Recent Development in the Processing, Properties, and Applications of Epoxy-Based Natural Fiber Polymer Biocomposites

Abstract

:1. Introduction

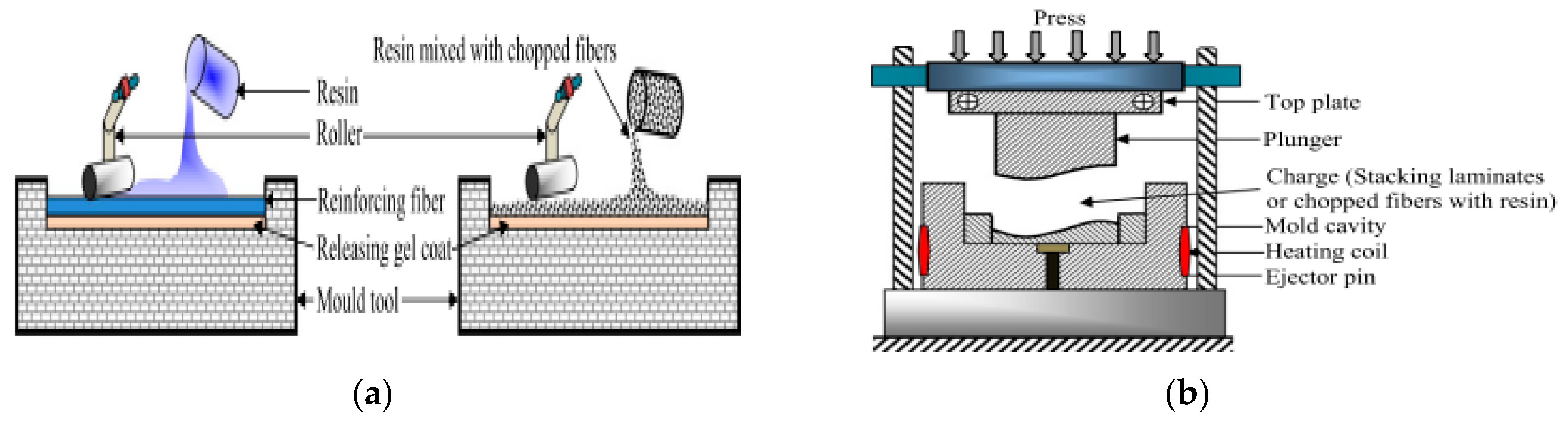

2. Processing of Epoxy-Based Natural Fiber Polymer Composite Materials

3. Mechanical Properties of Epoxy-Based Natural Fiber Biocomposite Materials

3.1. Tensile Properties

3.2. Flexural Properties

3.3. Impact Properties

3.4. Hardness Properties

4. Physical Properties of Epoxy-Based Natural Fiber Polymer Composite Materials

4.1. Water Absorption

4.2. Density

