Damage Monitoring of Composite Adhesive Joint Integrity Using Conductivity and Fiber Bragg Grating

Abstract

1. Introduction

2. Materials and Methods

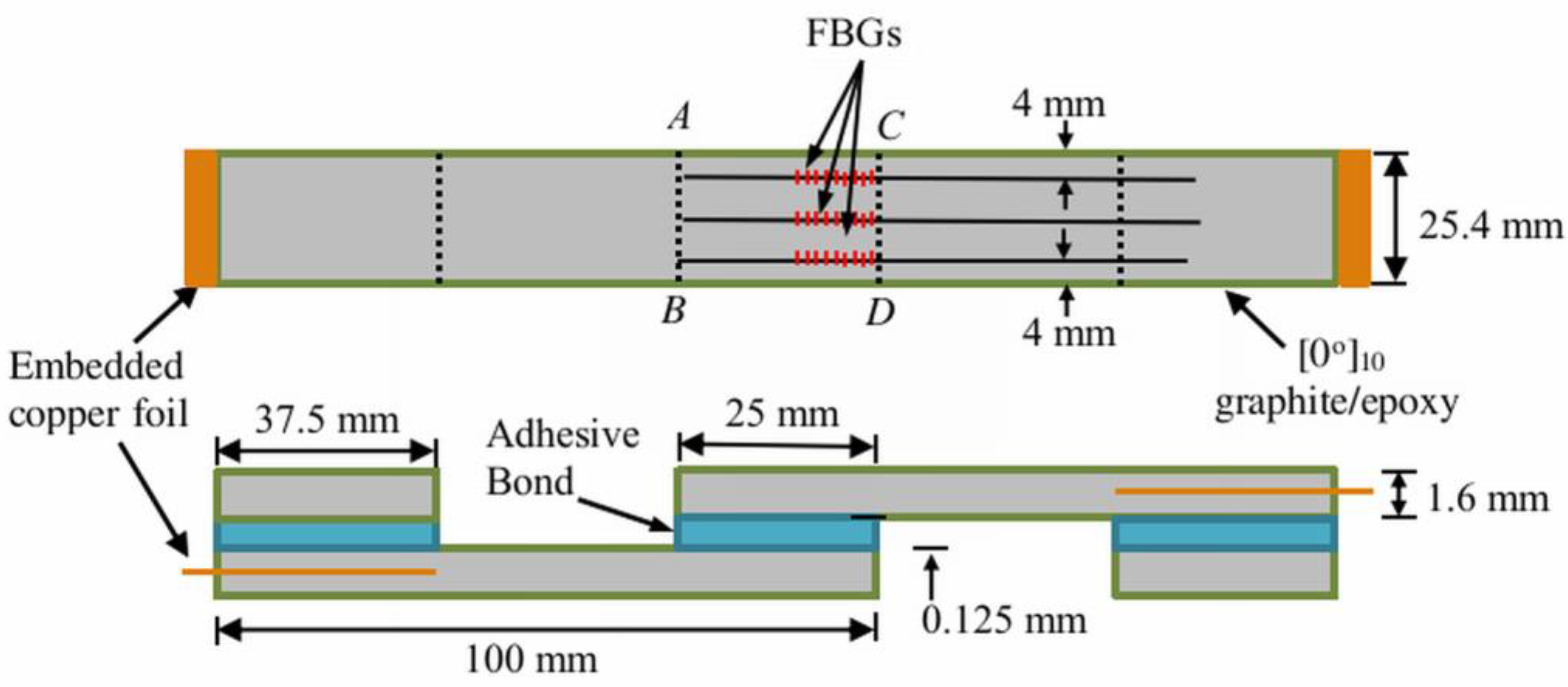

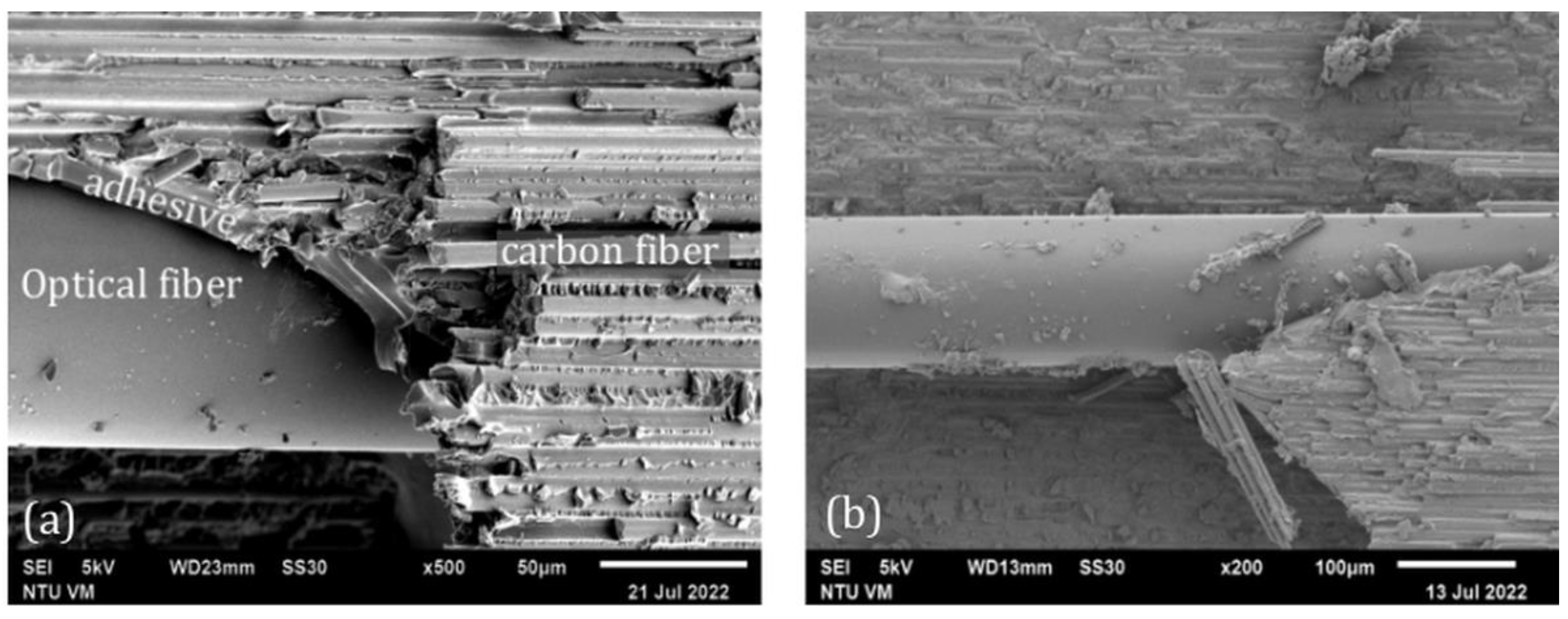

2.1. Single Lap Joint Specimen and Conductivity Measurement

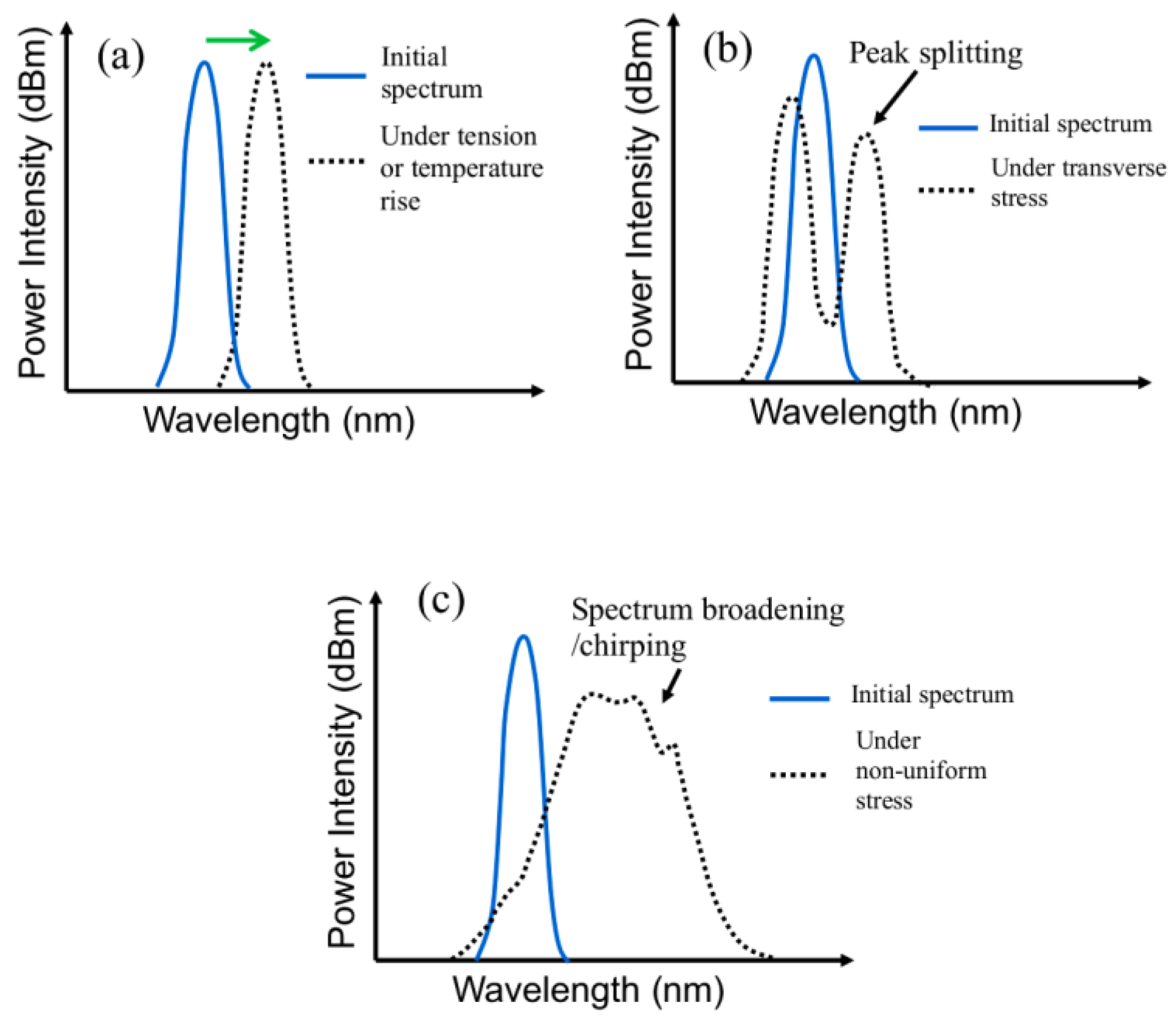

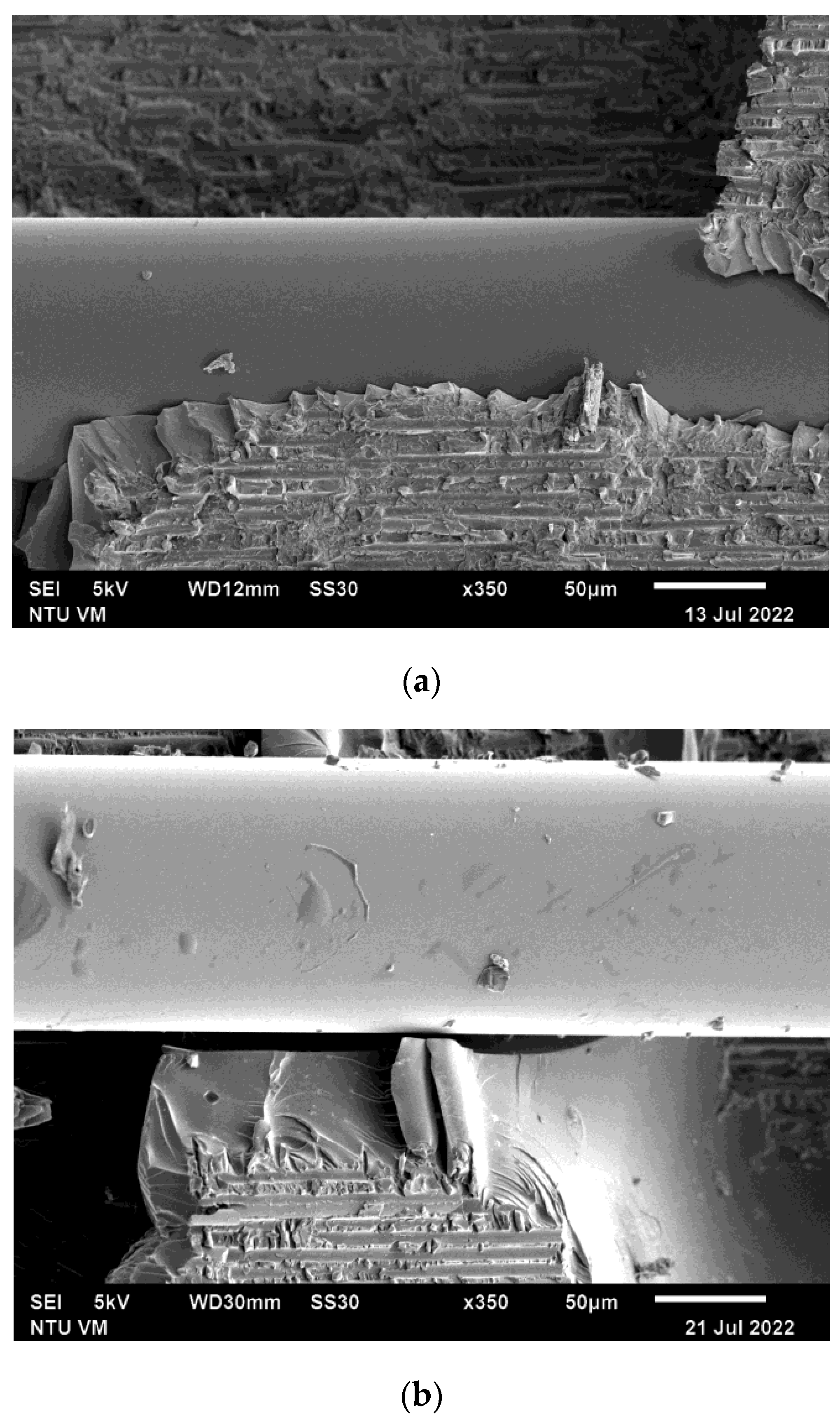

2.2. Fiber Bragg Grating Sensor

2.3. Quantitative Comparison of FBG Spectra

