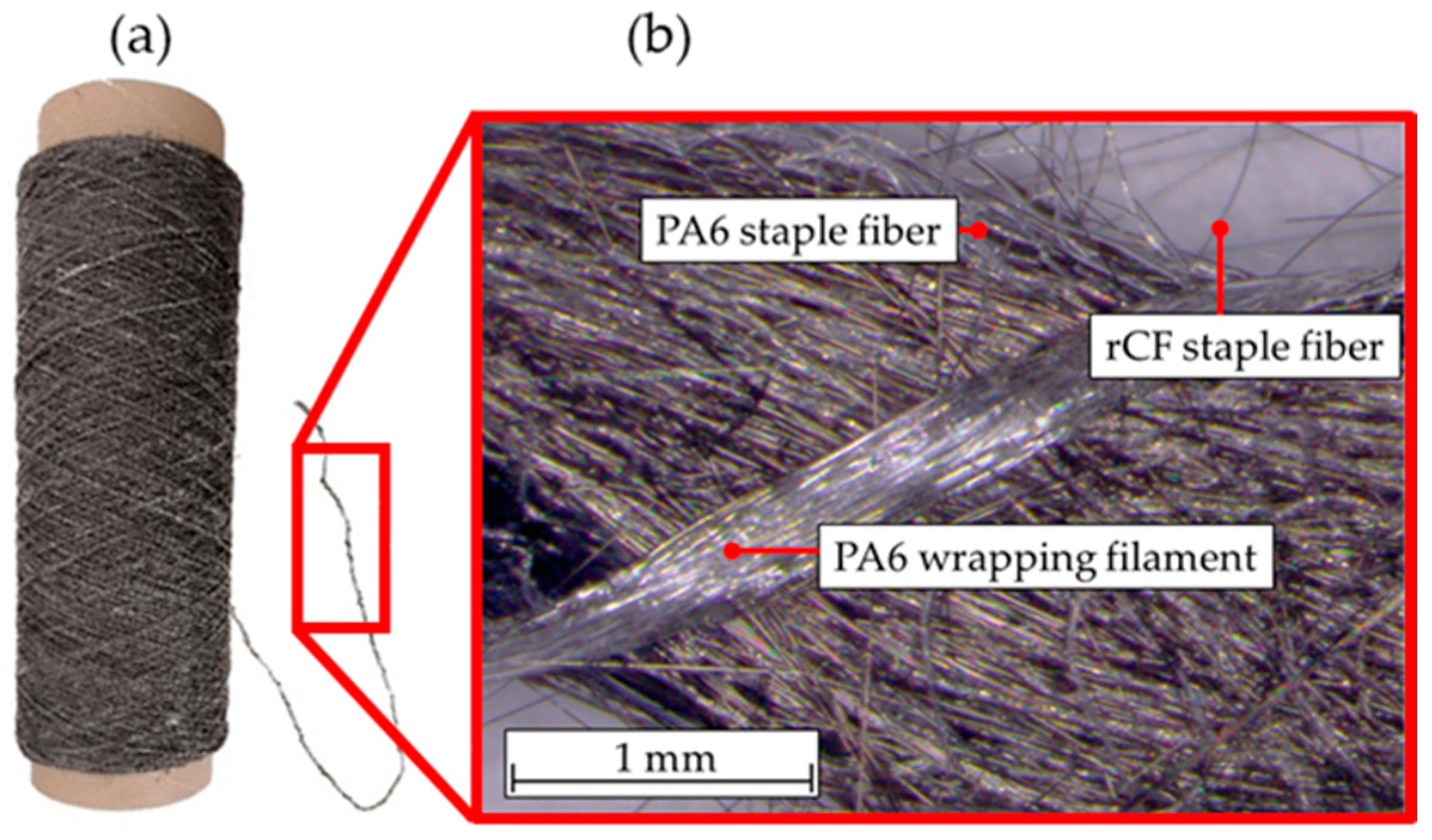

2.1. Staple Fiber Yarn

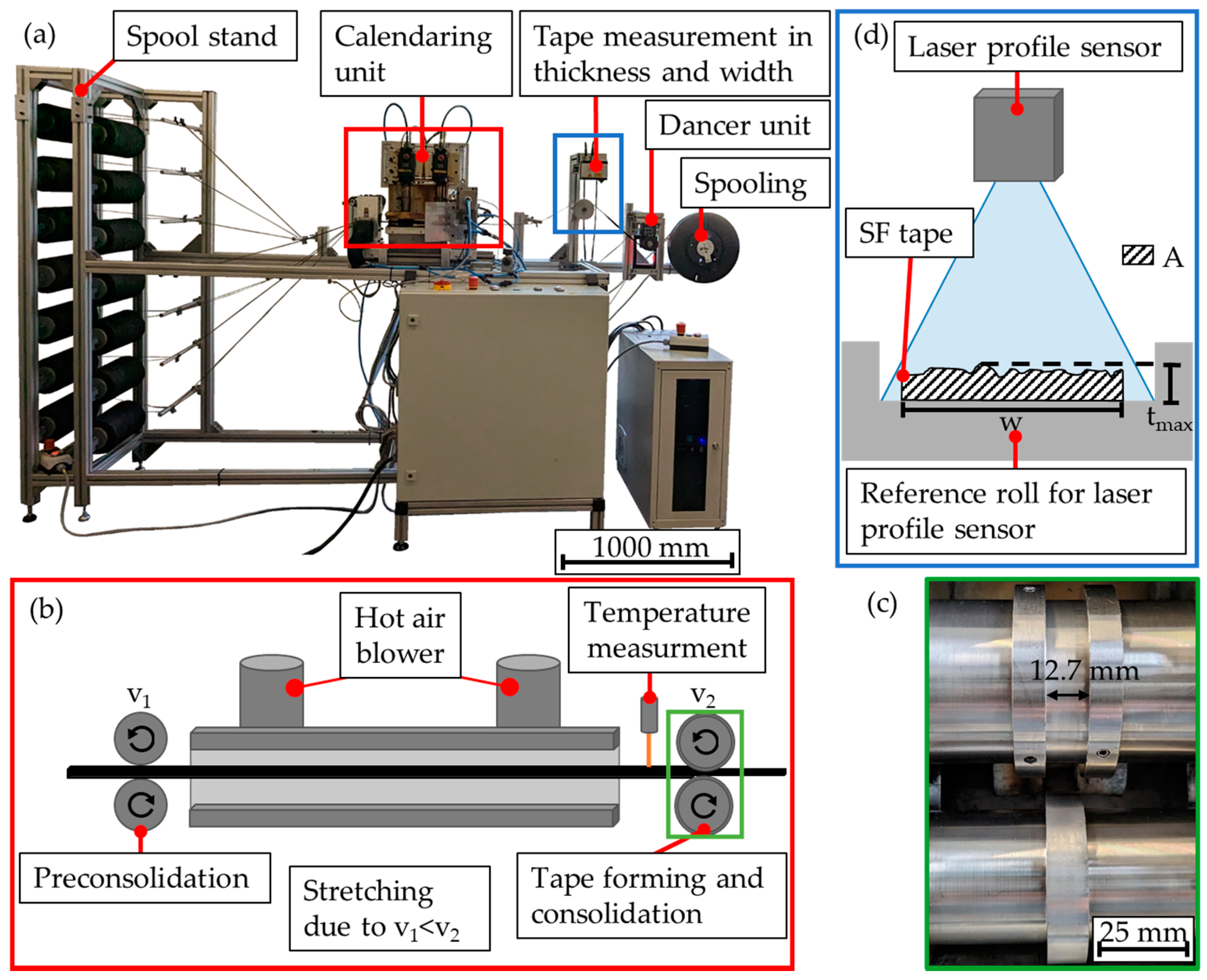

2.2. Tape Manufacturing

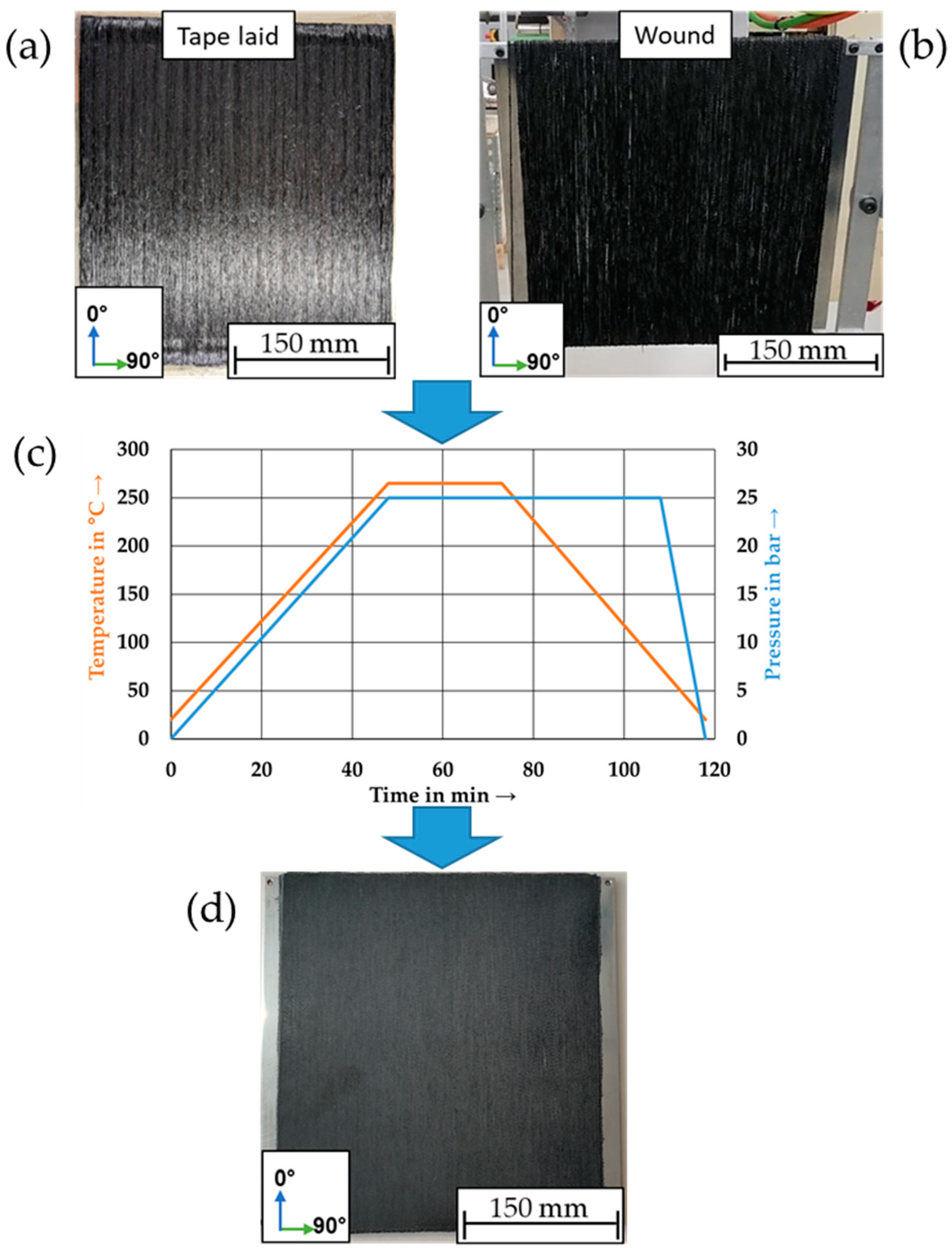

2.3. Manufacturing of Staple Fiber Organic Sheets

2.4. Characterization of the Staple Fiber Yarn and the Manufactured SF Tape

2.5. Characterization of the Thermal Properties

2.6. Determination of Fiber Orientation

2.7. Determination of the Fiber Volume Content

2.8. Mechanical Testing

2.8.1. Tensile Testing

2.8.2. Flexural Testing

2.9. Inspection of the Fracture Surface of the Composite Test Specimens

3. Results

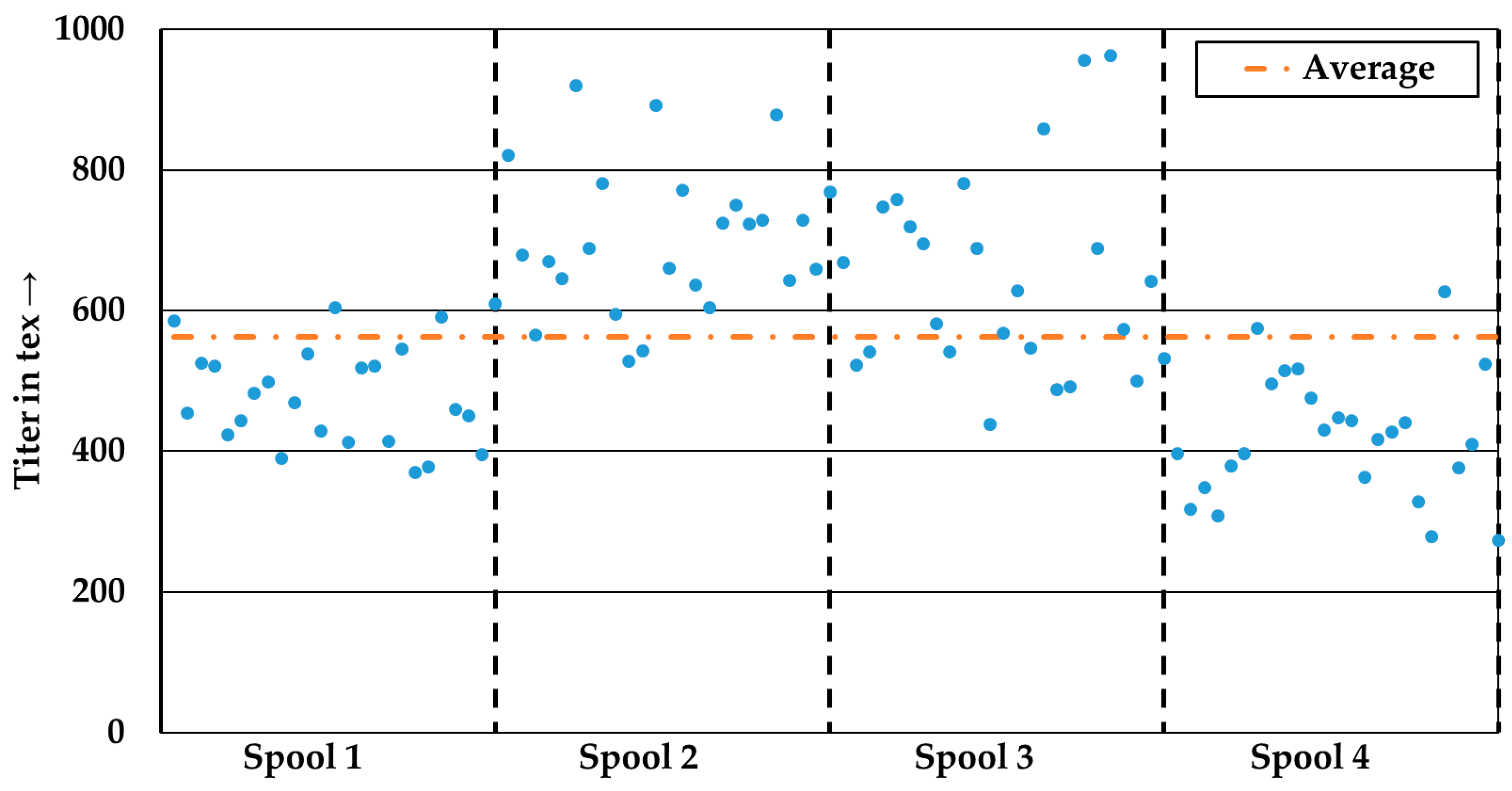

3.1. Characterization of the Staple Fiber Yarn

3.2. Characterization of the Staple Fiber Tape

3.3. Characterization of Staple Fiber Organic Sheets

3.3.1. Determination of the Fiber Volume Content

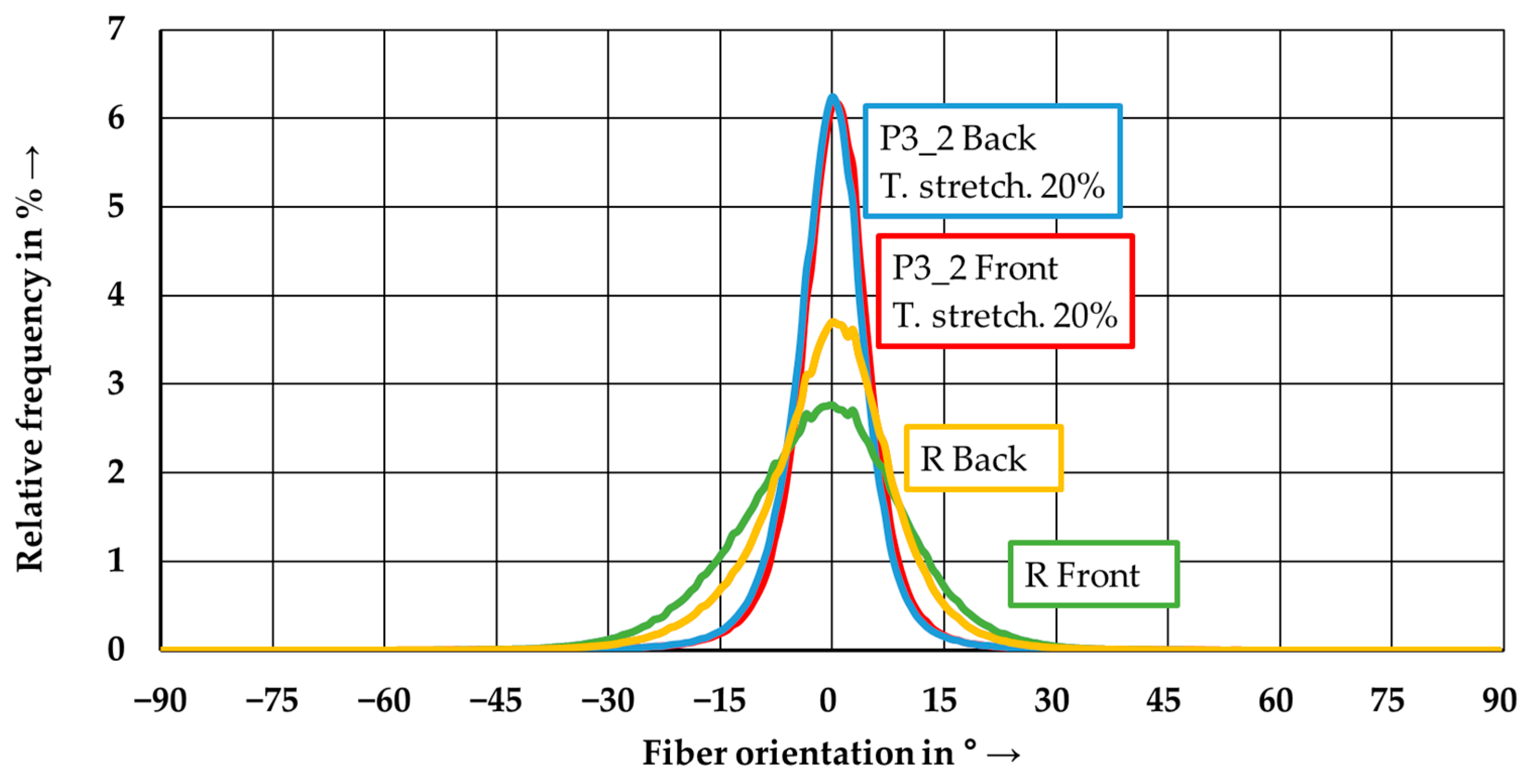

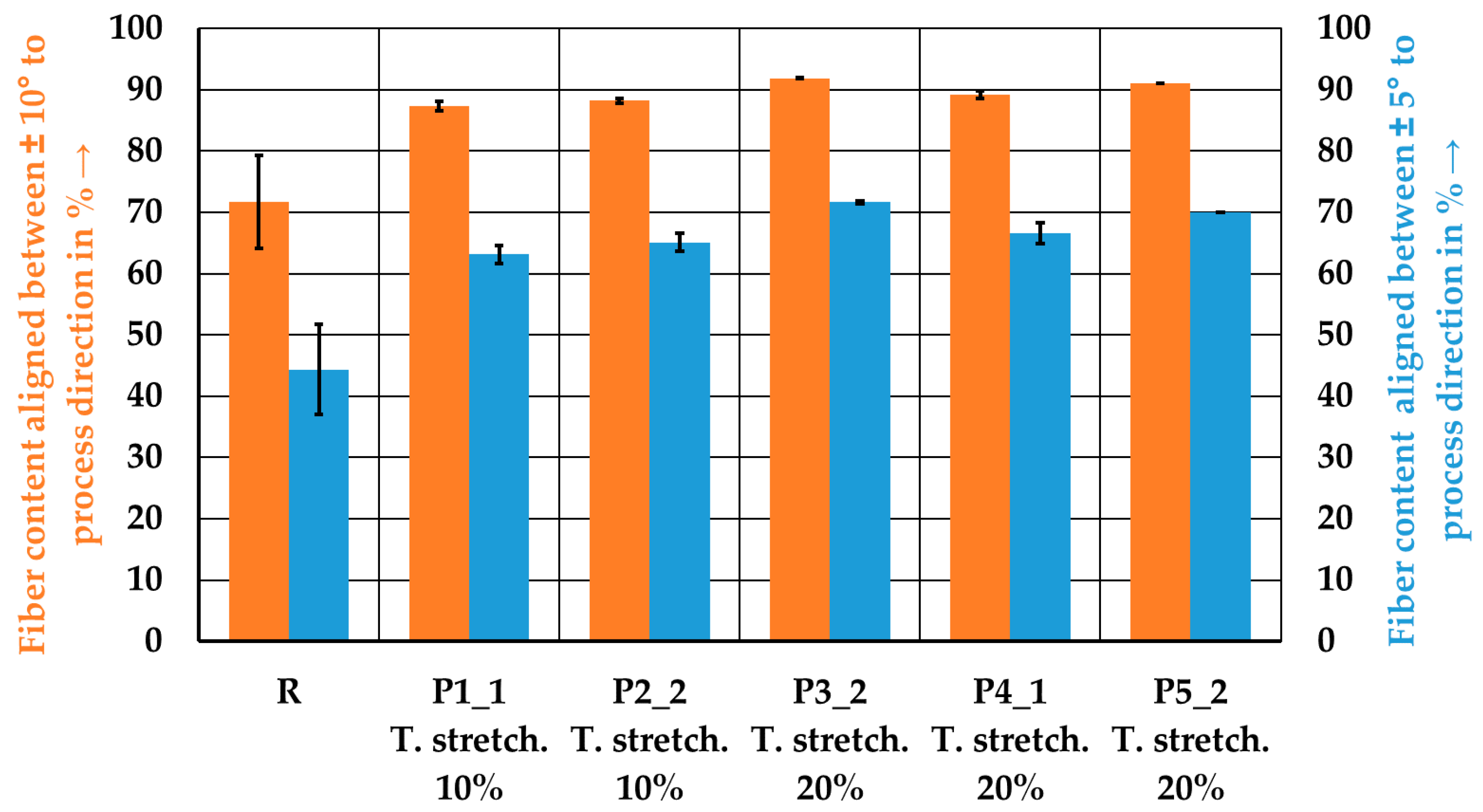

3.3.2. Determination of the Fiber Orientation

