Development of Novel Blown Shrink Films from Poly(Lactide)/Poly(Butylene-Adipate-co-Terephthalate) Blends for Sustainable Food Packaging Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Production of the Films

2.3. Film Characterization

3. Results and Discussion

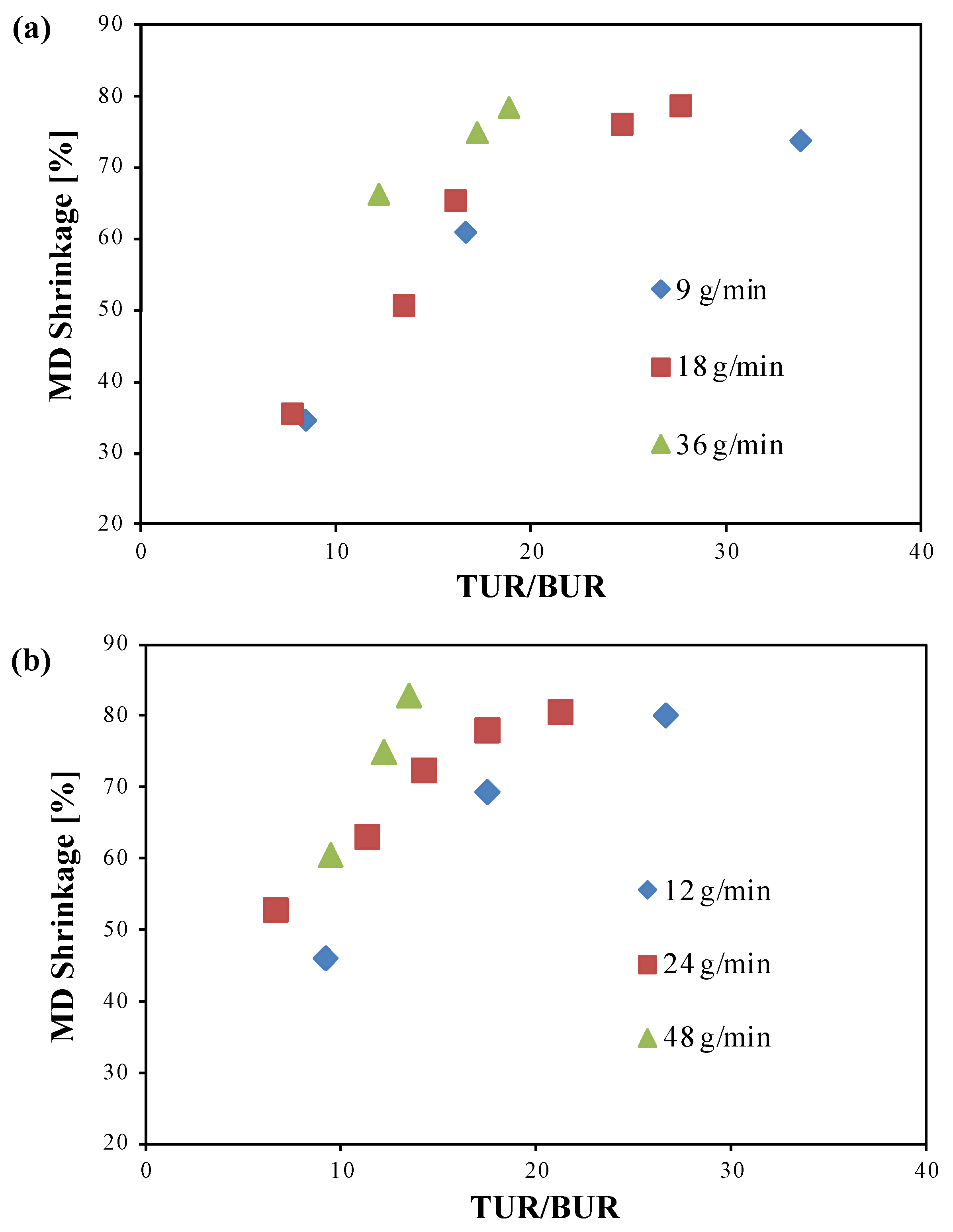

3.1. Shrink Properties

3.1.1. Effect of the TUR/BUR Ratio, Mass Flow Rate, and blend Composition

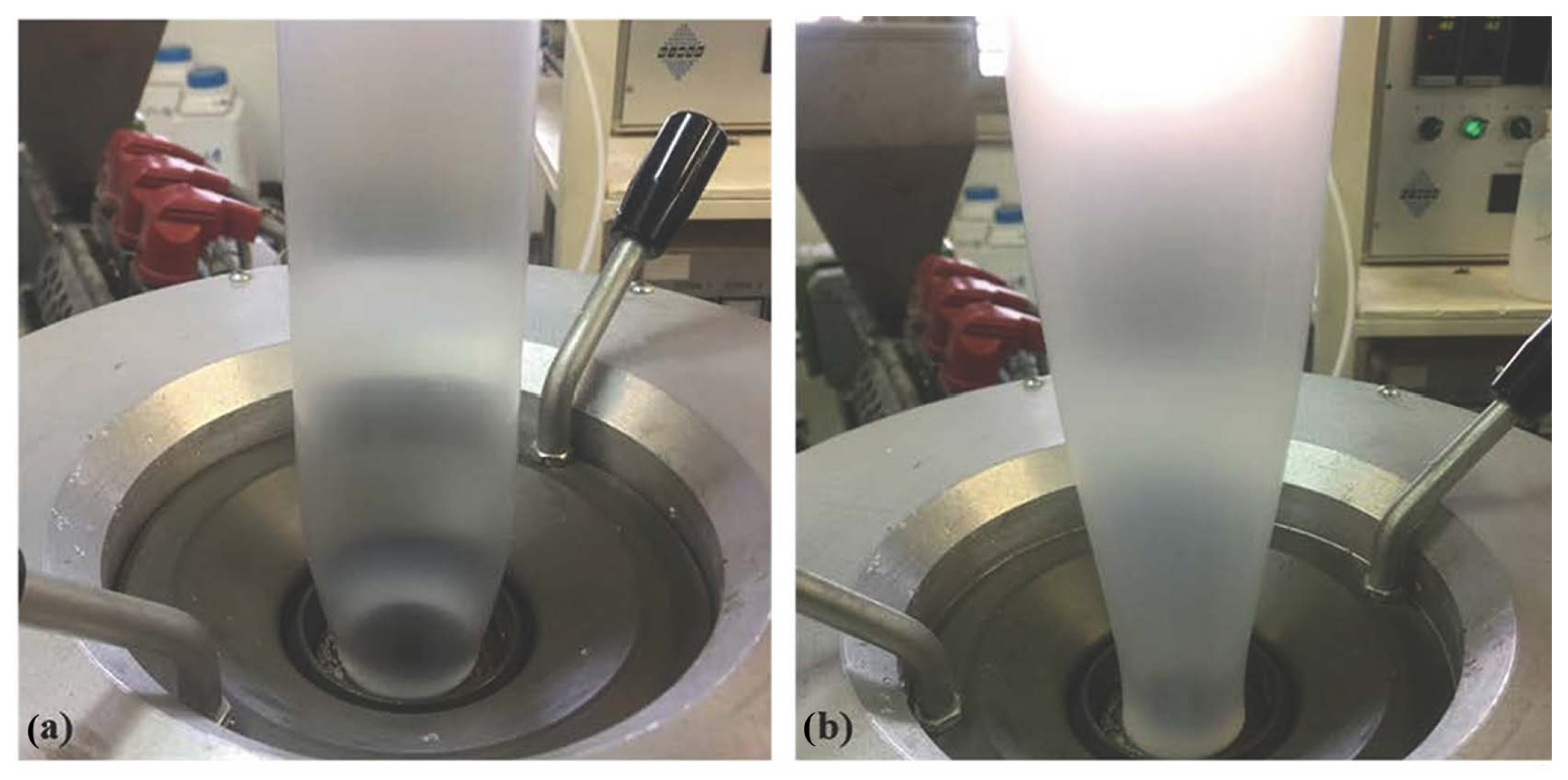

3.1.2. Effect of the Bubble Cooling

3.2. Functional Characterization of the Films

3.2.1. Thermal ANALYSIS

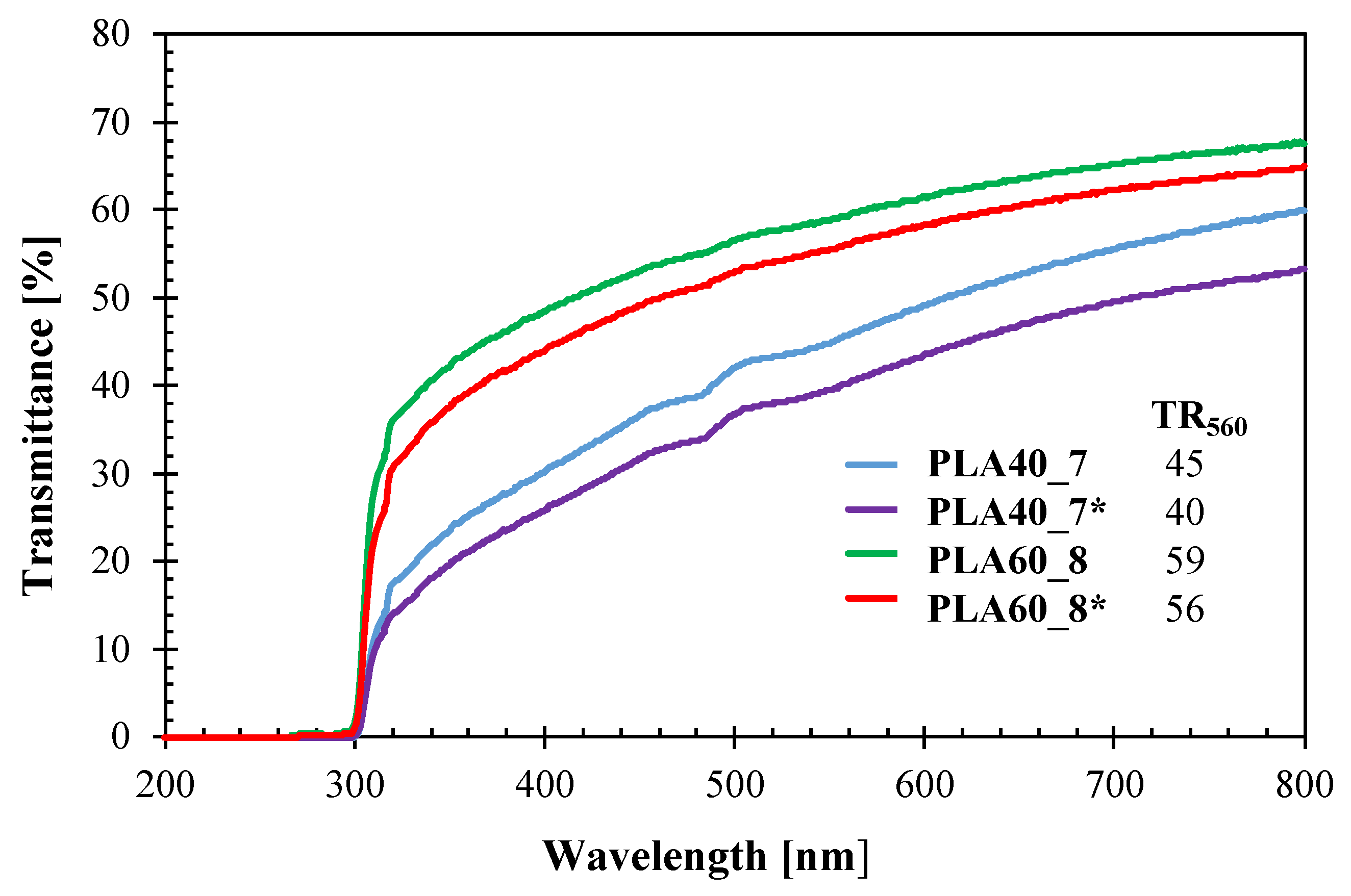

3.2.2. Optical Properties

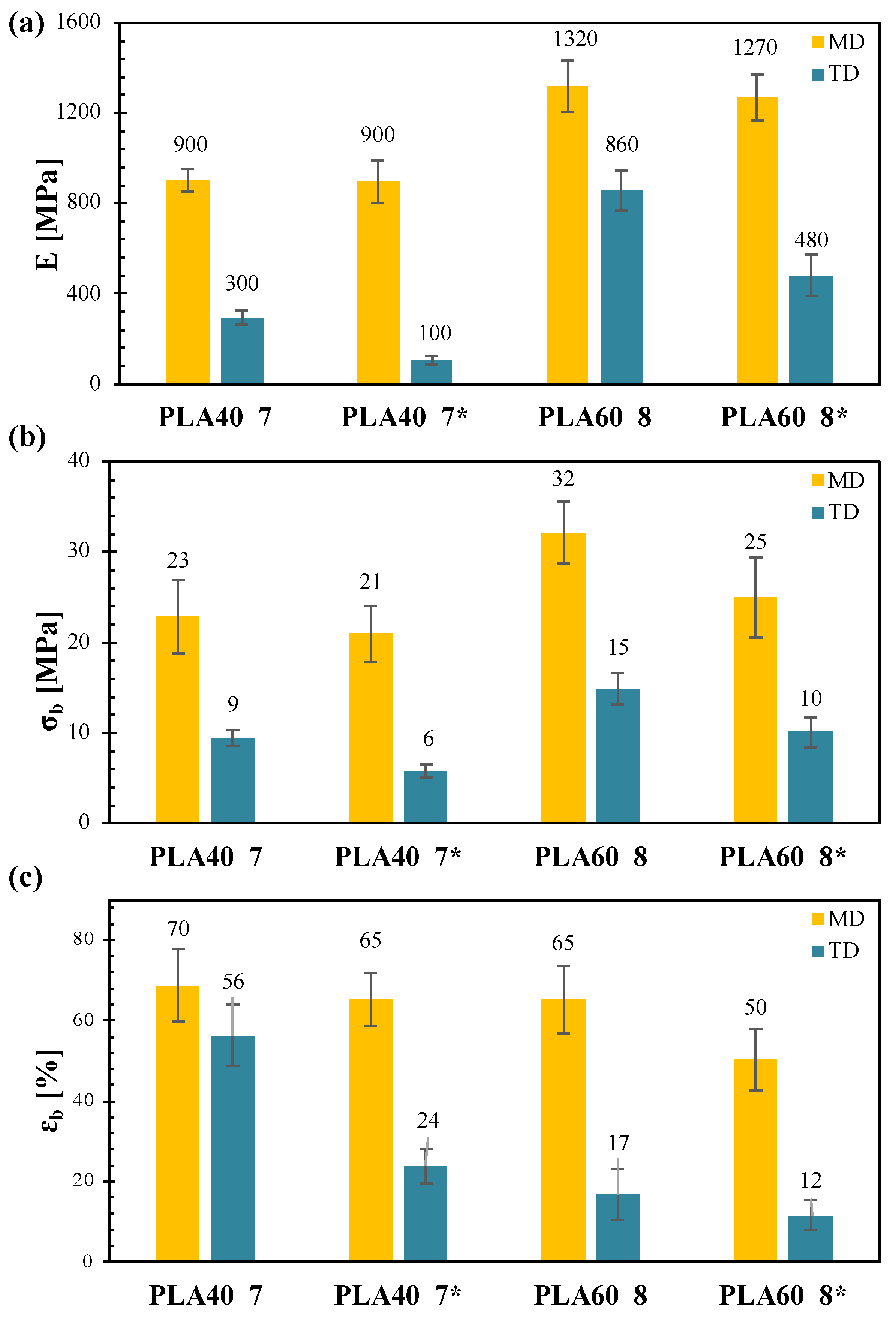

