Laser-Induced Graphene Formation on Polyimide Using UV to Mid-Infrared Laser Radiation

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

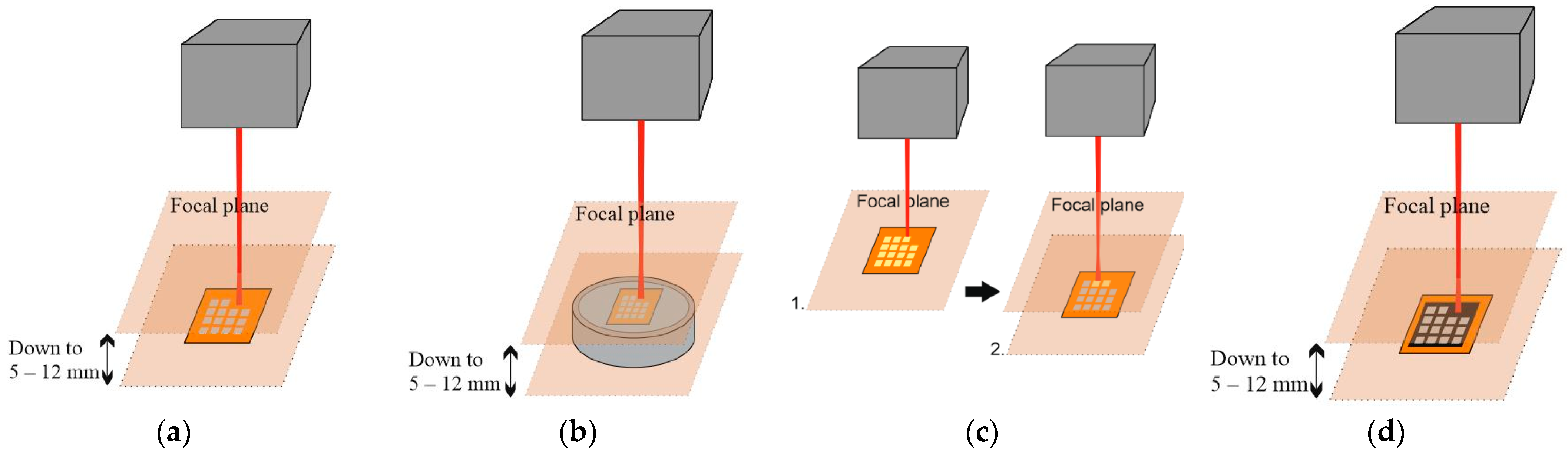

2.2. Laser Writing Techniques

- Samples were treated with a defocused laser beam in an ambient atmosphere.

- Samples were treated with a defocused laser beam in a nitrogen atmosphere.

- Samples were pretreated at the focal plane and then repeatedly treated out of focal plane.

- Samples were dyed with black marker and treated with the defocused beam.

