Mechanical Recycling and Its Effects on the Physical and Mechanical Properties of Polyamides

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

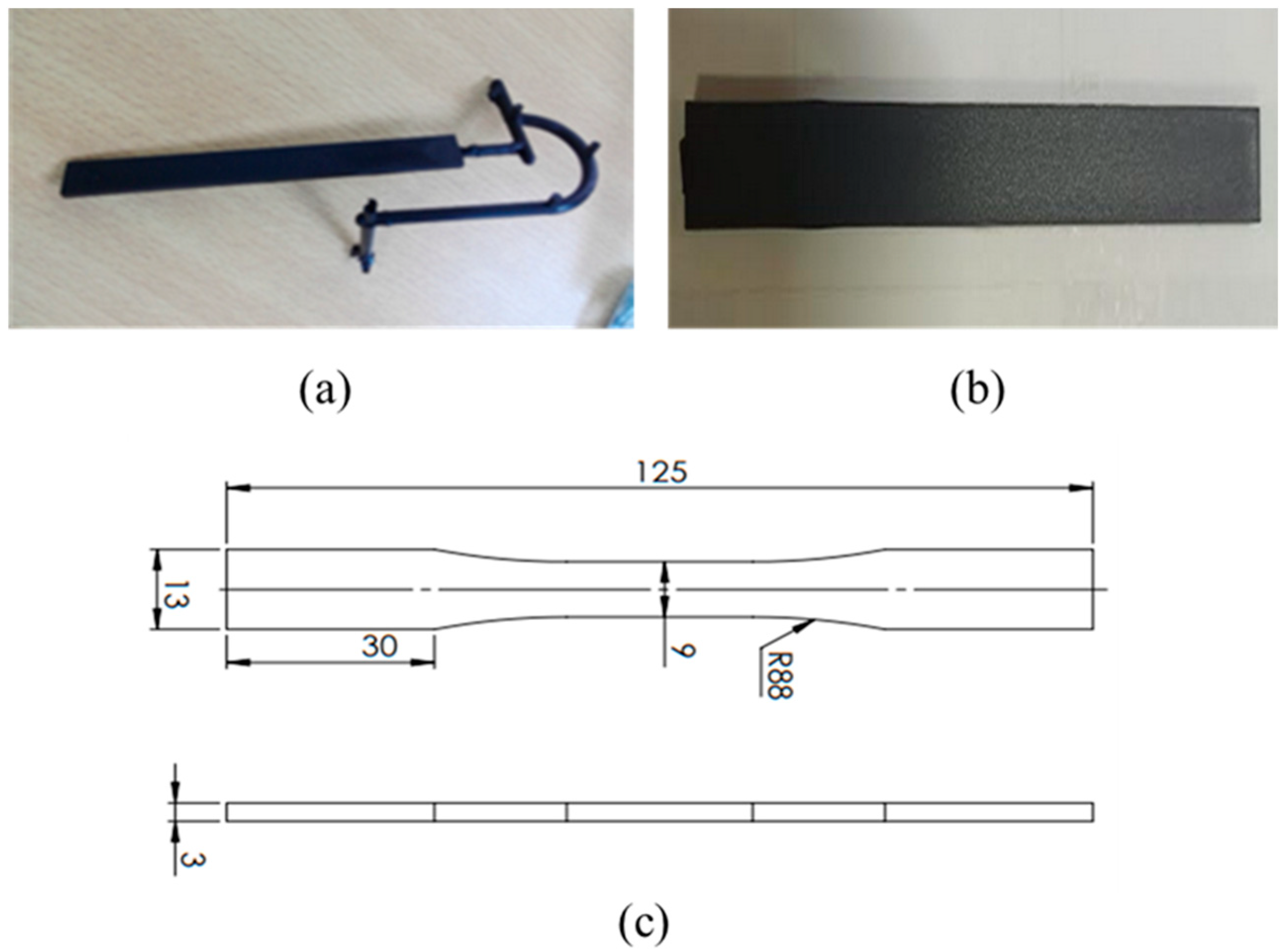

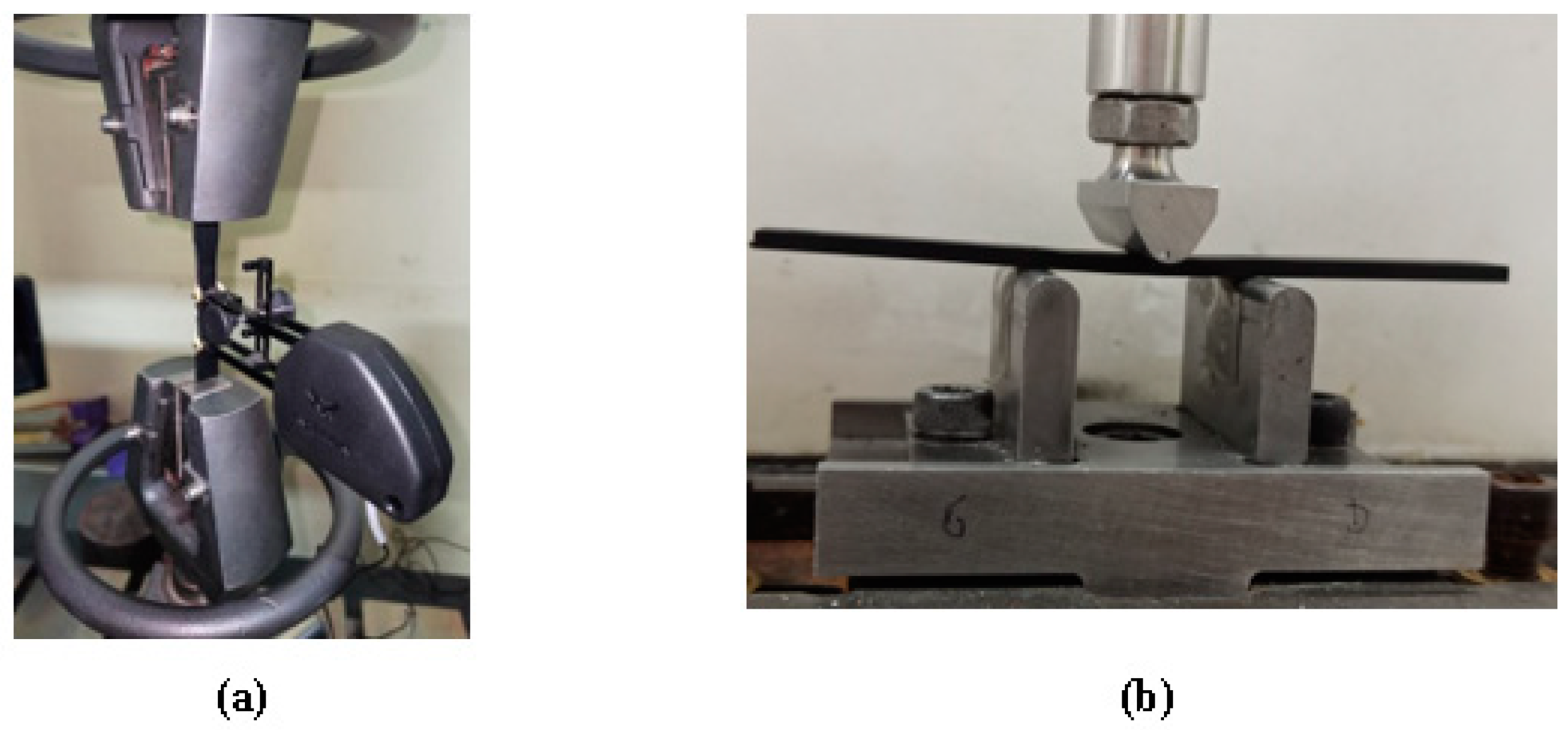

2.2. Sample Preparation