3.2.3. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Grand View Research. Stretch and Shrink Film Market Size, Share & Trends Analysis Report By Resin (LLDPE, LDPE, PVC), by Product (Hoods, Warps, Sleeve Labels), by Application (Food & Beverage, Consumer Goods), and Segment Forecasts, 2020–2027. 2020. Available online: https://www.grandviewresearch.com/industry-analysis/stretch-and-shrink-films-market (accessed on 27 June 2022).

- Khankrua, R.; Pongpanit, T.; Paneetjit, P.; Boonmark, R.; Seadan, M.; Suttiruengwong, S. Development of PLA/EVA Reactive Blends for Heat-Shrinkable Film. Polymers 2019, 11, 1925. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pettey, C.C.; Charlie, R. Multilayer Blown Films for Shrink Applications. US Patent 9,718,230 B2, 1 August 2017. [Google Scholar]

- Al-Robaidi, A. Processing of Polyethylene Films. In Handbook of Plastic Films; Abdel-Bary, E.M., Ed.; Rapra Technology Limited: Shrewsbury, UK, 2003; pp. 41–70. [Google Scholar]

- Luo, Y.; Chang, X.; Qu, J. Improved heat shrinkage and mechanical performances of polyethylene trilayer blown film prepared via novel multilayer coextrusion method. Packag. Technol. Sci. 2019, 32, 309–321. [Google Scholar] [CrossRef]

- Patel, R.M.; Butler, T.I.; Walton, K.L.; Knight, G.W. Investigation of processing-structure-properties relationships in polyethylene blown films. Polym. Eng. Sci. 1994, 34, 1506–1514. [Google Scholar] [CrossRef]

- Menges, G.; Predöhl, W.O. Certain aspects of film blowing of low-density polyethylene. Polym. Eng. Sci. 1975, 15, 394–399. [Google Scholar] [CrossRef]

- Torres, A.; Colls, N.; Méndez, F. Properties Predictor for HDPE/LDPE/LLDPE Blends for Shrink Film Applications. J. Plast. Film Sheeting 2006, 22, 29–37. [Google Scholar] [CrossRef] [Green Version]

- Credence Research. Shrink Films Market by Material Type (Polyvinyl Chloride (PVC) Shrink Films, Polyolefin, Petg (PET) Shrink Films, Oriented Polystyrene (OPS) Shrink Films, Polylactic Acid (PLA) Shrink Films), by Application (Food & Beverages, Pharmaceuticals, Automotive & Industrial Products, Electronics)—Growth, Share, Opportunities & Competitive Analysis, 2017–2025. 2017. Available online: https://www.credenceresearch.com/report/shrink-films-market (accessed on 27 June 2022).

