Path Planning and Bending Behaviors of 3D Printed Continuous Carbon Fiber Reinforced Polymer Honeycomb Structures

Abstract

:1. Introduction

2. Materials and Methods

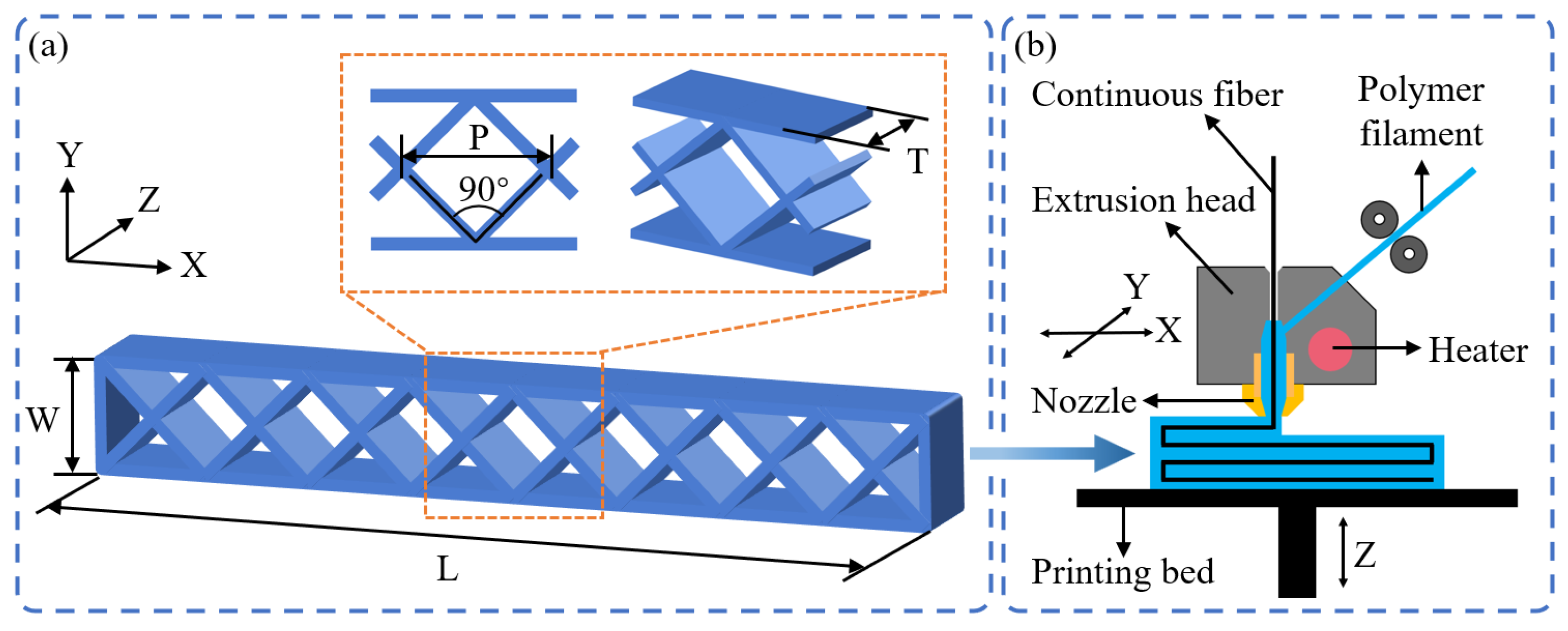