3.3.3. Determination of the Mechanical Properties

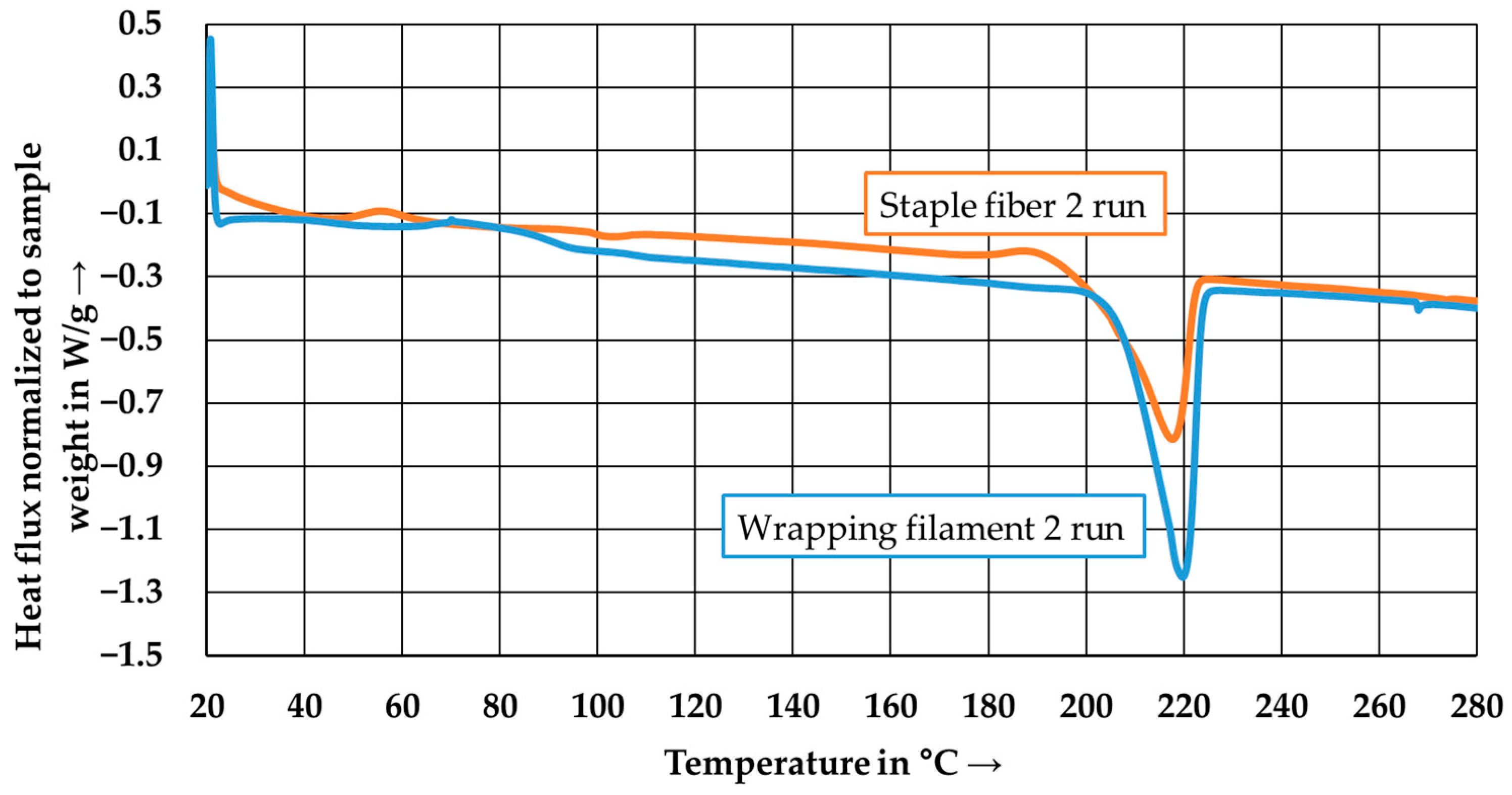

3.3.4. Determination of the Thermal Properties

3.3.5. Inspection of the Fracture Surface

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, J.; Chevali, V.S.; Wang, H.; Wang, C.-H. Current Status of Carbon Fibre and Carbon Fibre Composites Recycling. Compos. Part B Eng. 2020, 193, 108053. [Google Scholar] [CrossRef]

- Pakdel, E.; Kashi, S.; Varley, R.; Wang, X. Recent Progress in Recycling Carbon Fibre Reinforced Composites and Dry Carbon Fibre Wastes. Resour. Conserv. Recycl. 2021, 166, 105340. [Google Scholar] [CrossRef]

- Kooduvalli, K.; Unser, J.; Ozcan, S.; Vaidya, U.K. Embodied Energy in Pyrolysis and Solvolysis Approaches to Recycling for Carbon Fiber-Epoxy Reinforced Composite Waste Streams. Recycling 2022, 7, 6. [Google Scholar] [CrossRef]

- Sauer, M.; Schüppel, D. Market Report 2021. The Global Market for Carbon Fibers and Carbon Composites—Short Version; Composites United: Berlin, Germany, 2022. [Google Scholar]