- Sam, S.T.; Nuradibah, M.A.; Chin, K.M.; Hani, N. Current Application and Challenges on Packaging Industry Based on Natural Polymer Blending. In Natural Polymers; Olatunji, O., Ed.; Springer: Cham, Switzerland, 2016; pp. 163–185. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef] [Green Version]

- Tábi, T.; Ageyeva, T.; Kovács, J.G. Improving the ductility and heat deflection temperature of injection molded Poly(lactic acid) products: A comprehensive review. Polym. Test. 2021, 101, 107282. [Google Scholar] [CrossRef]

- Pietrosanto, A.; Scarfato, P.; Di Maio, L.; Incarnato, L. Development of PLA/PHB Blown Films with Improved Performance for Food Packaging Applications. Chem. Eng. Trans. 2021, 87, 91–96. [Google Scholar] [CrossRef]

- Coiai, S.; Di Lorenzo, M.; Cinelli, P.; Righetti, M.; Passaglia, E. Binary Green Blends of Poly(lactic acid) with Poly(butylene adipate-co-butylene terephthalate) and Poly(butylene succinate-co-butylene adipate) and Their Nanocomposites. Polymers 2021, 13, 2489. [Google Scholar] [CrossRef]

- Mistretta, M.C.; Botta, L.; La Mantia, F.P.; Di Fiore, A.; Cascone, M. Film Blowing of Biodegradable Polymer Nanocomposites for Agricultural Applications. Macromol. Mater. Eng. 2021, 306, 2100177. [Google Scholar] [CrossRef]

- Kultravut, K.; Kuboyama, K.; Ougizawa, T. Effect of Blending Procedure on Tensile and Degradation Properties of Toughened Biodegradable Poly(lactic acid) Blend with Poly(trimethylene terephthalate) and Reactive Compatibilizer. Macromol. Mater. Eng. 2019, 304, 1900323. [Google Scholar] [CrossRef]

- Pietrosanto, A.; Scarfato, P.; Di Maio, L.; Nobile, M.R.; Incarnato, L. Evaluation of the Suitability of Poly(Lactide)/Poly(Butylene-Adipate-co-Terephthalate) Blown Films for Chilled and Frozen Food Packaging Applications. Polymers 2020, 12, 804. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Apicella, A.; Scarfato, P.; Di Maio, L.; Incarnato, L. Oxygen absorption data of multilayer oxygen scavenger-polyester films with different layouts. Data Brief 2018, 19, 1530–1536. [Google Scholar] [CrossRef] [PubMed]

- Atta, O.; Manan, S.; Ahmed, A.; Awad, M.; Ul-Islam, M.; Subhan, F.; Ullah, M.; Yang, G. Development and Characterization of Yeast-Incorporated Antimicrobial Cellulose Biofilms for Edible Food Packaging Application. Polymers 2021, 13, 2310. [Google Scholar] [CrossRef]

- Bojda, J.; Piorkowska, E.; Pluta, M. Shear-induced non-isothermal crystallization of poly(butylene adipate-co-terephthalate). Polym. Test. 2020, 85, 106420. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, F.; Yu, Q.; Ni, C.; Gu, X.; Li, Y.; You, J. Fabrication of PLLA with High Ductility and Transparence by Blending with Tiny Amount of PVDF and Compatibilizers. Macromol. Mater. Eng. 2019, 304, 1970030. [Google Scholar] [CrossRef]

- Chinsirikul, W.; Rojsatean, J.; Hararak, B.; Kerddonfag, N.; Aontee, A.; Jaieau, K.; Kumsang, P.; Sripethdee, C. Flexible and Tough Poly(lactic acid) Films for Packaging Applications: Property and Processability Improvement by Effective Reactive Blending. Packag. Technol. Sci. 2015, 28, 741–759. [Google Scholar] [CrossRef]

- Pietrosanto, A.; Scarfato, P.; Di Maio, L.; Incarnato, L. Development of Eco-Sustainable PBAT-Based Blown Films and Performance Analysis for Food Packaging Applications. Materials 2020, 13, 5395. [Google Scholar] [CrossRef]

- Azevedo, J.V.C.; Dorp, E.R.-V.; Hausnerova, B.; Möginger, B. The Effects of Chain-Extending Cross-Linkers on the Mechanical and Thermal Properties of Poly(butylene adipate terephthalate)/Poly(lactic acid) Blown Films. Polymers 2021, 13, 3092. [Google Scholar] [CrossRef]

- Apicella, A.; Barbato, A.; Garofalo, E.; Incarnato, L.; Scarfato, P. Effect of PVOH/PLA + Wax Coatings on Physical and Functional Properties of Biodegradable Food Packaging Films. Polymers 2022, 14, 935. [Google Scholar] [CrossRef]

