Lightweight ZnO/Carbonated Cotton Fiber Nanocomposites for Electromagnetic Interference Applications: Preparation and Properties

Abstract

:1. Introduction

2. Experimental

2.1. Materials

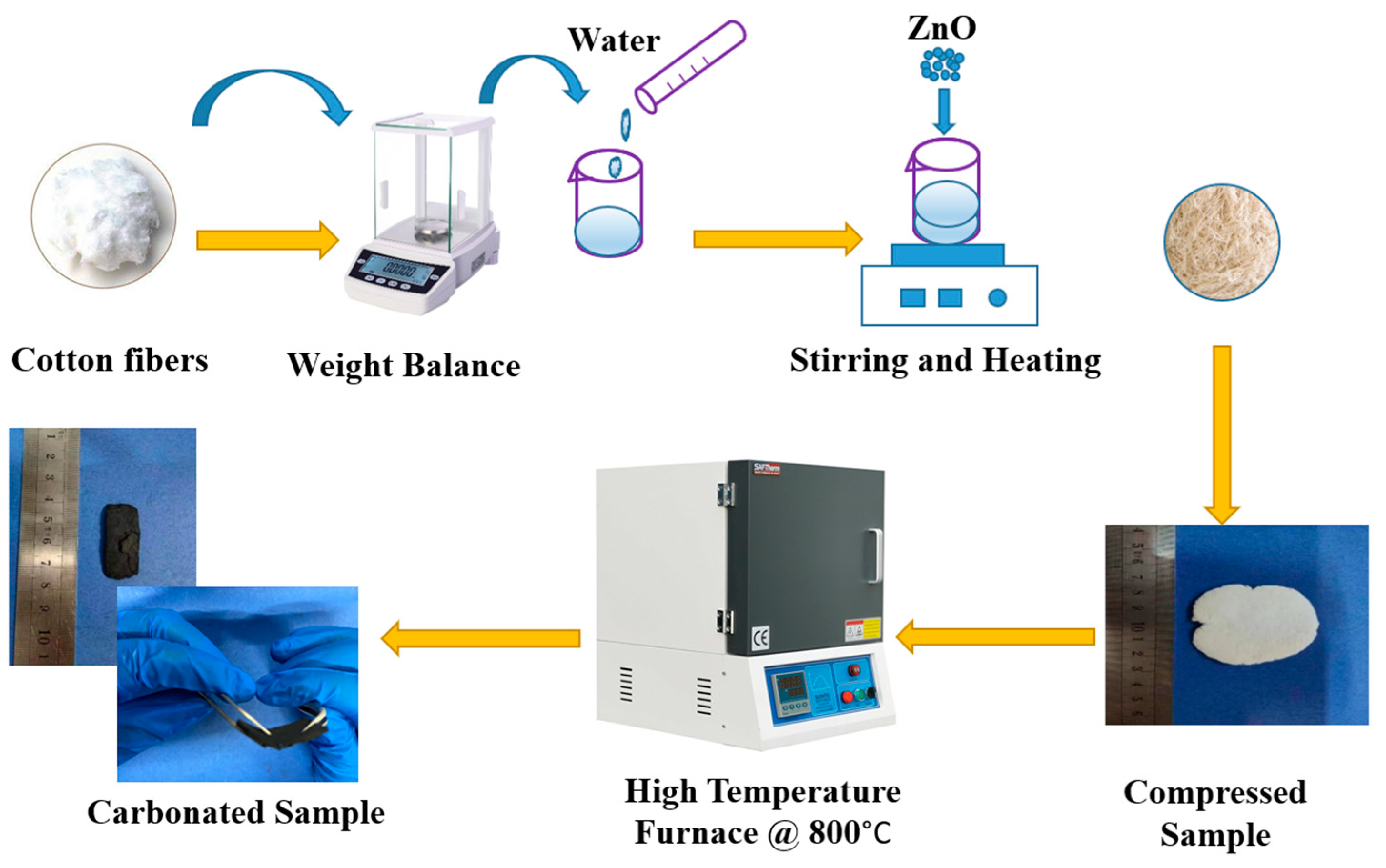

2.2. Preparation of Cotton Fiber/ZnO-Based EMI Shielding Materials

2.3. Characterizations

3. Results and Discussions

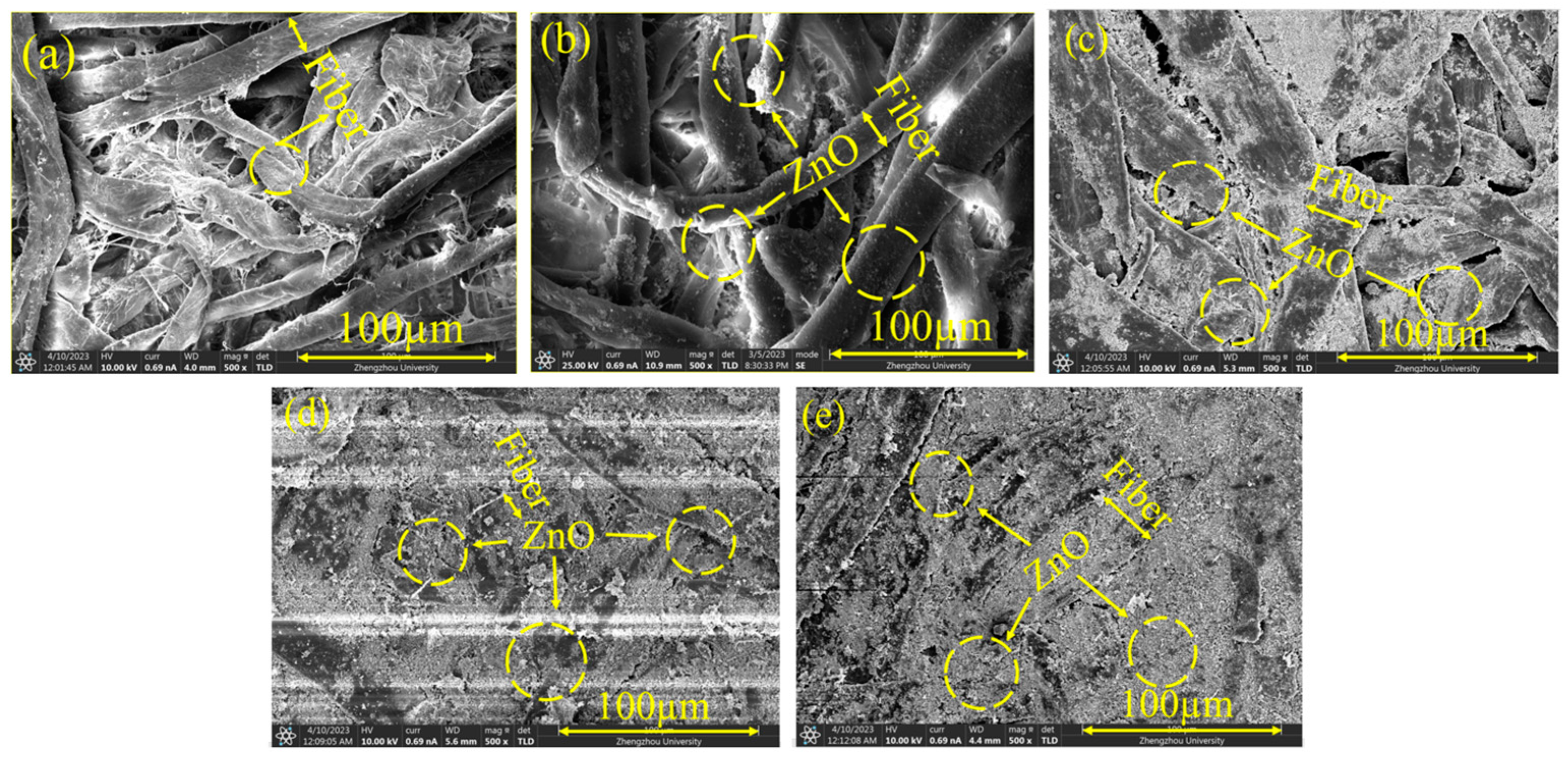

3.1. Morphologies of CF/ZnO Nanocomposites before and after Carbonization

3.2. FTIR Analysis

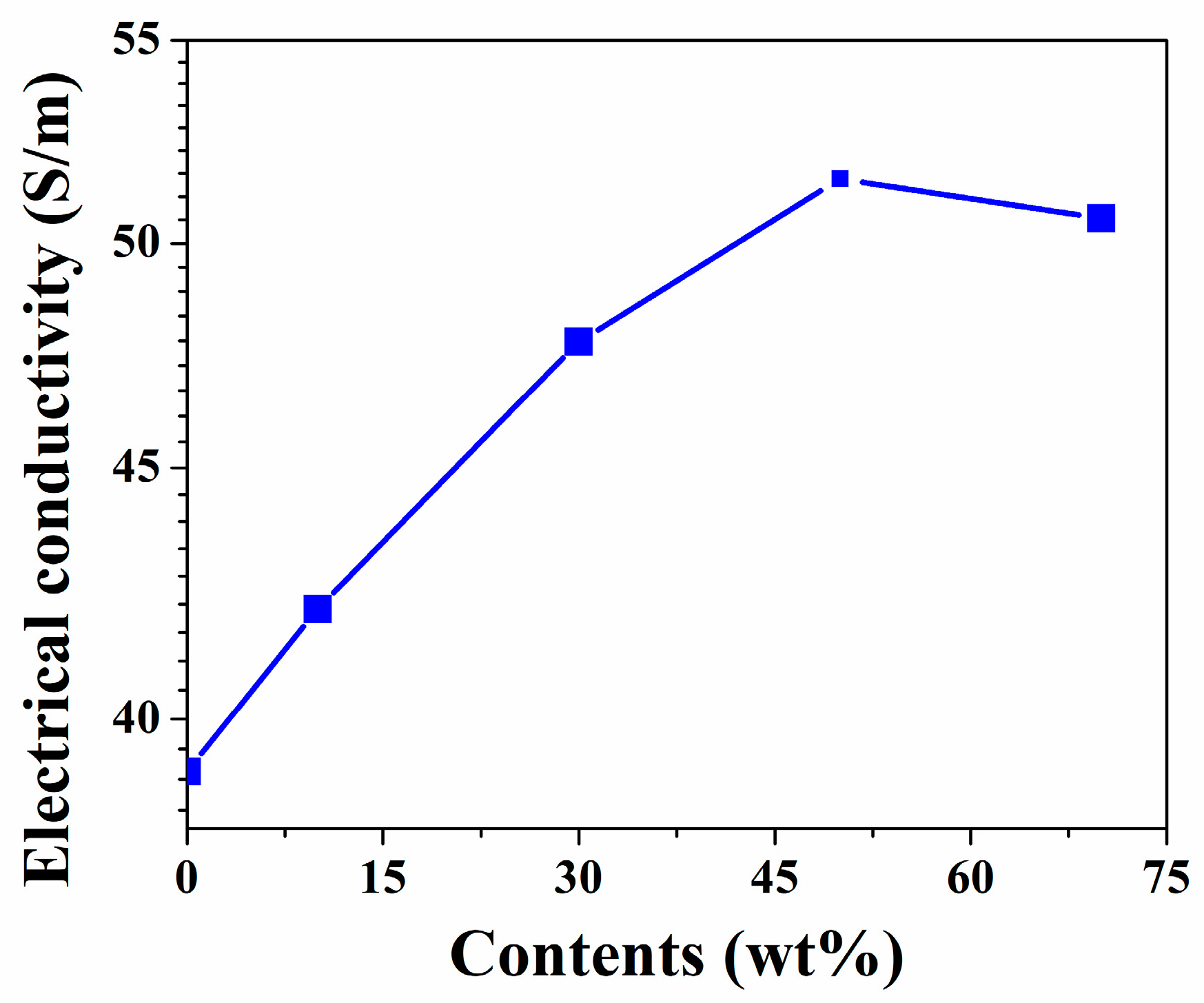

3.3. Performance of Electric Conductive Papers with Carbonated Cellulose Fibers