- Pimenta, S.; Pinho, S.T. Recycling Carbon Fibre Reinforced Polymers for Structural Applications: Technology Review and Market Outlook. Waste Manag. 2011, 31, 378–392. [Google Scholar] [CrossRef] [PubMed]

- Khurshid, M.F.; Hengstermann, M.; Hasan, M.M.B.; Abdkader, A.; Cherif, C. Recent Developments in the Processing of Waste Carbon Fibre for Thermoplastic Composites—A Review. J. Compos. Mater. 2020, 54, 1925–1944. [Google Scholar] [CrossRef]

- Barnett, P.R.; Ghossein, H.K. A Review of Recent Developments in Composites Made of Recycled Carbon Fiber Textiles. Textiles 2021, 1, 433–465. [Google Scholar] [CrossRef]

- May, D.; Goergen, C.; Friedrich, K. Multifunctionality of Polymer Composites Based on Recycled Carbon Fibers: A Review. Adv. Ind. Eng. Polym. Res. 2021, 4, 70–81. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current Status of Recycling of Fibre Reinforced Polymers: Review of Technologies, Reuse and Resulting Properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Neitzel, M.; Mitschang, P.; Breuer, U.P. (Eds.) Handbuch Verbundwerkstoffe: Werkstoffe, Verarbeitung, Anwendung; Aktualisierte und Erweiterte Auflage; Hanser: Munich, Germany, 2014; Volume 2, ISBN 978-3-446-43697-8. [Google Scholar]

- Sukanto, H.; Raharjo, W.W.; Ariawan, D.; Triyono, J. Carbon Fibers Recovery from CFRP Recycling Process and Their Usage: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1034, 012087. [Google Scholar] [CrossRef]

- Barnett, P.R.; Gilbert, C.L.; Penumadu, D. Repurposed/Recycled Discontinuous Carbon Fiber Organosheet Development and Composite Properties. Compos. Part C Open Access 2021, 4, 100092. [Google Scholar] [CrossRef]

- Heilos, K.; Fischer, H.; Hofmann, M.; Miene, A. Nonwovens Made of Recycled Carbon Fibres rCF Used for Production of Sophisticated Carbon Fibre-Reinforced Plastics. Fibres Text. 2020, 27, 65–75. [Google Scholar]

- Tietze, J.; Nendel, S.; Gebauer, F.; Schramm, S. Carbonfaserverstärkte Thermoplastische Halbzeuge Im Nassvliesstoff-Verfahren. nonwonensTRENDS 2020, 4–5, 100–103. [Google Scholar]

- Barnett, P.R.; Young, S.A.; Chawla, V.; Foster, D.M.; Penumadu, D. Thermo-Mechanical Characterization of Discontinuous Recycled/Repurposed Carbon Fiber Reinforced Thermoplastic Organosheet Composites. J. Compos. Mater. 2021, 55, 3409–3423. [Google Scholar] [CrossRef]

- Wong, K.H.; Turner, T.A.; Pickering, S.J. Challenges in Developing Nylon Composites Commingled with Discontinuous Recycled Carbon Fibre. In Proceedings of the 16th European Conference on Composite Materials ECCM16, Seville, Spain, 22–26 June 2014. [Google Scholar]

- Miyake, T.; Imaeda, S. A Dry Aligning Method of Discontinuous Carbon Fibers and Improvement of Mechanical Properties of Discontinuous Fiber Composites. Adv. Manuf. Polym. Compos. Sci. 2016, 2, 117–123. [Google Scholar] [CrossRef]

