Effects of Organic Montmorillonite (OMMT) and Pre-Orientation on Property of Poly(l-lactic acid) (PLLA)/Ethylene Propylene Diene Monomer (EPDM) Blends

Abstract

1. Introduction

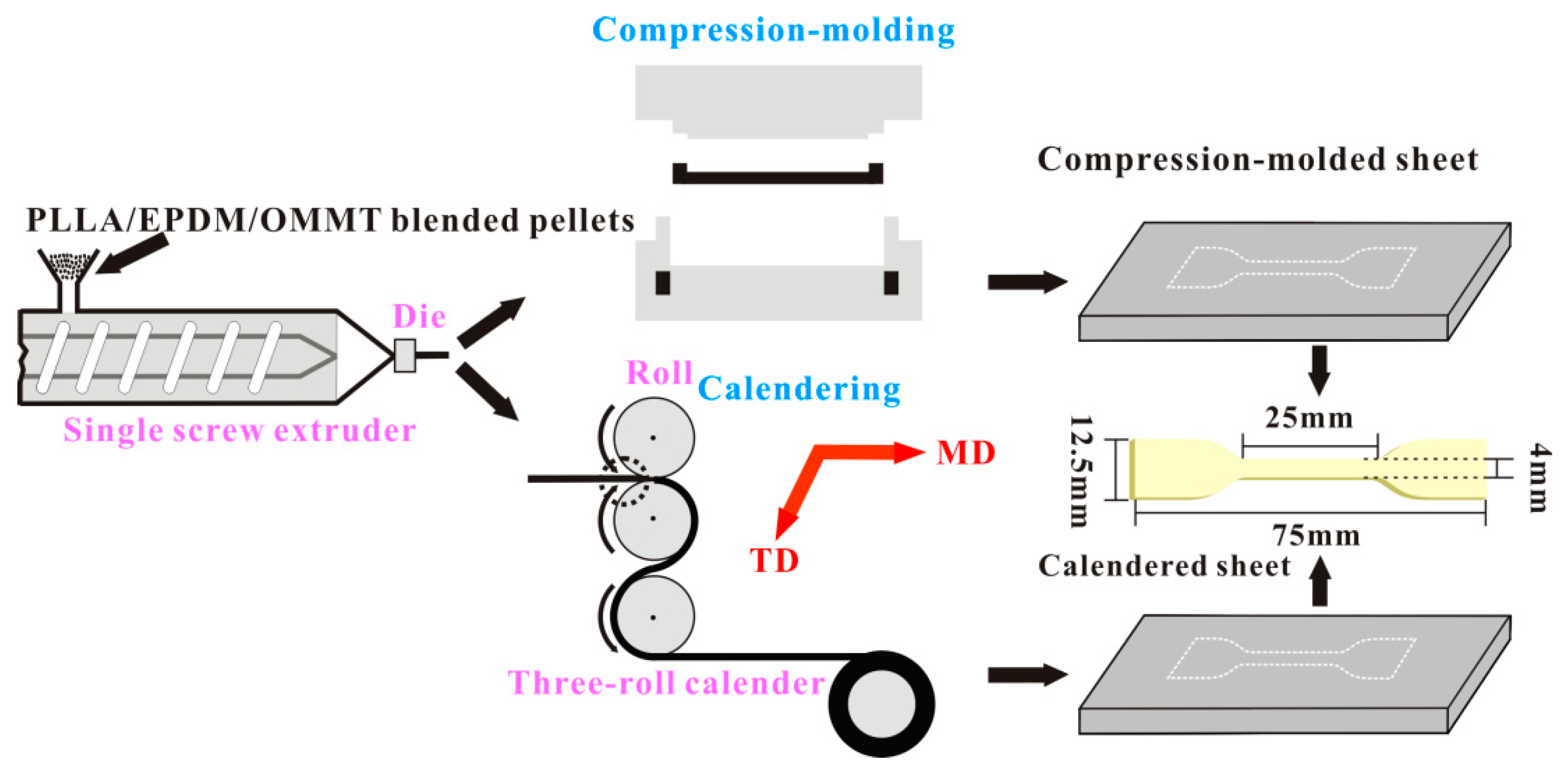

2. Materials and Methods

2.1. Materials and Processing

2.2. Characterization

2.2.1. Tensile Performance

2.2.2. Scanning Electron Microscopy

2.2.3. Differential Scanning Calorimetry

2.2.4. X-Ray Diffraction

3. Results and Discussion

3.1. Properties of PLLA/EPDM/OMMT (90/10/x) Samples

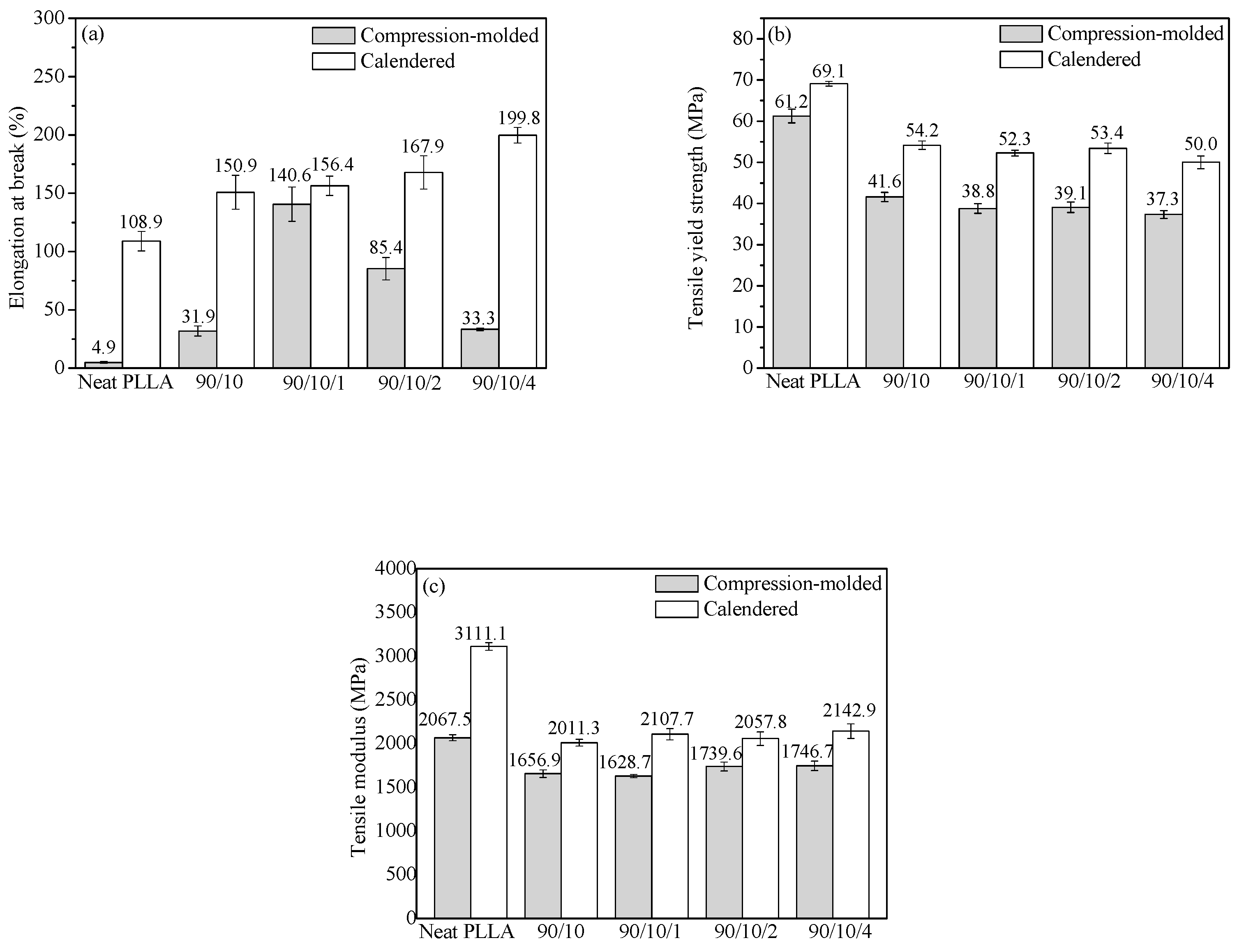

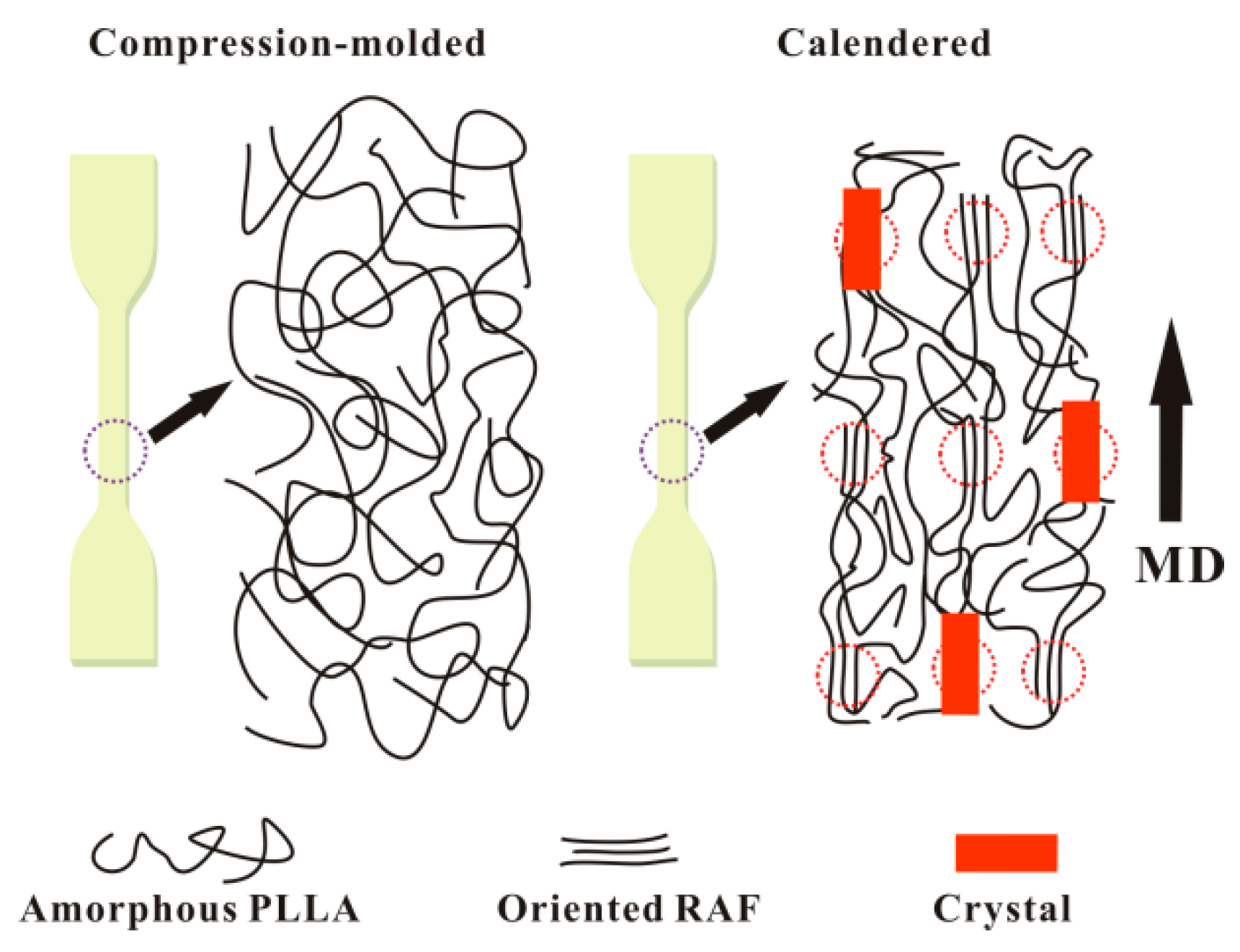

3.1.1. Tensile Properties

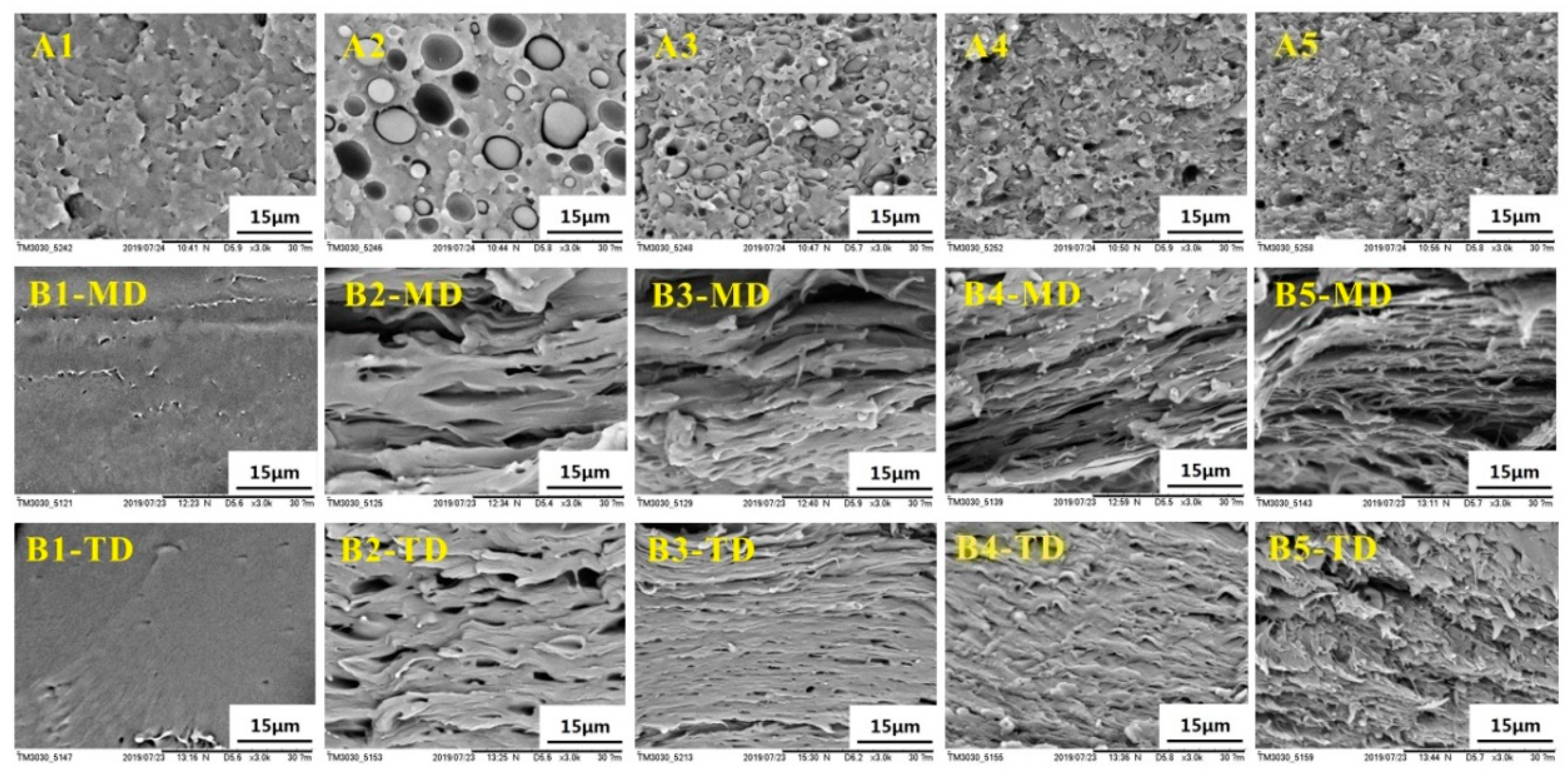

3.1.2. Microscopic Morphology Analysis

