Effect of Almond Skin Waste and Glycidyl Methacrylate on Mechanical and Color Properties of Poly(ε-caprolactone)/Poly(lactic acid) Blends

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Biocomposite Preparation

2.3. Biocomposites Characterization

2.4. Statistical Analysis

3. Results and Discussion

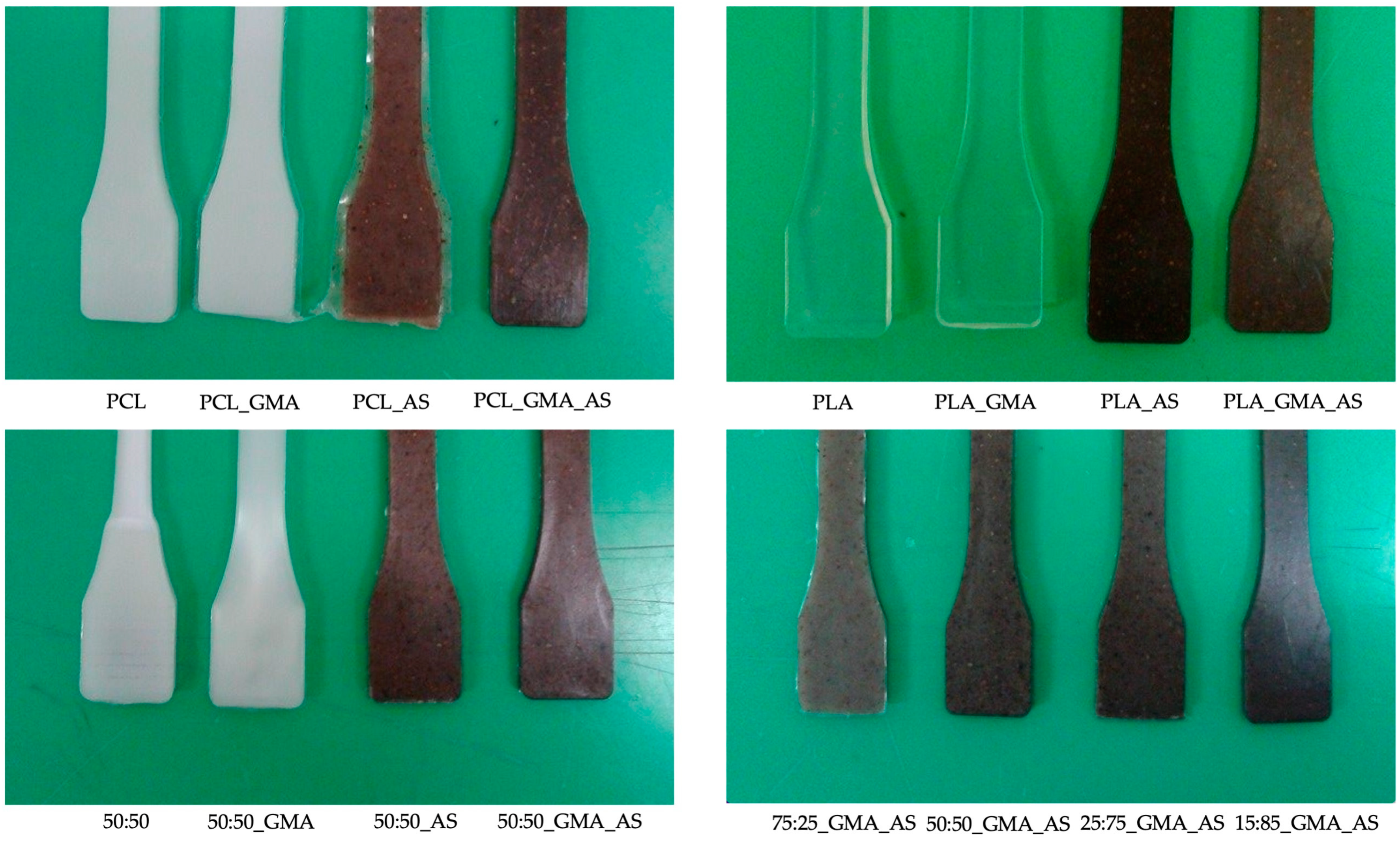

