Peeling Force Required for the Detachment of Non-Woven Plastic Tissue from the Surface of Mortar Prisms

Abstract

:1. Introduction

2. Experimental Program

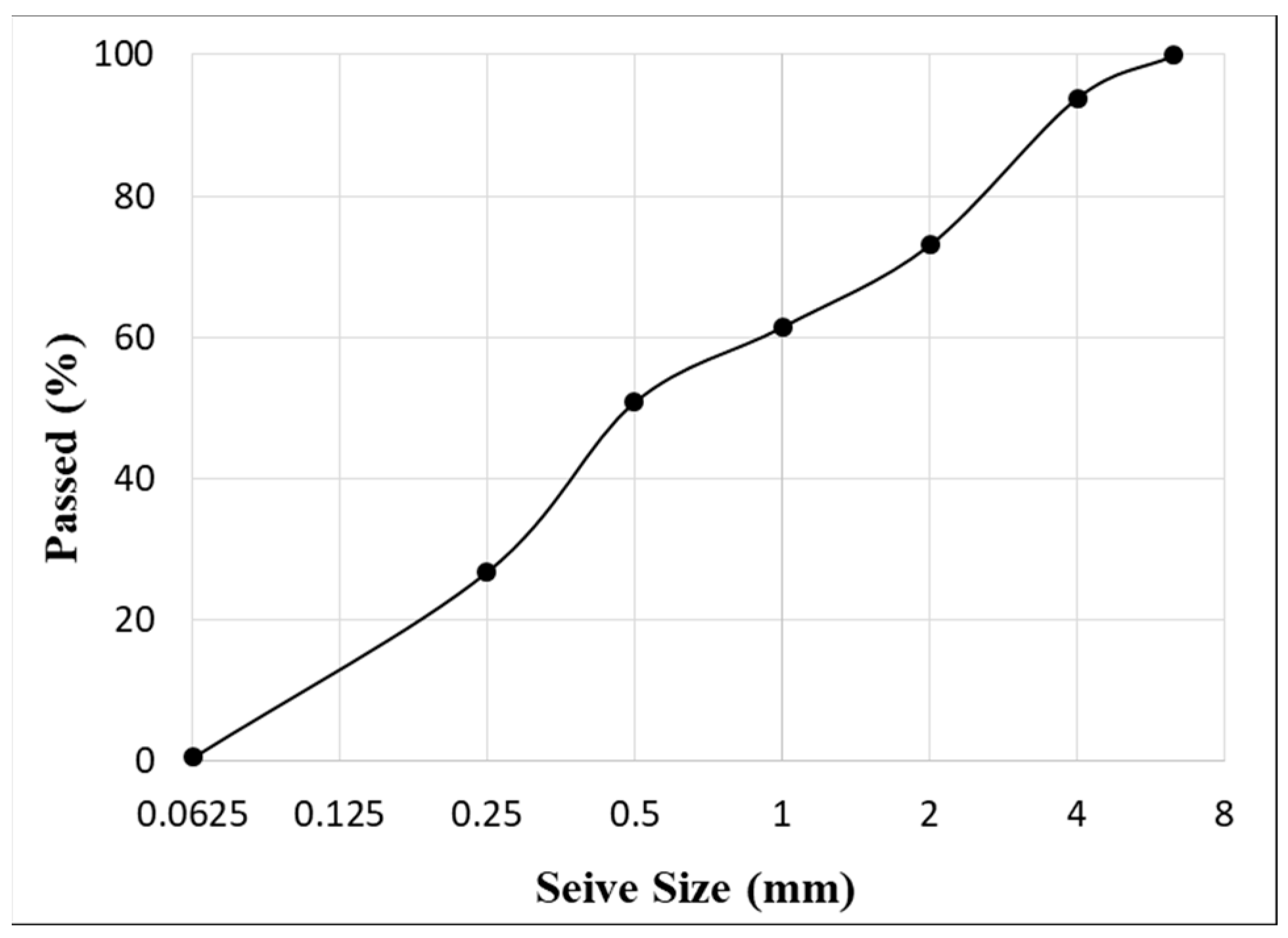

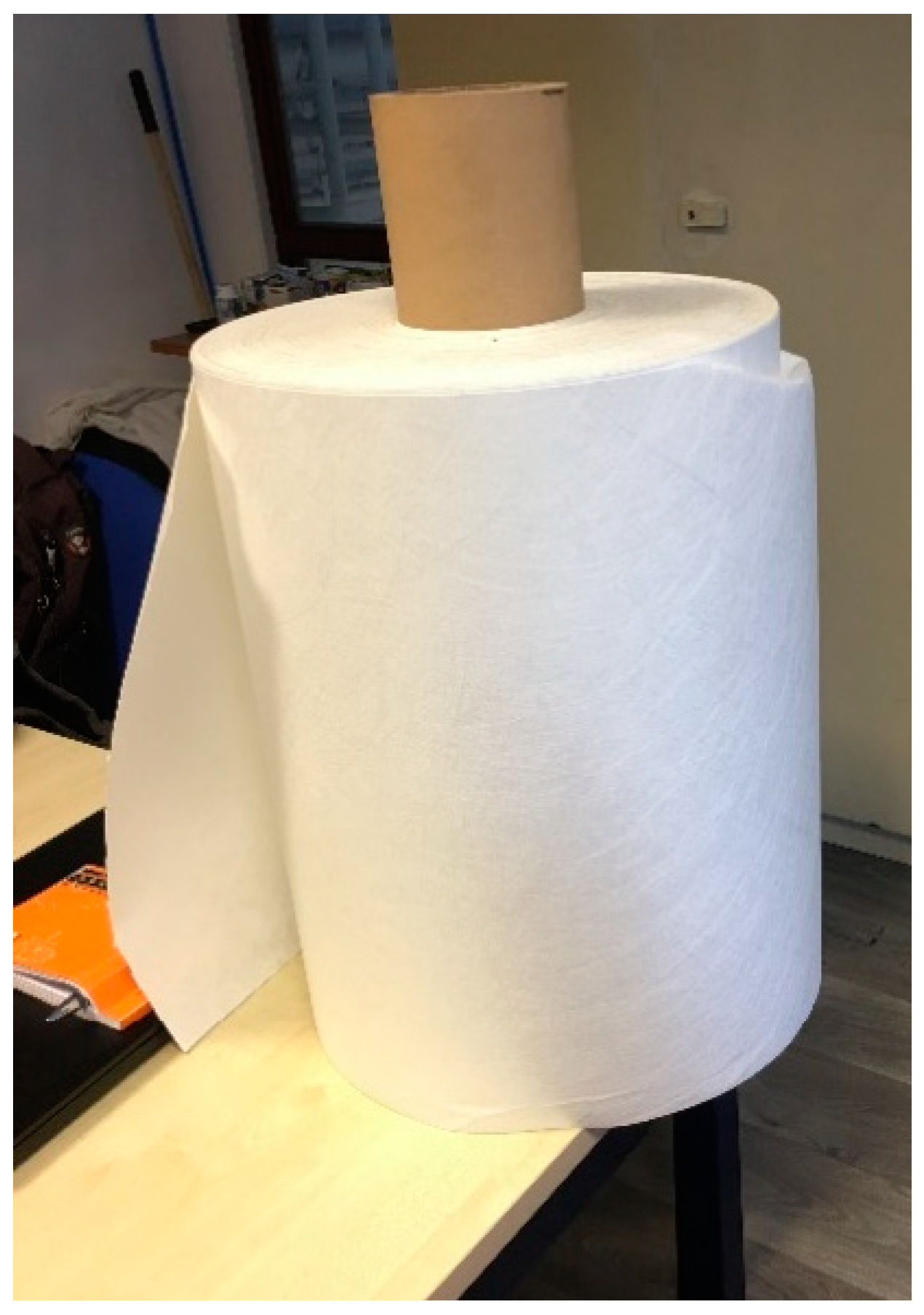

2.1. Materials

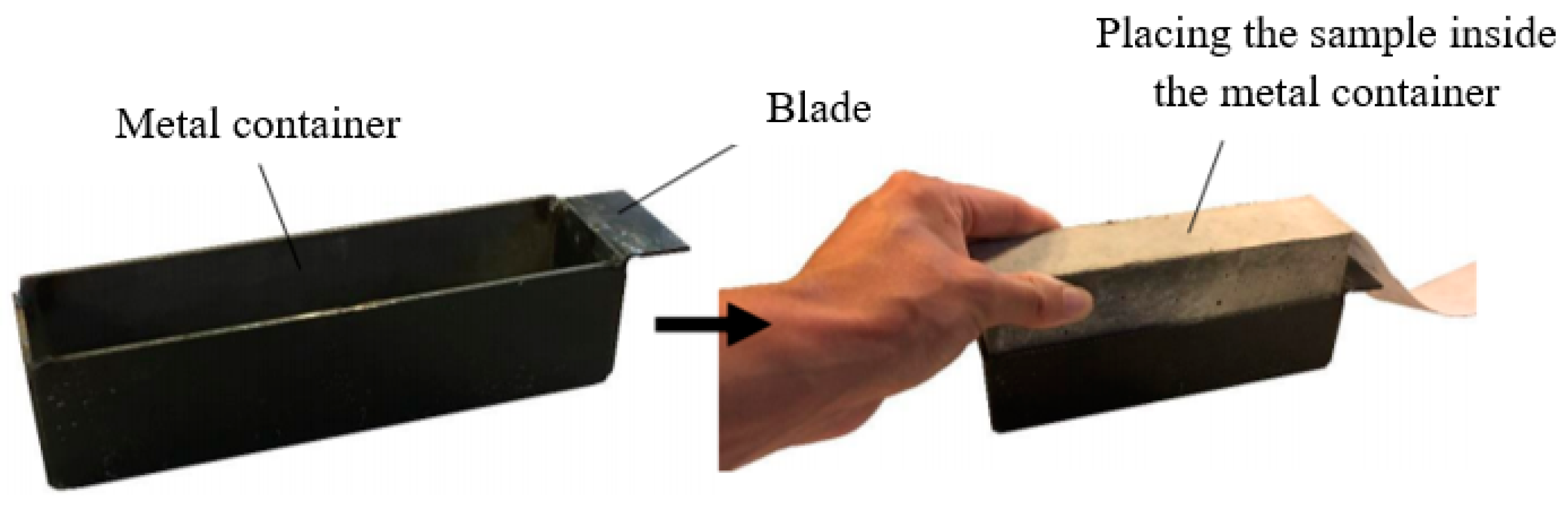