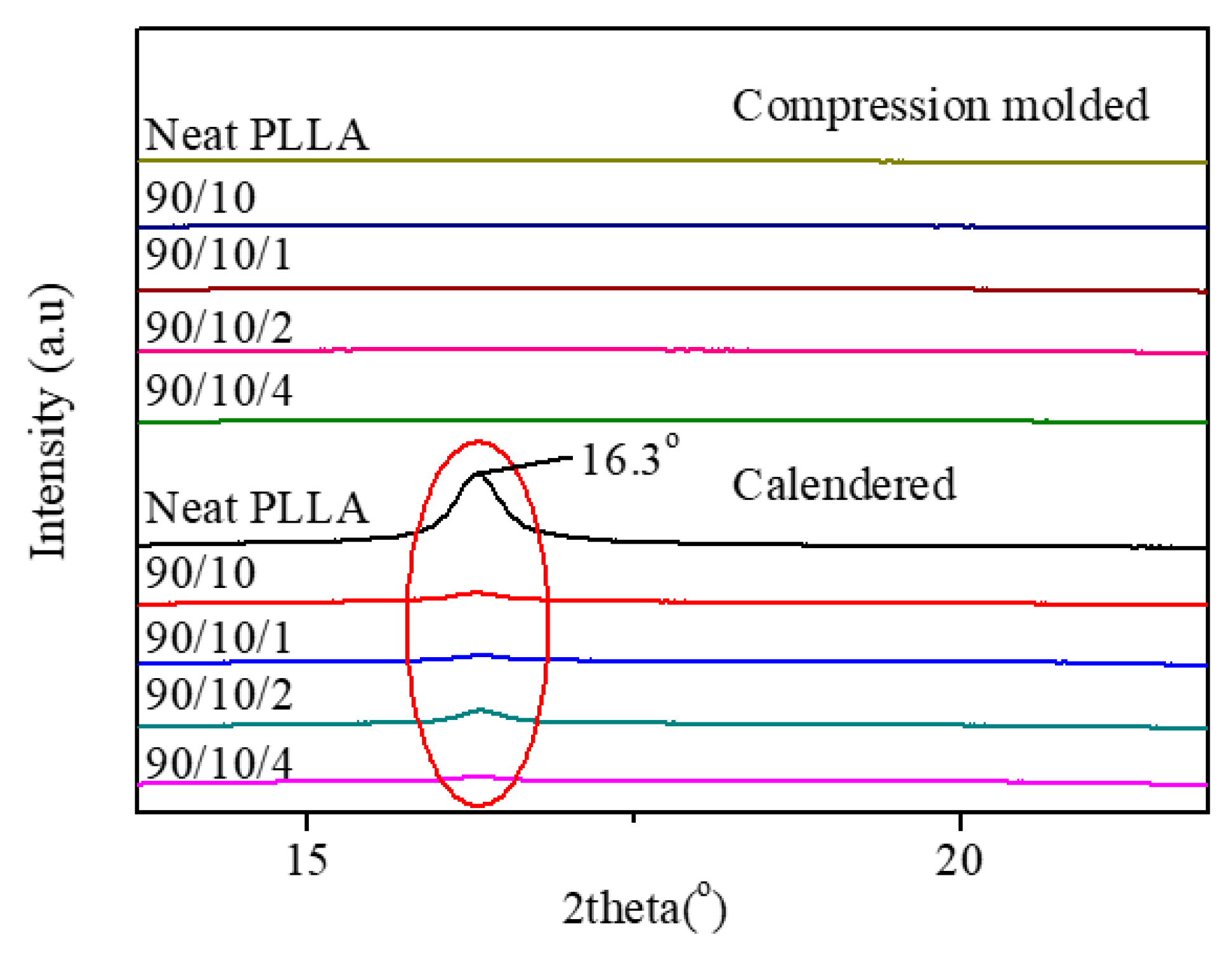

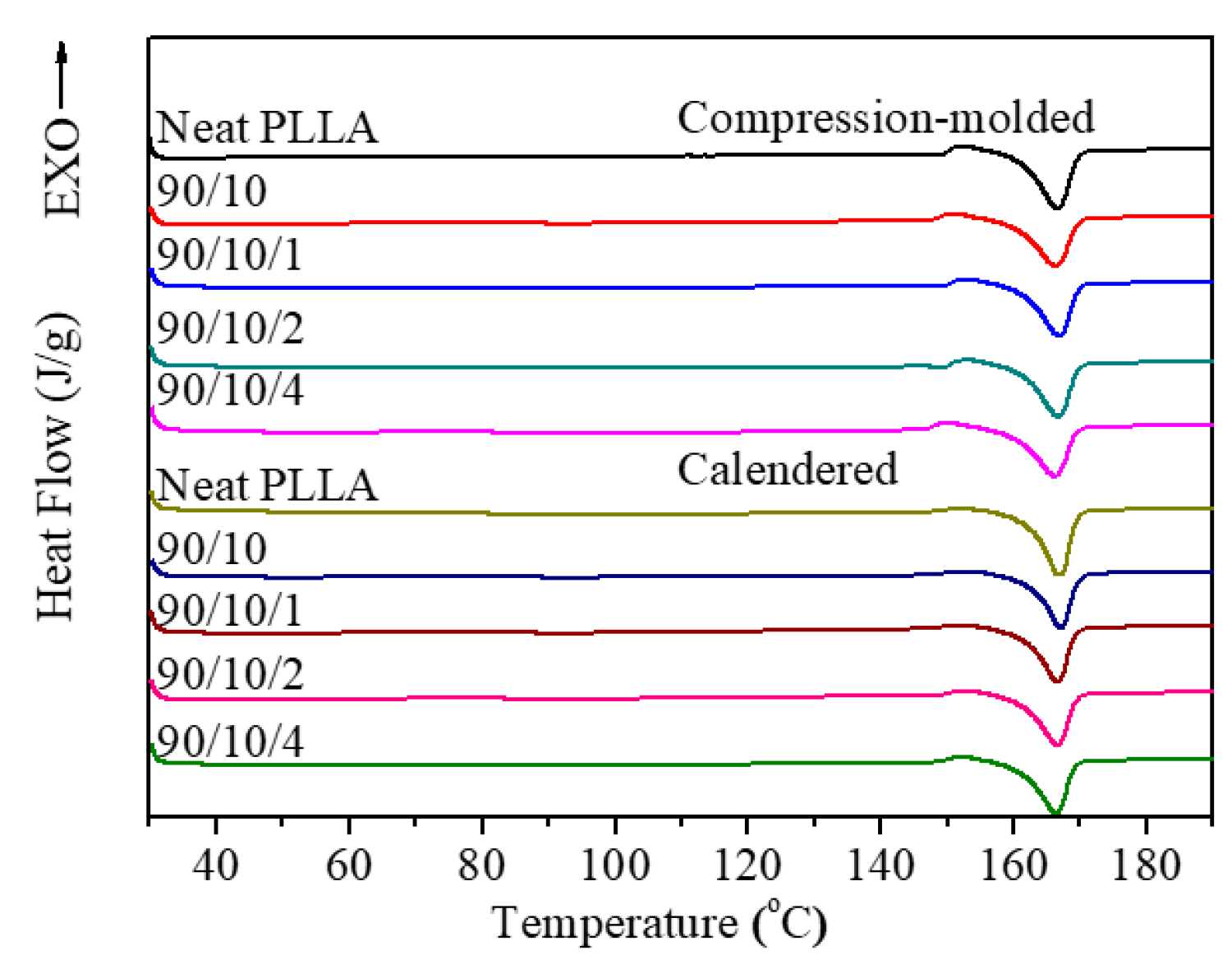

3.1.3. Crystallization Property

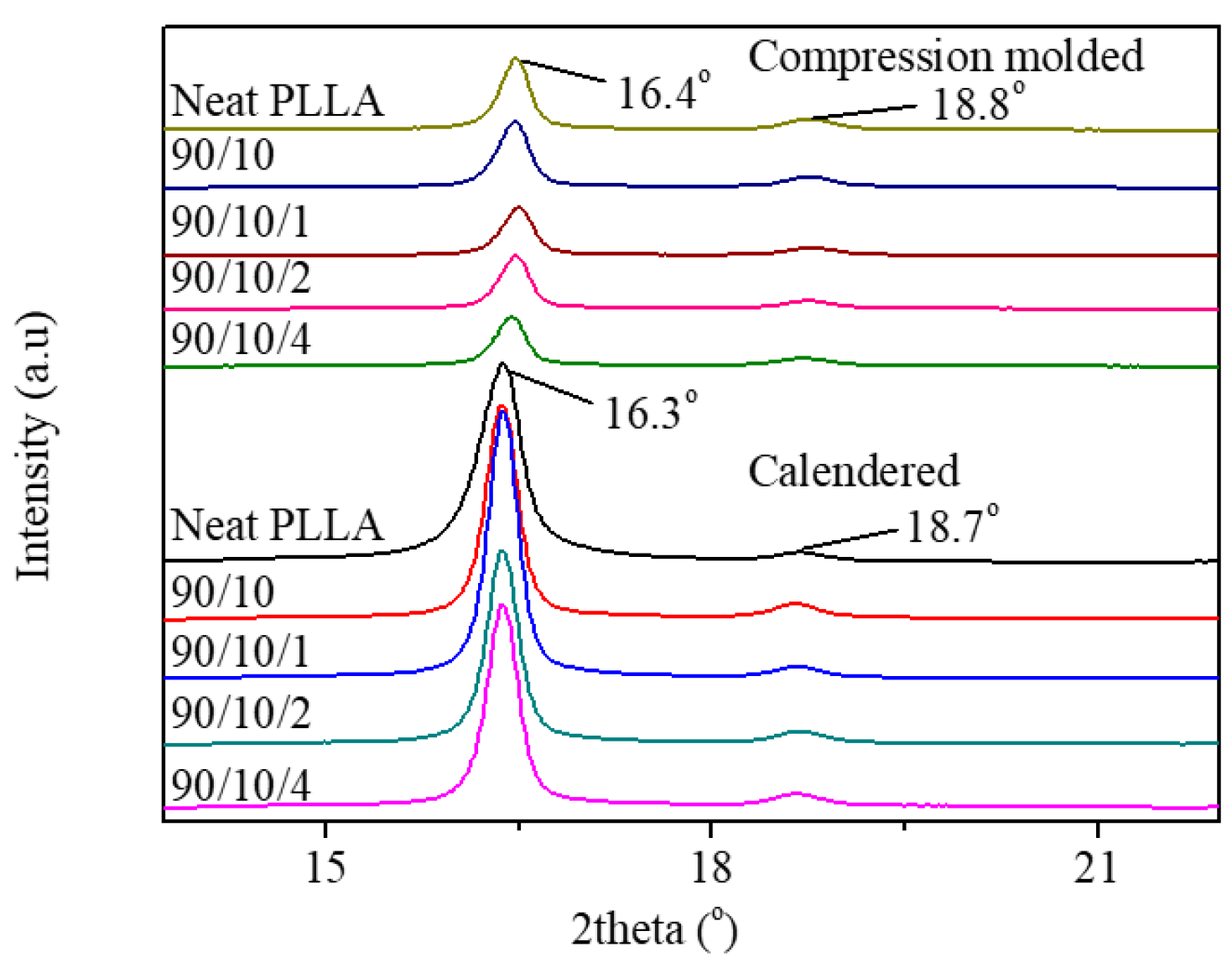

3.1.4. Intercalation Structure of OMMT

3.2. Properties of Annealed PLLA/EPDM/OMMT (90/10/x) Samples

3.2.1. Crystallization Property

3.2.2. Microscopic Morphology Analysis

3.2.3. Tensile Performance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Achmad, F.; Yamane, K.; Quan, S.; Kokugan, T. Synthesis of polylactic acid by direct polycondensation under vacuum without catalysts, solvents and initiators. Chem. Eng. J. 2009, 151, 342–350. [Google Scholar] [CrossRef]