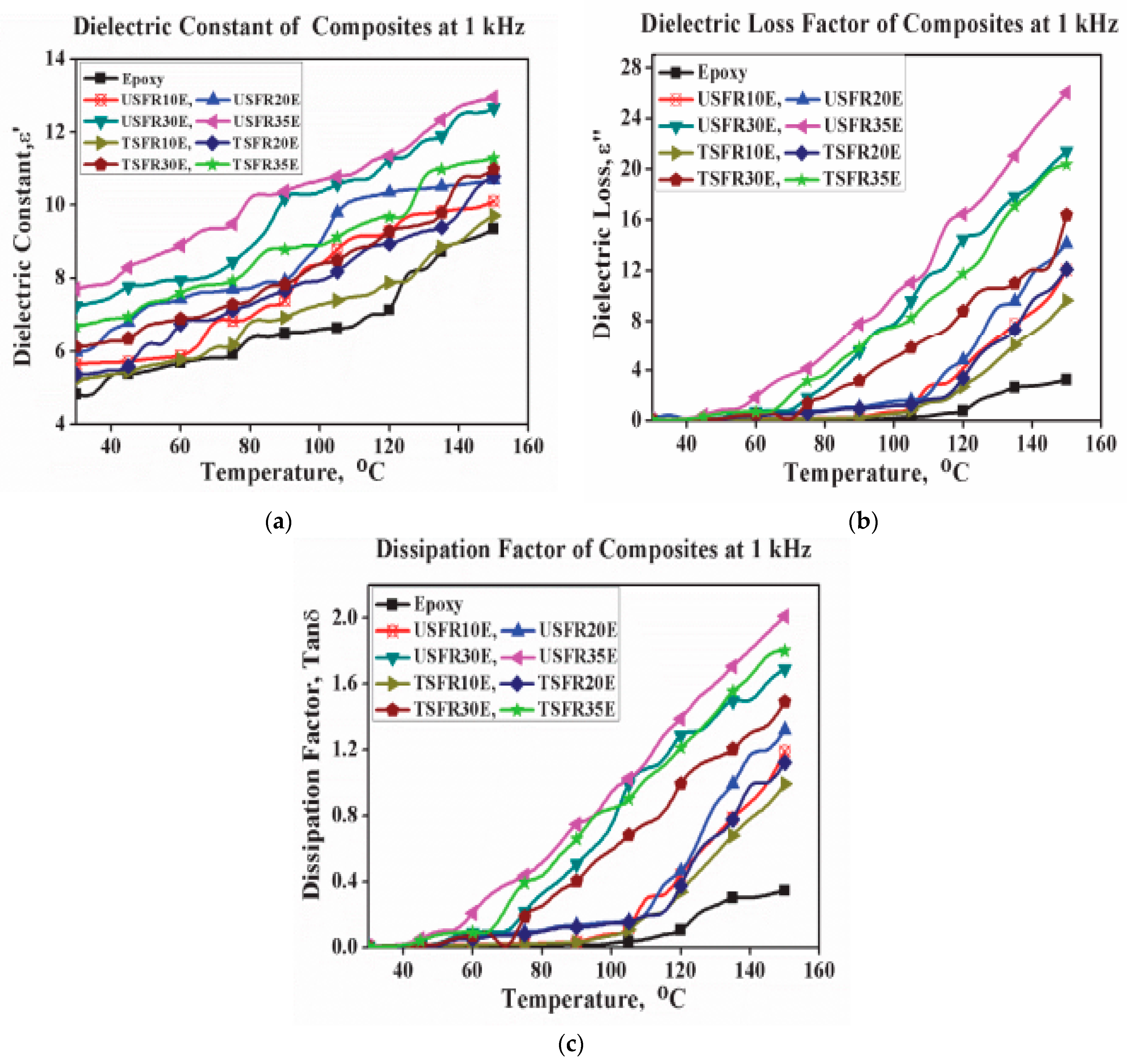

5. Electrical Properties of Epoxy-Based Natural Fiber Polymer Biocomposite Materials

5.1. Dielectric Properties of Epoxy-Based Natural Fiber Biocomposites

5.2. Electrical Conductivity of Epoxy Natural Fiber Biocomposites

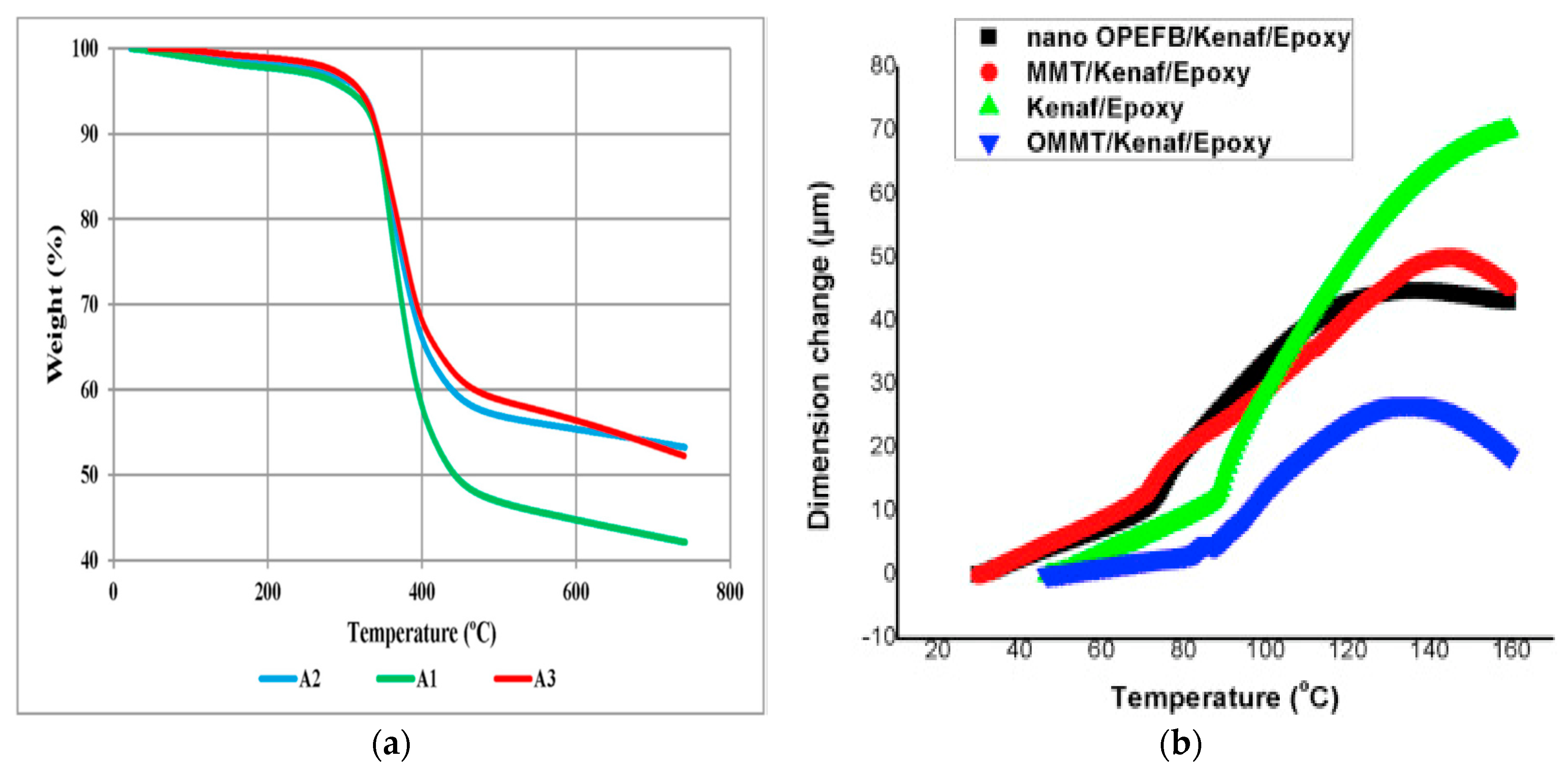

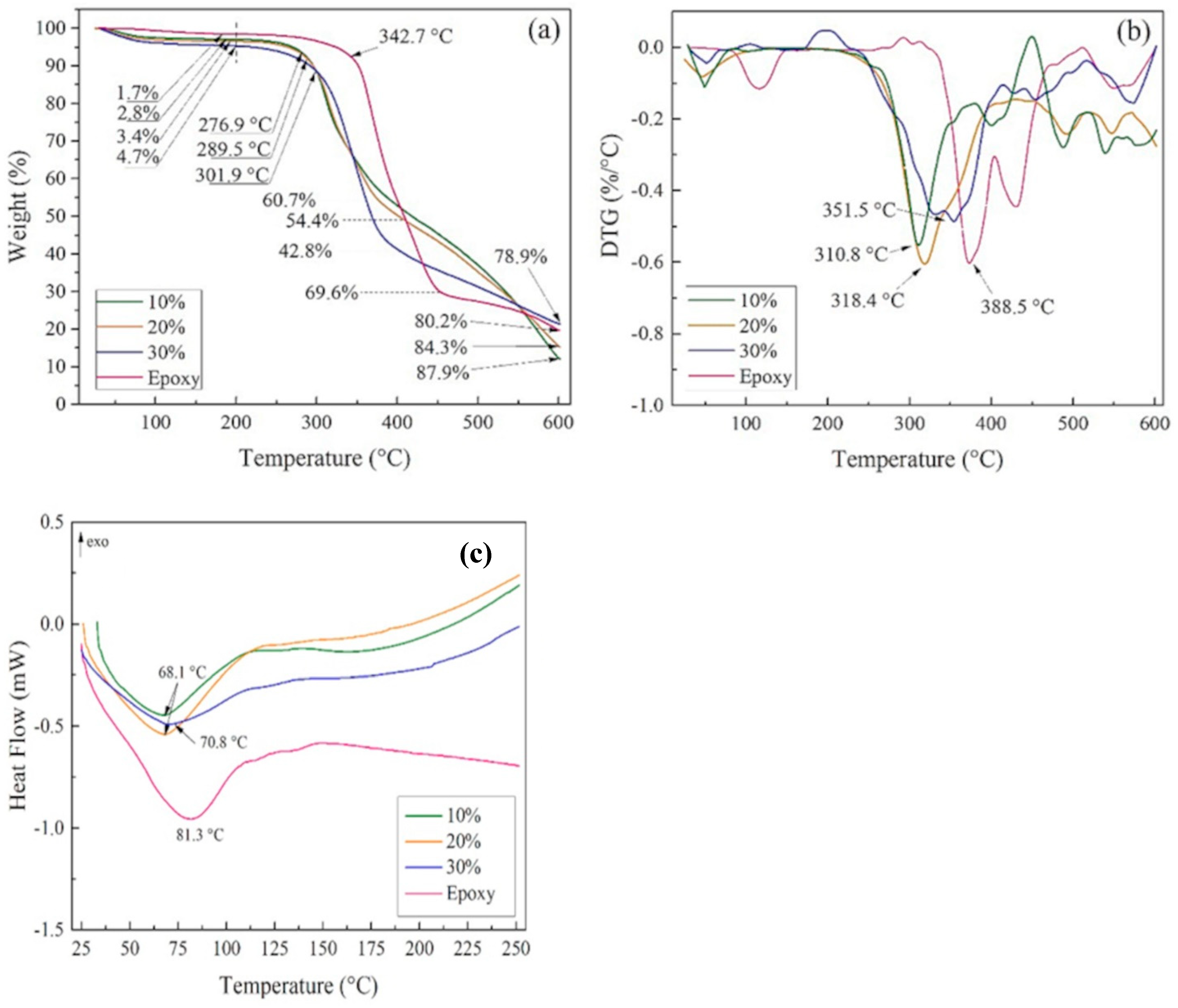

6. Thermal Properties of Epoxy-Based Natural Fiber Biocomposites

7. Characterization of Epoxy-Based Natural Fiber Polymer Composites

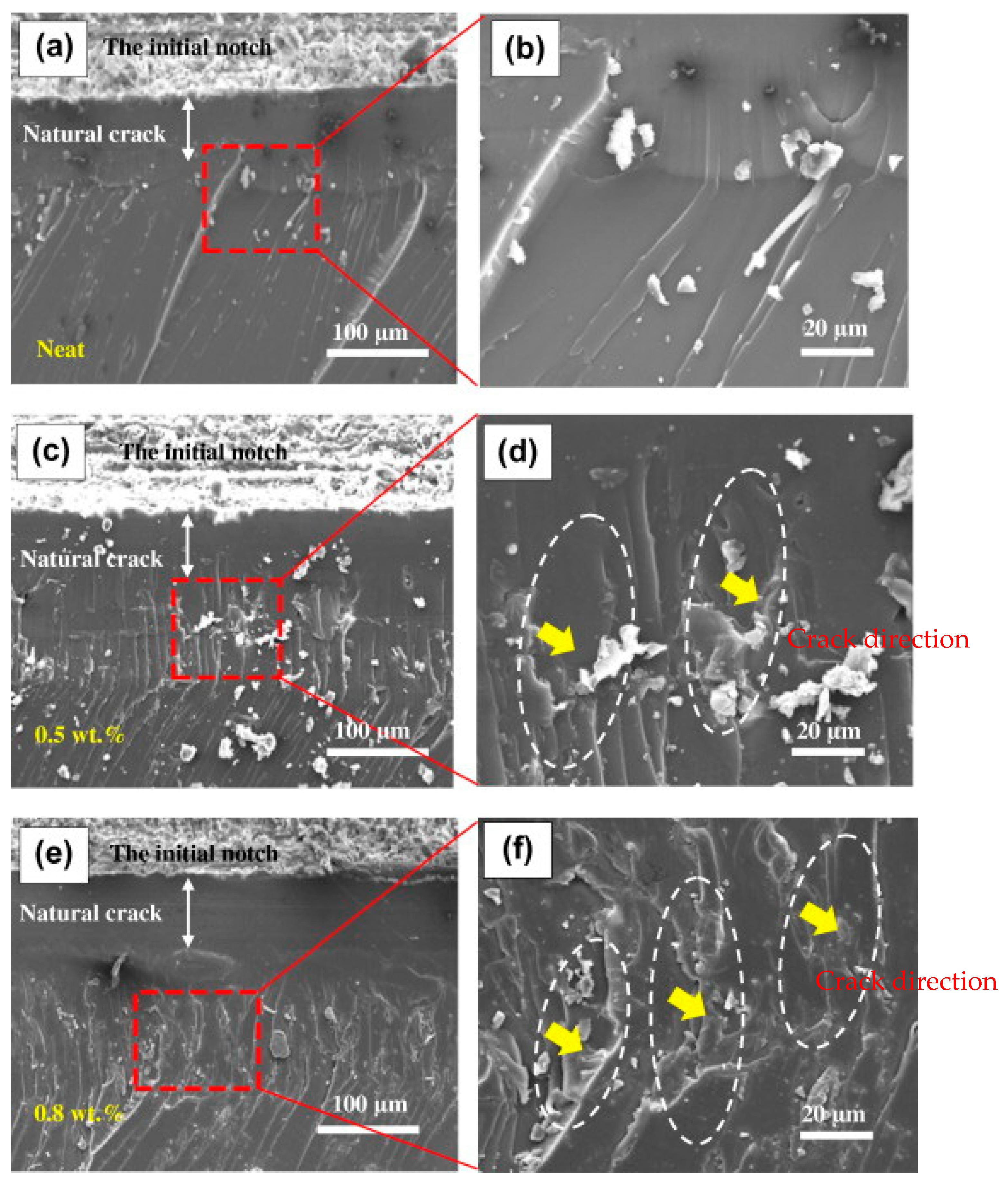

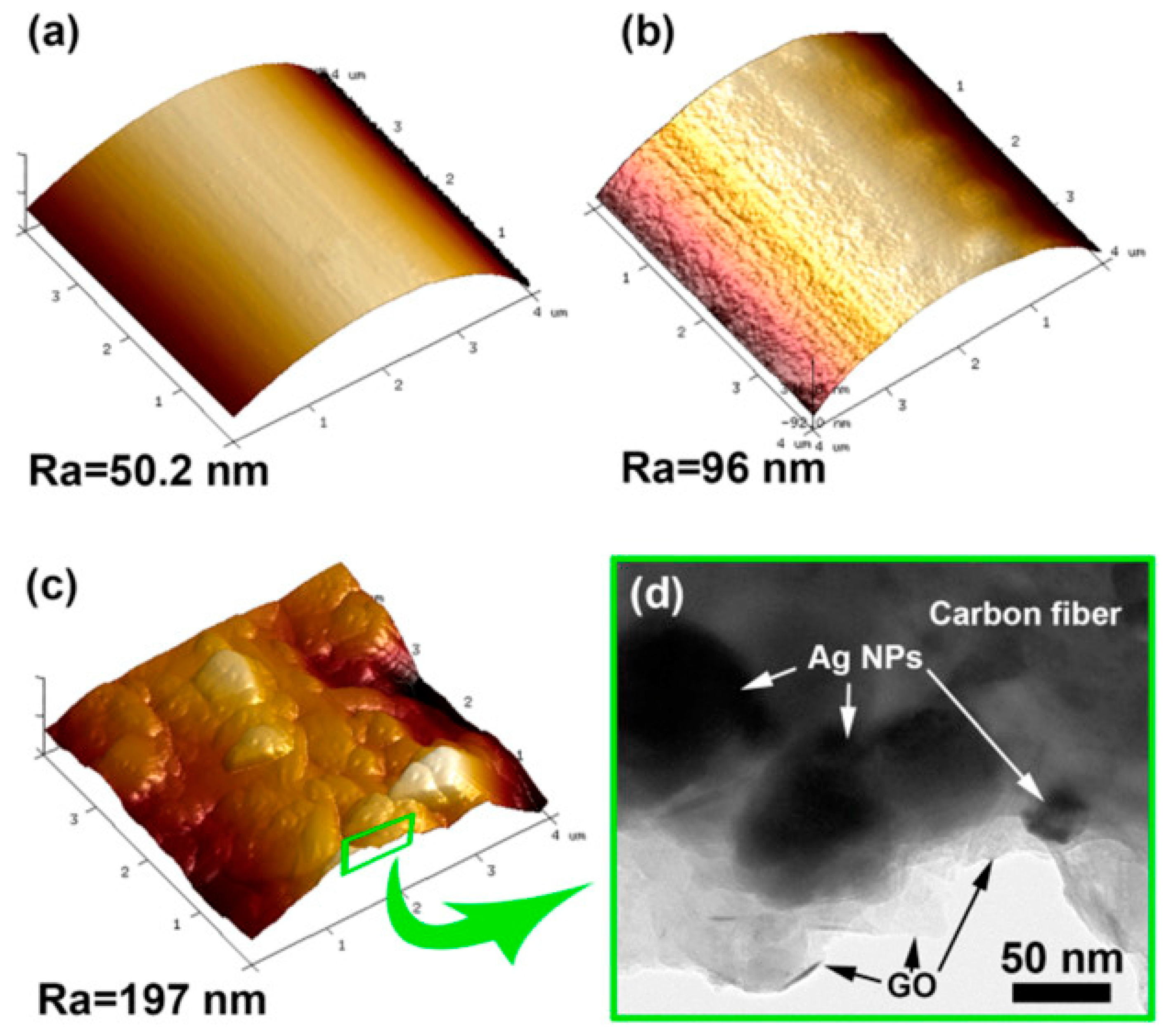

