The Effect of Dye and Pigment Concentrations on the Diameter of Melt-Electrospun Polylactic Acid Fibers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

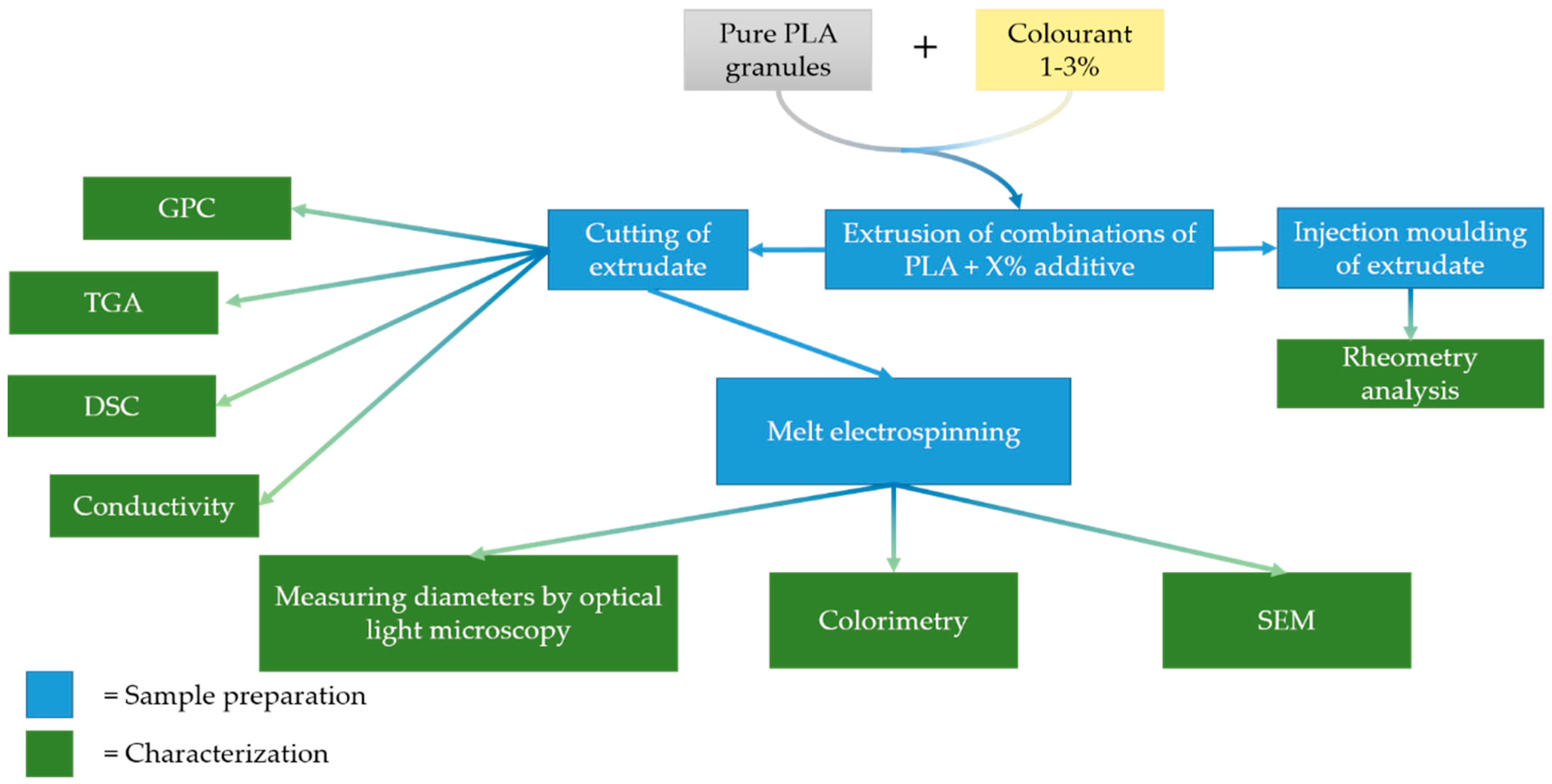

2.2. Methods

2.2.1. Microcompounder

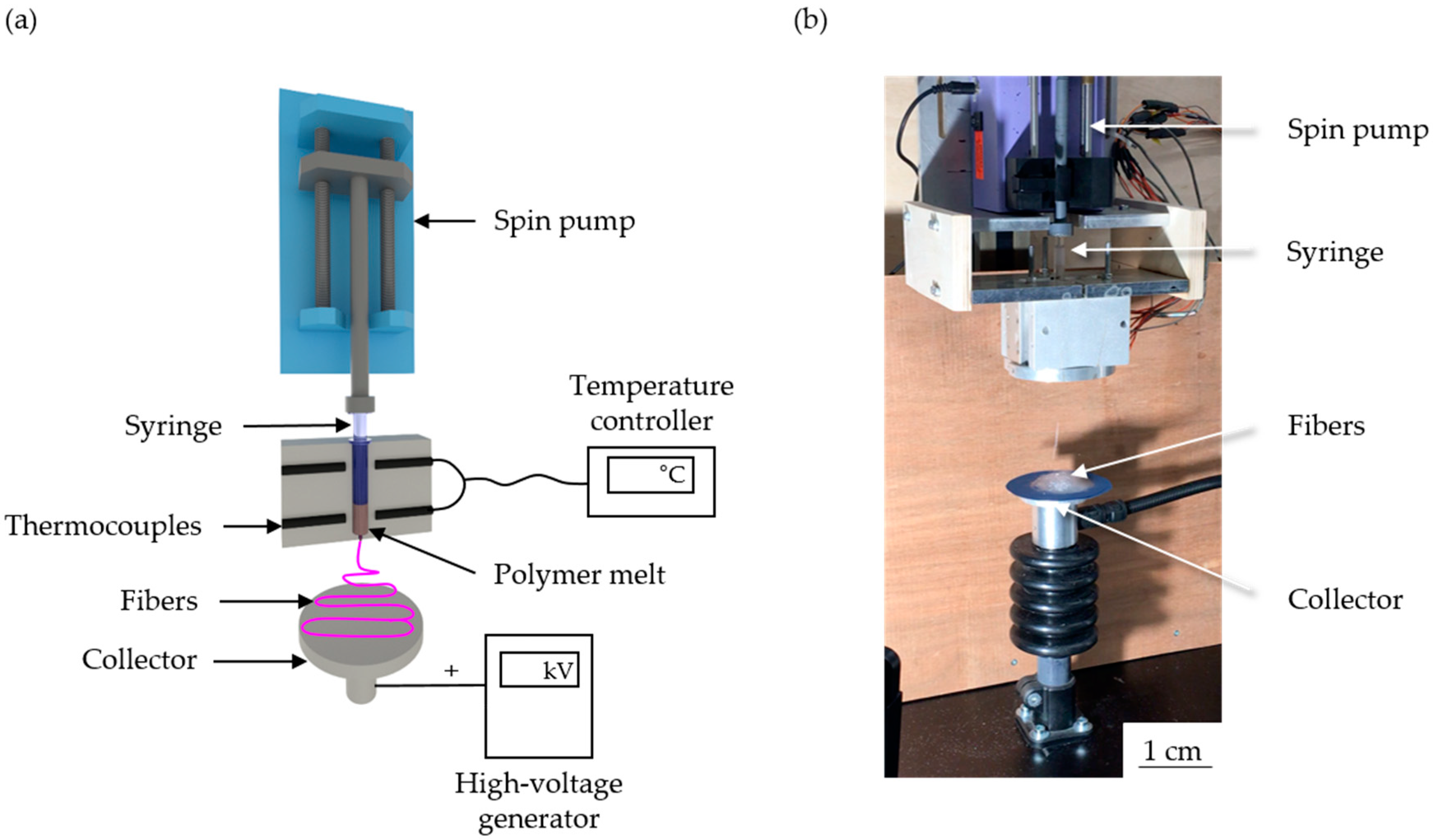

2.2.2. Melt Electrospinning Equipment

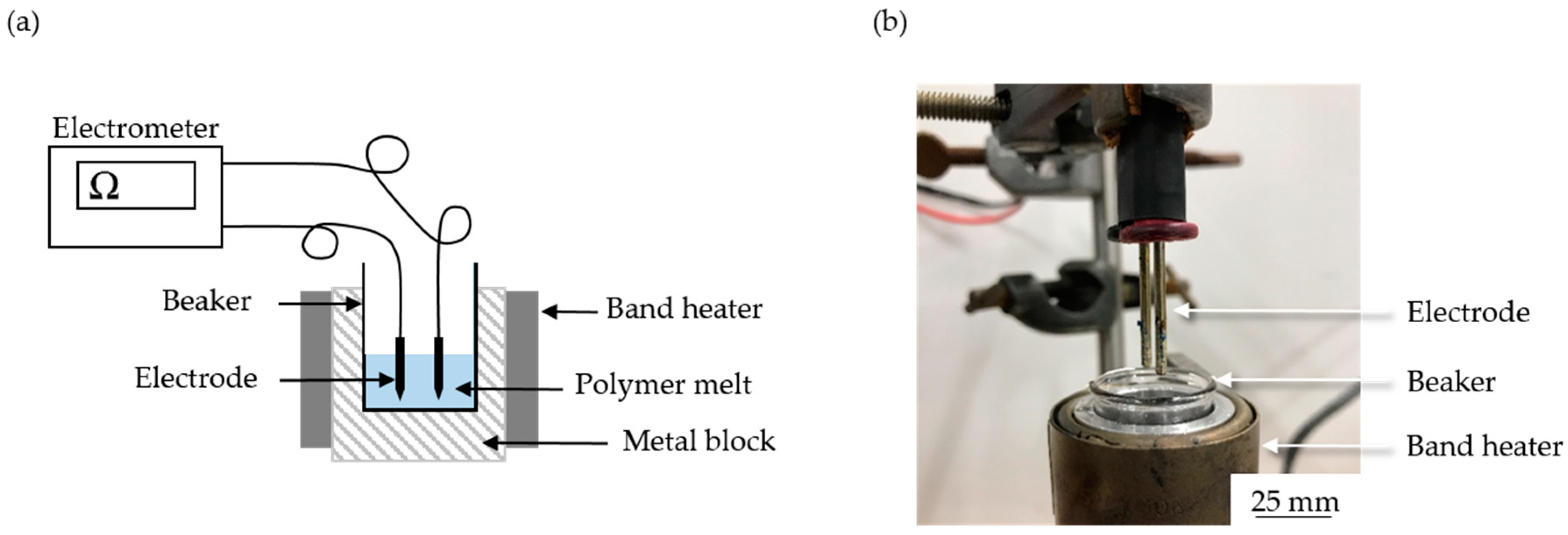

2.2.3. Characterization of Composites

2.2.4. Characterization of Fibers

2.2.5. Experimental Methodology

3. Results and Discussion

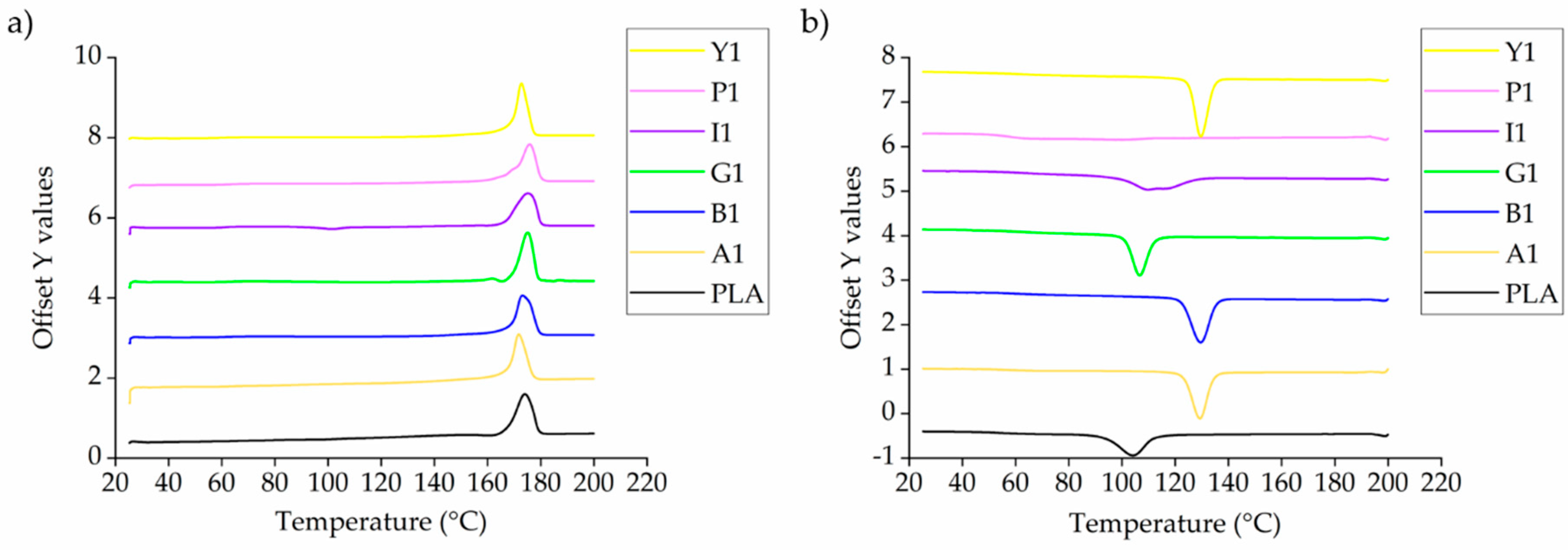

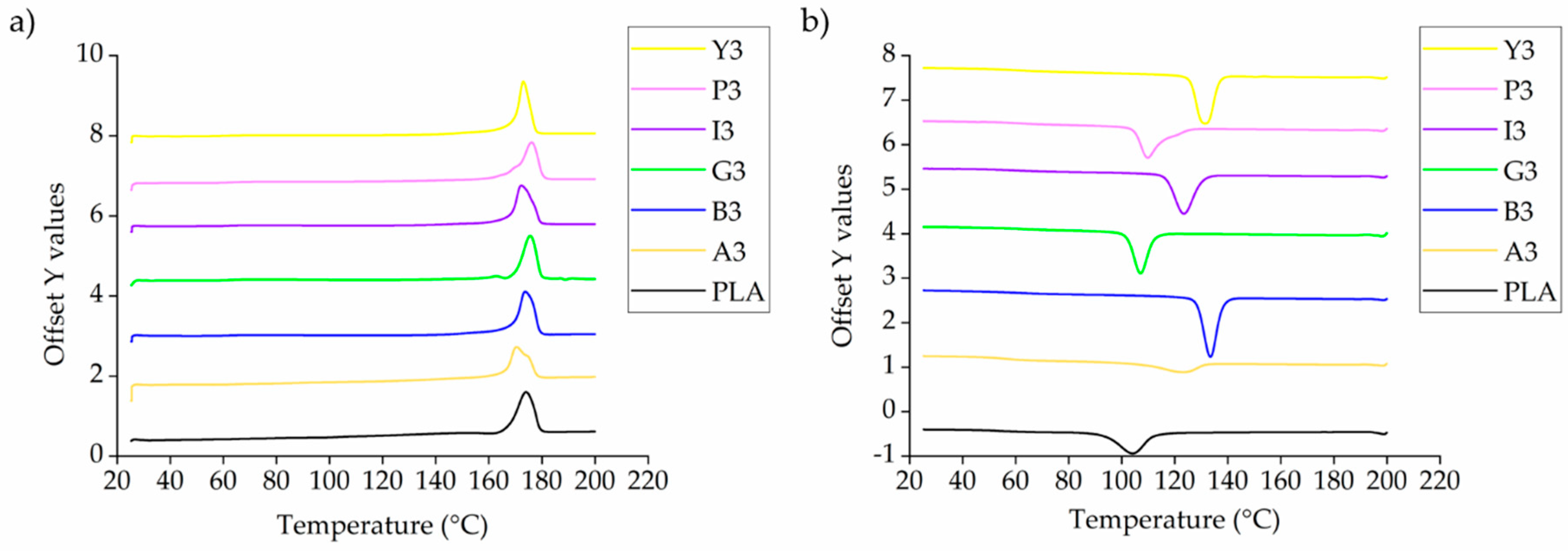

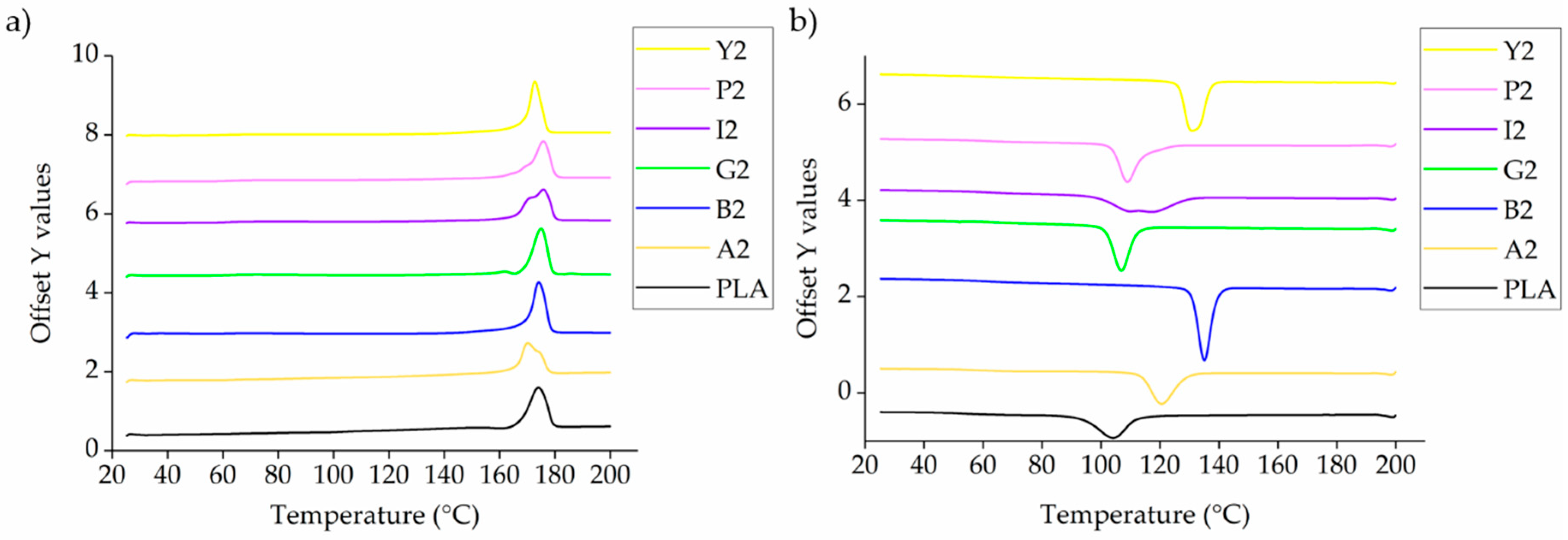

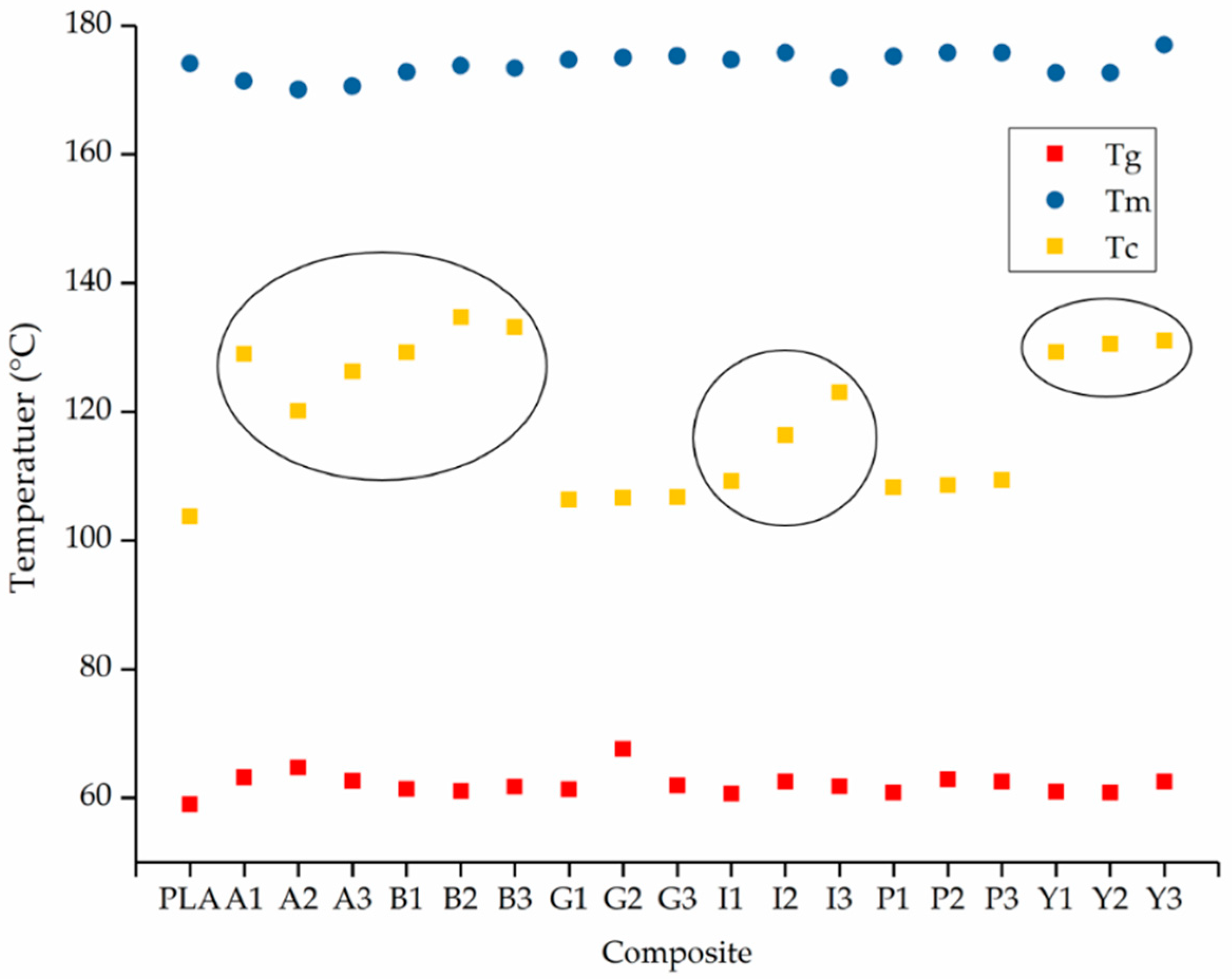

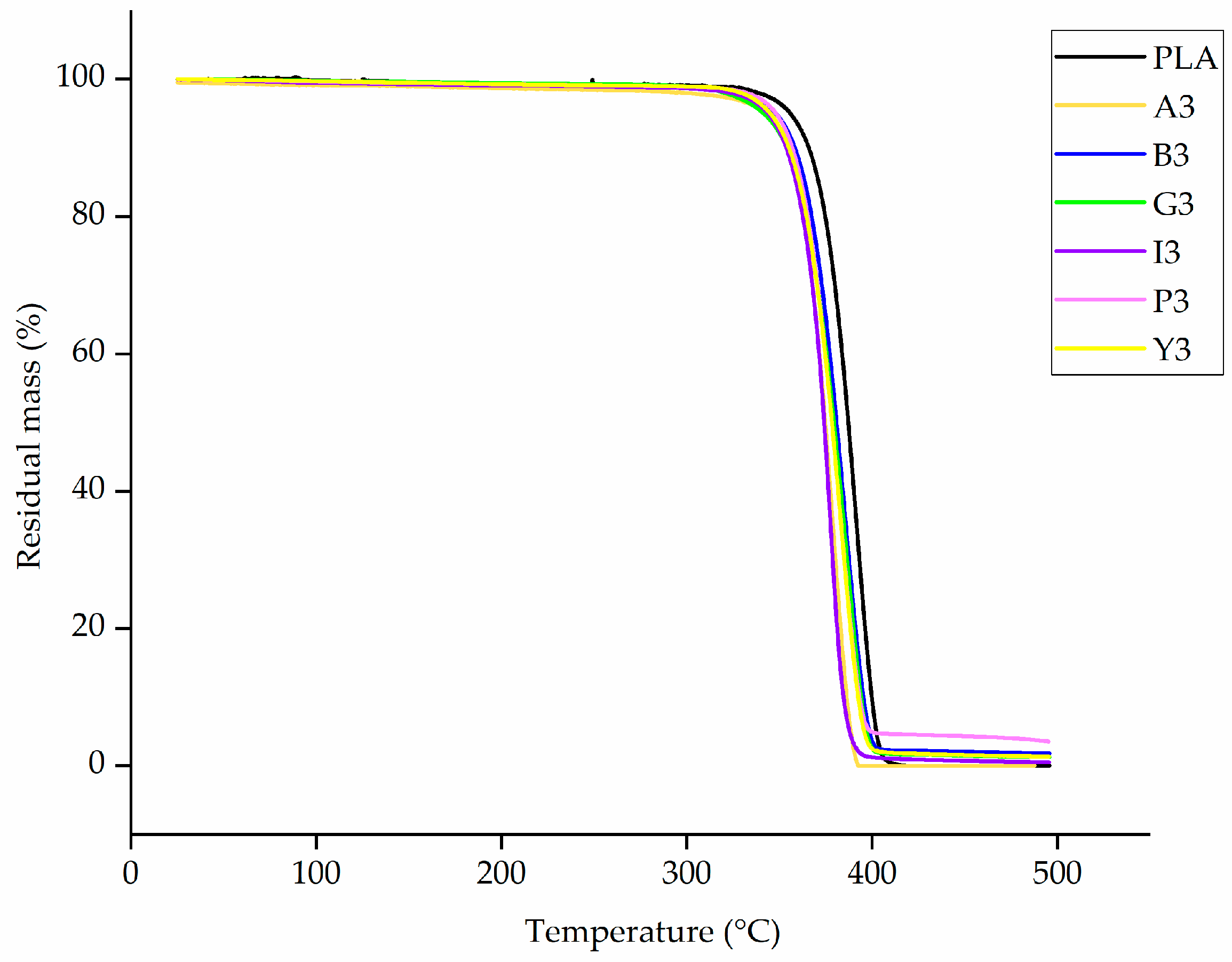

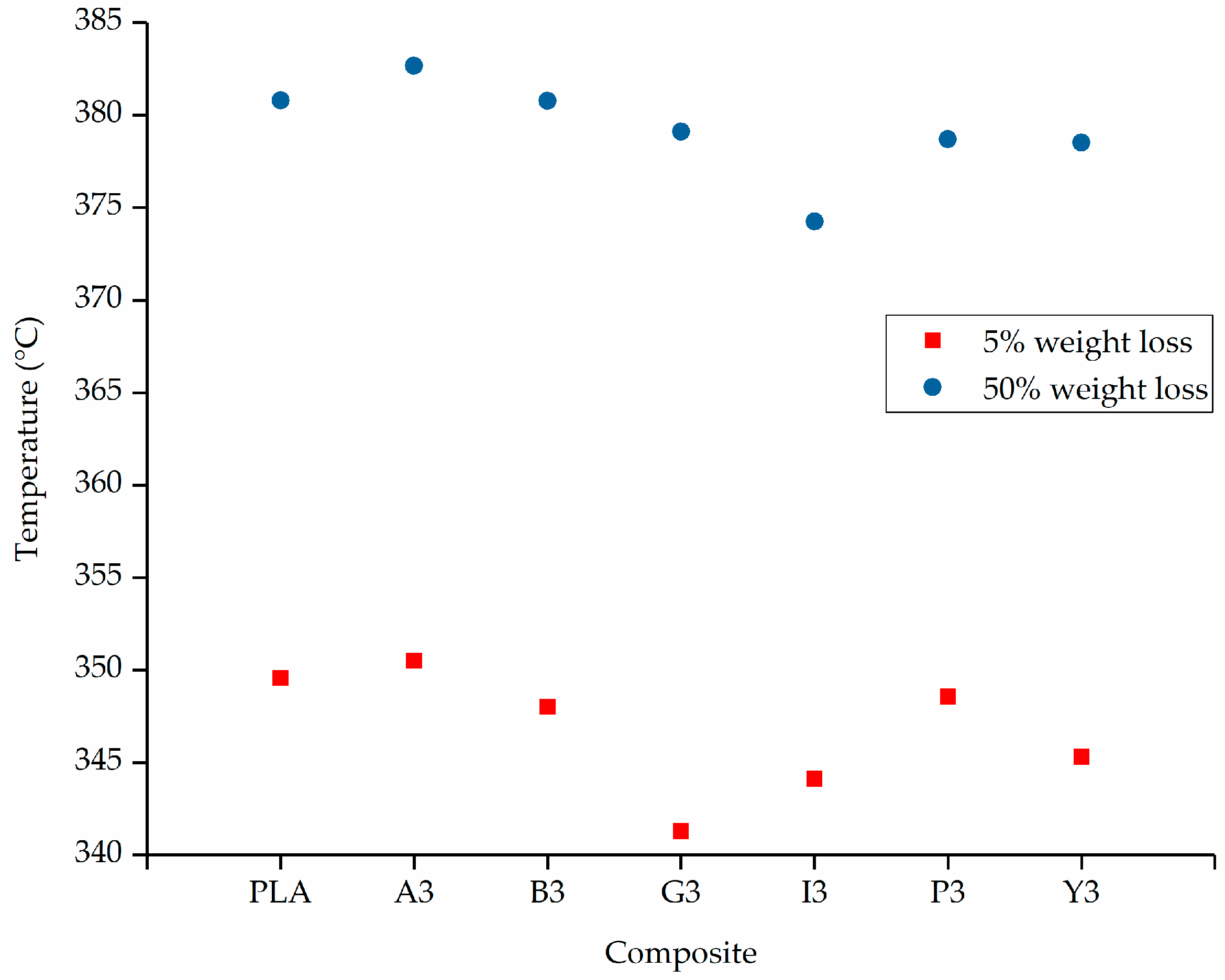

3.1. Thermal Properties of the PLA Composites

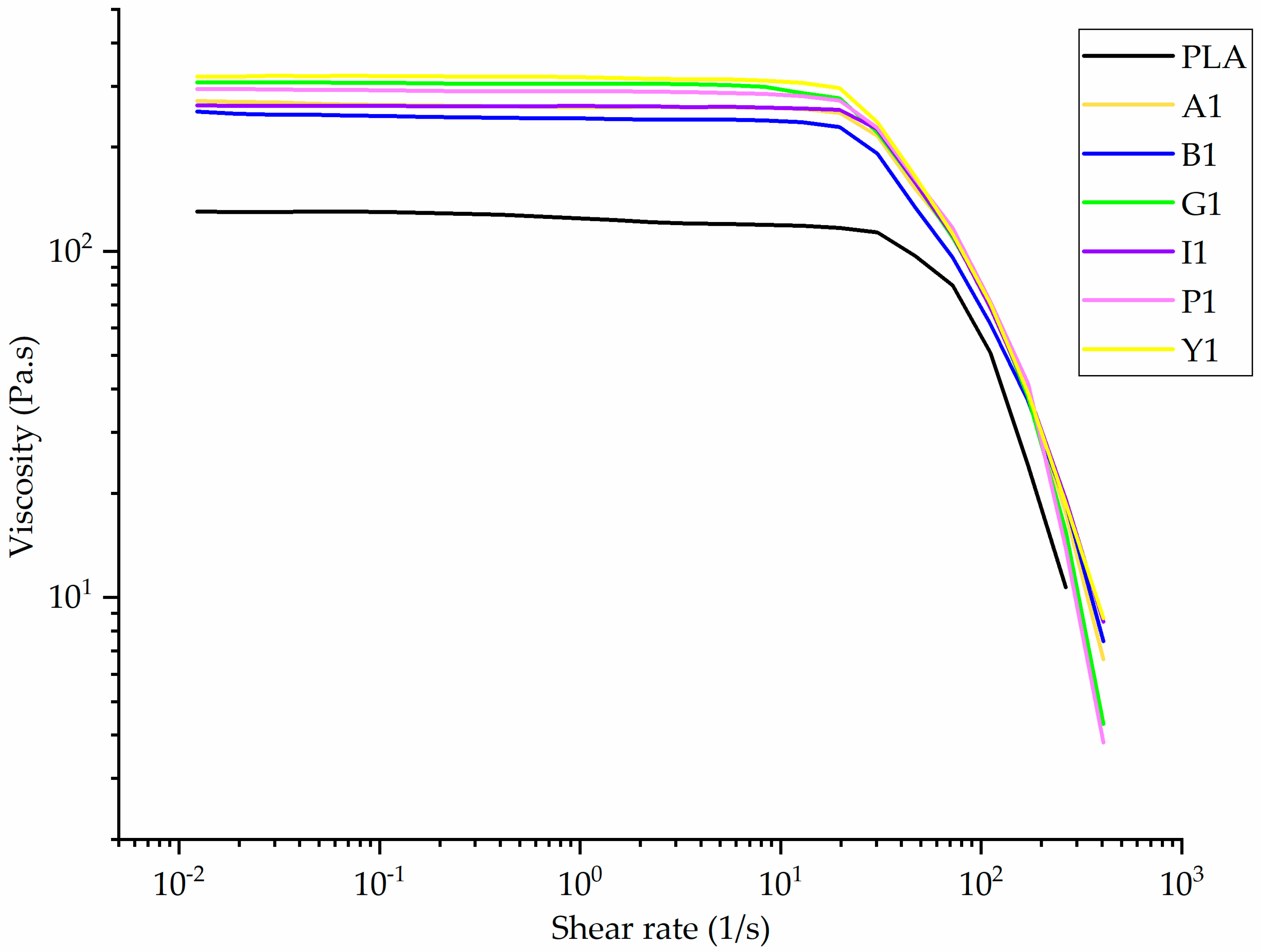

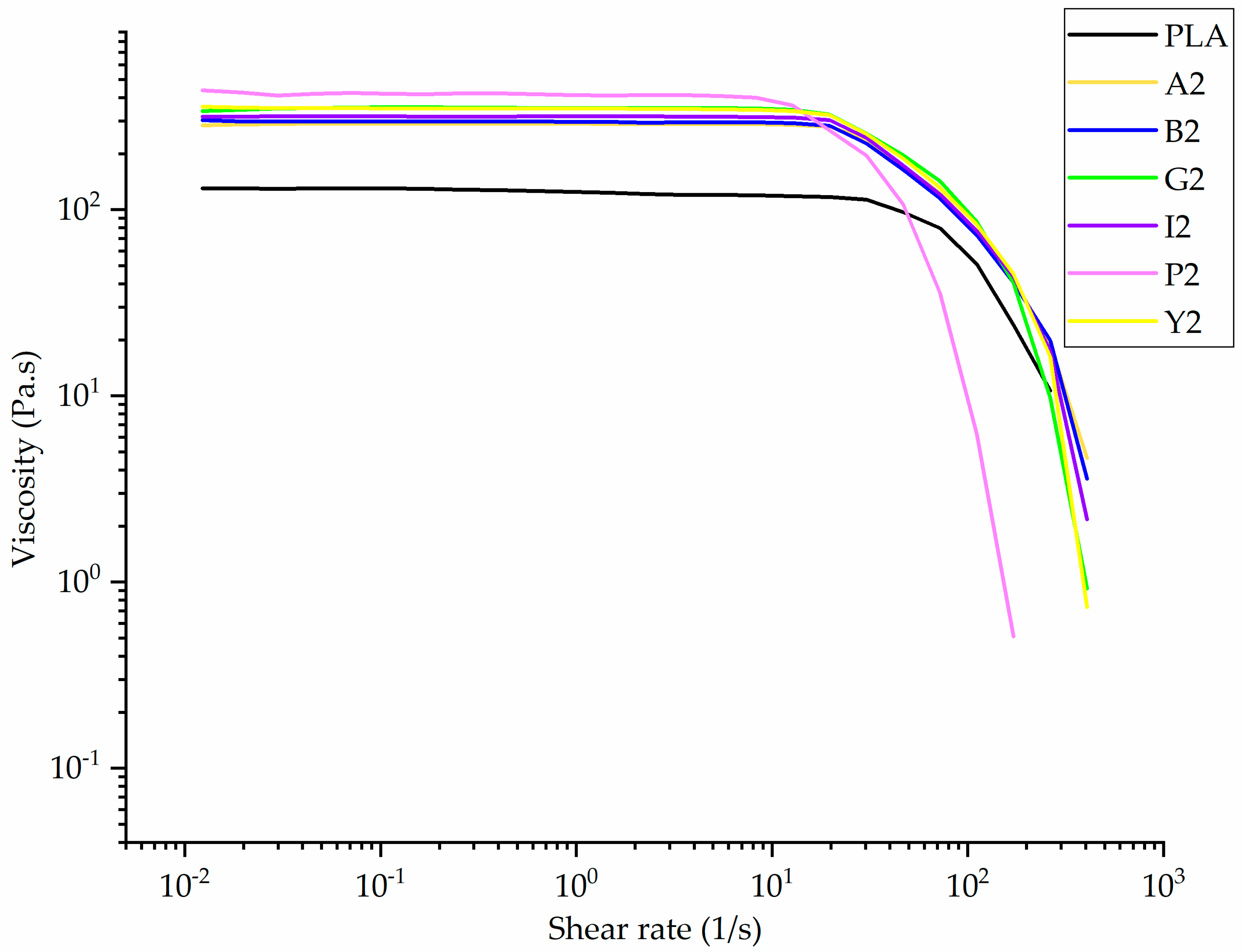

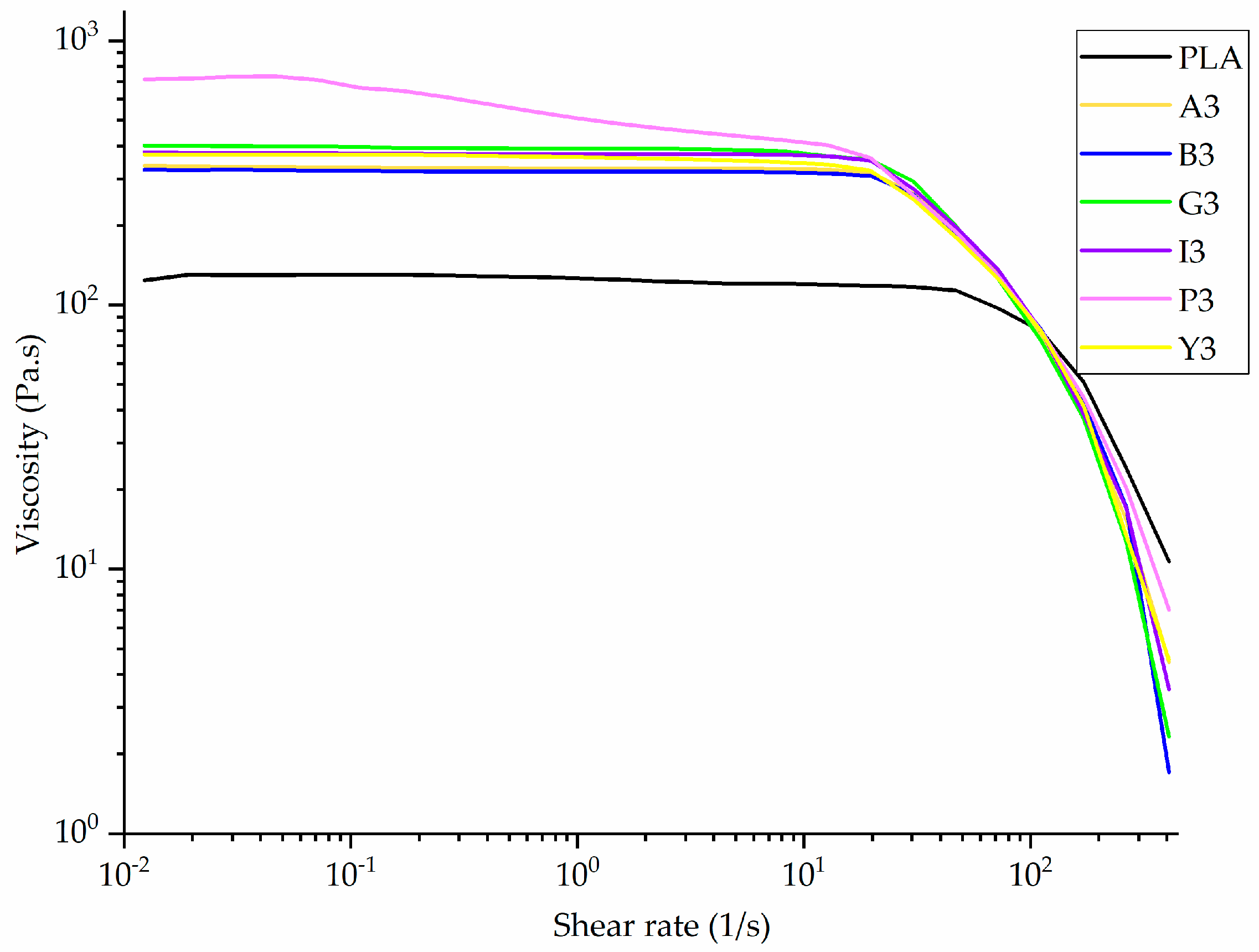

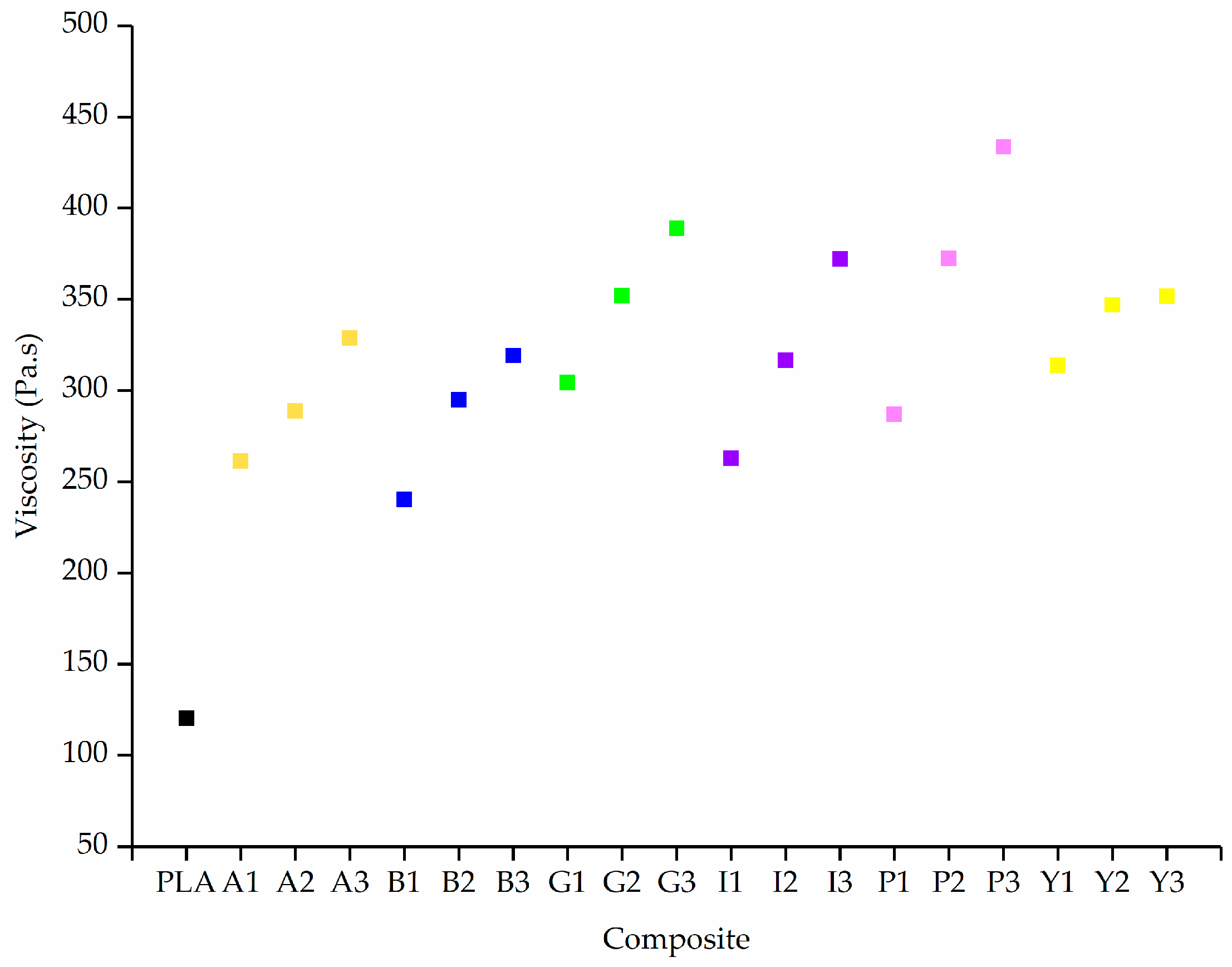

3.2. Effect of Additives on Melt Viscosity

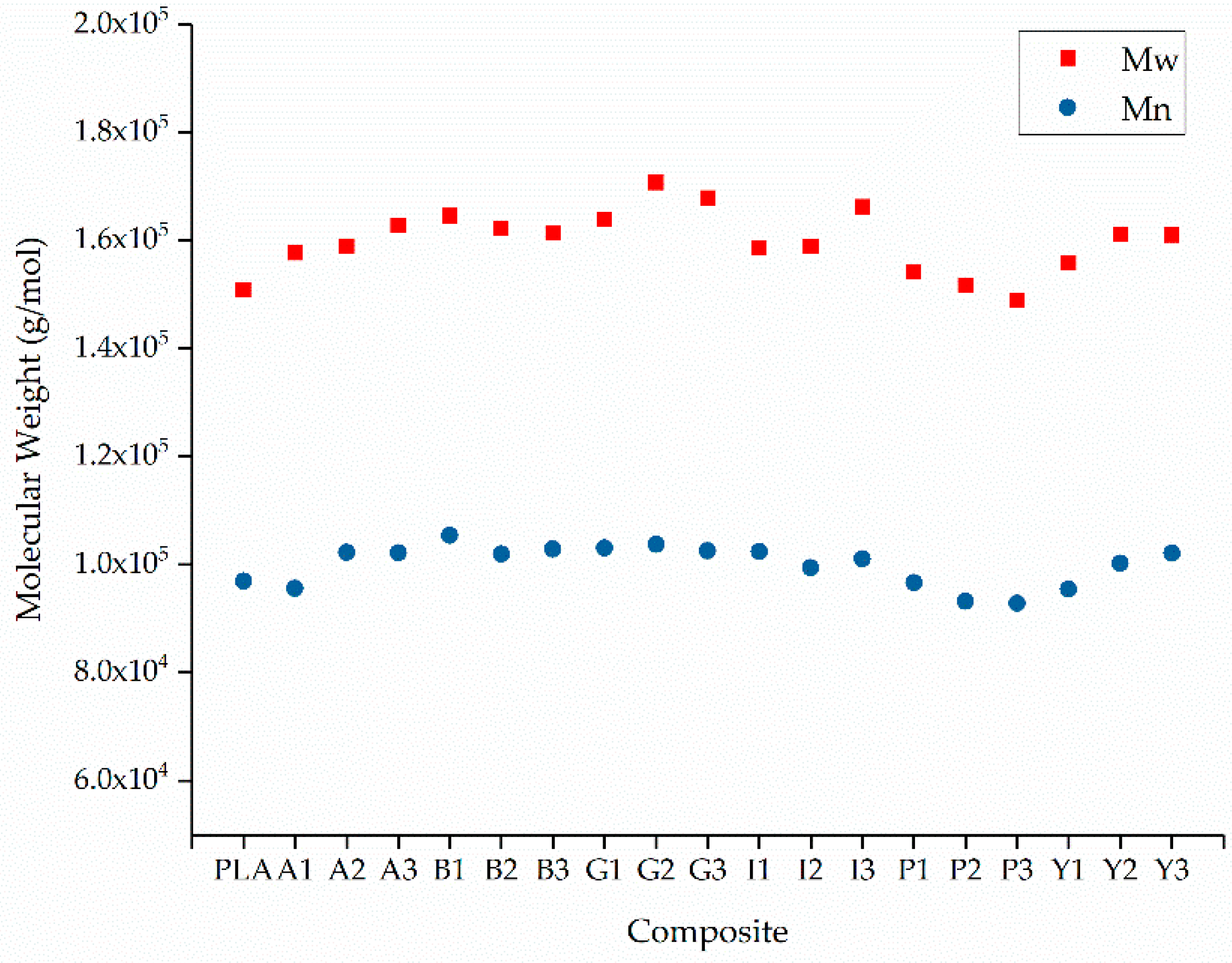

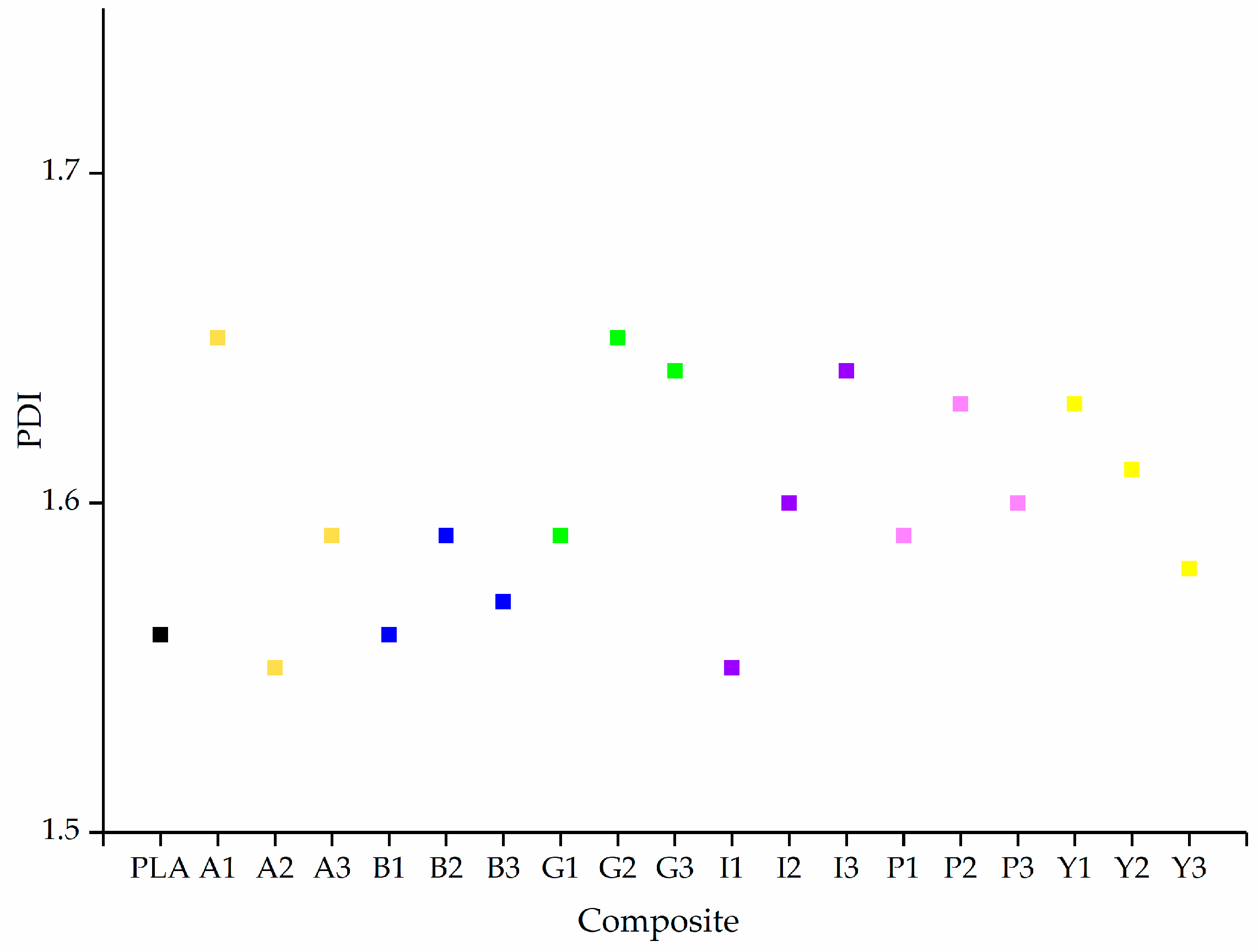

3.3. GPC Analysis of PLA and Its Composites

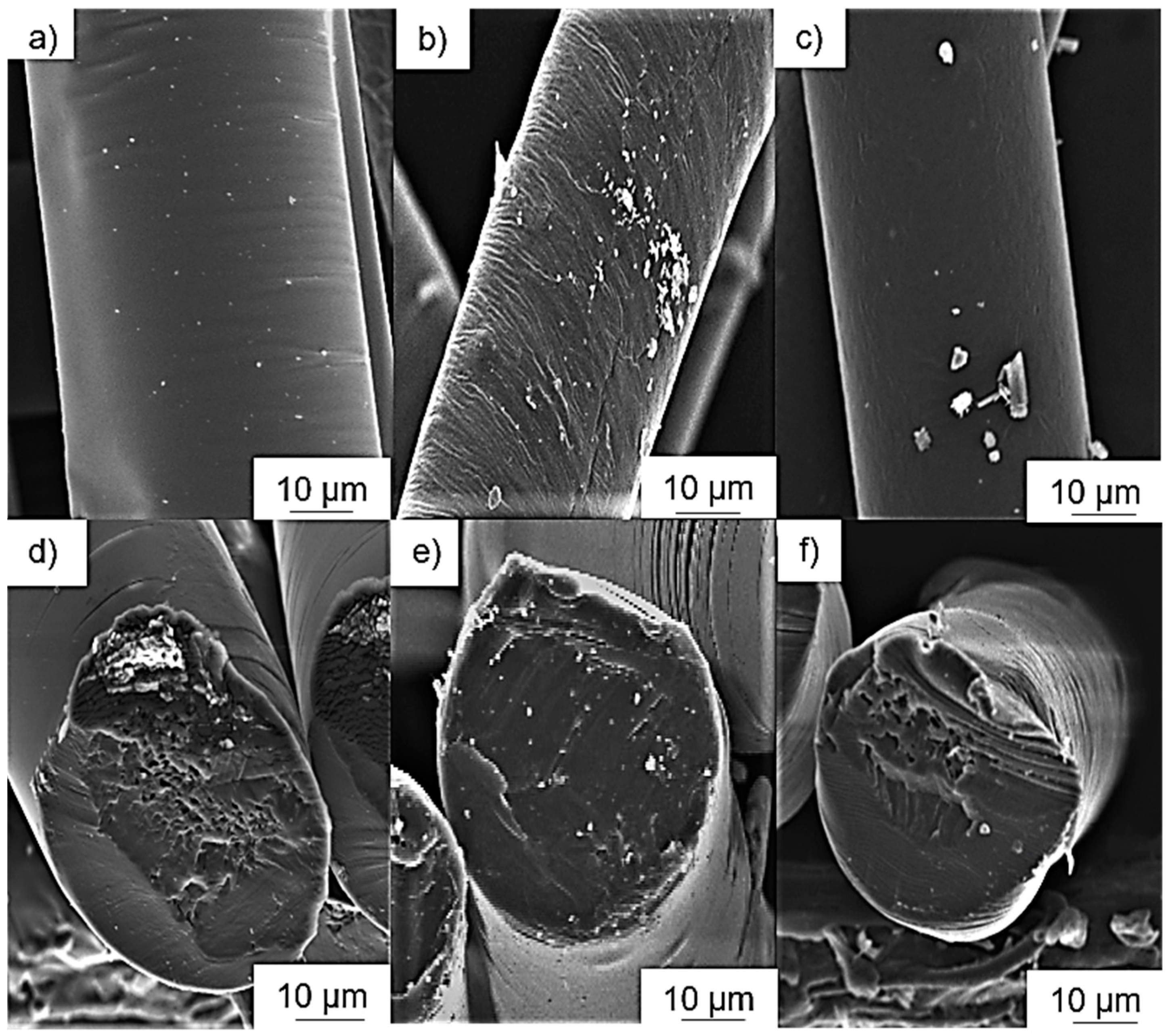

3.4. Analysis of Additive Dispersion by SEM

