Study of UHMWPE Fiber Surface Modification and the Properties of UHMWPE/Epoxy Composite

Abstract

1. Introduction

2. Experimental

2.1. Materials and Instruments

2.1.1. Materials

2.1.2. Instruments

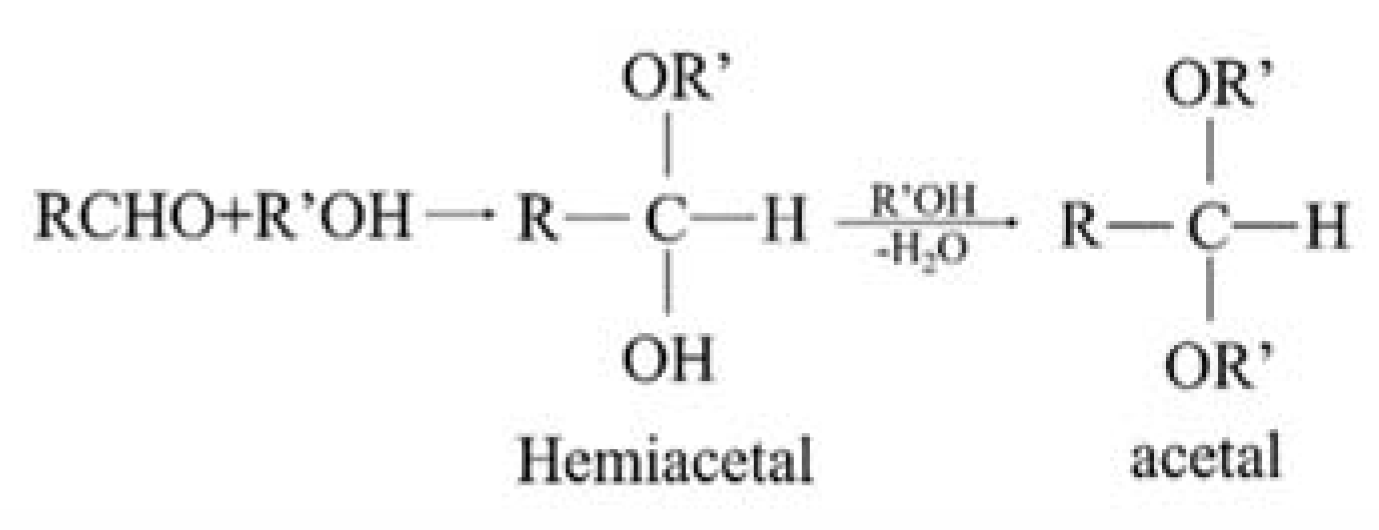

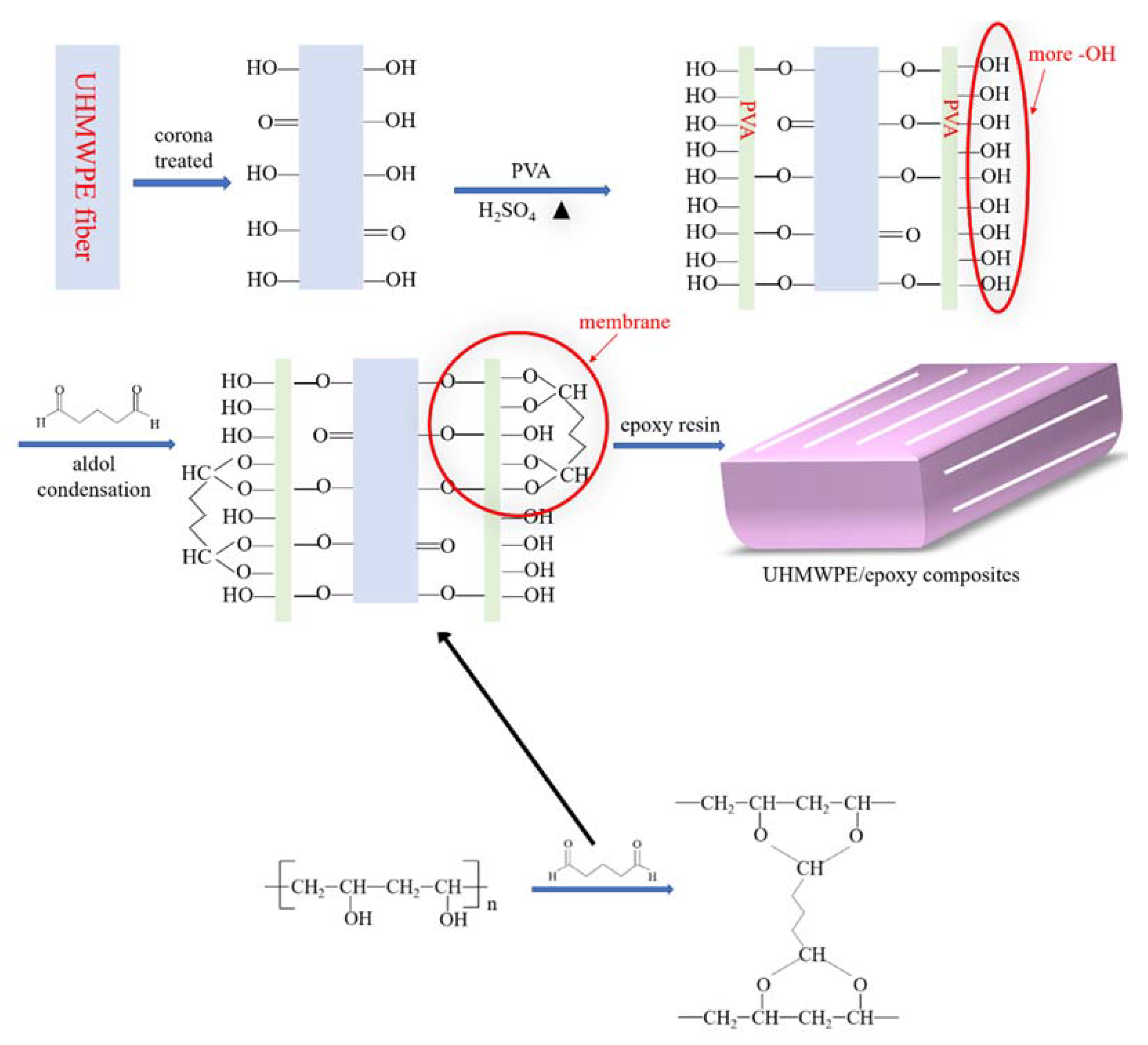

2.2. Modification of UHMWPE Fiber

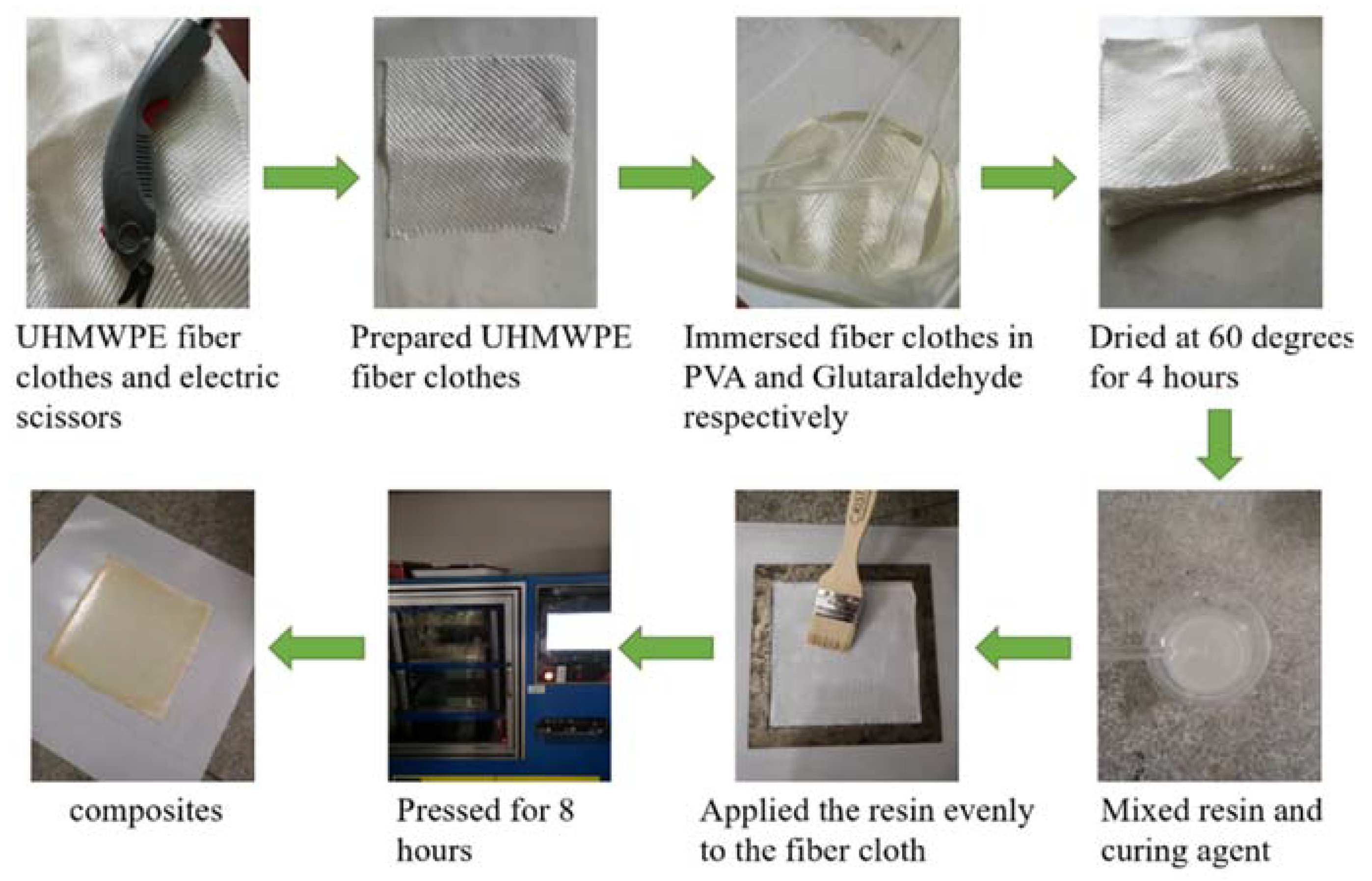

2.3. Preparation of UHMWPE/Epoxy Composite

2.4. Characterization

2.4.1. Characterization of UHMWPE Fiber

2.4.2. Characterization of UHMWPE/Epoxy Composite

3. Results and Discussion

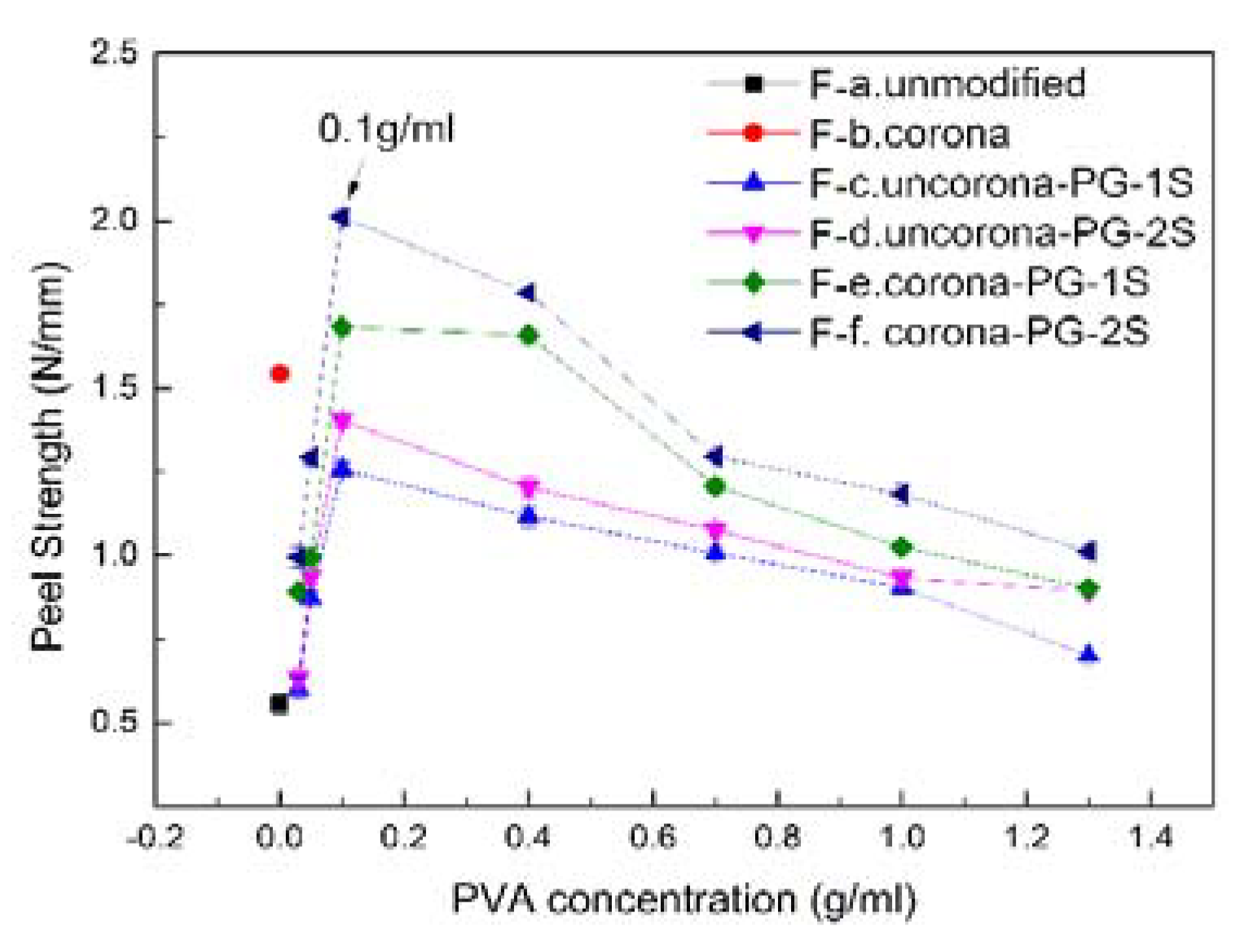

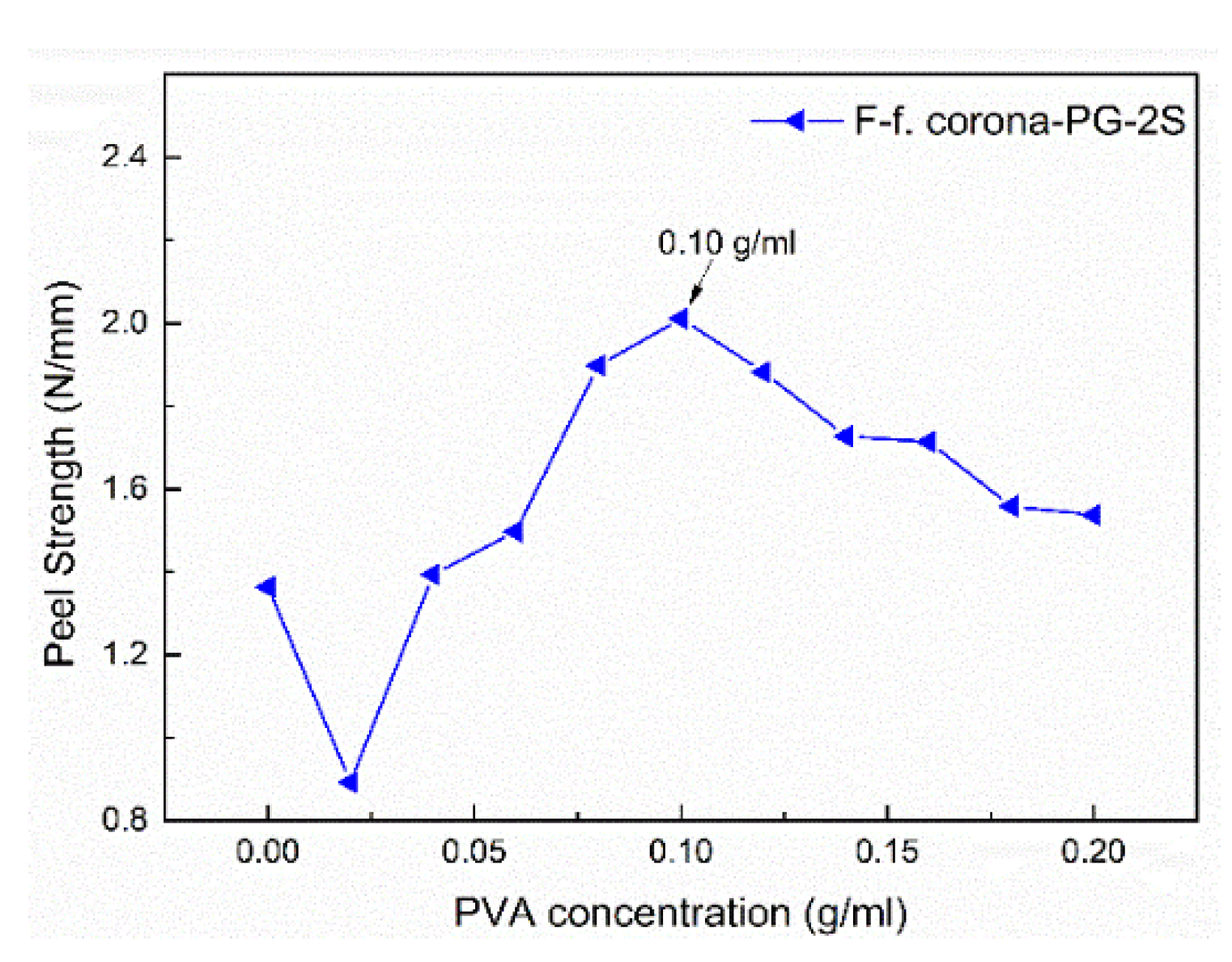

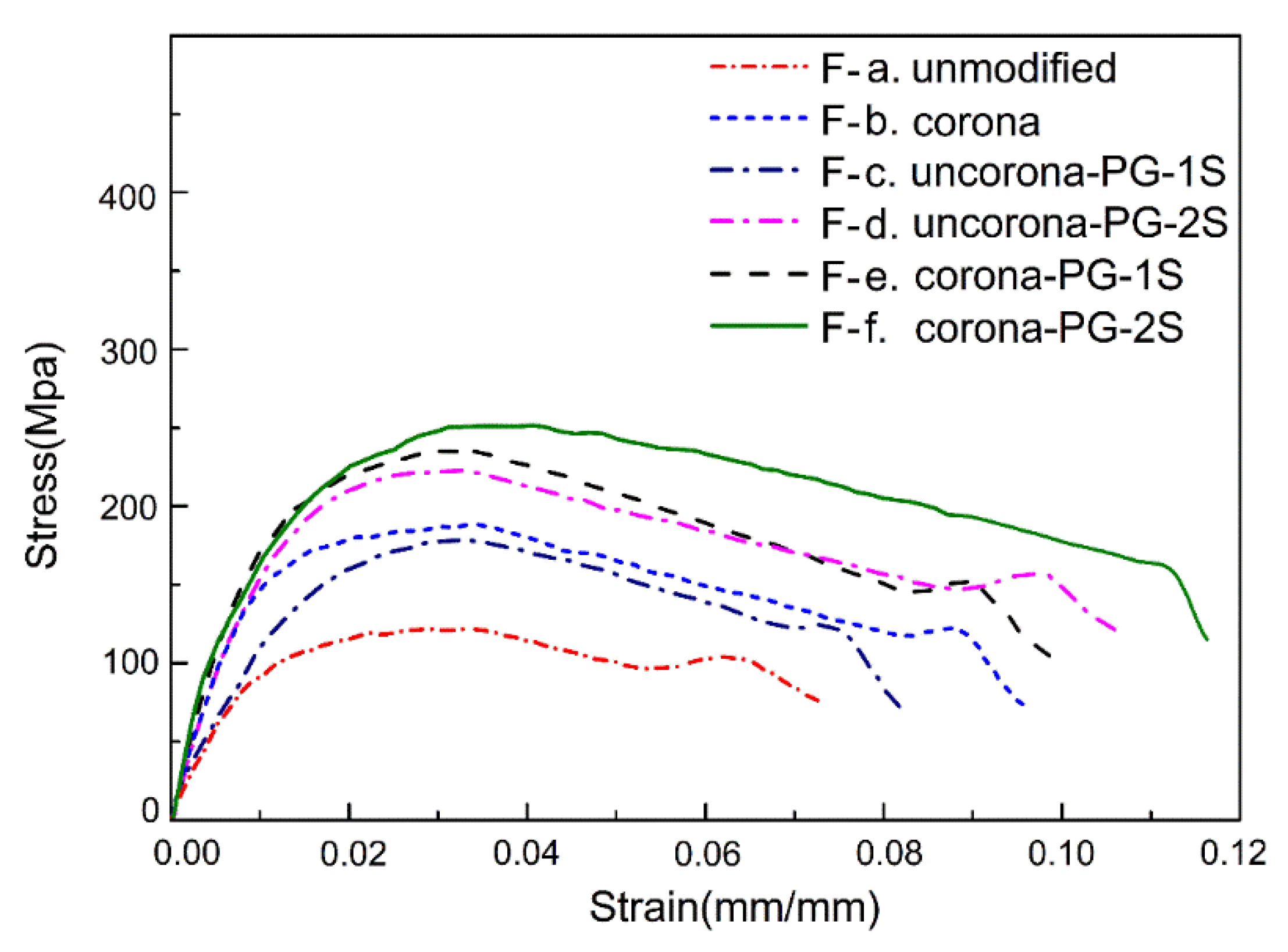

3.1. Properties of UHMWPE/Epoxy Composite

3.2. Properties of UHMWPE Fiber

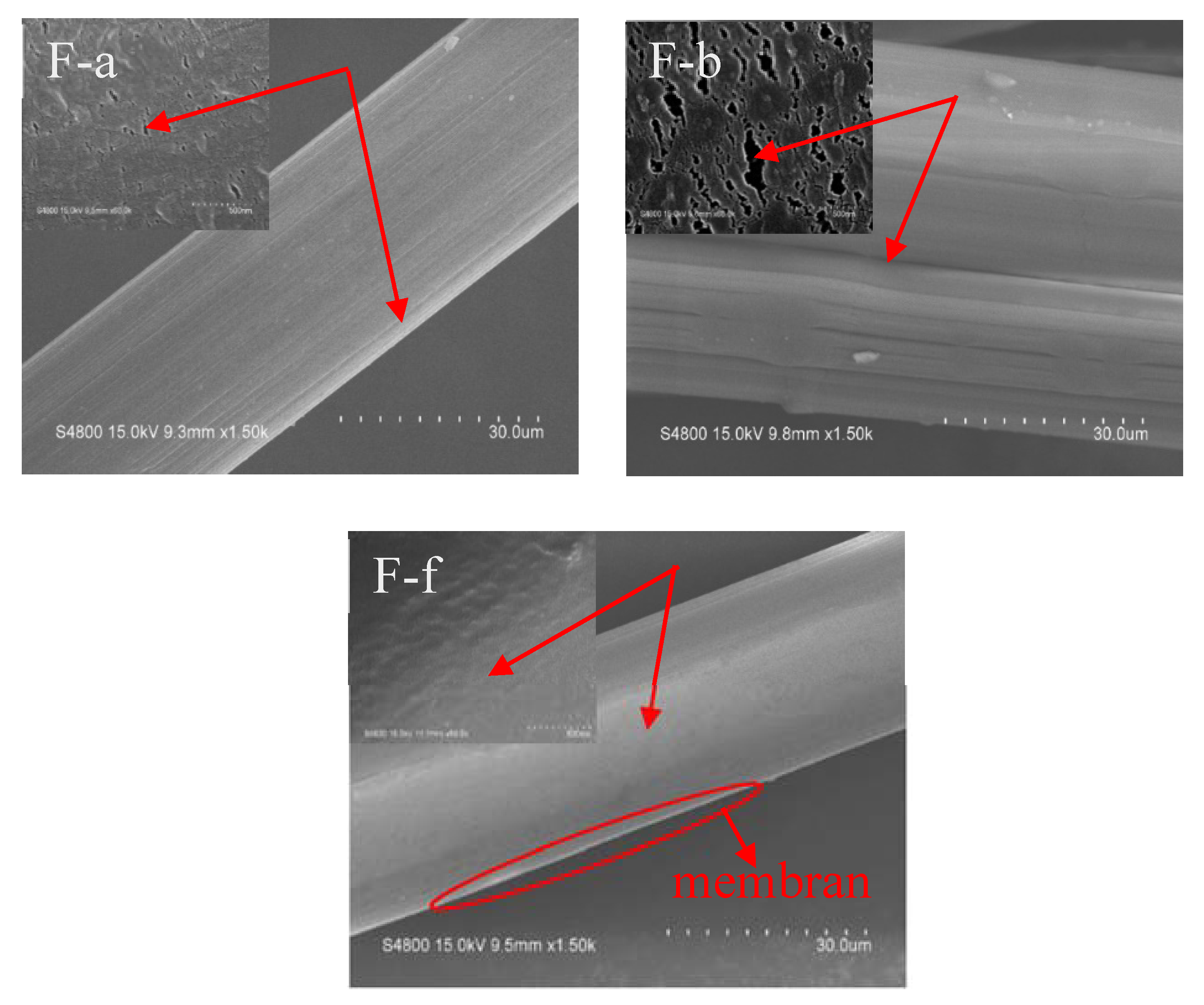