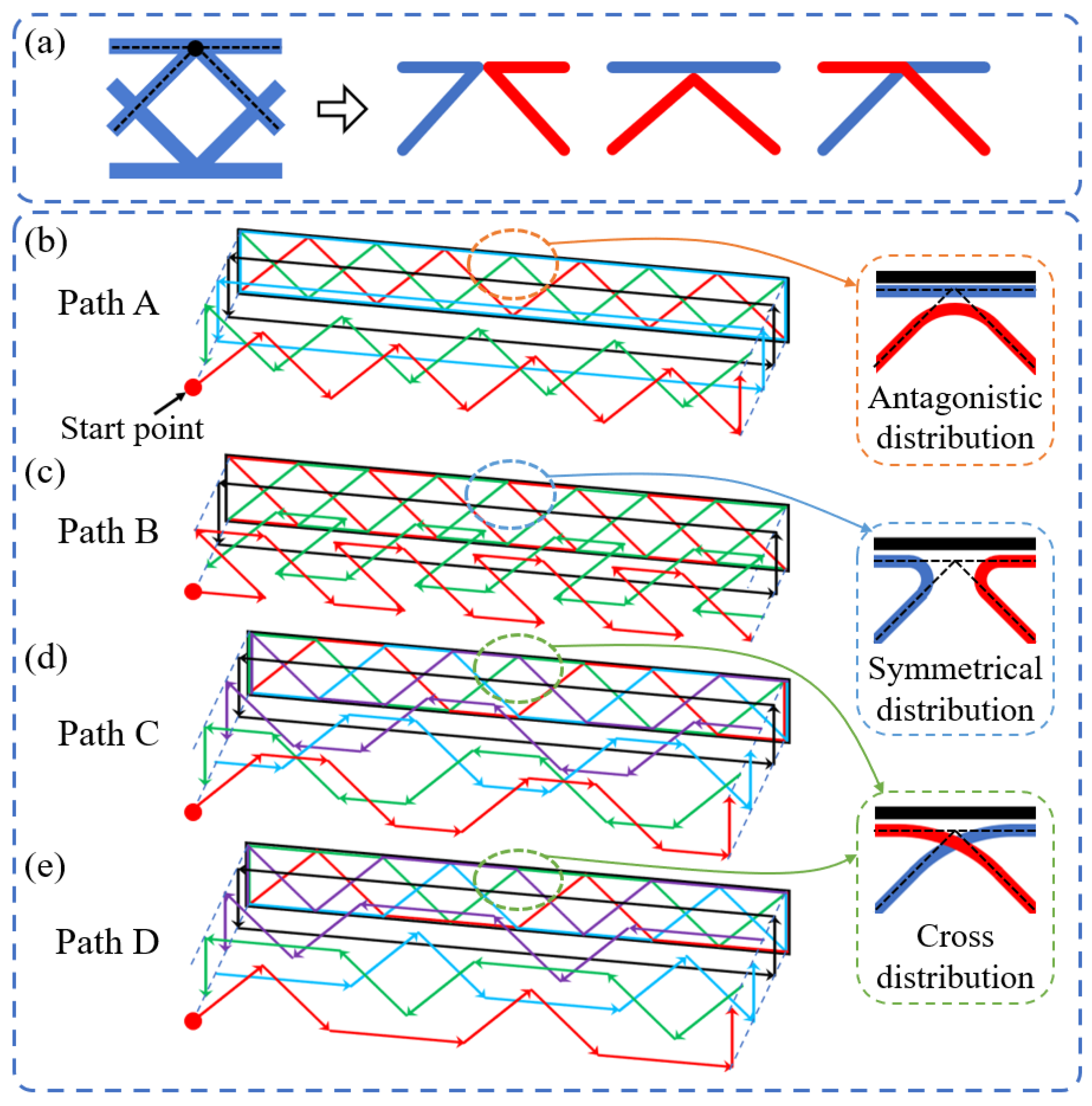

2.1. Design and Fabrication

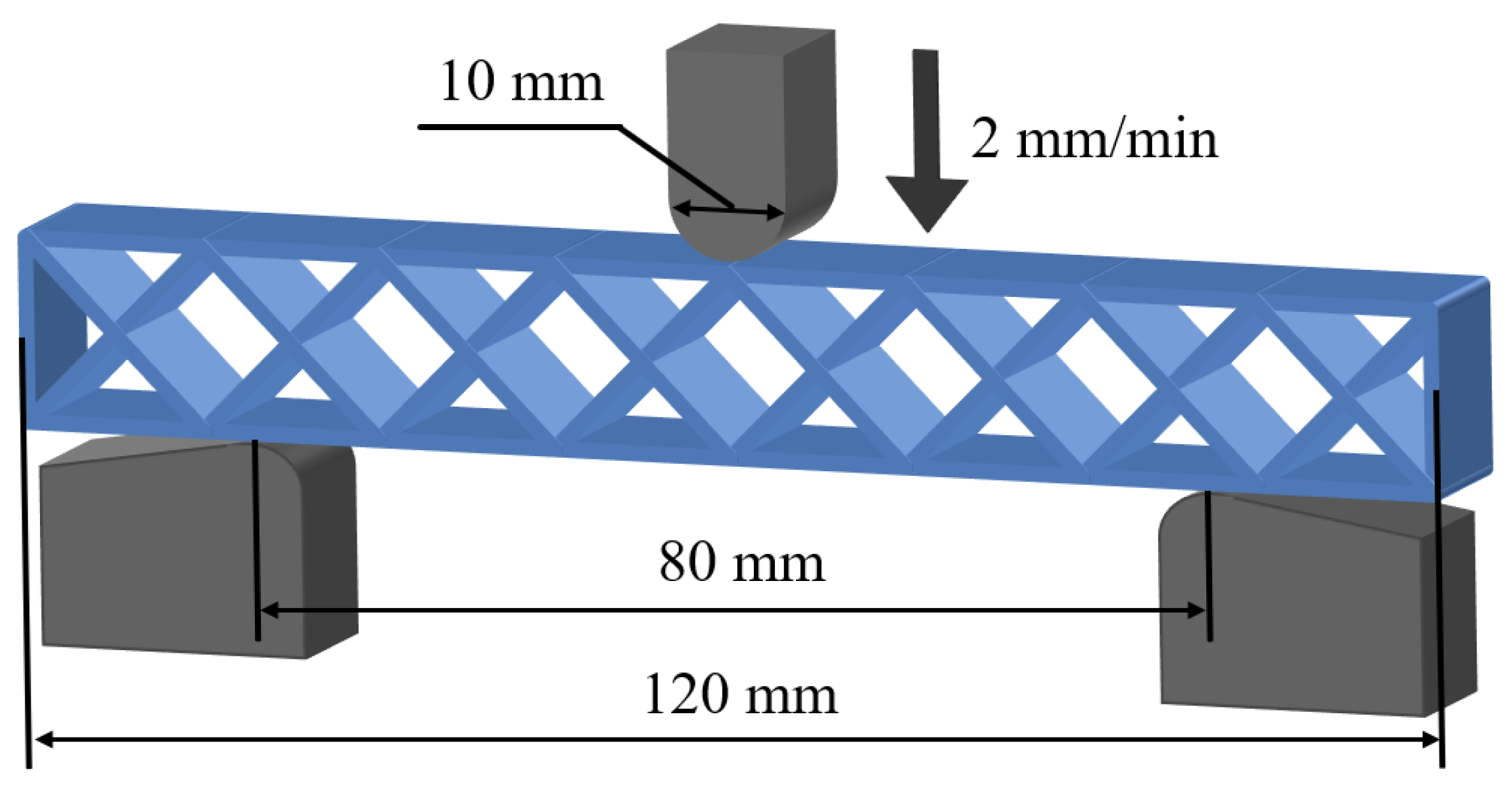

2.2. Experimental Methods

3. Results and Discussions

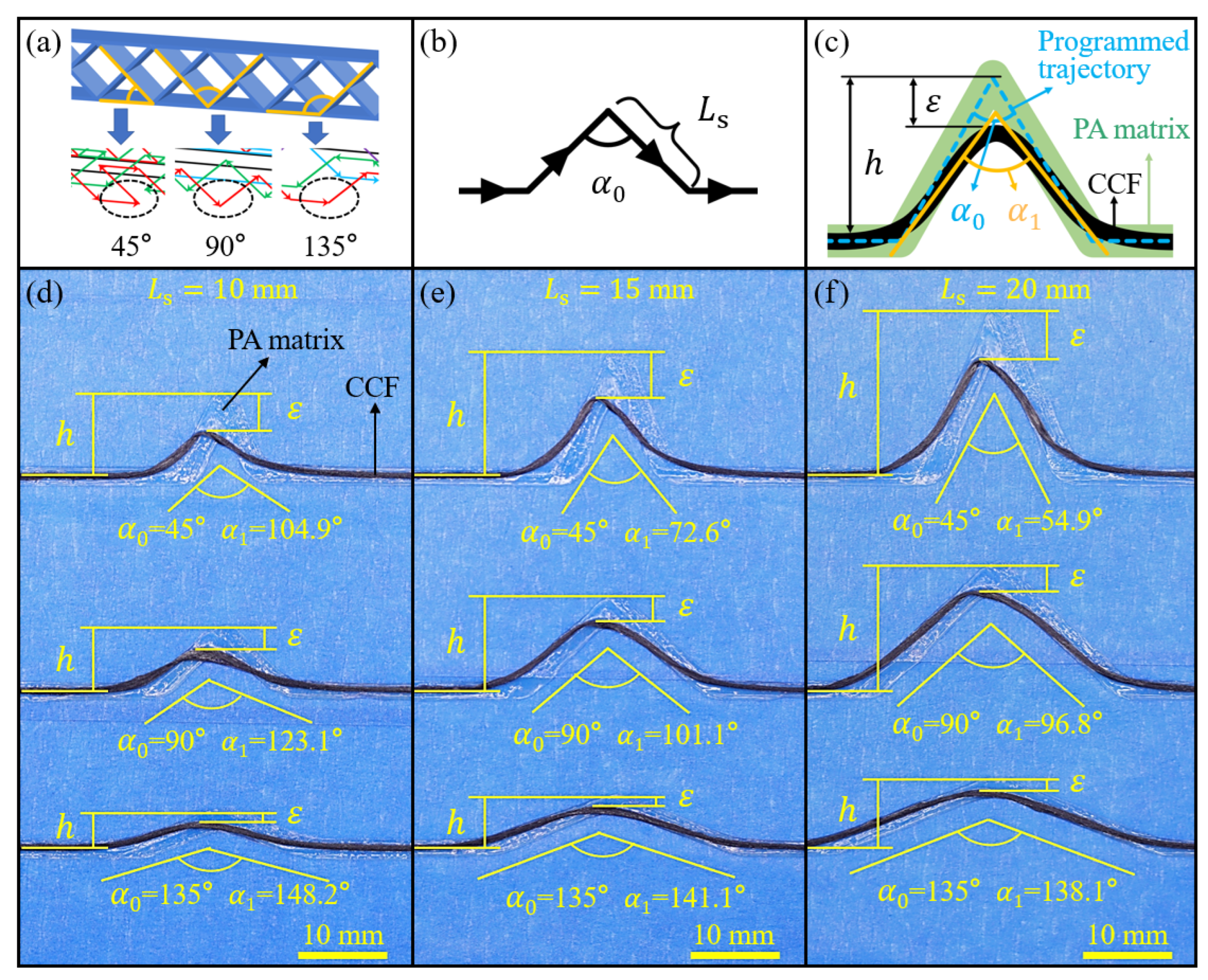