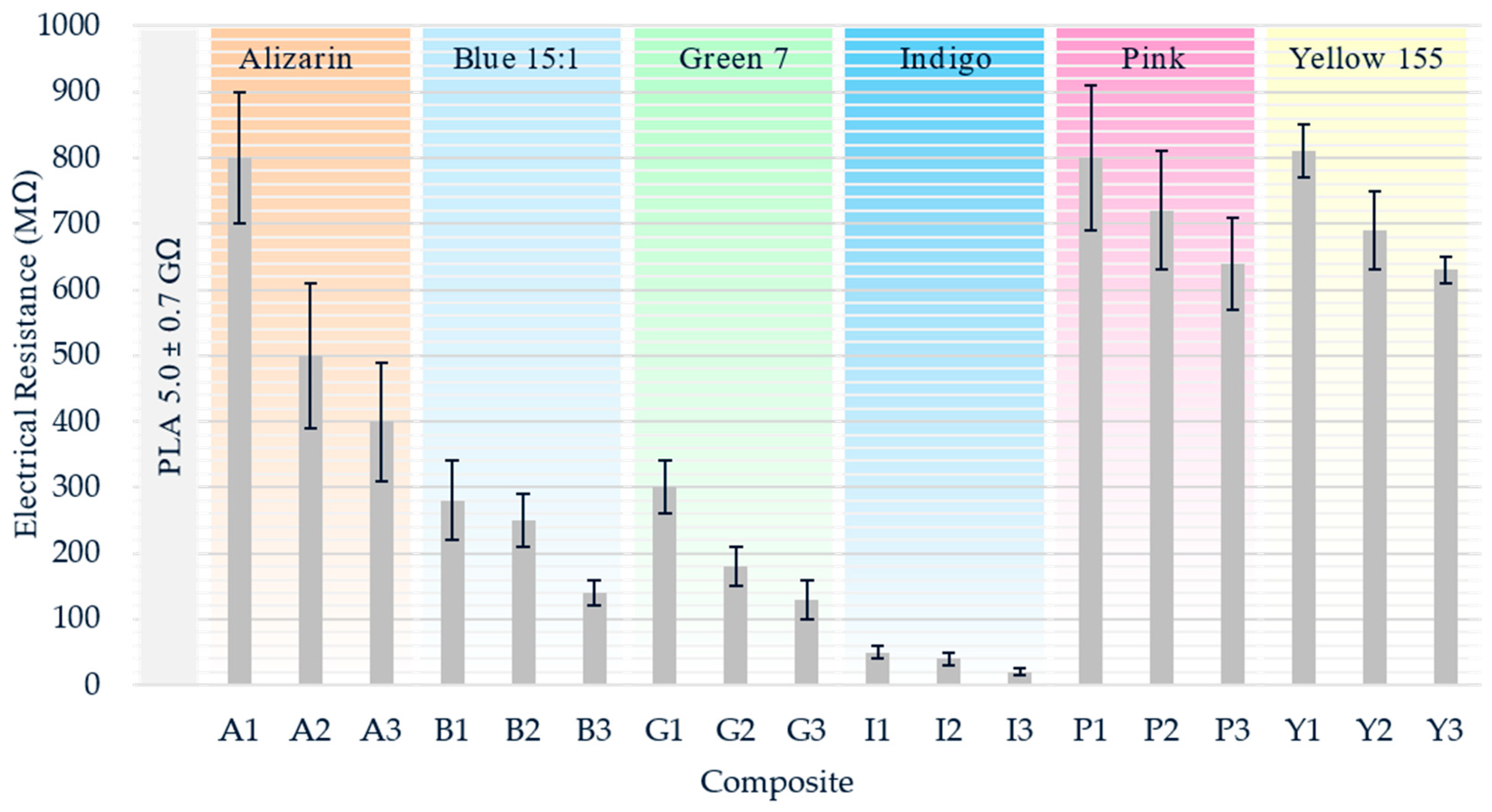

3.5. Effect of Additives on Melt Conductivity

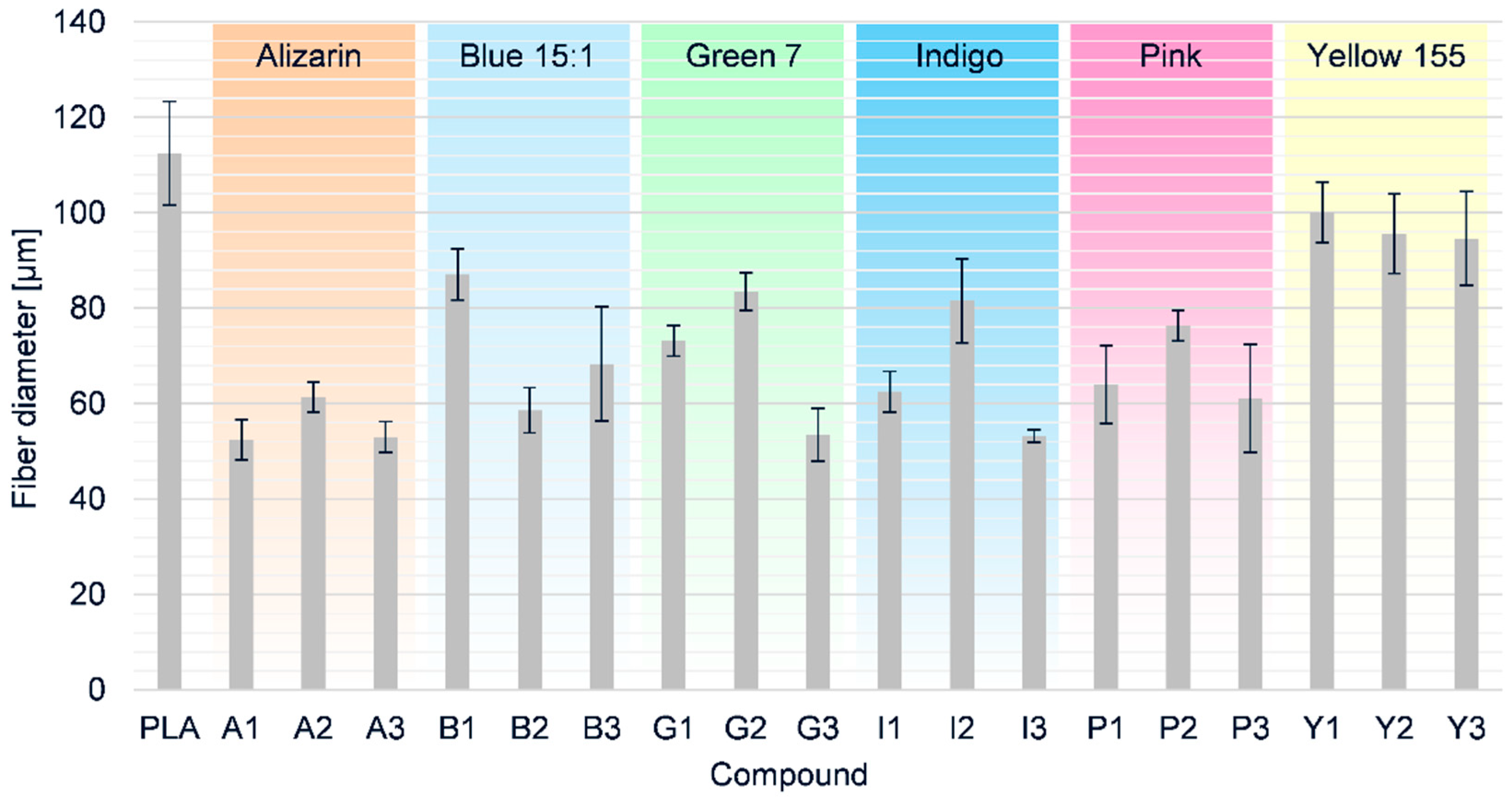

3.6. Fiber Diameters Achieved Using Different PLA Composites

3.7. Color Measurement of Electrospun Fibers

4. Conclusions and Further Perspectives

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- Brown, T.; Dalton, P.; Hutmacher, D.W. Melt electrospinning today: An opportune time for an emerging polymer process. Elsevier 2016, 56, 116–166. [Google Scholar] [CrossRef]

- Huang, Z.-M.; Zhang, Y.Z.; Kotaki, M.; Ramakrishna, S. A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos. Sci. Technol. 2003, 63, 2223–2253. [Google Scholar] [CrossRef]

- Greiner, A.; Wendorff, J.H. Electrospinning: A Fascinating Method for the Preparation of Ultrathin Fibers. Angew. Chem. Int. Ed. 2007, 46, 5670–5703. [Google Scholar] [CrossRef] [PubMed]

- Ma, B.; Xie, J.; Jiang, J. Rational design of nanofiber scaffolds for orthopedic tissue repair and regeneration. Nanomedicine 2013, 8, 1459–1481. [Google Scholar] [CrossRef] [PubMed]

- Shin, S.-H.; Purevdorj, O.; Castano, O. A short review: Recent advances in electrospinning for bone tissue regeneration. J. Tissue Eng. 2012, 3, 2041731412443530. [Google Scholar] [CrossRef] [PubMed]