2.3. Sheet Resistance Measurements

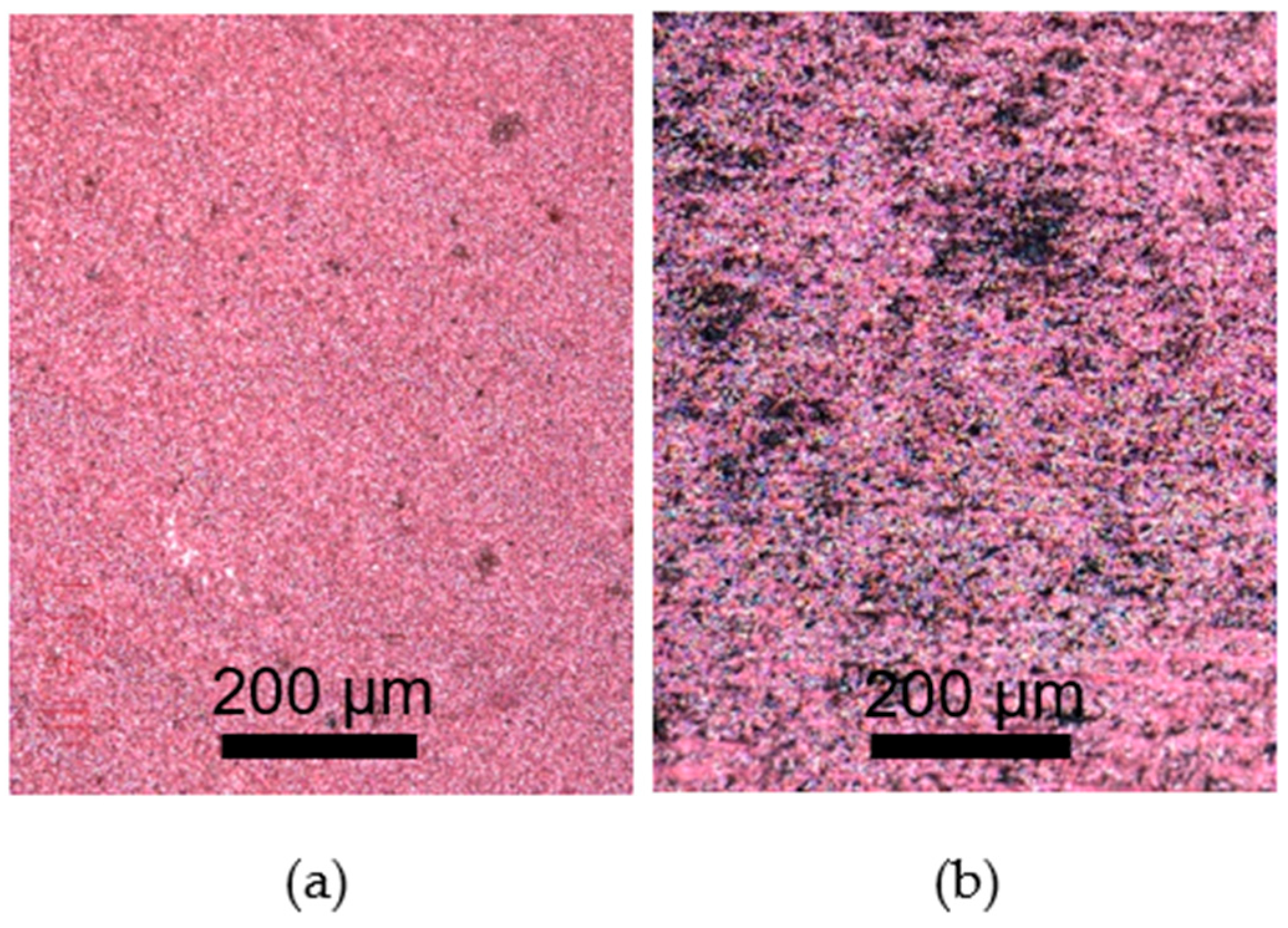

2.4. Surface Morphology Analysis

2.5. Raman Analysis

3. Results and Discussion

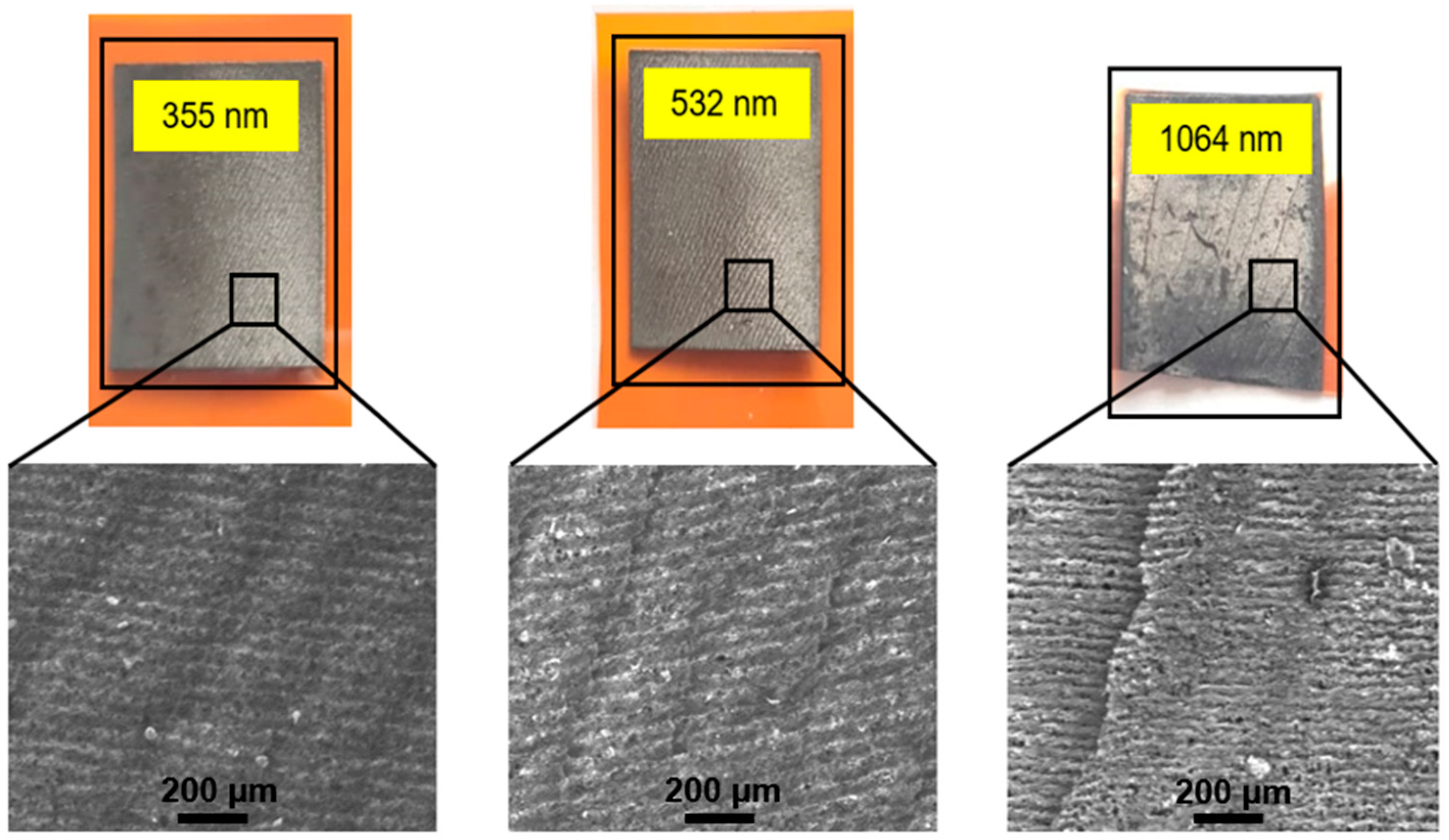

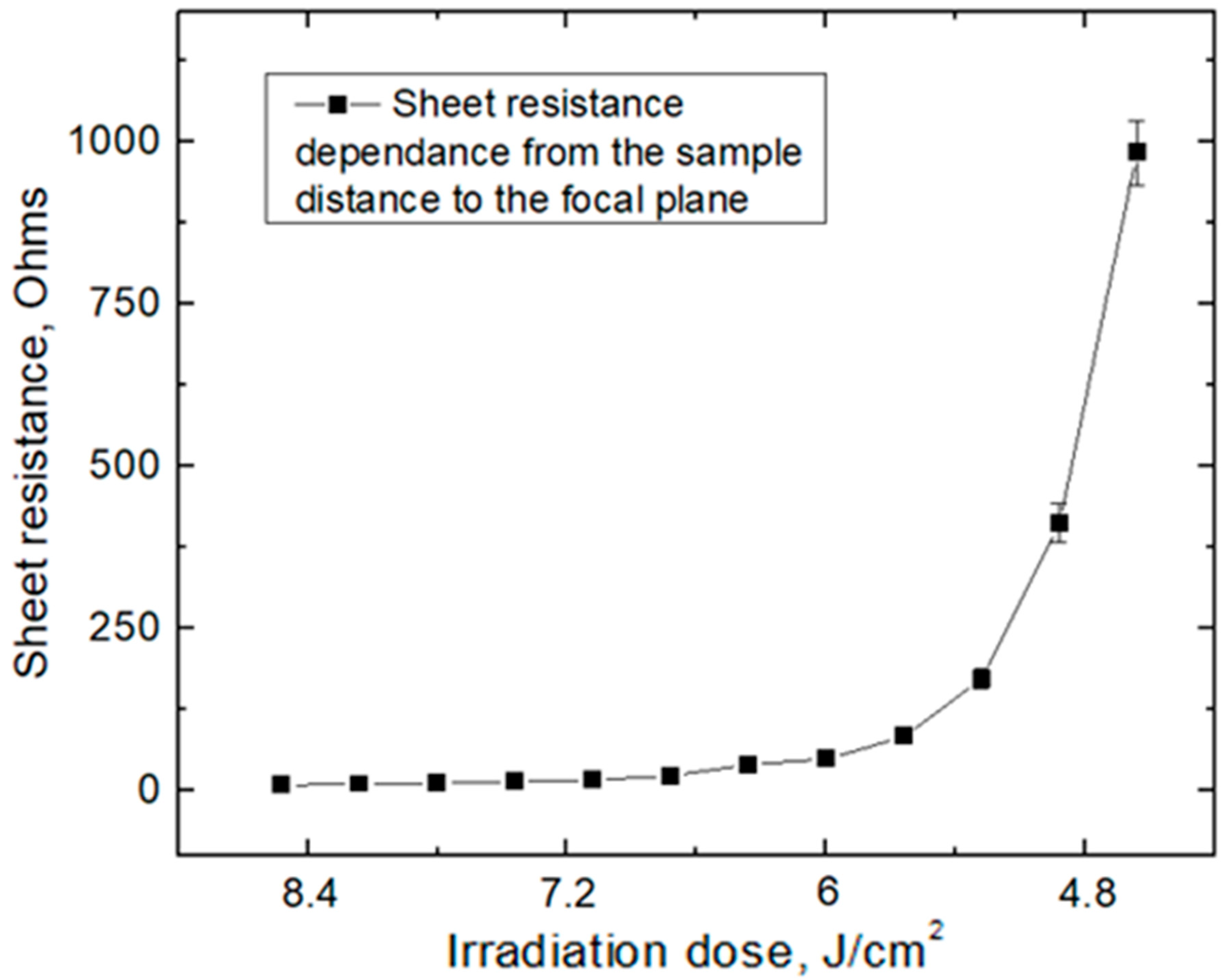

3.1. Fabricating with 355 nm, 532 nm, and 1064 nm out of the Focal Plane

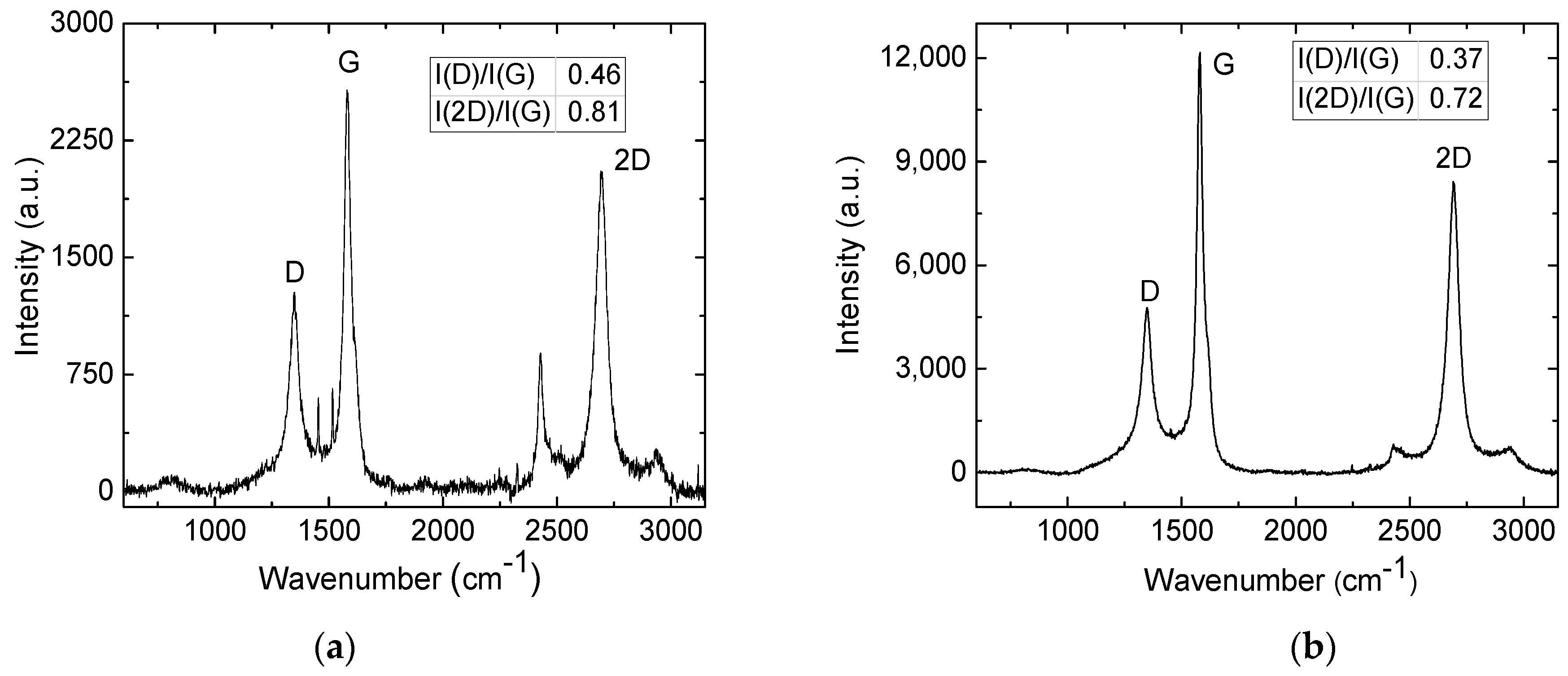

3.2. LIG Formation in the Nitrogen Atmosphere

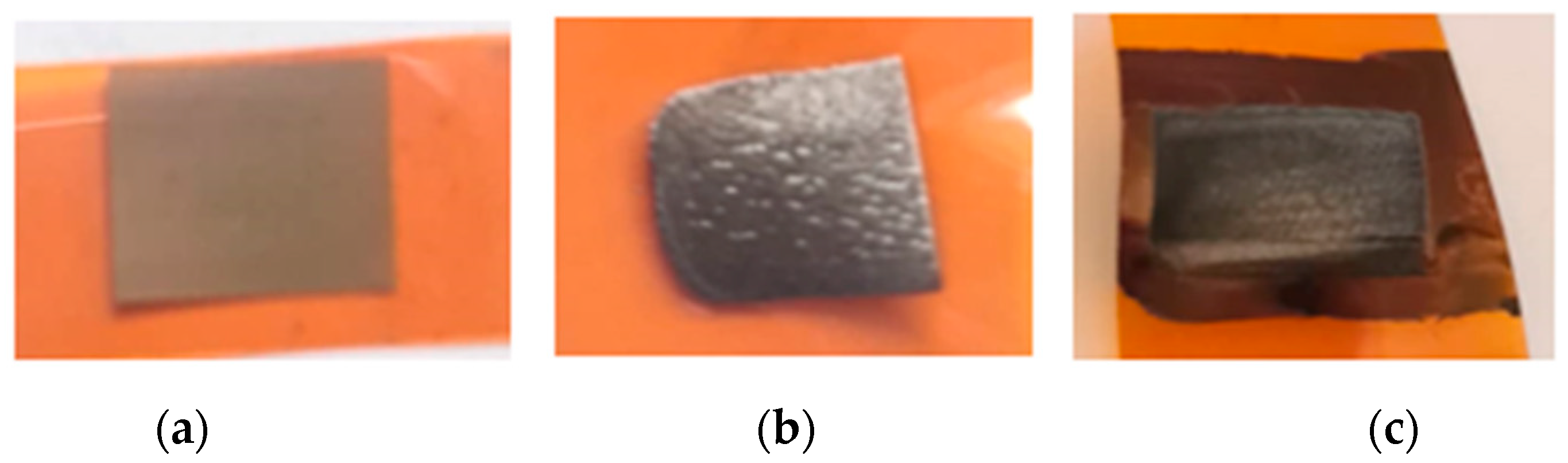

3.3. LIG formation on the Pretreated Area; LIG Formation on the Dyed Surface

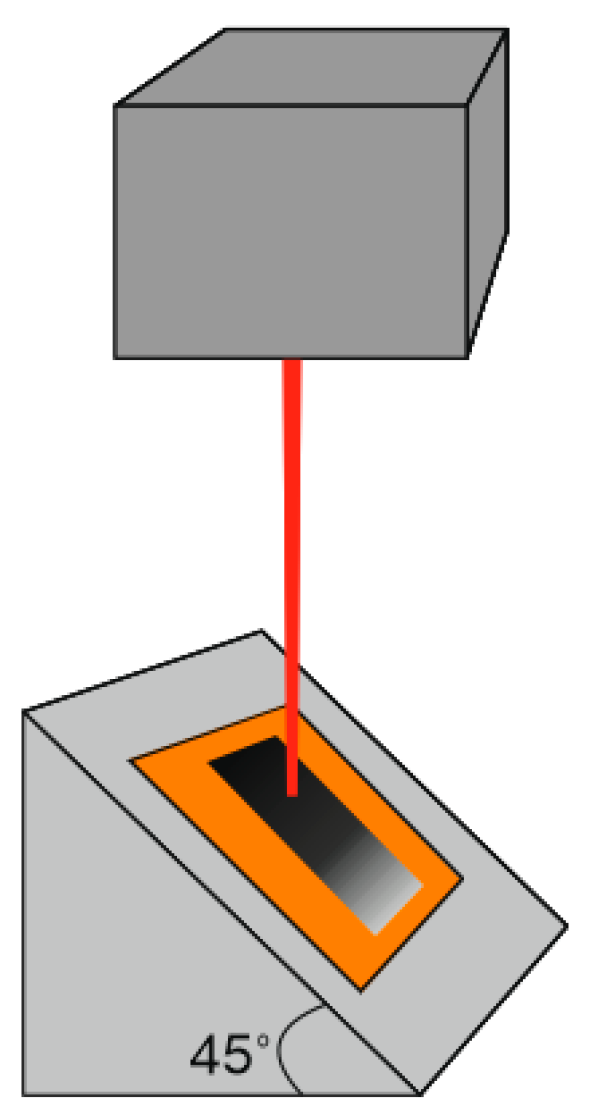

3.4. PI Processing with 10.6 µm Wavelength

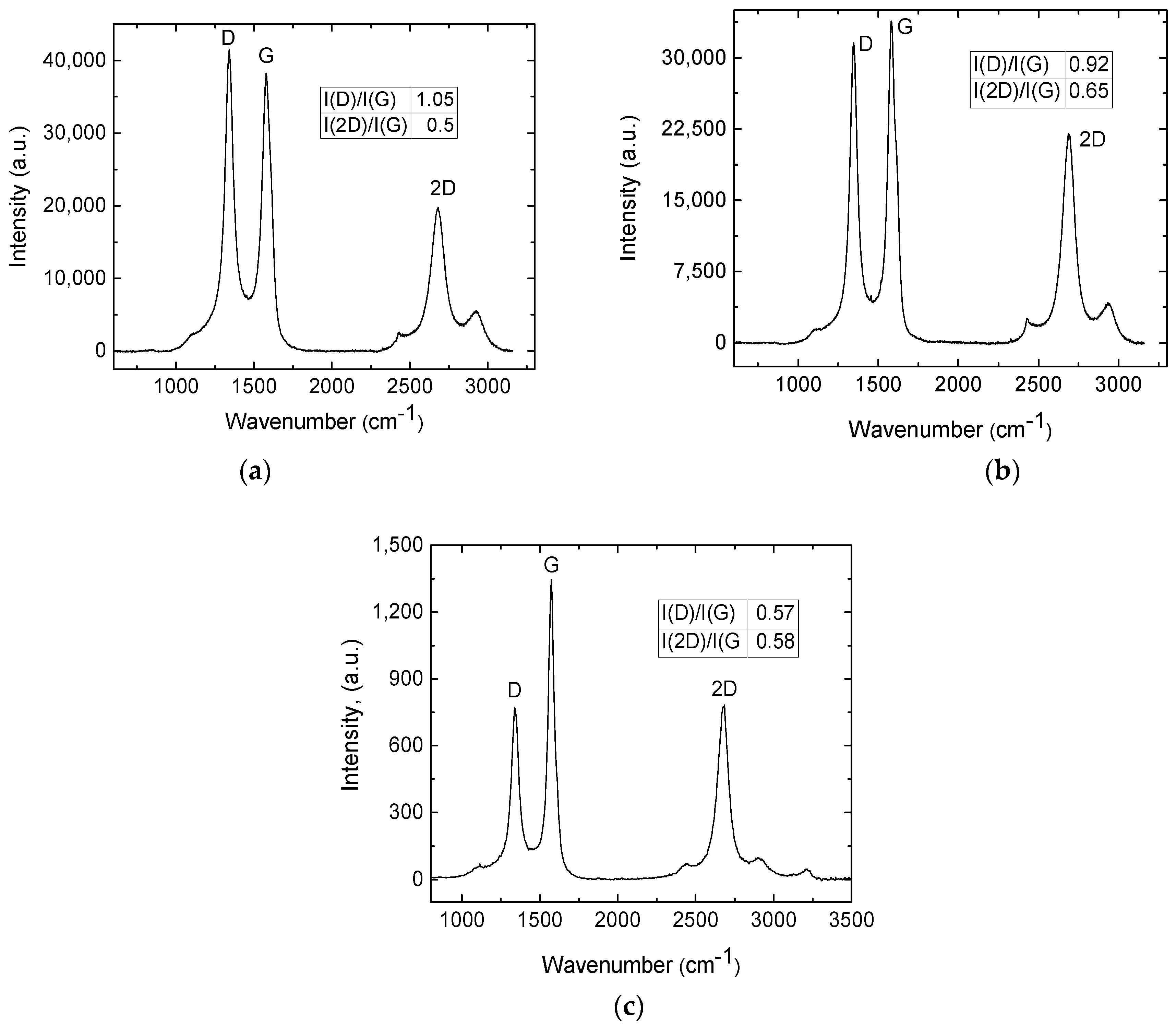

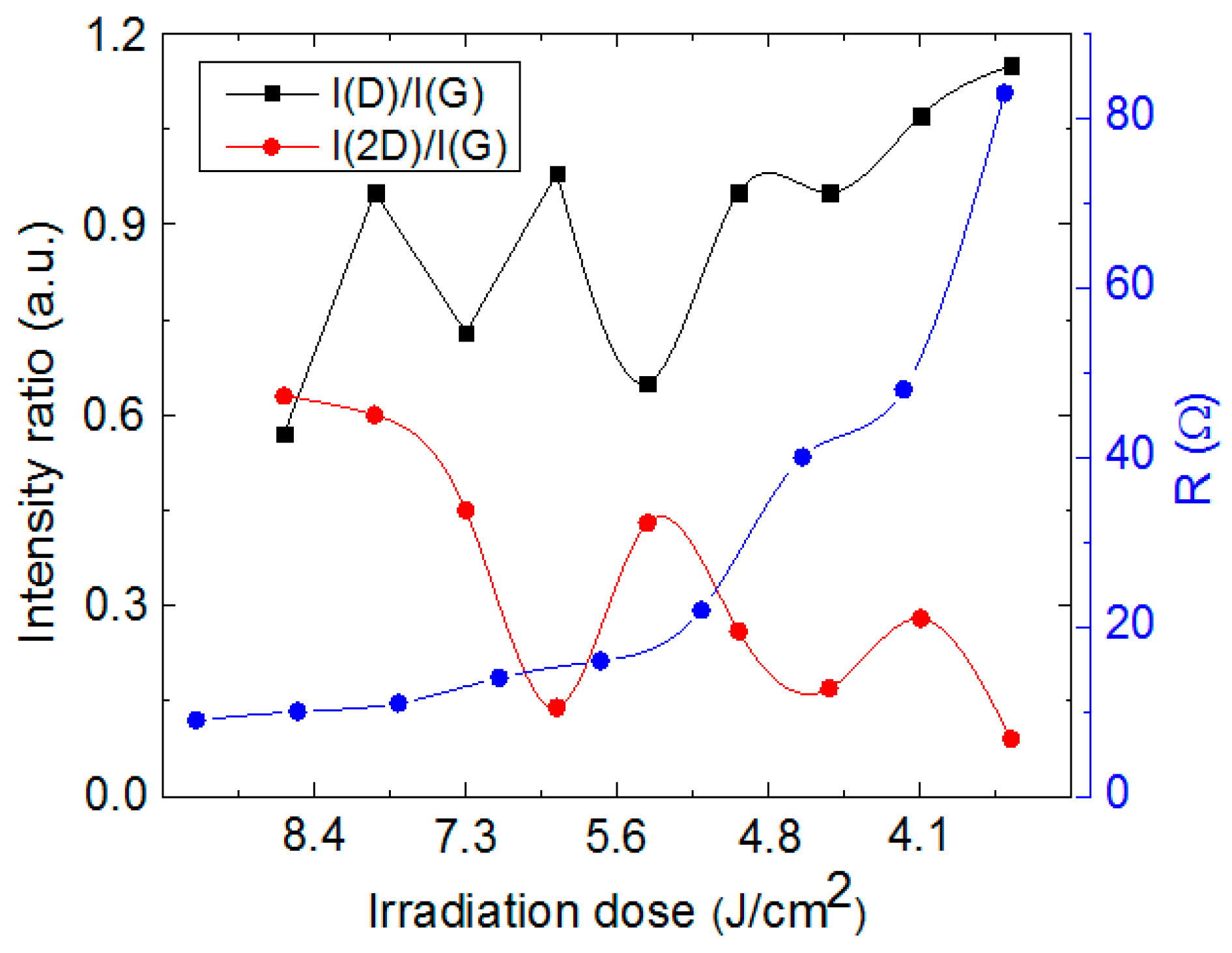

3.5. Structural Analysis by Raman Spectroscopy

3.6. Metal Plating on LIG

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

References