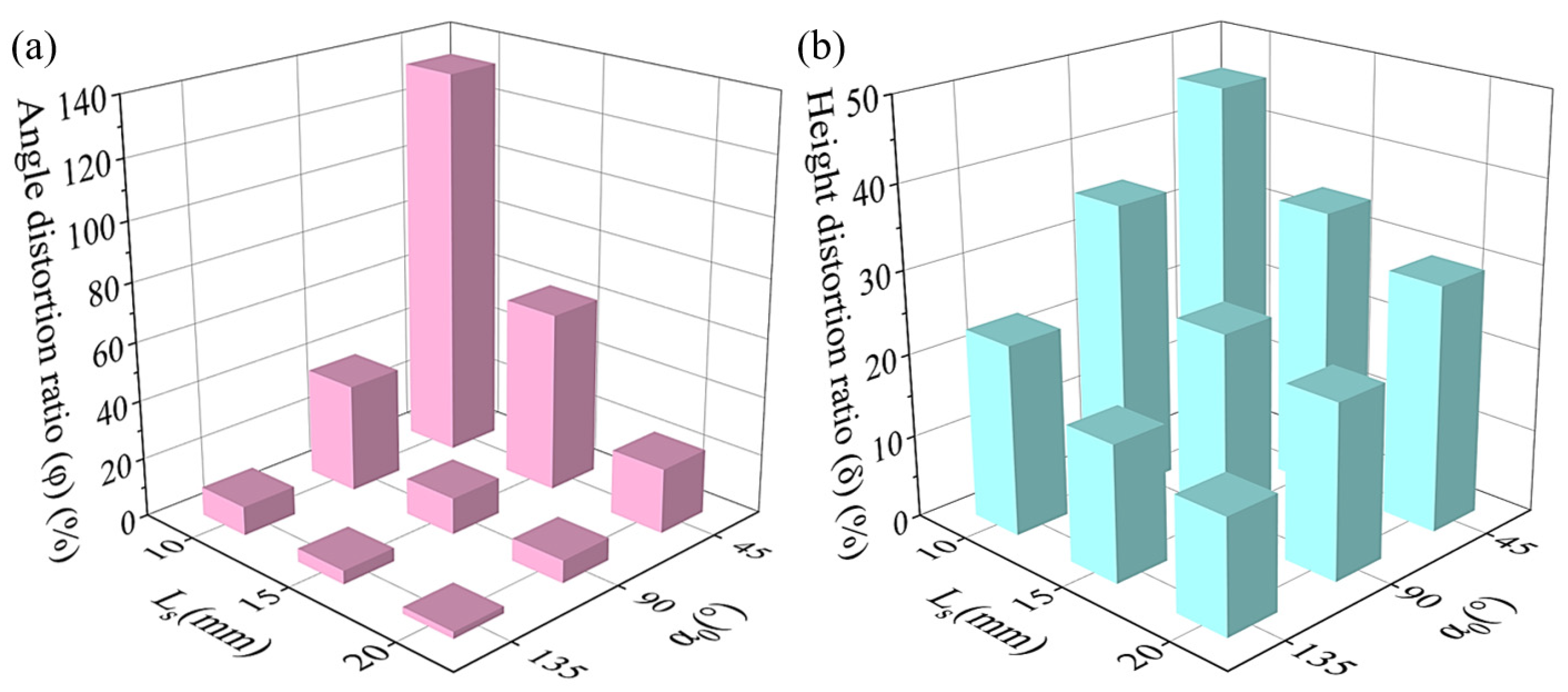

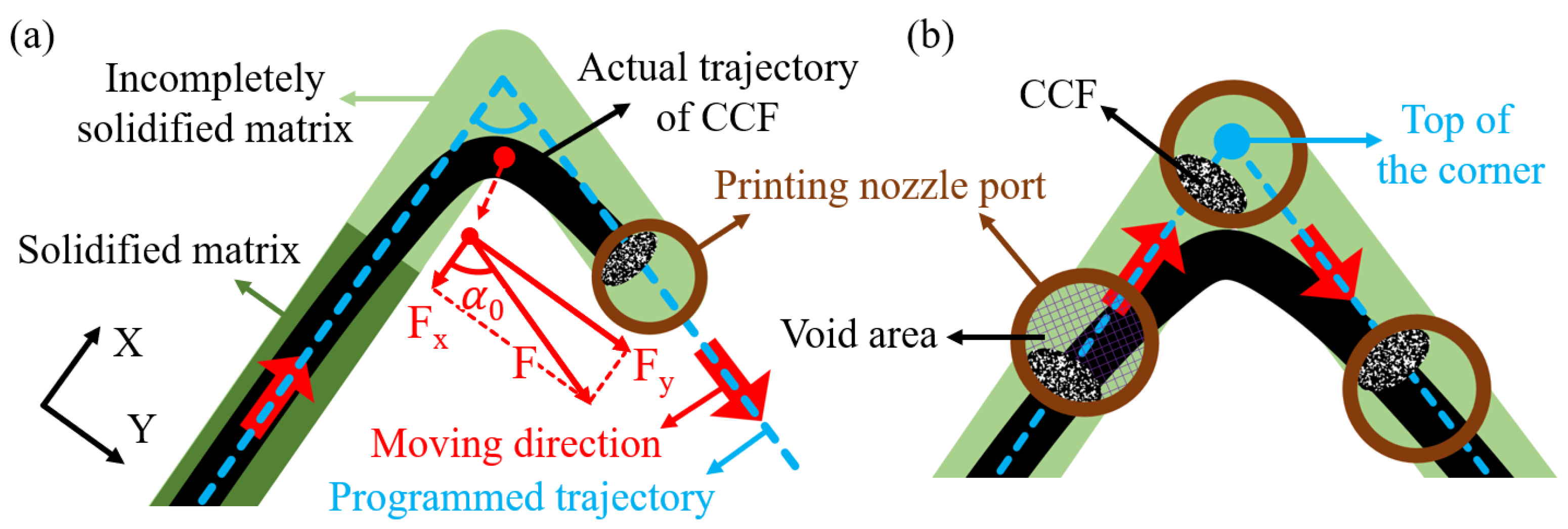

3.1. Investigation of Fiber Dislocation at Path Corners

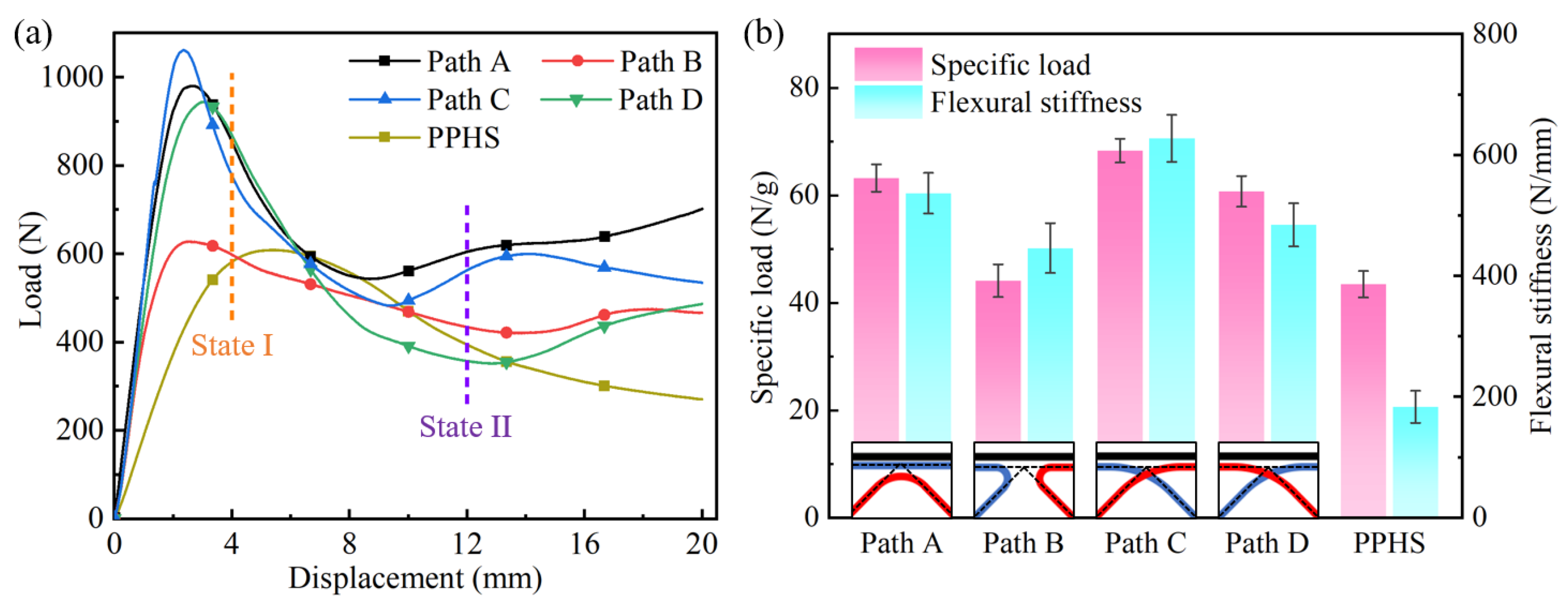

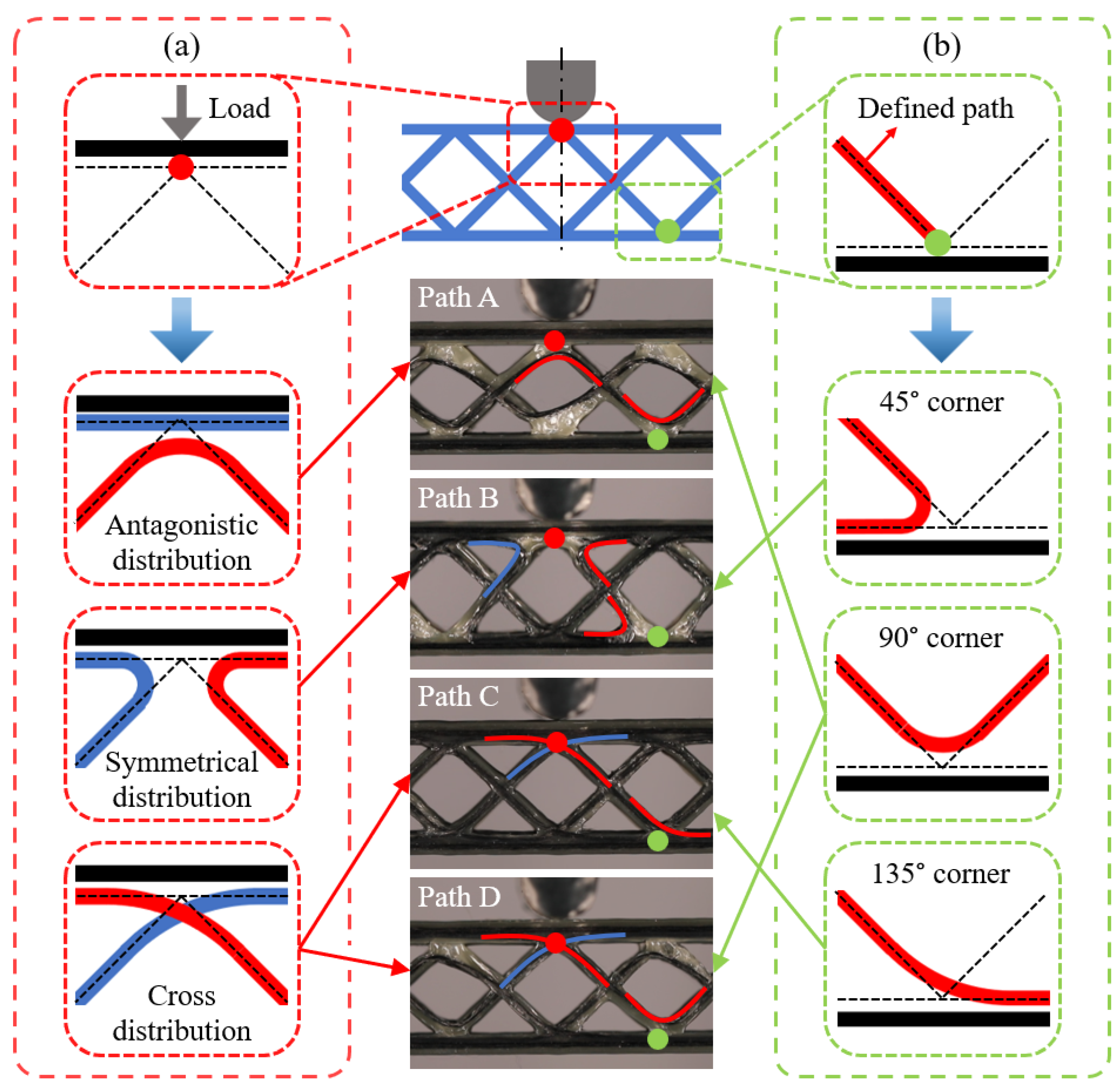