- McClellan, P.; Landis, W.J. Recent applications of coaxial and emulsion electrospinning methods in the field of tissue engineering. Biores. Open Access 2016, 5, 212–227. [Google Scholar] [CrossRef]

- Khajavi, R.; Abbasipour, M.; Bahador, A. Electrospun biodegradable nanofibers scaffolds for bone tissue engineering. J. Appl. Polym. Sci. 2016, 133, 42883. [Google Scholar] [CrossRef]

- Mani, M.P.; Jaganathan, S.K.; Ismail, A.F. Appraisal of electrospun textile scaffold comprising polyurethane decorated with ginger nanofibers for wound healing applications. J. Ind. Text. 2019, 49, 648–662. [Google Scholar] [CrossRef]

- Sundarrajan, S.; Tan, K.L.; Lim, S.H. Electrospun nanofibers for air filtration applications. Procedia Eng. 2014, 75, 159–163. [Google Scholar] [CrossRef]

- Scholten, E.; Bromberg, L.; Rutledge, G.C. Electrospun polyurethane fibers for absorption of volatile organic compounds from air. ACS Appl. Mater. Interfaces 2011, 3, 3902–3909. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Sun, X. Challenges and opportunities of nanostructured materials for aprotic rechargeable lithium–air batteries. Nano Energy 2013, 2, 443–467. [Google Scholar] [CrossRef]

