Introduction of Nanoscale Si3N4 to Improve the Dielectric Thermal Stability of a Si3N4/P(VDF-HFP) Composite Film

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fan, B.; Zhou, M.; Zhang, C.; He, D.; Bai, J. Polymer-based materials for achieving high energy density film capacitors. Prog. Polym. Sci. 2019, 97, 101143. [Google Scholar] [CrossRef]

- Tan, D.Q. Review of Polymer-Based Nanodielectric Exploration and Film Scale-Up for Advanced Capacitors. Adv. Funct. Mater. 2019, 30, 1808567. [Google Scholar] [CrossRef]

- Zhang, G.; Li, Q.; Allahyarov, E.; Li, Y.; Zhu, L. Challenges and Opportunities of Polymer Nanodielectrics for Capacitive Energy Storage. ACS Appl. Mater. Interfaces 2021, 13, 37939–37960. [Google Scholar] [CrossRef]

- Li, D.; Zeng, X.; Li, Z.; Shen, Z.-Y.; Hao, H.; Luo, W.; Wang, X.; Song, F.; Wang, Z.; Li, Y. Progress and perspectives in dielectric energy storage ceramics. J. Adv. Ceram. 2021, 10, 675–703. [Google Scholar] [CrossRef]

- Burn, I.; Smyth, D.M. Energy storage in ceramic dielectrics. J. Mater. Sci. 1972, 7, 339–343. [Google Scholar] [CrossRef]

- Luo, H.; Wang, F.; Guo, R.; Zhang, D.; He, G.; Chen, S.; Wang, Q. Progress on Polymer Dielectrics for Electrostatic Capacitors Application. Adv. Sci. 2022, 9, e2202438. [Google Scholar] [CrossRef] [PubMed]

- Chu, B.; Zhou, X.; Ren, K.; Neese, B.; Lin, M.; Wang, Q.; Bauer, F.; Zhang, Q.M. A Dielectric Polymer with High Electric Energy Density and Fast Discharge Speed. Science 2006, 313, 334–336. [Google Scholar] [CrossRef]

- Lovinger, A.J.J.S. Ferroelectric Polymers. Science 1983, 220, 1115–1121. [Google Scholar] [CrossRef] [PubMed]

- Ritamaki, M.; Rytoluoto, I.; Lahti, K. Performance metrics for a modern BOPP capacitor film. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 1229–1237. [Google Scholar] [CrossRef]

- Rožič, B.; Malič, B.; Uršič, H.; Holc, J.; Kosec, M.; Neese, B.; Zhang, Q.M.; Kutnjak, Z. Direct Measurements of the Giant Electrocaloric Effect in Soft and Solid Ferroelectric Materials. Ferroelectrics 2010, 405, 26–31. [Google Scholar] [CrossRef]

- Marshall, J.E.; Zhenova, A.; Roberts, S.; Petchey, T.; Zhu, P.; Dancer, C.E.J.; McElroy, C.R.; Kendrick, E.; Goodship, V. On the Solubility and Stability of Polyvinylidene Fluoride. Polymers 2021, 13, 1354. [Google Scholar] [CrossRef]

- Ho, J.S.; Greenbaum, S.G. Polymer Capacitor Dielectrics for High Temperature Applications. ACS Appl. Mater. Interfaces 2018, 10, 29189–29218. [Google Scholar] [CrossRef]

- Liu, S.; Xue, S.; Zhang, W.; Zhai, J.; Chen, G. The influence of crystalline transformation of Ba0.6Sr0.4TiO3 nanofibers/poly(vinylidene fluoride) composites on the energy storage properties by quenched technique. Ceram. Int. 2015, 41, S430–S434. [Google Scholar] [CrossRef]

- Xia, W.; Xu, Z.; Wen, F.; Zhang, Z. Electrical energy density and dielectric properties of poly(vinylidene fluoride-chlorotrifluoroethylene)/BaSrTiO3 nanocomposites. Ceram. Int. 2012, 38, 1071–1075. [Google Scholar] [CrossRef]

- Thomas, P.; Varughese, K.T.; Dwarakanath, K.; Varma, K.B.R. Dielectric properties of Poly(vinylidene fluoride)/CaCu3Ti4O12 composites. Compos. Sci. Technol. 2010, 70, 539–545. [Google Scholar] [CrossRef]

- Guo, Y.; Wu, S.; Liu, S.; Xu, J.; Pawlikowska, E.; Szafran, M.; Rydosz, A.; Gao, F. Enhanced dielectric tunability and energy storage density of sandwich-structured Ba0.6Sr0.4TiO3/PVDF composites. Mater. Lett. 2022, 306, 130910. [Google Scholar] [CrossRef]