2.4. Mechanical Testing

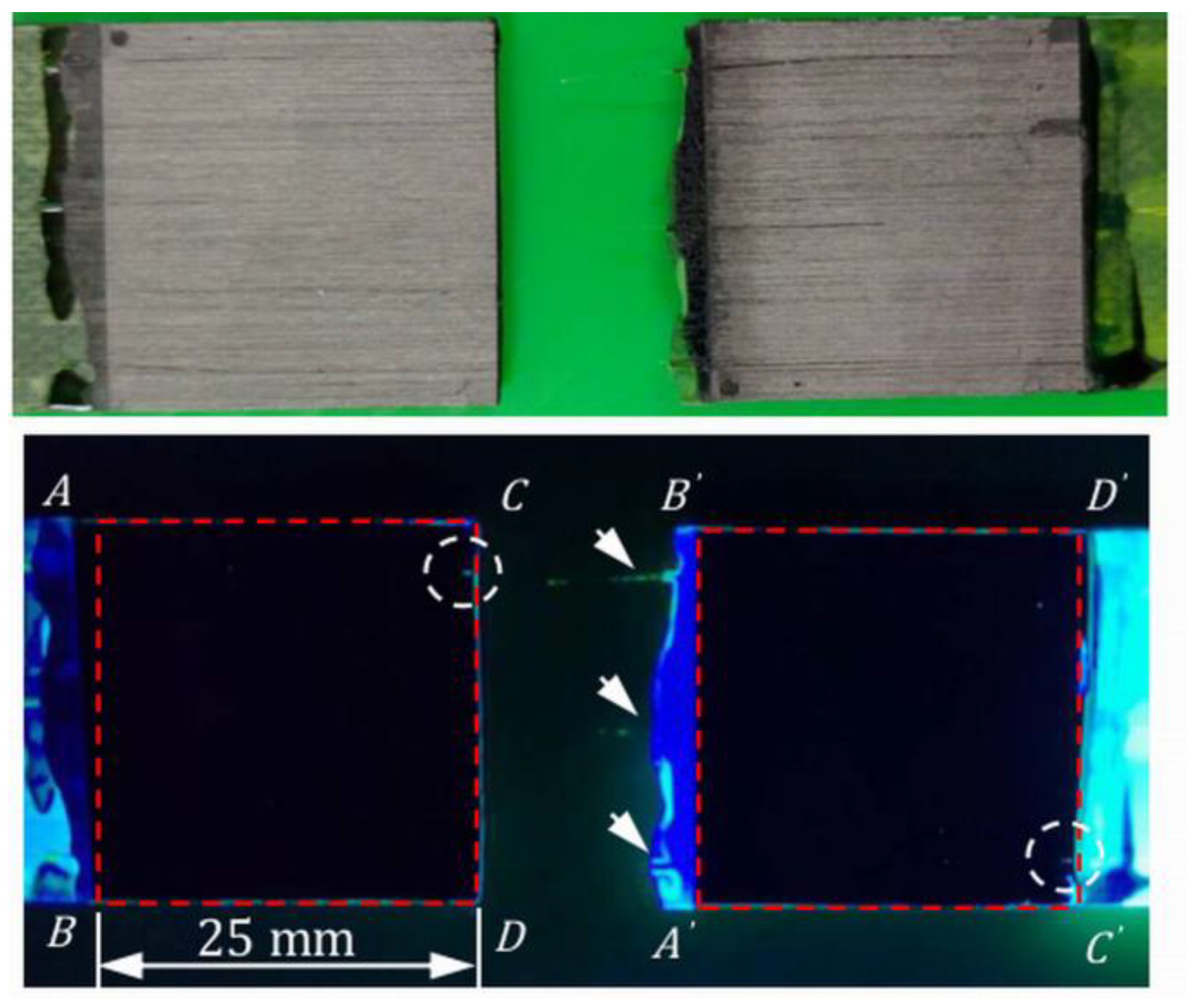

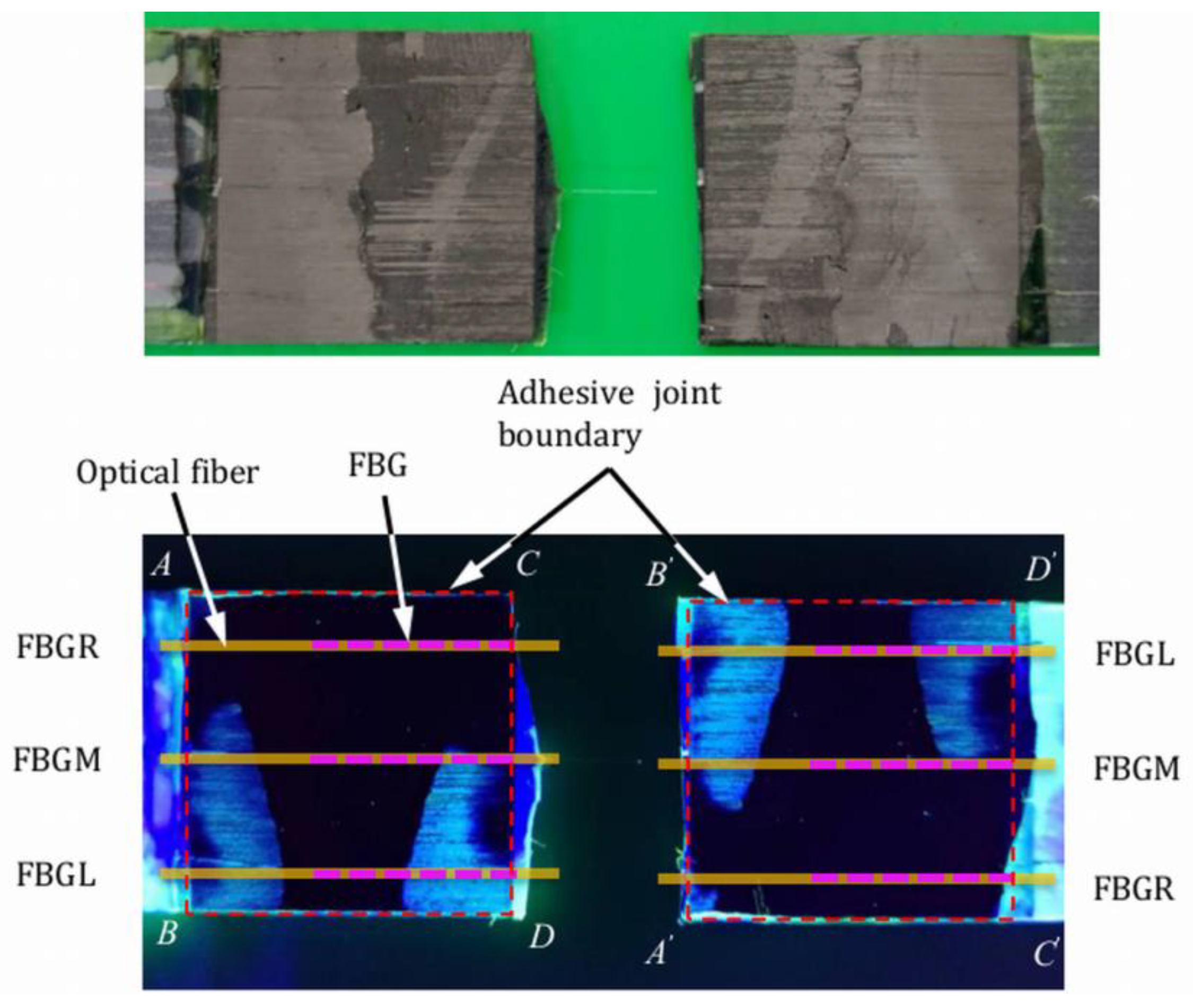

2.5. Liquid Fluorescent Penetrant Treatment

3. Results

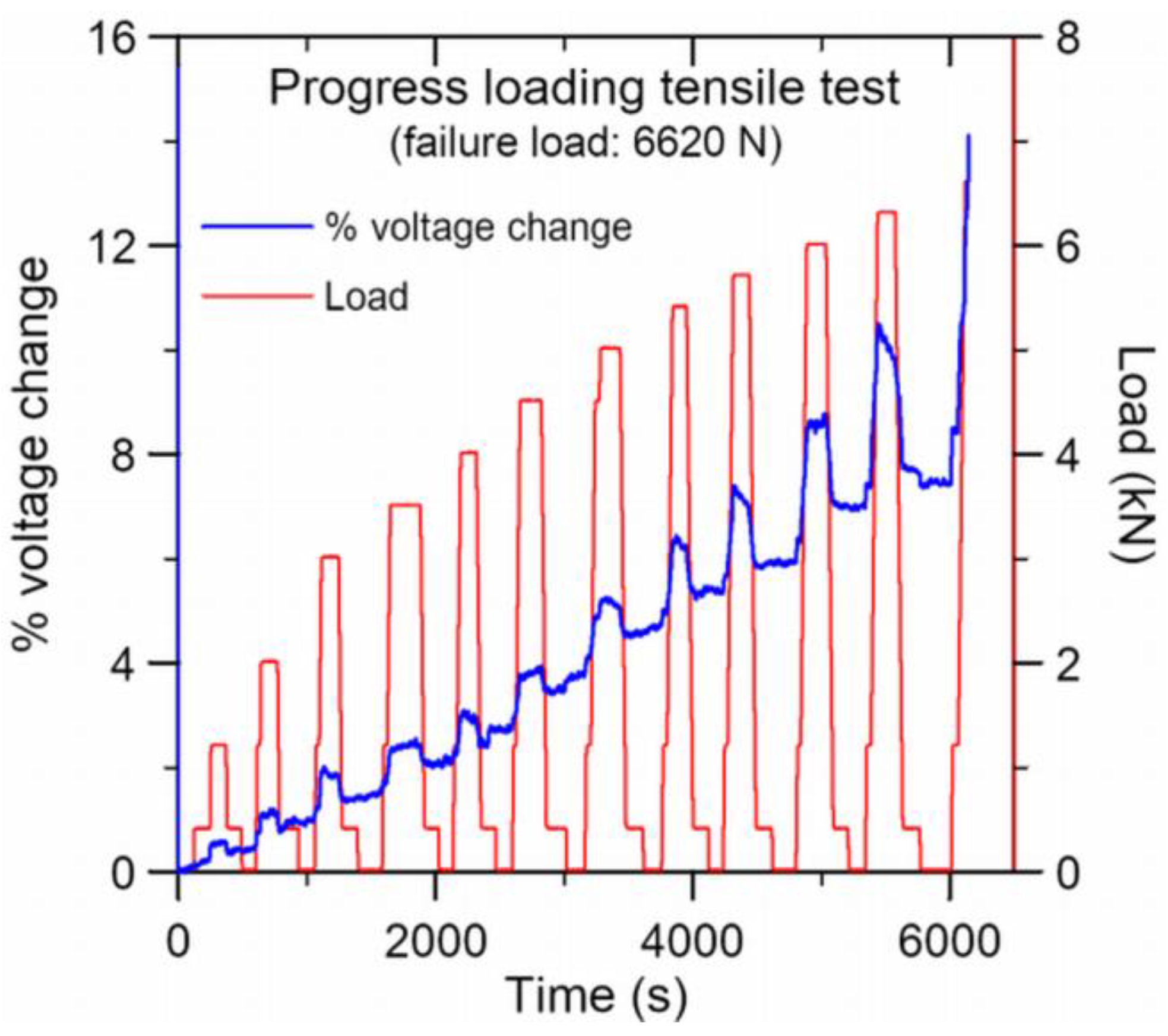

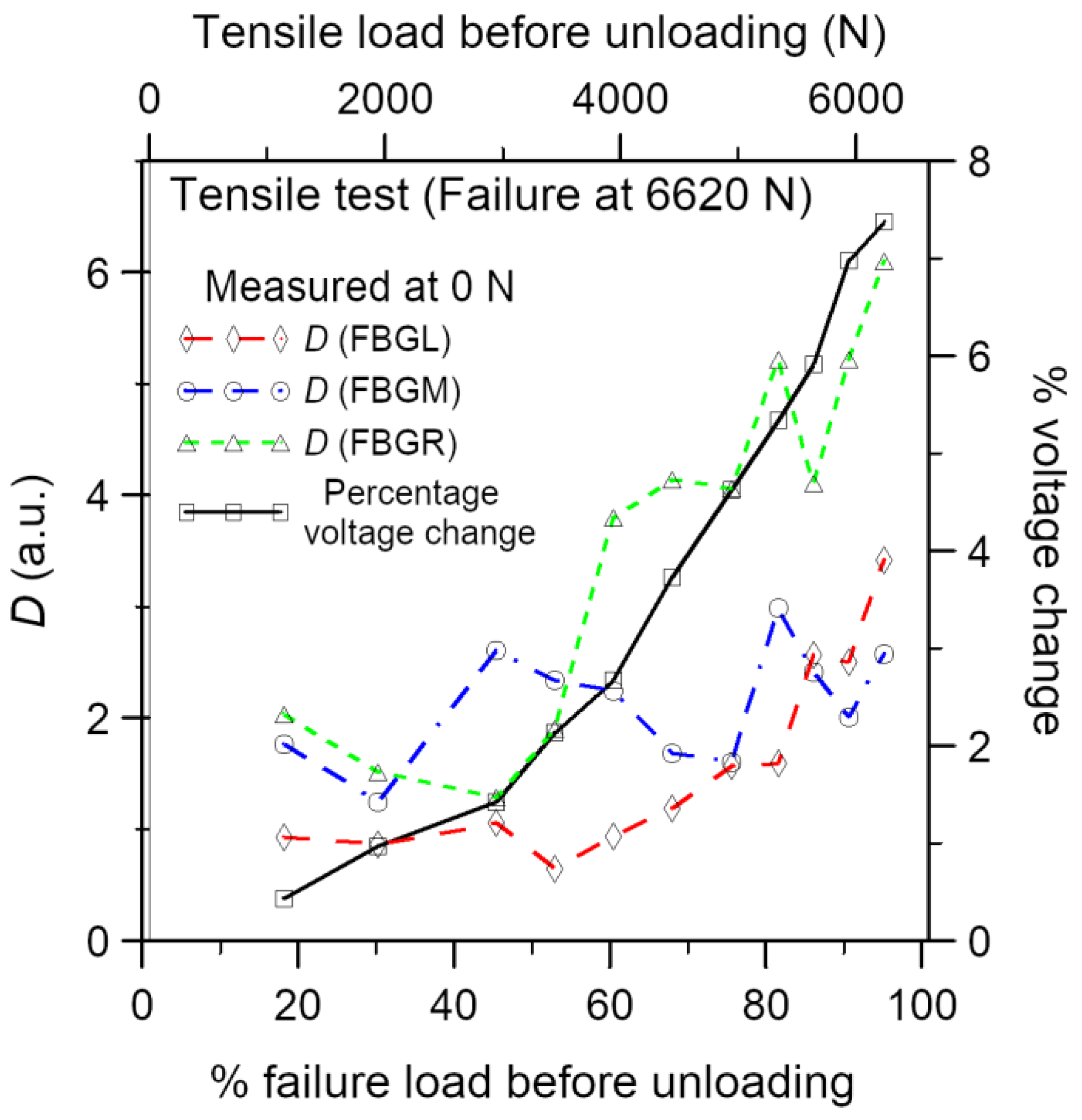

3.1. Monitoring of Tensile Damages

3.1.1. FBG Spectrum under Progressively Loading Up-Unloading Cycle

3.1.2. Conductivity Changes under Progressive Loading Up-Unloading

3.1.3. Examination of Damage in the Progressively Loaded Tensile Specimens