7.1. Microscopic Techniques

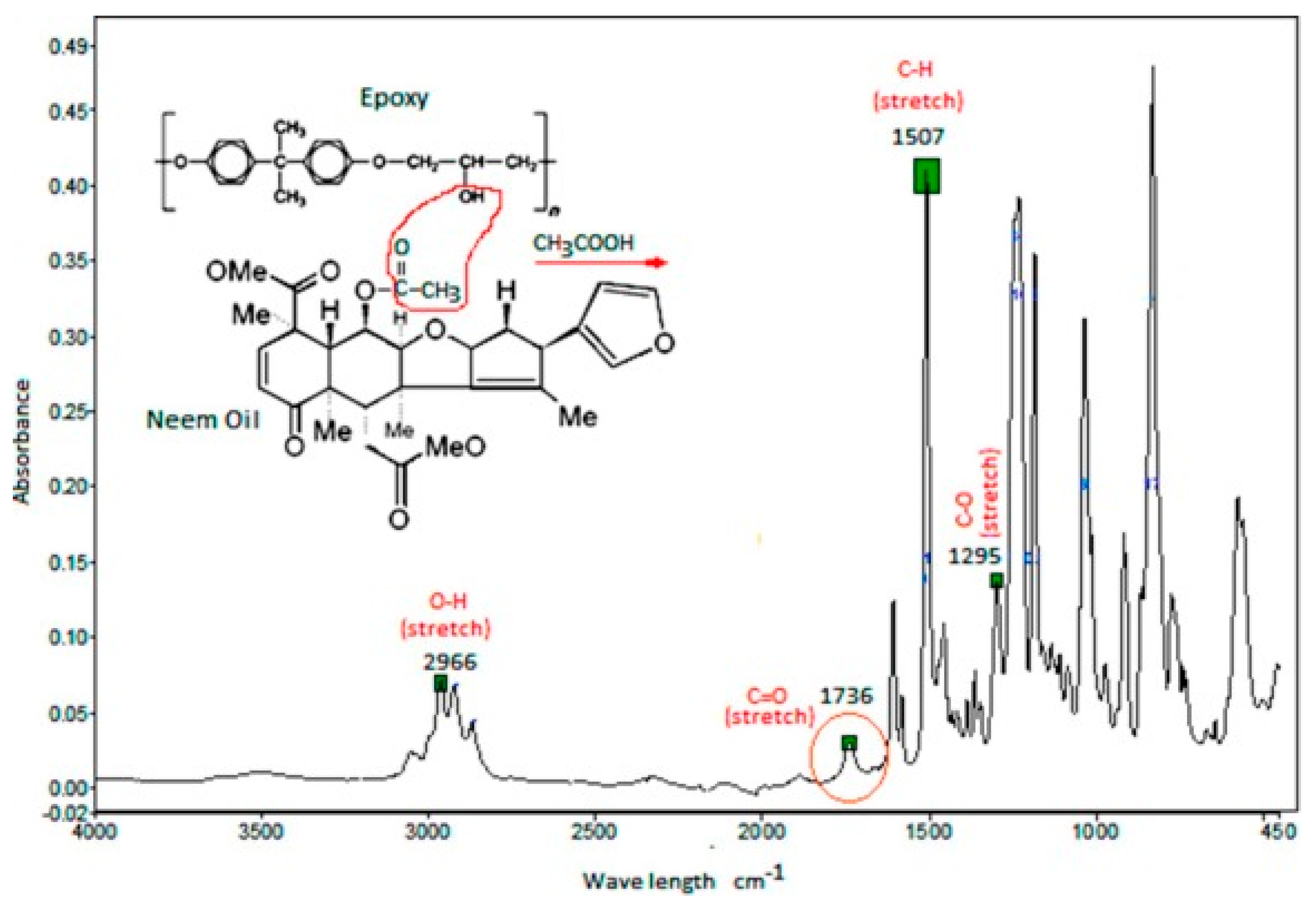

7.2. Fourier Transform Infrared (FTIR)

7.3. X-ray Photoelectron Spectroscopy (XPS)

7.4. Nuclear Magnetic Resonance (NMR)

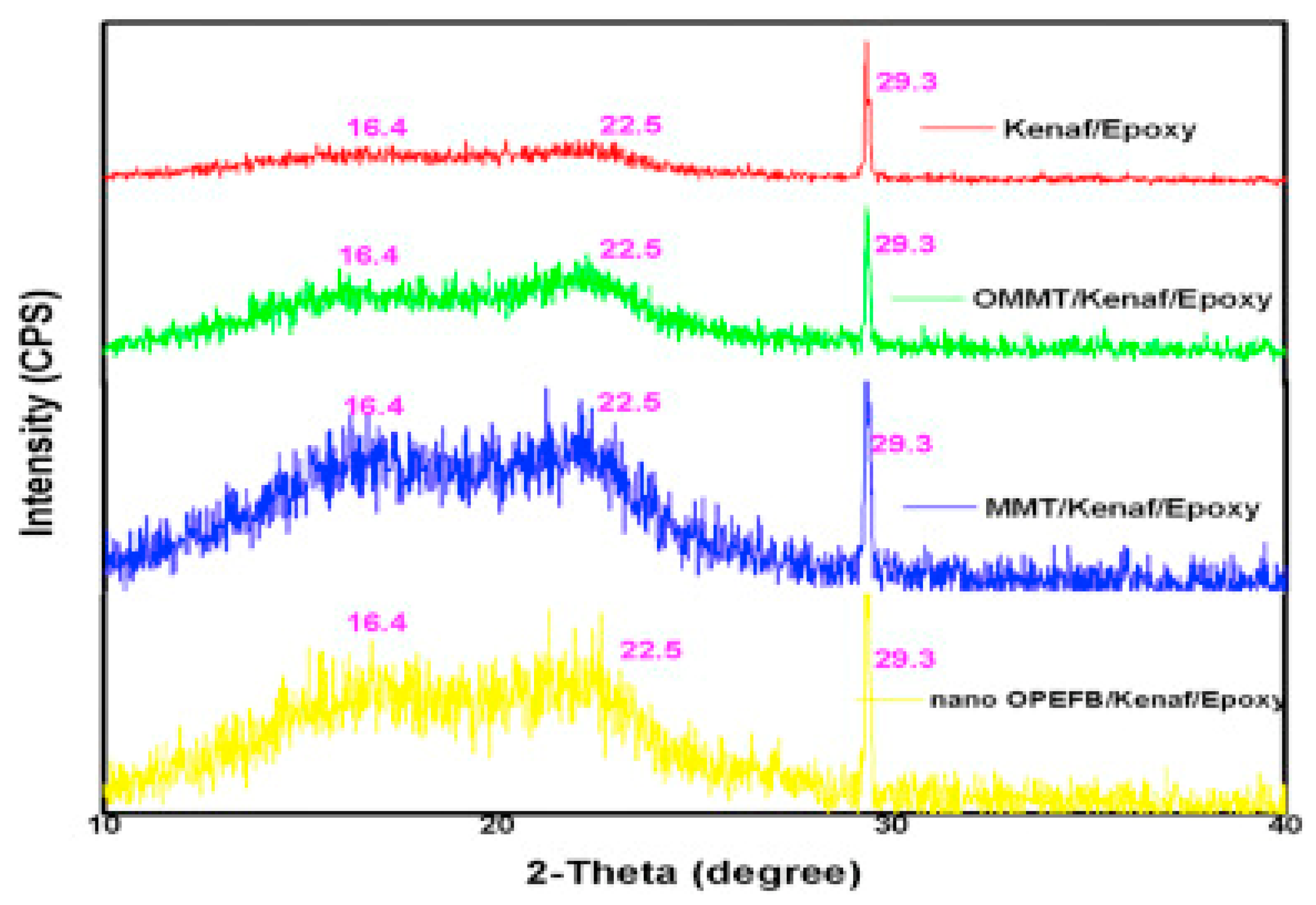

7.5. X-ray Diffraction

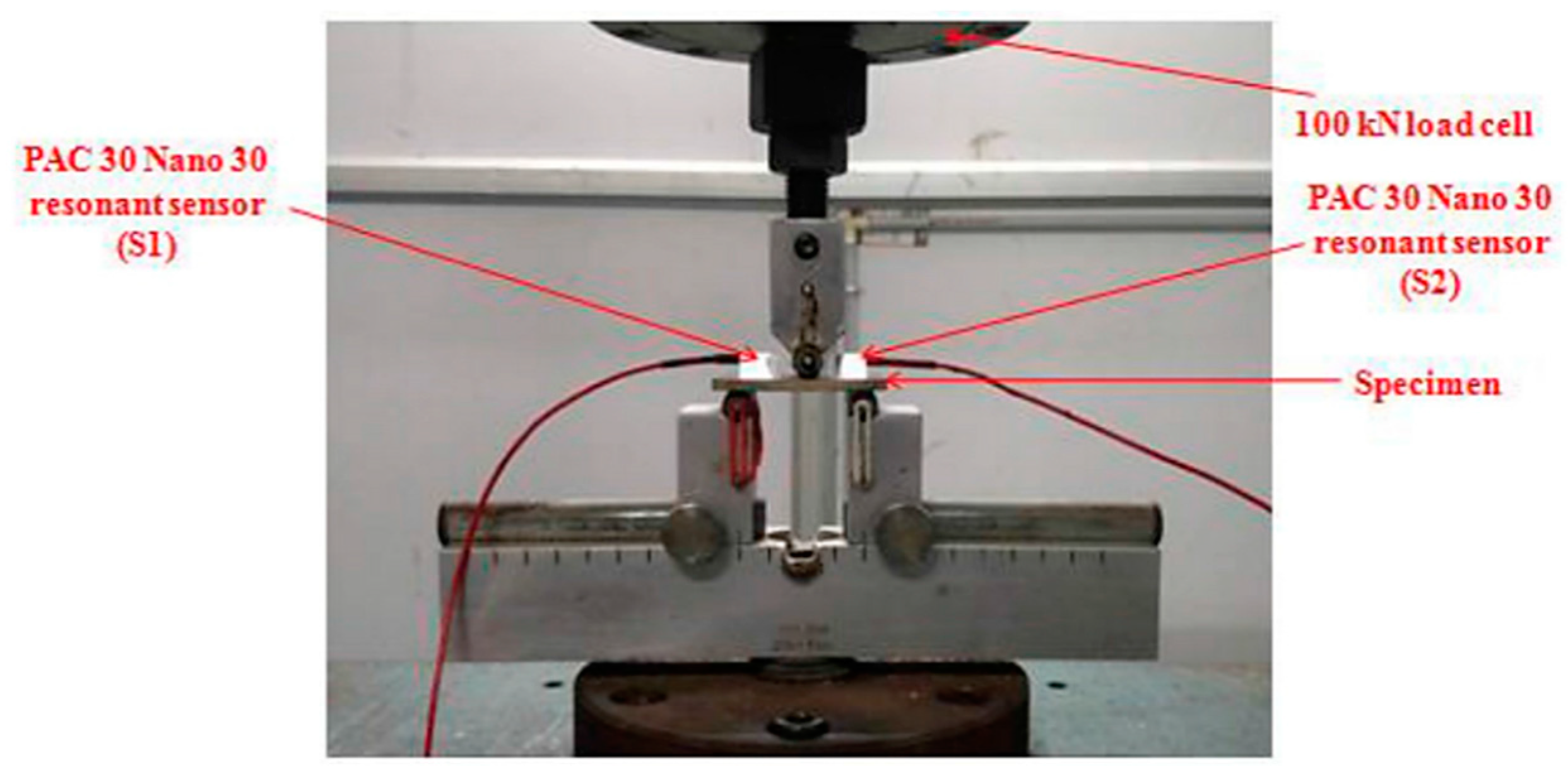

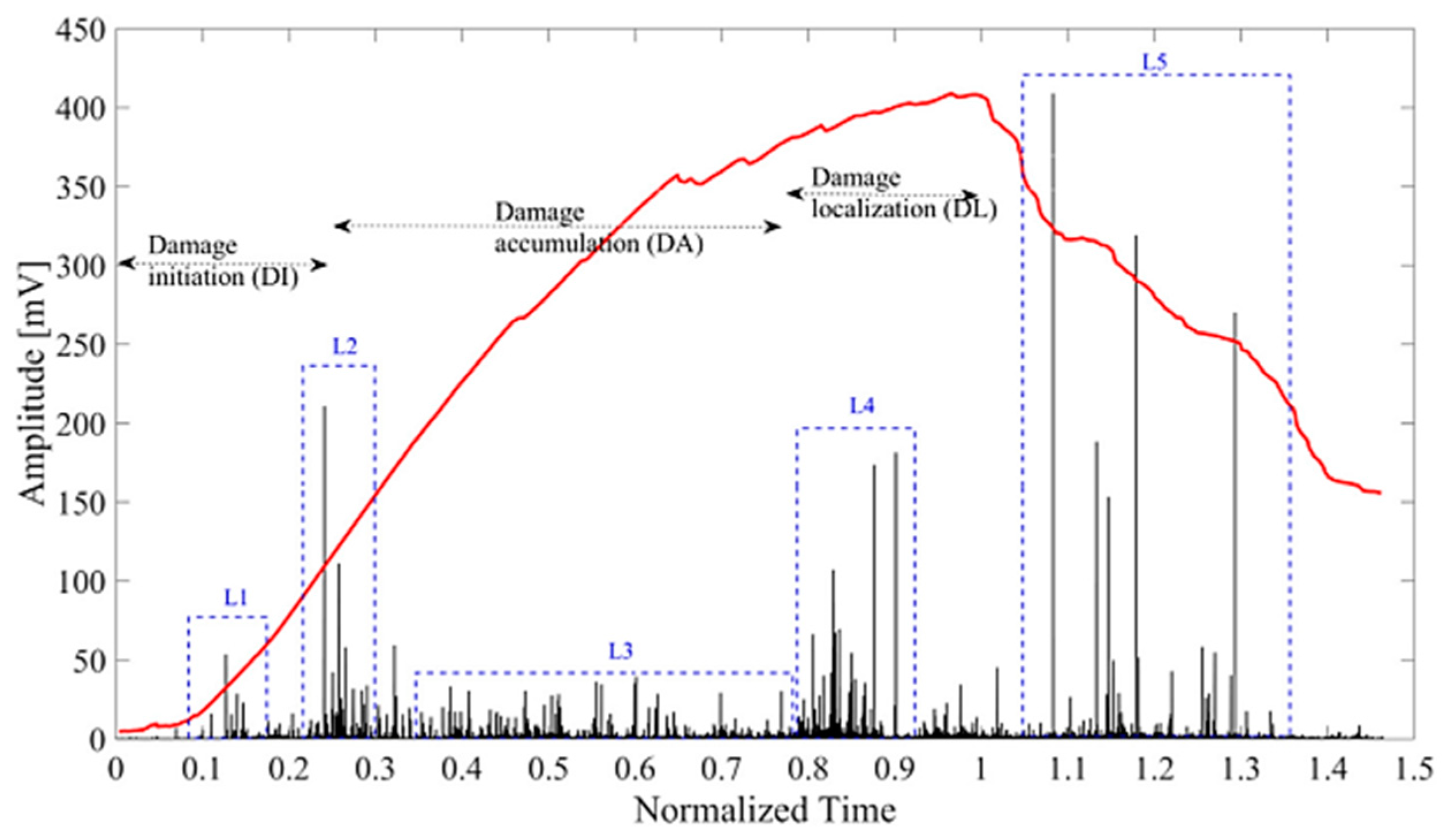

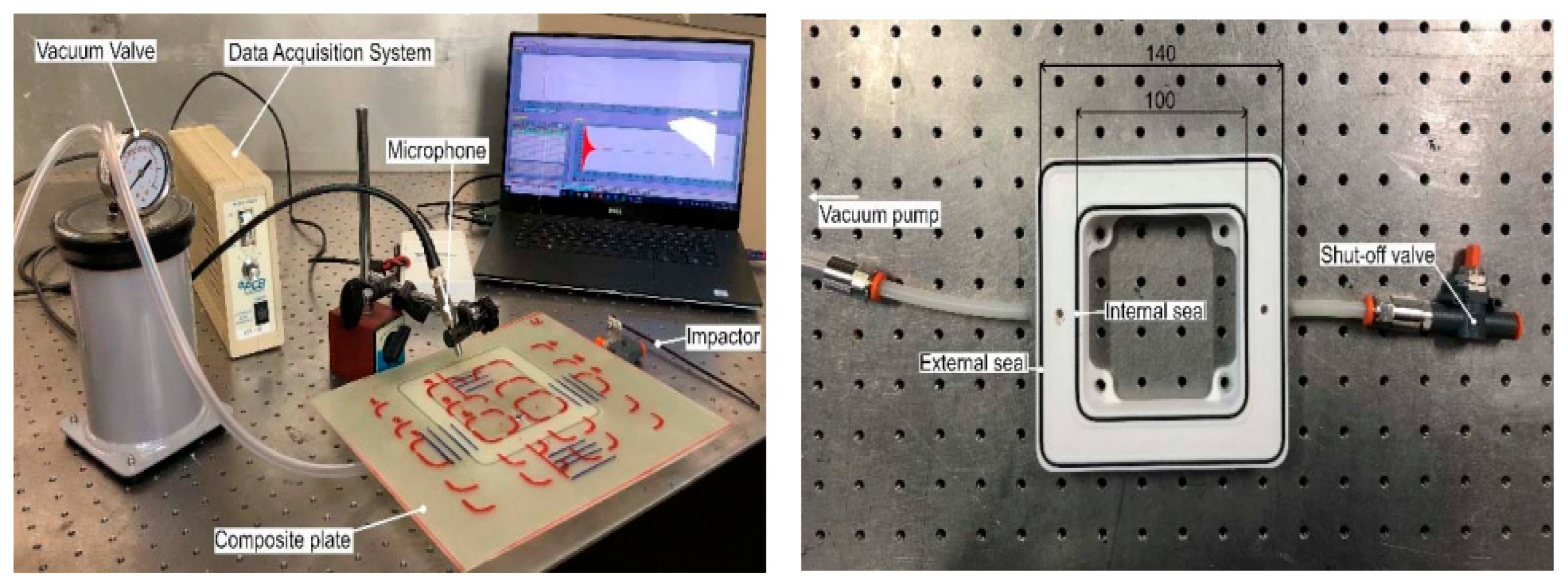

8. Application of Non-Destructive Testing in Epoxy-Based Natural Fiber Polymer Composites

Biodegradability Studies of Epoxy-Based Natural Fiber Polymer Composite Materials