- Chen, C.; Wang, L.; Liu, X.; Yang, W.; Lin, J.; Chen, G.; Yang, X. K0.5Na0.5NbO3-SrTiO3/PVDF Polymer Composite Film with Low Remnant Polarization and High Discharge Energy Storage Density. Polymers 2019, 11, 310. [Google Scholar] [CrossRef] [PubMed]

- Sang, X.; Li, X.; Zhang, D.; Zhang, X.; Wang, H.; Li, S. Improved dielectric properties and energy-storage densities of BaTiO3-doped PVDF composites by heat treatment and surface modification of BaTiO3. J. Phys. D Appl. Phys. 2022, 55, 215501. [Google Scholar] [CrossRef]

- Chen, W.; Xing, Z.; Wei, Y.; Zhang, X.; Zhang, Q. High thermal safety and conductivity gel polymer electrolyte composed of ionic liquid [EMIM][BF4] and PVDF-HFP for EDLCs. Polymer 2023, 268, 125727. [Google Scholar] [CrossRef]

- Zhao, Q.; Ma, L.; Xu, Y.; Wu, X.; Jiang, S.; Zheng, Q.; Hong, G.; He, B.; Li, C.; Cen, W.; et al. An upgraded polymeric composite with interparticle chemical bonding microstructure toward lithium-ion battery separators with enhanced safety and electrochemical performance. J. Energy Chem. 2023, 84, 402–413. [Google Scholar] [CrossRef]

- He, D.; Wang, Y.; Song, S.; Liu, S.; Deng, Y. Significantly Enhanced Dielectric Performances and High Thermal Conductivity in Poly(vinylidene fluoride)-Based Composites Enabled by SiC@SiO2 Core–Shell Whiskers Alignment. ACS Appl. Mater. Interfaces 2017, 9, 44839–44846. [Google Scholar] [CrossRef]

- Sun, D.; Chen, F.; Gao, Y.; Huang, S.; Wang, Y. Polymer-derived SiCN ceramics as fillers for polymer composites with high dielectric constants. J. Mater. Sci. 2019, 54, 6982–6990. [Google Scholar] [CrossRef]

- Zhou, J.; Zhou, W.; Li, B.; Cao, D.; Lin, N.; Shang, B.; Wang, F.; Feng, A.; Hou, C. Synchronous enhancements in dielectric performances and thermal conductivity of β-SiCw/PVDF nanocomposites through building crystalline SiO2 shell as an interlayer. J. Polym. Res. 2022, 29, 234. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Z.; Wu, Y.; Li, Y.; Yue, Z.; Chen, M. PVDF-HFP/PAN/PDA@LLZTO Composite Solid Electrolyte Enabling Reinforced Safety and Outstanding Low-Temperature Performance for Quasi-Solid-State Lithium Metal Batteries. ACS Appl. Mater. Interfaces 2023, 15, 21526–21536. [Google Scholar] [CrossRef]

- Xia, W.; Zhou, Z.; Liu, Y.; Wang, Q.; Zhang, Z. Crystal phase transition dependence of the energy storage performance of poly(vinylidene fluoride) and poly(vinylidene fluoride-hexafluoropropene) copolymers. J. Appl. Polym. Sci. 2018, 135, 46306. [Google Scholar] [CrossRef]

- Xia, W.; Chen, B.; Liu, Y.; Wang, Q.; Zhang, Z. Low Young’s moduli induced D–E loop dispersion and its effect on the energy discharging performance of PVDF and P(VDF-co-HFP) films. AIP Adv. 2018, 8, 035211. [Google Scholar] [CrossRef]