2.2. Preparation of the Specimens

2.3. Testing Setup and Procedure

3. Results and Discussions

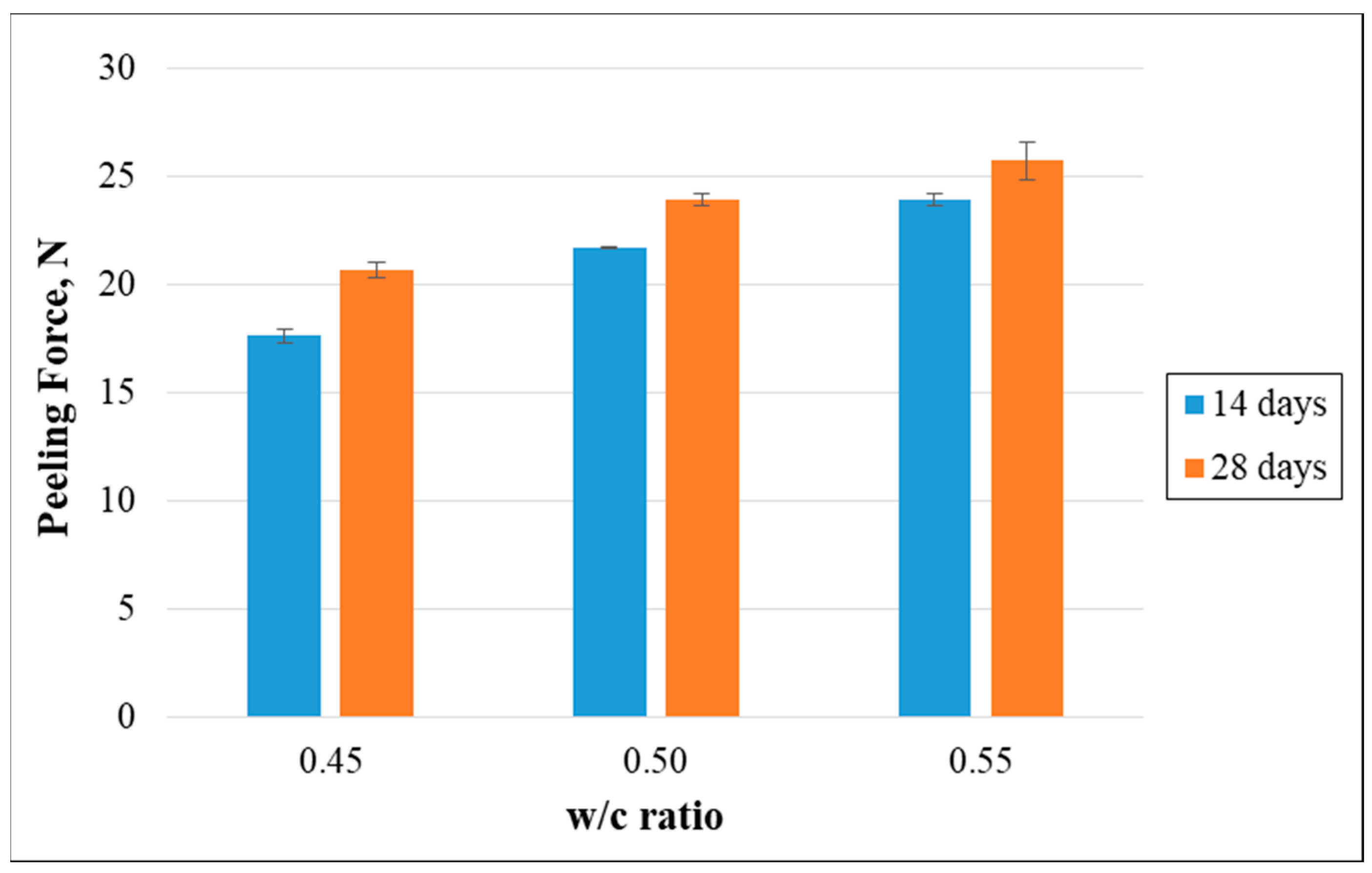

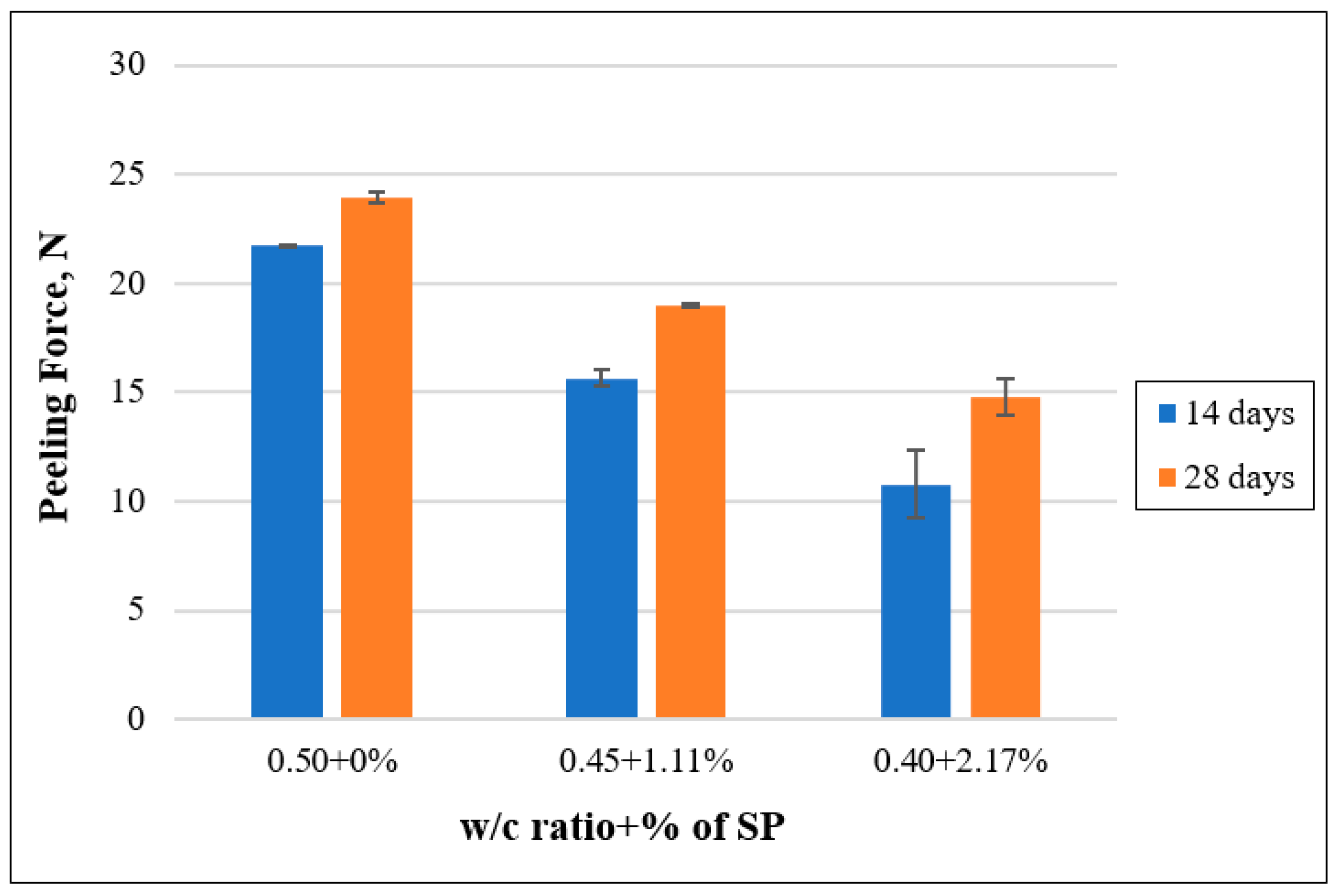

3.1. Effect of Water Content (w/c Ratio)

3.2. Effect of Superplasticizer Content