- Wang, X.; Drew, C.; Lee, S.H. Electrospun Nanofibrous membranes for highly sensitive optical sensors. Nano Lett. 2002, 2, 1273–1275. [Google Scholar] [CrossRef]

- Nan, N.; He, J.; You, X.; Sun, X.; Zhou, Y.; Qi, K.; Shao, W.; Liu, F.; Chu, Y.; Ding, B. A Stretchable, Highly Sensitive, and Multimodal Mechanical Fabric Sensor Based on Electrospun Conductive Nanofiber Yarn for Wearable Electronics. Adv. Mater. Technol. 2019, 4, 1800338. [Google Scholar] [CrossRef]

- Bhat, G.S. Advances in polymeric nanofiber manufacturing technologies. J. Nanomater. Mol. Nanotechnol. 2016, 5, 1800338. [Google Scholar] [CrossRef]

- Bhardwaj, N.; Kundu, S.C. Electrospinning: A fascinating fiber fabrication technique. Biotechnol. Adv. 2010, 28, 325–347. [Google Scholar] [CrossRef]

- Mehdi, M.; Mahar, F.K.; Qureshi, U.A.; Khatri, M.; Khatri, Z.; Ahmed, F.; Kim, I.S. Preparation of colored recycled polyethylene terephthalate nanofibers from waste bottles: Physicochemical studies. Adv. Polym. Technol. 2018, 37, 2820–2827. [Google Scholar] [CrossRef]

- Bubakir, M.; Li, H.; Yang, W. Handbook of Nanofibers, 1st ed.; Springer Nature: Basel, Switzerland, 2017; pp. 125–156. [Google Scholar]