- Azevedo, J.V.C.; Dorp, E.R.-V.; Grimmig, R.; Hausnerova, B.; Möginger, B. Process-Induced Morphology of Poly(Butylene Adipate Terephthalate)/Poly(Lactic Acid) Blown Extrusion Films Modified with Chain-Extending Cross-Linkers. Polymers 2022, 14, 1939. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Ai, X.; Pan, H.; Yang, J.; Gao, G.; Zhang, H.; Yang, H.; Dong, L. The morphological, mechanical, rheological, and thermal properties of PLA/PBAT blown films with chain extender. Polym. Adv. Technol. 2018, 29, 1706–1717. [Google Scholar] [CrossRef]

- McDaniel, J.B. Polylactic Acid Shrink Films and Methods of Manufacturing Same. US Patent 8.496,868 B2, 30 July 2013. [Google Scholar]

- Auffermann, J.; Skupin, G.; Kinkel, A. Method for Producing Shrink Films. US Patent 8,658,069 B2, 25 February 2014. [Google Scholar]

- Li, X.; Yan, X.; Yang, J.; Pan, H.; Gao, G.; Zhang, H.; Dong, L. Improvement of compatibility and mechanical properties of the poly(lactic acid)/poly(butylene adipate-co -terephthalate) blends and films by reactive extrusion with chain extender. Polym. Eng. Sci. 2018, 58, 1868–1878. [Google Scholar] [CrossRef]

- Nunes, E.D.C.D.; de Souza, A.G.; Rosa, D.D.S. Effect of the Joncryl® ADR Compatibilizing Agent in Blends of Poly(butylene adipate-co-terephthalate)/Poly(lactic acid). Macromol. Symp. 2019, 383, 1800035. [Google Scholar] [CrossRef] [Green Version]

- Zhou, J.; Zheng, Y.; Shan, G.; Bao, Y.; Wang, W.-J.; Pan, P. Stretch-induced crystalline structural evolution and cavitation of poly(butylene adipate-ran-butylene terephthalate)/poly(lactic acid) immiscible blends. Polymer 2020, 188, 122121. [Google Scholar] [CrossRef]

- Wang, X.; Peng, S.; Chen, H.; Yu, X.; Zhao, X. Mechanical properties, rheological behaviors, and phase morphologies of high-toughness PLA/PBAT blends by in-situ reactive compatibilization. Compos. Part B Eng. 2019, 173, 107028. [Google Scholar] [CrossRef]

- Al-Itry, R.; Lamnawar, K.; Maazouz, A.; Billon, N.; Combeaud, C. Effect of the simultaneous biaxial stretching on the structural and mechanical properties of PLA, PBAT and their blends at rubbery state. Eur. Polym. J. 2015, 68, 288–301. [Google Scholar] [CrossRef]

- Cranston, E.; Kawada, J.; Raymond, S.; Morin, F.G.; Marchessault, R.H. Cocrystallization Model for Synthetic Biodegradable Poly(butylene adipate-co-butylene terephthalate). Biomacromolecules 2003, 4, 995–999. [Google Scholar] [CrossRef]

- Shi, X.; Ito, H.; Kikutani, T. Characterization on mixed-crystal structure and properties of poly(butylene adipate-co-terephthalate) biodegradable fibers. Polymer 2005, 46, 11442–11450. [Google Scholar] [CrossRef]

- Sohel, M.A.; Mondal, A.; Sengupta, A. Effect of Physical Aging on Glass Transition and Enthalpy Relaxation in PLA Polymer Filament. In Recent Advances in Materials Science and Biophysics, Proceedings of International Conference RAMSB, Mangaluru, India, 23–25 January 2018; Kohinoor Computer Zone: Mangaluru, India, 2018; Volume 2018, pp. 191–194. [Google Scholar]

- Wang, L.-F.; Rhim, J.-W.; Hong, S.-I. Preparation of poly(lactide)/poly(butylene adipate-co-terephthalate) blend films using a solvent casting method and their food packaging application. LWT 2016, 68, 454–461. [Google Scholar] [CrossRef]

- Strobl, G. Crystallization and melting of bulk polymers: New observations, conclusions and a thermodynamic scheme. Prog. Polym. Sci. 2006, 31, 398–442. [Google Scholar] [CrossRef]

- Höhne, G. Another approach to the Gibbs–Thomson equation and the melting point of polymers and oligomers. Polymer 2002, 43, 4689–4698. [Google Scholar] [CrossRef]

- Fatahi, S.; Ajji, A.; Lafleur, P.G. Investigation on the Structure and Properties of Different PE Blown Films. Int. Polym. Processing 2007, 22, 334–345. [Google Scholar] [CrossRef]

- Fischer, C.; Drummer, D. Crystallization and Mechanical Properties of Polypropylene under Processing-Relevant Cooling Conditions with respect to Isothermal Holding Time. Int. J. Polym. Sci. 2016, 2016, 5450708. [Google Scholar] [CrossRef]