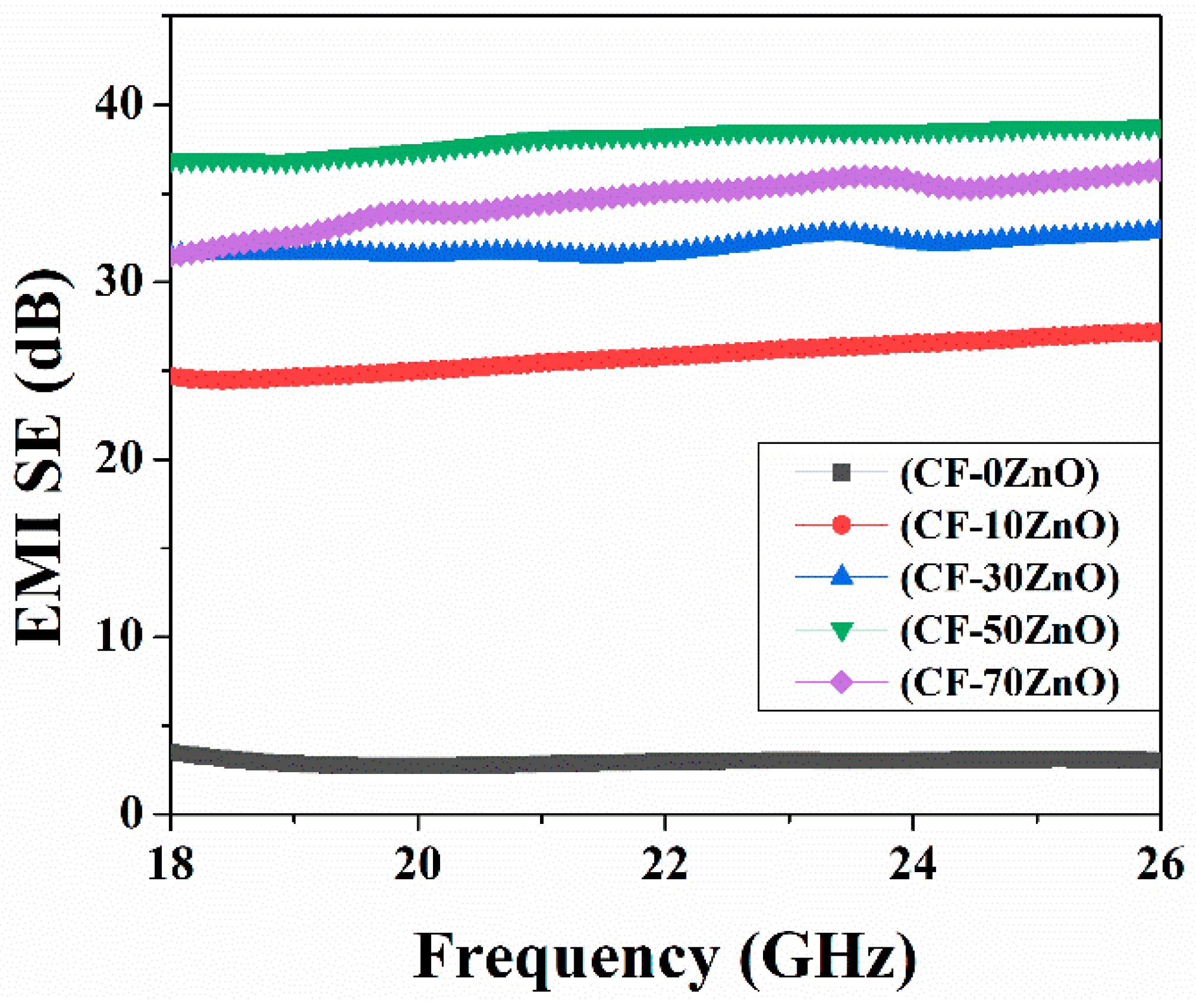

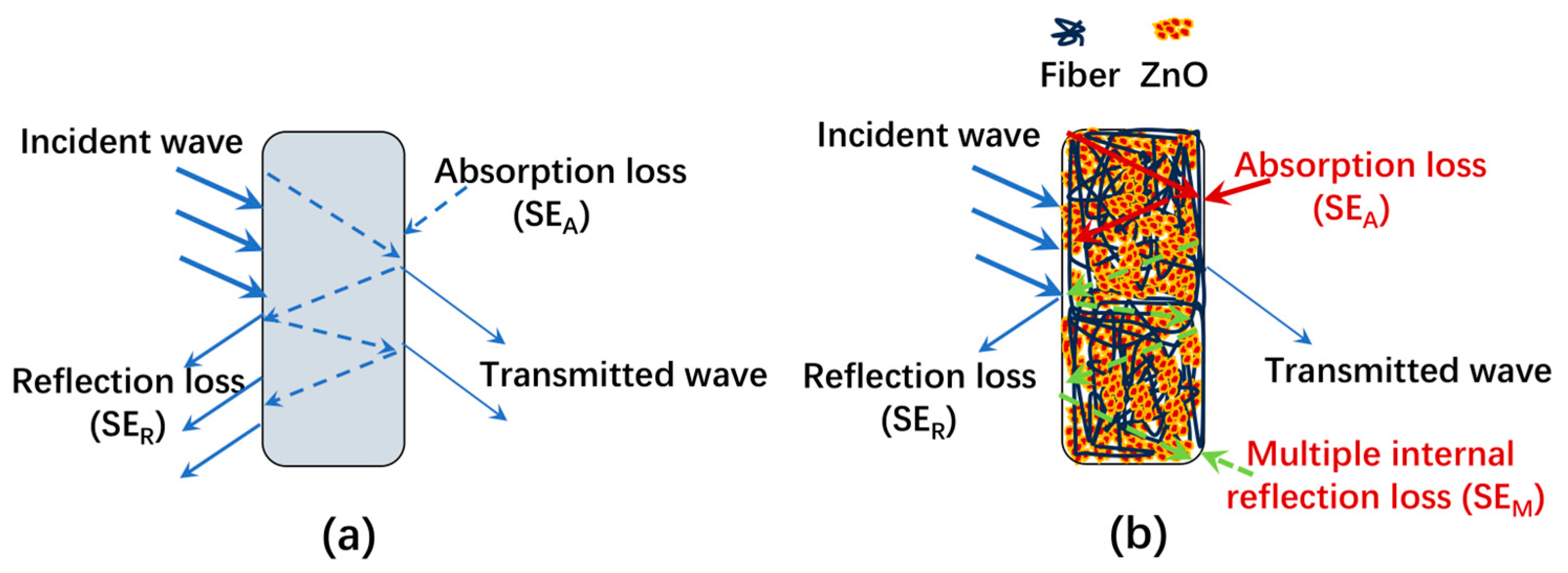

3.4. EMI Shielding Mechanism and Performance of the CF/ZnO Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Du, B.; Qian, J.; Hu, P.; He, C.; Cai, M.; Wang, X.; Shui, A. Fabrication of C-doped SiC nanocomposites with tailoring dielectric properties for the enhanced electromagnetic wave absorption. Carbon 2020, 157, 788–795. [Google Scholar] [CrossRef]

- Kong, L.; Yin, X.; Ye, F.; Li, Q.; Zhang, L.; Cheng, L. Electromagnetic Wave Absorption properties of