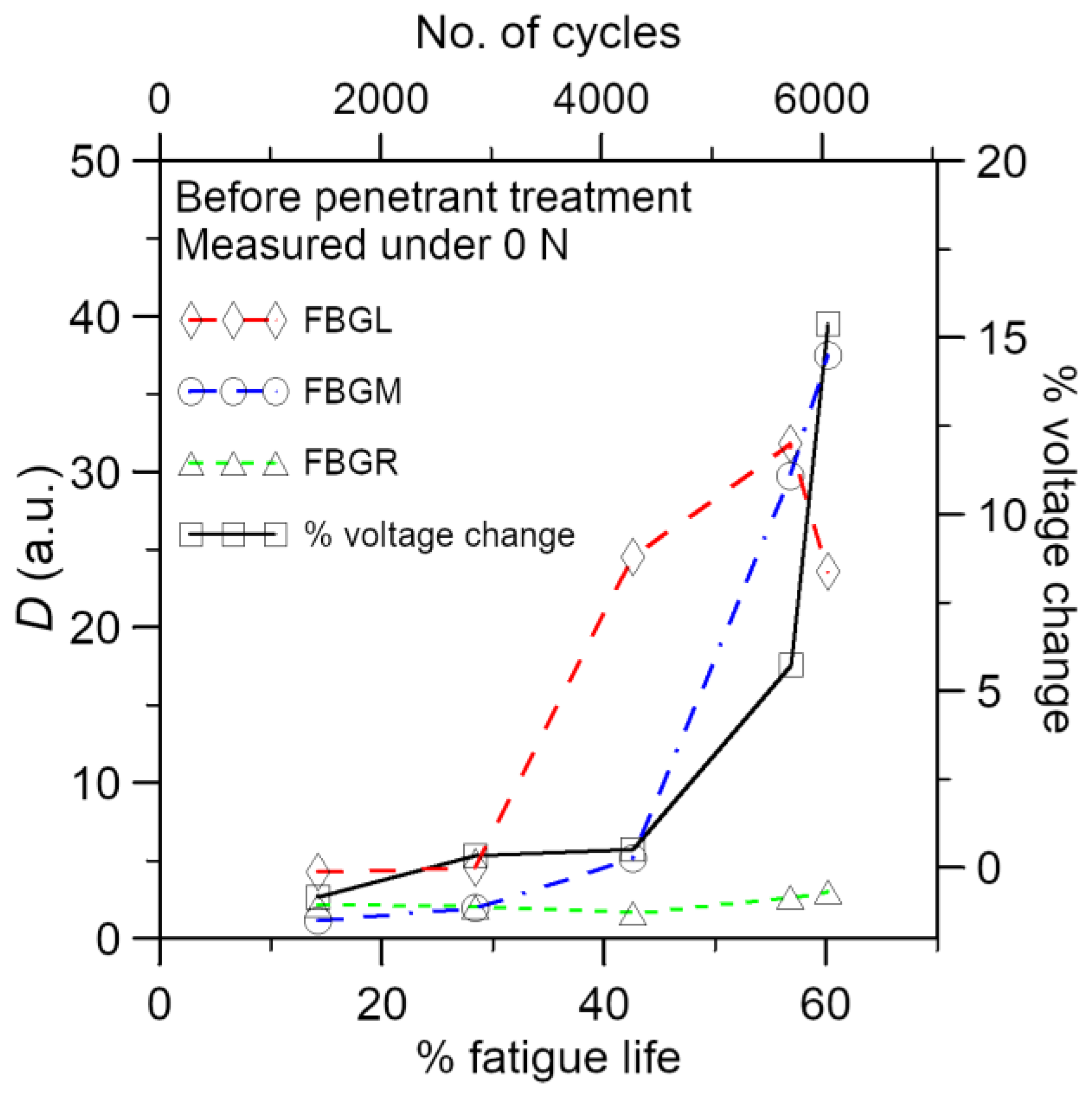

3.2. Monitoring of Fatigue Damages

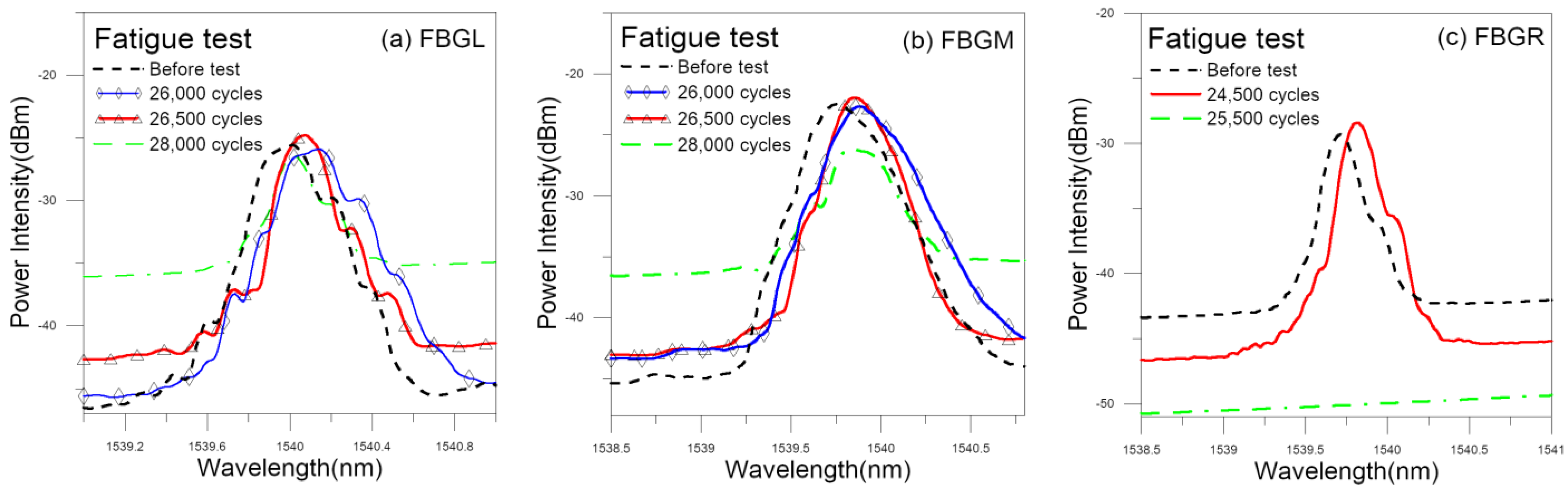

3.2.1. FBG Spectra under Cyclic Fatigue Loading

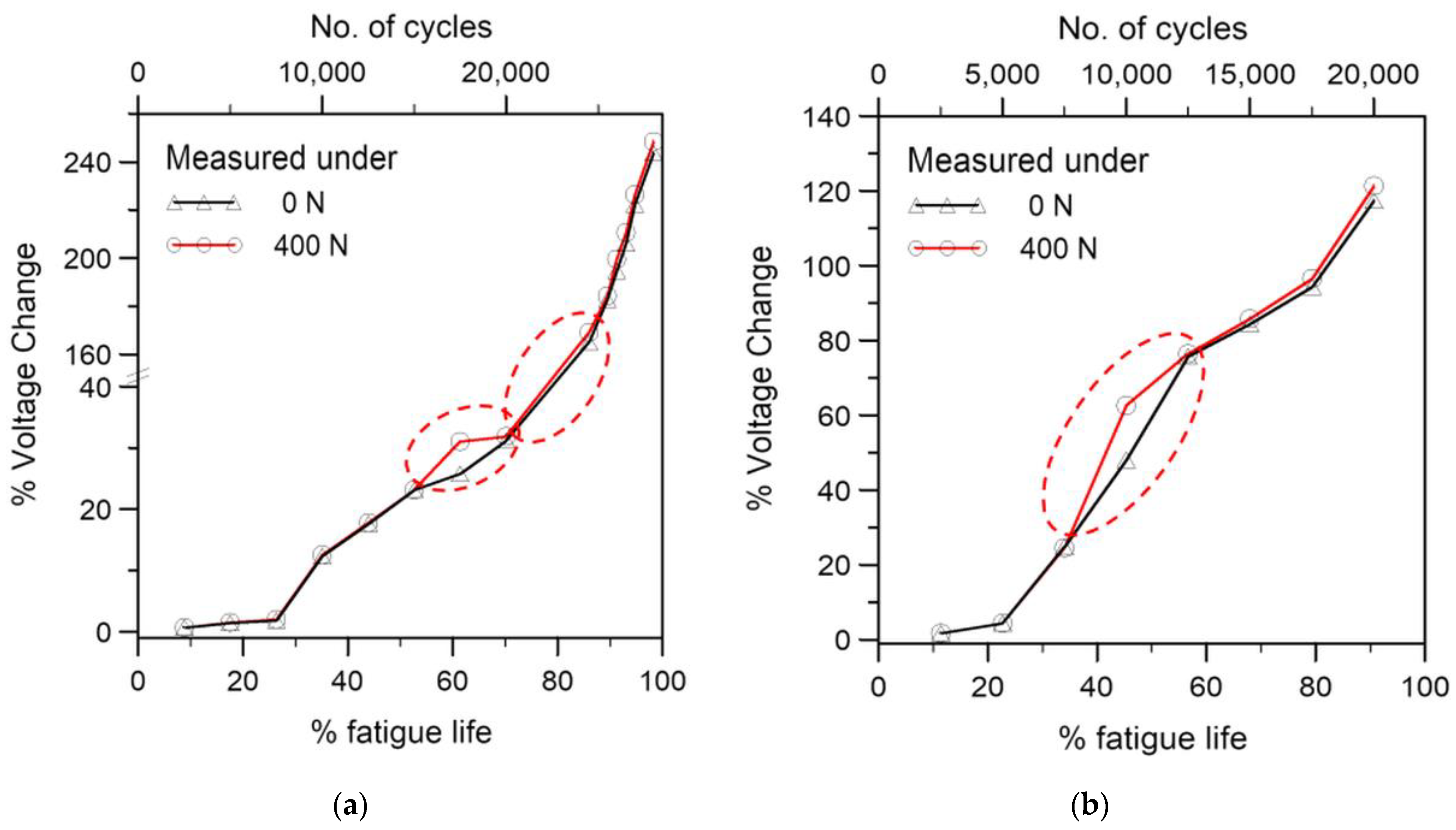

3.2.2. Development of Percentage Voltage Change under Cyclic Fatigue Loading

3.2.3. Examination of Damages in the Fatigue Specimens

4. Conclusions

- (1)

- Loading by itself will affect the FBG spectrum and the voltage across a conductive adhesive joint, even in the absence of joint damage. Hence, for damage monitoring, the percentage change in voltage and the FBG spectrum should preferably be measured at zero or a very low load, in order to exclude the effect of load.

- (2)

- The FBG spectrum and the associated D value only reflect the damages in the close vicinity of the FBG. The resistance or voltage drop across the joint under a constant current reflects the bulk condition of the joint.

- (3)

- Under tensile loading, the load-free percentage change in voltage and D increased with progressively increasing loading. At a loading of 95% of failure strength, the average percentage change in voltage and the D value are 7% and 9%, respectively. Fluorescent penetrant testing showed that at 92% of failure strength, where the percentage change in voltage and D are 5% and 7%, respectively, no debonding in the joint had been observed.