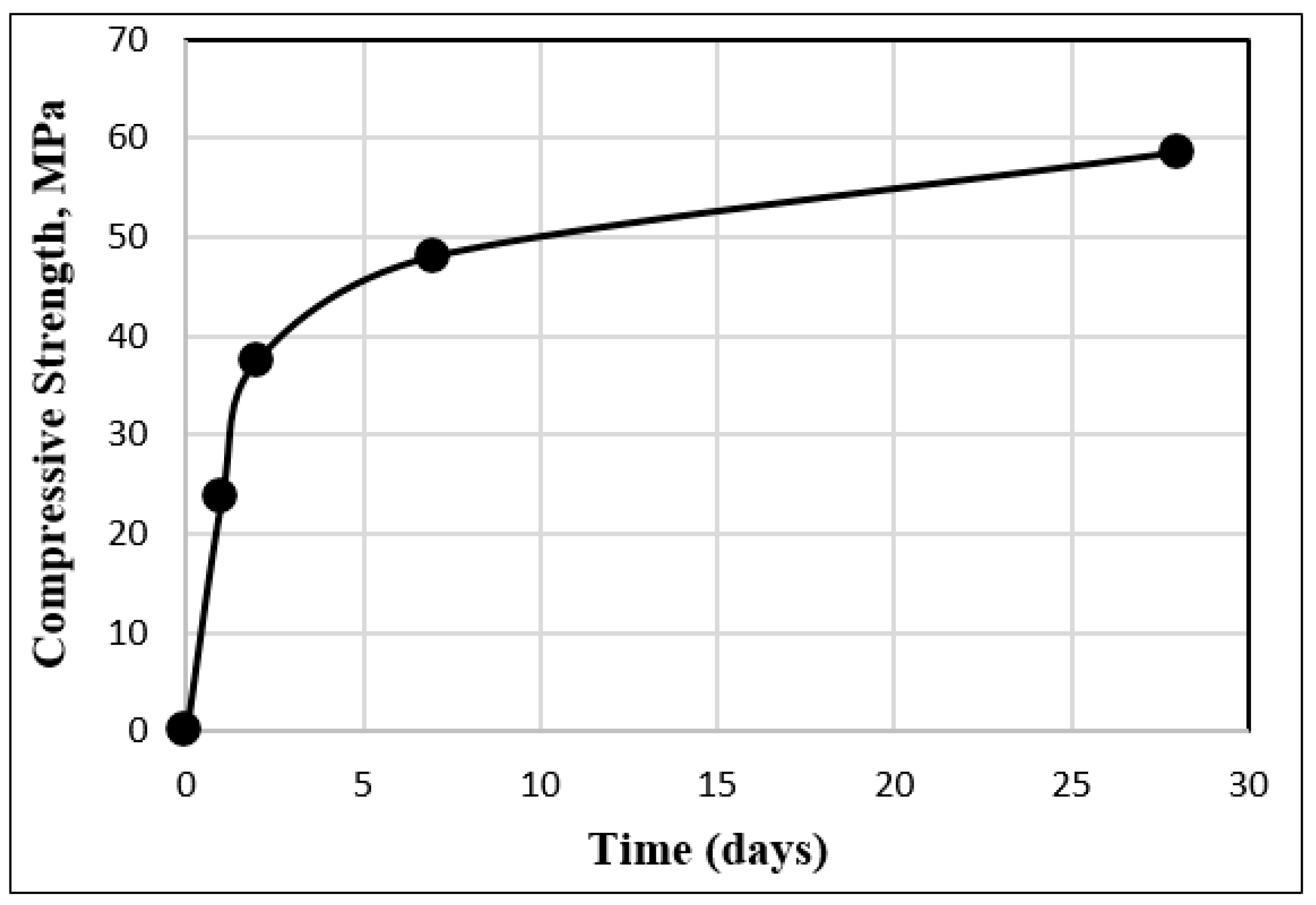

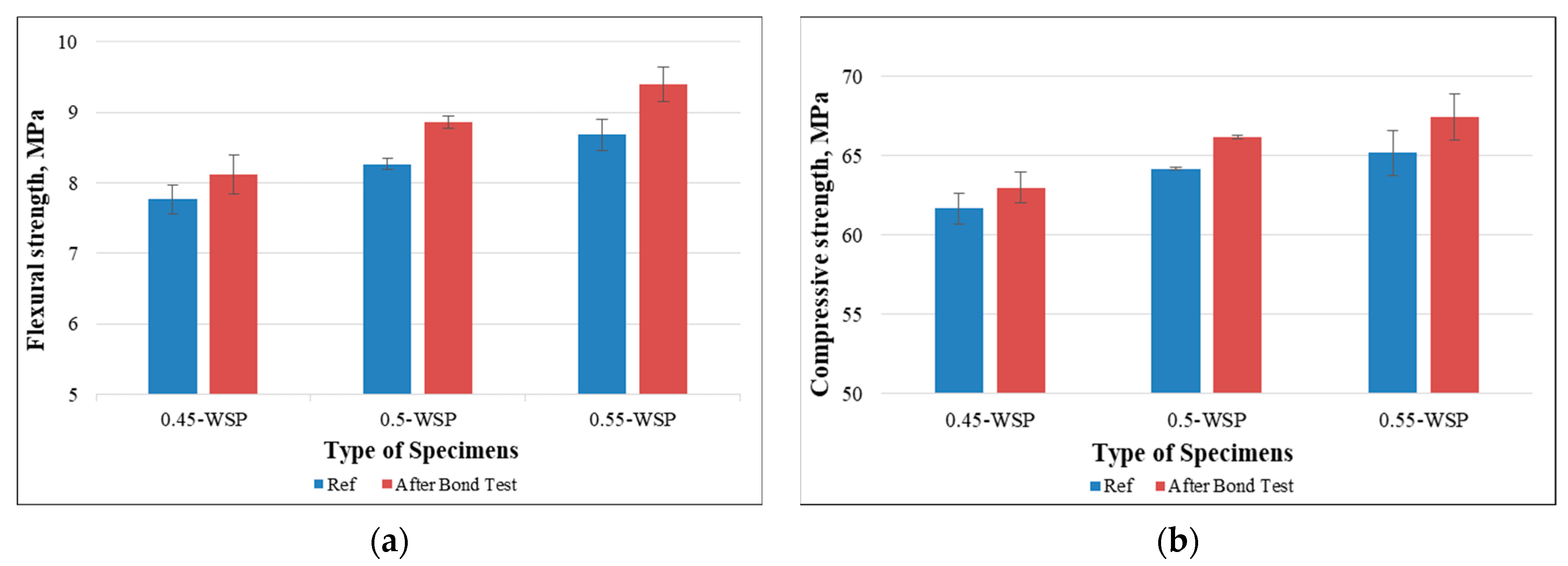

3.3. Mechanical Strengths

4. Conclusions

- In general, the adhesion between non-woven sheets and mortar specimens was consistently good using any w/c ratio or the quantity of superplasticizer;