3.1. Color Properties

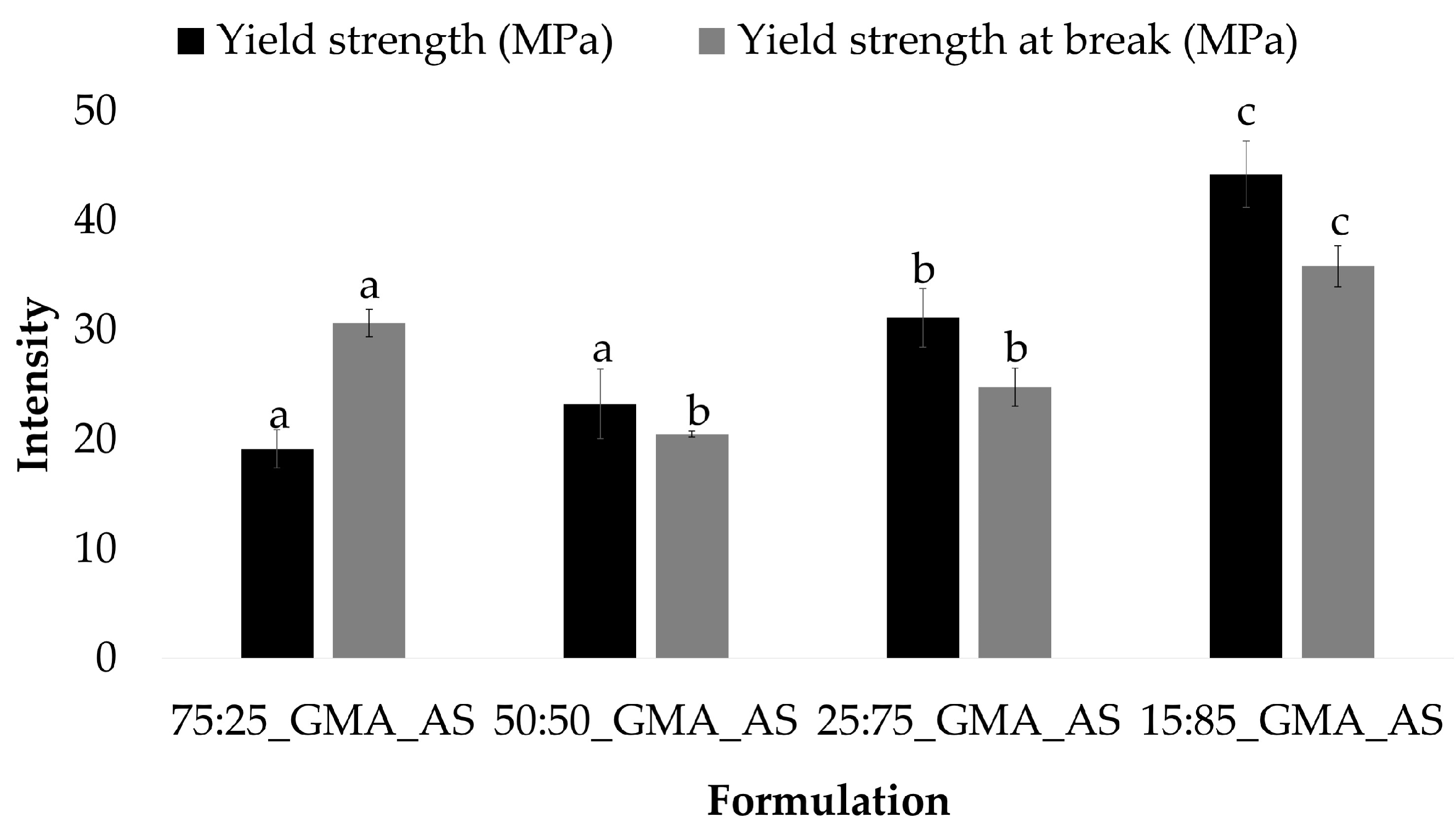

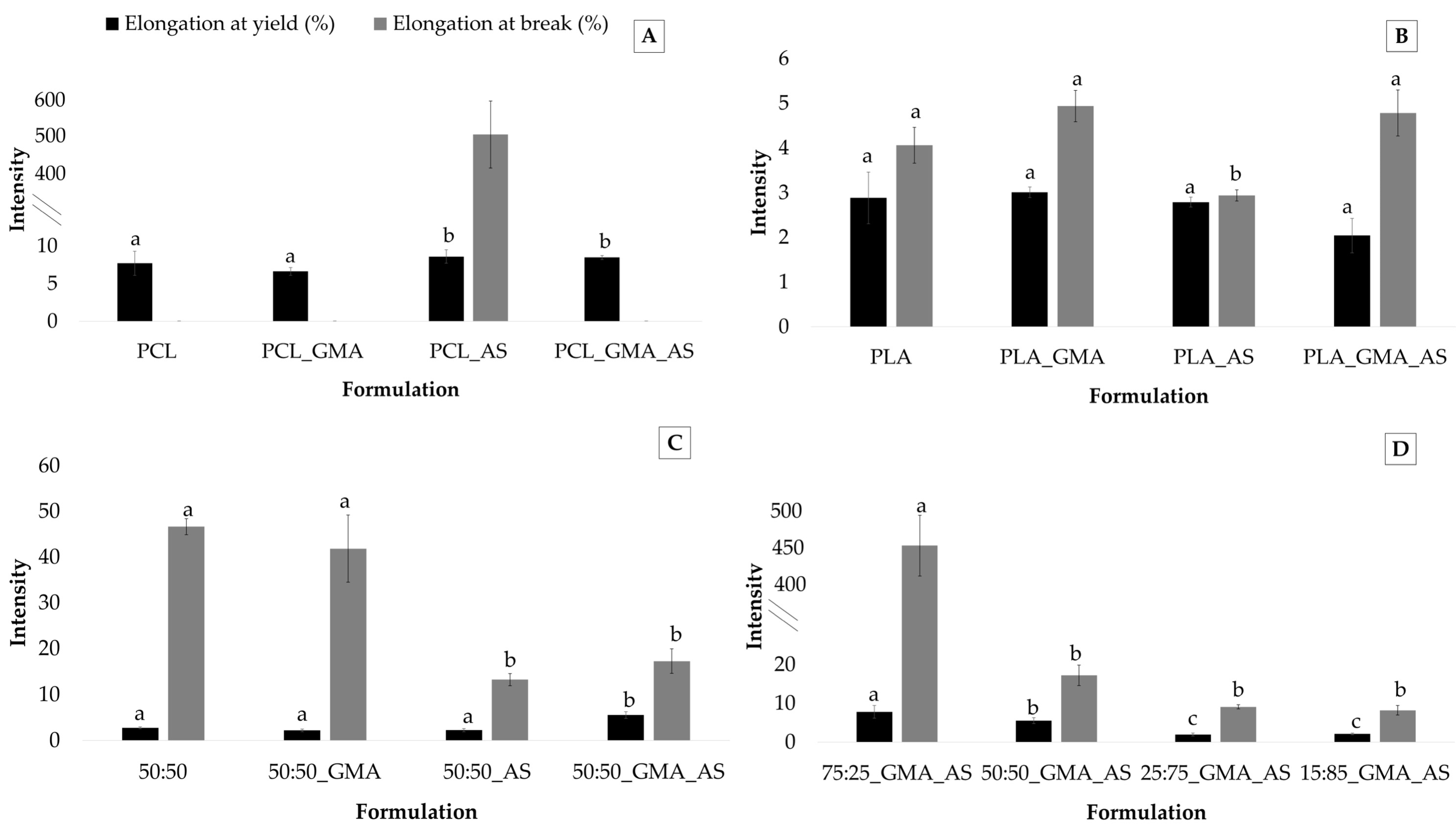

3.2. Mechanical and Shore D Hardness Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Geyer, R. Production, Use, and Fate of Synthetic Polymers; Academic Press: Cambridge, UK, 2020; ISBN 9780128178805. [Google Scholar]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- García-Depraect, O.; Bordel, S.; Lebrero, R.; Santos-Beneit, F.; Börner, R.A.; Börner, T.; Muñoz, R. Inspired by nature: Microbial production, degradation and valorization of biodegradable bioplastics for life-cycle-engineered products. Biotechnol. Adv. 2021, 53, 107772. [Google Scholar] [CrossRef] [PubMed]

