Effect of Graphene/Spherical Graphite Ratio on the Properties of PLA/TPU Composites

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials and Instruments

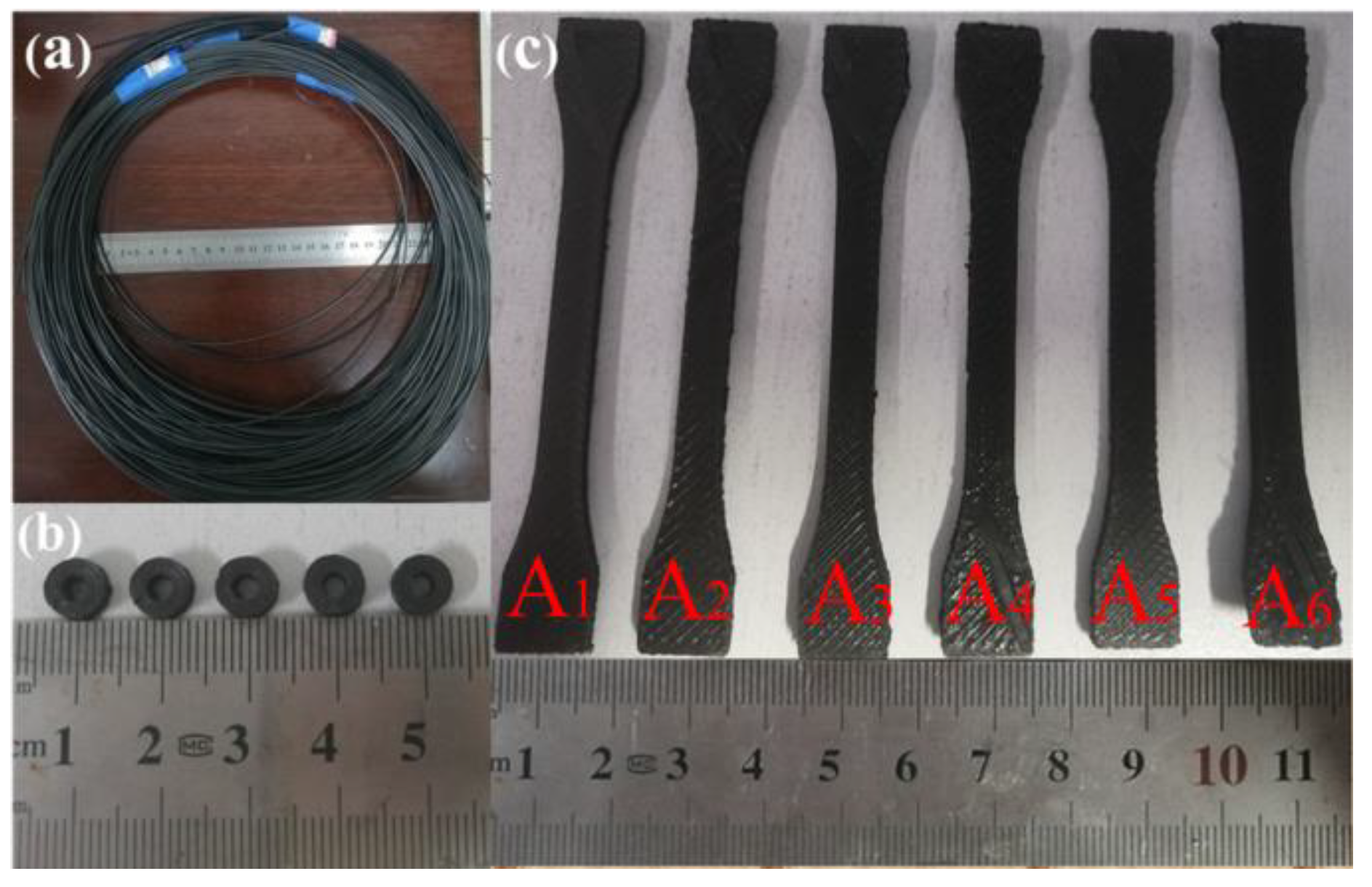

2.2. Preparation of SG/GR/PLA/TPU Composites

2.3. Performance Characterization

3. Results and Discussion

3.1. Material Characterization Analysis

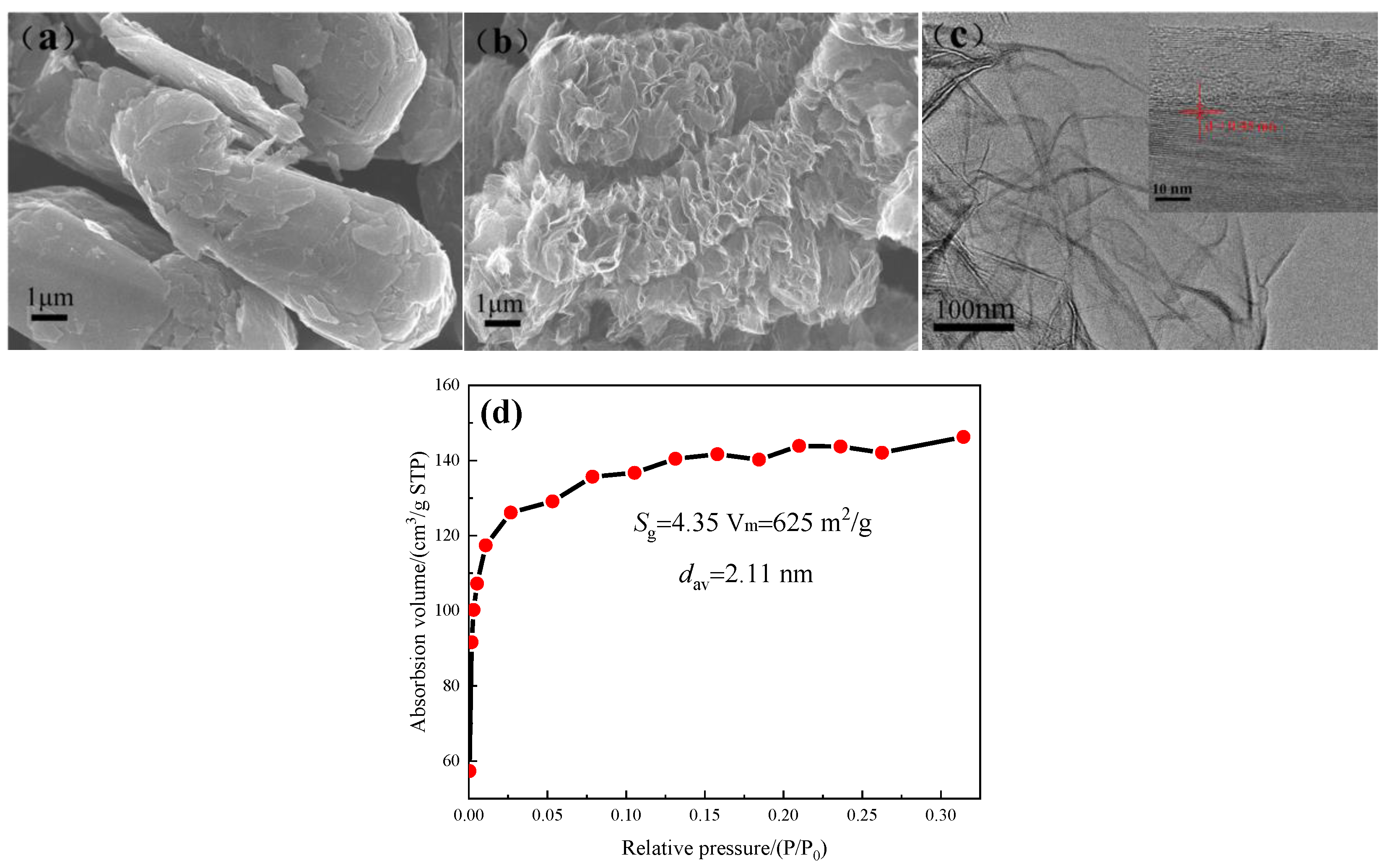

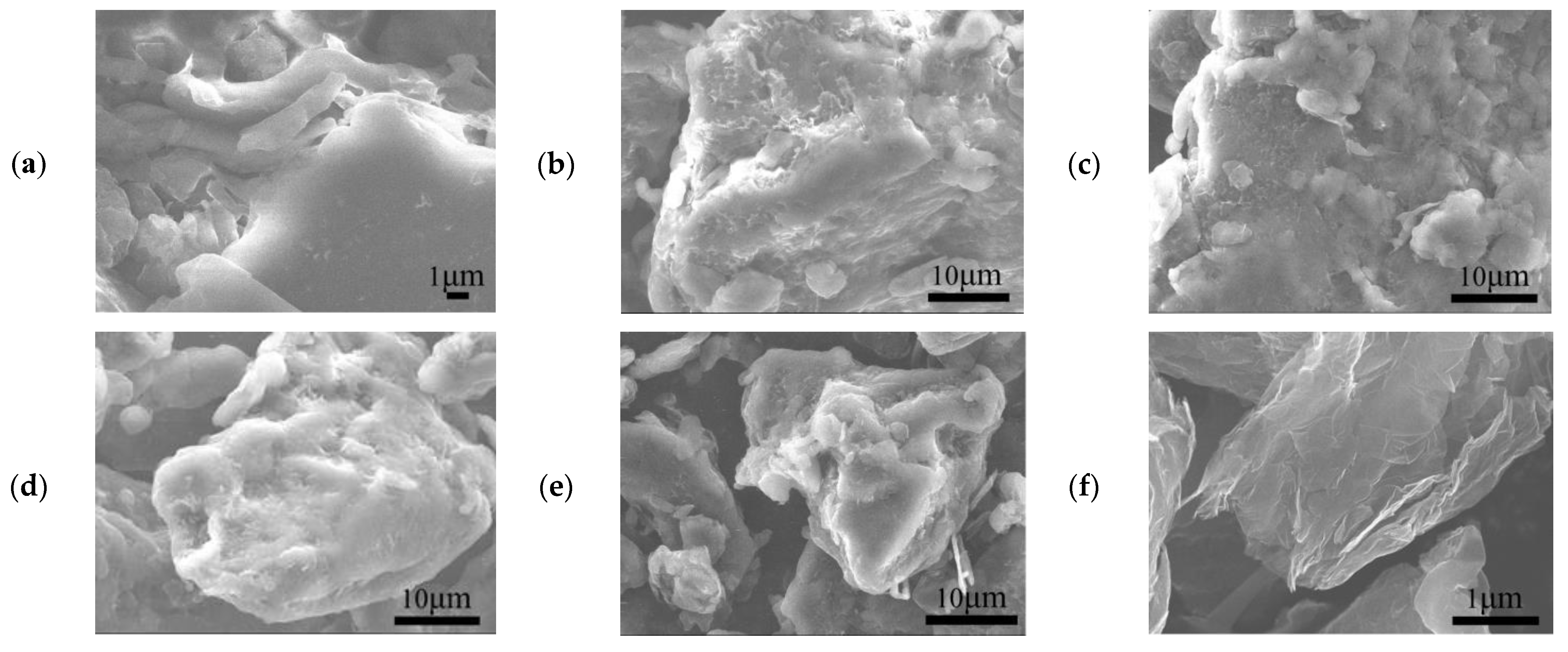

3.1.1. The Micro-Morphology and Size Structure of SG and GR

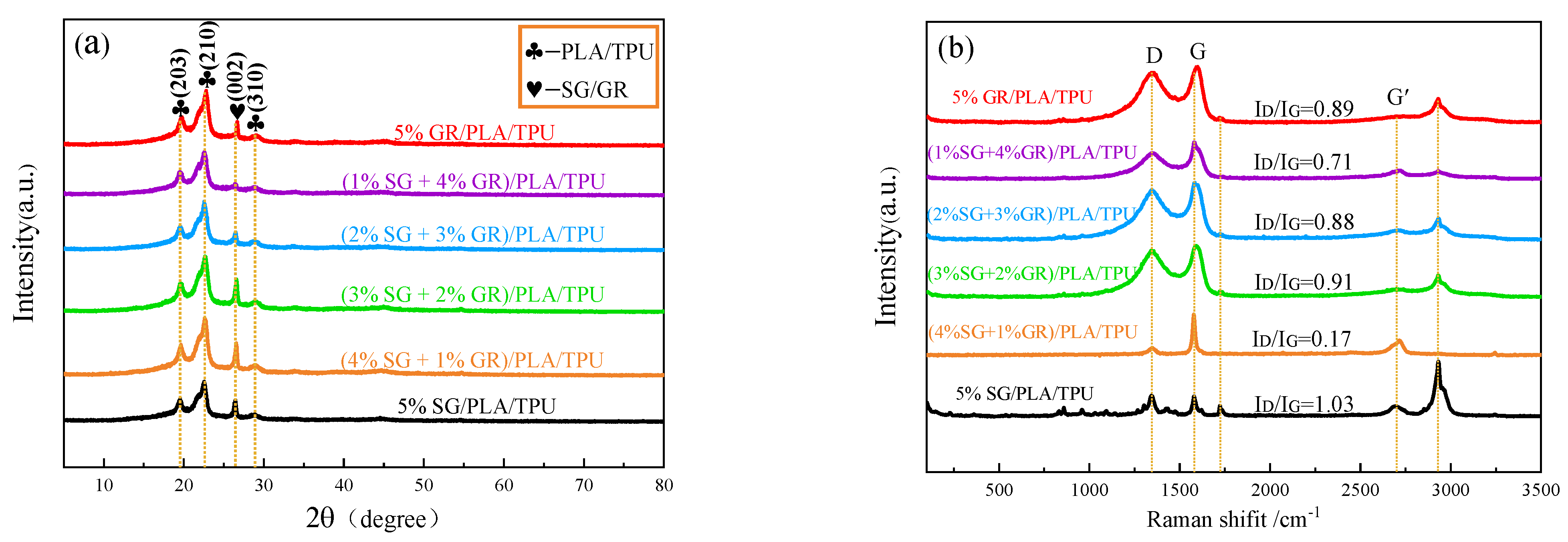

3.1.2. Phase Structure and Graphitization Degree of SG/GR/PLA/TPU Composites

3.2. Effect of SG/GR Ratio on Microwave Absorbing Properties of PLA/TPU Composites

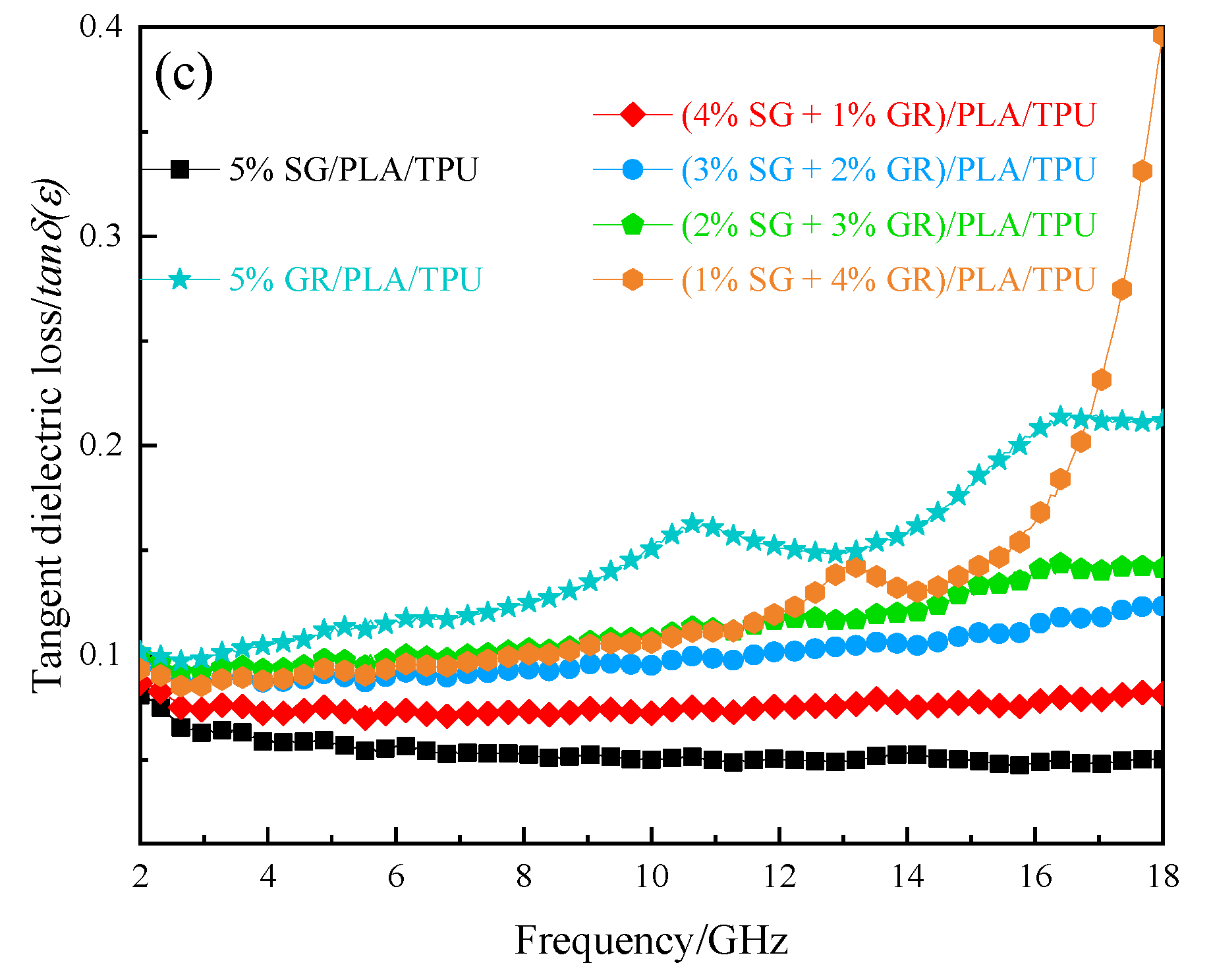

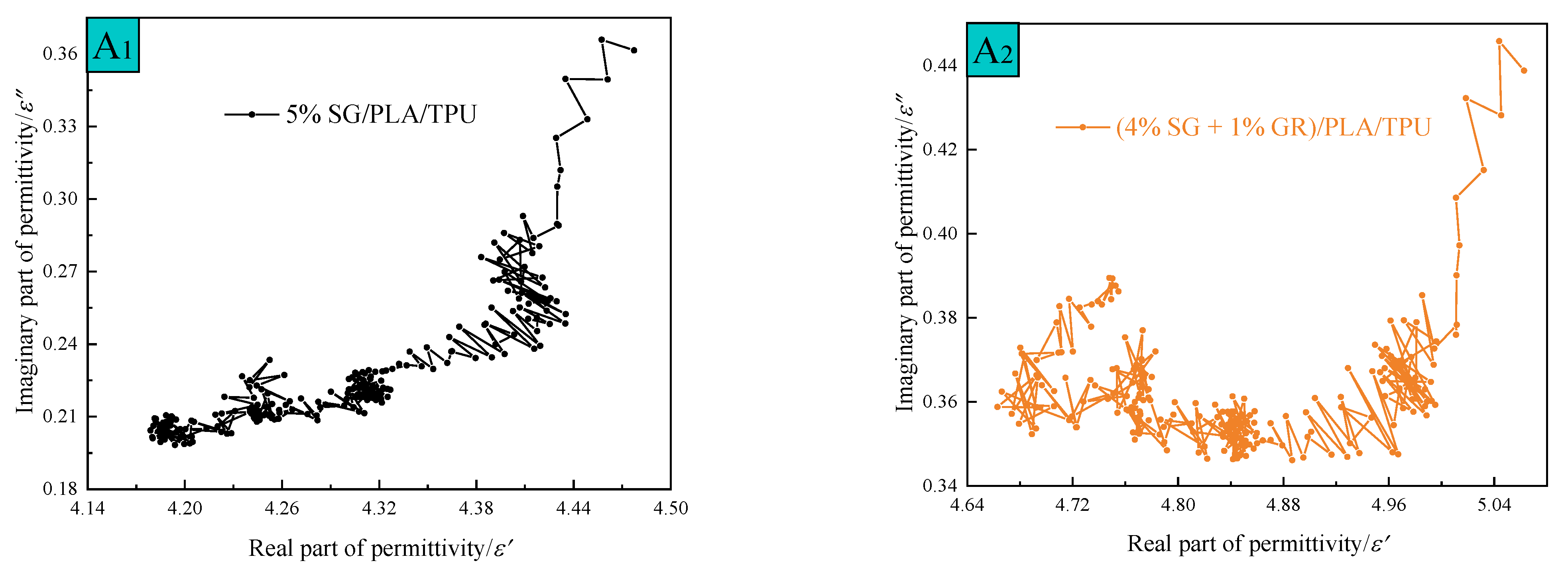

3.2.1. Dielectric Loss of Composites

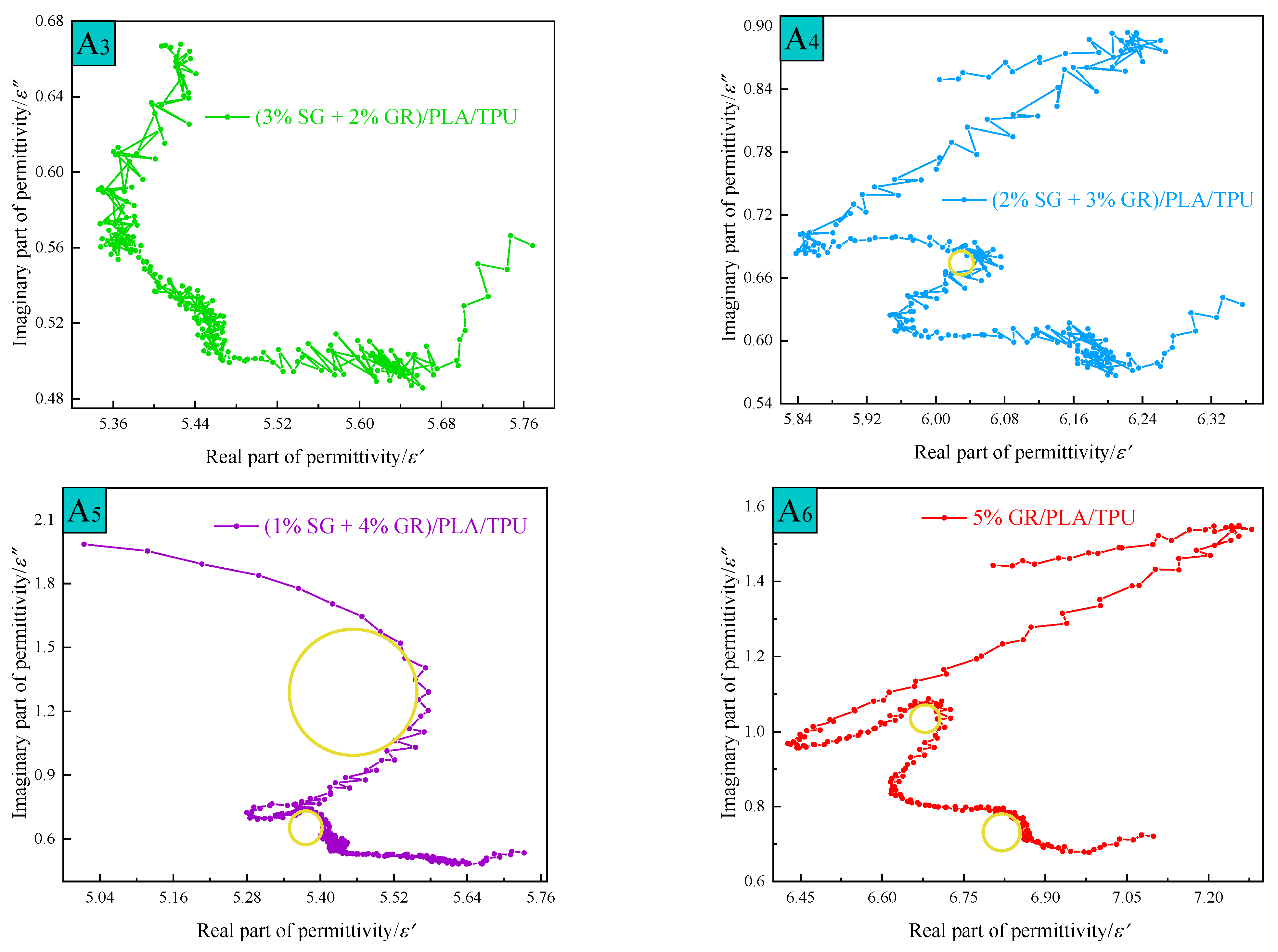

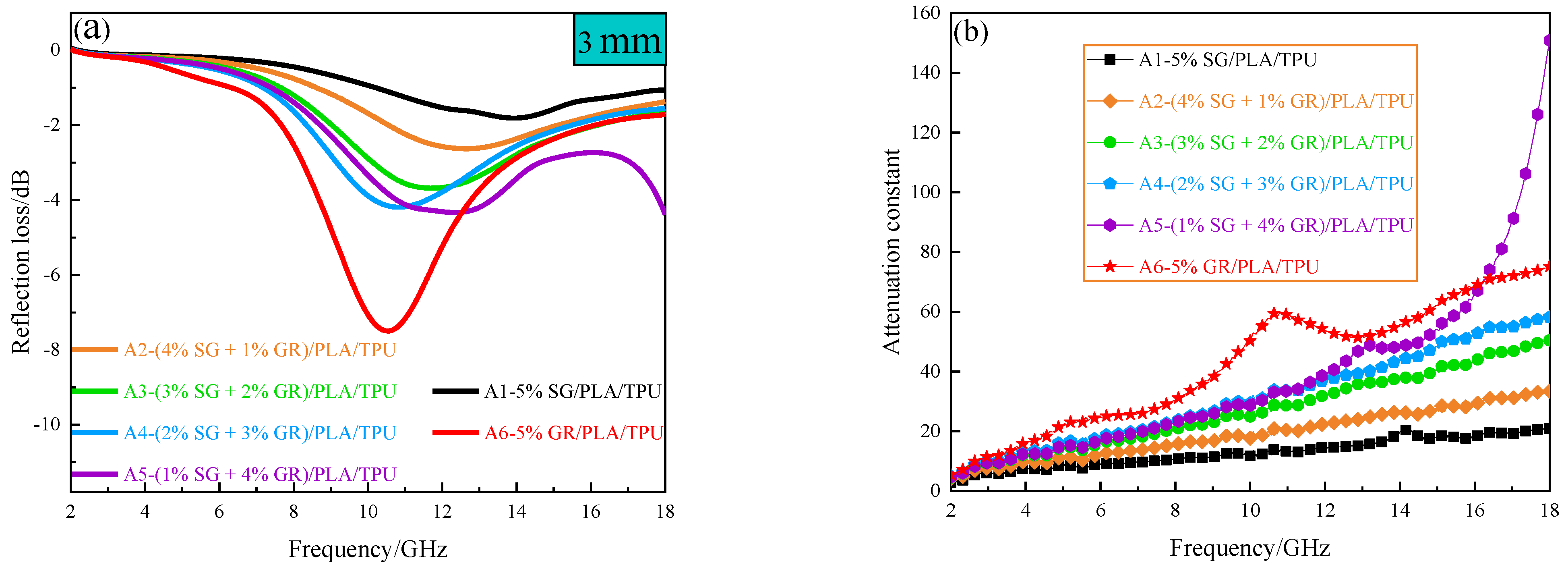

3.2.2. Microwave Absorption of Composites

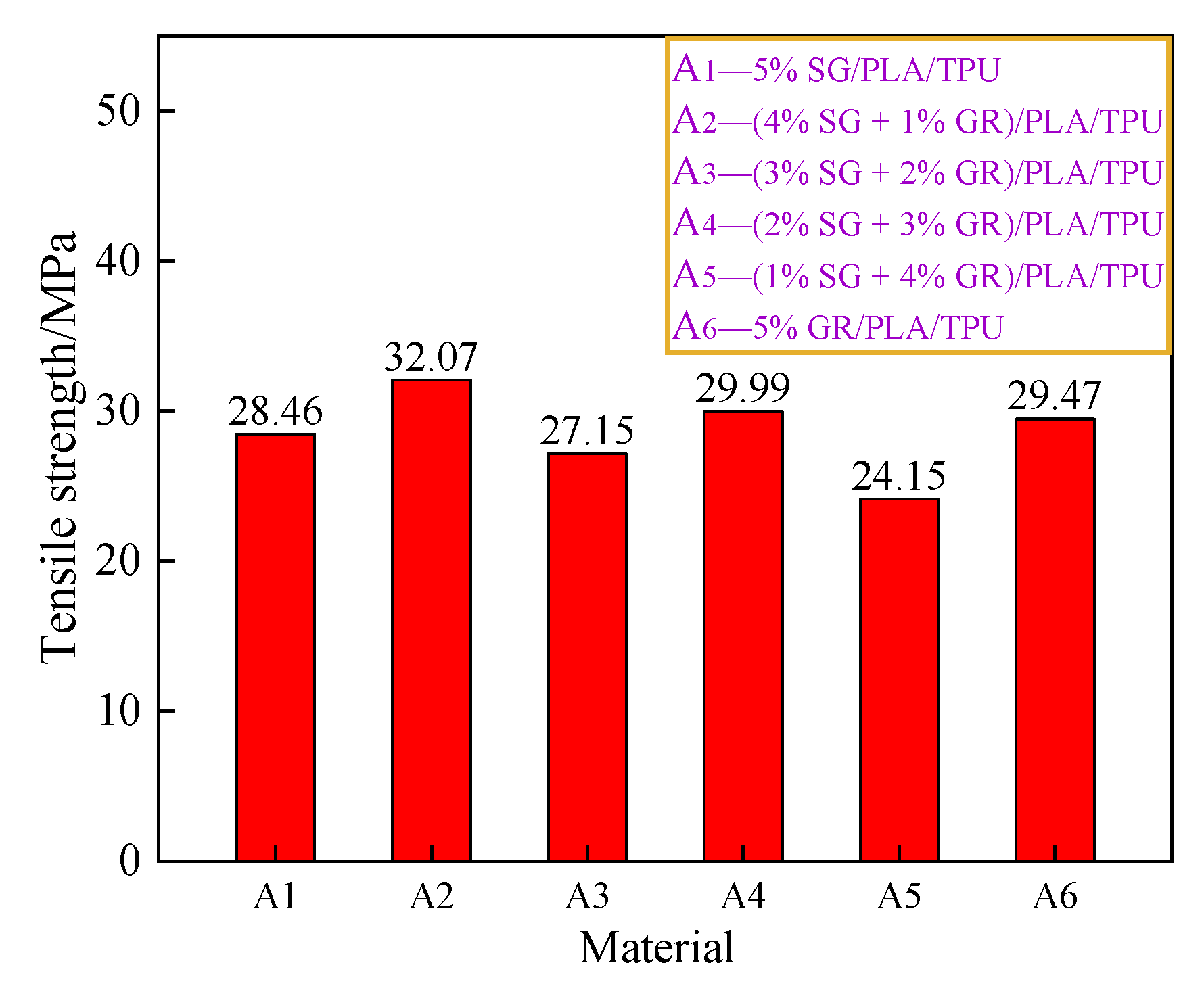

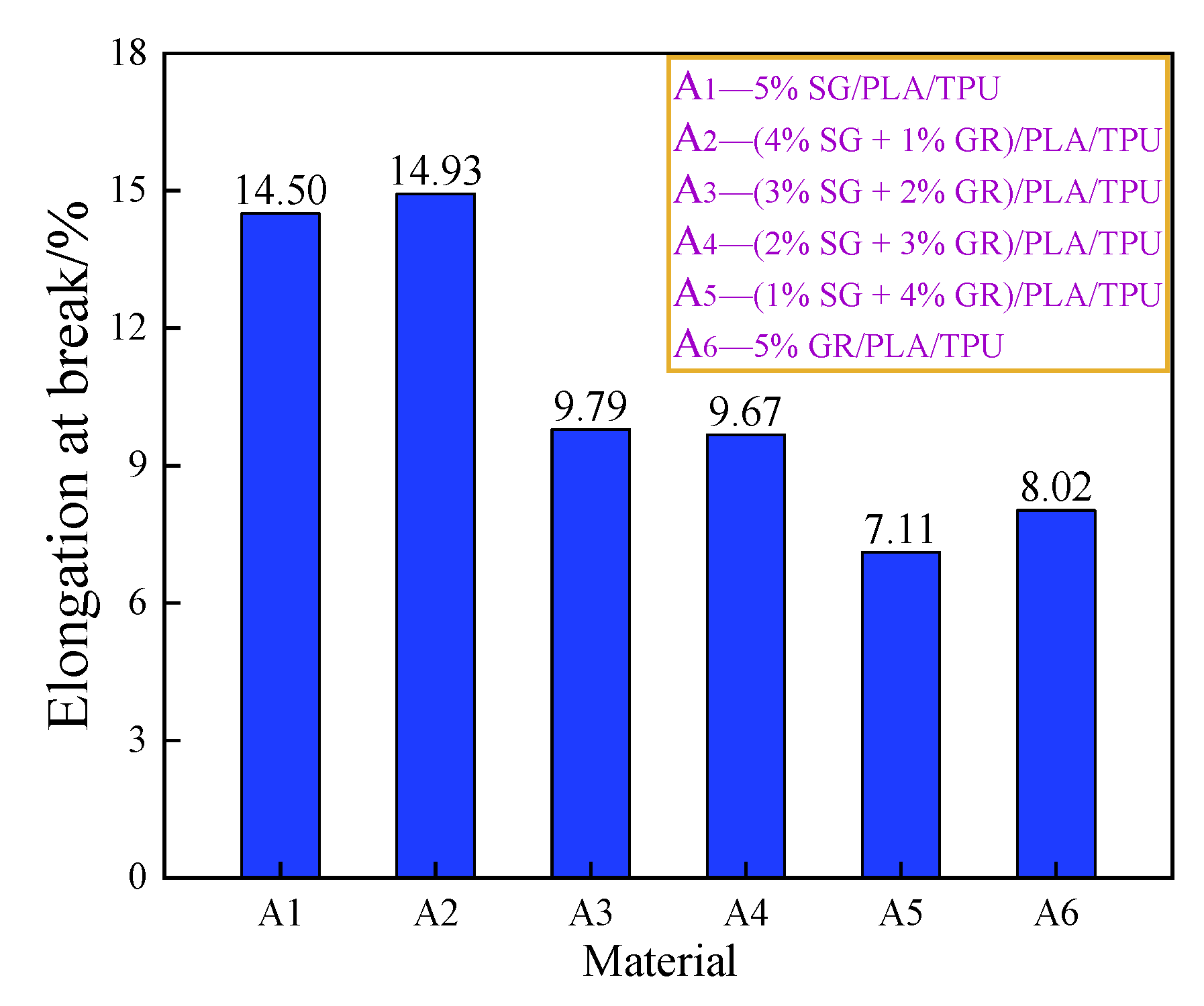

3.3. Effect of SG/GR Ratio on Mechanical Properties of PLA/TPU Composites

4. Conclusions