ZnO-based materials modified with ZnAl2O4 nanograins. J. Phys. Chem. C 2013, 117, 2135–2146. [Google Scholar] [CrossRef]

- Pavlov, A.; Shchepanyuk, T.; Skriabin, A.; Telekh, V. Gas dynamics processes above the polymers surface under irradiation with broadband high-brightness radiation in the vacuum ultraviolet spectrum region. Polymers 2022, 14, 3940. [Google Scholar] [CrossRef] [PubMed]

- Bulychev, N.A. Obtaining of gaseous hydrogen and silver nanoparticles by decomposition of hydrocarbons in ultrasonically stimulated low-temperature plasma. Int. J. Hydrogen Energy 2022, 47, 21323–21328. [Google Scholar] [CrossRef]

- Tang, W.; Lu, L.; Xing, D.; Fang, H.; Liu, Q.; Teh, K.S. A carbon-fabric/polycarbonate sandwiched film with high tensile and EMI shielding comprehensive properties: An experimental study. Compos. Part B Eng. 2018, 152, 8–16. [Google Scholar] [CrossRef]

- Wu, Y.; Yu, K.; Zhang, X.; Hou, J.; Chen, J. Lightweight electromagnetic interference shielding poly(L-lactic acid)/poly(D-lactic acid)/carbon nanotubes composite foams prepared by supercritical CO2 foaming. Int. J. Biol. Macromol. 2022, 210, 11–20. [Google Scholar] [CrossRef]