- Nagahata, R.; Sano, D.; Suzuki, H.; Takeuchi, K. Microwave-assisted single-step synthesis of poly(lactic acid) by direct polycondensation of lactic acid. Macromol. Rapid Commun. 2007, 28, 437–442. [Google Scholar] [CrossRef]

- Kohn, F.E.; Van Den Berg, J.W.A.; Van De Ridder, G.; Feijen, J. The ring-opening polymerization of D,L-lactide in the melt initiated with tetraphenyltin. J. Appl. Polym. Sci. 1984, 29, 4265–4277. [Google Scholar] [CrossRef]

- Drumright, R.E.; Gruber, P.R.; Henton, D.E. Polylactic acid technology. Adv. Mater. 2000, 12, 1841–1846. [Google Scholar] [CrossRef]

- Oyama, H.T.; Tanaka, Y.; Kadosaka, A. Rapid controlled hydrolytic degradation of poly(L-lactic acid) by blending with poly(aspartic acid-co-L-lactide). Polym. Degrad. Stab. 2009, 94, 1419–1426. [Google Scholar] [CrossRef]

- Auras, R.; Harte, B.; Selke, S. An overview of polylactides as packaging materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef] [PubMed]

- Elsawy, M.A.; Kim, K.-H.; Park, J.-W.; Deep, A. Hydrolytic degradation of polylactic acid (PLA) and its composites. Renew. Sustain. Energy Rev. 2017, 79, 1346–1352. [Google Scholar] [CrossRef]

- Wang, M.; Wu, Y.; Li, Y.-D.; Zeng, J.-B. Progress in Toughening Poly(Lactic Acid) with Renewable Polymers. Polym. Rev. 2017, 57, 557–593. [Google Scholar] [CrossRef]

- Nagarajan, V.; Mohanty, A.K.; Misra, M. Perspective on Polylactic Acid (PLA) based Sustainable Materials for Durable Applications: Focus on Toughness and Heat Resistance. ACS Sustain. Chem. Eng. 2016, 4, 2899–2916. [Google Scholar] [CrossRef]