2.3. Materials Characterization

2.3.1. Material Characterization

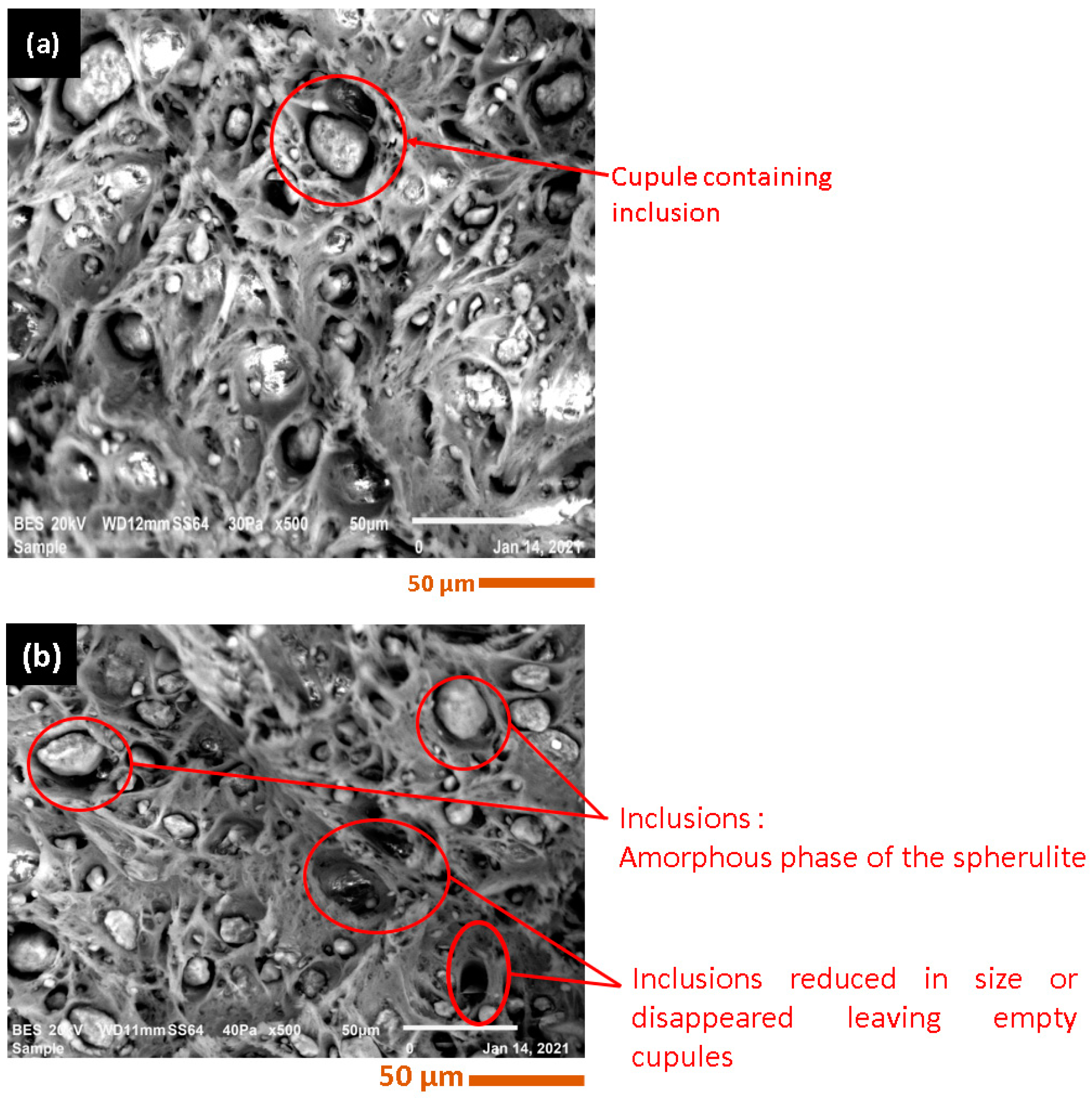

2.3.2. Microscopic Analysis

2.3.3. Fluidity Test

3. Results

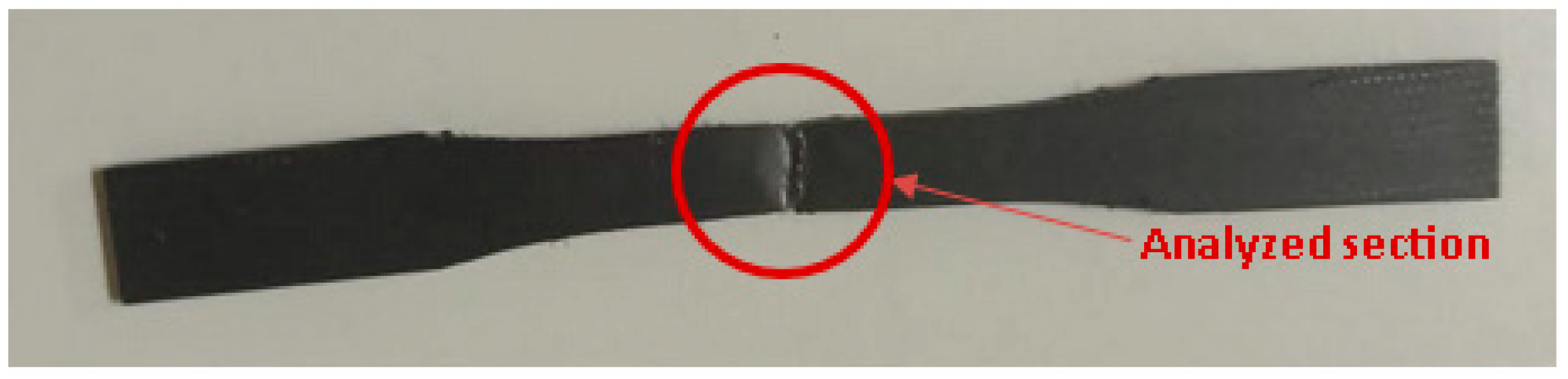

3.1. Tensile Test

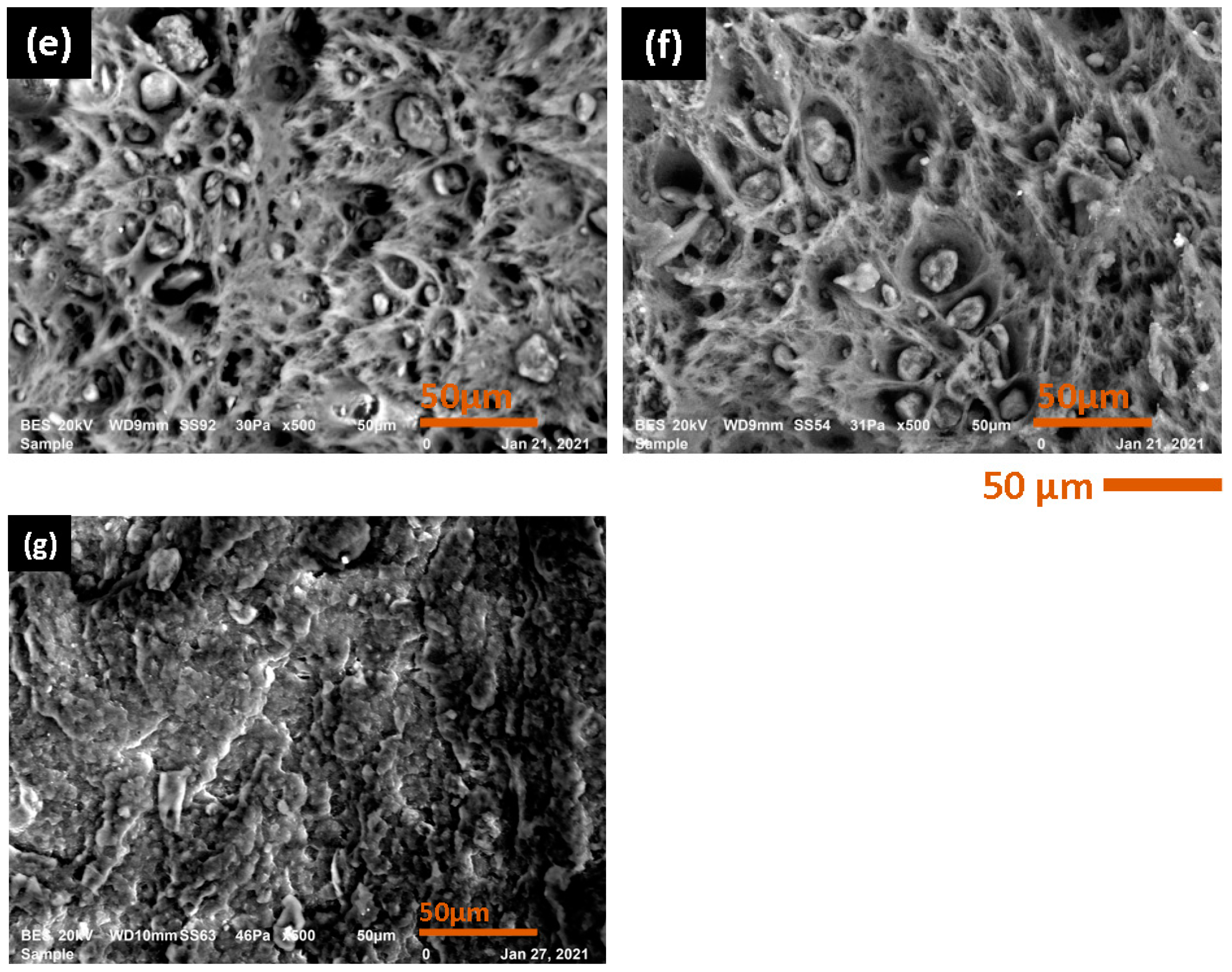