- (4)

- Under cyclic fatigue loading, the average change in voltage across the joint is 138%. This was measured at approximately 98% of fatigue life and was much larger than those recorded during tensile failure. D values from the FBG spectra varied widely, and most of them were also significantly larger than those recorded in tensile failure. Fluorescent penetrant tests revealed a strong correlation between the debonding depth in the vicinity of the FBG and their corresponding D value. However, the same percentage change in voltage may correspond to widely different de-bonded areas and elapsed fatigue life fractions.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- da Silva, L.F.M.; Öchsner, A.; Adams, R.D. Handbook of Adhesion Technology, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 1–7. [Google Scholar]

- Banea, M.D.; da Silva, L.F.M. Adhesively bonded joints in composite materials: An overview. J. Mater. Des. Appl. 2009, 223, 1–18. [Google Scholar] [CrossRef]

- Mojškerc, B.; Kek, T.; Grum, J. Ultrasonic Disbond Detection in Adhesive Joints. In Proceedings of the International Conference of the Slovenian Society for Non-Destructive Testing, Bernardin, Slovenia, 4–6 September 2017. [Google Scholar]

- Muhammad, A.; Muhammad, K.; Sohaib, K.; Rizwan, C.; Kamran, K. Identification of an effective nondestructive technique for bond defect determination in laminate composites—A technical review. J. Compos. Mater. 2018, 52, 3589–3599. [Google Scholar] [CrossRef]

- Yilmaz, B.; Ba, A.; Jasiūnienė, E.; Bui, H.-K.; Berthiau, G. Evaluation of Bonding Quality with Advanced Nondestructive Testing (NDT) and Data Fusion. Sensors 2020, 20, 5127. [Google Scholar] [CrossRef]

- Karpenko, O.; Khomenko, A.; Koricho, E.; Haq, M.; Udpa, L. Monitoring of fatigue damage in composite lap-joints using guided waves and FBG sensors. In Proceedings of the AIP Conference Proceedings 1706, 42nd Annual Review of Progress in Quantitative Nondestructive Evaluation, Minneapolis, MN, USA, 26–31 July 2015; Chimenti, D.E., Bond, L.J., Eds.; AIP Publishing: Melville, NY, USA, 2016; p. 120005. [Google Scholar] [CrossRef]

- Scarselli, G.; Nicassio, F. Analysis of debonding in single lap joints based on employment of ultrasounds. In Proceedings of the SPIE 10170, Health Monitoring of Structural and Biological Systems 2017, Portland, OR, USA, 26–29 March 2017; Kundu, T., Ed.; SPIE: Washington, DC, USA, 2017; p. 1017020. [Google Scholar] [CrossRef]

- Nagy, P.B. Ultrasonic detection of kissing bonds at adhesive interfaces. J. Adhes. Sci. Technol. 1991, 5, 619–630. [Google Scholar] [CrossRef]

- Yilmaz, B.; Jasiūnienė, E. Advanced Ultrasonic NDT for Weak Bond Detection in Composite-Adhesive Bonded Structures. Int. J. Adhes. Adhes. 2020, 102, 102675. [Google Scholar] [CrossRef]

- Liu, T.; Pei, C.; Cheng, X.; Zhou, H.; Xiao, P.; Chen, Z. Adhesive debonding inspection with a small EMAT in resonant mode. NDT E Int. 2018, 98, 110–116. [Google Scholar] [CrossRef]

- Roth, W.; Giurgiutiu, V. Structural health monitoring of an adhesive disbond through electromechanical impedance spectroscopy. Int. J. Adhes. Adhes. 2017, 73, 109–117. [Google Scholar] [CrossRef]

- Zhuang, Y.; Kopsaftopoulos, F.; Chang, F.-K. Bondline Integrity Monitoring of Adhesively Bonded Structures via an Electromechanical Impedance Based Approach. In Proceedings of the 10th International Workshop on Structural Health Monitoring 2015, Stanford, CA, USA, 1–3 September 2015. [Google Scholar] [CrossRef]

- Dugnani, R.; Chang, F.-K. Analytical model of lap-joint adhesive with embedded piezoelectric transducer for weak bond detection. J. Intell. Mater. Syst. Struct. 2017, 28, 124–140. [Google Scholar] [CrossRef]

- Dugnani, R.; Zhuang, Y.; Kopsaftopoulos, F.; Chang, F.-K. Adhesive bond-line degradation detection via a cross-correlation electromechanical impedance–based approach. Struct. Health Monit. 2016, 15, 650–667. [Google Scholar] [CrossRef]

- Martens, U.; Schröder, K.-U. Evaluation of infrared thermography methods for analysing the damage behaviour of adhesively bonded repair solutions. Compos. Struct. 2020, 240, 111991. [Google Scholar] [CrossRef]

- Shin, P.H.; Webb, S.C.; Peters, K.J. Pulsed phase thermography imaging of fatigue-loaded composite adhesively bonded joints. NDT E Int. 2016, 79, 7–16. [Google Scholar] [CrossRef]

- Kryukov, I.; Böhm, S. Prospects and limitations of eddy current shearography for non-destructive testing of adhesively bonded structural joints. J. Adhes. 2019, 95, 874–886. [Google Scholar] [CrossRef]

- Kryukov, I.; Thiede, H.; Böhm, S. Quality assurance for structural adhesively bonded joints by eddy current shearography. Weld World 2017, 61, 581–588. [Google Scholar] [CrossRef]

- Davis, M.J.; McGregor, A. Assessing adhesive bond failures: Mixed-mode bond failures explained. In Proceedings of the ISASI Australian Safety Seminar; The International Society of Air Safety Investigators, Canberra, Australia, 4–6 June 2010. [Google Scholar]

- Baker, A.A.; Wang, J. Chapter Six—Adhesively Bonded Repair/Reinforcement of Metallic Airframe Components: Materials, Processes, Design and Proposed Through-Life Management; Jones, R., Baker, A.A., Matthews, N., Champagne, V., Eds.; Aircraft Sustainment and Repair; Butterworth-Heinemann: Oxford, UK, 2018; pp. 191–252. [Google Scholar] [CrossRef]

- Sadeghi, M.Z.; Weiland, J.; Preisler, A.; Zimmermann, J.; Schiebahn, A.; Reisgen, U.; Schröder, K.U. Damage detection in adhesively bonded single lap joints by using backface strain: Proposing a new position for backface strain gauges. Int. J. Adhes. Adhes. 2020, 97, 102494. [Google Scholar] [CrossRef]

- Sadeghi, M.Z.; Weiland, J.; Zimmermann, J.; Schiebahn, A.; Reisgen, U.; Schröder, K.U. Experimental and FE investigations on the influential parameters in positioning and measurement of strain gauges in adhesively bonded single lap joints. Procedia Struct. Integr. 2020, 28, 1590–1600. [Google Scholar] [CrossRef]

- Solana, A.G.; Crocombe, A.D.; Ashcroft, I.A. Fatigue life and backface strain predictions in adhesively bonded joints. Int. J. Adhes. Adhes. 2010, 30, 36–42. [Google Scholar] [CrossRef]

- Sarfaraz, R.; Canal, L.P.; Violakis, G.; Botsis, J.; Michaud, V.; Limberger, H.G. An experimental-numerical investigation of hydrothermal response in adhesively bonded composite structures. Compos. Part A 2015, 73, 176–185. [Google Scholar] [CrossRef]

- Mora, V.B.; Mieloszyk, M.; Ostachowicz, W. Model of moisture absorption by adhesive joint, Mech. Sys. Signal Proc. 2018, 99, 534–549. [Google Scholar] [CrossRef]

- Jo, B.W.; Khan, R.M.A.; Lee, Y.S.; Jo, J.H.; Saleem, N. A Fiber Bragg Grating-Based Condition Monitoring and Early Damage Detection System for the Structural Safety of Underground Coal Mines Using the Internet of Things. J. Sens. 2018, 3, 9301873. [Google Scholar] [CrossRef]

- Papantoniou, A.; Rigas, G.; Alexopoulos, N.D. Assessment of the strain monitoring reliability of fiber Bragg grating sensor (FBGs) in advanced composite structures. Compos. Struct. 2011, 93, 2163–2172. [Google Scholar] [CrossRef]

- Kahandawa, G.C.; Epaarachchi, J.; Wang, H.; Lau, K.T. Use of FBG Sensors for SHM in Aerospace Structures. Photonic Sens. 2012, 2, 203–214. [Google Scholar] [CrossRef]

- Grefe, H.; Weiser, D.; Kandula, M.W.; Dilger, K. Deformation measurement within adhesive bonds of aluminium and CFRP using advanced fibre optic sensors. Manuf. Rev. 2020, 7, 14. [Google Scholar] [CrossRef]