- Ramos, Ó.L.; Reinas, I.; Silva, S.I.; Fernandes, J.C.; Cerqueira, M.A.; Pereira, R.N.; Vicente, A.A.; Poças, M.F.; Pintado, M.E.; Malcata, F.X. Effect of whey protein purity and glycerol content upon physical properties of edible films manufactured therefrom. Food Hydrocoll. 2013, 30, 110–122. [Google Scholar] [CrossRef] [Green Version]

- Pietrosanto, A.; Scarfato, P.; Di Maio, L.; Incarnato, L. Effect of Different Types of PLA on the Properties of PLA/PBAT Blown Films. Key Eng. Mater. 2021, 885, 115–120. [Google Scholar]

- Tabatabaei, S.H.; Carreau, P.J.; Ajji, A. Effect of processing on the crystalline orientation, morphology, and mechanical properties of polypropylene cast films and microporous membrane formation. Polymer 2009, 50, 4228–4240. [Google Scholar] [CrossRef]

- Tsuji, H.; Ikada, Y. Stereocomplex formation between enantiomeric poly(lactic acid)s. XI. Mechanical properties and morphology of solution-cast films. Polymer 1999, 40, 6699–6708. [Google Scholar] [CrossRef]

| Sample Name | Mass Flow Rate (g/min) | Cooling Air | Thickness (μm) | BUR | TUR | TUR/BUR |

|---|---|---|---|---|---|---|

| PLA40_1 | 9 | yes | 26 | 1.9 | 16 | 8 |

| PLA40_1* | 9 | no | 26 | 1.9 | 16 | 8 |

| PLA40_2 | 9 | yes | 15 | 1.8 | 30 | 17 |

| PLA40_2* | 9 | no | 15 | 1.8 | 30 | 17 |

| PLA40_3 | 9 | yes | 14 | 1.3 | 44 | 34 |

| PLA40_4 | 18 | yes | 31 | 1.8 | 14 | 8 |

| PLA40_5 | 18 | yes | 20 | 1.7 | 23 | 14 |

| PLA40_6 | 18 | yes | 16 | 1.8 | 29 | 16 |

| PLA40_7 | 18 | yes | 15 | 1.5 | 37 | 25 |

| PLA40_7* | 18 | no | 15 | 1.5 | 37 | 25 |

| PLA40_8 | 18 | yes | 10 | 1.7 | 47 | 28 |

| PLA40_8* | 18 | no | 10 | 1.7 | 47 | 28 |

| PLA40_9 | 36 | yes | 20 | 1.8 | 22 | 12 |

| PLA40_10 | 36 | yes | 15 | 1.8 | 31 | 17 |

| PLA40_11 | 36 | yes | 13 | 1.8 | 34 | 19 |

| Sample Name | Mass Flow Rate (g/min) | Cooling Air | Thickness (μm) | BUR | TUR | TUR/BUR |

|---|---|---|---|---|---|---|

| PLA60_1 | 12 | yes | 50 | 1.3 | 12 | 9 |

| PLA60_2 | 12 | yes | 33 | 1.2 | 21 | 18 |

| PLA60_2* | 12 | no | 33 | 1.2 | 21 | 18 |

| PLA60_3 | 12 | yes | 20 | 1.2 | 32 | 27 |

| PLA60_4 | 24 | yes | 50 | 1.5 | 10 | 7 |

| PLA60_5 | 24 | yes | 31 | 1.5 | 17 | 11 |

| PLA60_6 | 24 | yes | 28 | 1.4 | 20 | 14 |

| PLA60_7 | 24 | yes | 19 | 1.6 | 28 | 18 |

| PLA60_7* | 24 | no | 19 | 1.6 | 28 | 18 |

| PLA60_8 | 24 | yes | 15 | 1.6 | 34 | 21 |

| PLA60_8* | 24 | no | 15 | 1.6 | 34 | 21 |

| PLA60_9 | 48 | yes | 24 | 1.9 | 18 | 9 |

| PLA60_10 | 48 | yes | 20 | 1.8 | 22 | 12 |

| PLA60_11 | 48 | yes | 20 | 1.7 | 23 | 14 |

| Sample Name | Cooling Air | Mass Flow Rate (g/min) | TUR/BUR | MD Shrinkage (%) | TD Shrinkage (%) |