- Chomachayi, M.D.; Jalali-Arani, A.; Beltrán, F.R.; de la Orden, M.U.; Urreaga, J.M. Biodegradable Nanocomposites Developed from PLA/PCL Blends and Silk Fibroin Nanoparticles: Study on the Microstructure, Thermal Behavior, Crystallinity and Performance. J. Polym. Environ. 2020, 28, 1252–1264. [Google Scholar] [CrossRef]

- Samir, A.; Ashour, F.H.; Hakim, A.A.A.; Bassyouni, M. Recent advances in biodegradable polymers for sustainable applications. npj Mater. Degrad. 2022, 6, 68. [Google Scholar] [CrossRef]

- Khitas, N.; Aouachria, K.; Benaniba, M.T. Blending and plasticising effects on the behaviour of poly(lactic acid)/poly(ε-caprolactone). Polym. Polym. Compos. 2018, 26, 337–345. [Google Scholar] [CrossRef]

- Kellersztein, I.; Amir, E.; Dotan, A. Grafting of wheat straw fibers with poly (ε-caprolactone) via ring-opening polymerization for poly(lactic acid) reinforcement. Polym. Adv. Technol. 2015, 27, 657–664. [Google Scholar] [CrossRef]

- Ojijo, V.; Ray, S.S.; Sadiku, R. Role of Specific Interfacial Area in Controlling Properties of Immiscible Blends of Biodegradable Polylactide and Poly[(butylene succinate)-co-adipate]. ACS Appl. Mater. Interfaces 2012, 4, 6690–6701. [Google Scholar] [CrossRef]

- Shin, B.Y.; Han, D.H. Compatibilization of immiscible poly(lactic acid)/poly(ε-caprolactone) blend through electron-beam irradiation with the addition of a compatibilizing agent. Radiat. Phys. Chem. 2013, 83, 98–104. [Google Scholar] [CrossRef]

- Payne, J.; McKeown, P.; Jones, M.D. A circular economy approach to plastic waste. Polym. Degrad. Stab. 2019, 165, 170–181. [Google Scholar] [CrossRef]

- Niaounakis, M. Definitions and Assessment of (Bio)degradation. Biopolym. Reuse Recycl. Dispos. 2013, 77–94. [Google Scholar] [CrossRef]

- Niaounakis, M. Recycling of biopolymers—The patent perspective. Eur. Polym. J. 2019, 114, 464–475. [Google Scholar] [CrossRef]

- Simões, C.L.; Viana, J.C.; Cunha, A.M. Mechanical properties of poly(ε-caprolactone) and poly(lactic acid) blends. J. Appl. Polym. Sci. 2008, 112, 345–352. [Google Scholar] [CrossRef]

- Ferri, J.M.; Fenollar, O.; Jorda-Vilaplana, A.; García-Sanoguera, D.; Balart, R. Effect of miscibility on mechanical and thermal properties of poly(lactic acid)/ polycaprolactone blends. Polym. Int. 2016, 65, 453–463. [Google Scholar] [CrossRef]

- Shi, C.; Zhou, A.; Fang, D.; Lu, T.; Wang, J.; Song, Y.; Lyu, L.; Wu, W.; Huang, C.; Li, W. Oregano essential oil/β-cyclodextrin inclusion compound polylactic acid/polycaprolactone electrospun nanofibers for active food packaging. Chem. Eng. J. 2022, 445, 136746. [Google Scholar] [CrossRef]

- Yang, W.; Qi, G.; Ding, H.; Xu, P.; Dong, W.; Zhu, X.; Zheng, T.; Ma, P. Biodegradable poly (lactic acid)-poly (ε-caprolactone)-nanolignin composite films with excellent flexibility and UV barrier performance. Compos. Commun. 2020, 22, 100497. [Google Scholar] [CrossRef]