3.2.1. Surface Morphology

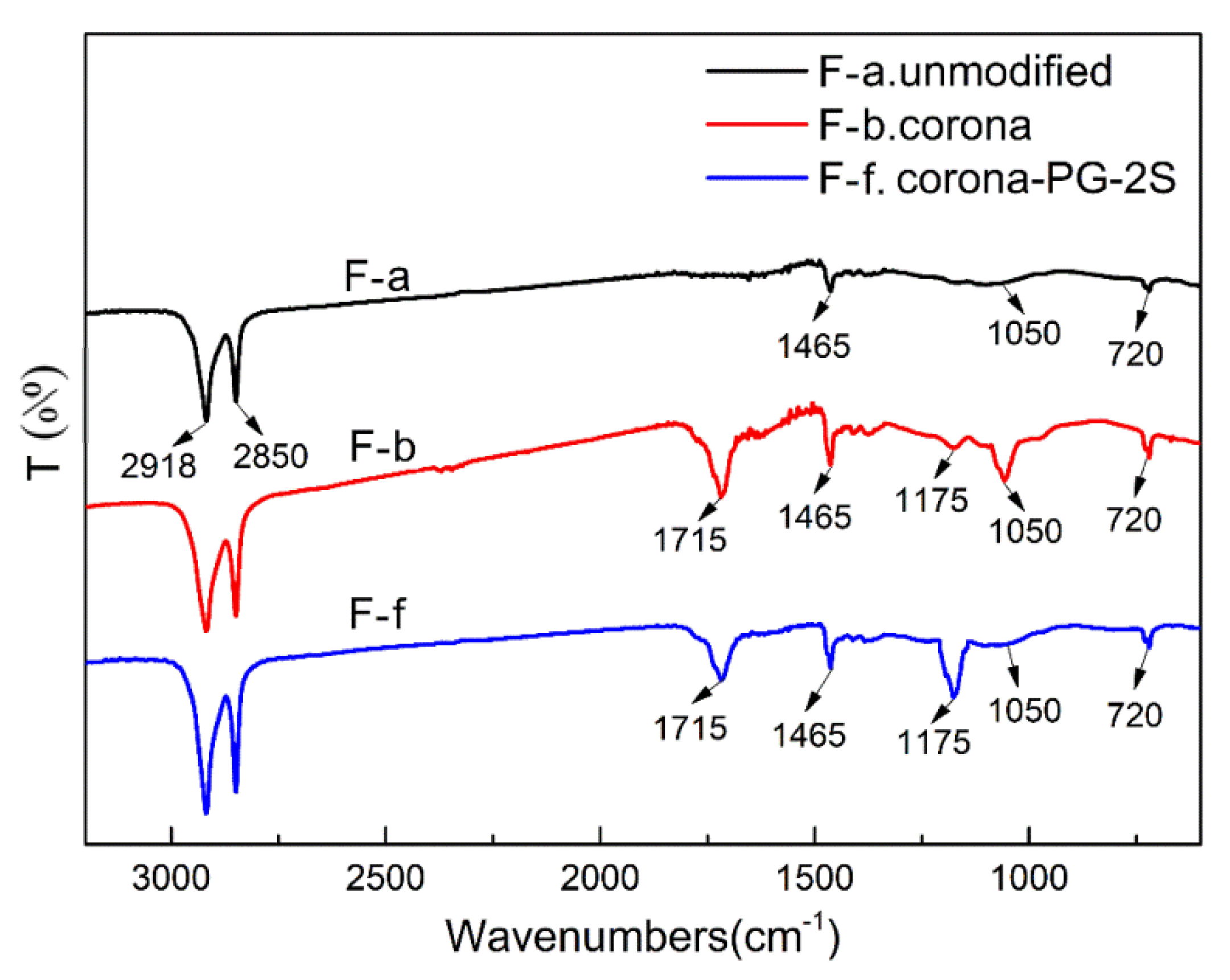

3.2.2. Functional Groups

3.2.3. Fiber Surface Element Content Analysis of EDS

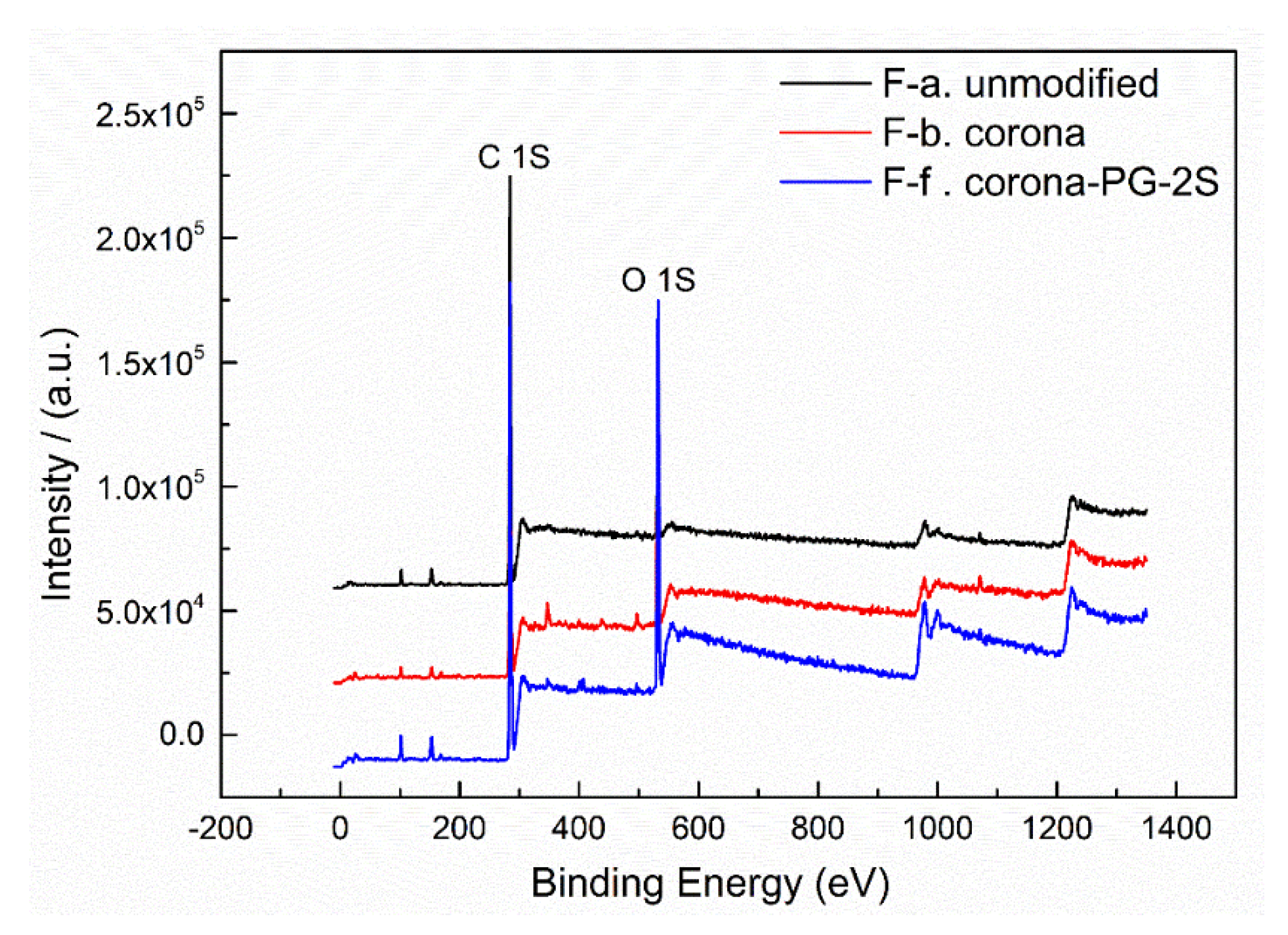

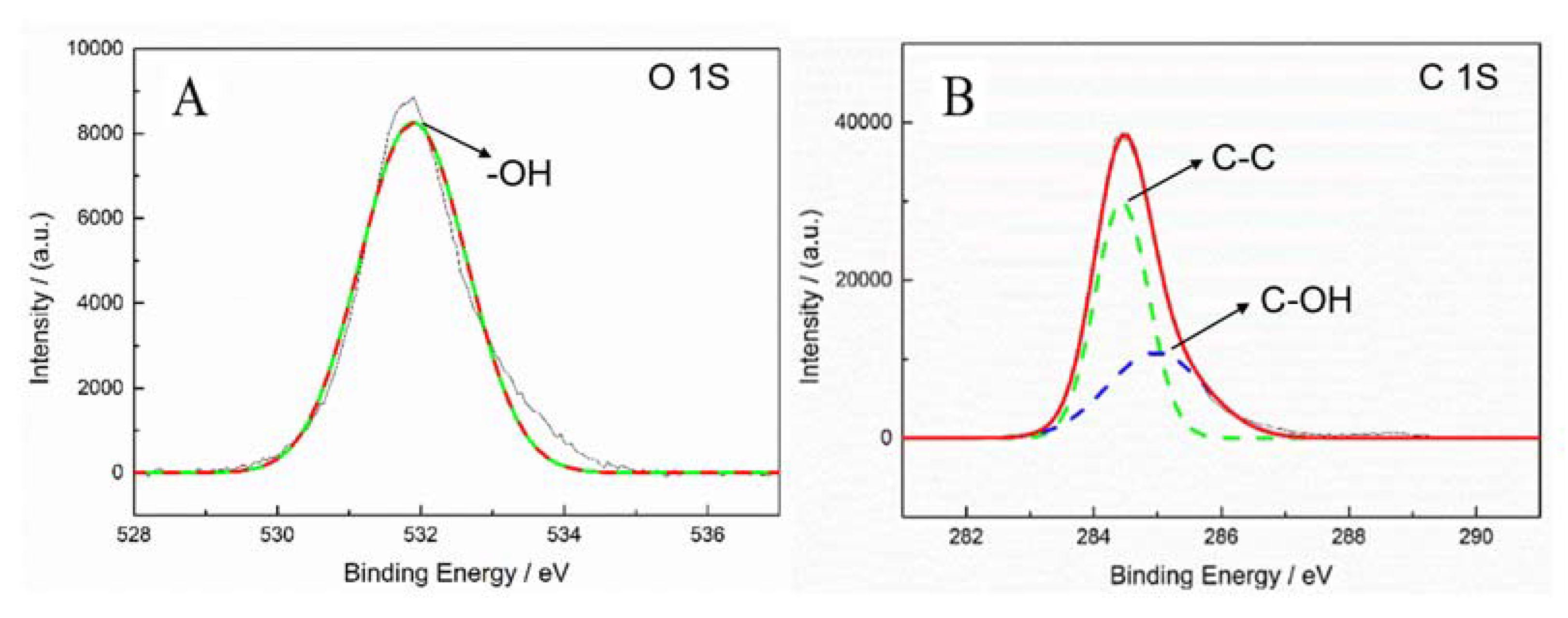

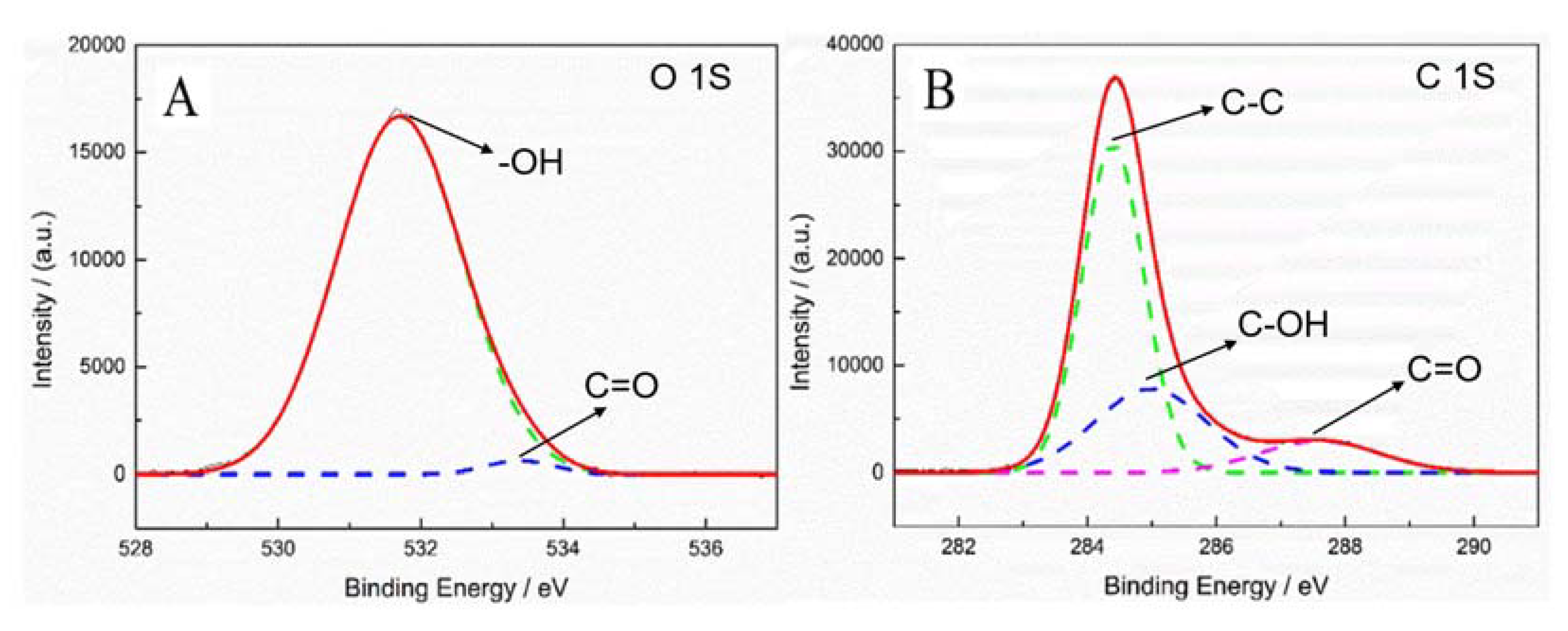

3.2.4. Fiber Surface Element Content Analysis of XPS Spectra

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Huang, W.; Wang, Y.; Xia, Y. Statistical dynamic tensile strength of UHMWPE-fibers. Polymer 2004, 45, 3729–3788. [Google Scholar] [CrossRef]

- Ratner, S.; Pegoretti, A.; Migliaresi, C.; Weinberg, A.; Marom, G. Relaxation processes and fatigue behavior of crosslinked UHMWPE fiber compacts. Compos. Sci. Technol. 2005, 65, 87–94. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, W.; Wang, X.; Mai, Y.; Zhang, Y. Surface modification of ultra high molecular weight polyethylene fibers via the sequential photoinduced graft polymerization. Appl. Surf. Sci. 2011, 257, 7600–7608. [Google Scholar] [CrossRef]

- Lin, S.; Han, J.; Yeh, J.; Chang, F.; Hsieh, K. Surface modification and physical properties of various UHMWPE fiber reinforced modified epoxy composites. J. Appl. Polym. Sci. 2007, 104, 655–665. [Google Scholar] [CrossRef]

- Ruan, S.; Gao, P.; Yu, T. Ultra-strong gel-spun UHMWPE fibers reinforced using multiwalled carbon nanotubes. Polymer 2006, 47, 1604–1611. [Google Scholar] [CrossRef]

- Yeh, J.T.; Lin, S.C.; Tu, C.W.; Hsie, K.H.; Chang, F.C. Investigation of the drawing mechanism of UHMWPE fibers. J. Mater. Sci. 2008, 43, 4892–4900. [Google Scholar] [CrossRef]

- Debnath, S.; Ranade, R.; Wunder, S.L.; Baran, G.R.; Zhang, J.; Fisher, E.R. Chemical surface treatment of ultrahigh molecular weight polyethylene for methacrylate resins. J. Appl. Polym. Sci. 2005, 96, 1564–1572. [Google Scholar] [CrossRef]

- Li, W.; Meng, L.; Wang, L.; Mu, J.; Pan, Q. Surface modification of ultra-high molecular weight polyethylene fibers by chromic acid. Surf. Interface Anal. 2016, 48, 1316–1319. [Google Scholar] [CrossRef]

- Chanunpanich, N.; Ulman, A.; Strzhemechny, Y.M.; Schwarz, S.A.; Janke, A.; Braun, H.G.; Kraztmuller, T. Surface modification of polyethylene through bromination. Langmuir 1999, 15, 2089–2094. [Google Scholar] [CrossRef]

- Balamurugana, S.; Mandaleb, A.B.; Badrinarayananb, S.; Vernekara, S.P. Photochemical bromination of polyolefin surfaces. Polymer 2001, 42, 2501–2512. [Google Scholar] [CrossRef]