- Qin, Y.; Cheng, L.; Zhang, Y.; Chen, X.; Wang, X.; He, X.; Yang, W.; An, Y.; Li, H. Efficient preparation of poly (lactic acid) nanofibers by melt differential electrospinning with addition of acetyl tributyl citrate. J. Appl. Polym. Sci. 2018, 135, 46554. [Google Scholar] [CrossRef]

- Nayak, R. Polypropylene nanofibers: Melt electrospinning versus Meltblowing; Springer International Publishing: Basel, Switzerland, 2017; pp. 1–7. [Google Scholar]

- Badami, A.S.; Kreke, M.R.; Thompson, M.S.; Riffle, J.S.; Goldstein, A.S. Effect of fiber diameter on spreading, proliferation, and differentiation of osteoblastic cells on electrospun poly(lactic acid) substrates. Biomaterials 2006, 27, 596–606. [Google Scholar] [CrossRef]

- Casasola, R.; Thomas, N.L.; Trybala, A.; Georgiadou, S. Electrospun poly lactic acid (PLA) fibres: Effect of different solvent systems on fibre morphology and diameter. Polymer 2014, 55, 4728–4737. [Google Scholar] [CrossRef]

- Dalton, P.D.; Grafahrend, D.; Klinkhammer, K.; Klee, D.; Moller, M. Electrospinning of polymer melts: Phenomenological observations. Polymer 2007, 48, 6823–6833. [Google Scholar] [CrossRef]