Microscopic Analysis

3.2. Flexural Test

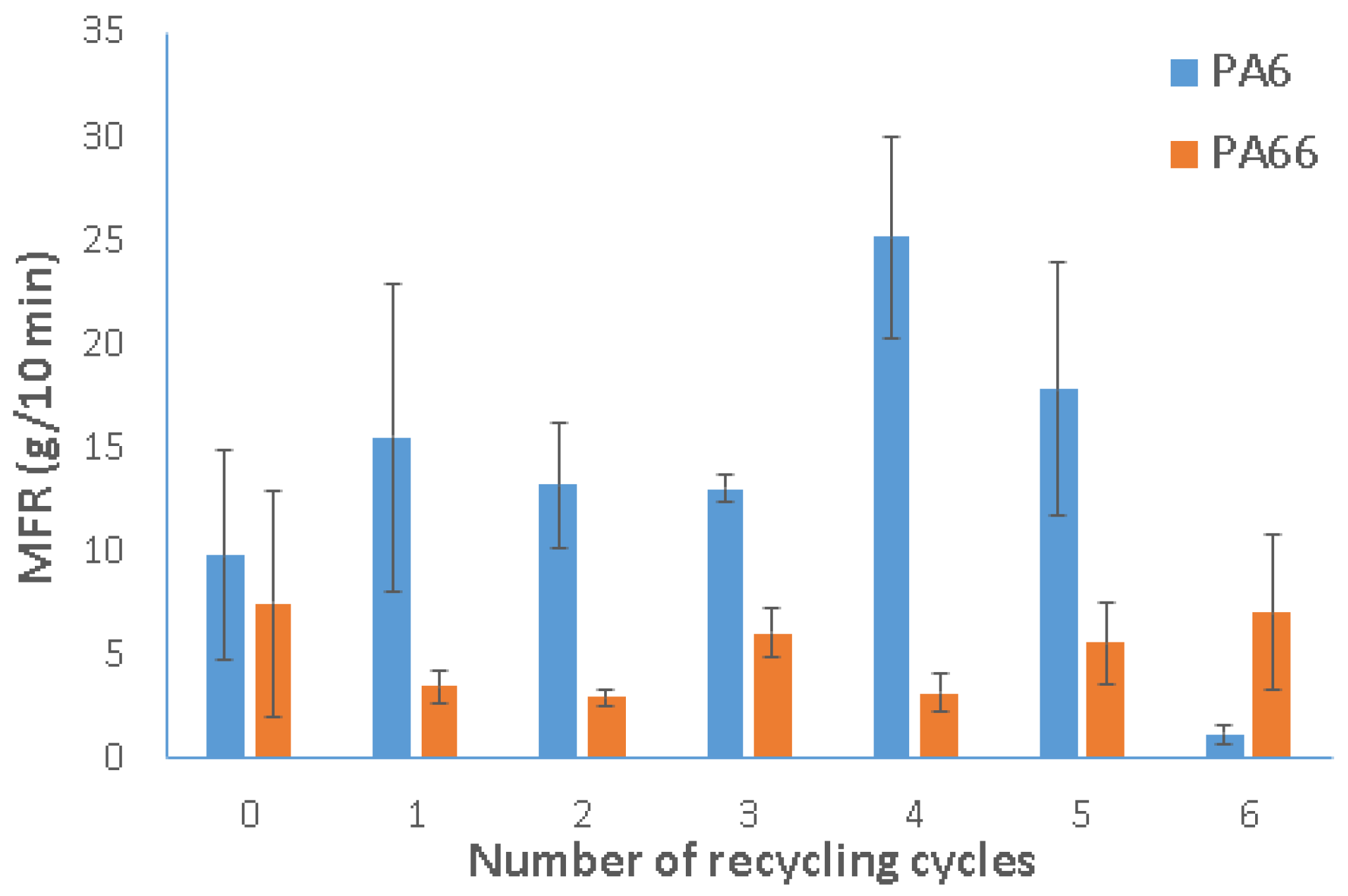

3.3. Fluidity Test

4. Conclusions

- There was a noticeable decrease in mechanical properties for both materials. Specifically, Young’s modulus reduced by 36% and 34% for PA6 and PA66, respectively, from the virgin state to the sixth cycle. The tensile strength showed reductions of 14% and 64% for PA6 and PA66, respectively.

- There was a notable average increase of 50% in elongation (%) for both materials. In the flexural test, similar trends were observed as in the tensile strength properties. These variations can be attributed to factors like chain scission, molecular weight degradation, and the accumulation of impurities during the recycling process.