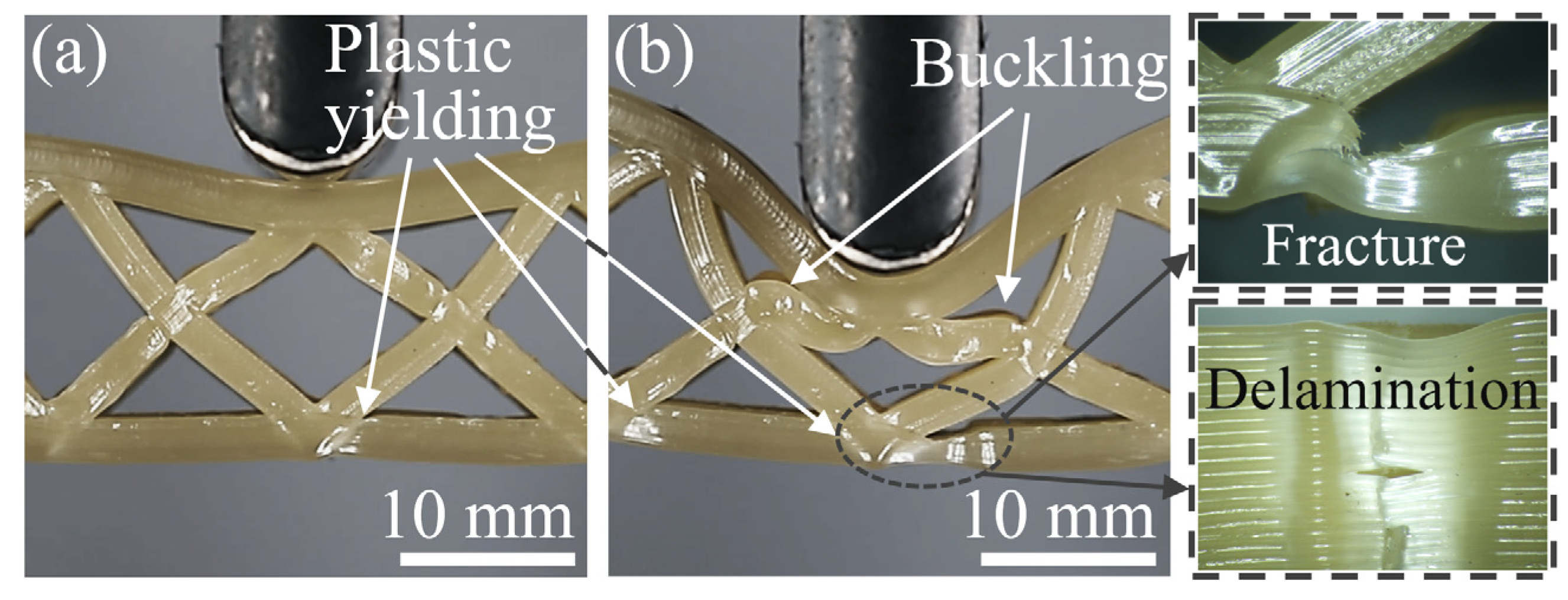

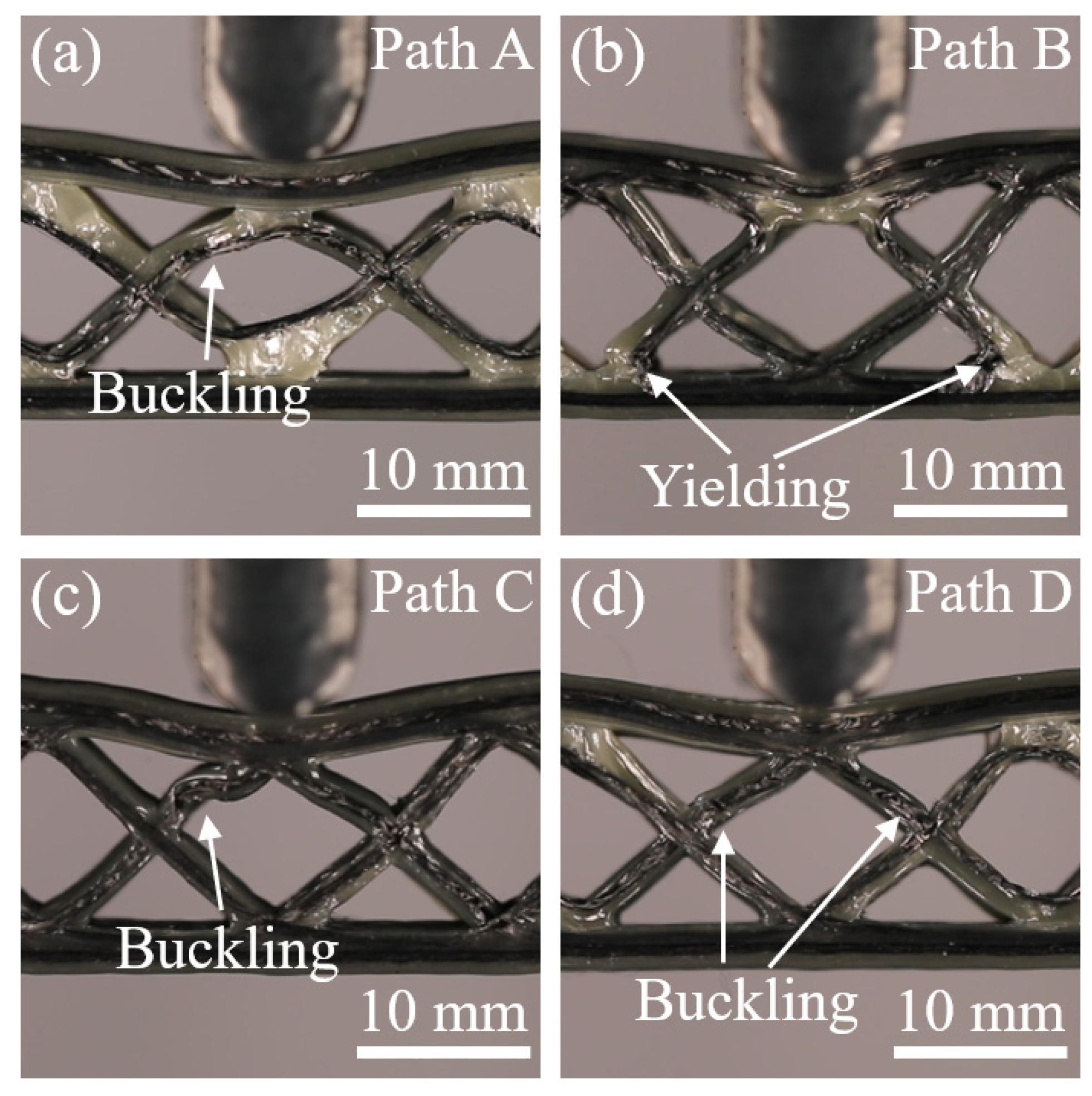

3.2. Effect of Printing Path on Bending Properties

4. Conclusions

- (1)

- There were three fiber distribution modes at the nodes lapped between the core and face sheets of the CFRPHSs, including symmetrical distribution, antagonistic distribution, and cross distribution, which were determined by the printing paths.