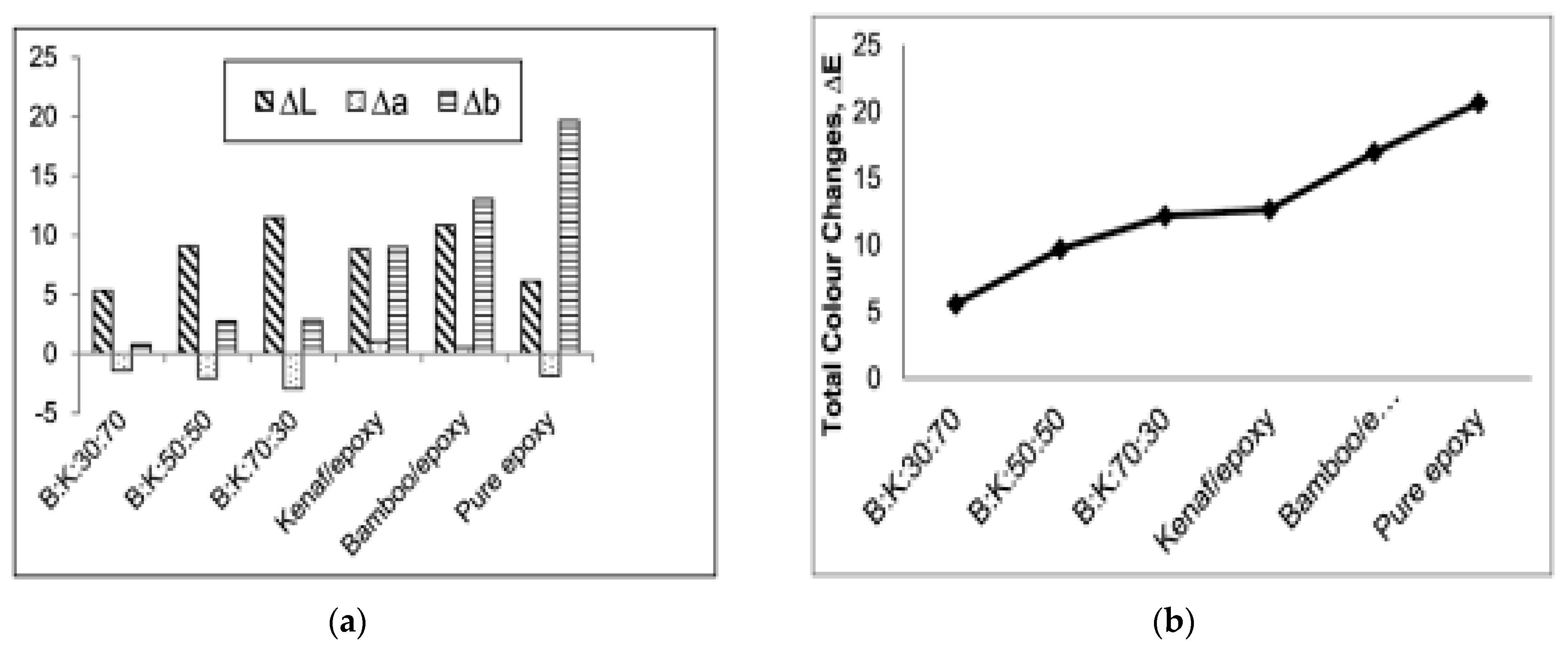

9. Accelerated Weathering Test

Soil Burial Biodegradability Test

10. Application of Epoxy-Based Natural Fibers Biocomposite Materials

11. Future Directions

12. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sanjay, M.R.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Pruncu, C.I.; Khan, A. A Comprehensive Review of Techniques for Natural Fibers as Reinforcement in Composites: Preparation, Processing and Characterization. Carbohydr. Polym. 2019, 207, 108–121. [Google Scholar] [CrossRef]

- Alotaibi, M.D.; Alshammari, B.A.; Saba, N.; Alothman, O.Y.; Sanjay, M.R.; Almutairi, Z.; Jawaid, M. Characterization of Natural Fiber Obtained from Different Parts of Date Palm Tree (Phoenix dactylifera L.). Int. J. Biol. Macromol. 2019, 135, 69–76. [Google Scholar] [CrossRef]

- Kerni, L.; Singh, S.; Patnaik, A.; Kumar, N. Materials Today: Proceedings A Review on Natural Fiber Reinforced Composites. Mater. Today Proc. 2020, 28, 1616–1621. [Google Scholar] [CrossRef]

- Daniyan, I.A.; Mpofu, K.; Adeodu, A.O.; Adesina, O. Development of Carbon Fibre Reinforced Polymer Matrix Composites and Optimization of the Process Parameters for Railcar Applications. Mater. Today Proc. 2021, 38, 628–634. [Google Scholar] [CrossRef]

- Uddin, M.F.; Sun, C.T. Improved Dispersion and Mechanical Properties of Hybrid Nanocomposites. Compos. Sci. Technol. 2010, 70, 223–230. [Google Scholar] [CrossRef]

- Zorko, D.; Tavčar, J.; Bizjak, M.; Šturm, R.; Bergant, Z. High Cycle Fatigue Behaviour of Autoclave-Cured Woven Carbon Fibre-Reinforced Polymer Composite Gears. Polym. Test. 2021, 102, 107339. [Google Scholar] [CrossRef]

- Lekrine, A.; Belaadi, A.; Makhlouf, A.; Amroune, S.; Bourchak, M.; Satha, H.; Jawaid, M. Structural, thermal, mechanical and physical properties of Washingtonia filifera fibres reinforced thermoplastic biocomposites. Mater. Today Commun. 2022, 31, 103574. [Google Scholar] [CrossRef]

- Helaili, S.; Chafra, M.; Chevalier, Y. Natural Fiber Alfa/Epoxy Randomly Reinforced Composite Mechanical Properties Identification. Structures 2021, 34, 542–549. [Google Scholar] [CrossRef]

- Reddy, B.M.; Reddy, P.V.; Reddy, Y.V.M.; Reddy, R.M. Mechanical, Thermal and Morphological Properties of Raw Cordia Dichotoma Fiber Reinforced Epoxy Composites. Curr. Res. Green Sustain. Chem. 2022, 5, 100264. [Google Scholar] [CrossRef]

- Jawaid, M.; Awad, S.; Fouad, H.; Asim, M.; Saba, N.; Dhakal, H.N. Improvements in the Thermal Behaviour of Date Palm/Bamboo Fibres Reinforced Epoxy Hybrid Composites. Compos. Struct. 2021, 277, 114644. [Google Scholar] [CrossRef]

- Ranjan, C.; Ahmed, Z.; Kumar, S.R.; Kumar, A.; Kumar, A.; Kumar, K. Fabrication and Strength Analysis of Rice Straw Fibers Reinforced Epoxy Biodegradable Composite. Mater. Today Proc. 2021, 46, 331–335. [Google Scholar] [CrossRef]

- Ranjan, C.; Ahmed, Z.; Kumar, S.R.; Kumar, A.; Kumar, A.; Kumar, K. Experimental Investigation and Comparative Analysis of Mechanical Properties of Cross Layer Rice Straw Fibers Filled Reinforced Epoxy Biodegradable Composite. Mater. Today Proc. 2021, 46, 340–344. [Google Scholar] [CrossRef]

- John, M.J.; Thomas, S. Biofibres and Biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Hinrichsen, G. Biofibres, Biodegradable Polymers and Biocomposites: An Overview. Macromol. Mater. Eng. 2000, 276–277, 1–24. [Google Scholar] [CrossRef]

- Khare, J.M.; Dahiya, S.; Gangil, B.; Ranakoti, L.; Sharma, S.; Huzaifah, M.R.M.; Ilyas, R.A.; Dwivedi, S.P.; Chattopadhyaya, S.; Kilinc, H.C.; et al. Comparative Analysis of Erosive Wear Behaviour of Epoxy, Polyester and Vinyl Esters Based Thermosetting Polymer Composites for Human Prosthetic Applications Using Taguchi Design. Polymers 2021, 13, 3607. [Google Scholar] [CrossRef]

- Kumar, S.; Somashekhar, H.; Hiremath, S. Natural Fiber Reinforced Composites in the Context of Biodegradability: A Review; Elsevier Ltd.: Amsterdam, The Netherlands, 2020; Volume 322. [Google Scholar] [CrossRef]

- Sathish, S.; Karthi, N.; Prabhu, L.; Gokulkumar, S.; Balaji, D.; Vigneshkumar, N.; Ajeem Farhan, T.S.; Akilkumar, A.; Dinesh, V.P. A Review of Natural Fiber Composites: Extraction Methods, Chemical Treatments and Applications. Mater. Today Proc. 2021, 45, 8017–8023. [Google Scholar] [CrossRef]

- Prabhu, L.; Krishnaraj, V.; Sathish, S.; Gokulkumar, S.; Karthi, N.; Rajeshkumar, L.; Balaji, D.; Vigneshkumar, N.; Elango, K.S. A Review on Natural Fiber Reinforced Hybrid Composites: Chemical Treatments, Manufacturing Methods and Potential Applications. Mater. Today Proc. 2021, 45, 8080–8085. [Google Scholar] [CrossRef]

- Zhang, K.; Weng, B.; Cheng, D.; Guo, Y.; Chen, T.; Wang, L.; Wang, C.; Xu, R.; Chen, Y. Influence of Chemical Treatment and Drying Method on the Properties of Cellulose Fibers of Luffa Sponge. Int. J. Biol. Macromol. 2021, 180, 112–120. [Google Scholar] [CrossRef]

- Mamidi, V.K.; Pugazhenthi, R.; Manikandan, G.; Vinoth Kumar, M. Mechanical and Microscopic Study on Tinospora Cordifolia and Tectona Grandis Composites. Mater. Today Proc. 2020, 22, 772–775. [Google Scholar] [CrossRef]

- Asim, M.; Jawaid, M.; Khan, A.; Asiri, A.M.; Malik, M.A. Effects of Date Palm Fibres Loading on Mechanical, and Thermal Properties of Date Palm Reinforced Phenolic Composites. J. Mater. Res. Technol. 2020, 9, 3614–3621. [Google Scholar] [CrossRef]

- Ramasamy, M.; Daniel, A.A.; Nithya, M.; Kumar, S.S.; Pugazhenthi, R. Characterization of Natural—Synthetic Fiber Reinforced Epoxy Based Composite—Hybridization of Kenaf Fiber and Kevlar Fiber. Mater. Today Proc. 2020, 37 Pt 2, 1699–1705. [Google Scholar] [CrossRef]

- Dinesh, S.; Kumaran, P.; Mohanamurugan, S.; Vijay, R.; Singaravelu, D.L.; Vinod, A.; Sanjay, M.R.; Siengchin, S.; Bhat, K.S. Influence of Wood Dust Fillers on the Mechanical, Thermal, Water Absorption and Biodegradation Characteristics of Jute Fiber Epoxy Composites. J. Polym. Res. 2020, 27, 9. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Barkhad, M.S.; Mourad, A.H.I.; Iqbal, M.Z. Date Palm Wood Waste-Based Composites for Green Thermal Insulation Boards. J. Build. Eng. 2021, 43, 103224. [Google Scholar] [CrossRef]

- Uflyand, I.; Irzhak, T.F.; Irzhak, V.I. Formation of Fiber Composites with an Epoxy Matrix: State-of-the-Art and Future Development. Mater. Manuf. Process. 2022, 37, 723–747. [Google Scholar] [CrossRef]

- Kumar, R.; Anand, A. Tribological Behavior of Natural Fiber Reinforced Epoxy Based Composites: A Review. Mater. Today Proc. 2019, 18, 3247–3251. [Google Scholar] [CrossRef]

- Torres-Arellano, M.; Renteria-Rodríguez, V.; Franco-Urquiza, E. Mechanical Properties of Natural-Fiber-Reinforced Biobased Epoxy Resins Manufactured by Resin Infusion Process. Polymers 2020, 12, 2841. [Google Scholar] [CrossRef]

- Ankit; Sharma, R.; Kumar Sharma, D.; Agarwal, R.; Lal Rinawa, M.; Subbiah, R.; Kumar, P.M. Investigating the Effect of Nanoclay Content on the Mechanical Characteristics of Natural Fiber Epoxy Composite. Mater. Today Proc. 2022, 66, 1319–1323. [Google Scholar] [CrossRef]

- Iliyasu, I.; Bitrus, J.; Nathaniel, A.; Adeniyi, K.; Oyewusi, E. Response Surface Methodology for the Optimization of the Effect of Fibre Parameters on the Physical and Mechanical Properties of Deleb Palm Fibre Reinforced Epoxy Composites. Sci. Afr. 2022, 16, e01269. [Google Scholar] [CrossRef]

- Ouchte, I.; Chafiq, J.; Ait El Fqih, M.; Chakir, H. Effect of Thermal Treatment on Mechanical Properties and Thermogravimetric Analysis of Laminate Composite Jute/Epoxy. Mater. Today Proc. 2022, 66, 135–139. [Google Scholar] [CrossRef]

- Saikumar Reddy, R.V.; Jeeru, L.R.; Venkateshwar Reddy, P.; Swamy, K. Mechanical Properties Evaluation of Pomegranate Peel Powder Filled Jute Fiber Reinforced Epoxy Composites. Mater. Today Proc. 2022, 62 Pt 13, 6923–6926. [Google Scholar] [CrossRef]

- Nigrawal, A.; Kumar Sharma, A.; Haque, F.Z. Influence of Surface Modification Technique on the Properties of Jute—Sisal Fibre Filled Epoxy Composites. Mater. Today Proc. 2022, 65, 2578–2580. [Google Scholar] [CrossRef]

- Arumugam, H.; Krishnasamy, B.; Perumal, G.; A, A.D.; Abdul Aleem, M.I.; Muthukaruppan, A. Bio-Composites of Rice Husk and Saw Dust Reinforced Bio-Benzoxazine/Epoxy Hybridized Matrices: Thermal, Mechanical, Electrical Resistance and Acoustic Absorption Properties. Constr. Build. Mater. 2021, 312, 125381. [Google Scholar] [CrossRef]

- Prabhudass, J.M.; Palanikumar, K. Experimental Investigation of Mechanical and Thermal Properties of Coir-Kenaf Reinforced Epoxy Composites. Mater. Today Proc. 2021, 44, 3834–3837. [Google Scholar] [CrossRef]

- Kishore Chowdari, G.; Krishna Prasad, D.V.V.; Devireddy, S.B.R. Physical and Thermal Behaviour of Areca and Coconut Shell Powder Reinforced Epoxy Composites. Mater. Today Proc. 2019, 26, 1402–1405. [Google Scholar] [CrossRef]

- Kumar, V.; Kumar, R. Dielectric and Mechanical Properties of Alkali- and Silane-Treated Bamboo-Epoxy Nanocomposites. J. Compos. Mater. 2012, 46, 3089–3101. [Google Scholar] [CrossRef]

- Omri, M.A.; Sanjay, M.R.; Triki, A.; Yogesha, B.; Kallel, A. Dielectric Properties and Interfacial Adhesion of Jute, Kenaf and E-Glass Fabrics Reinforcing Epoxy Composites. Polym. Compos. 2019, 40, 2142–2153. [Google Scholar] [CrossRef]

- Sreekumar, P.A.; Saiter, J.M.; Joseph, K.; Unnikrishnan, G.; Thomas, S. Electrical Properties of Short Sisal Fiber Reinforced Polyester Composites Fabricated by Resin Transfer Molding. Compos. Part A Appl. Sci. Manuf. 2012, 43, 507–511. [Google Scholar] [CrossRef]

- Suriani, M.J.; Ilyas, R.A.; Zuhri, M.Y.M.; Khalina, A.; Sultan, M.T.H.; Sapuan, S.M.; Ruzaidi, C.M.; Wan, F.N.; Zulkifli, F.; Harussani, M.M.; et al. Critical Review of Natural Fiber Reinforced Hybrid Composites: Processing, Properties, Applications and Cost. Polymers 2021, 13, 3514. [Google Scholar] [CrossRef]