- Zhao, F.; Liu, Y.; Yuan, H. Orthogonal design study on factors affecting the degradation of polylactic acid fibers of melt electrospinning. J. Appl. Polym. Sci. 2012, 125, 2652–2658. [Google Scholar] [CrossRef]

- Li, Q.; He, H.W.; Fan, Z.Z.; Zhao, R.H.; Chen, F.X.; Zhou, R.; Ning, X. Preparation and Performance of Ultra-Fine Polypropylene Antibacterial Fibers via Melt Electrospinning. Polymers 2020, 12, 606. [Google Scholar] [CrossRef] [PubMed]

- Larrondo, L.S.J.M.; St. John Manley, R. Electrostatic fiber spinning from polymer melts. I. Experimental observations on fiber formation and properties. J. Polym. Sci. Polym. Phys. Ed. 1981, 19, 909–920. [Google Scholar] [CrossRef]

- Dalton, P.D.; Lleixà Calvet, J.; Mourran, A. Melt electrospinning of poly-(ethylene glycol-block-ε-caprolactone). Biotechnol. J. 2006, 1, 998–1006. [Google Scholar] [CrossRef] [PubMed]

- Yoon, K.; Hsiao, B.S.; Chu, B. Functional nanofibers for environmental applications. J. Mater. Chem 2008, 18. [Google Scholar] [CrossRef]

- Zhou, H.; Green, T.B.; Joo, Y.L. The thermal effects on electrospinning of polylactic acid melts. Polymer 2006, 47, 7497–7505. [Google Scholar] [CrossRef]

- Brown, T.D.; Dalton, P.D.; Hutmacher, D.W. Direct writing by way of melt electrospinning. Adv. Mater. 2011, 23, 5651–5657. [Google Scholar] [CrossRef]