- Ye, R.; James, D.K.; Tour, J.M. Laser-induced graphene: From discovery to translation. Adv. Mater. 2019, 31, 1803621. [Google Scholar] [CrossRef]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef]

- Mensah, B.; Gupta, K.C.; Kim, H.; Wang, W.; Jeong, K.U.; Nah, C. Graphene-reinforced elastomeric nanocomposites: A review. Polym. Test. 2018, 68, 160–184. [Google Scholar] [CrossRef]

- Hiew, B.Y.Z.; Lee, L.Y.; Lee, X.J.; Thangalazhy-Gopakumar, S.; Gan, S.; Lim, S.S.; Pan, G.T.; Yang, T.C.K.; Chiu, W.S.; Khiew, P.S. Review on synthesis of 3D graphene-based configurations and their adsorption performance for hazardous water pollutants. Process Saf. Environ. Prot. 2018, 116, 262–286. [Google Scholar] [CrossRef]

- Li, L.; Zhang, J.; Peng, Z.; Li, Y.; Gao, C.; Ji, Y.; Ye, R.; Kim, N.D.; Zhong, Q.; Yang, Y.; et al. High-Performance Pseudocapacitive Microsupercapacitors from Laser-Induced Graphene. Adv. Mater. 2016, 28, 838–845. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, D.; Lau, A.; Ma, T.; Lin, H.; Jia, B. Hybridized graphene for supercapacitors: Beyond the limitation of pure graphene. Small 2021, 17, 2007311. [Google Scholar] [CrossRef] [PubMed]

- Chee, W.K.; Lim, H.N.; Zainal, Z.; Huang, N.M.; Harrison, I.; Andou, Y. Flexible graphene-based supercapacitors: A review. J. Phys. Chem. C 2016, 120, 4153–4172. [Google Scholar] [CrossRef]

- Nayak, P.; Kurra, N.; Xia, C.; Alshareef, H.N. Highly Efficient Laser Scribed Graphene Electrodes for On-Chip Electrochemical Sensing Applications. Adv. Electron. Mater. 2016, 2, 1600185. [Google Scholar] [CrossRef]

- Jian, M.; Wang, C.; Wang, Q.; Wang, H.; Xia, K.; Yin, Z.; Zhang, Y. Advanced carbon materials for flexible and wearable sensors. Sci. China Mater. 2017, 60, 1026–1062. [Google Scholar] [CrossRef]

- Choi, W.; Lahiri, I.; Seelaboyina, R.; Kang, Y.S. Synthesis of graphene and its applications: A review. Crit. Rev. Solid State Mater. Sci. 2010, 35, 52. [Google Scholar] [CrossRef]