- When the content of GR in SG/GR ratio is high, GR forms a number of “core-shell structures” in the PLA/TPU matrix. On the one hand, GR whose surface wrinkles, functional groups and defects enhance the electromagnetic wave attenuation ability (polarization loss and conductivity loss) by promoting polarization (interface polarization and dipole polarization) and multiple scattering. On the other hand, it is beneficial to improve impedance matching to improve the wave absorbing effect. Among them, when the ratio of SG/GR is 1:4, the recombination reaches the percolation threshold. At this time, there is the maximum reflection loss that is −12.84 dB (at 18 GHz), which is slightly higher than that of reference [37] but lower than that of reference [38].

- When the content of SG in SG/GR ratio is high, SG forms a large number of “island structures” in the PLA/TPU matrix, showing good dispersibility to improve the mechanical properties. Among them, when the ratio of SG/GR is 4:1, the graphitization degree of the composites is high. At this time, the maximum tensile strength and elongation at break are 32.07 MPa and 14.93%, respectively, which are higher than those in reference [39] but lower than the toughness of reference [40].

- When the ratio of SG/GR is moderate (2:3 or 3:2), SG/GR/PLA/TPU composites have a certain electromagnetic wave-absorption capacity on the basis of high strength and toughness.

- Compared with the single performance (wave-absorbing property or mechanical property) of carbon-based composites in Table 5, the combination of a multi-component absorbent (multiloss mechanism: electrical loss and magnetic loss) and multi-component matrix (high-strength and high-toughness matrix or particle-reinforced matrix) is the development trend for new carbon-based wave-absorbing materials to achieve the synergy of wave absorbency and mechanical properties. In addition, FDM 3D printing has obvious advantages in energy saving, environmental protection and complex structure manufacturing.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zeng, Q.; Wang, R.C.; Zhang, X.L.; Peng, H.N.; Hu, S.P.; Liu, Q. Research progress of electromagnetic wave absorption materials. Jiangxi Chem. Ind. 2021, 37, 100–103. [Google Scholar]