- (2)

- The structural defects at the nodes of the CFRPHSs were caused by the fiber dislocations at path corners. Low stiffness nodes filled with pure polymer caused by severe fiber dislocation led to uneven stiffness distribution in the loading region of the CFRPHSs. As the angle of the corner and the length of the straight path increased, the degree of fiber dislocation at path corners would decrease.

- (3)

- The enhancement effect of continuous fibers on the bending performance of honeycomb structures was affected by the printing paths. The path C with staggered trapezoidal distribution ensured a strong connection and good load transfer performance between the core and face sheets of the CFRPHSs, fully utilizing the supporting function of the honeycomb core, exhibiting the highest specific load capability (68.33 ± 2.25 N/g) and flexural stiffness (627.70 ± 38.78 N/mm).

- (4)

- The nodes of the CFRPHSs with fiber antagonistic distribution and cross distribution had good stiffness, providing better support to the loading region, leading to a stress concentration in the upper core and final core shear failure on the upper side caused by core member buckling. The failure mode of these CFRPHSs was similar to that of the PPHSs.

- (5)

- When the fibers were symmetrically distributed, the low-stiffness nodes filled with pure polymer caused uneven stiffness distribution in the loading region of the CFRPHSs, resulting in concentrated stress in the core members close to the lower face sheet, which ultimately led to yielding at the 45° corners.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Q.; Yang, X.; Li, P.; Huang, G.; Feng, S.; Shen, C.; Han, B.; Zhang, X.; Jin, F.; Xu, F.; et al. Bioinspired Engineering of Honeycomb Structure—Using Nature to Inspire Human Innovation. Prog. Mater. Sci. 2015, 74, 332–400. [Google Scholar] [CrossRef]

- Thomas, T.; Tiwari, G. Crushing Behavior of Honeycomb Structure: A Review. Int. J. Crashworthiness 2019, 24, 555–579. [Google Scholar] [CrossRef]

- Carneiro, V.H.; Rawson, S.D.; Puga, H.; Meireles, J.; Withers, P.J. Additive Manufacturing Assisted Investment Casting: A Low-Cost Method to Fabricate Periodic Metallic Cellular Lattices. Addit. Manuf. 2020, 33, 101085. [Google Scholar] [CrossRef]

- An, M.-R.; Wang, L.; Liu, H.-T.; Ren, F.-G. In-Plane Crushing Response of a Novel Bidirectional Re-Entrant Honeycomb with Two Plateau Stress Regions. Thin-Walled Struct. 2022, 170, 108530. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, J.; Cai, R.; Xiang, J.; Wang, K.; Yao, S.; Peng, Y. Effects of Loading Rate and Temperature on Crushing Behaviors of 3D Printed Multi-Cell Composite Tubes. Thin-Walled Struct. 2023, 182, 110311. [Google Scholar] [CrossRef]

- Habib, F.N.; Iovenitti, P.; Masood, S.H.; Nikzad, M. Cell Geometry Effect on In-Plane Energy Absorption of Periodic Honeycomb Structures. Int. J. Adv. Manuf. Technol. 2018, 94, 2369–2380. [Google Scholar] [CrossRef]

- Wang, Z. Recent Advances in Novel Metallic Honeycomb Structure. Compos. Part B Eng. 2019, 166, 731–741. [Google Scholar] [CrossRef]

- Qi, C.; Jiang, F.; Yang, S. Advanced Honeycomb Designs for Improving Mechanical Properties: A Review. Compos. Part B Eng. 2021, 227, 109393. [Google Scholar] [CrossRef]

- Wang, Z.; Lei, Z.; Li, Z.; Yuan, K.; Wang, X. Mechanical Reinforcement Mechanism of a Hierarchical Kagome Honeycomb. Thin-Walled Struct. 2021, 167, 108235. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, D. Mechanical Properties of Auxetic Cellular Material Consisting of Re-Entrant Hexagonal Honeycombs. Materials 2016, 9, 900. [Google Scholar] [CrossRef]

- Qi, C.; Jiang, F.; Yu, C.; Yang, S. In-Plane Crushing Response of Tetra-Chiral Honeycombs. Int. J. Impact Eng. 2019, 130, 247–265. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [PubMed]

- Ozkan, D.; Gok, M.S.; Karaoglanli, A.C. Carbon Fiber Reinforced Polymer (CFRP) Composite Materials, Their Characteristic Properties, Industrial Application Areas and Their Machinability. In Engineering Design Applications III: Structures, Materials and Processes; Öchsner, A., Altenbach, H., Eds.; Advanced Structured Materials; Springer International Publishing: Cham, Switzerland, 2020; pp. 235–253. ISBN 978-3-030-39062-4. [Google Scholar]

- Du, J.; Zhang, H.; Geng, Y.; Ming, W.; He, W.; Ma, J.; Cao, Y.; Li, X.; Liu, K. A Review on Machining of Carbon Fiber Reinforced Ceramic Matrix Composites. Ceram. Int. 2019, 45, 18155–18166. [Google Scholar] [CrossRef]

- Li, J.; Durandet, Y.; Huang, X.; Sun, G.; Ruan, D. Additively Manufactured Fiber-Reinforced Composites: A Review of Mechanical Behavior and Opportunities. J. Mater. Sci. Technol. 2022, 119, 219–244. [Google Scholar] [CrossRef]

- Kabir, S.M.F.; Mathur, K.; Seyam, A.-F.M. A Critical Review on 3D Printed Continuous Fiber-Reinforced Composites: History, Mechanism, Materials and Properties. Compos. Struct. 2020, 232, 111476. [Google Scholar] [CrossRef]

- Dickson, A.N.; Barry, J.N.; McDonnell, K.A.; Dowling, D.P. Fabrication of Continuous Carbon, Glass and Kevlar Fibre Reinforced Polymer Composites Using Additive Manufacturing. Addit. Manuf. 2017, 16, 146–152. [Google Scholar] [CrossRef]

- Xiang, J.; Liu, Y.; Wang, J.; Wang, K.; Peng, Y.; Rao, Y.; Matadi Boumbimba, R. Effect of Heat-Treatment on Compressive Response of 3D Printed Continuous Carbon Fiber Reinforced Composites under Different Loading Directions. J. Appl. Polym. Sci. 2023, 140, e53330. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, L.; Li, L.; Wei, J. Effects of Strain Rate and High Temperature Environment on the Mechanical Performance of Carbon Fiber Reinforced Thermoplastic Composites Fabricated by Hot Press Molding. Compos. Part A Appl. Sci. Manuf. 2020, 134, 105905. [Google Scholar] [CrossRef]

- Arulappan, C.; Duraisamy, A.; Adhikari, D.; Gururaja, S. Investigations on Pressure and Thickness Profiles in Carbon Fiber-Reinforced Polymers during Vacuum Assisted Resin Transfer Molding. J. Reinf. Plast. Compos. 2015, 34, 3–18. [Google Scholar] [CrossRef]