|---|---|---|---|---|---|

| PLA40_1 | yes | 9 | 8 | 35 ± 5 | 11 ± 3 |

| PLA40_1* | no | 9 | 8 | 33 ± 4 | 22 ± 3 |

| PLA40_2 | yes | 9 | 17 | 61 ± 4 | 9 ± 1 |

| PLA40_2* | no | 9 | 17 | 55 ± 4 | 11 ± 3 |

| PLA40_3 | yes | 9 | 34 | 74 ± 3 | 10 ± 2 |

| PLA40_4 | yes | 18 | 8 | 36 ± 3 | 25 ± 4 |

| PLA40_5 | yes | 18 | 14 | 51 ± 3 | 26 ± 3 |

| PLA40_6 | yes | 18 | 16 | 65 ± 7 | 15 ± 4 |

| PLA40_7 | yes | 18 | 25 | 76 ± 5 | 6 ± 3 |

| PLA40_7* | no | 18 | 25 | 73 ± 3 | 18 ± 2 |

| PLA40_8 | yes | 18 | 28 | 79 ± 4 | 9 ± 1 |

| PLA40_8* | no | 18 | 28 | 77 ± 6 | 13 ± 2 |

| PLA40_9 | yes | 36 | 12 | 66 ± 7 | 11 ± 3 |

| PLA40_10 | yes | 36 | 17 | 75 ± 3 | 8 ± 1 |

| PLA40_11 | yes | 36 | 19 | 78 ± 5 | 21 ± 4 |

| Sample Name | Cooling Air | Mass Flow Rate (g/min) | TUR/BUR | MD Shrinkage (%) | TD Shrinkage (%) |

|---|---|---|---|---|---|

| PLA60_1 | yes | 12 | 9 | 46 ± 5 | 0 ± 1 |

| PLA60_2 | yes | 12 | 18 | 72 ± 5 | 2 ± 1 |

| PLA60_2* | no | 12 | 18 | 69 ± 3 | 7 ± 2 |

| PLA60_3 | yes | 12 | 27 | 80 ± 3 | 1 ± 1 |

| PLA60_4 | yes | 24 | 7 | 53 ± 4 | 15 ± 3 |

| PLA60_5 | yes | 24 | 11 | 63 ± 4 | 10 ± 2 |

| PLA60_6 | yes | 24 | 14 | 72 ± 2 | 10 ± 3 |

| PLA60_7 | yes | 24 | 18 | 78 ± 2 | 15 ± 4 |

| PLA60_7* | no | 24 | 18 | 76 ± 2 | 19 ± 6 |

| PLA60_8 | yes | 24 | 21 | 81 ± 4 | 14 ± 6 |

| PLA60_8* | no | 24 | 21 | 79 ± 2 | 25 ± 4 |

| PLA60_9 | yes | 48 | 9 | 60 ± 1 | 9 ± 1 |

| PLA60_10 | yes | 48 | 12 | 75 ± 4 | 11 ± 3 |

| PLA60_11 | yes | 48 | 14 | 83 ± 5 | 21 ± 5 |

| Sample Name | Tg PBAT (°C) | Tg PLA (°C) | Tm1 PBAT (°C) | ΔHm1 PBAT (J/g) | Tm2 PBAT (°C) | Δ;Hm2 PBAT (J/g) | Xc PBAT (%) |

|---|---|---|---|---|---|---|---|

| PLA40_7 | −33.4 | 56.1 | 41.9 | 1.1 | 111.4 | 5.1 | 9.1 |

| PLA40_7* | −33.1 | 63.9 | 49.4 | 0.3 | 114.0 | 6.2 | 9.5 |

| PLA60_8 | −31.7 | 54.7 | 45.2 | 0.9 | 111.8 | 3.0 | 8.5 |

| PLA60_8* | −33.0 | 60.1 | 50.5 | 0.1 | 113.9 | 4.0 | 9.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pietrosanto, A.; Apicella, A.; Scarfato, P.; Incarnato, L.; Di Maio, L. Development of Novel Blown Shrink Films from Poly(Lactide)/Poly(Butylene-Adipate-co-Terephthalate) Blends for Sustainable Food Packaging Applications. Polymers 2022, 14, 2759. https://doi.org/10.3390/polym14142759

Pietrosanto A, Apicella A, Scarfato P, Incarnato L, Di Maio L. Development of Novel Blown Shrink Films from Poly(Lactide)/Poly(Butylene-Adipate-co-Terephthalate) Blends for Sustainable Food Packaging Applications. Polymers. 2022; 14(14):2759. https://doi.org/10.3390/polym14142759

Chicago/Turabian StylePietrosanto, Arianna, Annalisa Apicella, Paola Scarfato, Loredana Incarnato, and Luciano Di Maio. 2022. "Development of Novel Blown Shrink Films from Poly(Lactide)/Poly(Butylene-Adipate-co-Terephthalate) Blends for Sustainable Food Packaging Applications" Polymers 14, no. 14: 2759. https://doi.org/10.3390/polym14142759

APA StylePietrosanto, A., Apicella, A., Scarfato, P., Incarnato, L., & Di Maio, L. (2022). Development of Novel Blown Shrink Films from Poly(Lactide)/Poly(Butylene-Adipate-co-Terephthalate) Blends for Sustainable Food Packaging Applications. Polymers, 14(14), 2759. https://doi.org/10.3390/polym14142759