- Changes in the physical properties were evident in both materials, as demonstrated by the MFR and MVR measurements. These changes were linked to the increase in processing cycles, with MFR reaching 17.79 g/10 min and 5.51 g/10 min for PA6 and PA66, respectively, by the fifth recycling cycle. This indicates a reduction in viscosity likely due to chain breakage or hydrolysis, resulting in improved processability.

- The recycling process had an impact on the increase in the total area of porosity, reaching 33.1% for PA6. These alterations can have adverse effects on the material’s mechanical and other physical properties, leading to a decrease in performance over time.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bäckström, E.; Odelius, K.; Hakkarainen, M. Designed from Recycled: Turning Polyethylene Waste to Covalently Attached Polylactide Plasticizers. ACS Sustain. Chem. Eng. 2019, 7, 11004–11013. [Google Scholar] [CrossRef]

- Preka, R.; Fiorentino, G.; De Carolis, R.; Barberio, G. The Challenge of Plastics in a Circular Perspective. Front. Sustain. Cities 2022, 4, 920242. [Google Scholar] [CrossRef]

- Biresselioglu, M.E.; Demir, M.H.; Solak, B.; Turan, U. Understanding the Dynamics and Conceptualization of Environmental Citizenship and Energy Citizenship: Evidence from the Existing Literature. Front. Energy Res. 2022, 10, 1018035. [Google Scholar] [CrossRef]

- More, C.V.; Alsayed, Z.; Badawi, M.S.; Thabet, A.A.; Pawar, P.P. Polymeric Composite Materials for Radiation Shielding: A Review. Environ. Chem. Lett. 2021, 19, 2057–2090. [Google Scholar] [CrossRef] [PubMed]

- Singh, B.; Kumar, R.; Chohan, J.S. Processing and Recycling of Thermoplastic Polymers: Current Scenario and Future Challenges. Turk. J. Comput. Math. Educ. (TURCOMAT) 2021, 12, 2744–2753. [Google Scholar] [CrossRef]

- Samper, M.D.; Bertomeu, D.; Arrieta, M.P.; Ferri, J.M.; López-Martínez, J. Interference of Biodegradable Plastics in the Polypropylene Recycling Process. Materials 2018, 11, 1886. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Botta, L.; Mistretta, M.C.; Di Fiore, A.; Titone, V. Recycling of a Biodegradable Polymer Blend. Polymers 2020, 12, 2297. [Google Scholar] [CrossRef]

- Ding, Q.; Zhu, H. The Key to Solving Plastic Packaging Wastes: Design for Recycling and Recycling Technology. Polymers 2023, 15, 1485. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Karl, C.W.; Rocha, I.B.C.M.; Burlakovs, J.; Ozola-Davidane, R.; Gagani, A.I.; Starkova, O. Modelling of Environmental Ageing of Polymers and Polymer Composites—Modular and Multiscale Methods. Polymers 2022, 14, 216. [Google Scholar] [CrossRef]

- Zdiri, K.; Elamri, A.; Hamdaoui, M.; Harzallah, O.; Khenoussi, N.; Brendlé, J. Reinforcement of Recycled PP Polymers by Nanoparticles Incorporation. Green Chem. Lett. Rev. 2018, 11, 296–311. [Google Scholar] [CrossRef]

- Matykiewicz, D.; Olszewski, T.; Andrzejewski, J. Waste Management after the Injection Process by Manufacturing Polyamide Products Based on Regranulate. ChemEngineering 2023, 7, 51. [Google Scholar] [CrossRef]

- Kausar, A. Advances in Carbon Fiber Reinforced Polyamide-Based Composite Materials. Adv. Mater. Sci. 2019, 19, 67–82. [Google Scholar] [CrossRef]

- Yıldız, C.; Seki, Y.; Ekti, M.; Aker, S.; Leskeri, B.M.; Sarikanat, M.; Altay, L. Improving Flame Retardant Properties of Aliphatic Polyketone (POK)-Based Composites. ACS Omega 2023, 8, 9415–9422. [Google Scholar] [CrossRef] [PubMed]

- Sharma, P.; Sambale, A.; Stommel, M.; Maisl, M.; Herrmann, H.-G.; Diebels, S. Moisture Transport in PA6 and Its Influence on the Mechanical Properties. Contin. Mech. Thermodyn. 2020, 32, 307–325. [Google Scholar] [CrossRef]

- Alberti, C.; Figueira, R.; Hofmann, M.; Koschke, S.; Enthaler, S. Chemical Recycling of End-of-life Polyamide 6 via Ring Closing Depolymerization. ChemistrySelect 2019, 4, 12638–12642. [Google Scholar] [CrossRef]

