Healing Efficiency of CNTs-Modified-UF Microcapsules That Provide Higher Electrical Conductivity and EMI Shielding Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Nanomodification of the Shell-Wall

2.3. Encapsulation Process

2.4. Manufacturing of the Self-Healing Specimens

2.5. Manufacturing of the Specimens for Electrical Conductivity Measurements

2.6. Manufacturing of the Specimens for EMI Shielding Measurements

2.7. Characterization Techniques

2.7.1. Scanning Electron Microscopy (SEM)

2.7.2. Thermogravimetric Analysis (TGA)

2.7.3. Impedance Spectroscopy

2.7.4. EMI Shielding

3. Results and Discussion

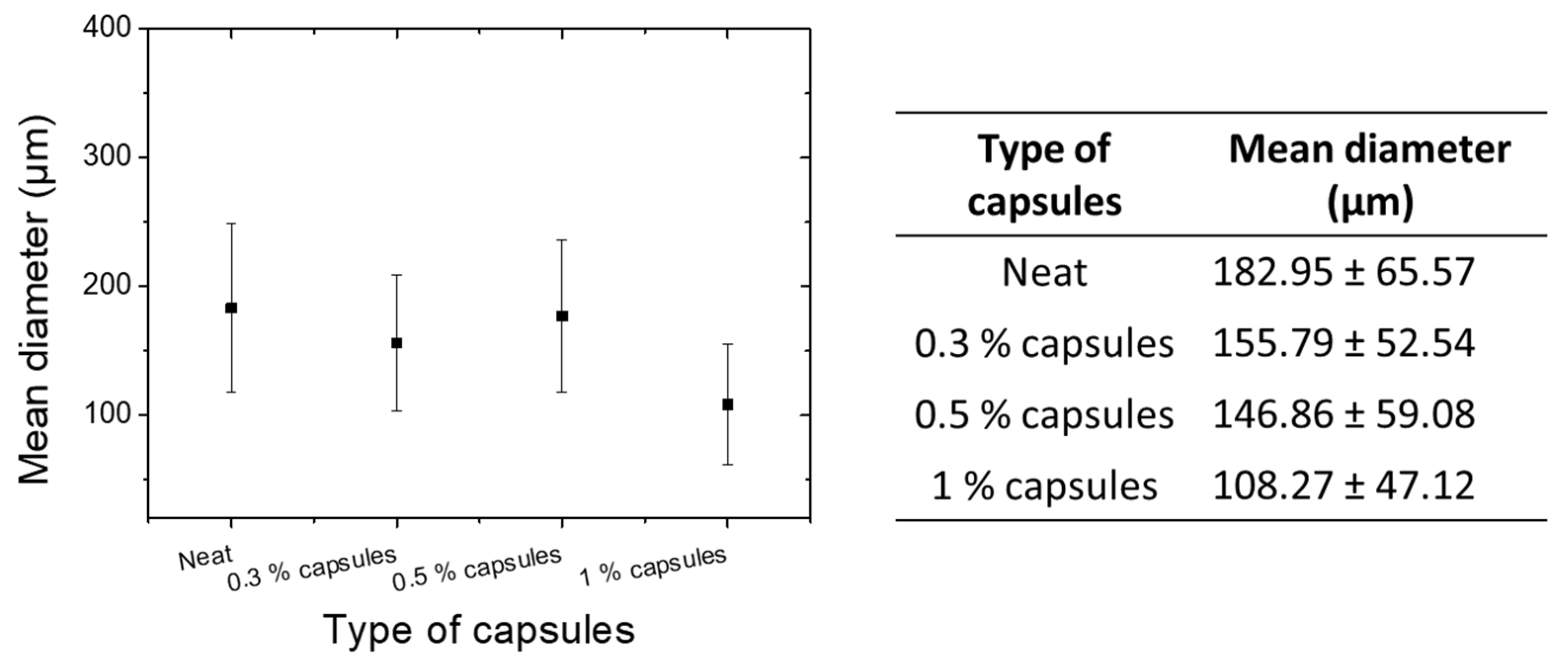

3.1. Size Distribution/SEM Images