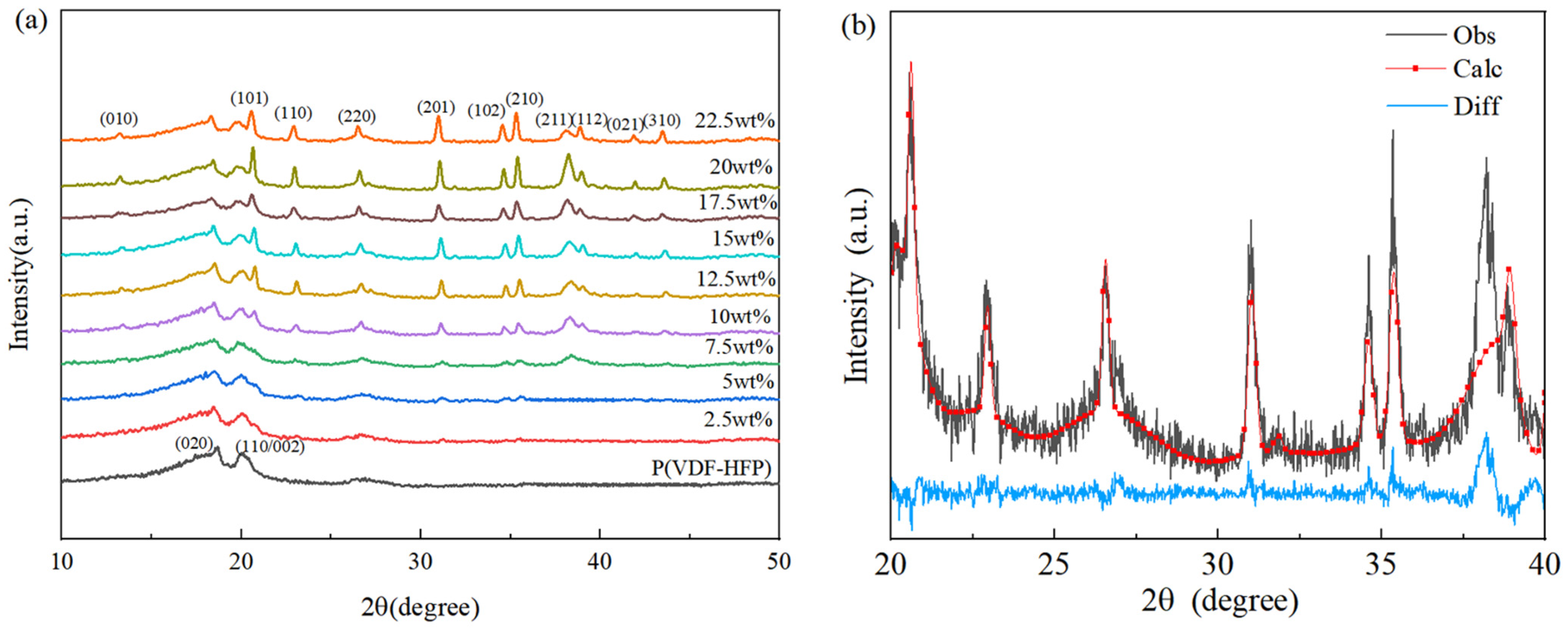

- Toraya, H. Crystal structure refinement of α-Si3N4 using synchrotron radiation powder diffraction data: Unbiased refinement strategy. J. Appl. Crystallogr. 2010, 33, 95–102. [Google Scholar] [CrossRef]

- Li, W.; Meng, Q.; Zheng, Y.; Zhang, Z.; Xia, W.; Xu, Z. Electric energy storage properties of poly(vinylidene fluoride). Appl. Phys. Lett. 2010, 96, 192905. [Google Scholar] [CrossRef]

- Cui, L.; Hu, M.; Wang, Q.; Xu, B.; Yu, D.; Liu, Z.; He, J. Prediction of novel hard phases of Si3N4: First-principles calculations. J. Solid State Chem. 2015, 228, 20–26. [Google Scholar] [CrossRef]

- Zhang, X.; Xia, W.; Liu, J.; Zhao, M.; Li, M.; Xing, J. PVDF-based and its Copolymer-Based Piezoelectric Composites: Preparation Methods and Applications. J. Electron. Mater. 2022, 51, 5528–5549. [Google Scholar] [CrossRef]

- Xia, W.; Xu, Z.; Wen, F.; Li, W.; Zhang, Z. Crystalline properties dependence of dielectric and energy storage properties of poly(vinylidene fluoride-chlorotrifluoroethylene). Appl. Phys. Lett. 2010, 97, 222905. [Google Scholar] [CrossRef]