- Louisy, E.; Samyn, F.; Bourbigot, S.; Fontaine, G.; Bonnet, F. Preparation of glass fabric/poly(L-lactide) composites by Thermoplastic Resin Transfer Molding. Polymers 2019, 11, 339. [Google Scholar] [CrossRef]

- Deng, Y.; Yu, C.; Wongwiwattana, P.; Thomas, N.L. Optimising Ductility of Poly(Lactic Acid)/Poly(Butylene Adipate-co-Terephthalate) Blends Through Co-continuous Phase Morphology. J. Polym. Environ. 2018, 26, 3802–3816. [Google Scholar] [CrossRef]

- Ojijo, V.; Ray, S.S. Super toughened biodegradable polylactide blends with non-linear copolymer interfacial architecture obtained via facile in-situ reactive compatibilization. Polymer 2015, 80, 1–17. [Google Scholar] [CrossRef]

- Gardella, L.; Calabrese, M.; Monticelli, O. PLA maleation: An easy and effective method to modify the properties of PLA/PCL immiscible blends. Colloid Polym. Sci. 2014, 292, 2391–2398. [Google Scholar] [CrossRef]

- Zolali, A.M.; Favis, B.D. Toughening of Cocontinuous Polylactide/Polyethylene Blends via an Interfacially Percolated Intermediate Phase. Macromolecules 2018, 51, 3572–3581. [Google Scholar] [CrossRef]

- Wang, X.-F.; He, Z.-Z.; Yang, J.-H.; Zhang, N.; Huang, T.; Wang, Y.; Zhou, Z.-W. Super toughened immiscible poly(L-lactide)/poly(ethylene vinyl acetate) (PLLA/EVA) blend achieved by in situ cross-linking reaction and carbon nanotubes. Compos. Part A 2016, 91, 105–116. [Google Scholar] [CrossRef]