- Li, H.; Chen, K.B.; Luo, Y.T.; Sun, L.Z.; Du, J. Absorbing Mechanism and Progress of Carbon-based Electromagnetic Wave Absorbing Nanocomposites. Mater. Rep. 2019, 33, 73–77. [Google Scholar]

- Wu, H.H.; Yang, Z.H.; Liu, L.; Zhang, R.J.; Deng, K.X.; Li, Y. Forming of Three-layer Graphene Absorber by Fused Deposition Modeling and Effect of Interlayer Material Distribution on Microwave Absorption Properties. Mater. Rep. 2023, 2, 1–12. [Google Scholar]

- Khayal, A.; Dawane, V.; Amin, M.A.; Tirth, V.; Yadav, V.K.; Algahtani, A.; Khan, S.H.; Islam, S.; Yadav, K.K.; Jeon, B.H. Advances in the Methods for the Synthesis of Carbon Dots and Their Emerging Applications. Polymers 2021, 13, 3190. [Google Scholar] [CrossRef]

- Tuccitto, N.; Riela, L.; Zammataro, A.; Spitaleri, L.; Li-Destri, G.; Sfuncia, G.; Nicotra, G.; Pappalardo, A.; Capizzi, G.; Sfrazzetto, G.T. Functionalized Carbon Nanoparticle-Based Sensors for Chemical Warfare Agents. ACS Appl. Nano Mater. 2020, 3, 8182–8191. [Google Scholar] [CrossRef]

- Wolfbeis, O.S. An overview of nanoparticles commonly used in fluorescent bioimaging. Chem. Soc. Rev. 2015, 44, 4743–4768. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cao, M.; Deng, Y.X.; Xu, K.; Hao, X.F.; Hu, J.Y.; Yang, X. Research progress of new carbon based magnetic composite electromagnetic waveabsorbing materials. Acta Mater. Compos. Sin. 2020, 37, 3004–3016. [Google Scholar]

- Prekodravac, J.R.; Kepic, D.P.; Colmenares, J.C.; Giannakoudakis, D.A.; Jovanovic, S.P. A comprehensive review on selected graphene synthesis methods: From electrochemical exfoliation through rapid thermal annealing towards biomass pyrolysis. J. Mater. Chem. C 2021, 9, 6722–6748. [Google Scholar] [CrossRef]

- Ion-Ebrasu, D.; Andrei, R.D.; Enache, S.; Caprarescu, S.; Negrila, C.C.; Jianu, C.; Enache, A.; Boerasu, I.; Carcadea, E.; Varlam, M.; et al. Nitrogen Functionalization of CVD Grown Three-Dimensional Graphene Foam for Hydrogen Evolution Reactions in Alkaline Media. Materials 2021, 14, 4952. [Google Scholar] [CrossRef]

- Xue, G. Study on Mechanical and Electromagnetic Properites of Graphene/Epoxy Resin Composites. Ph.D. Thesis, Harbin Engineering University, Harbin, China, 2020. [Google Scholar]