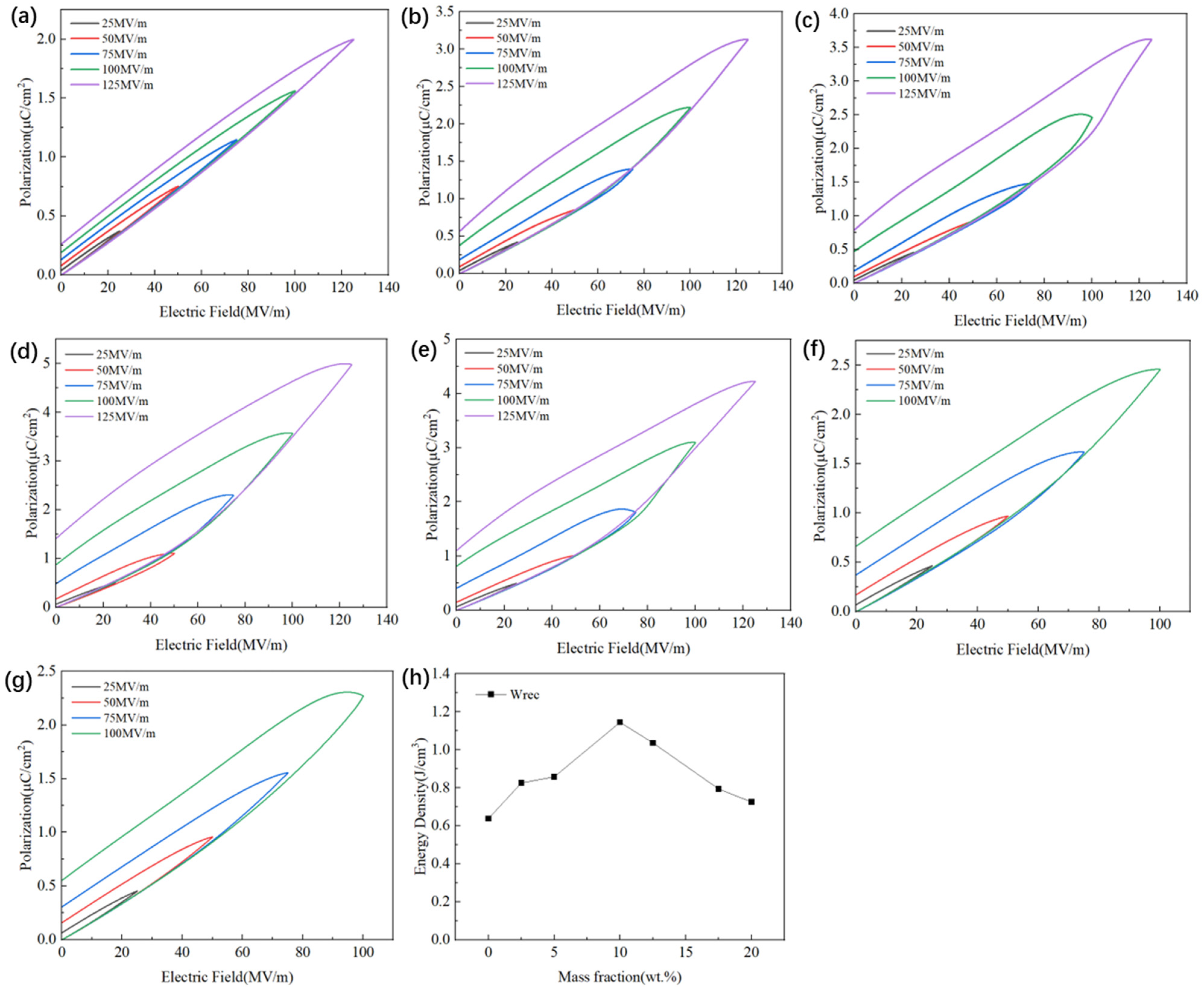

| Si3N4 Contents | Pm | Pr | Pm-Pr |

|---|---|---|---|

| 0.0 wt% | 1.56 | 0.19 | 1.37 |

| 2.5 wt% | 2.23 | 0.38 | 1.85 |

| 5.0 wt% | 2.5 | 0.47 | 2.03 |

| 10.0 wt% | 3.57 | 0.87 | 2.7 |

| 12.5 wt% | 3.1 | 0.81 | 2.29 |

| 17.5 wt% | 2.45 | 0.67 | 1.78 |

| 20.0 wt% | 2.3 | 0.55 | 1.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, J.; Cheng, L.; Fang, Y. Introduction of Nanoscale Si3N4 to Improve the Dielectric Thermal Stability of a Si3N4/P(VDF-HFP) Composite Film. Polymers 2023, 15, 4264. https://doi.org/10.3390/polym15214264

Guan J, Cheng L, Fang Y. Introduction of Nanoscale Si3N4 to Improve the Dielectric Thermal Stability of a Si3N4/P(VDF-HFP) Composite Film. Polymers. 2023; 15(21):4264. https://doi.org/10.3390/polym15214264

Chicago/Turabian StyleGuan, Jing, Laifei Cheng, and Ye Fang. 2023. "Introduction of Nanoscale Si3N4 to Improve the Dielectric Thermal Stability of a Si3N4/P(VDF-HFP) Composite Film" Polymers 15, no. 21: 4264. https://doi.org/10.3390/polym15214264

APA StyleGuan, J., Cheng, L., & Fang, Y. (2023). Introduction of Nanoscale Si3N4 to Improve the Dielectric Thermal Stability of a Si3N4/P(VDF-HFP) Composite Film. Polymers, 15(21), 4264. https://doi.org/10.3390/polym15214264