- Ning, X.; Murayama, H.; Kageyama, K.; Wada, D.; Kanai, M.; Ohsawa, I.; Hirotaka, I. Dynamic strain distribution measurement and crack detection of an adhesive-bonded single-lap joint under cyclic loading using embedded FBG. Smart Mater. Struct. 2014, 23, 105011. [Google Scholar] [CrossRef]

- Young, S.; Penumadu, D.; Foster, D.; Maeser, H.; Balijepalli, B.; Reese, J.; Bank, D.; Dahl, J.; Blanchard, P. Smart Adhesive Joint with High-Definition Fiber-Optic Sensing for Automotive Applications. Sensors 2020, 20, 614. [Google Scholar] [CrossRef]

- Jaiswal, P.R.; Kumar, R.I.; Saeedifar, M.; Saleh, M.; Luyckx, G.; De Waele, W. Deformation and damage evolution of a full-scale adhesive joint between a steel bracket and a sandwich panel for naval application. Proc. Inst. Mech. Engr. Part C J. Mech. Eng. Sci. 2021, 235, 571–584. [Google Scholar] [CrossRef]

- da Silva, L.F.M.; Moreira, P.M.G.P.; Loureiro, A.L.D. Determination of the strain distribution in adhesive joints using Fiber Bragg Grating (FBG). J. Adhes. Sci. Technol. 2014, 28, 1480–1499. [Google Scholar] [CrossRef]

- Haq, M.; Khomenko, A.; Udpa, L.; Udpa, S. Fiber Bragg-Grating Sensor Array for Health Monitoring of Bonded Composite Lap-Joints. In Proceedings of the 2013 SEM Annual Conference on Experimental and Applied Mechanics, Lombard, IL, USA, 3–5 June 2013; Tandon, G., Tekalur, S., Ralph, C., Sottos, N., Blaiszik, B., Eds.; Springer: Cham, Switzerland, 2014; Volume 6, pp. 189–195. [Google Scholar] [CrossRef]

- Karpenko, O.; Koricho, E.; Khomenko, A.; Dib, G.; Haq, M.; Udpa, L. Multitechnique monitoring of fatigue damage in adhesively bonded composite lap-joints. In Proceedings of the 41st Annual Review of Progress in Quantitative Nondestructive Evaluation, Boise, ID, USA, 20–25 July 2014; Chimenti, D.E., Bond, L.J., Eds.; AIP Publishing: Melville, NY, USA, 2015; Volume 1650, pp. 1102–1111. [Google Scholar] [CrossRef]

- Bento, T.; Maciel, R.; Braga, D.F.O.; da Silva, L.F.M.; Moreira, P.M.G.P.; Infante, V. Self-sensing FS Weld-bonded joints for structural monitoring. Proc. Struct. Integr. 2020, 25, 234–245. [Google Scholar] [CrossRef]

- Cabral, T.D.; Zimmermann, A.C.; Willemann, D.P.; Gonçalves, A.A., Jr. Pipeline Bonded Joints Assembly and Operation Health Monitoring with Embedded FBG Sensors. Eng. Proc. 2020, 2, 5. [Google Scholar] [CrossRef]

- Zeng, H.; Yan, R.; Xu, L.; Gui, S. Application study on fiber Bragg grating sensors in damage monitoring of sandwich composite joints. J. Sandw. Struct. Mater. 2020, 22, 1542–1563. [Google Scholar] [CrossRef]

- Scheel, I.; Udd, E. Fiber gratings strain sensor systems for composites and adhesive joints. Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems 2017. In Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, Portland, OR, USA, 25–29 March 2017; Volume 10168, p. 101681L. [Google Scholar] [CrossRef]

- Palaniappan, J.; Wang, H.; Ogin, S.L.; Thorne, A.M.; Reed, G.T.; Crocombe, A.D.; Rech, Y.; Tjin, S.C. Changes in the reflected spectra of embedded chirped fibre Bragg gratings used to monitor disbonding in bonded composite joints. Compos. Sci. Technol. 2007, 67, 2847–2853. [Google Scholar] [CrossRef]

- Palaniappan, J.; Ogin, S.L.; Thorne, A.M.; Reed, G.T.; Crocombe, A.D.; Capell, T.F.; Tjin, S.C.; Mohanty, L. Disbond growth detection in composite-composite single-lap joints using chirped FBG sensors. Compos. Sci. Technol. 2008, 68, 2410–2417. [Google Scholar] [CrossRef]

- Webb, S.; Shin, P.; Peters, K.; Zikry, M.A.; Stan, N.; Chadderdon, S.; Selfridge, R.; Schultz, S. Characterization of fatigue damage in adhesively bonded lap joints through dynamic, full spectral interrogation of fiber Bragg grating sensors: 1. Experiments. Smart Mater. Struct. 2014, 23, 025016. [Google Scholar] [CrossRef]

- Webb, S.; Shin, P.; Peters, K.; Zikry, M.A.; Stan, N.; Chadderdon, S.; Selfridge, R.; Schultz, S. Characterization of fatigue damage in adhesively bonded lap joints through dynamic, full spectral interrogation of fiber Bragg grating sensors: 2. Simulations. Smart Mater. Struct. 2014, 23, 025017. [Google Scholar] [CrossRef]

- Mieloszyk, M.; Ostachowicz, W. Moisture contamination detection in adhesive bond using embedded FBG sensors. Mech. Syst. Signal Processing 2017, 84, 1–14. [Google Scholar] [CrossRef]

- Fevery, S.; Hallez, H.; Vandepitte, D.; Debruyne, S. Measuring moisture absorption in structural adhesive joints with fibre Bragg grating sensors. Proc. IMechE Part E J. Process Mech. Eng. 2020, 234, 477–487. [Google Scholar] [CrossRef]

- Shin, C.-S.; Lin, T.-C. Adhesive Joint Integrity Monitoring Using the Full Spectral Response of Fiber Bragg Grating Sensors. Polymers 2021, 13, 2954. [Google Scholar] [CrossRef]

- Shin, C.-S.; Lin, T.-C. Hygrothermal Damage Monitoring of Composite Adhesive Joint Using the Full Spectral Response of Fiber Bragg Grating Sensors. Polymers 2022, 14, 368. [Google Scholar] [CrossRef]

- Sosamma, S.; Kasinathan, M.; Pandian, C.; Babu Rao, C.; Jayakumar, T.; Murali, N.; Raj, B. Bond monitoring in temperature-dependent applications by FBG spectra decomposition. Insight 2010, 52, 617–619. [Google Scholar] [CrossRef]

- Karakelas, D.; Cugnoni, J.; Botsis, J. Monitoring of hygrothermal ageing effects in an epoxy resin using FBG sensor: A methodological study. Compos. Sci. Technol. 2009, 69, 507–514. [Google Scholar] [CrossRef]

- Zhang, C.; Sun, L.; Huang, B.; Yang, X.; Chu, Y.; Zhan, B. Electrical and mechanical properties of CNT/CB dual filler conductive adhesives (DFCAs) for automotive multi-material joints. Comp. Struct. 2019, 225, 111183. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Farahani, M.; Faller, L.-M.; Zangl, H. Structural health monitoring of defective single lap adhesive joints using graphene nanoplatelets. J. Manuf. Processes 2020, 55, 119–130. [Google Scholar] [CrossRef]

- Yang, M.; Chuang, P.-C.; Tsai, J.-L. Monitoring the crack length of adhesively bonded carbon-fiber-reinforced polymer by using aligned graphene. Comp. Commun. 2022, 32, 101177. [Google Scholar] [CrossRef]

- Takada, T.; Narita, F. Fracture behavior and crack sensing capability of bonded carbon fiber composite joints with carbon nanotube-based polymer adhesive layer under Mode I loading. Comp. Sci. Tech. 2017, 146, 26–33. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Faller, L.-M.; Farahani, M.; Zangl, H. Structural health monitoring of adhesive joints under pure mode I loading using the electrical impedance measurement. Eng. Fract. Mech. 2021, 245, 107585. [Google Scholar] [CrossRef]

- Lim, A.S.; Melrose, Z.; Thostenson, E.; Chou, T.-W. Damage sensing of adhesively-bonded hybrid composite/steel joints using carbon nanotubes. Comp. Sci. Tech. 2011, 71, 1183–1189. [Google Scholar] [CrossRef]