- Rides, M.; Allen, C.; Omloo, H.; Nakayama, K.; Cancelli, G. Interlaboratory Comparison of Melt Flow Rate Testing of Moisture Sensitive Plastics. Polym. Test. 2009, 28, 572–591. [Google Scholar] [CrossRef]

- Abacha, N.; Kubouchi, M.; Sakai, T. Diffusion Behavior of Water in Polyamide 6 Organoclay Nanocomposites. Express Polym. Lett. 2009, 3, 245–255. [Google Scholar] [CrossRef]

- Arhant, M.; Le Gac, P.-Y.; Le Gall, M.; Burtin, C.; Briançon, C.; Davies, P. Modelling the Non Fickian Water Absorption in Polyamide 6. Polym. Degrad. Stab. 2016, 133, 404–412. [Google Scholar] [CrossRef]

- Kuda-Malwathumullage, C.P.S.; Small, G.W. Determination of Moisture Content of Polyamide 66 Directly from Combination Region Near-infrared Spectra. J. Appl. Polym. Sci. 2014, 131, 40645. [Google Scholar] [CrossRef]

- Boukal, I. Effect of Water on the Mechanism of Deformation of Nylon 6. J. Appl. Polym. Sci. 1967, 11, 1483–1494. [Google Scholar] [CrossRef]

- Buchdahl, R.; Zaukelies, D.A. Deformationsprozesse und die Struktur von Kristallinen Polymeren. Angew. Chem. Weinh. Bergstr. Ger. 1962, 74, 569–573. [Google Scholar] [CrossRef]

- Thirumalai, D.P.R.; Andersen, T.L.; Lystrup, A. Influence of Moisture Absorption on Properties of Fiber Reinforced Polyamide 6 Composites. In Proceedings of the 26th Annual Technical Conference of the American Society for Composites 2011 and the 2nd Joint US-Canada Conference on Composites, Montreal, QC, Canada, 26–28 September 2011; DEStech Publications Inc.: Lancaster, PA, USA, 2011; pp. 500–510. [Google Scholar]

- Rajeesh, K.R.; Gnanamoorthy, R.; Velmurugan, R. Effect of Humidity on the Indentation Hardness and Flexural Fatigue Behavior of Polyamide 6 Nanocomposite. Mater. Sci. Eng. A Struct. Mater. 2010, 527, 2826–2830. [Google Scholar] [CrossRef]

- Krzyżak, A.; Gąska, J.; Duleba, B. Water Absorption of Thermoplastic Matrix Composites with Polyamide 6. Zesz. Nauk./Akad. Morska W Szczecinie 2013, 33, 62–68. [Google Scholar]

- Mondragon, G.; Kortaberria, G.; Mendiburu, E.; González, N.; Arbelaiz, A.; Peña-Rodriguez, C. Thermomechanical Recycling of Polyamide 6 from Fishing Nets Waste. J. Appl. Polym. Sci. 2020, 137, 48442. [Google Scholar] [CrossRef]

- Chandrasekaran, V.C. Rubbers, Chemicals and Compounding for “O” Rings and Seals; Elsevier eBooks: Amsterdam, The Netherlands, 2010; pp. 57–69. [Google Scholar] [CrossRef]

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2014.

- ISO 527-4:2023; Plastics: Determination of tensile properties—Part 4: Test conditions for isotropic and orthotropic fibre-reinforced plastic composites. ISO: Geneva, Switzerland, 2023.

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM: West Conshohocken, PA, USA, 2017.

- ISO 1133-1:2022; Plastics: Determination of the melt mass-flow rate (MFR) and melt volume-flow rate (MVR) of thermoplastics—Part 1: Standard method. ISO: Geneva, Switzerland, 2022.

- Maspoch, M.L.; Ferrando, H.E.; Velasco, J.I. Characterisation of Filled and Recycled PA6. Macromol. Symp. 2003, 194, 295–304. [Google Scholar] [CrossRef]

- Crespo, J.E.; Parres, F.; Peydró, M.A.; Navarro, R. Study of Rheological, Thermal, and Mechanical Behavior of Reprocessed Polyamide 6. Polym. Eng. Sci. 2013, 53, 679–688. [Google Scholar] [CrossRef]

- Djeddi, F.; Mohellebi, M. Valorisation de Déchets Plastiques à base de Polyamide par Recyclage. Int. J. Sci. Res. Eng. Technol. 2019, 8, 1–6. [Google Scholar]