- Zeraati, A.S.; Sundararaj, U. Carbon nanotube/ZnO nanowire/polyvinylidene fluoride hybrid nanocomposites for enhanced electromagnetic interference shielding. Can. J. Chem. Eng. 2020, 98, 1036–1046. [Google Scholar] [CrossRef]

- Huang, Y.; Xie, Y.; Zhao, J.; Yin, X.; Chai, C. Variety of ZIF-8/MXene-based lightweight microwave-absorbing materials: Preparation and performances of ZnO/MXene nanocomposites. J. Phys. Chem. C 2022, 126, 13847–13853. [Google Scholar] [CrossRef]

- Tahir, D.; Ilyas, S.; Rahmat, R.; Heryanto, H.; Fahri, A.N.; Rahmi, M.H.; Abdullah, B.; Hong, C.C.; Kang, H.J. Enhanced visible-light absorption of Fe2O3 covered by activated carbon for multifunctional purposes: Tuning the structural, electronic, optical, and magnetic properties. ACS Omega 2021, 6, 28334–28346. [Google Scholar] [CrossRef]

- Li, X.; Shu, R.; Wu, Y.; Li, N. Fabrication of Ni/ZnO/C hollow microspheres decorated graphene composites towards high-efficiency electromagnetic wave absorption in the Ku-band. Ceram. Int. 2021, 47, 24372–24383. [Google Scholar] [CrossRef]

- Ma, X.; Shen, B.; Zhang, L.; Liu, Y.; Zhai, W.; Zheng, W. Porous superhydrophobic polymer/carbon composites for lightweight and self-cleaning EMI shielding application. Compos. Sci. Technol. 2018, 158, 86–93. [Google Scholar] [CrossRef]

- Anju, R.S.; Potschke, Y.P.; Pionteck, J.; Krause, B.; Kuritka, I.; Vilcakova, J.; Skoda, D.; Urbanek, P.; Machovsky, M.; Masar, M.; et al. High-performance, lightweight, and flexible thermoplastic polyurethane nanocomposites with Zn(2+)-Substituted CoFe2O4 nanoparticles and reduced graphene oxide as shielding materials against electromagnetic pollution. ACS Omega 2021, 6, 28098–28118. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Tu, T.; Dai, Y.; Tang, P.; Zhang, Y.; Deng, Z.; Li, L.; Zhang, H.B.; Yu, Z.Z. Direct ink writing of highly conductive MXene frames for tunable electromagnetic interference shielding and electromagnetic wave-induced thermochromism. Nanomicro Lett. 2021, 13, 148. [Google Scholar] [CrossRef] [PubMed]

- Mondal, S.; Ganguly, S.; Das, P.; Bhawal, P.; Das, T.K.; Nayak, L.; Khastgir, D.; Das, N.C. High-performance carbon nanofiber coated cellulose filter paper for electromagnetic interference shielding. Cellulose 2017, 24, 5117–5131. [Google Scholar] [CrossRef]

- Chen, H.; Huang, Z.; Huang, Y.; Zhang, Y.; Ge, Z.; Qin, B.; Liu, Z.; Shi, Q.; Xiao, P.; Yang, Y.; et al. Synergistically assembled MWCNT/graphene foam with highly efficient microwave absorption in both C and X bands. Carbon 2017, 124, 506–514. [Google Scholar] [CrossRef]

- Aghvami-Panah, M.; Ameli, A. MXene/Cellulose composites as electromagnetic interference shields: Relationships between microstructural design and shielding performance. Compos. Part A Appl. Sci. Manuf. 2024, 176, 107879. [Google Scholar] [CrossRef]

- Xu, M.K.; Liu, J.; Zhang, H.B.; Zhang, Y.; Wu, X.; Deng, Z.; Yu, Z.Z. Electrically conductive Ti3C2Tx MXene/polypropylene nanocomposites with an ultralow percolation threshold for efficient electromagnetic interference shielding. Ind. Eng. Chem. Res. 2021, 60, 4342–4350. [Google Scholar] [CrossRef]

- Zhang, Y.; Ruan, K.; Shi, X.; Qiu, H.; Pan, Y.; Yan, Y.; Gu, J. Ti3C2Tx/rGO porous composite films with superior electromagnetic interference shielding performances. Carbon 2021, 175, 271–280. [Google Scholar] [CrossRef]

- Song, P.; Liang, C.; Wang, L.; Qiu, H.; Gu, H.; Kong, J.; Gu, J.W. Obviously improved electromagnetic interference shielding performances for epoxy composites via constructing honeycomb structural reduced graphene oxide. Compos. Sci. Technol. 2019, 181, 107698. [Google Scholar] [CrossRef]

- Jia, X.; Shen, B.; Chen, Z.; Zhang, L.; Zheng, W. High-performance carbonized waste corrugated boards reinforced with epoxy coating as lightweight structured electromagnetic shields. ACS Sustain. Chem. Eng. 2019, 7, 18718–18725. [Google Scholar] [CrossRef]

- Cai, M.; Shui, A.; Wang, X.; He, C.; Qian, J.; Du, B. A facile fabrication and high-performance electromagnetic microwave absorption of ZnO nanoparticles. J. Alloys Compd. 2020, 842, 155638. [Google Scholar] [CrossRef]