- Hengstermann, M.; Hasan, M.M.B.; Abdkader, A.; Cherif, C. Development of a New Hybrid Yarn Construction from Recycled Carbon Fibers (rCF) for High-Performance Composites. Part-II: Influence of Yarn Parameters on Tensile Properties of Composites. Text. Res. J. 2017, 87, 1655–1664. [Google Scholar] [CrossRef]

- Hengstermann, M.; Bardl, G.; Rao, H.; Abdkader, A.; Hasan, M.M.B.; Cherif, C. Development of a Method for Characterization of the Fibre Length of Long Staple Carbon Fibres Based on Image Analysis. Fibres Text. East. Eur. 2016, 24, 39–44. [Google Scholar] [CrossRef]

- Abdkader, A.; Hengstermann, M.; Hasan, M.M.B.; Cherif, C.; Weber, D. Spinnverfahren zur Herstellung von Hybridgarnen aus Recyclten Carbonfasern für CFK-Bauteile. Tech. Textilien 2017, 60, 243–246. [Google Scholar]

- Hasan, M.M.B.; Abdkader, A.; Cherif, C.; Spennato, F. Fibre Hybrid Composites Consisting of Discontinuous Waste Carbon Fibre and Fibre Hybrid Composites Consisting of Discontinuous Waste Carbon Fibre and Continuous Glass Filaments Developed for Load-Bearing Structures with Improved Impact Strength. Compos. Part Appl. Sci. Manuf. 2019, 126, 105610. [Google Scholar] [CrossRef]

- Hengstermann, M.; Raithel, N.; Abdkader, A.; Cherif, C. Spinning of Staple Hybrid Yarn from Carbon Fiber Wastes for Lightweight Constructions. Mater. Sci. Forum 2015, 825–826, 695–698. [Google Scholar] [CrossRef]

- Hasan, M.M.B.; Hengstermann, M.; Dilo, R.; Abdkader, A.; Cherif, C. Investigations on the Manufacturing and Mechanical Properties of Spun Yarns Made from Staple CF for Thermoset Composites. Autex Res. J. 2017, 17, 395–404. [Google Scholar] [CrossRef]

- Hasan, M.M.B.; Nitsche, S.; Abdkader, A.; Cherif, C. Properties of CF/PA6 Friction Spun Hybrid Yarns for Textile Reinforced Thermoplastic Composites. IOP Conf. Ser. Mater. Sci. Eng. 2017, 254, 042013. [Google Scholar] [CrossRef]

- Akonda, M.H.; Lawrence, C.A.; Weager, B.M. Recycled Carbon Fibre-Reinforced Polypropylene Thermoplastic Composites. Compos. Part Appl. Sci. Manuf. 2012, 43, 79–86. [Google Scholar] [CrossRef]

- Georgen, C.; Baz, S.; Mitschang, P.; Gresser, G.T. Highly Drapable Organic Sheets Made of Recycled Carbon Staple Fiber Yarns. In Proceedings of the 21st International Conference on Composite Materials ICCM21, Xi’an, China, 20–25 August 2017. [Google Scholar]

- Becker, C.; Hausmann, J.; Krummenacker, J.; Motsch-Eichmann, N. First Conclusions on Damage Behaviour of Recycled Carbon Staple Fibre Yarn Using X-Ray and Acoustic Emission Techniques. Materials 2023, 16, 4842. [Google Scholar] [CrossRef] [PubMed]

- Rimmel, O.; May, D.; Goergen, C.; Poeppel, A.; Mitschang, P. Development and Validation of Recycled Carbon Fiber-Based Binder Tapes for Automated Tape Laying Processes. J. Compos. Mater. 2019, 53, 3257–3268. [Google Scholar] [CrossRef]

- Oliveux, G.; Bailleul, J.-L.; Gillet, A.; Mantaux, O.; Leeke, G.A. Recovery and Reuse of Discontinuous Carbon Fibres by Solvolysis: Realignment and Properties of Remanufactured Materials. Compos. Sci. Technol. 2017, 139, 99–108. [Google Scholar] [CrossRef]

- Faure, A.; Mantaux, O.; Gillet, A.; Cazaurang, G. New Intelligent Semi-Products Based on Recycled Carbon Fibres. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1226, 012102. [Google Scholar] [CrossRef]

- Gillet, A.; Mantaux, O.; Cazaurang, G. Characterization of Composite Materials Made from Discontinuous Carbon Fibres within the Framework of Composite Recycling. Compos. Part Appl. Sci. Manuf. 2015, 75, 89–95. [Google Scholar] [CrossRef]

- Ayfre, M.; Mantaux, O. Innovative semi-products made of recycled carbon fibres. Jec Compos. Mag. 2019, 131, 27–28. [Google Scholar]

- Yu, H.; Potter, K.D.; Wisnom, M.R. A Novel Manufacturing Method for Aligned Discontinuous Fibre Composites (High Performance-Discontinuous Fibre Method). Compos. Part Appl. Sci. Manuf. 2014, 65, 175–185. [Google Scholar] [CrossRef]

- Longana, M.L.; Yu, H.; Jalavand, M.; Wisnom, M.R.; Potter, K.D. Aligned Discontinuous Intermingled Reclaimed/Virgin Carbon Fibre Composites for High Performance and Pseudo-Ductile Behaviour in Interlaminated Carbon-Glass Hybrids. Compos. Sci. Technol. 2017, 143, 13–21. [Google Scholar] [CrossRef]

- Yu, H.; Longana, M.L.; Grail, G.; Pimenta, S.; Robinson, P.; Wisnom, M.R.; Potter, K.D. Aligned Short Fibre Composites with Nonlinear Behaviour. In Proceedings of the 20th International Conference on Composite Materials ICCM20, Copenhagen, Denmark, 19–24 July 2015. [Google Scholar]

- Longana, M.L.; Yu, H.; Hamerton, I.; Potter, K.D. Development and Application of a Quality Control and Property Assurance Methodology for Reclaimed Carbon Fibers Based on the HiPerDiF (High Performance Discontinuous Fibre) Method and Interlaminated Hybrid Specimens. Adv. Manuf. Polym. Compos. Sci. 2018, 4, 48–55. [Google Scholar] [CrossRef]

- Finley, J.; Yu, H.; Longana, M.; Pimenta, S.; Shaffer, M.S. Grouping Similar Fibre Types in Hybrid Discontinuous Composite Materials. In Proceedings of the 21st International Conference on Composite Materials, Xi’an, China, 20–25 August 2017. [Google Scholar]