- Wu, H.H.; Liu, L.; Cai, Y.; Zhang, C.; Xing, L.; Li, Y.F.; Hu, Z.-L.; Qiang, P. Microwave structural absorbers perparation and absorbing properties of magnetic/dielectric composite. Trans. Mater. Heat Treat. 2020, 41, 34–41. [Google Scholar]

- He, Y.; Yang, Z.; Qu, J. Super-toughened poly (lactic acid)/thermoplastic poly (ether) urethane nanofiber composites with in-situ formation of aligned nanofibers prepared by an innovative eccentric rotor extruder. Compos. Sci. Technol. 2019, 169, 135–141. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, J. Research progress in toughening modification of poly(lactic acid). J. Polym. Sci. B Polym. Phys. 2011, 49, 1051–1083. [Google Scholar] [CrossRef]

- Yu, F.; Huang, H.X. Simultaneously toughening and reinforcing poly (lactic acid)/thermoplastic polyurethane blend via enhancing interfacial adhesion by hydrophobic silica nanoparticles. Polym. Test. 2015, 45, 107–113. [Google Scholar] [CrossRef]

- Giofre, S.V.; Tiecco, M.; Celesti, C.; Patane, S.; Triolo, C.; Gulino, A.; Spitaleri, L.; Scalese, S.; Scuderi, M.; Iannazzo, D. Eco-Friendly 1,3-Dipolar Cycloaddition Reactions on Graphene Quantum Dots in Natural Deep Eutectic Solvent. Nanomaterials 2020, 10, 2549. [Google Scholar] [CrossRef] [PubMed]