- Sachan, R.; Warkar, S.G.; Purwar, R. An overview on synthesis, properties and applications of polycaprolactone copolymers, blends & composites. Polym. Technol. Mater. 2023, 62, 327–358. [Google Scholar] [CrossRef]

- Decol, M.; Pachekoski, W.M.; Becker, D. Compatibilization and ultraviolet blocking of PLA/PCL blends via interfacial localization of titanium dioxide nanoparticles. J. Appl. Polym. Sci. 2018, 135, 44849. [Google Scholar] [CrossRef]

- Yang, W.; Dominici, F.; Fortunati, E.; Kenny, J.; Puglia, D. Effect of lignin nanoparticles and masterbatch procedures on the final properties of glycidyl methacrylate- g -poly (lactic acid) films before and after accelerated UV weathering. Ind. Crop. Prod. 2015, 77, 833–844. [Google Scholar] [CrossRef]

- Haider, K.; Kharaghani, D.; Sun, L.; Ullah, S.; Sarwar, M.N.; Ullah, A.; Khatri, M.; Yoshiko, Y.; Gopiraman, M.; Kim, I.S. Synthesized bioactive lignin nanoparticles/polycaprolactone nanofibers: A novel nanobiocomposite for bone tissue engineering. Biomater. Adv. 2023, 144, 213203. [Google Scholar] [CrossRef]

- Sharma, D.; Banerjee, A.; Bhattacharyya, J.; Satapathy, B.K. Structurally stable and surface-textured polylactic acid/copolymer/poly (ε-caprolactone) blend-based electrospun constructs with tunable hydroxyapatite responsiveness. Colloids Surf. B Biointerfaces 2023, 221, 112969. [Google Scholar] [CrossRef]

- Arrieta, M.; Fortunati, E.; Dominici, F.; Rayón, E.; López, J.; Kenny, J. Multifunctional PLA–PHB/cellulose nanocrystal films: Processing, structural and thermal properties. Carbohydr. Polym. 2014, 107, 16–24. [Google Scholar] [CrossRef] [PubMed]

- Goriparthi, B.K.; Suman, K.; Nalluri, M.R. Processing and characterization of jute fiber reinforced hybrid biocomposites based on polylactide/polycaprolactone blends. Polym. Compos. 2012, 33, 237–244. [Google Scholar] [CrossRef]

- Rytlewski, P.; Gohs, U.; Stepczyńska, M.; Malinowski, R.; Karasiewicz, T.; Moraczewski, K. Electron-induced structural changes in flax fiber reinforced PLA/PCL composites, analyzed using the rule of mixtures. Ind. Crop. Prod. 2022, 188, 115587. [Google Scholar] [CrossRef]

- Priselac, D.; Poljaček, S.M.; Tomašegović, T.; Leskovac, M. Blends Based on Poly(ε-Caprolactone) with Addition of Poly(Lactic Acid) and Coconut Fibers: Thermal Analysis, Ageing Behavior and Application for Embossing Process. Polymers 2022, 14, 1792. [Google Scholar] [CrossRef] [PubMed]

- Ostafinska, A.; Fortelny, I.; Nevoralova, M.; Hodan, J.; Kredatusova, J.; Slouf, M. Synergistic effects in mechanical properties of PLA/PCL blends with optimized composition, processing, and morphology. RSC Adv. 2015, 5, 98971–98982. [Google Scholar] [CrossRef]

- Takayama, T.; Todo, M.; Tsuji, H.; Arakawa, K. Effect of LTI content on impact fracture property of PLA/PCL/LTI polymer blends. J. Mater. Sci. 2006, 41, 6501–6504. [Google Scholar] [CrossRef]

- FAOSTAT Food and Agriculture Organization of the United States. Available online: https://www.fao.org/statistics/en/ (accessed on 9 January 2023).