- Phothisarattana, D.; Wongphan, P.; Promhuad, K.; Promsorn, J.; Harnkarnsujarit, N. Biodegradable Poly(Butylene Adipate-Co-Terephthalate) and Thermoplastic Starch-Blended TiO2 Nanocomposite Blown Films as Functional Active Packaging of Fresh Fruit. Polymers 2021, 13, 4192. [Google Scholar] [CrossRef]

- Kaisersberger, E.; Knappe, S.; Opfermann, J.; Möhler, H. The Influence of Recycled Material on the Crystallization Kinetics of Thermoplastic Polymers. J. Therm. Anal. Calorim. 1993, 40, 821–829. [Google Scholar] [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 Years of Image Analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef]

- Daumann, B.; Nirschl, H. Assessment of the Mixing Efficiency of Solid Mixtures by Means of Image Analysis. Powder Technol. 2008, 182, 415–423. [Google Scholar] [CrossRef][Green Version]

- Su, K.-H.; Lin, J.-H.; Lin, C.-C. Influence of Reprocessing on the Mechanical Properties and Structure of Polyamide 6. J. Mater. Process. Technol. 2007, 192–193, 532–538. [Google Scholar] [CrossRef]

| Property | PA6 | PA66 |

|---|---|---|

| Density, g/cm3 | 1.18 | 1.14 |

| Molding shrinkage, % | 1.1–1.5 | |

| Water absorption (Equilibrium, 23 °C, 50% RH), % | 2.5 | 2.6 |

| Tensile modulus, MPa | 2900 | 3100 |

| Tensile stress, MPa | 70 | 82 |

| Tensile strain, % | 4.0 | 4.5 |

| Flexural modulus, MPa | 3100 | 2800 |

| Flexural stress (strain de 3.5%), MPa | 85 | 115 |

| Heat deflection temperature 1.8 MPa, unannealed, °C | 80 | 70 |

| Coefficient of thermal expansion, cm/cm/°C | 6.0 × 10−5 | 1.0 × 10−4 |

| Thermal conductivity, W/m·K | 0.34 | 0.16 |

| Injection Parameters, Units | PA6 | PA66 |

|---|---|---|

| Processing melt temperature, °C | 240–260 | 280–300 |

| Mold temperature, °C | 60–80 | 50–90 |

| Holding pressure, MPa | 140 | 100 |

| Back pressure, MPa | 15 | - |

| Screw Speed, m/min | 30 | 24 |

| Materials | Loads, kg | T, °C |

|---|---|---|

| PA6 | 1.2 | 235 |

| PA66 | 0.325 | 275 |

| Number of Recycling Cycles | Mean Area of Inclusion (μm2) | Total Area of Inclusion (µm2) | Area of Porosity (µm2) |

|---|---|---|---|

| 0 | 68.3 | 5532.0 (10.2%) | 6822.7 (12.6%) |

| 1 | 52.3 | 3823.9 (7.1%) | 7542.0 (14.0%) |

| 2 | 42.8 | 3602.3 (6.6%) | 9318.1 (17.3%) |

| 3 | 37.2 | 2420.1 (4.5%) | 10,374.0 (19.2%) |

| 4 | 33.9 | 2376.8 (4.4%) | 15,341.2 (28.5%) |

| 5 | 27.3 | 2184.5 (4.0%) | 17,719.2 (32.9%) |

| 6 | 13.3 | 1122.8 (2%) | 17,854.5 (33.1%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ben Amor, I.; Klinkova, O.; Baklouti, M.; Elleuch, R.; Tawfiq, I. Mechanical Recycling and Its Effects on the Physical and Mechanical Properties of Polyamides. Polymers 2023, 15, 4561. https://doi.org/10.3390/polym15234561

Ben Amor I, Klinkova O, Baklouti M, Elleuch R, Tawfiq I. Mechanical Recycling and Its Effects on the Physical and Mechanical Properties of Polyamides. Polymers. 2023; 15(23):4561. https://doi.org/10.3390/polym15234561

Chicago/Turabian StyleBen Amor, Ichrak, Olga Klinkova, Mouna Baklouti, Riadh Elleuch, and Imad Tawfiq. 2023. "Mechanical Recycling and Its Effects on the Physical and Mechanical Properties of Polyamides" Polymers 15, no. 23: 4561. https://doi.org/10.3390/polym15234561

APA StyleBen Amor, I., Klinkova, O., Baklouti, M., Elleuch, R., & Tawfiq, I. (2023). Mechanical Recycling and Its Effects on the Physical and Mechanical Properties of Polyamides. Polymers, 15(23), 4561. https://doi.org/10.3390/polym15234561