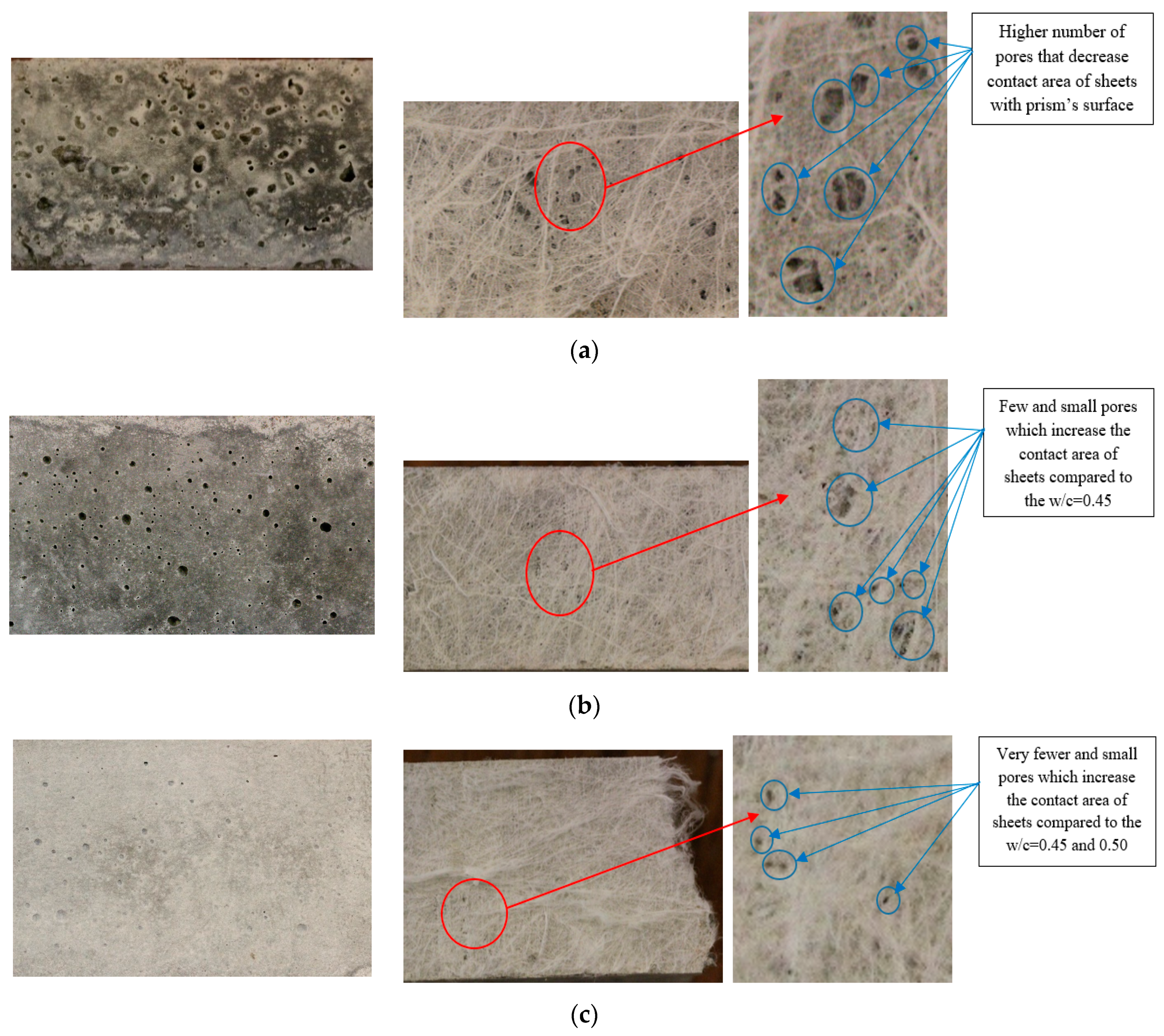

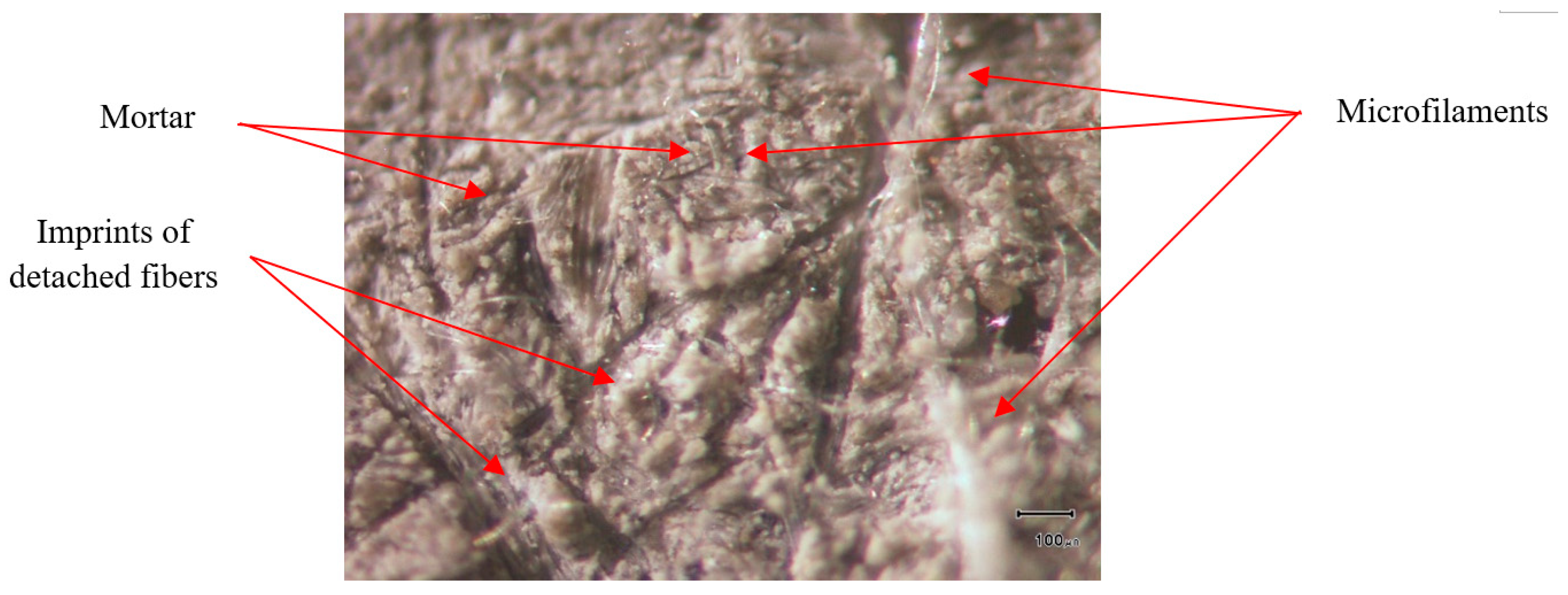

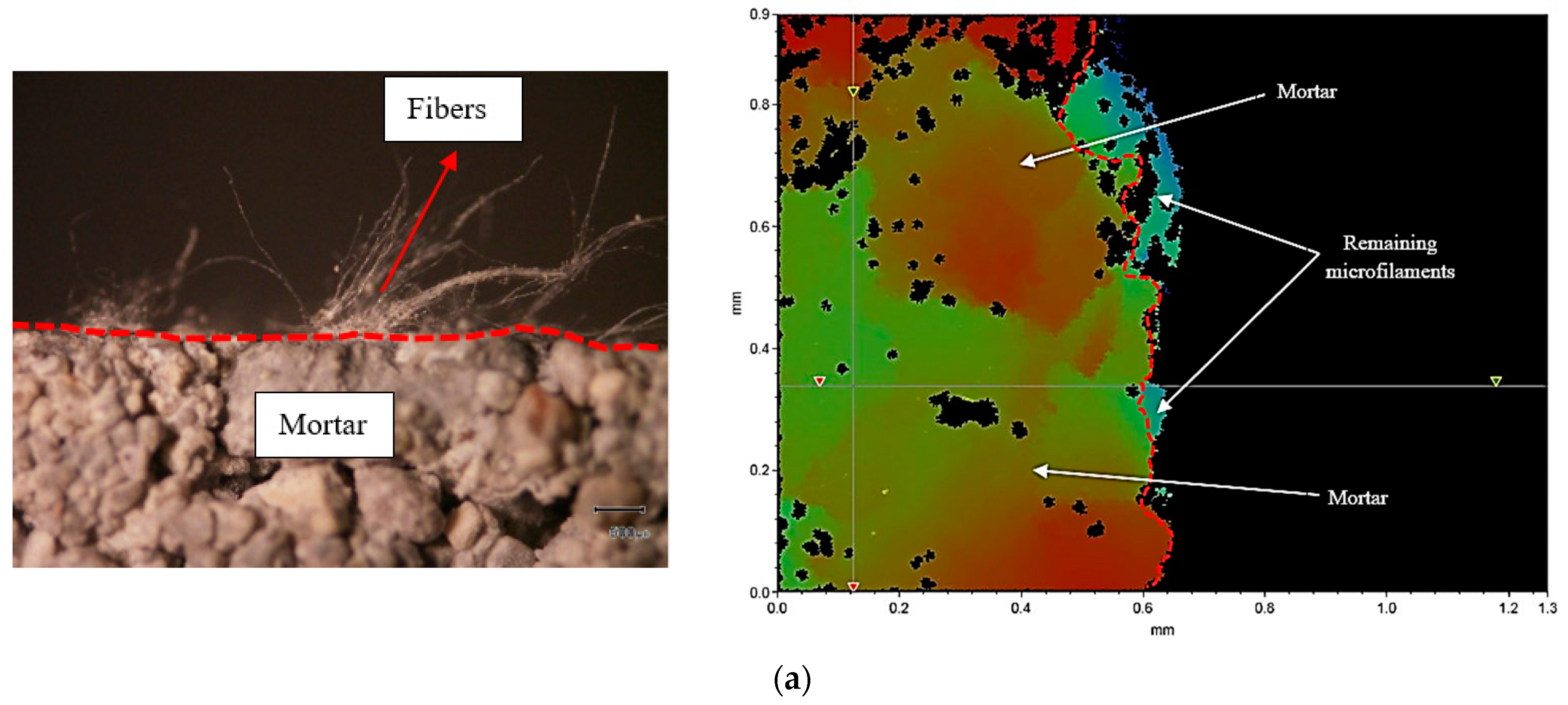

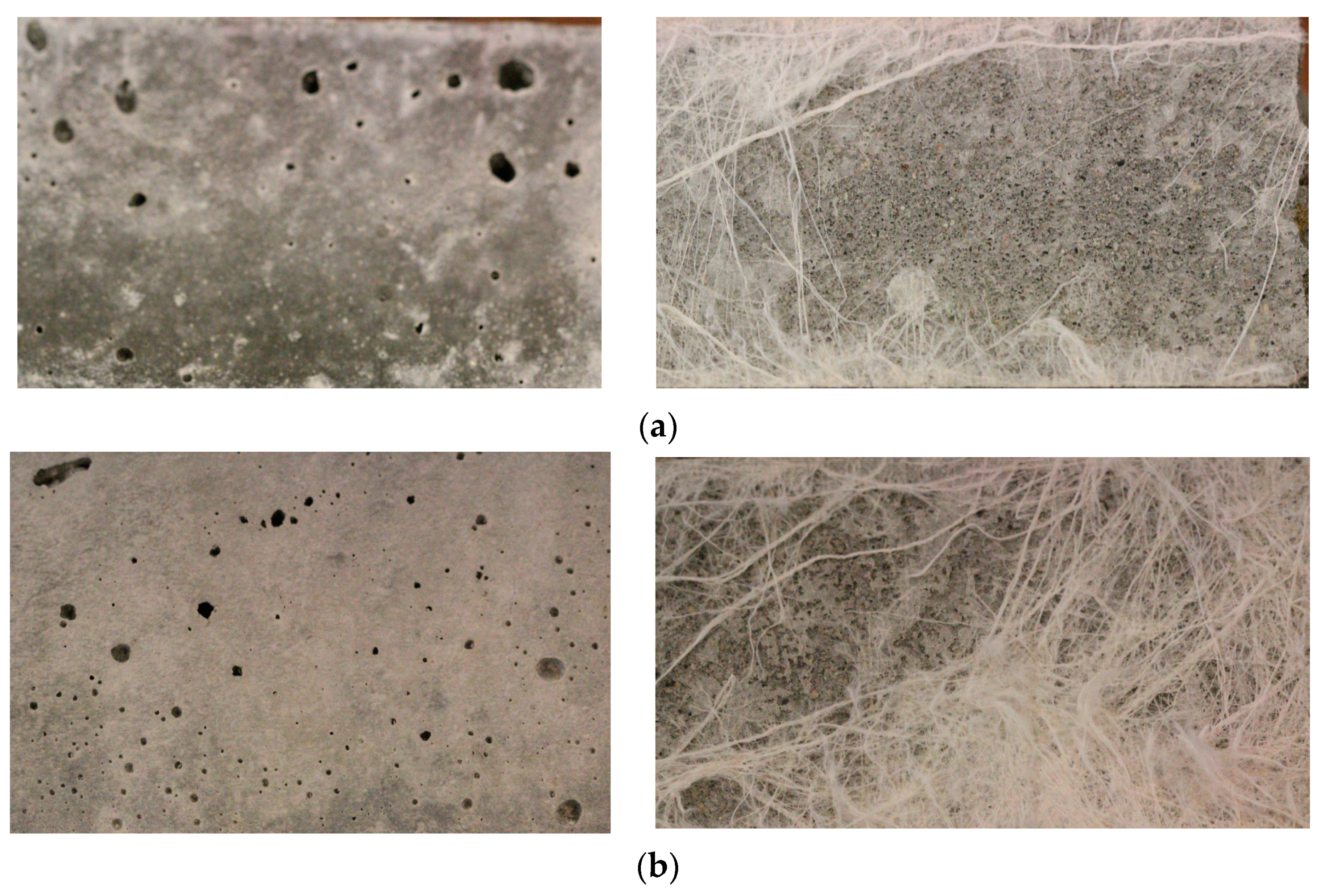

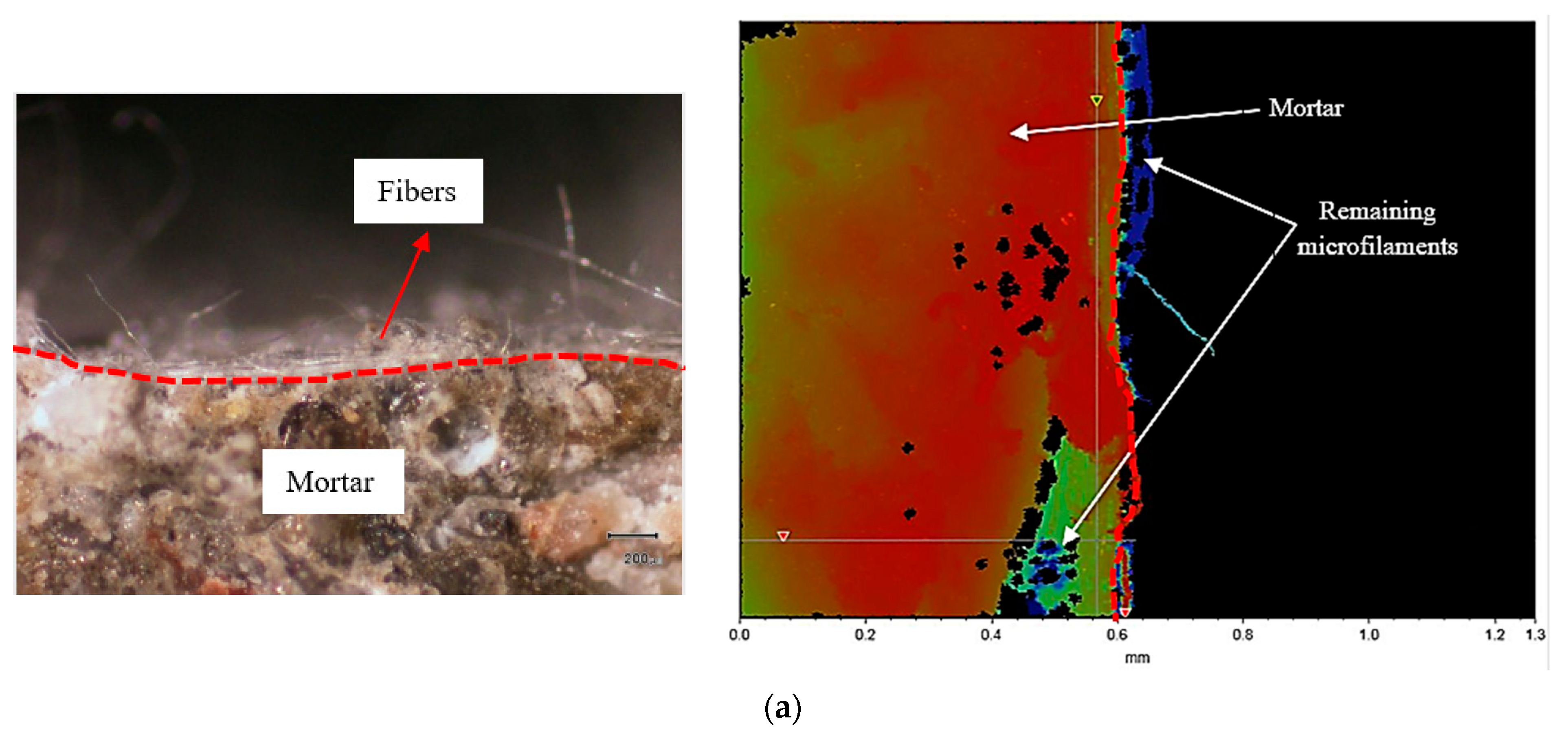

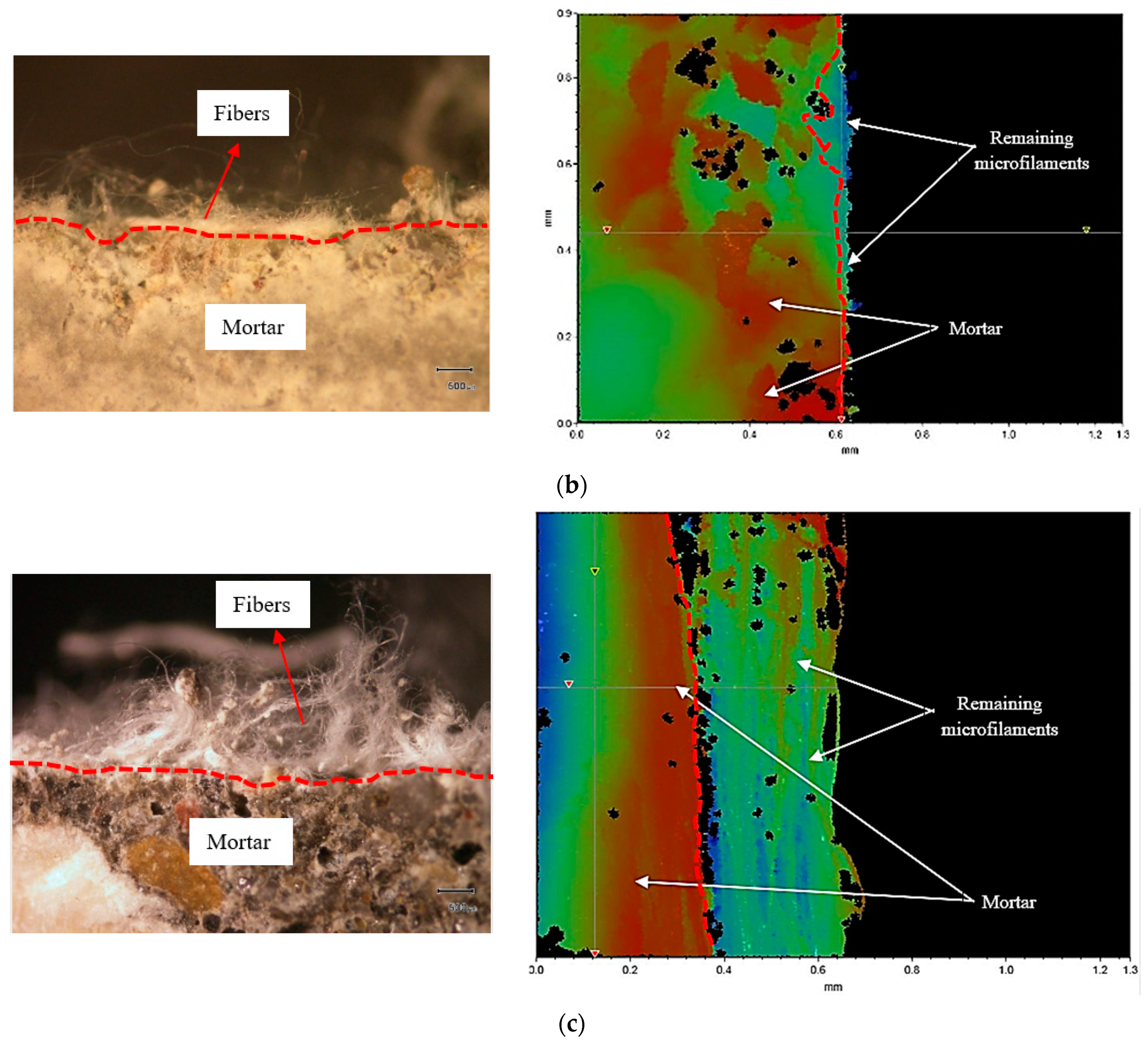

- The peeling force notably increased as the w/c ratio was raised. This enhancement could be attributed to the smoother surface and sufficient presence of cement paste on the surfaces of prisms. In essence, specimens with a higher w/c ratio exhibited a greater density of microfilaments with thicker layers adhering to their surfaces, in contrast to those with lower w/c ratios. The thicker layer of the remaining microfilaments led to a larger contact area between the sheets and prisms, ultimately resulting in a stronger adhesion;

- Furthermore, augmenting the content of the superplasticizer exhibited a significant impact on bonding characteristics. The peeling force exhibited a notable decrease as water content was reduced and the superplasticizer amount was increased. This reduction can be attributed to the phenomenon of bleeding that occurs when a substantial quantity of superplasticizer is present alongside a reduced amount of cement paste on the prism surfaces. Additionally, the quantity and thickness of the remaining fibers reduced with the increase of superplasticizer content, leading to a corresponding decline in the peeling force;

- This phenomenon was clearly confirmed by interferometry and microscopic analyses. The observations revealed that reducing the w/c ratio or introducing a superplasticizer led to increased surface irregularities and porosity, coupled with a decrease in both the quantity and thickness of the remaining microfilaments;