- Till, A.; Julian, K.; Benedikt, K.; Bodo, F. Health monitoring of scarfed CFRP joints under cyclic loading via electrical resistance measurements using carbon nanotube modified adhesive films. Comp. Part A Appl. Sci. Manuf. 2018, 105, 150–155. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Faller, L.-M.; Farahani, M.; Zangl, H.; Roshanghias, A.; Araee, A.; Baniassadi, M.; Oberlercher, H.; Zangl, H. Impedance Analysis For Condition Monitoring of Single Lap CNT-Epoxy Adhesive Joint. Int. J. Adhes. Adhes. 2019, 88, 59–65. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Faller, L.-M.; Farahani, M.; Bregar, T.; An, D.; Gharavian, S. Carbon nanotube embedded adhesives for real-time monitoring of adhesion failure in high performance adhesively bonded joints. Sci. Rep. 2020, 10, 16833. [Google Scholar] [CrossRef]

- Li, A.; Stahl, J.; Bogdanovich, A.; Bradford, P. Strain sensing in fiberglass textile composites and joints using carbon nanotube sheets. In Proceedings of the 12th International Conference on Textile Composites (TEXCOMP-12), Raleigh, NC, USA, 26–29 May 2015. [Google Scholar]

- Sbarufatti, C.; Sánchez-Romate, X.F.; Scaccabarozzi, D.I.; Cinquemani, S.I.; Libonati, F.L.; Güemes, A.; Ureña, A. On the Dynamic Acquisition of Electrical Signals for Structural Health Monitoring of Carbon Nanotube Doped Composites. In Proceedings of the Conference: Structural Health Monitoring 2017, Real-Time Material State Awareness and Data-Driven Safety Assurance, Stanford, CA, USA, 12–14 September 2017. [Google Scholar] [CrossRef]

- Sánchez-Romate, X.F.; Jiménez-Suárez, A.; Molinero, J.; Sánchez, M.; Guemes, A.; Ureña, A. Development of bonded joints using novel CNT doped adhesive films: Mechanical and electrical properties. Int. J. Adhes. Adhes. 2018, 86, 98–104. [Google Scholar] [CrossRef]

- Ahmed, S.; Schumacher, T.; McConnell, J.; Thostenson, E. Experimental and Numerical Investigation on the Bond Strength of Self-Sensing Composite Joints. Int. J. Adhes. Adhes. 2018, 84, 227–237. [Google Scholar] [CrossRef]

- Kumar, S.; Falzon, B.G.; Hawkins, S. Ultrasensitive Embedded Sensor for Composite Joints Based on a Highly Aligned Carbon Nanotube Web. Carbon 2019, 149, 380–389. [Google Scholar] [CrossRef]

- Sanchez-Romate, X.F.; Moriche, R.; Jimenez-Suarez, A.; Sanchez, M.; Güemes, A.; Urena, A. An Approach Using Highly Sensitive Carbon Nanotube Adhesive Films for Crack Growth Detection under Flexural Load in Composite Structures. Comp. Struct. 2019, 224, 111087. [Google Scholar] [CrossRef]

- Doshi, S.M.; Lyness, T.B.; Thostenson, E.T. Damage monitoring of adhesively bonded composite-metal hybrid joints using carbon nanotube-based sensing layer. Nanocomposites 2020, 6, 12–21. [Google Scholar] [CrossRef]

- Sánchez-Romate, X.F.; Sbarufatti, C.; Sánchez, M.; Bernasconi, A.; Scaccabarozzi, D.; Libonati, F.; Cinquemani, S.; Güemes, A.; Ureña, A. Fatigue crack growth identification in bonded joints by using carbon nanotube doped adhesive films. Smart Mater. Struct. 2020, 29, 035032. [Google Scholar] [CrossRef]

- Sánchez-Romate, X.F.; García, C.; Rams, J.; Sánchez, M.; Ureña, A. Structural Health Monitoring of a CFRP Structural Bonded Repair by Using a Carbon Nanotube Modified Adhesive Film. Comp. Struct. 2021, 270, 114091. [Google Scholar] [CrossRef]

- Shin, C.S.; Chiang, C.C. Deformation monitoring by using optical fiber grating sensor. J. Chin. Inst. Eng. 2005, 28, 985–992. [Google Scholar] [CrossRef]

- Lee, B.M.; Loh, K.J. A 2D percolation-based model for characterizing the piezoresistivity of carbon nanotube-based films. J. Mater. Sci. 2015, 50, 2973–2983. [Google Scholar] [CrossRef]

- Li, C.; Chou, T. Modeling of damage sensing in fiber composites using carbon nanotube networks. Comp. Sci. Tech. 2008, 68, 3373–3379. [Google Scholar] [CrossRef]

- Hu, N.; Karube, Y.; Arai, M.; Watanabe, T.; Yan, C.; Li, Y.; Liu, Y.; Fukunaga, H. Investigation on sensitivity of a polymer/carbon nanotube composite strain sensor. Carbon 2010, 48, 680–687. [Google Scholar] [CrossRef]

- Hu, N.; Karube, Y.; Yan, C.; Masuda, Z.; Fukunaga, H. Tunneling effect in a polymer/carbon nanotube nanocomposite strain sensor. Acta Mater. 2008, 56, 2929–2936. [Google Scholar] [CrossRef]

- Stampfer, C.; Helbling, T.; Jungen, A.; Hierold, C. Piezoresistance of Single-Walled Carbon Nanotubes. In Proceedings of the Transducers & Eurosensors ’07, The 14th International Conference on Solid-State Sensors, Actuators and Microsystems, Lyon, France, 10–14 June 2007; pp. 1565–1568. [Google Scholar] [CrossRef]

- Yang, L.; Anantram, M.P.; Han, J.; Lu, J. Bandgap change of carbon nanotubes: Effect of small uniaxial and torsional strain. Phys. Rev. B 1999, 60, 13874–13878. [Google Scholar] [CrossRef]

- Gonçalves, J.P.M.; de Moura, M.F.S.F.; de Castro, P.M.S.T. A three-dimensional finite element model for stress analysis of adhesive joints. Int. J. Adhes. Adhes. 2002, 22, 357–365. [Google Scholar] [CrossRef]

- Shin, C.S.; Yang, Y.J.; Liaw, S.K. Monitoring fatigue damage of an adhesive joint using fiber optics sensors. J. Phys. Conf. Ser. 2017, 843, 012032. [Google Scholar] [CrossRef]

- Kersey, A.D.; Davis, M.A.; Patrick, H.J.; Leblanc, M.; Koo, K.P.; Askins, C.G.; Putnam, M.A.; Friebele, E.J. Fiber Grating Sensors. J. Light. Tech. 1997, 15, 1442–1463. [Google Scholar] [CrossRef]

- Menendez, J.M.; Guemes, J.A. Bragg-grating-based multiaxial strain sensing: Its application to residual strain measurement in composite laminates. In Proceedings of the SPIE 3986, Smart Structures and Materials 2000: Sensory Phenomena and Measurement Instrumentation for Smart Structures and Materials, SPIE’s 7th Annual International Symposium on Smart Structures and Materials, Newport Beach, CA, USA, 12 June 2000. [Google Scholar] [CrossRef]

- Chen, L.W.; Tong, X.Y.; Shin, C.S. Quantitative analysis of adhesive joint failure using the full spectral response of Fiber Bragg gratings. In Proceedings of the C4-012, the 38th Nature Academic Symposium of Chinese Society of Mechanical Engineering, Tainan, Taiwan, 3–4 December 2021. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, C.-S.; Chen, L.-W. Damage Monitoring of Composite Adhesive Joint Integrity Using Conductivity and Fiber Bragg Grating. Polymers 2023, 15, 1575. https://doi.org/10.3390/polym15061575

Shin C-S, Chen L-W. Damage Monitoring of Composite Adhesive Joint Integrity Using Conductivity and Fiber Bragg Grating. Polymers. 2023; 15(6):1575. https://doi.org/10.3390/polym15061575

Chicago/Turabian StyleShin, Chow-Shing, and Liang-Wei Chen. 2023. "Damage Monitoring of Composite Adhesive Joint Integrity Using Conductivity and Fiber Bragg Grating" Polymers 15, no. 6: 1575. https://doi.org/10.3390/polym15061575

APA StyleShin, C.-S., & Chen, L.-W. (2023). Damage Monitoring of Composite Adhesive Joint Integrity Using Conductivity and Fiber Bragg Grating. Polymers, 15(6), 1575. https://doi.org/10.3390/polym15061575