- Zuo, T.; Wang, W.; Yu, D. MXene/Ag@ZnO/WPU/Melamine gradient composite foams prepared by a unidirectional evaporation approach for absorption-dominated electromagnetic interference shielding. J. Alloys Compd. 2023, 966, 171644. [Google Scholar] [CrossRef]

- Thi, Q.V.; Park, S.; Jeong, J.; Lee, H.; Hong, J.; Koo, C.M.; Tung, N.T.; Sohn, D. A nanostructure of reduced graphene oxide and NiO/ZnO hollow spheres toward attenuation of electromagnetic waves. Mater. Chem. Phys. 2021, 266, 124530. [Google Scholar] [CrossRef]

- Singh, A.K.; Kumar, A.; Srivastava, A.; Yadav, A.N.; Haldar, K.; Gupta, V.; Singh, K. Lightweight reduced graphene oxide-ZnO nanocomposite for enhanced dielectric loss and excellent electromagnetic interference shielding. Compos. Part B Eng. 2019, 172, 234–242. [Google Scholar] [CrossRef]

- Singh, A.K.; Prasad, J.; Kumar, A.; Srivastava, A.; Tyagi, U.P.; Prajapati, B.; Singh, K. One-step facile synthesis of MoS2—Reduced graphene oxide/ZnO nanostructure for high-performance microwave absorption. Mater. Sci. Eng. B 2023, 293, 116450. [Google Scholar] [CrossRef]

- Abhilash, G.P.; Sushmita, K.; Bose, S.; Shivakumara, C. Functionalization of dielectric BaTiO3 and semiconducting ZnO nanoparticles on rGO layers and their polymer composites: Applications in EMI shielding. Synth. Met. 2023, 297, 117387. [Google Scholar] [CrossRef]

- Luo, J.; Zhang, K.; Cheng, M.; Gu, M.; Sun, X. MoS2 spheres decorated on hollow porous ZnO microspheres with strong wideband microwave absorption. Chem. Eng. J. 2020, 380, 122625. [Google Scholar] [CrossRef]

- Kong, L.; Yin, X.; Han, M.; Zhang, L.; Cheng, L. Carbon nanotubes modified with ZnO nanoparticles: High-efficiency electromagnetic wave absorption at high-temperatures. Ceram. Int. 2015, 41, 4906–4915. [Google Scholar] [CrossRef]

- Zhang, N.; Huang, Y.; Wang, M. 3D ferromagnetic graphene nanocomposites with ZnO nanorods and Fe3O4 nanoparticles co-decorated for efficient electromagnetic wave absorption. Compos. Part B Eng. 2018, 136, 135–142. [Google Scholar] [CrossRef]

- Olad, A.; Shakoori, S. Electromagnetic interference attenuation and shielding effect of quaternary Epoxy-PPy/Fe3O4 -ZnO nanocomposite as a broad band microwave-absorber. J. Magn. Magn. Mater. 2018, 458, 335–345. [Google Scholar] [CrossRef]

- Jin, C.; Li, J.; Han, S.; Wang, J.; Sun, Q. A durable, superhydrophobic, superoleophobic and corrosion-resistant coating with rose-like ZnO nanoflowers on a bamboo surface. Appl. Surf. Sci. 2014, 320, 322–327. [Google Scholar] [CrossRef]

- Wu, F.; Xia, Y.; Wang, Y.; Wang, M. Two-step reduction of self-assembed three-dimensional (3D) reduced graphene oxide (RGO)/zinc oxide (ZnO) nanocomposites for electromagnetic absorption. J. Mater. Chem. 2014, 2, 20307–20315. [Google Scholar] [CrossRef]

- Ameli, A.; Jung, P.U.; Park, C.B. Electrical properties and electromagnetic interference shielding effectiveness of polypropylene/carbon fiber composite foams. Carbon 2013, 60, 379–391. [Google Scholar] [CrossRef]

- Cheng, H.; Wei SJi, Y.; Zhai, J.; Zhang, X.; Chen, J.; Shen, C. Synergetic effect of Fe3O4 nanoparticles and carbon on flexible poly (vinylidence fluoride) based films with higher heat dissipation to improve electromagnetic shielding. Compos. Part A Appl. Sci. Manuf. 2019, 121, 139–148. [Google Scholar] [CrossRef]

- Fu, L.; Li, K.; Qin, H.; Hou, J.; Zhang, X.; He, G.; Liu, B.; Ren, C.; Chen, J. Sandwich structured iPP/CNTs nanocomposite foams with high electromagnetic interference shielding performance. Compos. Sci. Technol. 2022, 220, 109297. [Google Scholar] [CrossRef]

- Qian, Y.; Wei, H.; Dong, J.; Du, Y.; Fang, X.; Zheng, W.; Sun, Y.; Jiang, Z. Fabrication of urchin-like ZnO-MXene nanocomposites for high-performance electromagnetic absorption. Ceram. Int. 2017, 43, 10757–10762. [Google Scholar] [CrossRef]

- Ma, C.; Liu, T.; Xin, W.; Xi, G.Q.; Ma, M.G. Breathable and wearable MXene-decorated air-laid paper with superior folding endurance and electromagnetic interference-shielding performances. Front. Mater. 2019, 6, 308. [Google Scholar] [CrossRef]