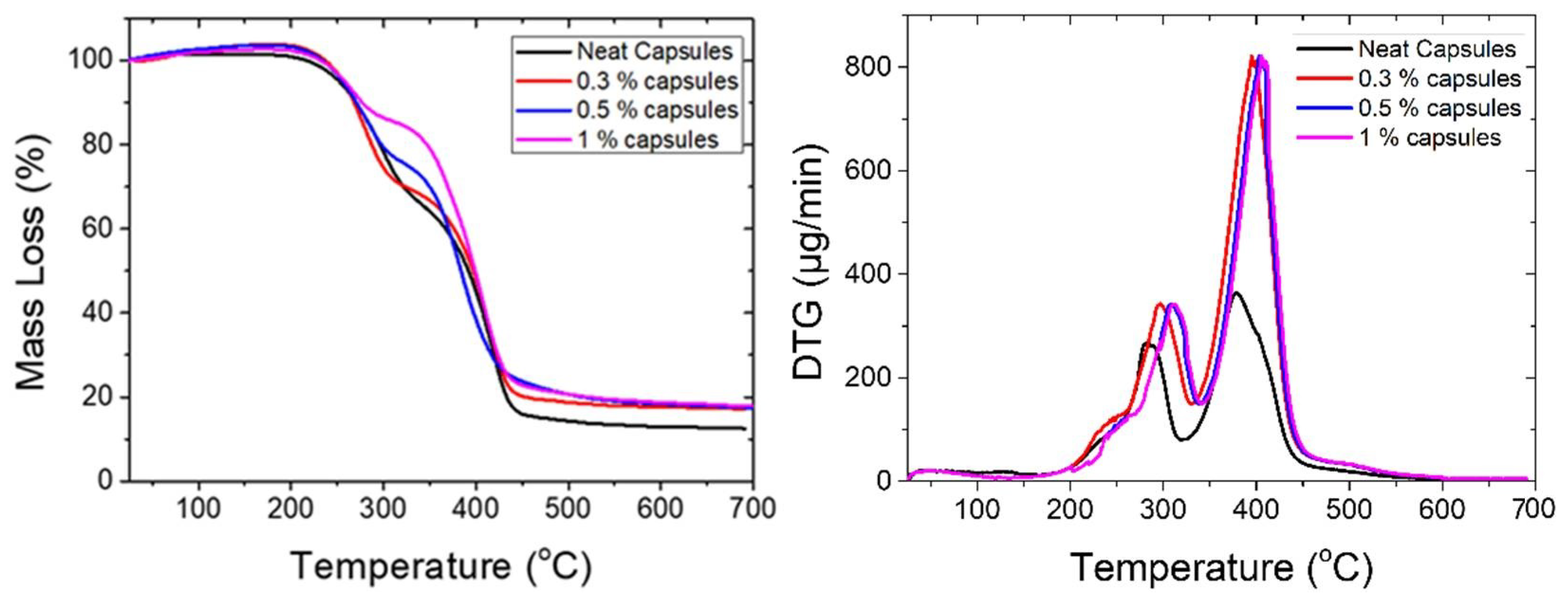

3.2. Thermal Stability of Microcapsules

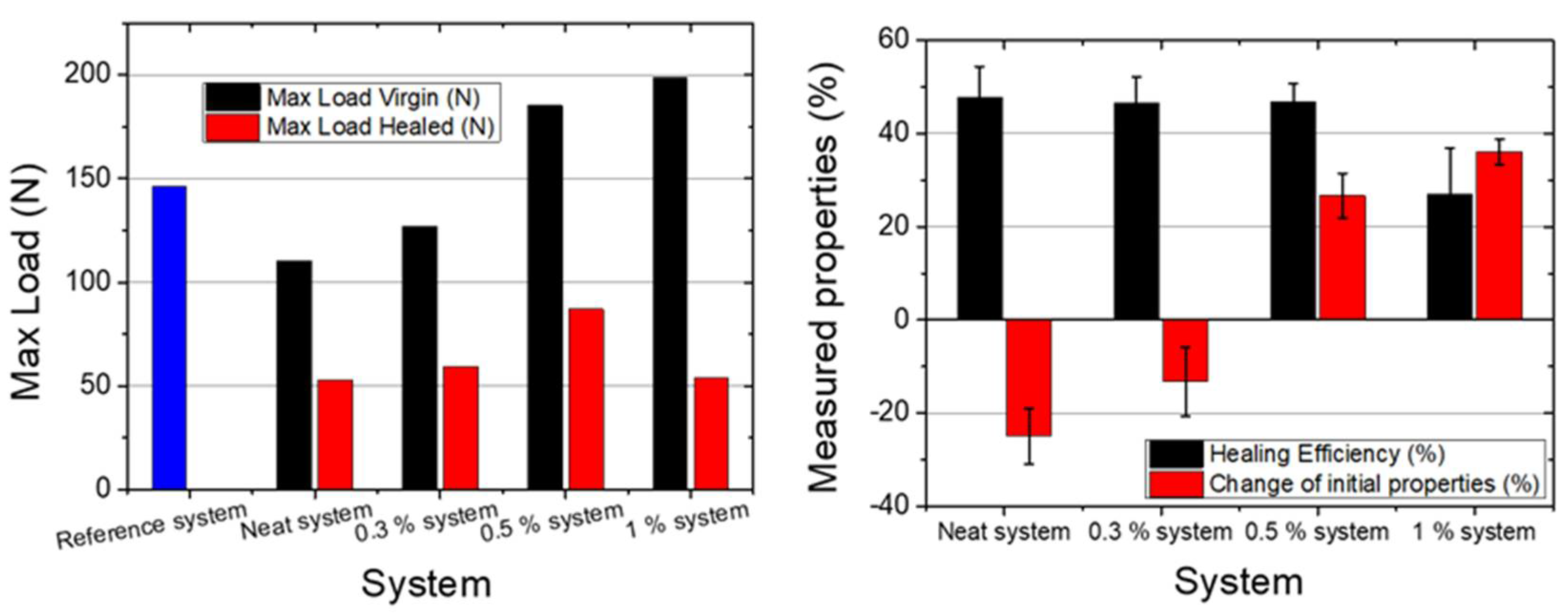

3.3. Evaluation of the Healing Efficiency

3.4. Conductive Network

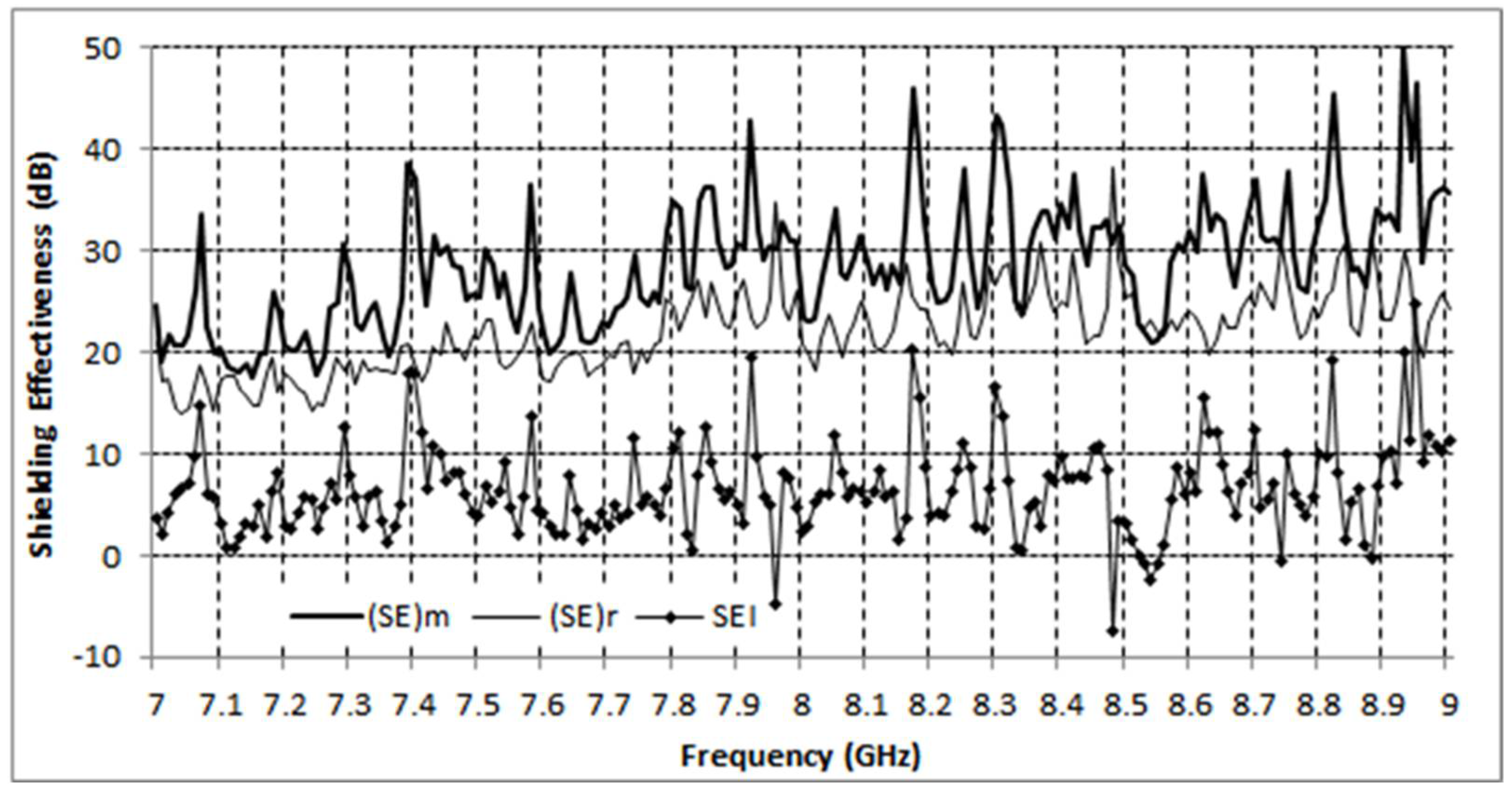

3.5. EMI Shielding Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Lincoln, R.L.; Scarpa, F.; Ting, V.P.; Trask, R.S. Multifunctional composites: A metamaterial perspective. Multifunct. Mater. 2019, 2, 043001. [Google Scholar] [CrossRef]

- Karalis, G.; Mytafides, C.; Polymerou, A.; Tsirka, K.; Tzounis, L.; Gergidis, L.; Paipetis, A.S. Hierarchical reinforcing fibers for energy harvesting applications—A strength study. Key Eng. Mater. 2020, 827, 252–257. [Google Scholar] [CrossRef]