- Gayathri, N.; Shanmuganathan, V.K.; Joyson, A.; Aakash, M.; Joseph, A.G. Mechanical properties investigation on natural fiber reinforced epoxy polymer composite. Mater. Today Proc. In press. 2022. [Google Scholar] [CrossRef]

- Jin, F.L.; Park, S.J. Preparation and Characterization of Carbon Fiber-Reinforced Thermosetting Composites: A Review. Carbon Lett. 2015, 16, 67–77. [Google Scholar] [CrossRef] [Green Version]

- Arun Kumar, S.; Lakshamankumar, A.; Balasivaramareddy, K.; Ramprasath, B. Fabrication and Study on Carbon Fiber with Epoxy and Vinyl Ester Resins. IOP Conf. Ser. Mater. Sci. Eng. 2018, 402, 012160. [Google Scholar] [CrossRef]

- Patro, B.; Shashidhar, D.; Rajeshwer, B.; Padhi, S.K. Preparation and Testing of PAN Carbon/Epoxy Resin Composites. Open Mech. Eng. J. 2017, 11, 14–24. [Google Scholar] [CrossRef] [Green Version]

- Bazli, M.; Abolfazli, M. Mechanical Properties of Fibre Reinforced Polymers under Elevated Temperatures: An Overview. Polymers 2020, 12, 2600. [Google Scholar] [CrossRef]

- Chen, R.S.; Muhammad, Y.H.; Ahmad, S. Physical, Mechanical and Environmental Stress Cracking Characteristics of Epoxy/Glass Fiber Composites: Effect of Matrix/Fiber Modification and Fiber Loading. Polym. Test. 2021, 96, 107088. [Google Scholar] [CrossRef]

- Fu, Y.; Kabir, I.I.; Yeoh, G.H.; Peng, Z. A Review on Polymer-Based Materials for Underwater Sound Absorption. Polym. Test. 2021, 96, 107115. [Google Scholar] [CrossRef]

- Shaid Sujon, M.A.; Islam, A.; Nadimpalli, V.K. Damping and Sound Absorption Properties of Polymer Matrix Composites: A Review. Polym. Test. 2021, 104, 107388. [Google Scholar] [CrossRef]

- Gibeop, N.; Lee, D.W.; Prasad, C.V.; Toru, F.; Kim, B.S.; Song, J., II. Effect of Plasma Treatment on Mechanical Properties of Jute Fiber/Poly (Lactic Acid) Biodegradable Composites. Adv. Compos. Mater. 2013, 22, 389–399. [Google Scholar] [CrossRef]

- Ragoubi, M.; George, B.; Molina, S.; Bienaimé, D.; Merlin, A.; Hiver, J.M.; Dahoun, A. Effect of Corona Discharge Treatment on Mechanical and Thermal Properties of Composites Based on Miscanthus Fibres and Polylactic Acid or Polypropylene Matrix. Compos. Part A Appl. Sci. Manuf. 2012, 43, 675–685. [Google Scholar] [CrossRef]

- Jang, J.Y.; Jeong, T.K.; Oh, H.J.; Youn, J.R.; Song, Y.S. Thermal Stability and Flammability of Coconut Fiber Reinforced Poly(Lactic Acid) Composites. Compos. Part B Eng. 2012, 43, 2434–2438. [Google Scholar] [CrossRef]

- Werchefani, M.; Lacoste, C.; Elloumi, A.; Belghith, H.; Gargouri, A.; Bradai, C. Enzyme-Treated Tunisian Alfa Fibers Reinforced Polylactic Acid Composites: An Investigation in Morphological, Thermal, Mechanical, and Water Resistance Properties. Polym. Compos. 2020, 41, 1721–1735. [Google Scholar] [CrossRef]

- Kovačević, Z.; Bischof, S.; Vujasinović, E.; Fan, M. The Influence of Pre-Treatment of Spartium junceum L. Fibres on the Structure and Mechanical Properties of PLA Biocomposites. Arab. J. Chem. 2019, 12, 449–463. [Google Scholar] [CrossRef] [Green Version]

- Huang, X.; Netravali, A. Biodegradable Green Composites Made Using Bamboo Micro/Nano-Fibrils and Chemically Modified Soy Protein Resin. Compos. Sci. Technol. 2009, 69, 1009–1015. [Google Scholar] [CrossRef]

- Usman, M.A.; Momohjimoh, I.; Gimba, A.S.B. Effect of Groundnut Shell Powder on the Mechanical Properties of Recycled Polyethylene and Its Biodegradability. J. Miner. Mater. Charact. Eng. 2016, 4, 228–240. [Google Scholar] [CrossRef] [Green Version]

- Rajeshkumar, G.; Hariharan, V.; Indran, S.; Sanjay, M.R.; Siengchin, S.; Maran, J.P.; Al-Dhabi, N.A.; Karuppiah, P. Influence of Sodium Hydroxide (NaOH) Treatment on Mechanical Properties and Morphological Behaviour of Phoenix sp. Fiber/Epoxy Composites. J. Polym. Environ. 2021, 29, 765–774. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Krishnamurthy, K.; Rajeshkumar, G.; Asim, M. Dynamic Mechanical Properties and Free Vibration Characteristics of Surface Modified Jute Fiber/Nano-Clay Reinforced Epoxy Composites. J. Polym. Environ. 2021, 29, 1076–1088. [Google Scholar] [CrossRef]

- Senthamaraikannan, P.; Kathiresan, M. Characterization of Raw and Alkali Treated New Natural Cellulosic Fi Ber from Coccinia grandis L. Carbohydr. Polym. 2018, 186, 332–343. [Google Scholar] [CrossRef]

- Nik Baihaqi, N.M.Z.; Khalina, A.; Mohd Nurazzi, N.; Aisyah, H.A.; Sapuan, S.M.; Ilyas, R.A. Effect of Fiber Content and Their Hybridization on Bending and Torsional Strength of Hybrid Epoxy Composites Reinforced with Carbon and Sugar Palm Fibers. Polimery/Polymers 2021, 66, 36–43. [Google Scholar] [CrossRef]

- Safri, S.N.A.; Sultan, M.T.H.; Jawaid, M.; Abdul Majid, M.S. Analysis of Dynamic Mechanical, Low-Velocity Impact and Compression after Impact Behaviour of Benzoyl Treated Sugar Palm/Glass/Epoxy Composites. Compos. Struct. 2019, 226, 111308. [Google Scholar] [CrossRef]

- Aiza Jaafar, C.N.; Zainol, I.; Ishak, N.S.; Ilyas, R.A.; Sapuan, S.M. Effects of the Liquid Natural Rubber (LNR) on Mechanical Properties and Microstructure of Epoxy/Silica/Kenaf Hybrid Composite for Potential Automotive Applications. J. Mater. Res. Technol. 2021, 12, 1026–1038. [Google Scholar] [CrossRef]

- Chee, S.S.; Jawaid, M.; Alothman, O.Y.; Fouad, H. Effects of Nanoclay on Mechanical and Dynamic Mechanical Properties of Bamboo/Kenaf Reinforced Epoxy Hybrid Composites. Polymers 2021, 13, 395. [Google Scholar] [CrossRef]

- Hammami, H.; Jawaid, M.; Kallel, A. Effects of Oil Palm and Montmorillonite Nanofillers on Stiffness and Interfacial Adhesion of Kenaf/Epoxy Hybrid Nanocomposites. Polym. Compos. 2021, 42, 2948–2957. [Google Scholar] [CrossRef]

- Yahaya, R.; Sapuan, S.M.; Jawaid, M.; Leman, Z.; Zainudin, E.S. Mechanical Performance of Woven Kenaf-Kevlar Hybrid Composites. J. Reinf. Plast. Compos. 2014, 33, 2242–2254. [Google Scholar] [CrossRef]

- Ismail, A.S.; Jawaid, M.; Naveen, J. Void Content, Tensile, Vibration and Acoustic Properties of Kenaf/Bamboo Fiber Reinforced Epoxy Hybrid Composites. Materials 2019, 12, 2094. [Google Scholar] [CrossRef] [Green Version]

- Siregar, J.P.; Zalinawati, M.; Cionita, T.; Rejab, M.R.M.; Mawarnie, I.; Jaafar, J.; Hamdan, M.H.M. Mechanical Properties of Hybrid Sugar Palm/Ramie Fibre Reinforced Epoxy Composites. Mater. Today Proc. 2020, 46, 1729–1734. [Google Scholar] [CrossRef]

- Prabhu, L.; Krishnaraj, V.; Gokulkumar, S.; Sathish, S.; Sanjay, M.R.; Siengchin, S. Mechanical, Chemical and Sound Absorption Properties of Glass/Kenaf/Waste Tea Leaf Fiber-Reinforced Hybrid Epoxy Composites. J. Ind. Text. 2022, 51, 1674–1700. [Google Scholar] [CrossRef]

- Sakinah, F.; Suriani, M.J.; Ilyas, R.A.; Petru, M.; Sapuan, S.M. Flammability, Tensile, and Morphological Properties of Oil. Polymers 2021, 13, 1282. [Google Scholar]

- Osorio, L.; Trujillo, E.; Van Vuure, A.W.; Verpoest, I. Morphological Aspects and Mechanical Properties of Single Bamboo Fibers and Flexural Characterization of Bamboo/ Epoxy Composites. J. Reinf. Plast. Compos. 2011, 30, 396–408. [Google Scholar] [CrossRef]

- Biswas, S.; Satapathy, A.; Patnaik, A. Effect of Ceramic Fillers on Mechanical Properties of Bamboo Fiber Reinforced Epoxy Composites: A Comparative Study. Adv. Mater. Res. 2010, 123–125, 1031–1034. [Google Scholar] [CrossRef]

- Aruchamy, K.; Pavayee Subramani, S.; Palaniappan, S.K.; Sethuraman, B.; Velu Kaliyannan, G. Study on Mechanical Characteristics of Woven Cotton/Bamboo Hybrid Reinforced Composite Laminates. J. Mater. Res. Technol. 2020, 9, 718–726. [Google Scholar] [CrossRef]

- Davoodi, M.M.; Sapuan, S.M.; Ahmad, D.; Ali, A.; Khalina, A.; Jonoobi, M. Mechanical Properties of Hybrid Kenaf/Glass Reinforced Epoxy Composite for Passenger Car Bumper Beam. Mater. Des. 2010, 31, 4927–4932. [Google Scholar] [CrossRef]

- Suriani, M.J.; Zainudin, H.A.; Ilyas, R.A.; Petrů, M.; Sapuan, S.M.; Ruzaidi, C.M.; Mustapha, R. Kenaf fiber/pet yarn reinforced epoxy hybrid polymer composites: Morphological, tensile, and flammability properties. Polymers 2021, 13, 1532. [Google Scholar] [CrossRef]

- Supian, A.B.M.; Sapuan, S.M.; Zuhri, M.Y.M.; Zainudin, E.S.; Ya, H.H.; Hisham, H.N. Effect of Winding Orientation on Energy Absorption and Failure Modes of Filament Wound Kenaf/Glass Fibre Reinforced Epoxy Hybrid Composite Tubes under Intermediate-Velocity Impact (IVI) Load. J. Mater. Res. Technol. 2021, 10, 1–14. [Google Scholar] [CrossRef]

- Chandrakala, K.; Vanaja, A.; Rao, R. Storage Life Studies on RT Cure Glass-Epoxy Pre-Pregs. J. Reinf. Plast. Compos. 2009, 28, 1987–1997. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A Review on the Tensile Properties of Natural Fiber Reinforced Polymer Composites. Compos. Part B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef] [Green Version]

- Dayo, A.Q.; Gao, B.-C.; Wang, J.; Liu, W.-B.; Derradji, M.; Shah, A.H.; Babar, A.A. Natural Hemp Fiber Reinforced Polybenzoxazine Composites: Curing Behavior, Mechanical and Thermal Properties. Compos. Sci. Technol. 2017, 144, 114–124. [Google Scholar] [CrossRef]

- Fuqua, M.A.; Huo, S.; Ulven, C.A. Natural Fiber Reinforced Composites. Polym. Rev. 2012, 52, 259–320. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and Properties of Natural Fiber Polymer Composites: A Comprehensive Review; Elsevier: Amsterdam, The Netherlands, 2018; Volume 172. [Google Scholar] [CrossRef]

- Angelov, I.; Wiedmer, S.; Evstatiev, M.; Friedrich, K.; Mennig, G. Pultrusion of a Flax/Polypropylene Yarn. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1431–1438. [Google Scholar] [CrossRef]

- Vemuganti, S.; Chennareddy, R.; Riad, A.; Reda Taha, M.M. Pultruded Gfrp Reinforcing Bars Using Nanomodified Vinyl Ester. Materials 2020, 13, 5710. [Google Scholar] [CrossRef]

- Rangappa, S.M.; Parameswaranpillai, J.; Siengchin, S.; Jawaid, M.; Ozbakkaloglu, T. Bioepoxy Based Hybrid Composites from Nano-Fillers of Chicken Feather and Lignocellulose Ceiba Pentandra. Sci. Rep. 2022, 12, 397. [Google Scholar] [CrossRef]

- Atmakuri, A.; Palevicius, A.; Kolli, L.; Vilkauskas, A.; Janusas, G. Development and Analysis of Mechanical Properties of Caryota and Sisal Natural Fibers Reinforced Epoxy Hybrid Composites. Polymers 2021, 13, 864. [Google Scholar] [CrossRef]

- Xia, C.; Garcia, A.C.; Shi, S.Q.; Qiu, Y.; Warner, N.; Wu, Y.; Cai, L.; Rizvi, H.R.; D’Souza, N.A.; Nie, X. Hybrid Boron Nitride-Natural Fiber Composites for Enhanced Thermal Conductivity. Sci. Rep. 2016, 6, 34726. [Google Scholar] [CrossRef]

- Supian, A.B.M.; Jawaid, M.; Rashid, B.; Fouad, H.; Saba, N.; Dhakal, H.N.; Khiari, R. Mechanical and Physical Performance of Date Palm/Bamboo Fibre Reinforced Epoxy Hybrid Composites. J. Mater. Res. Technol. 2021, 15, 1330–1341. [Google Scholar] [CrossRef]