- Xiang, Z.; Huang, C.; Songa, Y.; Denga, B.; Zhanga, X.; Zhua, X.; Bataluc, D.; Tutunarud, O.; Lua, W. Rational construction of hierarchical accordion-like Ni@porous carbon nanocomposites derived from metal-organic frameworks with enhanced microwave absorption. Carbon 2020, 167, 364–377. [Google Scholar] [CrossRef]

- Ellingford, C.; Bowen, C.; McNally, T.; Wan, C.Y. Intrinsically Tuning the Electromechanical Properties of Elastomeric Dielectrics: A Chemistry Perspective. Macromol. Rapid Commun. 2018, 39, 1800340. [Google Scholar] [CrossRef]

- Liu, Y.H.; Li, H.F.; Yang, K. Effect of copper nanomaterials dimensions on the dielectric properties and percolation threshold of P (VDF-HFP)-based composites. J. Funct. Mater. 2019, 50, 12020–12034. [Google Scholar]

- Tao, J.; Zhou, J.; Yao, Z.; Jiao, Z.; Wei, B.; Tan, R.; Li, Z. Multi-shell hollow porous carbon nanoparticles with excellent microwave absorption properties. Carbon 2021, 172, 542–555. [Google Scholar] [CrossRef]

- Ren, F.; Yu, H.; Wang, L.; Saleem, M.; Tian, Z.; Ren, P. Current progress on the modification of carbon nanotubes and their application in electromagnetic wave absorption. RSC Adv. 2014, 4, 14419. [Google Scholar] [CrossRef]

- Cheng, Y.; Seow, J.Z.Y.; Zhao, H.; Xu, Z.J.; Ji, G. A Flexible and Lightweight Biomass-Reinforced Microwave Absorber. Nano-Micro Lett. 2020, 12, 5–19. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, S.H.; Duan, Y.P.; Guan, H.-T.; Wen, B. Electromagnetic Characteristics of Carbon Black Doped with Nanometer Manganese Dioxide. J. Aeronaut. Mater. 2007, 2, 58–61. [Google Scholar]

- Jia, K.; Wang, D.H.; Li, K.X.; Gu, J.Y.; Liu, W. Progress and Future Developments of Graphene Composites Serving as Microwave Absorbing Materials. Mater. Rep. 2019, 33, 805–811. [Google Scholar]

- Deng, J.; Zhang, X.; Zhao, B.; Bai, Z.; Wen, S.; Li, S.; Li, S.; Yang, J.; Zhang, R. Fluffy microrods to heighten the microwave absorption properties through tuning the electronic state of Co/CoO. J. Mater. Chem. C 2018, 26, 7128–7140. [Google Scholar] [CrossRef]

- Chen, X.; Shi, T.; Wu, G.; Lu, Y. Design of molybdenum disulfide@polypyrrole compsite decorated with Fe3O4 and superior electromagnetic wave absorption performance. J. Colloid Interface Sci. 2020, 572, 227–235. [Google Scholar] [CrossRef]

- Huang, B.; Yue, J.; Wei, Y.; Huang, X.; Tang, X.; Du, Z. Enhanced microwave absorption properties of carbon nanofibers functionalized by FeCo coatings. Appl. Surf. Sci. 2019, 483, 98–105. [Google Scholar] [CrossRef]

- Chen, S.; Tan, G.; Gu, X.; Man, Q.; Li, F.; Chang, C.; Wang, X.; Li, R.-W. Microwave absorbing properties of FeCrMoNiPBCSi amorphous powders composite. J. Alloys Compd. 2017, 705, 309–313. [Google Scholar] [CrossRef]

- Qiao, M.; Lei, X.; Ma, Y. Dependency of tunable microwave absorption performance on morphology-controlled hierarchical shells for core-shell Fe3O4@MnO2 composite microspheres. Chem. Eng. J. 2016, 304, 552–562. [Google Scholar] [CrossRef]

- Kim, S.S.; Jo, S.B.; Gueon, K.I.; Choi, K.K.; Kim, J.M.; Churn, K.S. Complex permeability and permittivity and microwave absorption of ferrite-rubber composite at X-band frequencies. IEEE Trans. Magn. 1991, 27 Pt 6, 5462–5464. [Google Scholar] [CrossRef]

- Shu, X.; Ren, H.; Jiang, Y.; Zhou, J.; Wang, Y.; Wang, Y.; Liu, Y.; Oh, W.-C. Enhanced electromagnetic wave absorption performance of silane coupling agent KH550@Fe3O4 hollow nanospheres/graphene composites. J. Mater. Chem. C Mater. Opt. Electron. Devices 2020, 8, 2913–2926. [Google Scholar] [CrossRef]

- Cheng, J.B.; Zhao, H.B.; Li, M.E.; Li, S.L.; Wang, Y.Z. Research Progress on Carbon-Based Microwave Absorption Materials. Mater. China 2019, 38, 897–905. [Google Scholar]

- Zhi, M.; Yi, Z.; Chen, T.C.; Yuan, J.; Liu, Q.; Wang, J. Attractive microwave absorption and the impedance match effect in zincoxide and carbonyl iron composite. Phys. B Condens. Matter 2011, 406, 4620–4624. [Google Scholar]

- Lian, Y.; Han, B.; Liu, D.; Wang, Y.; Zhao, H.; Xu, P.; Han, X.; Du, Y. Solvent-Free Synthesis of Ultrafine Tungsten Carbide Nanoparticles-Decorated Carbon Nanosheets for Microwave Absorption. Nano-Micro Lett. 2020, 12, 145–157. [Google Scholar] [CrossRef] [PubMed]

- Lei, Y.Z.; Wang, S.W.; Lv, Q.N.; Li, Z.Z. Crystallization and rheological properites of carbon fiber/poly(lactic acid) composites. Acta Mater. Compos. Sin. 2018, 35, 1402–1406. [Google Scholar]

- Lu, Y.D.; Guo, J.H.; Jiang, X.H. Research progress of Core-shell Absorption Fillers and its Polymer Composites. Spec. Purp. Rubber Prod. 2021, 42, 56–63+66. [Google Scholar]

- Zhou, X.; Hu, B.; Xiao, W.; Jiang, H.; Zhang, L.; Wang, Z.; Lin, H.; Bian, J.; Zhao, X. Preparation and Properties of Composites of Polyvinyl Alcohol Grafted Graphene Oxide/thermoplastic Polyurethane. Chin. J. Mater. Res. 2017, 31, 874–880. [Google Scholar]

- Zhao, R. The Research of Carbon black/Carbon Fiber with Epoxy Composite Absorbing Material. Master’s Thesis, Hainan University, Hainan, China, 2012. [Google Scholar]

- Hu, Z.L.; Wu, H.H.; Yang, Z.H.; Jiang, J.T.; Zhou, J.X. Preparation of graphene-iron-nickel alloy-polylactic acid composites and their microwave absorption properties. Acta Mater. Compos. Sin. 2022, 39, 3310–3323. [Google Scholar]