- Karalis, G.; Tzounis, L.; Lambrou, E.; Gergidis, L.N.; Paipetis, A.S. A carbon fiber thermoelectric generator integrated as a lamina within an 8-ply laminate epoxy composite: Efficient thermal energy harvesting by advanced structural materials. Appl. Energy 2019, 253, 113512. [Google Scholar] [CrossRef]

- Karalis, G.; Tsirka, K.; Tzounis, L.; Mytafides, C.; Koutsotolis, L.; Paipetis, A.S. Epoxy/glass fiber nanostructured p- and n-type thermoelectric enabled model composite interphases. Appl. Sci. 2020, 10, 5352. [Google Scholar] [CrossRef]

- Bekas, D.G.; Paipetis, A.S. Study of the effect of damage on the electrical impedance of carbon nanotube reinforced epoxy nanocomposites. J. Sens. 2015, 2015, 805303. [Google Scholar] [CrossRef]

- Bekas, D.G.; Sharif-Khodaei, Z.; Aliabadi, F.M.H. A smart multi-functional printed sensor for monitoring curing and damage of composite repair patch. Smart Mater. Struct. 2019, 28, 085029. [Google Scholar] [CrossRef]

- Bekas, D.G.; Sharif-Khodaei, Z.; Baltzis, D.; Aliabadi, M.H.F.; Paipetis, A.S. Quality assessment and damage detection in nanomodified adhesively-bonded composite joints using inkjet-printed interdigital sensors. Compos. Struct. 2019, 211, 557–563. [Google Scholar] [CrossRef]

- Foteinidis, G.; Paipetis, A.S. A Novel Composite with Structural Health Monitoring Functionality via 2D and 3D Impedance Mapping Topography. Appl. Sci. 2021, 11, 1647. [Google Scholar] [CrossRef]