- Sanjay, M.; Yogesha, B. Studies on Natural/Glass Fiber Reinforced Polymer Hybrid Composites: An Evolution. Mater. Today Proc. 2017, 4, 2739–2747. [Google Scholar] [CrossRef]

- da Costa Garcia Filho, F.; da Luz, F.S.; Nascimento, L.F.C.; Satyanarayana, K.G.; Drelich, J.W.; Monteiro, S.N. Mechanical Properties of Boehmeria Nivea Natural Fabric Reinforced Epoxy Matrix Composite Prepared by Vacuum-Assisted Resin Infusion Molding. Polymers 2020, 12, 1311. [Google Scholar] [CrossRef]

- Barczewski, M.; Sałasińska, K.; Szulc, J. Application of Sunflower Husk, Hazelnut Shell and Walnut Shell as Waste Agricultural Fillers for Epoxy-Based Composites: A Study into Mechanical Behavior Related to Structural and Rheological Properties. Polym. Test. 2019, 75, 1–11. [Google Scholar] [CrossRef]

- Gopal Krishna, U.B.; Srinivasa, C.S.; Amara, N.S.; Gudoor, S. Processing, Characterization and Property Evaluation of Seashell and Glass Fibre Added Epoxy Based Polymer Matrix Composite. Mater. Today Proc. 2019, 35, 417–422. [Google Scholar] [CrossRef]

- Ramana, M.V.; Ramprasad, S. Experimental Investigation on Jute/Carbon Fibre Reinforced Epoxy Based Hybrid Composites. Mater. Today Proc. 2017, 4, 8654–8664. [Google Scholar] [CrossRef]

- Gairola, S.P.; Tyagi, Y.K.; Gangil, B.; Sharma, A. Fabrication and Mechanical Property Evaluation of Non-Woven Banana Fibre Epoxy-Based Polymer Composite. Mater. Today Proc. 2020, 44, 3990–3996. [Google Scholar] [CrossRef]

- Kyriazis, A.; Kilian, R.; Sinapius, M.; Rager, K.; Dietzel, A. Tensile Strength and Structure of the Interface between a Room-Curing Epoxy Resin and Thermoplastic Films for the Purpose of Sensor Integration. Polymers 2021, 13, 330. [Google Scholar] [CrossRef]

- dos Reis, A.K.; Monticelli, F.M.; Neves, R.M.; de Paula Santos, L.F.; Botelho, E.C.; Luiz Ornaghi, H. Creep Behavior of Polyetherimide Semipreg and Epoxy Prepreg Composites: Structure vs. Property Relationship. J. Compos. Mater. 2020, 54, 4121–4131. [Google Scholar] [CrossRef]

- Klosterman, D.; Browning, C.; Hakim, I.; Lach, K. Investigation of Various Techniques for Controlled Void Formation in Fiberglass/Epoxy Composites. J. Compos. Mater. 2021, 55, 489–506. [Google Scholar] [CrossRef]

- Sienkiewicz, N.; Dominic, M.; Parameswaranpillai, J. Natural Fillers as Potential Modifying Agents for Epoxy Composition: A Review. Polymers 2022, 14, 265. [Google Scholar] [CrossRef]

- Sinha, A.K.; Narang, H.K.; Bhattacharya, S. Tensile Strength of Abaca Epoxy Laminated Composites. Mater. Today Proc. 2018, 5, 27861–27864. [Google Scholar] [CrossRef]

- Vijaya Ramnath, B.; Junaid Kokan, S.; Niranjan Raja, R.; Sathyanarayanan, R.; Elanchezhian, C.; Rajendra Prasad, A.; Manickavasagam, V.M. Evaluation of Mechanical Properties of Abaca-Jute-Glass Fibre Reinforced Epoxy Composite. Mater. Des. 2013, 51, 357–366. [Google Scholar] [CrossRef]

- Vidyashri, V.; Lewis, H.; Narayanasamy, P.; Mahesha, G.T.; Bhat, K.S. Preparation of Chemically Treated Sugarcane Bagasse Fiber Reinforced Epoxy Composites and Their Characterization. Cogent Eng. 2019, 6, 1708644. [Google Scholar] [CrossRef]

- Tewari, M.; Singh, V.K.; Gope, P.C.; Chaudhary, A.K. Evaluation of Mechanical Properties of Bagasse-Glass Fiber Reinforced Composite. J. Mater. Environ. Sci. 2012, 3, 171–184. [Google Scholar]

- Kushwaha, P.K.; Kumar, R. Influence of Chemical Treatments on the Mechanical and Water Absorption Properties of Bamboo Fiber Composites. J. Reinf. Plast. Compos. 2011, 30, 73–85. [Google Scholar] [CrossRef]

- Latha, P.S.; Rao, M.V.; Kumar, V.V.K.; Raghavendra, G.; Ojha, S.; Inala, R. Evaluation of Mechanical and Tribological Properties of Bamboo–Glass Hybrid Fiber Reinforced Polymer Composite. J. Ind. Text. 2016, 46, 3–18. [Google Scholar] [CrossRef] [Green Version]

- Venkateshwaran, N.; Elaya Perumal, A.; Arunsundaranayagam, D. Fiber Surface Treatment and Its Effect on Mechanical and Visco-Elastic Behaviour of Banana/Epoxy Composite. Mater. Des. 2013, 47, 151–159. [Google Scholar] [CrossRef]

- Batu, T.; Lemu, H.G. Investigation of Mechanical Properties of False Banana/Glass Fiber Reinforced Hybrid Composite Materials. Results Mater. 2020, 8, 100152. [Google Scholar] [CrossRef]

- Biswas, S.; Kindo, S.; Patnaik, A. Effect of Fiber Length on Mechanical Behavior of Coir Fiber Reinforced Epoxy Composites. Fibers Polym. 2011, 12, 73–78. [Google Scholar] [CrossRef]

- Bhagat, V.K.; Biswas, S.; Dehury, J. Physical, Mechanical, and Water Absorption Behavior of Coir/Glass Fiber Reinforced Epoxy Based Hybrid Composites. Polym. Compos. 2014, 35, 925–930. [Google Scholar] [CrossRef]

- Do Carmo Amorim, F.; De Souzaa, J.F.B.; Dos Reis, J.M.L. The Quasi-Static and Dynamic Mechanical Behavior of Epoxy Matrix Composites Reinforced with Curaua Fibers. Mater. Res. 2018, 21, 1–6. [Google Scholar] [CrossRef]

- Saba, N.; Alothman, O.Y.; Almutairi, Z.; Jawaid, M.; Ghori, W. Date Palm Reinforced Epoxy Composites: Tensile, Impact and Morphological Properties. J. Mater. Res. Technol. 2019, 8, 3959–3969. [Google Scholar] [CrossRef]

- Van de Weyenberg, I.; Ivens, J.; De Coster, A.; Kino, B.; Baetens, E.; Verpoest, I. Influence of Processing and Chemical Treatment of Flax Fibres on Their Composites. Compos. Sci. Technol. 2003, 63, 1241–1246. [Google Scholar] [CrossRef]

- Wang, H.; Yang, L.; Wu, H. Study on Mechanical and Thermomechanical Properties of Flax/Glass Fiber Hybrid-Reinforced Epoxy Composites. Polym. Compos. 2021, 42, 714–723. [Google Scholar] [CrossRef]

- Islam, M.S.; Pickering, K.L.; Foreman, N.J. Influence of Alkali Fiber Treatment and Fiber Processing on the Mechanical Properties of Hemp/Epoxy Composites. J. Appl. Polym. Sci. 2011, 119, 3696–3707. [Google Scholar] [CrossRef]

- Somashekar, S.M.; Manjunath, V.; Gowtham, M.J.; Balasubramaniam, N.S. Investigation on Mechanical Properties of Hemp-e Glass Fiber Reinforced Polymer Composites. Int. J. Mech. Eng. Technol. 2016, 7, 182–192. [Google Scholar]

- Gonzalez-Murillo, C.; Ansell, M.P. Mechanical Properties of Henequen Fibre/Epoxy Resin Composites. Mech. Compos. Mater. 2009, 45, 435–442. [Google Scholar] [CrossRef]

- De Jesús, A.M.; Ramírez, J.M.O.; Reyes-Araiza, J.L.; Manzano-Ramírez, A.; Apatiga, L.M.; Eleazar, U.A.; Ramírez, J.R.; Arroyo, C.M. Tensile and Flexural Strength of Untreated Woven Henequen-Glass Fabric Reinforced Epoxy Hybrid Composites. Key Eng. Mater. 2014, 600, 569–575. [Google Scholar] [CrossRef]

- Guptaa, M.K.; Srivastava, R.K. Mechanical, Thermal and Dynamic Mechanical Analysis of Jute Fibre Reinforced Epoxy Composite. Indian J. Fibre Text. Res. 2017, 42, 64–71. [Google Scholar]

- Gujjala, R.; Ojha, S.; Acharya, S.K.; Pal, S.K. Mechanical Properties of Woven Jute-Glass Hybrid-Reinforced Epoxy Composite. J. Compos. Mater. 2014, 48, 3445–3455. [Google Scholar] [CrossRef]

- Ismail, N.F.; Mohd Radzuan, N.A.; Sulong, A.B.; Muhamad, N.; Che Haron, C.H. The Effect of Alkali Treatment on Physical, Mechanical and Thermal Properties of Kenaf Fiber and Polymer Epoxy Composites. Polymers 2021, 13, 2005. [Google Scholar] [CrossRef]

- Zuhri, M.; Yusoff, M.; Mohd Sapuan, S.; Ismail, N.; Wirawan, R. Mechanical Properties of Short Random Oil Palm Fibre Reinforced Epoxy Composites. Sains Malays. 2010, 39, 87–92. [Google Scholar]

- Nagarajan, T.T.; Babu, A.S.; Palanivelu, K.; Nayak, S.K. Mechanical and Thermal Properties of PALF Reinforced Epoxy Composites. Macromol. Symp. 2016, 361, 57–63. [Google Scholar] [CrossRef]

- Mittal, M.; Chaudhary, R. Development of PALF/Glass and COIR/Glass Fiber Reinforced Hybrid Epoxy Composites. J. Mater. Sci. Surf. Eng. 2018, 6, 851–861. [Google Scholar]

- Nascimento, D.C.O.; Ferreira, A.S.; Monteiro, S.N.; Aquino, R.C.M.P.; Kestur, S.G. Studies on the Characterization of Piassava Fibers and Their Epoxy Composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 353–362. [Google Scholar] [CrossRef]

- Gu, Y.; Tan, X.; Yang, Z.; Li, M.; Zhang, Z. Hot Compaction and Mechanical Properties of Ramie Fabric/Epoxy Composite Fabricated Using Vacuum Assisted Resin Infusion Molding. Mater. Des. 2014, 56, 852–861. [Google Scholar] [CrossRef]

- Rong, M.Z.; Zhang, M.Q.; Liu, Y.; Yang, G.C.; Zeng, H.M. The Effect of Fiber Treatment on the Mechanical Properties of Unidirectional Sisal-Reinforced Epoxy Composites. Compos. Sci. Technol. 2001, 61, 1437–1447. [Google Scholar] [CrossRef]

- B, A.Z.; Gebremedhen, H.S. Characterization of Sisal-Glass Fiber Reinforced; Springer International Publishing: Cham, Switzerland, 2021; Volume 1. [Google Scholar] [CrossRef]

- Mittal, V.; Saini, R.; Sinha, S. Natural Fiber-Mediated Epoxy Composites—A Review. Compos. Part B Eng. 2016, 99, 425–435. [Google Scholar] [CrossRef]

- Coroller, G.; Lefeuvre, A.; Le Duigou, A.; Bourmaud, A.; Ausias, G.; Gaudry, T.; Baley, C. Effect of Flax Fibres Individualisation on Tensile Failure of Flax/Epoxy Unidirectional Composite. Compos. Part A Appl. Sci. Manuf. 2013, 51, 62–70. [Google Scholar] [CrossRef]

- Alamri, H.; Low, I.M. Mechanical Properties and Water Absorption Behaviour of Recycled Cellulose Fibre Reinforced Epoxy Composites. Polym. Test. 2012, 31, 620–628. [Google Scholar] [CrossRef]

- Mishra, V.; Biswas, S. Physical and Mechanical Properties of Bi-Directional Jute Fiber Epoxy Composites. Procedia Eng. 2013, 51, 561–566. [Google Scholar] [CrossRef]

- Romli, F.I.; Alias, A.N.; Rafie, A.S.M.; Majid, D.L.A.A. Factorial Study on the Tensile Strength of a Coir Fiber-Reinforced Epoxy Composite. AASRI Procedia 2012, 3, 242–247. [Google Scholar] [CrossRef]

- Lu, T.; Jiang, M.; Jiang, Z.; Hui, D.; Wang, Z.; Zhou, Z. Effect of Surface Modification of Bamboo Cellulose Fibers on Mechanical Properties of Cellulose/Epoxy Composites. Compos. Part B Eng. 2013, 51, 28–34. [Google Scholar] [CrossRef]

- Newman, R.H.; Clauss, E.C.; Carpenter, J.E.P.; Thumm, A. Epoxy Composites Reinforced with Deacetylated Phormium Tenax Leaf Fibres. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2164–2170. [Google Scholar] [CrossRef]

- Mylsamy, K.; Rajendran, I. The Mechanical Properties, Deformation and Thermomechanical Properties of Alkali Treated and Untreated Agave Continuous Fibre Reinforced Epoxy Composites. Mater. Des. 2011, 32, 3076–3084. [Google Scholar] [CrossRef]

- Fang, T.W.; Asyikin, N.S.S.N.; Shawkataly, A.K.H.P.; Kassim, M.H.M.; Syakir, M.I. Water Absorption and Thickness Swelling of Oil Palm Empty Fruit Bunch (OPEFB) and Seaweed Composite for Soil Erosion Mitigation. J. Phys. Sci. 2017, 28, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Bera, T.; Mohanta, N.; Prakash, V.; Pradhan, S.; Acharya, S.K. Moisture Absorption and Thickness Swelling Behaviour of Luffa Fibre/Epoxy Composite. J. Reinf. Plast. Compos. 2019, 38, 923–937. [Google Scholar] [CrossRef]