- Yu, H.; Longana, M.L.; Swolfs, Y.; Wisnom, M.R.; Potter, K.D. Hybrid Effect of Carbon/Glass Composites as a Function of the Strength Distribution of Aligned Short Carbon Fibres. In Proceedings of the 17th European Conference on Composite Materials ECCM17, Munich, Germany, 26–30 June 2016. [Google Scholar]

- Longana, M.L.; Ong, N.; Yu, H.; Potter, K.D. Multiple Closed Loop Recycling of Carbon Fibre Composites with the HiPerDiF (High Performance Discontinuous Fibre) Method. Compos. Struct. 2016, 153, 271–277. [Google Scholar] [CrossRef]

- Kandemir, A.; Longana, M.L.; Panzera, T.H.; Del Pino, G.G.; Hamerton, I.; Eichhorn, S.J. Natural Fibres as a Sustainable Reinforcement Constituent in Aligned Discontinuous Polymer Composites Produced by the HiPerDiF Method. Materials 2021, 14, 1885. [Google Scholar] [CrossRef] [PubMed]

- Longana, M.L.; Ondra, V.; Yu, H.; Potter, K.; Hamerton, I. Reclaimed Carbon and Flax Fibre Composites: Manufacturing and Mechanical Properties. Recycling 2018, 3, 52. [Google Scholar] [CrossRef]

- Longana, M.L.; Yu, H.; Lee, J.; Pozegic, T.R.; Huntley, S.; Rendall, T.; Potter, K.D.; Hamerton, I. Quasi-Isotropic and Pseudo-Ductile Highly Aligned Discontinuous Fibre Composites Manufactured with the HiPerDiF (High Performance Discontinuous Fibre) Technology. Materials 2019, 12, 1794. [Google Scholar] [CrossRef]

- Aravindan, P.; Becagli, F.; Longana, M.L.; Blok, L.G.; Pozegic, T.R.; Huntley, S.J.; Rendall, T.; Hamerton, I. Remanufacturing of Woven Carbon Fibre Fabric Production Waste into High Performance Aligned Discontinuous Fibre Composites. J. Compos. Sci. 2020, 4, 68. [Google Scholar] [CrossRef]

- Kandemir, A.; Longana, M.L.; Hamerton, I.; Eichhorn, S.J. Developing Aligned Discontinuous Flax Fibre Composites: Sustainable Matrix Selection and Repair Performance of Vitrimers. Compos. Part B Eng. 2022, 243, 110139. [Google Scholar] [CrossRef]

- Heider, D.; Tierney, J.; Henchir, M.; Gargitter, V.; Yarlagadda, S.; Gillespie, J., Jr.; Sun, J.; Sietins, J.; Knorr, D. Microstructural Evaluation of Aligned, Short Fiber TUFF Material. In Proceedings of the SAMPE, Charlote, NC, USA, 20–23 May 2019. [Google Scholar]

- Cender, T.A.; Fidlow, H.; Yarlagadda, S.; Heider, D.; Simacek, P.; Advani, S.G.; Gillespie, J.W., Jr. Forming Limits of TuFF Composites in Stretch Forming Processes. In Proceedings of the SAMPE 2022, Hamburg, Germany, 15–17 November 2022. [Google Scholar]

- Heider, D.; Tierney, J.; Deitzel, J.; Kubota, M.; Thiravong, J.; Gargitter, V.; Burris, W.; Morris, J.; Shevchenko, N.; Yarlagadda, S.; et al. Closed Loop Recycling of Cfrp into Highly Aligned High Performance Short Fiber Composites Using the Tuff Process. In Proceedings of the SAMPE, Charlote, NC, USA, 20–23 May 2019. [Google Scholar]

- Heider, D.; Yarlagadda, S.; Blackwell, C.; Crane, R.; Davis, M.; Emmerich, R.; Deitzel, J.; Ozdemir, T. Carbon Fiber Composites Recycling Technology Enabled by the TuFF Technology. Sampe J. 2022, 11–17. [Google Scholar]

- Yarlagadda, S.; Advani, S.; Deitzel, J.; Heider, D.; Molligan; Roseman, D.; Simacek, P.; Tierney, J.; Gillespie, J.W., Jr. Formability of TuFF Composite Blanks. In Proceedings of the SAMPE, Charlote, NC, USA, 20–23 May 2019. [Google Scholar]

- Yarlagadda, S.; Deitzel, J.; Heider, D.; Tierney, J.; Gillespie, J.W., Jr. Tailorable Universal Feedstock for Forming (TUFF): Overview and Performance. In Proceedings of the SAMPE, Charlote, NC, USA, 20–23 May 2019. [Google Scholar]

- Khurshid, M.F.; Abdkader, A.; Cherif, C. Process Development for Uni Directional Tape Structure Based on Recycled Carbon Fiber and Thermoplastic Fibers for Fiber Reinforced Plastics. In Proceedings of the 19th World Textile Conference on Textiles at the Crossroads, Ghent, Belgium, 11–15 June 2019. [Google Scholar]

- Khurshid, M.F.; Hasan, M.M.B.; Abdkader, A.; Cherif, C. Processing of Waste Carbon and Polyamide Fibers for High Performance Thermoplastic Composites: A Novel Manufacturing Technology for Unidirectional Tapes Structure. J. Ind. Text. 2022, 51, 7256S–7276S. [Google Scholar] [CrossRef]

- Hasan, M.M.B.; Hobel, S.; Abdkader, A.; Cherif, C. Hochdrapierbare Thermoplastfaserbandstrukturen Aus rCF für Komplex Geformte Composites. Tech. Textilien 2021, 64, 124–126. [Google Scholar]

- Akonda, M.H.; Stefanova, M.; Potluri, P. Du Shah Mechanical Properties of Recycled Carbon Fibre/Polyester Thermoplastic Tape Composites. J. Compos. Mater. 2017, 51, 2655–2663. [Google Scholar] [CrossRef]

- Reichert, O.; Ausheyks, L.; Baz, S.; Hehl, J.; Gresser, G.T. Innovative rC Staple Fiber Tapes—New Potentials for CF Recyclates in CFRP through Highly Oriented Carbon Staple Fiber Structures. Key Eng. Mater. 2019, 809, 509–514. [Google Scholar] [CrossRef]

- Möbitz, C.; Cloppenburg, F. MAI RecyTape—Prozesslinie zur Herstellung von Tapes Aus Hochorientierten Recycling—Carbonfasern. Available online: https://composites-united.com/projects/mai-recytape/ (accessed on 5 December 2022).