- Kim, H.; Lee, H.; Lim, H.R.; Cho, H.B.; Choa, Y.H. Electrically conductive and anti-corrosive coating on copper foil assisted by polymer-nanocomposites embedded with graphene. Appl. Surf. Sci. 2019, 476, 123–127. [Google Scholar] [CrossRef]

- He, Y.; Li, S.; Zhou, L.; Wei, C.; Yu, C.; Chen, Y.; Liu, H. Cellulose nanofibrils-based hybrid foam generated from pickering emulsion toward high-performance microwave absorption. Carbohydr. Polym. 2021, 255, 117333. [Google Scholar] [CrossRef] [PubMed]

- Hu, D.; Huang, X.; Li, S.; Jiang, P. Flexible and durable cellulose/MXene nanocomposite paper for efficient electromagnetic interference shielding. Compos. Sci. Technol. 2020, 188, 107995. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, W.; Xu, R.; Zhu, M.F.; Yu, D. Flexible, durable and thermal conducting thiol-modified rGO-WPU_cotton fabric for robust electromagnetic interference shielding. Chem. Eng. J. 2019, 360, 817–828. [Google Scholar] [CrossRef]

- Zhang, X.; Ding, W.; Zhao, N.; Chen, J.; Park, C.B. Effects of compressed CO2 and cotton fibers on the crystallization and foaming behaviors of polylactide. Ind. Eng. Chem. Res. 2018, 57, 2094–2104. [Google Scholar] [CrossRef]

- Ghosh, S.; Mondal, S.; Ganguly, S.; Remanan, S.; Singha, N.; Das, N.C. Carbon nanostructures based mechanically robust conducting cotton fabric for improved electromagnetic interference shielding. Fiber. Polym. 2018, 19, 1064–1073. [Google Scholar] [CrossRef]

- Xu, J.; Chen, R.; Yun, Z.; Bai, Z.; Li, K.; Shi, S.; Hou, J.; Guo, X.; Zhang, X.; Chen, J. Lightweight epoxy/cotton fiber-based nanocomposites with carbon and Fe3O4 for electromagnetic interference shielding. ACS Omega 2022, 7, 15215–15222. [Google Scholar] [CrossRef]

- Zhang, X.; Ding, W.; Chang, E.; Chen, X.; Chen, J.; Park, C.B.; Shen, C. Foaming behaviors and mechanical properties of injection-molded polylactide/cotton-fiber composites. Ind. Eng. Chem. Res. 2020, 59, 17885–17893. [Google Scholar] [CrossRef]

- Lin, J.H.; Lin, Z.I.; Pan, Y.J.; Huang, C.L.; Chen, C.K.; Lou, C.W. Polymer composites made of multi-walled carbon nanotubes and graphene nano-sheets: Effects of sandwich structures on their electromagnetic interference shielding effectiveness. Compos. Part B Eng. 2016, 89, 424–431. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, G.; Tang, M.; Zhou, L.; Li, J.; Fan, X.; Shi, X.; Qin, J. Synergistic effect of carbon nanotube and graphene nanoplates on the mechanical, electrical and electromagnetic interference shielding properties of polymer composites and polymer composite foams. Chem. Eng. J. 2018, 353, 381–393. [Google Scholar] [CrossRef]

- Tian, M.; Du, M.; Qu, L.; Chen, S.; Zhu, S.; Han, G. Electromagnetic interference shielding cotton fabrics with high electrical conductivity and electrical heating behavior via layer-by-layer self-assembly route. RSC. Adv. 2017, 7, 42641–42652. [Google Scholar] [CrossRef]

- Zhang, K.; Gu, X.; Dai, Q.; Yuan, B.; Yan, Y.; Guo, M. Flexible polyaniline-coated poplar fiber composite membranes with effective electromagnetic shielding performance. Vacuum 2019, 170, 108990. [Google Scholar] [CrossRef]

- Yu, T.; Ren, J.; Li, S.; Yuan, H.; Li, Y. Effect of fiber surface-treatments on the properties of poly(lactic acid)/ramie composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 499–505. [Google Scholar] [CrossRef]

- Abdelmouleh, M.; Boufi, S.; Belgacem, M.; Dufresne, A. Short natural-fibre reinforced polyethylene and natural rubber composites: Effect of silane coupling agents and fibres loading. Compos. Sci. Technol. 2007, 67, 1627–1639. [Google Scholar] [CrossRef]

- Sgriccia, N.; Hawley, M.C.; Misra, M. Characterization of natural fiber surfaces and natural fiber composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1632–1637. [Google Scholar] [CrossRef]

- Tian, K.; Hu, D.; Wei, Q.; Fu, Q.; Deng, H. Recent progress on multifunctional electromagnetic interference shielding polymer composites. J. Mater. Sci. Technol. 2023, 134, 106–131. [Google Scholar] [CrossRef]

- Jia, X.; Li, Y.; Shen, B.; Zheng, W. Evaluation, fabrication and dynamic performance regulation of green EMI-shielding materials with low reflectivity: A review. Compos. Part B Eng. 2022, 233, 109652. [Google Scholar] [CrossRef]

- Lee, T.W.; Lee, S.E.; Jeong, Y.G. Carbon nanotube/cellulose papers with high performance in electric heating and electromagnetic interference shielding. Compos. Sci. Technol. 2016, 131, 77–87. [Google Scholar] [CrossRef]