- Edhirej, A.; Sapuan, S.M.; Jawaid, M.; Zahari, N.I. Cassava/Sugar Palm Fiber Reinforced Cassava Starch Hybrid Composites: Physical, Thermal and Structural Properties. Int. J. Biol. Macromol. 2017, 101, 75–83. [Google Scholar] [CrossRef]

- Mushtaq, M. Materials Today: Proceedings Investigation of Mechanical Properties and Water Absorption Behaviour on Tamarind Shell Fiber—Reinforced Epoxy Composite Laminates. Mater. Today Proc. 2021, 45, 440–446. [Google Scholar] [CrossRef]

- Ranakoti, L.; Gangil, B.; Kumar, P.; Singh, T. Effect of Surface Treatment and Fiber Loading on the Physical, Mechanical, Sliding Wear, and Morphological Characteristics of Tasar Silk Fiber Waste-Epoxy Composites for Multifaceted Biomedical and Engineering Applications: Fabrication and Characteriz. J. Mater. Res. Technol. 2022, 19, 2863–2876. [Google Scholar] [CrossRef]

- Uppal, N.; Pappu, A.; Kumar, V.; Gowri, S.; Kumar, V. Industrial Crops & Products Cellulosic Fibres-Based Epoxy Composites: From Bioresources to a Circular Economy. Ind. Crop. Prod. 2022, 182, 114895. [Google Scholar] [CrossRef]

- Verma, R.; Shukla, M.; Shukla, D.K. Materials Today: Proceedings Effect of Glass Fibre Hybridization on the Water Absorption and Thickness of Alkali Treated Kenaf-Epoxy Composites. Mater. Today Proc. 2021, 44, 2093–2096. [Google Scholar] [CrossRef]

- Izzah, N.; Haris, N.; Zaki, M.; Ilyas, R.A.; Azlan, M.; Sapuan, S.M.; Dolah, R.; Mohammad, R.; Asyraf, M.R.M. Dynamic Mechanical Properties of Natural Fiber Reinforced Hybrid Polymer Composites: A Review. J. Mater. Res. Technol. 2022, 19, 167–182. [Google Scholar] [CrossRef]

- Sulardjaka, S.; Iskandar, N.; Nugroho, S.; Alamsyah, A.; Prasetya, M.Y. Heliyon The Characterization of Unidirectional and Woven Water Hyacinth Fi Ber Reinforced with Epoxy Resin Composites. Heliyon 2022, 8, e10484. [Google Scholar] [CrossRef]

- Dash, C.; Bisoyi, D.K. Significance of Dielectric and Mechanical Properties on Fiber Loading of Sunn Hemp Reinforced Epoxy Composite. AIP Conf. Proc. 2020, 2220, 080027. [Google Scholar] [CrossRef]

- Chand, N.; Jain, D. Effect of Sisal Fibre Orientation on Electrical Properties of Sisal Fibre Reinforced Epoxy Composites. Compos. Part A Appl. Sci. Manuf. 2005, 36, 594–602. [Google Scholar] [CrossRef]

- Nimanpure, S.; Hashmi, S.A.R.; Kumar, R.; Nigrawal, A.; Naik, A. Electrical and Dynamic Mechanical Analysis of Sisal Fibril Reinforced Epoxy Composite. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 2020–2028. [Google Scholar] [CrossRef]

- Jayamani, E.; Hamdan, S.; Rahman, M.R.; Bakri, M.K.B. Dielectric Properties of Lignocellulosic Fibers Reinforced Polymer Composites: Effect of Fiber Loading and Alkaline Treatment. Mater. Today Proc. 2015, 2, 2757–2766. [Google Scholar] [CrossRef]

- Jayamani, E.; Hamdan, S.; Rahman, M.R.; Bakri, M.K.B. Comparative Study of Dielectric Properties of Hybrid Natural Fiber Composites. Procedia Eng. 2014, 97, 536–544. [Google Scholar] [CrossRef] [Green Version]

- Triki, A.; Karray, M.; Poilâne, C.; Picart, P.; Gargouri, M. Dielectric Analysis of the Interfacial Polarization of Alkali Treated Woven Flax Fibers Reinforced Epoxy Composites. J. Electrostat. 2015, 76, 67–72. [Google Scholar] [CrossRef]

- Paul, A.; Joseph, K.; Thomas, S. Effect of Surface Treatments on the Electrical Properties of Low-Density Polyethylene Composites Reinforced with Short Sisal Fibers. Compos. Sci. Technol. 1997, 57, 67–79. [Google Scholar] [CrossRef]

- Patra, A.; Bisoyi, D.K. Investigation of the Electrical and Mechanical Properties of Short Sisal Fiber-Reinforced Epoxy Composite in Correlation with Structural Parameters of the Reinforced Fiber. J. Mater. Sci. 2011, 46, 7206–7213. [Google Scholar] [CrossRef]

- Goud, G.; Rao, R.N. Mechanical and Electrical Performance of Roystonea Regia/Glass Fibre Reinforced Epoxy Hybrid Composites. Bull. Mater. Sci. 2012, 35, 595–599. [Google Scholar] [CrossRef] [Green Version]

- Joven, R.; Das, R.; Ahmed, A.; Roozbehjavan, P.; Minaie, B. Thermal Properties of Carbon Fiber-Epoxy Composites with Different Fabric Weaves. In Proceedings of the SAMPE International Symposium Proceedings, Charleston, SC, USA, 22–25 October 2012. [Google Scholar]

- Singh, Y.; Singh, J.; Sharma, S.; Lam, T.D.; Nguyen, D.N. Fabrication and Characterization of Coir/Carbon-Fiber Reinforced Epoxy Based Hybrid Composite for Helmet Shells and Sports-Good Applications: Influence of Fiber Surface Modifications on the Mechanical, Thermal and Morphological Properties. J. Mater. Res. Technol. 2020, 9, 15593–15603. [Google Scholar] [CrossRef]

- Chee, S.S.; Jawaid, M.; Sultan, M.T.H.; Alothman, O.Y.; Abdullah, L.C. Thermomechanical and Dynamic Mechanical Properties of Bamboo/Woven Kenaf Mat Reinforced Epoxy Hybrid Composites. Compos. Part B Eng. 2019, 163, 165–174. [Google Scholar] [CrossRef]

- Saba, N.; Paridah, M.T.; Abdan, K.; Ibrahim, N.A. Physical, Structural and Thermomechanical Properties of Oil Palm Nano Filler/Kenaf/Epoxy Hybrid Nanocomposites. Mater. Chem. Phys. 2016, 184, 64–71. [Google Scholar] [CrossRef]

- Sankar lal, S.; Kannan, S.; Sahoo, S.K. Influence of Flax Fiber Orientation on Mechanical, Thermo-Mechanical and Interfacial Adhesion Properties of Epoxidized Methyl Ricinoleate Modified Epoxy Composite: A Sustainable Green Composite for Cleaner Production. Mater. Today Commun. 2022, 33, 104648. [Google Scholar] [CrossRef]

- Fouad, H.; Jawaid, M.; Azeem, M.A. Flexural, Impact and Dynamic Mechanical Analysis of Hybrid Composites: Olive Tree Leaves Powder/Pineapple Leaf Fibre/Epoxy Matrix. J. Mater. Res. Technol. 2022, 21, 4241–4252. [Google Scholar] [CrossRef]

- Dhanapal, D.; Kumar, S.A.; Ranjitha, J. Areca Fiber/Epoxy Nano-Composite Reinforced with Amine-Functionalized Nano-Alumina-Enhancement in Thermal and Thermo-Mechanical Properties. Mater. Today Commun. 2022, 33, 104798. [Google Scholar] [CrossRef]

- Sreenivasulu, A.; Ashraff Ali, K.S.; Arumugam, P.; Basha, S.R.; Velmurugan, P.; Rajkumar, S.; Suresh Kumar, S. Investigation on Thermal Properties of Tamarind Shell Particles Reinforced Hybrid Polymer Matrix Composites. Mater. Today Proc. 2021, 59, 1305–1311. [Google Scholar] [CrossRef]

- Chidhananda, R.S.; Prakash, S.D.; Nireeksha, P.; Mungara, S.R. Materials Today: Proceedings A Study on Hardness and Thermal Properties of Fibre Based Particulate Polymer Composites. Mater. Today Proc. 2021, 47, 4495–4501. [Google Scholar] [CrossRef]

- Agrawal, A.; Satapathy, A. Mathematical Model for Evaluating Effective Thermal Conductivity of Polymer Composites with Hybrid Fillers. Int. J. Therm. Sci. 2015, 89, 203–209. [Google Scholar] [CrossRef]

- Ribeiro, M.P.; Neuba, L.D.M.; Da Silveira, P.H.P.M.; Da Luz, F.S.; Figueiredo, A.B.H.D.S.; Monteiro, S.N.; Moreira, M.O. Mechanical, Thermal and Ballistic Performance of Epoxy Composites Reinforced with Cannabis Sativa Hemp Fabric. J. Mater. Res. Technol. 2021, 12, 221–233. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Calado, V.; Rodriguez, R.J.S.; Margem, F.M. Thermogravimetric Behavior of Natural Fibers Reinforced Polymer Composites-An Overview. Mater. Sci. Eng. A 2012, 557, 17–28. [Google Scholar] [CrossRef]

- Mohanty, S.; Verma, S.K.; Nayak, S.K. Dynamic Mechanical and Thermal Properties of MAPE Treated Jute/HDPE Composites. Compos. Sci. Technol. 2006, 66, 538–547. [Google Scholar] [CrossRef]

- Alothman, O.Y.; Jawaid, M.; Senthilkumar, K.; Chandrasekar, M.; Alshammari, B.A.; Fouad, H.; Hashem, M.; Siengchin, S. Thermal Characterization of Date Palm/Epoxy Composites with Fillers from Different Parts of the Tree. J. Mater. Res. Technol. 2020, 9, 15537–15546. [Google Scholar] [CrossRef]

- Azhary, T.; Kusmono; Wildan, M.W.; Herianto. Mechanical, Morphological, and Thermal Characteristics of Epoxy/Glass Fiber/Cellulose Nanofiber Hybrid Composites. Polym. Test. 2022, 110, 107560. [Google Scholar] [CrossRef]

- Prabhu, L.; Krishnaraj, V.; Gokulkumar, S.; Sathish, S.; Ramesh, M. Mechanical, Chemical and Acoustical Behavior of Sisal—Tea Waste—Glass Fiber Reinforced Epoxy Based Hybrid Polymer Composites. Mater. Today Proc. 2019, 16, 653–660. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Y.; Chen, C. Synergic Effects of Cellulose Nanocrystals and Alkali on the Mechanical Properties of Sisal Fibers and Their Bonding Properties with Epoxy. Compos. Part A Appl. Sci. Manuf. 2017, 101, 480–489. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. Chemical Modification of Hemp, Sisal, Jute, and Kapok Fibers by Alkalization. J. Appl. Polym. Sci. 2002, 84, 2222–2234. [Google Scholar]

- Low, I.M.; McGrath, M.; Lawrence, D.; Schmidt, P.; Lane, J.; Latella, B.A.; Sim, K.S. Mechanical and Fracture Properties of Cellulose-Fibre-Reinforced Epoxy Laminates. Compos. Part A Appl. Sci. Manuf. 2007, 38, 963–974. [Google Scholar] [CrossRef]

- Phong, N.T.; Gabr, M.H.; Okubo, K.; Chuong, B.; Fujii, T. Enhancement of Mechanical Properties of Carbon Fabric/Epoxy Composites Using Micro/Nano-Sized Bamboo Fibrils. Mater. Des. 2013, 47, 624–632. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, M.; Li, J.; Yu, J.; Sun, S.; Ge, S.; Guo, X.; Xie, F.; Jiang, B.; Wujcik, E.K.; et al. Silver Nanoparticles/Graphene Oxide Decorated Carbon Fiber Synergistic Reinforcement in Epoxy-Based Composites. Polymer 2017, 131, 263–271. [Google Scholar]

- Chen, J.; Zhao, D.; Jin, X.; Wang, C.; Wang, D.; Ge, H. Modifying Glass Fibers with Graphene Oxide: Towards High-Performance Polymer Composites. Compos. Sci. Technol. 2014, 97, 41–45. [Google Scholar] [CrossRef]

- Sumesh, K.R.; Kavimani, V.; Rajeshkumar, G.; Indran, S.; Saikrishnan, G. Effect of Banana, Pineapple and Coir Fly Ash Filled with Hybrid Fiber Epoxy Based Composites for Mechanical and Morphological Study. J. Mater. Cycles Waste Manag. 2021, 23, 1277–1288. [Google Scholar] [CrossRef]

- Sumesh, K.R.; Kanthavel, K.; Kavimani, V. Peanut Oil Cake-Derived Cellulose Fiber: Extraction, Application of Mechanical and Thermal Properties in Pineapple/Flax Natural Fiber Composites. Int. J. Biol. Macromol. 2020, 150, 775–785. [Google Scholar] [CrossRef]

- Balaji, A.; Sivaramakrishnan, K.; Karthikeyan, B.; Purushothaman, R.; Swaminathan, J.; Kannan, S.; Udhayasankar, R.; Madieen, A.H. Study on Mechanical and Morphological Properties of Sisal/Banana/Coir Fiber-Reinforced Hybrid Polymer Composites. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 386. [Google Scholar] [CrossRef]

- Prakash, V.R.A.; Viswanthan, R. Fabrication and Characterization of Echinoidea Spike Particles and Kenaf Natural Fibre-Reinforced Azadirachta-Indica Blended Epoxy Multi-Hybrid Bio Composite. Compos. Part A Appl. Sci. Manuf. 2019, 118, 317–326. [Google Scholar] [CrossRef]

- Qin, W.; Vautard, F.; Drzal, L.T.; Yu, J. Mechanical and Electrical Properties of Carbon Fiber Composites with Incorporation of Graphene Nanoplatelets at the Fiber—Matrix Interphase. Compos. Part B Eng. 2015, 69, 335–341. [Google Scholar] [CrossRef]

- Batista, M.D.R.; Drzal, L.T. Carbon Fiber/Epoxy Matrix Composite Interphases Modified with Cellulose Nanocrystals. Composites Science and Technology. Compos. Sci. Technol. 2018, 164, 274–281. [Google Scholar] [CrossRef]