- Mukherjee, R.; Thomas, A.V.; Krishnamurthy, A.; Koratkar, N. Photothermally reduced graphene as high-power anodes for lithium-ion batteries. ACS Nano 2012, 6, 7867–7878. [Google Scholar] [CrossRef]

- Otsuji, T.; Tombet, S.A.B.; Satou, A.; Fukidome, H.; Suemitsu, M.; Sano, E.; Popov, V.; Ryzhii, M.; Ryzhii, V. Graphene-based devices in terahertz science and technology. J. Phys. D. 2012, 45, 303001. [Google Scholar] [CrossRef]

- Wu, H.Q.; Linghu, C.Y.; Lu, H.M.; Qian, H. Graphene applications in electronic and optoelectronic devices and circuits. Chin. Phys. B 2013, 22, 098106. [Google Scholar] [CrossRef]

- Jang, S.; Hwang, E.; Lee, Y.; Lee, S.; Cho, J.H. Multifunctional graphene optoelectronic devices capable of detecting and storing photonic signals. Nano Lett. 2015, 15, 2542–2547. [Google Scholar] [CrossRef]

- Zhang, C.; Xie, Y.; Deng, H.; Tumlin, T.; Zhang, C.; Su, J.-W.; Yu, P.; Lin, J. Monolithic and Flexible ZnS/SnO2 Ultraviolet Photodetectors with Lateral Graphene Electrodes. Small 2017, 13, 1604197. [Google Scholar] [CrossRef]

- Liu, C.H.; Chang, Y.C.; Norris, T.B.; Zhong, Z. Graphene photodetectors with ultra-broadband and high responsivity at room temperature. Nat. Nanotechnol. 2014, 9, 273–278. [Google Scholar] [CrossRef]

- Larki, F.; Abdi, Y.; Kameli, P.; Salamati, H. An effort towards full graphene photodetectors. Photonic Sens. 2022, 12, 1–37. [Google Scholar]

- Jayasena, B.; Subbiah, S. A novel mechanical cleavage method for synthesizing few-layer graphenes. Nanoscale Res. Lett. 2011, 6, 95. [Google Scholar] [CrossRef]

- Annett, J.; Cross, G.L. Self-assembly of graphene ribbons by spontaneous self-tearing and peeling from a substrate. Nature 2016, 535, 271–275. [Google Scholar] [CrossRef]