- Kazimi, M.R.; Shah, T.; Ahmed, I. Sulfonation of low density polyethylene and its impact on polymer properties. Polym. Eng. Sci. 2014, 54, 2522–2530. [Google Scholar] [CrossRef]

- Huang, C.Y.; Wu, J.Y.; Tsai, C.S.; Hsieh, K.H.; Yeh, J.T.; Chen, K.N. Effects of argon plasma treatment on the adhesive property of ultra high molecular weight polyethylene (UHMWPE) textile. Surf. Coat. Technol. 2013, 231, 507–511. [Google Scholar] [CrossRef]

- Ji, F.; Hong, Y.; Peng, S.; He, T.; Sun, J.; Yao, L.; Qiu, Y. Effect of glycerol coating on the atmospheric pressure plasma treatment of UHMWPE fibers. J. Adhes. Sci. Technol. 2012, 26, 289–301. [Google Scholar]

- Moon, S.I.; Jang, J. The effect of the oxygen-plasma treatment of UHMWPE fiber on the transverse properties of UHMWPE-fiber/vinylester composites. Compos. Sci. Technol. 1999, 59, 487–493. [Google Scholar] [CrossRef]

- Teodoru, S.; Kusano, Y.; Rozlosnik, N.; Michelsen, P.K. Continuous plasma treatment of ultra-high-molecular-weight polyethylene (UHMWPE) fibres for adhesion improvement. Plasma Process. Polym. 2009, 6, S375–S381. [Google Scholar] [CrossRef]

- Ren, Y.; Wang, C.; Qiu, Y. Aging of surface properties of ultra high modulus polyethylene fibers treated with He/O2 atmospheric pressure plasma jet. Surf. Coat. Technol. 2008, 202, 2670–2676. [Google Scholar] [CrossRef]

- Wang, J.; Liang, G.; Zhao, W.; Lü, S.; Zhang, Z. Studies on surface modification of UHMWPE fibers via UV initiated grafting. Appl. Surf. Sci. 2006, 253, 668–673. [Google Scholar] [CrossRef]

- Sakurai, K.; Kondo, Y.; Miyazaki, K.; Okamoto, T.; Irie, S.; Sasaki, T. Ultrahigh-molecular-weight-polyethylene-fiber surface treatment by electron-beam-irradiation-induced graft polymerization and its effect on adhesion in a styrene butadiene rubber matrix. J. Polym. Sci. Part. B-Polym. 2004, 42, 2595–2603. [Google Scholar] [CrossRef]

- Xing, Z.; Wang, M.; Hu, J.; Wu, G. Crystal structure and mechanical properties of UHMWPE-g-PMA fiber prepared by radiation grafting. Radiat. Phys. Chem. 2013, 86, 84–89. [Google Scholar] [CrossRef]

- Enomoto, I.; Katsumura, Y.; Kudo, H.; Soeda, S. Graft polymerization using radiation-induced peroxides and application to textile dyeing. Radiat. Phys. Chem. 2011, 80, 169–174. [Google Scholar] [CrossRef]