- Manimaran, P.; Senthamaraikannan, P.; Sanjay, M.R.; Marichelvam, M.K.; Jawaid, M. Study on Characterization of Furcraea Foetida New Natural Fiber as Composite Reinforcement for Lightweight Applications. Carbohydr. Polym. 2018, 181, 650–658. [Google Scholar] [CrossRef] [PubMed]

- Tavares, M.I.B.; De Araújo, C.R.; Mothé, C.G. Solid State NMR Study of Natural Fibres. Int. J. Polym. Mater. 2001, 49, 231–236. [Google Scholar] [CrossRef]

- Idumah, C.I.; Hassan, A. Characterization and Preparation of Conductive Exfoliated Graphene Nanoplatelets Kenaf Fibre Hybrid Polypropylene Composites. Synth. Met. 2016, 212, 91–104. [Google Scholar] [CrossRef]

- Idolor, O.; Berkowitz, K.; Guha, R.D.; Grace, L. Nondestructive Examination of Polymer Composites by Analysis of Polymer-Water Interactions and Damage-Dependent Hysteresis. Compos. Struct. 2022, 287, 115377. [Google Scholar] [CrossRef]

- Kumar, C.S.; Fotouhi, M.; Saeedifar, M.; Arumugam, V. Acoustic Emission Based Investigation on the Effect of Temperature and Hybridization on Drop Weight Impact and Post-Impact Residual Strength of Hemp and Basalt Fibres Reinforced Polymer Composite Laminates. Compos. Part B 2019, 173, 106962. [Google Scholar] [CrossRef]

- Liu, P.F.; Chu, J.K.; Liu, Y.L.; Zheng, J.Y. A Study on the Failure Mechanisms of Carbon Fiber / Epoxy Composite Laminates Using Acoustic Emission. Mater. Des. 2012, 37, 228–235. [Google Scholar] [CrossRef]

- Friedrich, L.; Colpo, A.; Maggi, A.; Becker, T.; Lacidogna, G.; Iturrioz, I. Damage Process in Glass Fi Ber Reinforced Polymer Specimens Using Acoustic Emission Technique with Low Frequency Acquisition. Compos. Struct. 2021, 256, 113105. [Google Scholar] [CrossRef]

- Nsengiyumva, W.; Zhong, S.; Lin, J.; Zhang, Q.; Zhong, J.; Huang, Y. Advances, Limitations and Prospects of Nondestructive Testing and Evaluation of Thick Composites and Sandwich Structures: A State-of-the-Art Review. Compos. Struct. 2021, 256, 112951. [Google Scholar] [CrossRef]

- Gholizadeh, S. A Review of Non-Destructive Testing Methods of Composite Materials. Procedia Struct. Integr. 2016, 1, 50–57. [Google Scholar] [CrossRef] [Green Version]

- Niutta, C.B.; Tridello, A.; Belingardi, G.; Paolino, D.S. ScienceDirect ScienceDirect An Innovative Nondestructive Technique for the Local Assessment of Residual Elastic Properties in Laminated Composites. Procedia Struct. Integr. 2021, 33, 347–356. [Google Scholar] [CrossRef]

- Na, W.S. Distinguishing Crack Damage from Debonding Damage of Glass Fiber Reinforced Polymer Plate Using a Piezoelectric Transducer Based Nondestructive Testing Method. Compos. Struct. 2017, 159, 517–527. [Google Scholar] [CrossRef]

- Alves, C.L. Fracture Characterization of Continuous Fibre-Reinforced Polymer XV Matrix Composite Laminates by Nuclear Magnetic Resonance. Procedia Struct. Integr. 2016, 2, 136–143. [Google Scholar] [CrossRef]

- Park, J.; Kong, J.; Kim, J.; Yoon, D. Interfacial Evaluation of Electrodeposited Single Carbon Fiber / Epoxy Composites by Fiber Fracture Source Location Using Fragmentation Test and Acoustic Emission. Compos. Sci. Technol. 2004, 64, 983–999. [Google Scholar] [CrossRef]

- Prakash, S.O.; Sahu, P.; Madhan, M.; Johnson Santhosh, A. A Review on Natural Fibre-Reinforced Biopolymer Composites: Properties and Applications. Int. J. Polym. Sci. 2022, 2022, 7820731. [Google Scholar] [CrossRef]

- Memon, H.; Wei, Y.; Zhu, C. Recyclable and Reformable Epoxy Resins Based on Dynamic Covalent Bonds—Present, Past, and Future. Polym. Test. 2022, 105, 107420. [Google Scholar] [CrossRef]

- Chee, S.S.; Jawaid, M.; Sultan, M.T.H.; Alothman, O.Y.; Abdullah, L.C. Accelerated Weathering and Soil Burial Effects on Colour, Biodegradability and Thermal Properties of Bamboo/Kenaf/Epoxy Hybrid Composites. Polym. Test. 2019, 79, 106054. [Google Scholar] [CrossRef]

- Butylina, S.; Hyvärinen, M.; Kärki, T. A Study of Surface Changes of Wood-Polypropylene Composites as the Result of Exterior Weathering. Polym. Degrad. Stab. 2012, 97, 337–345. [Google Scholar] [CrossRef]

- Pandey, P.; Bajwa, S.G.; Bajwa, D.S.; Englund, K. Performance of UV Weathered HDPE Composites Containing Hull Fiber from DDGS and Corn Grain. Ind. Crop. Prod. 2017, 107, 409–419. [Google Scholar] [CrossRef]

- Awad, S.A.; Fellows, C.M.; Mahini, S.S. Effects of Accelerated Weathering on the Chemical, Mechanical, Thermal and Morphological Properties of an Epoxy/Multi-Walled Carbon Nanotube Composite. Polym. Test. 2018, 66, 70–77. [Google Scholar] [CrossRef]

- Schlagenhauf, L.; Nüesch, F.; Wang, J. Release of Carbon Nanotubes from Polymer Nanocomposites. Fibers 2014, 2, 108–127. [Google Scholar] [CrossRef]

- Fabiyi, J.S.; McDonald, A.G.; Wolcott, M.P.; Griffiths, P.R. Wood Plastic Composites Weathering: Visual Appearance and Chemical Changes. Polym. Degrad. Stab. 2008, 93, 1405–1414. [Google Scholar] [CrossRef]

- Obasi, H.C.; Igwe, I.O.; Madufor, I.C. Effect of Soil Burial on Tensile Properties of Polypropylene/Plasticized Cassava Starch Blends. Adv. Mater. Sci. Eng. 2013, 2013, 326538. [Google Scholar] [CrossRef] [Green Version]

- Maran, J.P.; Sivakumar, V.; Thirugnanasambandham, K.; Sridhar, R. Degradation Behavior of Biocomposites Based on Cassava Starch Buried under Indoor Soil Conditions. Carbohydr. Polym. 2014, 101, 20–28. [Google Scholar] [CrossRef] [PubMed]

- Methacanon, P.; Weerawatsophon, U.; Sumransin, N.; Prahsarn, C.; Bergado, D.T. Properties and Potential Application of the Selected Natural Fibers as Limited Life Geotextiles. Carbohydr. Polym. 2010, 82, 1090–1096. [Google Scholar] [CrossRef]

- Mittal, M.; Chaudhary, R. Biodegradability and Mechanical Properties of Pineapple Leaf/Coir Fiber Reinforced Hybrid Epoxy Composites. Mater. Res. Express 2019, 6, 045301. [Google Scholar] [CrossRef]

- Saha, P.; Manna, S.; Sen, R.; Roy, D.; Adhikari, B. Durability of Lignocellulosic Fibers Treated with Vegetable Oil-Phenolic Resin. Carbohydr. Polym. 2012, 87, 1628–1636. [Google Scholar] [CrossRef]

- Sathishkumar, T.P.; Navaneethakrishnan, P.; Shankar, S.; Rajasekar, R. Characterization of New Cellulose Sansevieria Ehrenbergii Fibers for Polymer Composites. Compos. Interfaces 2013, 20, 575–593. [Google Scholar] [CrossRef]

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6, 226. [Google Scholar] [CrossRef] [Green Version]

- Rusdi, R.A.A.; Halim, N.A.; Nurazzi, N.M.; Abidin, Z.H.Z.; Abdullah, N.; Ros, F.C.; Ahmad, N.; Azmi, A.F.M. The Effect of Layering Structures on Mechanical and Thermal Properties of Hybrid Bacterial Cellulose/Kevlar Reinforced Epoxy Composites. Heliyon 2022, 8, e09442. [Google Scholar] [CrossRef] [PubMed]

| Fiber | Fiber Content (wt%) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Elongation at Break (%) | Flexural Strength (MPa) | Flexural Modulus (GPa) | Impact Energy (KJ/m2) | Hardness | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Abaca | 2.6–7.9 | 21.67–29.87 | 2.14 | 19.07 | [95] | ||||

| Abaca + glass | 40 | 44.5 | 0.27 | 15.05 | 12.5 | [96] | |||

| Alfa | 10 | 3.89–28.01 | 3.92–4.62 | 0.09–0.6 | [8] | ||||

| Bagasse | 30 | 20.43–42.86 | 1.33–1.54 | 1.4–2.5 | [97] | ||||

| Bagasse + glass | 15–30 | 1.56–4.69 | 20.5–56.7 | 20.5–56.7 | 0.82–3.96 | 39.80–53 HRA | [98] | ||

| Bamboo | 64 | 87–135 | 6.74–8.2 | 92–154 | 5.66–11.9 | 8.95–30.25 | [99] | ||

| Bamboo + glass | 10 | 92–100 | 3.7–5.4 | 145–165 | 5.6–7 | 23.4–25.3 HV | [100] | ||

| Banana | 25 | 16–35 | 0.5–1.7 | 35–68 | 7.8–13 | 2–12 (J/m) | [101] | ||

| Banana + glass | 10–40 | 45–135 | 0.44–1.38 | 10.5–13 | 30–200 | [102] | |||

| Coir | 30 | 3.21–13.05 | 1.33–2.06 | 25.41–35.42 | 16–17.5 | 15–16.9 HV | [103] | ||

| Coir + glass | 5–10 | 13.5–18 | 1.2–1.85 | 40–65 | 10–23 HV | [104] | |||

| Curaua | 30–50 | 20.2–30.29 | 2.27–4.24 | 1.4–2 | 52.02–67.45 | 2.94–4.37 | [105] | ||

| Date Palm | 40–60 | 21.43–24.35 | 0.61–1.32 | 1.17–1.35 | 68.13–98.71 (J/m) | [106] | |||

| Flax | 40 | 4.5–133 | 2.7–28 | 8–218 | 0.36–18 | [107] | |||

| Flax + glass | 16.5 | 225 | 9.06 | 5 | 170–420 | 4.2–14.6 | [108] | ||

| Hemp | 40–65 | 65–162 | 0.008–0.018 | 145–180 | 8–10.5 | 7–15 | [109] | ||

| Hemp + glass | 11–28 | 21.79–23.86 | 0.143–0.222 | 9–15 | 47.77–61.54 | 87.03–100.2 | [110] | ||

| Henequen | 64 | 233–234 | 15–17 | 0.9–1.7 | 197.32–199.52 | 11.90–12.23 | 90.81–116.04 | [111] | |

| Henequen + glass | 10–50 | 60.8–156.2 | 2.3–3.2 | 2.7–5.3 | 80.65–128.6 | 7.0–11.4 | [112] | ||

| Jute | 30 | 78.21 | 1.52 | 203.48 | 9.76 | 5.67–13.89 | [113] | ||

| Jute + glass | 8.75 | 80–85 | 2.6–4.8 | 93–165 | 4.6–6.6 | [114] | |||

| Kenaf | 50 | 138.92–159.98 | 5.77–8.2 | 1.8–2.4 | [115] | ||||

| Kenaf + glass | 14 | 150 | 7.5 | 220–240 | 3.87–14.2 | [71] | |||

| Oil Palm | 5–20 | 28–30 | 1.34–1.44 | 40–56 | [116] | ||||

| PALF | 5–25 | 2.13–3.44 | 4.4–6.25 | 22–32.5 (J/m) | [117] | ||||

| PALF + glass | 10–20 | 38–48 | 1.2–1.75 | 88–152 | 3.5–7 | 3.5–7 | [118] | ||

| Piassava | 10–40 | 58.97–89.33 | 2.46–2.87 | 39.35–78.41 | 2.56–3.46 | 75–210 (J/m) | [119] | ||

| Ramie | 42–49 | 85–117 | 8.3–11.8 | 130–152 | 7–9.5 | [120] | |||

| Sisal | 50–58 | 240–375 | 4–9.75 | 3–5.25 | 200–325 | 15–24 | [121] | ||

| Sisal + glass | 15–35 | 53.77–72.13 | 80.2–87 | 27.13–48.59 | [122] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alsuwait, R.B.; Souiyah, M.; Momohjimoh, I.; Ganiyu, S.A.; Bakare, A.O. Recent Development in the Processing, Properties, and Applications of Epoxy-Based Natural Fiber Polymer Biocomposites. Polymers 2023, 15, 145. https://doi.org/10.3390/polym15010145

Alsuwait RB, Souiyah M, Momohjimoh I, Ganiyu SA, Bakare AO. Recent Development in the Processing, Properties, and Applications of Epoxy-Based Natural Fiber Polymer Biocomposites. Polymers. 2023; 15(1):145. https://doi.org/10.3390/polym15010145

Chicago/Turabian StyleAlsuwait, Raed B., Miloud Souiyah, Ibrahim Momohjimoh, Saheed Adewale Ganiyu, and Azeez Oladipupo Bakare. 2023. "Recent Development in the Processing, Properties, and Applications of Epoxy-Based Natural Fiber Polymer Biocomposites" Polymers 15, no. 1: 145. https://doi.org/10.3390/polym15010145

APA StyleAlsuwait, R. B., Souiyah, M., Momohjimoh, I., Ganiyu, S. A., & Bakare, A. O. (2023). Recent Development in the Processing, Properties, and Applications of Epoxy-Based Natural Fiber Polymer Biocomposites. Polymers, 15(1), 145. https://doi.org/10.3390/polym15010145