- Finally, the mechanical properties of prisms were studied after the bond test. It was found that the flexural and compressive strengths have improved for the prisms, which have a higher w/c ratio and less superplasticizer.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Jawdhari, A.; Peiris, A.; Harik, I. Experimental study on RC beams strengthened with CFRP rod panels. Eng. Struct. 2018, 173, 693–705. [Google Scholar] [CrossRef]

- Hosen, A.; Zamin, M.; Alengaram, U.J.; Sulong, N.H.R. CFRP strips for enhancing flexural performance of RC beams by SNSM strengthening technique. Constr. Build. Mater. 2018, 165, 28–44. [Google Scholar] [CrossRef]

- Adel, A.; Hamed, A.; El-kashif, K.F.O. Flexural strengthening of preloaded reinforced concrete continuous beams: An experimental investigation. Alex. Eng. J. 2018, 58, 207–216. [Google Scholar] [CrossRef]

- Ahmad, S.; Sharif, A.M.A.; Al-Osta, M.A.; Al-Zahrani, M.M.; Sharif, A.M.; Al-Huri, M.A. Flexural performance of pre-damaged RC beams strengthened with different configurations of UHPFRC layer—Experimental and analytical investigation. Structures 2023, 48, 1772–1787. [Google Scholar] [CrossRef]

- Alkhateeb, M.Y.; Hejazi, F. Reinforced concrete beams externally strengthened by CFRP rods with steel plate, anchorage bolts, and concrete jacketing. Structures 2022, 46, 1994–2013. [Google Scholar] [CrossRef]

- Askar, M.K.; Hassan, A.F.; Al-Kamaki, Y.S.S. Flexural and shear strengthening of reinforced concrete beams using FRP composites: A state of the art. Case Stud. Constr. Mater. 2022, 17, e01189. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, H.; Qin, Y.; Huang, S.; Fan, W. Experimental and analytical studies on the flexural behavior of steel plate-UHPC composite strengthened RC beams. Eng. Struct. 2023, 283, 115834. [Google Scholar] [CrossRef]

- Sun, X.; Gong, Z.; Zuo, Y.; Hu, J.; Li, Y.; Wu, H. Flexural behavior of the hollow slab girders strengthened with ultra-high performance concrete: Field full-scale experiment and analysis. Constr. Build. Mater. 2023, 408, 133608. [Google Scholar] [CrossRef]

- Zhu, Z.; Abdelbaset, H.; Li, X.; Tang, Q. Flexural behavior of long-term loaded RC beams strengthened by ultra-high performance concrete. Constr. Build. Mater. 2023, 407, 133428. [Google Scholar] [CrossRef]

- Alharthi, Y.M.; Emara, M.; Elamary, A.S.; Sharaky, I.A. Flexural response and load capacity of reinforced concrete beams strengthened with reinforced mortar layer. Eng. Struct. 2021, 245, 112884. [Google Scholar] [CrossRef]

- Peng, G.; Hu, X.; Niu, D.; Zhong, S.; Huang, D. Experimental study on the shear behavior of RC beams strengthened with cementitious grout. Structures 2023, 50, 1403–1415. [Google Scholar] [CrossRef]

- Bahij, S.; Omary, S.; Feugeas, F.; Faqiri, A. Structural Strengthening/Repair of Reinforced Concrete (RC) Beams by Different Fiber-Reinforced Cementitious Materials—A State-of-the-Art Review. J. Civ. Environ. Eng. 2020, 10. [Google Scholar] [CrossRef]

- Pan, B.; Liu, F.; Zhuge, Y.; Zeng, J.J.; Liao, J.J. ECCs/UHPFRCCs with and without FRP reinforcement for structural strengthening/repairing: A state-of-the-art review. Constr. Build. Mater. 2022, 316, 125824. [Google Scholar] [CrossRef]

- Al-zu’bi, H.; Abdel-Jaber, M.; Katkhuda, H. Flexural Strengthening of Reinforced Concrete Beams with Variable Compressive Strength Using Near-Surface Mounted Carbon-Fiber-Reinforced Polymer Strips [NSM-CFRP]. Fibers 2022, 10, 86. [Google Scholar] [CrossRef]

- Sivasankar, S.; Bharathy, T.; Vinodh Kumar, R. Flexural Behaviour of RC beams using GFRP Composites. Int. J. Eng. Technol. 2018, 7, 744. [Google Scholar] [CrossRef]

- Pham, T.M.; Chen, W.; Elchalakani, M.; Karrech, A.; Hao, H. Experimental investigation on lightweight rubberized concrete beams strengthened with BFRP sheets subjected to impact loads. Eng. Struct. 2020, 205, 110095. [Google Scholar] [CrossRef]

- Sinh, L.H.; Komuro, M.; Kawarai, T.; Kishi, N. Failure Modes of Reinforced Concrete Beams Strengthened in Flexure with Externally Bonded Aramid Fiber-Reinforced Polymer Sheets under Impact Loading. Buildings 2022, 12, 584. [Google Scholar] [CrossRef]

- Soluit, A.K.; Motawea, M.A.; El-sayed, K.M.; Shalaby, S.H. Torsional Behavior of RC Beams Strengthened with Fiber Reinforced Polymer Sheets. Eng. Res. J. 2007, 114, C102–C119. [Google Scholar]

- Li, A.; Diagana, C.; Delmas, Y. CRFP contribution to shear capacity of strengthened RC beams. Eng. Struct. 2001, 23, 1212–1220. [Google Scholar] [CrossRef]

- Reda, R.M.; Sharaky, I.A.; Ghanem, M.; Seleem, M.H.; Sallam, H.E.M. Flexural behavior of RC beams strengthened by NSM GFRP Bars having different end conditions. Compos. Struct. 2016, 147, 131–142. [Google Scholar] [CrossRef]

- Mostosi, S.; Meda, A.; Riva, P.; Maringoni, S. Shear Strengthening of RC Beams with High Performance Jacket. In Proceedings of the Fib Symposium 2011: Concrete Engineering for Excellence and Efficiency, Prague, Czech Republic, 8–10 June 2011. [Google Scholar]

- Al-Bayati, G.; Al-Mahaidi, R.; Kalfat, R. Experimental investigation into the use of NSM FRP to increase the torsional resistance of RC beams using epoxy resins and cement-based adhesives. Constr. Build. Mater. 2016, 124, 1153–1164. [Google Scholar] [CrossRef]

- Bahij, S.; Omary, S.; Steiner, V.; Feugeas, F.; Ibrahimkhil, M.H. Effect of Non-Woven Polyethylene Terephthalate (PET) Tissue on Fresh and Hardened Properties of Concrete. Materials 2022, 15, 8766. [Google Scholar] [CrossRef] [PubMed]

- Bahij, S.; Omary, S.; Steiner, V.; Feugeas, F.; Faqiri, A. Experimental Study on Concrete Specimens Strengthened with Non-woven Plastic Sheets. Int. J. Civ. Infrastruct. 2021, 4, 128–137. [Google Scholar] [CrossRef]

- Bahij, S.; Omary, S.; Feugeas, F.; Faqiri, A. Use of Non-Woven Polyethylene Terephthalate (PET) Tissue to improve Certain Properties of Concrete. In Proceedings of the 6th International Conference on Civil, Structural and Transportation Engineering (ICCSTE’21), Niagara Falls, ON, Canada, 17–19 May 2021; pp. 1–10. [Google Scholar] [CrossRef]

- Bahij, S. Valorization of Plastic Non-Woven Sheets of Polyethylene Terephthalate (PET) for the Development of Environmental Friendly Concrete. Ph.D. Thesis, University of Strasbourg, Strasbourg, France, 2021. [Google Scholar]

- Shim, E.; Pourdeyhimi, B.; Latifi, M. Three-dimensional analysis of segmented pie bicomponent nonwovens. J. Text. Inst. 2010, 101, 773–787. [Google Scholar] [CrossRef]

- Kamela, M.; Helmy, H.; Meshaly, H.; Abou-Okeil, A. Antibacterial Activity of Cationised Cotton Dyed with Some Natural Dyes. J. Text. Sci. Eng. 2015, 5, 1–5. [Google Scholar] [CrossRef]

- Zhang, H.; Qian, X.; Zhen, Q.; Yang, Z. Research on structure characteristics and filtration performances of PET-PA6 hollow segmented-pie bicomponent spunbond nonwovens fibrillated by hydro entangle method. J. Ind. Text. 2015, 45, 48–65. [Google Scholar] [CrossRef]

- Long, J.H.; Paul, S.L.; Lampo, R.G. Bond strength between geotextiles and concrete. Geotext. Geomembr. 1989, 8, 113–132. [Google Scholar] [CrossRef]

- EN 197-1/A1; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. European Standard: Brussels, Belgium, 2012.