- Boon, Y.D.; Joshi, S.C.; Bhudolia, S.K. Review: Filament Winding and Automated Fiber Placement with In Situ Consolidation for Fiber Reinforced Thermoplastic Polymer Composites. Polymers 2021, 13, 1951. [Google Scholar] [CrossRef]

- Ning, H.; Janowski, G.M.; Vaidya, U.K.; Husman, G. Thermoplastic Sandwich Structure Design and Manufacturing for the Body Panel of Mass Transit Vehicle. Compos. Struct. 2007, 80, 82–91. [Google Scholar] [CrossRef]

- Chen, X.; Yu, G.; Wang, Z.; Feng, L.; Wu, L. Enhancing Out-of-Plane Compressive Performance of Carbon Fiber Composite Honeycombs. Compos. Struct. 2021, 255, 112984. [Google Scholar] [CrossRef]

- Wang, J.; Liu, Y.; Wang, K.; Yao, S.; Peng, Y.; Rao, Y.; Ahzi, S. Progressive Collapse Behaviors and Mechanisms of 3D Printed Thin-Walled Composite Structures under Multi-Conditional Loading. Thin-Walled Struct. 2022, 171, 108810. [Google Scholar] [CrossRef]

- Liu, Y.; Tan, Q.; Lin, H.; Wang, J.; Wang, K.; Peng, Y.; Yao, S. Integrated Design and Additive Manufacturing of Lattice-Filled Multi-Cell Tubes. Compos. Sci. Technol. 2023, 243, 110252. [Google Scholar] [CrossRef]

- Xie, G.; Wang, K.; Wu, X.; Wang, J.; Li, T.; Peng, Y.; Zhang, H. A Hybrid Multi-Stage Decision-Making Method with Probabilistic Interval-Valued Hesitant Fuzzy Set for 3D Printed Composite Material Selection. Eng. Appl. Artif. Intell. 2023, 123, 106483. [Google Scholar] [CrossRef]

- Alexander, A.E.; Wake, N.; Chepelev, L.; Brantner, P.; Ryan, J.; Wang, K.C. A Guideline for 3D Printing Terminology in Biomedical Research Utilizing ISO/ASTM Standards. 3D Print. Med. 2021, 7, 8. [Google Scholar] [CrossRef] [PubMed]

- Ekinci, A.; Johnson, A.A.; Gleadall, A.; Engstrøm, D.S.; Han, X. Layer-Dependent Properties of Material Extruded Biodegradable Polylactic Acid. J. Mech. Behav. Biomed. Mater. 2020, 104, 103654. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Huang, T.; Jiang, Q.; He, L.; Bismarck, A.; Hu, Q. Recent Progress of 3D Printed Continuous Fiber Reinforced Polymer Composites Based on Fused Deposition Modeling: A Review. J. Mater. Sci. 2021, 56, 12999–13022. [Google Scholar] [CrossRef]

- Li, H.; Lou, R.; Liu, B.; Chen, Y.; Wang, Y. Research on the Fusion of Continuous Fiber Reinforced Thermoplastic Filaments for Fused Filament Fabrication. Int. J. Solids Struct. 2023, 276, 112328. [Google Scholar] [CrossRef]

- Cheng, P.; Peng, Y.; Wang, K.; Le Duigou, A.; Yao, S.; Chen, C. Quasi-Static Penetration Property of 3D Printed Woven-like Ramie Fiber Reinforced Biocomposites. Compos. Struct. 2023, 303, 116313. [Google Scholar] [CrossRef]

- Cheng, P.; Peng, Y.; Li, S.; Rao, Y.; Le Duigou, A.; Wang, K.; Ahzi, S. 3D Printed Continuous Fiber Reinforced Composite Lightweight Structures: A Review and Outlook. Compos. Part B Eng. 2023, 250, 110450. [Google Scholar] [CrossRef]

- Cheng, Y.; Li, J.; Qian, X.; Rudykh, S. 3D Printed Recoverable Honeycomb Composites Reinforced by Continuous Carbon Fibers. Compos. Struct. 2021, 268, 113974. [Google Scholar] [CrossRef]

- Dou, H.; Ye, W.; Zhang, D.; Cheng, Y.; Huang, K.; Yang, F.; Rudykh, S. Research on Drop-Weight Impact of Continuous Carbon Fiber Reinforced 3D Printed Honeycomb Structure. Mater. Today Commun. 2021, 29, 102869. [Google Scholar] [CrossRef]

- Sugiyama, K.; Matsuzaki, R.; Ueda, M.; Todoroki, A.; Hirano, Y. 3D Printing of Composite Sandwich Structures Using Continuous Carbon Fiber and Fiber Tension. Compos. Part A Appl. Sci. Manuf. 2018, 113, 114–121. [Google Scholar] [CrossRef]

- Dou, H.; Ye, W.; Zhang, D.; Cheng, Y.; Wu, C. Comparative Study on In-Plane Compression Properties of 3D Printed Continuous Carbon Fiber Reinforced Composite Honeycomb and Aluminum Alloy Honeycomb. Thin-Walled Struct. 2022, 176, 109335. [Google Scholar] [CrossRef]

- Huang, Y.; Tian, X.; Wu, L.; Zia, A.A.; Liu, T.; Li, D. Progressive Concurrent Topological Optimization with Variable Fiber Orientation and Content for 3D Printed Continuous Fiber Reinforced Polymer Composites. Compos. Part B Eng. 2023, 255, 110602. [Google Scholar] [CrossRef]

- Hou, Z.; Tian, X.; Zhang, J.; Zhe, L.; Zheng, Z.; Li, D.; Malakhov, A.V.; Polilov, A.N. Design and 3D Printing of Continuous Fiber Reinforced Heterogeneous Composites. Compos. Struct. 2020, 237, 111945. [Google Scholar] [CrossRef]

- Zhu, W.; Li, S.; Peng, Y.; Wang, K.; Ahzi, S. Effect of Continuous Fiber Orientations on Quasi-Static Indentation Properties in 3D Printed Hybrid Continuous Carbon/Kevlar Fiber Reinforced Composites. Polym. Adv. Technol. 2023, 34, 1565–1574. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, Y.; He, J.; Xiong, Y. A Graph-Based Path Planning Method for Additive Manufacturing of Continuous Fiber-Reinforced Planar Thin-Walled Cellular Structures. Rapid Prototyp. J. 2023, 29, 344–353. [Google Scholar] [CrossRef]

- Huang, Y.; Fang, G.; Zhang, T.; Wang, C.C.L. Turning-Angle Optimized Printing Path of Continuous Carbon Fiber for Cellular Structures. Addit. Manuf. 2023, 68, 103501. [Google Scholar] [CrossRef]

- Zeng, C.; Liu, L.; Bian, W.; Leng, J.; Liu, Y. Compression Behavior and Energy Absorption of 3D Printed Continuous Fiber Reinforced Composite Honeycomb Structures with Shape Memory Effects. Addit. Manuf. 2021, 38, 101842. [Google Scholar] [CrossRef]