- Garrido, I.; Monagas, M.; Gómez-Cordovés, C.; Bartolomé, B. Polyphenols and Antioxidant Properties of Almond Skins: Influence of Industrial Processing. J. Food Sci. 2008, 73, C106–C115. [Google Scholar] [CrossRef] [PubMed]

- Valdés, A.; Vidal, L.; Beltrán, A.; Canals, A.; Garrigós, M.C. Microwave-Assisted Extraction of Phenolic Compounds from Almond Skin Byproducts (Prunus amygdalus): A Multivariate Analysis Approach. J. Agric. Food Chem. 2015, 63, 5395–5402. [Google Scholar] [CrossRef]

- García, A.V.; Santonja, M.R.; Sanahuja, A.B.; Selva, M.D.C.G. Characterization and degradation characteristics of poly(ε-caprolactone)-based composites reinforced with almond skin residues. Polym. Degrad. Stab. 2014, 108, 269–279. [Google Scholar] [CrossRef]

- Valdés, A.; Fenollar, O.; Beltrán, A.; Balart, R.; Fortunati, E.; Kenny, J.M.; Garrigós, M.C. Characterization and enzymatic degradation study of poly(ε-caprolactone)-based biocomposites from almond agricultural by-products. Polym. Degrad. Stab. 2016, 132, 181–190. [Google Scholar] [CrossRef]

- Edward, M.S.G.; Louis, A.C.F.; Srinivasan, H.; Venkatachalam, S. A mechanochemical approach for synthesizing almond shell nanoparticles and their potential application on the enhancement of polylactic acid film properties. Iran. Polym. J. 2022, 31, 1523–1535. [Google Scholar] [CrossRef]

- ISO 527e2; Plastics. Determination of Tensile Properties. Part 2: Test Conditions for Moulding and Extrusion Plastics. American National Standards Institute (ANSI): Washington, DC, USA, 1993.

- Pereda, M.; Dufresne, A.; Aranguren, M.I.; Marcovich, N.E. Polyelectrolyte films based on chitosan/olive oil and reinforced with cellulose nanocrystals. Carbohydr. Polym. 2014, 101, 1018–1026. [Google Scholar] [CrossRef] [PubMed]

- ISO 527e1; Plastics-Determination of Tensile Properties. Part 1: General Principles. American National Standards Institute (ANSI): Washington, DC, USA, 1993.

- ASTM. D 882-09; Standard Test Method for Tensile Properties of Thin Plastic Sheeting. In Annual Book of ASTM Standards Amer Soc for Testing & Materials; Astm International: Philadelphia, PA, USA, 2009.

- UNE-EN ISO 868:2003; Standard. Plastics and Ebonite—Determination of Indentation Hardness by Means of a Durometer (Shore Hardness) (ISO 868:2003). Asociacion Espanola de Normalizacion: Madrid, Spain. Available online: Https://Www.Iso.Org/Standard/34804.Html (accessed on 9 September 2022).

- Jeong, B.J.; Xanthos, M. Reactive modification of PBT with applications in low density extrusion foaming. Polym. Eng. Sci. 2007, 47, 244–253. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Pineiro, F.; Jorda-Vilaplana, A.; Torres-Giner, S. Ductility and Toughness Improvement of Injection-Molded Compostable Pieces of Polylactide by Melt Blending with Poly(ε-caprolactone) and Thermoplastic Starch. Materials 2018, 11, 2138. [Google Scholar] [CrossRef] [PubMed]

- Chomachayi, M.D.; Solouk, A.; Mirzadeh, H. Electrospun silk-based nanofibrous scaffolds: Fiber diameter and oxygen transfer. Prog. Biomater. 2016, 5, 71–80. [Google Scholar] [CrossRef]