- NF EN 12620/IN1; Aggregates for Concrete. European Standard: Brussels, Belgium, 2008.

- EN 934-2; Admixtures for Concrete, Mortar and Grout. European Standard: Brussels, Belgium, 2012.

- SikaCem® Fluidifiant. Superplastifiant Haut Reducteur d’eau. Sika 2017. Available online: https://fra.sika.com/content/dam/dms/fr01/y/sikacem_fluidifiant.pdf (accessed on 27 April 2021).

- Hollowell, K.B. Hybrid Mixed Media Nonwovens: An Investigation of Structure-Property Relationships. Ph.D. Thesis, North Carolina State University, Raleigh, NC, USA, 2012. [Google Scholar]

- Baysal, G.; Önder, S.; Göcek, I.; Trabzon, L.; Kizil, H.; Kök, F.N.; Kayaoğlu, B.K. Design and fabrication of a new nonwoven-textile based platform for biosensor construction. Sens. Actuators B Chem. 2015, 208, 475–484. [Google Scholar] [CrossRef]

- Freudenberg, Web Bonding. n.d. Available online: https://www.freudenberg-pm.com/Materials/Webbonding (accessed on 13 October 2023).

- Xiang, P.; Kuznetsov, A.V.; Seyam, A.M. Experimental and numerical investigation of the peeling force required for the detachment of fabric from the forming belt in the hydroentanglement process. J. Text. Inst. 2009, 100, 99–110. [Google Scholar] [CrossRef]

- NF EN 29092; Textiles—Nonwovens. European Standard: Brussels, Belgium, 1992.

- NF EN ISO 9073-1; Nowovens—Test methods—Part 1: Determination of Mass per Unit Area. European Standard: Brussels, Belgium, 2023.

- NF EN ISO 9073-2; Nowovens—Textiles—Test Methods for Nonwovens—Part 2: Determination of Thickness. European Standard: Brussels, Belgium, 2023.

- NF EN ISO 13934-1; Textiles—Tensile Oroperties of Fabrics—Part 1: Determination of Maximum Force and Elongation at Maximum Force Using the Strip Method. European Standard: Brussels, Belgium, 2013.

- NF EN ISO 13937-1; Textiles—Tear Properties of Fabrics—Part 1: Determination of Tear Force Using Ballistic Pendulum Method (Elmendorf). European Standard: Brussels, Belgium, 2000.

- DIN 53923-78; Testing of Textiles—Determination of Water Absorption of Textile Fabrics. German National Standard: Berlin, Germany, 2022.

- NF EN 196-1; Methods of Testing Cement—Part 1: Determination of Strength. European Standard: Brussels, Belgium, 2016.

- ASTM D 903-98; Standard Test Method for Peel or Stripping Strength of Adhesive Bonds. American Society for Testing and Materials: West Conshohocken, PA, USA, 2004; Volume 01, pp. 5–8.

- EN 1015-11; Test Methods for Masonry Mortars—Part 11: Determination of the Flexural and Compressive Strength of Hardened Mortar. European Standard: Brussels, Belgium, 2019.

| Components | Weight (%) | Phases | Weight (%) |

|---|---|---|---|

| CaO | 61.3 | C3S | 63 |

| SiO2 | 20 | ||

| Al2O3 | 4.8 | ||

| Fe2O3 | 3.1 | ||

| K2O | 1.12 | C2S | 20 |

| MgO | 4.9 | ||

| Na2O | 0.26 | ||

| S-- | 0.03 | ||

| Cl- | 0.07 | C3A | 7 |

| CO2 | 0.7 | ||

| SO3 | 3.7 | ||

| PAF | 0.8 | ||

| INS | 0.2 | ||

| CaO Free | 1.6 | C4AF | 10 |

| Na2Oeq active | 1 |

| Properties | Value/Type |

|---|---|

| Color | Dark brown |

| State | Liquid |

| Density | 1150 ± 0.03 kg/m3 |

| pH | 7.5 ± 1.0 |

| Chloride content | ≤0.1% |

| Recommended dosage | 5 dm3 for 1 m3 of concrete |

| Properties | Unit | Test Method | Values |

|---|---|---|---|

| Web bonding | - | NF EN 29092 [39] | Hydrolase |

| Mas per unit area | g/m2 | NF EN ISO 9073-1 [40] | Target 100 |

| Thickness | mm | NF EN ISO 9073-2 [41] | Target 0.37 |

| Tensile strength (machine direction) | N | NF EN ISO 13934-1 [42] | Target 300 |

| Tensile strength (cross direction) | N | NF EN ISO 13934-1 [42] | Target 290 |

| Tear strength (machine direction) | N | NF EN ISO 13937-1 [43] | Target 8 |

| Tear strength (cross direction) | N | NF EN ISO 13937-1 [43] | Target 8 |

| Elongation at break (machine direction) | % | NF EN ISO 13937-1 [43] | Target 45 |

| Elongation at break (cross direction) | % | NF EN ISO 13937-1 [43] | Target 50 |

| Water absorption | mL/m2 | DIN 53923-78 [44] | Target 430 (Washed product) |

| Materials | Weight of Materials (g) |

|---|---|

| Sand | 1350 |

| Cement | 450 |

| Water | 225 |

| Number of Parameters | Sample Name | Cement (g) | Water (g) | % of SP (by Weight of Cement) | w/c Ratio | Slump (mm) |

|---|---|---|---|---|---|---|

| 1 | 0.55-WSP | 450 | 247.5 | 0.0 | 0.55 | 33.5 |

| 2 | 0.50-WSP | 450 | 225.0 | 0.0 | 0.50 | 17.0 |

| 3 | 0.45-WSP | 450 | 202.5 | 0.0 | 0.45 | 5.3 |

| 4 | 0.45-SP | 450 | 202.5 | 1.11 | 0.45 | 17.5 |

| 5 | 0.40-SP | 450 | 180.0 | 2.17 | 0.40 | 18.5 |

| Mixture | Layer Thickness of the Remaining Microfilaments (mm) |

|---|---|

| 0.45-WSP | 0.08 |

| 0.50-WSP | 0.25 |

| 0.55-WSP | 0.52 |

| Mixture | Layer Thickness of the Remaining Microfilaments (mm) |

|---|---|

| 0.40 + 1.11% SP | 0.05 |

| 0.45 + 2.17% SP | 0.08 |

| 0.50 + 0% SP | 0.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bahij, S.; Omary, S.; Belhaj, E.; Steiner, V.; Feugeas, F. Peeling Force Required for the Detachment of Non-Woven Plastic Tissue from the Surface of Mortar Prisms. Polymers 2023, 15, 4286. https://doi.org/10.3390/polym15214286

Bahij S, Omary S, Belhaj E, Steiner V, Feugeas F. Peeling Force Required for the Detachment of Non-Woven Plastic Tissue from the Surface of Mortar Prisms. Polymers. 2023; 15(21):4286. https://doi.org/10.3390/polym15214286

Chicago/Turabian StyleBahij, Sifatullah, Safiullah Omary, Essia Belhaj, Vincent Steiner, and Francoise Feugeas. 2023. "Peeling Force Required for the Detachment of Non-Woven Plastic Tissue from the Surface of Mortar Prisms" Polymers 15, no. 21: 4286. https://doi.org/10.3390/polym15214286

APA StyleBahij, S., Omary, S., Belhaj, E., Steiner, V., & Feugeas, F. (2023). Peeling Force Required for the Detachment of Non-Woven Plastic Tissue from the Surface of Mortar Prisms. Polymers, 15(21), 4286. https://doi.org/10.3390/polym15214286