- Ruan, F.; Bao, L. Mechanical enhancement of UHMWPE fibers by coating with carbon nanoparticles. Fibers Polym. 2014, 15, 723–728. [Google Scholar] [CrossRef]

- Hegemann, D.; Brunner, H.; Oehr, C. Plasma treatment of polymers for surface and adhesion improvement. Nucl. Instrum. Methods Phys. Res. Sect. B-Beam Interact. Mater. At. 2003, 208, 281–286. [Google Scholar] [CrossRef]

- Salem, T.; Uhlmann, S.; Nitschke, M.; Calvimontes, A.; Hund, R.D.; Simon, F. Modification of plasma pre-treated PET fabrics with poly-DADMAC and its surface activity towards acid dyes. Prog. Org. Coat. 2011, 72, 168–174. [Google Scholar] [CrossRef]

- Shahidi, S.; Ghoranneviss, M.; Wiener, J. Improving synthetic and natural dyeability of polyester fabrics by dielectric barrier discharge. J. Plast. Film. Sheeting 2015, 31, 286–308. [Google Scholar] [CrossRef]

- Chen, C.; Ogino, A.; Wang, X.; Nagatsu, M. Plasma treatment of multiwall carbon nanotubes for dispersion improvement in water. Appl. Phys. Lett. 2010, 96, 131504. [Google Scholar] [CrossRef]

- Rodrigues, M.M.; Fontoura, C.P.; Martins, S.T.; Figueroa, C.A. Investigation of plasma treatment on UHMWPE surfaces: Impact on physicochemical properties, sterilization and fibroblastic adhesion. Mater. Sci. Eng. C-Mater. Biol. Appl. 2019, 102, 264–275. [Google Scholar] [CrossRef]

- Shi, S.C.; Chang, T.W. FTIR study of the surface properties and tribological behaviors of plasma-modified UHMWPE and zirconia. Opt. Quantum Electron. 2018, 50, 12. [Google Scholar] [CrossRef]

- Ren, Y.; Zhang, Y.; Wang, X.N.; Zang, C.F.; Zhang, W. Surface properties and adhesion force of air dielectric barrier discharge treated UHMWPE fibers. Acta Polym. Sin. 2016, 10, 1439–1446. [Google Scholar]

- Li, W.W.; Liu, X.J.; Huang, M.M.; Ma, R.L. Ultra-High Molecular Weight Polyethylene Fibers/Epoxy Composites: Effect of Fiber Treatment on Properties. Fibers Polym. 2019, 20, 421–427. [Google Scholar] [CrossRef]

- Yuan, W.J.; Cui, J.Y.; Cai, Y.B.; Xu, S.A. A novel surface modification for calcium sulfate whisker used for reinforcement of poly(vinyl chloride). J. Polym. Res. 2015, 22, 173–182. [Google Scholar] [CrossRef]

- Lu, Y.H.; Wu, C.F.; Xu, S.A. Mechanical, thermal and flame retardant properties of magnesium hydroxide filled poly(vinyl chloride) composites: The effect of filler shape. Compos. Part. A-Appl. Sci. Manuf. 2018, 113, 1–11. [Google Scholar] [CrossRef]

- Meng, L.; Li, W.W.; Ma, R.L.; Huang, M.M.; Cao, Y.B.; Wang, J.W. Mechanical properties of rigid polyurethane composites reinforced with surface treated ultrahigh molecular weight polyethylene fibers. Polym. Adv. Technol. 2018, 29, 843–851. [Google Scholar] [CrossRef]

- Ren, Y.; Ding, Z.R.; Wang, C.X.; Zang, C.F.; Zhang, Y.; Xu, L. Influence of DBD plasma pretreatment on the deposition of chitosan onto UHMWPE fiber surfaces for improvement of adhesion and dyeing properties. Appl. Surf. Sci. 2017, 396, 1571–1579. [Google Scholar] [CrossRef]

| Molecular Weight | Density (g/cm3) | Elastic Modulus (MPa) | Water Absorption (%) |

|---|---|---|---|

| 5.3 × 106 | 0.927–0.941 | 600 | <0.01 |

| Modification | Abbreviation | ||||||

|---|---|---|---|---|---|---|---|

| F-a | F-b | F-c | F-d | F-e | F-f | ||

| Corona | N | Y | N | N | Y | Y | |

| PG-1S | N | N | Y | N | Y | N | |

| PG-2S | N | N | N | Y | N | Y | |

| Element | Sample | ||||||

|---|---|---|---|---|---|---|---|

| F-a | F-b | F-c | F-d | F-e | F-f | ||

| Epoxy Resin | Weight (wt %) | 35 ± 0.5 | 35 ± 0.5 | 35 ± 0.5 | 35 ± 0.5 | 35 ± 0.5 | 35 ± 0.5 |

| Curing Agent | Weight (wt %) | 5 ± 0.2 | 5 ± 0.2 | 5 ± 0.2 | 5 ± 0.2 | 5 ± 0.2 | 5 ± 0.2 |

| Dried UHMWPE | Weight (wt %) | 60 ± 1.0 | 60 ± 1.0 | 60 ± 1.0 | 60 ± 1.0 | 60 ± 1.0 | 60 ± 1.0 |

| Element | Unmodified | Corona | Corona-PG-2S |

|---|---|---|---|

| [wt %] | [wt %] | [wt %] | |

| Carbon | 92.31 | 81.82 | 74.93 |

| Oxygen | 7.69 | 18.18 | 25.07 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, L.; Cai, H.; Chen, X.; Zheng, C.; Guo, W. Study of UHMWPE Fiber Surface Modification and the Properties of UHMWPE/Epoxy Composite. Polymers 2020, 12, 521. https://doi.org/10.3390/polym12030521

Han L, Cai H, Chen X, Zheng C, Guo W. Study of UHMWPE Fiber Surface Modification and the Properties of UHMWPE/Epoxy Composite. Polymers. 2020; 12(3):521. https://doi.org/10.3390/polym12030521

Chicago/Turabian StyleHan, Lei, Haifeng Cai, Xu Chen, Cheng Zheng, and Weihong Guo. 2020. "Study of UHMWPE Fiber Surface Modification and the Properties of UHMWPE/Epoxy Composite" Polymers 12, no. 3: 521. https://doi.org/10.3390/polym12030521

APA StyleHan, L., Cai, H., Chen, X., Zheng, C., & Guo, W. (2020). Study of UHMWPE Fiber Surface Modification and the Properties of UHMWPE/Epoxy Composite. Polymers, 12(3), 521. https://doi.org/10.3390/polym12030521