- Wu, H.H.; Wang, J.; Cai, Y.; Peng, J.H.; Zhong, J.H.; Wei, Z.Y. Preparations and Properties of graphene/PLA composite wire for 3D printing. Carbon Technol. 2018, 37, 61–65. [Google Scholar]

- Wang, Y.; Li, Z.Q.; Xia, Y.T.; Cui, H.; Cheng, S.K. Preparation and Properties of PP/POE/CB Semi-Conductive Shielding Composite. Plastics 2020, 49, 32–35. [Google Scholar]

| Name | Trademark | Preparation Method/Average Particle Size | Source |

|---|---|---|---|

| PLA | 4032D | The average particle size is 62 μm | NatureWorks Inc. (Minnetonka, MN, USA). |

| TPU | 5377A | The average particle size is 114 μm | Bayer company (Leverkusen, Germany) |

| SG | - | Coarse crushing, trimming, magnetic separation and high-temperature purification of natural flake graphite. | Qingdao Xinghe graphite company (Qingdao, China) |

| GR | - | Graphite oxidation reduction process | Yichang Xincheng graphite company (Yichang, China) |

| Name | Model | Manufacturer |

|---|---|---|

| Electrothermal constant-temperature blast drying oven | BPG-43BG | Guangzhou Bilang instrument Co., Ltd. (Guangzhou, China) |

| Horizontal planetary ball mill | QM-WX4 | Nanjing Nanda Instrument Co., Ltd. (Nanjing, China) |

| Single screw extruder | SHSJ-25 | Dongguan Songhu machinery Co., Ltd. (Dongguan, China) |

| Double nozzle printer | Allcct Tank | Wuhan Allcct Co., Ltd. (Wuhan, China) |

| Number | Name | Content (wt%) | |||||

|---|---|---|---|---|---|---|---|

| Ratio | SG | GR | PLA | TPU | Ratio | ||

| A1 | 5% SG/PLA/TPU | 5:0 | 5 | 0 | 85.5 | 9.5 | 9:1 |

| A2 | (4% SG + 1% GR)/PLA/TPU | 4:1 | 4 | 1 | 85.5 | 9.5 | 9:1 |

| A3 | (3% SG + 2% GR)/PLA/TPU | 3:2 | 3 | 2 | 85.5 | 9.5 | 9:1 |

| A4 | (2% SG + 3% GR)/PLA/TPU | 2:3 | 2 | 3 | 85.5 | 9.5 | 9:1 |

| A5 | (1% SG + 4% GR)/PLA/TPU | 1:4 | 1 | 4 | 85.5 | 9.5 | 9:1 |

| A6 | 5% GR/PLA/TPU | 0:5 | 0 | 5 | 85.5 | 9.5 | 9:1 |

| Name | Model | Manufacturer | Test Parameters and Scope | Characterization |

|---|---|---|---|---|

| Specific surface and aperture analyzer | Novatouch | Quantachrome (Boynton Beach, FL, USA) | Accuracy of pressure sensor < 0.1%. The A/D converter signal resolution reaches 24 bit. | Specific surface area and pore diameter of GR |

| Laser particle size analyzer | S3500 | Microtrac, America (Montgomeryville, PA, USA) | Measuring range: 0.02–2000 μm. Analysis accuracy: error ≤ 0.6%. Repeatability: error ≤ 1%. | Particle size distribution of SG |

| Field scanning electron microscope | JSM-7500F | Japan electronics Co., Ltd. (Tokyo, Japan) | Resolution: 1.0 nm (15 KV), 1.4 nm (1 KV). Magnification: 250–1,000,000 times. | Microstructure of SG, GR and their composite powders |

| Field high resolution transmission electron microscope | JEOL-F200 | Japan electronics Co., Ltd. (Tokyo, Japan) | Resolution: 0.10 nm (TEM mode), 0.14 nm (STEM mode). Magnification: 20–2,000,000 times. | Lattice structure of GR |

| Fourier transform infrared spectrometer | Spectrum 100 | Perkin Elmer, America (Waltham, MA, USA) | The wave number is in the range of 4000~450 cm−1. | Chemical structure and functional groups of SG and GR |

| X-ray diffractomer | Ultima IVXRD | Japan Neo-Confucianism Corporation (Tokyo, Japan) | With copper target Ka ray, scanning speed 5 (°)/min, step distance 0.02°, diffraction scanning angle 2θ = 5~80°. | Element composition and crystal type of composites |

| Laser confocal Raman spectrometer | Thermo Scientific DXR | Thermo Fisher Scientific (Waltham, MA, USA) | Raman shift is in the range of 100~3500 cm−1. | Graphitization degree of composites |

| Vector network analyzer | R&S ZNA | Rhodes & Schwartz Co., Ltd. (Munich, Germany) | Test the electromagnetic parameters of coaxial ring at 2~18 GHz. | Electromagnetic properties of composites |

| Electro mechanical universal testing machines | 5569 | Instron, America (Norwood, MA, USA) | The tensile rate is 2 mm/min, and each group of tensile samples is measured for 3 times and averaged. | Tensile strength and elongation at break of composites |

| Material | Absorbent | Matrix | Content | Absorption Maximum/dB | Tensile Strength/MPa | Elongation at Break/% | Ref. |

|---|---|---|---|---|---|---|---|

| CB/EP | Carbon black | Epoxy resin | 5% | −10 | - | - | [37] |

| GR/FeNi50/PLA | Graphene/FeNi50 (magnetic) | Polylactide | 5% | −20.8 | - | - | [38] |

| GR/PLA | Graphene | Polylactide | 5% | - | 21.4 | 3.8 | [39] |

| PP/POE/CB | Carbon black | Polypropylene/polyoxyethylene | 5% | - | 16.8 | 650 | [40] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Wu, H.; Zhang, R.; Deng, K.; Li, Y.; Liu, Z.; Zhong, Q.; Kang, Y. Effect of Graphene/Spherical Graphite Ratio on the Properties of PLA/TPU Composites. Polymers 2022, 14, 2538. https://doi.org/10.3390/polym14132538

Yang Z, Wu H, Zhang R, Deng K, Li Y, Liu Z, Zhong Q, Kang Y. Effect of Graphene/Spherical Graphite Ratio on the Properties of PLA/TPU Composites. Polymers. 2022; 14(13):2538. https://doi.org/10.3390/polym14132538

Chicago/Turabian StyleYang, Zenghui, Haihua Wu, Renjing Zhang, Kaixin Deng, Yan Li, Zhi Liu, Qiang Zhong, and Yi Kang. 2022. "Effect of Graphene/Spherical Graphite Ratio on the Properties of PLA/TPU Composites" Polymers 14, no. 13: 2538. https://doi.org/10.3390/polym14132538

APA StyleYang, Z., Wu, H., Zhang, R., Deng, K., Li, Y., Liu, Z., Zhong, Q., & Kang, Y. (2022). Effect of Graphene/Spherical Graphite Ratio on the Properties of PLA/TPU Composites. Polymers, 14(13), 2538. https://doi.org/10.3390/polym14132538