- Yi, M.; Shen, Z. A review on mechanical exfoliation for the scalable production of graphene. J. Mater. Chem. A 2015, 3, 11700–11715. [Google Scholar] [CrossRef]

- Dash, P.; Dash, T.; Rout, T.K.; Sahu, A.K.; Biswal, S.K.; Mishra, B.K. Preparation of graphene oxide by dry planetary ball milling process from natural graphite. RSC Adv. 2016, 6, 12657–12668. [Google Scholar] [CrossRef]

- Campos-Delgado, J.; Botello-Méndez, A.R.; Algara-Siller, G.; Hackens, B.; Pardoen, T.; Kaiser, U.; Dresselhaus, M.S.; Charlier, J.C.; Raskin, J.P. CVD synthesis of mono-and few-layer graphene using alcohols at low hydrogen concentration and atmospheric pressure. Chem. Phys. Lett. 2013, 584, 142–146. [Google Scholar] [CrossRef]

- Min, B.H.; Kim, D.W.; Kim, K.H.; Choi, H.O.; Jang, S.W.; Jung, H.T. Bulk scale growth of CVD graphene on Ni nanowire foams for a highly dense and elastic 3D conducting electrode. Carbon 2014, 80, 446–452. [Google Scholar] [CrossRef]

- Kataria, S.; Wagner, S.; Ruhkopf, J.; Gahoi, A.; Pandey, H.; Bornemann, R.; Vaziri, S.; Smith, A.D.; Ostling, M.; Lemme, M.C. Chemical vapor deposited graphene: From synthesis to applications. Phys. Status Solidi A 2014, 211, 2439–2449. [Google Scholar] [CrossRef]

- Mishra, N.; Boeckl, J.; Motta, N.; Iacopi, F. Graphene growth on silicon carbide: A review. Phys. Status Solidi A 2016, 213, 2277–2289. [Google Scholar] [CrossRef]

- Tetlow, H.; De Boer, J.P.; Ford, I.J.; Vvedensky, D.D.; Coraux, J.; Kantorovich, L. Growth of epitaxial graphene: Theory and experiment. Phys. Rep. 2014, 542, 195–295. [Google Scholar] [CrossRef]

- Yang, W.; Chen, G.; Shi, Z.; Liu, C.C.; Zhang, L.; Xie, G.; Cheng, M.; Wang, D.; Yang, R.; Shi, D.; et al. Epitaxial growth of single-domain graphene on hexagonal boron nitride. Nat. Mater. 2013, 12, 792–797. [Google Scholar] [CrossRef]

- Lin, J.; Peng, Z.; Liu, Y.; Ruiz-Zepeda, F.; Ye, R.; Samuel, E.L.; Yacaman, M.J.; Yakobson, B.O.; Tour, J.M. Laser-induced porous graphene films from commercial polymers. Nat. Commun. 2014, 5, 5714. [Google Scholar] [CrossRef]

- Huang, L.; Su, J.; Song, Y.; Ye, R. Laser-induced graphene: En route to smart sensing. Nano-Micro Lett. 2020, 12, 157. [Google Scholar] [CrossRef]

- Tiliakos, A.; Ceaus, C.; Iordache, S.M.; Vasile, E.; Stamatin, I. Morphic transitions of nanocarbons via laser pyrolysis of polyimide films. J. Anal. Appl. Pyrolysis 2016, 121, 275–286. [Google Scholar] [CrossRef]

- Carvalho, A.F.; Fernandes, A.J.; Leitão, C.; Deuermeier, J.; Marques, A.C.; Martins, R.; Fortunato, E.; Costa, F.M. Laser-induced graphene strain sensors produced by ultraviolet irradiation of polyimide. Adv. Funct. Mater. 2018, 28, 1805271. [Google Scholar] [CrossRef]

- Santos, N.F.; Pereira, S.O.; Moreira, A.; Girão, A.V.; Carvalho, A.F.; Fernandes, A.J.; Costa, F.M. IR and UV Laser-Induced Graphene: Application as Dopamine Electrochemical Sensors. Adv. Mater. Technol. 2021, 6, 2100007. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Z.; Bakhtiyari, A.N.; Zheng, H. A comparative study of laser-induced graphene by CO2 infrared laser and 355 nm ultraviolet (UV) laser. Micromachines 2020, 11, 1094. [Google Scholar] [CrossRef]

- Trusovas, R.; Ratautas, K.; Račiukaitis, G.; Barkauskas, J.; Stankevičienė, I.; Niaura, G.; Mažeikienė, R. Reduction of graphite oxide to graphene with laser irradiation. Carbon 2013, 52, 574–582. [Google Scholar] [CrossRef]

- Zhang, Z.; Song, M.; Hao, J.; Wu, K.; Li, C.; Hu, C. Visible light laser-induced graphene from phenolic resin: A new approach for directly writing graphene-based electrochemical devices on various substrates. Carbon 2018, 127, 287–296. [Google Scholar] [CrossRef]

- Cai, J.; Lv, C.; Watanabe, A. Cost-effective fabrication of high-performance flexible all-solid-state carbon micro-supercapacitors by blue-violet laser direct writing and further surface treatment. J. Mater. Chem. A 2016, 4, 1671–1679. [Google Scholar] [CrossRef]

- Fiodorov, V.; Ratautas, K.; Mockus, Z.; Trusovas, R.; Mikoliūnaitė, L.; Račiukaitis, G. Laser-assisted selective fabrication of copper traces on polymers by electroplating. Polymers 2022, 14, 781. [Google Scholar] [CrossRef] [PubMed]

- Peng, Z.; Lin, J.; Ye, R.; Samuel, E.L.; Tour, J.M. Flexible and stackable laser-induced graphene supercapacitors. ACS Appl. Mater. Interfaces 2015, 7, 3414–3419. [Google Scholar] [CrossRef] [PubMed]

- Stanford, M.G.; Yang, K.; Chyan, Y.; Kittrell, C.; Tour, J.M. Laser-induced graphene for flexible and embeddable gas sensors. ACS Nano 2019, 13, 3474–3482. [Google Scholar] [CrossRef]