| Formulation | PCL (wt. %) | PLA (wt. %) | GMA (wt. %) | AS (wt. %) |

|---|---|---|---|---|

| PCL | 100.00 | |||

| PCL_GMA | 97.00 | 3 | ||

| PCL_AS | 90.00 | 10 | ||

| PCL_GMA_AS | 87.00 | 3 | 10 | |

| PLA | 100.00 | |||

| PLA_GMA | 97.00 | 3 | ||

| PLA_AS | 90.00 | 10 | ||

| PLA_GMA_AS | 87.00 | 3 | 10 | |

| 50:50 | 50.00 | 50.00 | ||

| 50:50_GMA | 48.50 | 48.50 | 3 | |

| 50:50_AS | 45.00 | 45.00 | 10 | |

| 50:50_GMA_AS | 43.50 | 43.50 | 3 | 10 |

| 75:25_GMA_AS | 65.25 | 21.75 | 3 | 10 |

| 25:75_GMA_AS | 43.50 | 43.50 | 3 | 10 |

| 15:85_GMA_AS | 21.75 | 65.25 | 3 | 10 |

| Formulation | L* | a* | b* | WI |

|---|---|---|---|---|

| PCL | 79.9 ± 6.9 a | -0.53 ± 0.16 a | 1.42 ± 0.45 a | 79.9 ± 6.9 a |

| PCL_GMA | 80.9 ± 0.6 a | -0.58 ± 0.06 a | 1.75 ± 0.08 a | 80.8 ± 0.6 a |

| PCL_AS | 38.5 ± 4.3 b | 5.48 ± 0.49 bd | 6.33 ± 0.49 b | 38.0 ± 4.3 b |

| PCL_GMA_AS | 33.9 ± 3.2 b | 5.45 ± 0.65 bd | 6.99 ± 1.42 bc | 33.2 ± 3.3 b |

| PLA | 83.2 ± 5.2 a | -0.15 ± 0.03 a | 6.18 ± 0.54 bc | 82.0 ± 4.7 a |

| PLA_GMA | 80.9 ± 4.7 a | -0.12 ± 0.02 a | 4.37 ± 2.36 c | 80.2 ± 4.1 a |

| PLA_AS | 27.4 ± 2.6 b | 3.99 ± 0.34 c | 4.21 ± 0.16 bc | 27.1 ± 2.6 b |

| PLA_GMA_AS | 29.9 ± 2.7 b | 4.64 ± 0.39 bcd | 5.22 ± 0.20 bc | 29.6 ± 2.7 b |

| 50:50 | 78.8 ± 3.1 a | -0.98 ± 0.12 a | 1.02 ± 0.35 a | 78.7 ± 3.1 a |

| 50:50_GMA | 75.1 ± 2.1 a | -0.45 ± 0.39 a | 2.53 ± 0.40 ac | 74.9 ± 2.1 a |

| 50:50_AS | 35.1 ± 0.9 b | 5.43 ± 0.18 bd | 6.90 ± 0.13 b | 34.6 ± 0.9 b |

| 50:50_GMA_AS | 35.2 ± 0.7 b | 5.98 ± 0.17 d | 7.62 ± 0.14 b | 34.5 ± 0.7 b |

| 75:25_GMA_AS | 40.0 ± 1.4 b | 6.18 ± 0.15 d | 8.34 ± 0.38 b | 39.1 ± 1.3 b |

| 25:75_GMA_AS | 34.8 ± 0.2 b | 5.49 ± 0.05 bd | 7.19 ± 0.05 b | 34.2 ± 0.2 b |

| 15:85_GMA_AS | 30.2 ± 0.6 b | 5.05 ± 0.22 bd | 5.20 ± 0.25 bc | 29.8 ± 0.6 b |

| Formulation | Young Modulus (MPa) | Yield Strength (MPa) | Elongation at Yield (%) | Yield Strength at Break (MPa) | Elongation at Break (%) | Shore D Hardness |

|---|---|---|---|---|---|---|

| PCL | 240 ± 17 a | 15.9 ± 1.7 a | 7.7 ± 1.6 ac | Not break | Not break | 95.0 ± 0.5 a |

| PCL_GMA | 244 ± 5 a | 17.1 ± 0.2 a | 6.6 ± 0.5 ad | Not break | Not break | 94.8 ± 0.3 ac |

| PCL_AS | 157 ± 3 b | 17.7 ± 0.8 a | 8.6 ± 0.9 c | 27.0 ± 1.6 ae | 534.8 ± 19.4 a | 92.7 ± 0.6 c |

| PCL_GMA_AS | 215 ± 4 c | 16.8 ± 0.3 a | 8.5 ± 0.3 c | Not break | Not break | 95.2 ± 0.8 a |