- Zhmayev, E.; Cho, D.; Joo, Y.L. Nanofibers from gas-assisted polymer melt electrospinning. Polymer 2010, 51, 4140–4144. [Google Scholar] [CrossRef]

- Yoon, Y.I.; Park, K.E.; Lee, S.J.; Park, W.H. Fabrication of Microfibrous and Nano-/Microfibrous Scaffolds: Melt and Hybrid Electrospinning and Surface Modification of Poly(L-lactic acid) with Plasticizer. BioMed Res. Int. 2013, 2013. [Google Scholar] [CrossRef]

- Nayak, R.; Kyratzis, I.L.; Truong, Y.B.; Padhye, R.; Arnold, L. Melt electrospinning of polypropylene with conductive additives. J. Mater. Sci. 2012, 47, 6387–6396. [Google Scholar] [CrossRef]

- Hacker, C.; Fourné, R.; Rübsam, U.; Seide, G.; Gries, T. Challenges of the meltelectrospinning process: An economical and technical window of opportunity [Herausforderungen des Schmelzelektrospinns: Wirtschaftliche und technische Potentiale und Möglichkeiten]. In Proceedings of the 52nd Dornbirn Man-Made Fiber Congress, Dornbirn, Austria, 11 September 2013. [Google Scholar]

- Lee, K.S.; Lee, B.S.; Park, Y.H.; Park, Y.C.; Kim, Y.M.; Jeong, S.H.; Kim, S.D. Dyeing properties of nylon 66 nano fiber with high molecular mass acid dyes. Fibers Polym. 2005, 6, 35–41. [Google Scholar] [CrossRef]