- Bekas, D.G.; Tsirka, K.; Baltzis, D.; Paipetis, A.S. Self-healing materials: A review of advances in materials, evaluation, characterization and monitoring techniques. Compos. Part B Eng. 2016, 87, 92–119. [Google Scholar] [CrossRef]

- Blaiszik, B.; Kramer, S.L.B.; Moore, J.S.; Sottos, N.R.; Blaiszik, B.J.; Kramer, S.L.B.; Olugebefola, S.C.; Moore, J.S.; Sottos, N.R.; White, S.R. Self-Healing Polymers and Composites. Annu. Rev. Mater. Res. 2010, 40, 179–211. [Google Scholar] [CrossRef]

- Bekas, D.G.; Baltzis, D.; Tsirka, K.; Exarchos, D.; Matikas, T.; Meristoudi, A.; Pispas, S.; Paipetis, A.S. Self-healing polymers: Evaluation of self-healing process via non-destructive techniques. Plast. Rubber Compos. 2016, 45, 147–156. [Google Scholar] [CrossRef]

- Kostopoulos, V.; Kotrotsos, A.; Tsantzalis, S.; Tsokanas, P.; Loutas, T.; Bosman, A.W. Toughening and healing of continuous fibre reinforced composites by supramolecular polymers. Compos. Sci. Technol. 2016, 128, 84–93. [Google Scholar] [CrossRef]

- Kostopoulos, V.; Kotrotsos, A.; Baltopoulos, A.; Tsantzalis, S.; Tsokanas, P.; Loutas, T.; Bosman, A.W. Mode II fracture toughening and healing of composites using supramolecular polymer interlayers. Express Polym. Lett. 2016, 10, 914–926. [Google Scholar] [CrossRef]

- Kostopoulos, V.; Kotrotsos, A.; Tsantzalis, S.; Tsokanas, P.; Christopoulos, A.C.; Loutas, T. Toughening and healing of continuous fibre reinforced composites with bis-maleimide based pre-pregs. Smart Mater. Struct. 2016, 25, 084011. [Google Scholar] [CrossRef]

- Bekas, D.G.; Baltzis, D.; Paipetis, A.S. Nano-reinforced polymeric healing agents for vascular self-repairing composites. Mater. Des. 2017, 116, 538–544. [Google Scholar] [CrossRef]

- White, S.R.; Sottos, N.R.; Geubelle, P.H.; Moore, J.S.; Kessler, M.R.; Sriram, S.R.; Brown, E.N.; Viswanathan, S. Autonomic healing of polymer composites. Nature 2001, 409, 794–797. [Google Scholar] [CrossRef]

- Ilyaei, S.; Sourki, R.; Akbari, Y.H.A. Capsule-based healing systems in composite materials: A review. Crit. Rev. Solid State Mater. Sci. 2020, 1–41. [Google Scholar] [CrossRef]

- Esser-Kahn, A.P.; Odom, S.A.; Sottos, N.R.; White, S.R.; Moore, J.S. Triggered release from polymer capsules. Macromolecules 2011, 44, 5539–5553. [Google Scholar] [CrossRef]

- Zhu, D.Y.; Rong, M.Z.; Zhang, M.Q. Self-healing polymeric materials based on microencapsulated healing agents: From design to preparation. Prog. Polym. Sci. 2015, 49–50, 175–220. [Google Scholar] [CrossRef]

- Coope, T.S.; Mayer, U.F.J.; Wass, D.F.; Trask, R.S.; Bond, I.P. Self-healing of an epoxy resin using scandium(III) triflate as a catalytic curing agent. Adv. Funct. Mater. 2011, 21, 4624–4631. [Google Scholar] [CrossRef]

- Kosarli, M.; Bekas, D.G.; Tsirka, K.; Baltzis, D.; Vaimakis-Tsogkas, D.; Orfanidis, S.; Papavassiliou, G.; Paipetis, A.S. Microcapsule-based self-healing materials: Healing efficiency and toughness reduction vs. capsule size. Compos. Part B Eng. 2019, 171, 78–86. [Google Scholar] [CrossRef]

- Tsilimigkra, X.; Bekas, D.; Kosarli, M.; Tsantzalis, S.; Paipetis, A.; Kostopoulos, V. Mechanical properties assessment of low-content capsule-based self-healing structural composites. Appl. Sci. 2020, 10, 5739. [Google Scholar] [CrossRef]