- Wang, S.; Pang, S.; Pan, L.; Xu, N.; Huang, H.; Li, T. Compatibilization of poly(lactic acid)/ethylene-propylene-diene rubber blends by using organic montmorillonite as a compatibilizer. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Dogan, S.K.; Reyes, E.A.; Rastogi, S.; Ozkoc, G. Reactive compatibilization of PLA/TPU blends with a diisocyanate. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Bitinis, N.; Verdejo, R.; Cassagnau, P.; Lopez-Manchado, M.A. Structure and properties of polylactide/natural rubber blends. Mater. Chem. Phys. 2011, 129, 823–831. [Google Scholar] [CrossRef]

- Liu, L.; Hou, J.; Wang, L.; Zhang, J.; Duan, Y. Role of Dicumyl Peroxide on Toughening PLLA via Dynamic Vulcanization. Ind. Eng. Chem. Res. 2016, 55, 9907–9914. [Google Scholar] [CrossRef]

- Takayama, T.; Todo, M.; Tsuji, H.; Arakawa, K. Effect of LTI content on impact fracture property of PLA/PCL/LTI polymer blends. J. Mater. Sci. 2006, 41, 6501–6504. [Google Scholar] [CrossRef]

- Lu, X.; Lv, Q.; Huang, X.; Song, Z.; Xu, N.; Pang, S.; Pan, L.; Li, T. Isothermal melt crystallization and performance evaluation of polylactide/thermoplastic polyester blends with multi-functional epoxy. J. Appl. Polym. Sci. 2018, 135. [Google Scholar] [CrossRef]

- Visco, A.; Scolaro, C.; Giamporcaro, A.; De Caro, S.; Tranquillo, E.; Catauro, M. Threads made with blended biopolymers: Mechanical, physical and biological features. Polymers 2019, 11, 901. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Hillmyer, M.A. Polyethylene-poly(L-lactide) diblock copolymers: Synthesis and compatibilization of poly(L-lactide)/polyethylene blends. J. Polym. Sci. Part A Polym. Chem. 2001, 39, 2755–2766. [Google Scholar] [CrossRef]

- Anderson, K.S.; Lim, S.H.; Hillmyer, M.A. Toughening of polylactide by melt blending with linear low-density polyethylene. J. Appl. Polym. Sci. 2003, 89, 3757–3768. [Google Scholar] [CrossRef]

- Wang, Y.-L.; Hu, X.; Li, H.; Ji, X.; Li, Z.-M. Polyamide-6/Poly(lactic acid) Blends Compatibilized by the Maleic Anhydride Grafted Polyethylene-Octene Elastomer. Polym.-Plast. Technol. Eng. 2010, 49, 1241–1246. [Google Scholar] [CrossRef]

- Ho, C.-H.; Wang, C.-H.; Lin, C.-I.; Lee, Y.-D. Synthesis and characterization of TPO-PLA copolymer and its behavior as compatibilizer for PLA/TPO blends. Polymer 2008, 49, 3902–3910. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, Y.; Wang, Z.; Sun, N.; Li, H. Enhancement of electrical conductivity by changing phase morphology for composites consisting of polylactide and poly(ε-caprolactone) filled with acid-oxidized multiwalled carbon nanotubes. ACS Appl. Mater. Interfaces 2011, 3, 4858–4864. [Google Scholar] [CrossRef]

- Shi, Y.; Li, Y.; Xiang, F.; Huang, T.; Chen, C.; Peng, Y.; Wang, Y. Carbon nanotubes induced microstructure and mechanical properties changes in cocontinuous poly( L-lactide)/ethylene-co-vinyl acetate blends. Polym. Adv. Technol. 2012, 23, 783–790. [Google Scholar] [CrossRef]

- Xiu, H.; Huang, C.; Bai, H.; Jiang, J.; Chen, F.; Deng, H.; Wang, K.; Zhang, Q.; Fu, Q. Improving impact toughness of polylactide/poly(ether)urethane blends via designing the phase morphology assisted by hydrophilic silica nanoparticles. Polymer 2014, 55, 1593–1600. [Google Scholar] [CrossRef]

- Yu, F.; Huang, H.-X. Simultaneously toughening and reinforcing poly(lactic acid)/thermoplastic polyurethane blend via enhancing interfacial adhesion by hydrophobic silica nanoparticles. Polym. Test. 2015, 45, 107–113. [Google Scholar] [CrossRef]

- Monticelli, O.; Calabrese, M.; Gardella, L.; Fina, A.; Gioffredi, E. Silsesquioxanes: Novel compatibilizing agents for tuning the microstructure and properties of PLA/PCL immiscible blends. Eur. Polym. J. 2014, 58, 69–78. [Google Scholar] [CrossRef]

- Taguet, A.; Cassagnau, P.; Lopez-Cuesta, J.-M. Structuration, selective dispersion and compatibilizing effect of (nano)fillers in polymer blends. Prog. Polym. Sci. 2014, 39, 1526–1563. [Google Scholar] [CrossRef]

- Fenouillot, F.; Cassagnau, P.; Majesté, J.-C. Uneven distribution of nanoparticles in immiscible fluids: Morphology development in polymer blends. Polymer 2009, 50, 1333–1350. [Google Scholar] [CrossRef]

- Cao, J.-P.; Zhao, X.; Zhao, J.; Zha, J.-W.; Hu, G.-H.; Dang, Z.-M. Improved thermal conductivity and flame retardancy in polystyrene/poly(vinylidene fluoride) blends by controlling selective localization and surface modification of SiC nanoparticles. ACS Appl. Mater. Interfaces 2013, 5, 6915–6924. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.; Zhang, Y.; Zhang, M.; Yu, W. Selective localization of multiwalled carbon nanotubes in poly(ε-caprolactone)/polylactide blend. Biomacromolecules 2009, 10, 417–424. [Google Scholar] [CrossRef] [PubMed]