- Varghese, S.S.; Lonkar, S.; Singh, K.K.; Swaminathan, S.; Abdala, A. Recent advances in graphene-based gas sensors. Sens. Actuators B Chem. 2015, 218, 160–183. [Google Scholar] [CrossRef]

- Cruz-Martínez, H.; Rojas-Chávez, H.; Montejo-Alvaro, F.; Peña-Castañeda, Y.A.; Matadamas-Ortiz, P.T.; Medina, D.I. Recent developments in graphene-based toxic gas sensors: A theoretical overview. Sensors 2021, 21, 1992. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.H.; Lee, J.; Byeon, M.; Hong, T.E.; Park, H.; Lee, C.Y. Graphene-based gas sensors with high sensitivity and minimal sensor-to-sensor variation. ACS Appl. Nano Mater. 2020, 3, 2257–2265. [Google Scholar] [CrossRef]

- Trusovas, R.; Raciukaitis, G.; Barkauskas, J.; Mazeikiene, R. Laser-induced graphite oxide/graphene transformation. J. Laser Micro Nanoeng. 2012, 7, 49. [Google Scholar] [CrossRef]

- Ye, R.; Chyan, Y.; Zhang, J.; Li, Y.; Han, X.; Kittrell, C.; Tour, J.M. Laser-induced graphene formation on wood. Adv. Mater. 2017, 29, 1702211. [Google Scholar] [CrossRef] [PubMed]

- Nosrati, H.; Sarraf-Mamoory, R.; Karimi Behnagh, A.; Zolfaghari Emameh, R.; Aidun, A.; Le, D.Q.S.; Perez, M.C.; Bünger, C.E. Comparison of the effect of argon, hydrogen, and nitrogen gases on the reduced graphene oxide-hydroxyapatite nanocomposites characteristics. BMC Chem. 2020, 14, 59. [Google Scholar] [CrossRef]

- Graf, D.; Molitor, F.; Ensslin, K.; Stampfer, C.; Jungen, A.; Hierold, C.; Wirtz, L. Raman mapping of a single-layer to double-layer graphene transition. Eur. Phys. J. Spec. Top. 2007, 148, 171–176. [Google Scholar] [CrossRef][Green Version]

- Ohring, M. Engineering Materials Science; Elsevier: Amsterdam, The Netherlands, 1995; 561p. [Google Scholar]

- Tous, L.; Russell, R.; Das, J.; Labie, R.; Ngamo, M.; Horzel, J.; Philipsen, H.; Sniekers, J.; Vandermissen, K.; van den Brekel, L.; et al. Large area copper plated silicon solar cell exceeding 19.5% efficiency. Energy Procedia 2012, 21, 58–65. [Google Scholar] [CrossRef]

- Noh, B.I.; Yoon, J.W.; Lee, B.Y.; Jung, S.B. Adhesion characteristics of Cu/Ni–Cr/polyimide flexible copper clad laminates according to Ni: Cr ratio and Cu electroplating layer thickness. J. Mater. Sci. Mater. Electron. 2009, 20, 885–890. [Google Scholar] [CrossRef]

- Xu, X.; Xie, D.; Huang, J.; Liu, K.; He, G.; Zhang, Y.; Jiang, P.; Tang, L.; Wu, W. Influence of Pretreatment Processes on Adhesion of Ni/Cu/Ni Multilayer on Polyetherimide Resin Reinforced with Glass Fibers. Metals 2022, 12, 1359. [Google Scholar] [CrossRef]

| Wavelength, nm | Irradiation Dose, J/cm2 | Sheet Resistance, Ω | Adhesion | I(D)/I(G) | I(2D)/I(G) |

|---|---|---|---|---|---|

| 355 | 7.5 | 18 | Strong | 1.05 | 0.5 |

| 532 | 6.8 | 13 | Strong | 0.92 | 0.65 |

| 1064 | 7.3 | 8 | Weak | 0.57 | 0.58 |

| 10,600 | 8.6 | 7 | Weak | 0.57 | 0.63 |

| 1064, in the nitrogen atmosphere | 7.3 | 5 | Weak | 0.46 | 0.81 |

| 1064, in the nitrogen atmosphere | 7.8 | 5 | Weak | 0.37 | 0.72 |

| Metal | Solution | Current Density, mA/cm2 | Plating Speed, µm/min |

|---|---|---|---|

| Cu | H2SO4 50 g/L, CuSO4 ·H2O 200 g/L | 20 | 0.44 |

| Ni | NiSO4·7H2O 250 g/L, NiCl2·6H2O 45 g/L, H3BO3 38 g/L | 20 | 0.41 |

| Ag | Commercial cyanide bath | 4 | 0.256 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fiodorov, V.; Trusovas, R.; Mockus, Z.; Ratautas, K.; Račiukaitis, G. Laser-Induced Graphene Formation on Polyimide Using UV to Mid-Infrared Laser Radiation. Polymers 2023, 15, 4229. https://doi.org/10.3390/polym15214229

Fiodorov V, Trusovas R, Mockus Z, Ratautas K, Račiukaitis G. Laser-Induced Graphene Formation on Polyimide Using UV to Mid-Infrared Laser Radiation. Polymers. 2023; 15(21):4229. https://doi.org/10.3390/polym15214229

Chicago/Turabian StyleFiodorov, Vitalij, Romualdas Trusovas, Zenius Mockus, Karolis Ratautas, and Gediminas Račiukaitis. 2023. "Laser-Induced Graphene Formation on Polyimide Using UV to Mid-Infrared Laser Radiation" Polymers 15, no. 21: 4229. https://doi.org/10.3390/polym15214229

APA StyleFiodorov, V., Trusovas, R., Mockus, Z., Ratautas, K., & Račiukaitis, G. (2023). Laser-Induced Graphene Formation on Polyimide Using UV to Mid-Infrared Laser Radiation. Polymers, 15(21), 4229. https://doi.org/10.3390/polym15214229