| PLA | 99 ± 2 d | 71.0 ± 4.9 b | 2.9 ± 0.6 b | 58.5 ± 5.0 b | 4.1 ± 0.4 b | 90.7 ± 1.0 b |

| PLA_GMA | 99 ± 3 d | 69.4 ± 3.8 b | 3.0 ± 0.2 b | 59.5 ± 2.3 b | 4.9 ± 0.3 b | 93.9 ± 0.7 ac |

| PLA_AS | 100 ± 6 d | 61.5 ± 2.0 b | 2.8 ± 0.2 b | 59.6 ± 2.4 b | 2.9 ± 0.2 e | 95.3 ± 0.6 ac |

| PLA_GMA_AS | 101 ± 3 d | 45.6 ± 5.1 c | 2.0 ± 0.4 b | 38.6 ± 4.0 c | 4.8 ± 0.5 b | 94.7 ± 0.6 ac |

| 50:50 | 55 ± 4 e | 36.1 ± 0.6 d | 2.8 ± 0.2 b | 27.0 ± 0.2 a | 46.7 ± 1.8 c | 94.6 ± 0.4 ac |

| 50:50_GMA | 50 ± 9 e | 38.4 ± 7.9 cd | 2.2 ± 0.3 b | 27.5 ± 1.1 a | 41.9 ± 7.4 c | 92.0 ± 1.0 d |

| 50:50_AS | 72 ± 5 f | 34.4 ± 2.3 d | 2.3 ± 0.3 b | 28.0 ± 1.4 a | 13.2 ± 1.3 d | 96.5 ± 0.5 a |

| 50:50_GMA_AS | 107 ± 5 e | 23.2 ± 3.2 a | 5.5 ± 0.7 d | 20.5 ± 0.3 d | 14.3 ± 2.7 d | 95.3 ± 0.6 a |

| 75:25_GMA_AS | 134 ± 13 e | 19.1 ± 1.8 a | 7.8 ± 1.6 ac | 30.6 ± 1.3 a | 450.8 ± 17.8 f | 95.0 ± 1.0 a |

| 25:75_GMA_AS | 142 ± 5 b | 31.1 ± 2.7 d | 2.0 ± 0.4 b | 24.8 ± 1.7 a | 9.1 ± 0.5 d | 94.0 ± 1.3 acd |

| 15:85_GMA_AS | 112 ± 5 d | 44.2 ± 3.0 c | 2.1 ± 0.2 b | 35.9 ± 1.9 e | 8.2 ± 1.2 d | 94.7 ± 0.6 ac |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valdés, A.; Dominici, F.; Fortunati, E.; Kenny, J.M.; Jiménez, A.; Garrigós, M.C. Effect of Almond Skin Waste and Glycidyl Methacrylate on Mechanical and Color Properties of Poly(ε-caprolactone)/Poly(lactic acid) Blends. Polymers 2023, 15, 1045. https://doi.org/10.3390/polym15041045

Valdés A, Dominici F, Fortunati E, Kenny JM, Jiménez A, Garrigós MC. Effect of Almond Skin Waste and Glycidyl Methacrylate on Mechanical and Color Properties of Poly(ε-caprolactone)/Poly(lactic acid) Blends. Polymers. 2023; 15(4):1045. https://doi.org/10.3390/polym15041045

Chicago/Turabian StyleValdés, Arantzazu, Franco Dominici, Elena Fortunati, Jose María Kenny, Alfonso Jiménez, and María Carmen Garrigós. 2023. "Effect of Almond Skin Waste and Glycidyl Methacrylate on Mechanical and Color Properties of Poly(ε-caprolactone)/Poly(lactic acid) Blends" Polymers 15, no. 4: 1045. https://doi.org/10.3390/polym15041045

APA StyleValdés, A., Dominici, F., Fortunati, E., Kenny, J. M., Jiménez, A., & Garrigós, M. C. (2023). Effect of Almond Skin Waste and Glycidyl Methacrylate on Mechanical and Color Properties of Poly(ε-caprolactone)/Poly(lactic acid) Blends. Polymers, 15(4), 1045. https://doi.org/10.3390/polym15041045