- Ahangaran, F.; Navarchian, A.H.; Picchioni, F. Material encapsulation in poly(methyl methacrylate) shell: A review. J. Appl. Polym. Sci. 2019, 136, 1–21. [Google Scholar] [CrossRef]

- Icduygu, M.G.; Asilturk, M.; Yalcinkaya, M.A.; Hamidi, Y.K.; Altan, M.C. Three-Dimensional Nano-Morphology of Carbon Nanotube/Epoxy Filled Poly(methyl methacrylate) Microcapsules. Materials 2019, 12, 1387. [Google Scholar] [CrossRef] [PubMed]

- Ahangaran, F.; Hayaty, M.; Navarchian, A.H.; Pei, Y.; Picchioni, F. Development of self-healing epoxy composites via incorporation of microencapsulated epoxy and mercaptan in poly(methyl methacrylate) shell. Polym. Test. 2019, 73, 395–403. [Google Scholar] [CrossRef]

- Alizadegan, F.; Pazokifard, S.; Mirabedini, S.M.; Danaei, M.; Farnood, R. Polyurethane-based microcapsules containing reactive isocyanate compounds: Study on preparation procedure and solvent replacement. Colloids Surf. A Physicochem. Eng. Asp. 2017, 529, 750–759. [Google Scholar] [CrossRef]

- Liu, X.; Zheng, H.; Li, G.; Li, H.; Zhang, P.; Tong, W.; Gao, C. Fabrication of polyurethane microcapsules with different shapes and their influence on cellular internalization. Colloids Surf. B Biointerfaces 2017, 158, 675–681. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.Y.; Lee, S.J.; Cheong, I.W.; Kim, J.H. Microencapsulation of fragrant oil via in situ polymerization: Effects of pH and melamine-formaldehyde molar ratio. J. Microencapsul. 2002, 19, 559–569. [Google Scholar] [CrossRef] [PubMed]

- Su, J.F.; Wang, X.Y.; Dong, H. Micromechanical properties of melamine-formaldehyde microcapsules by nanoindentation: Effect of size and shell thickness. Mater. Lett. 2012, 89, 1–4. [Google Scholar] [CrossRef]

- Hu, J.; Chen, H.Q.; Zhang, Z. Mechanical properties of melamine formaldehyde microcapsules for self-healing materials. Mater. Chem. Phys. 2009, 118, 63–70. [Google Scholar] [CrossRef]

- Tzavidi, S.; Zotiadis, C.; Porfyris, A.; Korres, D.M.; Vouyiouka, S. Epoxy loaded poly(urea-formaldehyde) microcapsules via in situ polymerization designated for self-healing coatings. J. Appl. Polym. Sci. 2020, 137, 49323. [Google Scholar] [CrossRef]

- Katoueizadeh, E.; Zebarjad, S.M.; Janghorban, K. Investigating the effect of synthesis conditions on the formation of urea-formaldehyde microcapsules. J. Mater. Res. Technol. 2019, 8, 541–552. [Google Scholar] [CrossRef]

- Yan, X.; Chang, Y.; Qian, X. Preparation and Self-Repairing Properties of Urea Formaldehyde-Coated Epoxy Resin Microcapsules. Int. J. Polym. Sci. 2019, 2019, 7215783. [Google Scholar] [CrossRef]

- Du, G.; Hu, J.; Zhou, J.; Wang, G.; Guan, S.; Liu, H.; Geng, M.; Lü, C.; Ming, Y.; Qu, J. The study on the mechanical properties of PU/MF double shell self-healing microcapsules. Chin. J. Chem. Eng. 2020, 28, 1459–1473. [Google Scholar] [CrossRef]

- Keller, M.W.; Sottos, N.R. Mechanical properties of microcapsules used in a self-healing polymer. Exp. Mech. 2006, 46, 725–733. [Google Scholar] [CrossRef]

- Sun, G.; Zhang, Z. Mechanical strength of microcapsules made of different wall materials. Int. J. Pharm. 2002, 242, 307–311. [Google Scholar] [CrossRef]