- Li, Y.; Shen, B.; Yi, D.; Zhang, L.; Zhai, W.; Wei, X.; Zheng, W. The influence of gradient and sandwich configurations on the electromagnetic interference shielding performance of multilayered thermoplastic polyurethane/graphene composite foams. Compos. Sci. Technol. 2017, 138, 209–216. [Google Scholar] [CrossRef]

- Sankaran, S.; Deshmukh, K.; Ahamed, M.B.; Khadheer Pasha, S.K. Recent advances in electromagnetic interference shielding properties of metal and carbon filler reinforced flexible polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2018, 114, 49–71. [Google Scholar] [CrossRef]

- Zhu, S.; Cheng, Q.; Yu, C.; Pan, X.; Zuo, X.; Liu, J.; Chen, M.; Li, W.; Li, Q.; Liu, L. Flexible Fe3O4/graphene foam/poly dimethylsiloxane composite for high-performance electromagnetic interference shielding. Compos. Sci. Technol. 2020, 189, 108012. [Google Scholar] [CrossRef]

- Lu, L.; Xing, D.; Teh, K.S.; Liu, H.; Xie, Y.; Liu, X.; Tang, Y. Structural effects in a composite nonwoven fabric on EMI shielding. Mater. Design. 2017, 120, 354–362. [Google Scholar] [CrossRef]

- Bera, R.; Das, A.K.; Maitra, A.; Paria, S.; Karan, S.K.; Khatua, B.B. Salt leached viable porous Fe3O4 decorated polyaniline—SWCNH/PVDF composite spectacles as an admirable electromagnetic shielding efficiency in extended Ku-band region. Composites Part B Eng. 2017, 129, 210–220. [Google Scholar] [CrossRef]

| Name | Zinc Oxide (g) | Cotton (g) | Sample (g) |

|---|---|---|---|

| CF-0% ZnO | 0 | 1.5 | 1.5 |

| CF-10% ZnO | 0.15 | 1.35 | 1.5 |

| CF-30% ZnO | 0.45 | 1.05 | 1.5 |

| CF-50% ZnO | 0.75 | 0.75 | 1.5 |

| CF-70% ZnO | 1.05 | 0.45 | 1.5 |

| ZnO Weight (%) | Concentration | SEA | SER | SET |

|---|---|---|---|---|

| 0 | CF-0% ZnO | 2.93 | 0.03 | 2.96 |

| 10 | CF-10% ZnO | 20.12 | 5.75 | 25.88 |

| 30 | CF-30% ZnO | 26.32 | 5.73 | 32.06 |

| 50 | CF-50% ZnO | 28.94 | 5.74 | 34.69 |

| 70 | CF-70% ZnO | 33.55 | 4.5 | 38.08 |

| Materials | Carbon Contents (wt.%) | Thickness (mm) | EMI SE (dB) | SEA (dB) | Frequency Range (GHz) | Reference |

|---|---|---|---|---|---|---|

| rGO-ZnO | rGO 40 | 1 | 38 | 16.71 | 8–12.4 | [24] |

| MoS2-rGO/ZnO | rGO 17.5 | 1.5 | 32 | 24 | 8.2–12.4 | [25] |

| ZnO-MXene Ti3C2Tx | Ti3C2Tx 70 | 4 | 26.3 | 10 | 10–18 | [36] |

| cellulose nanofiber/polyaniline | Fiber 50 | 0.28 | 25.2 | 20.1 | 8–12.4 | [49] |

| rGH/epoxy | rGO 1.2 | 2 | 38 | 6 | 8–12.4 | [19] |

| Polyaniline-WCNH/PVDF | WCNH 1 | 2 | 29.7 | 17.5 | 14.5–20 | [60] |

| CF-50% ZnO | Fiber 50 | 3.6 | 38.08 | 28.94 | 18–26.5 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Waseem, M.; Xie, Y.; Yu, K.; Zhou, X.; Cai, Y.; Zhang, X.; Liu, B.; Chen, J. Lightweight ZnO/Carbonated Cotton Fiber Nanocomposites for Electromagnetic Interference Applications: Preparation and Properties. Polymers 2024, 16, 116. https://doi.org/10.3390/polym16010116

Waseem M, Xie Y, Yu K, Zhou X, Cai Y, Zhang X, Liu B, Chen J. Lightweight ZnO/Carbonated Cotton Fiber Nanocomposites for Electromagnetic Interference Applications: Preparation and Properties. Polymers. 2024; 16(1):116. https://doi.org/10.3390/polym16010116

Chicago/Turabian StyleWaseem, Muhammad, Yuxiang Xie, Kesong Yu, Xiling Zhou, Yingchun Cai, Xiaoli Zhang, Baochen Liu, and Jingbo Chen. 2024. "Lightweight ZnO/Carbonated Cotton Fiber Nanocomposites for Electromagnetic Interference Applications: Preparation and Properties" Polymers 16, no. 1: 116. https://doi.org/10.3390/polym16010116

APA StyleWaseem, M., Xie, Y., Yu, K., Zhou, X., Cai, Y., Zhang, X., Liu, B., & Chen, J. (2024). Lightweight ZnO/Carbonated Cotton Fiber Nanocomposites for Electromagnetic Interference Applications: Preparation and Properties. Polymers, 16(1), 116. https://doi.org/10.3390/polym16010116