- Schommer, D.; Duhovic, M.; Hoffmann, T.; Ernst, J.; Schladitz, K.; Moghiseh, A.; Gortner, F.; Hausmann, J.; Mitschang, P.; Steiner, K. Polarization Imaging for Surface Fiber Orientation Measurements of Carbon Fiber Sheet Molding Compounds. Compos. Commun. 2023, 37, 101456. [Google Scholar] [CrossRef]

- DIN EN ISO 1172; Prepregs, Formmassen und Laminate—Bestimmung Des Textilglas- und Mineralfüllstoffgehalts Kalzinierungsverfahren (ISO 1172: 1996). DIN: Berlin, Germany, 1998.

- DIN EN ISO 527-5; Kunststoffe Bestimmung Der Zugeigenschaften Teil 5: Prüfbedingungen Für Unidirektional Faserverstärkte Kunststoffverbundwerkstoffe (ISO 527-5:2009). DIN: Berlin, Germany, 2009.

- DIN EN ISO 14125; Faserverstärkte Kunststoffe Bestimmung Der Biegeeigenschaften (ISO 14125:1998 + Cor.1:2001 + Amd.1:2011). DIN: Berlin, Germany, 2011.

- Khurshid, M.F.; Abdkader, A.; Cherif, C.; Schmolke, W. Entwicklung Einer Industriellen Prozesskette zur Herstellung von UD-Tapes auf der Basis von Recycelten Carbonstapelfasern und Thermoplastfasern. Available online: https://www.dbu.de/OPAC/ab/DBU-Abschlussbericht-AZ-33809_01-Hauptbericht.pdf (accessed on 24 October 2023).

- Celanese Corporation Data Sheet CELSTRAN® CFR-TP PA6 CF60-03. Available online: https://materials.celanese.com/gb/products/pdf/SI/CELSTRAN%C2%AE%20CFR-TP%20PA6%20CF60-03-gb.pdf (accessed on 26 October 2023).

| Material Overview | SI |

|---|---|

| Tensile strength in MPa | 4137 |

| Tensile modulus in GPa | 242 |

| Elongation at break in% | 1.5 |

| Density in g/cm3 | 1.81 |

| Fiber diameter in µm | 7.2 |

| Parameter Set | Temperature in °C Pass 1/ Pass 2 | Speed v1 in m/min Pass 1/ Pass 2 | Stretching Factor Pass 1/ Pass 2 | Total Stretching Factor |

|---|---|---|---|---|

| P1_1 (Pass 1) | 550 | 1.4 | 1.1 | 1.1 |

| P2_1 (Pass 1) P2_2 (Pass 2) | 550 550 | 1.4 1.1 | 1.1 1.0 | 1.1 |

| P3_1 (Pass 1) P3_2 (Pass 2) | 550 550 | 1.4 1.1 | 1.1 1.09 | 1.2 |

| P4_1 (Pass 1) | 550 | 1.4 | 1.2 | 1.2 |

| P5_1 (Pass 1) P5_2 (Pass 2) | 550 550 | 1.4 1.1 | 1.2 1.0 | 1.2 |

| Parameter Set | Width in mm | Thickness in mm |

|---|---|---|

| P1_1 | 12.88 ± 0.32 | 0.65 ± 0.14 |

| P2_1 | 12.98 ± 0.41 | 0.70 ± 0.14 |

| P2_2 | 12.86 ± 0.30 | 0.54 ± 0.07 |

| P3_1 | 13.01 ± 0.31 | 0.67 ± 0.15 |

| P3_2 | 12.87 ± 0.29 | 0.47 ± 0.07 |

| P4_1 | 13.05 ± 0.40 | 0.60 ± 0.13 |

| P5_1 | 13.05 ± 0.33 | 0.58 ± 0.11 |

| P5_2 | 12.82 ± 0.29 | 0.46 ± 0.06 |

| Parameter Set | Tensile Modulus in GPa | Tensile Strength in MPa | Flexural Modulus in GPa | Flexural Strength in MPa |

|---|---|---|---|---|

| R | 82.2 ± 3.4 | 581.6 ± 78.0 | 79.3 ± 4.7 | 1001.0 ± 61.9 |

| P1_1 T. stretch. 10% | 82.0 ± 3.3 | 524.5 ± 44.3 | 83.3 ± 2.2 | 798.9 ± 63.7 |

| P2_2 T. stretch. 10% | 87.0 ± 4.4 | 497.3 ± 50.8 | 86.6 ± 3.4 | 858.3 ± 82.9 |

| P3_2 T. stretch. 20% | 86.0 ± 2.0 | 479.7 ± 30.9 | 81.9 ± 4.1 | 858.1 ± 149.2 |

| P4_1 T. stretch. 20% | 85.8 ± 4.9 | 496.0 ± 38.5 | 85.8 ± 3.7 | 903.8 ± 81.5 |

| P5_2 T. stretch. 20% | 86.7 ± 6.4 | 499.1 ± 44.3 | 87.3 ± 3.0 | 941.9 ± 77.1 |

| Reference rCF material [61] | 89.0 ± 11.0 | 988.9 ± 33.9 | 72.2 ± 8.3 | 721.1 ± 51.4 |

| Virgin UD-tape [62] | 103.1 | 1969.1 | 101.1 | 1072.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Detzel, M.; Mitschang, P.; Breuer, U. New Approach for Processing Recycled Carbon Staple Fiber Yarns into Unidirectionally Reinforced Recycled Carbon Staple Fiber Tape. Polymers 2023, 15, 4575. https://doi.org/10.3390/polym15234575

Detzel M, Mitschang P, Breuer U. New Approach for Processing Recycled Carbon Staple Fiber Yarns into Unidirectionally Reinforced Recycled Carbon Staple Fiber Tape. Polymers. 2023; 15(23):4575. https://doi.org/10.3390/polym15234575

Chicago/Turabian StyleDetzel, Martin, Peter Mitschang, and Ulf Breuer. 2023. "New Approach for Processing Recycled Carbon Staple Fiber Yarns into Unidirectionally Reinforced Recycled Carbon Staple Fiber Tape" Polymers 15, no. 23: 4575. https://doi.org/10.3390/polym15234575

APA StyleDetzel, M., Mitschang, P., & Breuer, U. (2023). New Approach for Processing Recycled Carbon Staple Fiber Yarns into Unidirectionally Reinforced Recycled Carbon Staple Fiber Tape. Polymers, 15(23), 4575. https://doi.org/10.3390/polym15234575