- Fereidoon, A.; Ahangari, M.G.; Jahanshahi, M. Effect of nanoparticles on the morphology and thermal properties of self-healing poly(urea-formaldehyde) microcapsules. J. Polym. Res. 2013, 20, 151. [Google Scholar] [CrossRef]

- Ahangari, M.G.; Fereidoon, A.; Jahanshahi, M.; Sharifi, N. Effect of nanoparticles on the micromechanical and surface properties of poly(urea-formaldehyde) composite microcapsules. Compos. Part B Eng. 2014, 56, 450–455. [Google Scholar] [CrossRef]

- Kosarli, M.; Foteinidis, G.; Tsirka, K.; Bekas, D.G.; Paipetis, A.S. Concurrent recovery of mechanical and electrical properties in nanomodified capsule-based self-healing epoxies. Polymer 2021, 227, 123843. [Google Scholar] [CrossRef]

- Odom, S.A.; Tyler, T.P.; Caruso, M.M.; Ritchey, J.A.; Schulmerich, M.V.; Robinson, S.J.; Bhargava, R.; Sottos, N.R.; White, S.R.; Hersam, M.C.; et al. Autonomic restoration of electrical conductivity using polymer-stabilized carbon nanotube and graphene microcapsules. Appl. Phys. Lett. 2012, 101, 043106. [Google Scholar] [CrossRef][Green Version]

- Blaiszik, B.J.; Kramer, S.L.B.; Grady, M.E.; McIlroy, D.A.; Moore, J.S.; Sottos, N.R.; White, S.R. Autonomic restoration of electrical conductivity. Adv. Mater. 2012, 24, 398–401. [Google Scholar] [CrossRef] [PubMed]

- Jeong, Y.R.; Oh, S.Y.; Kim, J.W.; Jin, S.W.; Ha, J.S. A highly conductive and electromechanically self-healable gold nanosheet electrode for stretchable electronics. Chem. Eng. J. 2020, 384, 123336. [Google Scholar] [CrossRef]

- Jeong, Y.J.; Jung, J.; Suh, E.H.; Yun, D.J.; Oh, J.G.; Jang, J. Self-Healable and Stretchable Organic Thermoelectric Materials: Electrically Percolated Polymer Nanowires Embedded in Thermoplastic Elastomer Matrix. Adv. Funct. Mater. 2019, 30, 1905809. [Google Scholar] [CrossRef]

- Wang, T.; Yu, W.C.; Zhou, C.G.; Sun, W.J.; Zhang, Y.P.; Jia, L.C.; Gao, J.F.; Dai, K.; Yan, D.X.; Li, Z.M. Self-healing and flexible carbon nanotube/polyurethane composite for efficient electromagnetic interference shielding. Compos. Part B Eng. 2020, 193, 108015. [Google Scholar] [CrossRef]

- Lee, Y.H.; Ko, W.C.; Zhuang, Y.N.; Wang, L.Y.; Yu, T.W.; Lee, S.Y.; Way, T.F.; Rwei, S.P. Development of self-healable organic/inorganic hybrid materials containing a biobased copolymer via Diels-Alder chemistry and their application in electromagnetic interference shielding. Polymers 2019, 11, 1755. [Google Scholar] [CrossRef]

- Narayana, K.J.; Burela, R.G. A review of recent research on multifunctional composite materials and structures with their applications. Mater. Today Proc. 2018, 5, 5580–5590. [Google Scholar] [CrossRef]

- Singh, A.K.; Shishkin, A.; Koppel, T.; Gupta, N. A review of porous lightweight composite materials for electromagnetic interference shielding. Compos. Part B Eng. 2018, 149, 188–197. [Google Scholar] [CrossRef]

- Brown, E.N. Use of the tapered double-cantilever beam geometry for fracture toughness measurements and its application to the quantification of self-healing. J. Strain Anal. Eng. Des. 2011, 46, 167–186. [Google Scholar] [CrossRef]

- Foteinidis, G.; Tsirka, K.; Tzounis, L.; Baltzis, D.; Paipetis, A.S. The Role of Synergies of MWCNTs and Carbon Black in the Enhancement of the Electrical and Mechanical Response of Modified Epoxy Resins. Appl. Sci. 2019, 9, 3757. [Google Scholar] [CrossRef]