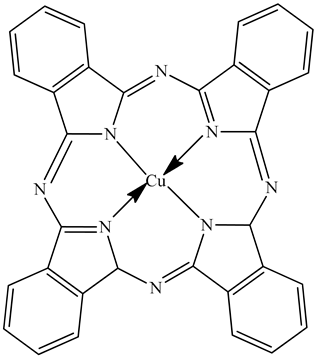

- Wang, T.; He, Z.; Zheng, X.; Wang, Y.; Zhang, C.; Zhang, W. Electrical properties of Copper (II) phthalocyanine derivative thin films. Optoelectron. Lett. 2007, 3, 43–46. [Google Scholar] [CrossRef]

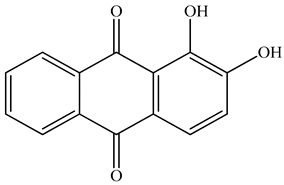

- Sun, C.; Li, Y.; Qi, D.; Li, H.; Song, P. Optical and electrical properties of purpurin and alizarin complexone as sensitizers for dye-sensitized solar cells. J. Mater. Sci. Mater. Electron. 2016, 27, 8027–8039. [Google Scholar] [CrossRef]

- Luong, T.T.T.; Chen, Z.; Zhu, H. Flexible solar cells based on copper phthalocyanine and buckminsterfullerene. Sol. Energy Mater. Sol. Cells 2010, 94, 1059–1063. [Google Scholar] [CrossRef]

- Gsänger, M.; Bialas, D.; Huang, L.; Stolte, M.; Würthner, F. Organic Semiconductors based on Dyes and Color Pigments. Adv. Mater. 2016, 28, 3615–3645. [Google Scholar] [CrossRef]

- Gabr, M. Electric and Dielectric Properties of Some Fluorescent Dye/PMMA Solar Concentrators. Int. J. Polym. Mater. Polym. Biomater. 2008, 57, 569–583. [Google Scholar] [CrossRef]

- Maqsood, M.; Langensiepen, F.; Seide, G. Investigation of melt spinnability of plasticized polylactic acid biocomposites-containing intumescent flame retardant. J. Therm. Anal. Calorim. 2020, 139, 305–318. [Google Scholar] [CrossRef]

- Koenig, K.; Balakrishnan, N.; Hermanns, S.; Langensiepen, F.; Seide, G. Biobased Dyes as Conductive Additives to Reduce the Diameter of Polylactic Acid Fibers during Melt Electrospinning. Materials 2020, 13, 1055. [Google Scholar] [CrossRef]

- Puzyn, T. Organic Pollutants Ten Years After the Stockholm Convention—Environmental and Analytical Update; InTechOpen Publishing: London, UK, 2017; pp. 55–88. [Google Scholar]

- Sigma Aldrich. Available online: https://www.sigmaaldrich.com/catalog/product/sial/122777?lang=en®ion=NL (accessed on 20 August 2020).

- Chemical Book. Available online: https://www.chemicalbook.com/ProductChemicalPropertiesCB7399460_EN.htm#MSDSA (accessed on 20 August 2020).

- Jia, S.; Yu, D.; Zhu, Y.; Wang, Z.; Chen, L.; Fu, L. Morphology, Crystallization and Thermal Behaviors of PLA-Based Composites: Wonderful Effects of Hybrid GO/PEG via Dynamic Impregnating. Polymers 2017, 9, 528. [Google Scholar] [CrossRef]

- Su, Z.; Li, Q.; Liu, Y.; Hu, G.-H.; Wu, C. Multiple melting behavior of poly(lactic acid) filled with modified carbon black. J. Polym. Sci. Part B Polym. Phys. 2009, 47, 1971–1980. [Google Scholar] [CrossRef]

- Lascano, D.; Quiles-Carrillo, L.; Balart, R.; Boronat, T.; Montanes, N. Toughened Poly (Lactic Acid)—PLA Formulations by Binary Blends with Poly (Butylene Succinate-co-Adipate)—PBSA and Their Shape Memory Behaviour. Materials 2019, 12, 622. [Google Scholar] [CrossRef] [PubMed]

- Broda, J. Structure of polypropylene fibres coloured with a mixture of pigments with different nucleating ability. Polymer 2003, 44, 6943–6949. [Google Scholar] [CrossRef]

- Broda, J. Nucleating activity of the quinacridone and phthalocyanine pigments in polypropylene crystallization. J. Appl. Polym. Sci. 2003, 90, 3957–3964. [Google Scholar] [CrossRef]

- Ohkita, T.; Lee, S.-H. Thermal degradation and biodegradability of poly (lactic acid)/corn starch biocomposites. J. Appl. Polym. Sci. 2006, 100, 3009–3017. [Google Scholar] [CrossRef]

- Wang, N.; Zhang, X.; Ma, X.; Fang, J. Influence of carbon black on the properties of plasticized poly (lactic acid) composites. Polym. Degrad. Stab. 2008, 93, 1044–1052. [Google Scholar] [CrossRef]

- Slark, A.T.; Hadgett, P.M. The effect of polymer structure on specific interactions between dye solutes and polymers. Polymer 1999, 40, 1325–1332. [Google Scholar] [CrossRef]

- Marks, A.F.; Orr, P.; McNally, G.M.; Murphy, W.R. Effect of Pigment Type and Concentration on the Rheological Properties of Polypropylene. Dev. Chem. Eng. Miner. Process. 2008, 11, 127–136. [Google Scholar] [CrossRef]

- Nayak, R. Effect of viscosity and electrical conductivity on the morphology and fiber diameter in melt electrospinning of polypropylene. Text. Res. J. 2013, 83, 606. [Google Scholar] [CrossRef]

- Király, A.; Ronkay, F. Effect of filler dispersion on the electrical conductivity and mechanical properties of carbon/polypropylene composites. Polym. Compos. 2013, 34, 1195–1203. [Google Scholar] [CrossRef]

- Pan, Y.; Li, L.; Chan, S.H.; Zhao, J. Correlation between dispersion state and electrical conductivity of MWCNTs/PP composites prepared by melt blending. Compos. Part A 2010, 41, 419–426. [Google Scholar] [CrossRef]

- Baykuş, O.; Tugce Celik, I.; Dogan, S.D.; Davulcu, A.; Dogan, M. Enhancing the dyeability of poly(lactic acid) fiber with natural dyes of alizarin, lawsone, and indigo. Fibers Polym. 2017, 18, 1906–1914. [Google Scholar] [CrossRef]

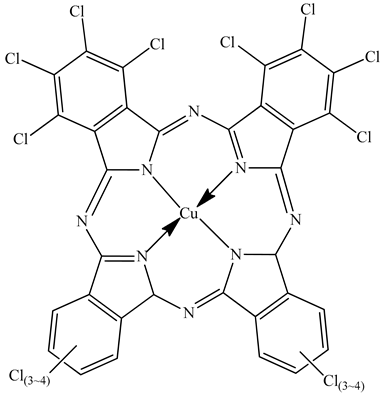

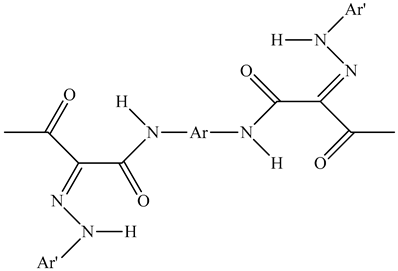

| Additive | Chemical Structure | Melting Point (°C) |

|---|---|---|

| Alizarin |  | 279–283 |

| Blue pigment 15:1 |  | 350 |

| Green pigment 7 |  | 480 |

| Indigo |  | >300 |

| Pink pigment PR122 |  | Not available |

| Yellow pigment 155 |  | >280 |

| Composite Abbreviation | Colorant Name | % (w/w) of Colorant |

|---|---|---|

| A1 | Alizarin dye | 1 |

| A2 | 2 | |

| A3 | 3 | |

| B1 | Blue pigment | 1 |

| B2 | 2 | |

| B3 | 3 | |

| G1 | Green pigment | 1 |

| G2 | 2 | |

| G3 | 3 | |

| I1 | Indigo dye | 1 |

| I2 | 2 | |

| I3 | 3 | |

| P1 | Pink pigment | 1 |

| P2 | 2 | |

| P3 | 3 | |

| Y1 | Yellow pigment | 1 |

| Y2 | 2 | |

| Y3 | 3 |

| Composite | L* | A* | B* |

|---|---|---|---|

| PLA | 67.22 | −0.25 | 2.06 |

| A1 | 40.42 | −7.94 | 36.22 |

| A2 | 37.69 | −3.58 | 39.05 |

| A3 | 31.42 | −1.46 | 32.79 |

| B1 | 19.45 | 6.01 | −27.8 |

| B2 | 16.95 | 5.14 | −23.09 |

| B3 | 13.53 | 7.5 | −20.53 |

| G1 | 36.27 | −31.88 | −0.42 |

| G2 | 32.61 | −32.28 | −0.97 |

| G3 | 25.16 | −22.43 | −1.84 |

| I1 | 29.7 | 0.3 | −15.54 |

| I2 | 25.58 | 4.42 | −22.78 |

| I3 | 23.96 | 4.41 | −20.86 |

| P1 | 27.09 | 43.75 | −5.42 |

| P2 | 24.03 | 39.14 | 3.01 |

| P3 | 22.35 | 36.95 | 2.92 |

| Y1 | 50.9 | −15.03 | 49.66 |

| Y2 | 54.82 | −9.52 | 61.13 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Balakrishnan, N.K.; Koenig, K.; Seide, G. The Effect of Dye and Pigment Concentrations on the Diameter of Melt-Electrospun Polylactic Acid Fibers. Polymers 2020, 12, 2321. https://doi.org/10.3390/polym12102321

Balakrishnan NK, Koenig K, Seide G. The Effect of Dye and Pigment Concentrations on the Diameter of Melt-Electrospun Polylactic Acid Fibers. Polymers. 2020; 12(10):2321. https://doi.org/10.3390/polym12102321

Chicago/Turabian StyleBalakrishnan, N.K., K. Koenig, and G. Seide. 2020. "The Effect of Dye and Pigment Concentrations on the Diameter of Melt-Electrospun Polylactic Acid Fibers" Polymers 12, no. 10: 2321. https://doi.org/10.3390/polym12102321

APA StyleBalakrishnan, N. K., Koenig, K., & Seide, G. (2020). The Effect of Dye and Pigment Concentrations on the Diameter of Melt-Electrospun Polylactic Acid Fibers. Polymers, 12(10), 2321. https://doi.org/10.3390/polym12102321