- Zonder, L.; Mccarthy, S.; Rios, F.; Ophir, A.; Kenig, S. Viscosity ratio and interfacial tension as carbon nanotubes distributing factors in melt-mixed blends of polyamide 12 and high-density polyethylene. Adv. Polym. Technol. 2014, 33. [Google Scholar] [CrossRef]

- Wang, L.; Jing, X.; Cheng, H.; Hu, X.; Yang, L.; Huang, Y. Blends of Linear and Long-Chain Branched Poly(L-lactide)s with High Melt Strength and Fast Crystallization Rate. Ind. Eng. Chem. Res. 2012, 51, 10088–10099. [Google Scholar] [CrossRef]

- Magoń, A.; Pyda, M. Study of crystalline and amorphous phases of biodegradable poly (lactic acid) by advanced thermal analysis. Polymer 2009, 50, 3967–3973. [Google Scholar] [CrossRef]

- Zhou, Z. Influence of thermal treatment on the thermal behavior of poly-L-lactide. J. Macromol. Sci. Part B Phys. 2007, 46, 1247–1254. [Google Scholar] [CrossRef]

- Zhou, C.; Li, H.; Zhang, W.; Li, J.; Huang, S.; Meng, Y.; Christiansen, J.D.; Yu, D.; Wu, Z.; Jiang, S. Direct investigations on strain-induced cold crystallization behavior and structure evolutions in amorphous poly(lactic acid) with SAXS and WAXS measurements. Polymer 2016, 90, 111–121. [Google Scholar] [CrossRef]

- Bucknall, C.B.; Clayton, D. Rubber-Toughening of Plastics; Springer: Dordrecht, The Netherlands, 1972; pp. 202–210. [Google Scholar] [CrossRef]

- Wu, S. Phase structure and adhesion in polymer blends: A criterion for rubber toughening. Polymer 1985, 26, 1855–1863. [Google Scholar] [CrossRef]

- Liu, S.; Zhou, S.B.; Xu, Y. Evaluation of cracking properties of SBS-modified binders containing organic montmorillonite. Constr. Build. Mater. 2018, 175, 196–205. [Google Scholar] [CrossRef]

- Li, Y.; Han, C. Isothermal and Nonisothermal Cold Crystallization Behaviors of Asymmetric Poly(L-lactide)/Poly(D-lactide) Blends. Ind. Eng. Chem. Res. 2012, 51, 15927–15935. [Google Scholar] [CrossRef]

- Zhang, J.; Tashiro, K.; Tsuji, H.; Domb, A.J. Disorder-to-order phase transition and multiple melting behavior of poly (L-lactide ) investigated by simultaneous measurements of WAXD and DSC. Macromolecules 2008, 41, 1352–1357. [Google Scholar] [CrossRef]

- Li, Z.; Ye, L.; Zhao, X.; Coates, P.; Caton-Rose, F.; Martyn, M. Structure and biocompatibility of highly oriented poly(lactic acid) film produced by biaxial solid hot stretching. J. Ind. Eng. Chem. 2017, 52, 338–348. [Google Scholar] [CrossRef]

- Zhao, X.; Ye, L.; Coates, P.; Caton-Rose, F.; Martyn, M. Structure and blood compatibility of highly oriented poly(lactic acid)/thermoplastic polyurethane blends produced by solid hot stretching. Polym. Adv. Technol. 2013, 24, 853–860. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, X.; Ye, L.; Coates, P.; Caton-Rose, F.; Martyn, M. Structure and blood compatibility of highly oriented PLA/MWNTs composites produced by solid hot drawing. J. Biomater. Appl. 2014, 28, 978–989. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, D.; Wang, K.; Shen, J.; Zhao, L.; Xu, N.; Pang, S.; Pan, L. Effects of Organic Montmorillonite (OMMT) and Pre-Orientation on Property of Poly(l-lactic acid) (PLLA)/Ethylene Propylene Diene Monomer (EPDM) Blends. Polymers 2020, 12, 106. https://doi.org/10.3390/polym12010106

Song D, Wang K, Shen J, Zhao L, Xu N, Pang S, Pan L. Effects of Organic Montmorillonite (OMMT) and Pre-Orientation on Property of Poly(l-lactic acid) (PLLA)/Ethylene Propylene Diene Monomer (EPDM) Blends. Polymers. 2020; 12(1):106. https://doi.org/10.3390/polym12010106

Chicago/Turabian StyleSong, Di, Kai Wang, Jianing Shen, Long Zhao, Nai Xu, Sujuan Pang, and Lisha Pan. 2020. "Effects of Organic Montmorillonite (OMMT) and Pre-Orientation on Property of Poly(l-lactic acid) (PLLA)/Ethylene Propylene Diene Monomer (EPDM) Blends" Polymers 12, no. 1: 106. https://doi.org/10.3390/polym12010106

APA StyleSong, D., Wang, K., Shen, J., Zhao, L., Xu, N., Pang, S., & Pan, L. (2020). Effects of Organic Montmorillonite (OMMT) and Pre-Orientation on Property of Poly(l-lactic acid) (PLLA)/Ethylene Propylene Diene Monomer (EPDM) Blends. Polymers, 12(1), 106. https://doi.org/10.3390/polym12010106