- Brown, E.N.; Kessler, M.R.; Sottos, N.R.; White, S.R. In situ poly(urea-formaldehyde) microencapsulation of dicyclopentadiene. J. Microencapsul. 2003, 20, 719–730. [Google Scholar] [CrossRef]

- Bekas, D.; Grammatikos, S.A.; Kouimtzi, C.; Paipetis, A.S. Linear and non-linear electrical dependency of carbon nanotube reinforced composites to internal damage. IOP Conf. Ser. Mater. Sci. Eng. 2015, 74, 12002. [Google Scholar] [CrossRef]

- Vavouliotis, A.; Karapappas, P.; Loutas, T.; Voyatzi, T.; Paipetis, A.; Kostopoulos, V. Multistage fatigue life monitoring on carbon fibre reinforced polymers enhanced with multiwall carbon nanotubes. Plast. Rubber Compos. 2009, 38, 124–130. [Google Scholar] [CrossRef]

- Baltzis, D.; Bekas, D.G.; Tzachristas, G.; Parlamas, A.; Karabela, M.; Zafeiropoulos, N.E.; Paipetis, A.S. Multi-scaled carbon reinforcements in ternary epoxy composite materials: Dispersion and electrical impedance study. Compos. Sci. Technol. 2017, 153, 7–17. [Google Scholar] [CrossRef]

- Al-Saleh, M.; Saadeh, W.; Sundararaj, U. EMI shielding effectiveness of carbon based nanostructured polymeric materials: A comparative study. Carbon. 2013, 60, 146–156. [Google Scholar] [CrossRef]

- Vazouras, C.; Polymerou, A.; Kyriakou, S.; Tsigopoulos, A.; Karagianni, E.; Paipetis, A.; Melantis, N. Measuring the radar cross section of carbon fiber reinforced composite panels in a non-anechoic environment. In Proceedings of the 9th International Conference on Experiments/Process/System Modeling/Simulation/Optimization, Athens, Greece, 7–10 July 2021; pp. 226–230. [Google Scholar]

- Ruck, G.; Barrick, D.E.; Stuart, W.D.; Krichbaum, C.K. Radar Cross Section Handbook; Plenum Press: New York, NY, USA, 1970. [Google Scholar]

| System | Max Load Virgin (N) | Max Load Healed (N) | Healing Efficiency (%) | Change of Initial Properties (%) |

|---|---|---|---|---|

| Reference system | 146.2 | - | - | - |

| Neat system | 110.2 | 52.7 | 47.8 ± 6.6 | −24.9 ± 6.0 |

| 0.3% system | 126.9 | 59.2 | 46.6 ± 5.5 | −13.2 ± 7.4 |

| 0.5% system | 185.2 | 87.0 | 46.9 ± 3.8 | +26.7 ± 4.8 |

| 1% system | 198.9 | 53.7 | 27.0 ± 9.9 | +36.1 ± 2.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kosarli, M.; Polymerou, A.; Foteinidis, G.; Vazouras, C.; Paipetis, A.S. Healing Efficiency of CNTs-Modified-UF Microcapsules That Provide Higher Electrical Conductivity and EMI Shielding Properties. Polymers 2021, 13, 2753. https://doi.org/10.3390/polym13162753

Kosarli M, Polymerou A, Foteinidis G, Vazouras C, Paipetis AS. Healing Efficiency of CNTs-Modified-UF Microcapsules That Provide Higher Electrical Conductivity and EMI Shielding Properties. Polymers. 2021; 13(16):2753. https://doi.org/10.3390/polym13162753

Chicago/Turabian StyleKosarli, Maria, Anastasia Polymerou, Georgios Foteinidis, Christos Vazouras, and Alkiviadis S. Paipetis. 2021. "Healing Efficiency of CNTs-Modified-UF Microcapsules That Provide Higher Electrical Conductivity and EMI Shielding Properties" Polymers 13, no. 16: 2753. https://doi.org/10.3390/polym13162753

APA StyleKosarli, M., Polymerou, A., Foteinidis, G., Vazouras, C., & Paipetis, A. S. (2021). Healing Efficiency of CNTs-Modified-UF Microcapsules That Provide Higher Electrical Conductivity and EMI Shielding Properties. Polymers, 13(16), 2753. https://doi.org/10.3390/polym13162753