- Feng, J.; Yao, L.; Lyu, Z.; Wu, Z.; Zhang, G.; Zhao, H. Mechanical Properties and Damage Failure of 3D-Printed Continuous Carbon Fiber-Reinforced Composite Honeycomb Sandwich Structures with Fiber-Interleaved Core. Polym. Compos. 2023, 44, 1980–1992. [Google Scholar] [CrossRef]

- Quan, C.; Han, B.; Hou, Z.; Zhang, Q.; Tian, X.; Lu, T.J. 3D Printed Continuous Fiber Reinforced Composite Auxetic Honeycomb Structures. Compos. Part B Eng. 2020, 187, 107858. [Google Scholar] [CrossRef]

- Dong, K.; Liu, L.; Huang, X.; Xiao, X. 3D Printing of Continuous Fiber Reinforced Diamond Cellular Structural Composites and Tensile Properties. Compos. Struct. 2020, 250, 112610. [Google Scholar] [CrossRef]

- Yamamoto, K.; Luces, J.V.S.; Shirasu, K.; Hoshikawa, Y.; Okabe, T.; Hirata, Y. A Novel Single-Stroke Path Planning Algorithm for 3D Printers Using Continuous Carbon Fiber Reinforced Thermoplastics. Addit. Manuf. 2022, 55, 102816. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, Y.; Qiu, W.; Dong, K.; Xiong, Y. Geometric Characteristics of Single Bead Fabricated by Continuous Fiber Reinforced Polymer Composite Additive Manufacturing. Mater. Today Proc. 2022, 70, 431–437. [Google Scholar] [CrossRef]

- Liu, J.; Kang, Y.; Ma, C.; Wang, Y. Research on a Fiber Corner Compensation Algorithm in a 3D Printing Layer of Continuous Fiber-Reinforced Composite Materials. Appl. Sci. 2022, 12, 6687. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, J.; Yang, D. Fibre Misalignment and Breakage in 3D Printing of Continuous Carbon Fibre Reinforced Thermoplastic Composites. Addit. Manuf. 2021, 38, 101775. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Nakamura, T.; Sugiyama, K.; Ueda, M.; Todoroki, A.; Hirano, Y.; Yamagata, Y. Effects of Set Curvature and Fiber Bundle Size on the Printed Radius of Curvature by a Continuous Carbon Fiber Composite 3D Printer. Addit. Manuf. 2018, 24, 93–102. [Google Scholar] [CrossRef]

- Cui, Z.; Huang, X.; Jia, M.; Panahi-Sarmad, M.; Hossen, M.I.; Dong, K.; Xiao, X. 3D Printing of Continuous Fiber Reinforced Cellular Structural Composites for the Study of Bending Performance. J. Reinf. Plast. Compos. 2023, 42, 673–684. [Google Scholar] [CrossRef]

- Li, T.; Wang, L. Bending Behavior of Sandwich Composite Structures with Tunable 3D-Printed Core Materials. Compos. Struct. 2017, 175, 46–57. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, H.; Xing, S. Mechanical Performances of Metal-Polymer Sandwich Structures with 3D-Printed Lattice Cores Subjected to Bending Load. Arch. Civ. Mech. Eng. 2020, 20, 89. [Google Scholar] [CrossRef]

- Zeng, C.; Liu, L.; Bian, W.; Leng, J.; Liu, Y. Bending Performance and Failure Behavior of 3D Printed Continuous Fiber Reinforced Composite Corrugated Sandwich Structures with Shape Memory Capability. Compos. Struct. 2021, 262, 113626. [Google Scholar] [CrossRef]

- Zárybnická, L.; Machotová, J.; Pagáč, M.; Rychlý, J.; Vykydalová, A. The Effect of Filling Density on Flammability and Mechanical Properties of 3D-Printed Carbon Fiber-Reinforced Nylon. Polym. Test. 2023, 120, 107944. [Google Scholar] [CrossRef]

- Wang, T.; Li, N.; Link, G.; Jelonnek, J.; Fleischer, J.; Dittus, J.; Kupzik, D. Load-Dependent Path Planning Method for 3D Printing of Continuous Fiber Reinforced Plastics. Compos. Part A Appl. Sci. Manuf. 2021, 140, 106181. [Google Scholar] [CrossRef]

- Cai, L.; Zhang, D.; Zhou, S.; Xu, W. Investigation on Mechanical Properties and Equivalent Model of Aluminum Honeycomb Sandwich Panels. J. Mater. Eng. Perform. 2018, 27, 6585–6596. [Google Scholar] [CrossRef]

- Wang, B.; Ming, Y.; Zhou, J.; Xiao, H.; Wang, F.; Duan, Y.; Kazancı, Z. Fabrication of Triangular Corrugated Structure Using 3D Printed Continuous Carbon Fiber-Reinforced Thermosetting Epoxy Composites. Polym. Test. 2022, 106, 107469. [Google Scholar] [CrossRef]

| Filament Type | Density (g/cm3) | Tensile Strength (MPa) | Tensile Modulus (GPa) | Elongation (%) |

|---|---|---|---|---|

| PA | 1.12 | 31.40 | 1.05 | 216.50 |

| CCF | 1.77 | 4100.00 | 240.00 | 1.70 |

| Properties | Path A | Path B | Path C | Path D | PPHSs |

|---|---|---|---|---|---|

| Specific load capability (N/g) | 63.23 ± 2.53 | 44.12 ± 3.04 | 68.33 ± 2.25 | 60.74 ± 2.85 | 43.48 ± 2.46 |

| Flexural stiffness (N/mm) | 627.70 ± 33.59 | 696.44 ± 41.28 | 627.70 ± 38.78 | 484.56 ± 35.64 | 183.62 ± 26.57 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.; Wang, D.; Liu, Y.; Gao, H.; Yang, C.; Peng, Y. Path Planning and Bending Behaviors of 3D Printed Continuous Carbon Fiber Reinforced Polymer Honeycomb Structures. Polymers 2023, 15, 4485. https://doi.org/10.3390/polym15234485

Wang K, Wang D, Liu Y, Gao H, Yang C, Peng Y. Path Planning and Bending Behaviors of 3D Printed Continuous Carbon Fiber Reinforced Polymer Honeycomb Structures. Polymers. 2023; 15(23):4485. https://doi.org/10.3390/polym15234485

Chicago/Turabian StyleWang, Kui, Depeng Wang, Yisen Liu, Huijing Gao, Chengxing Yang, and Yong Peng. 2023. "Path Planning and Bending Behaviors of 3D Printed Continuous Carbon Fiber Reinforced Polymer Honeycomb Structures" Polymers 15, no. 23: 4485. https://doi.org/10.3390/polym15234485

APA StyleWang, K., Wang, D., Liu, Y., Gao, H., Yang, C., & Peng, Y. (2023). Path Planning and Bending Behaviors of 3D Printed Continuous Carbon Fiber Reinforced Polymer Honeycomb Structures. Polymers, 15(23), 4485. https://doi.org/10.3390/polym15234485