Modification of Rigid Polyurethane Foams with the Addition of Nano-SiO2 or Lignocellulosic Biomass

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Synthesis of Polyurethane Foam

2.3. Foams Characterization

3. Result and Discussion

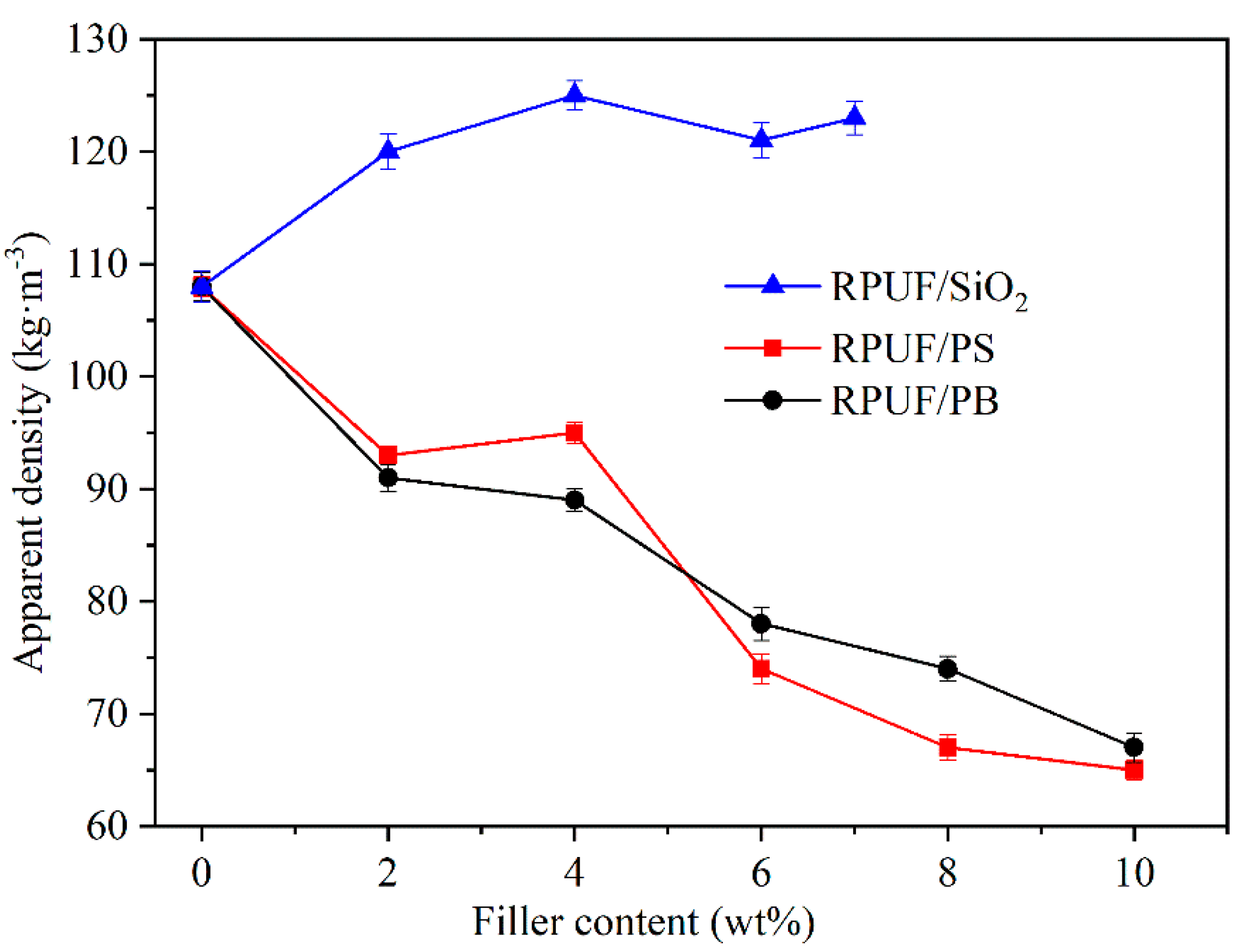

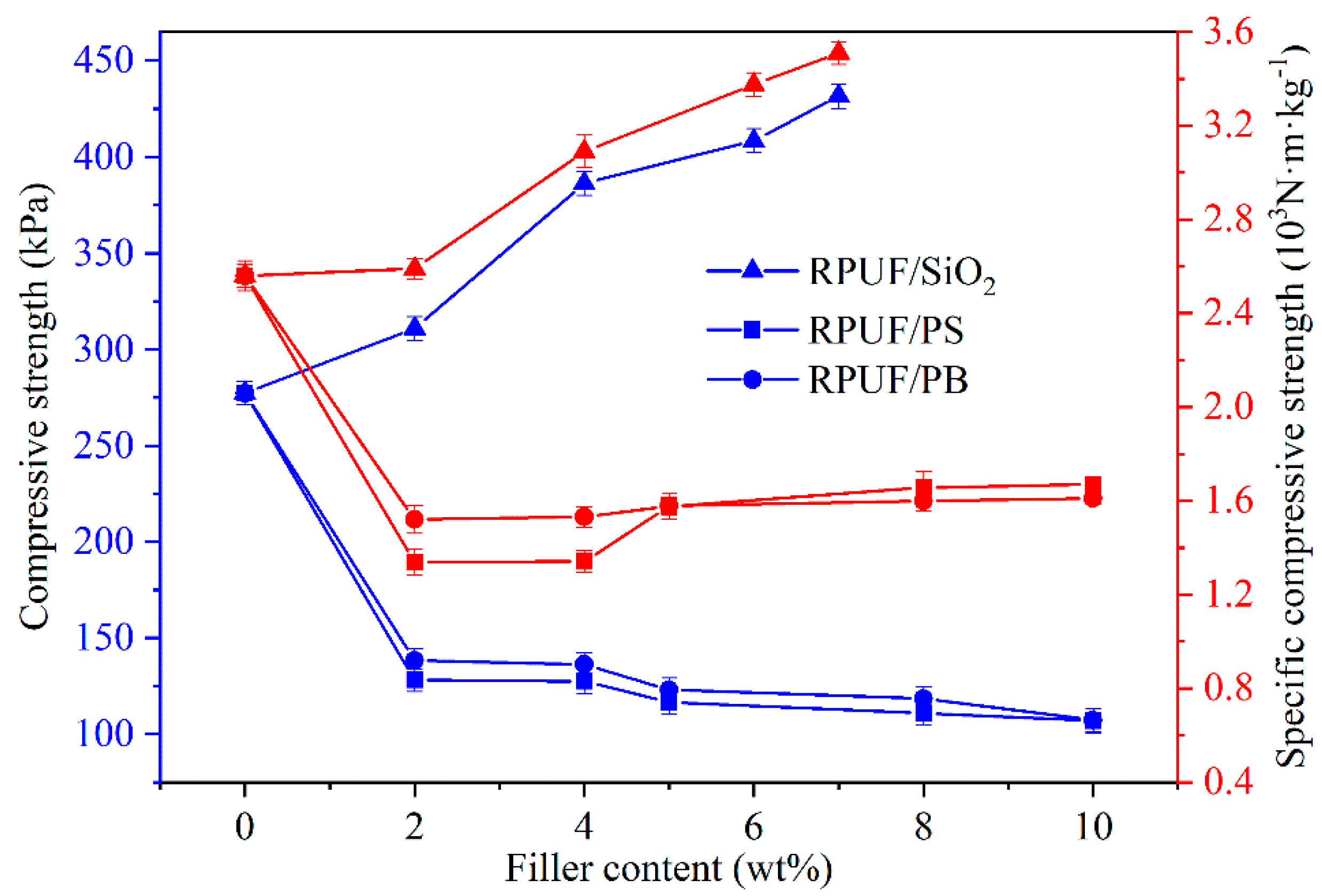

3.1. Compressive Strength

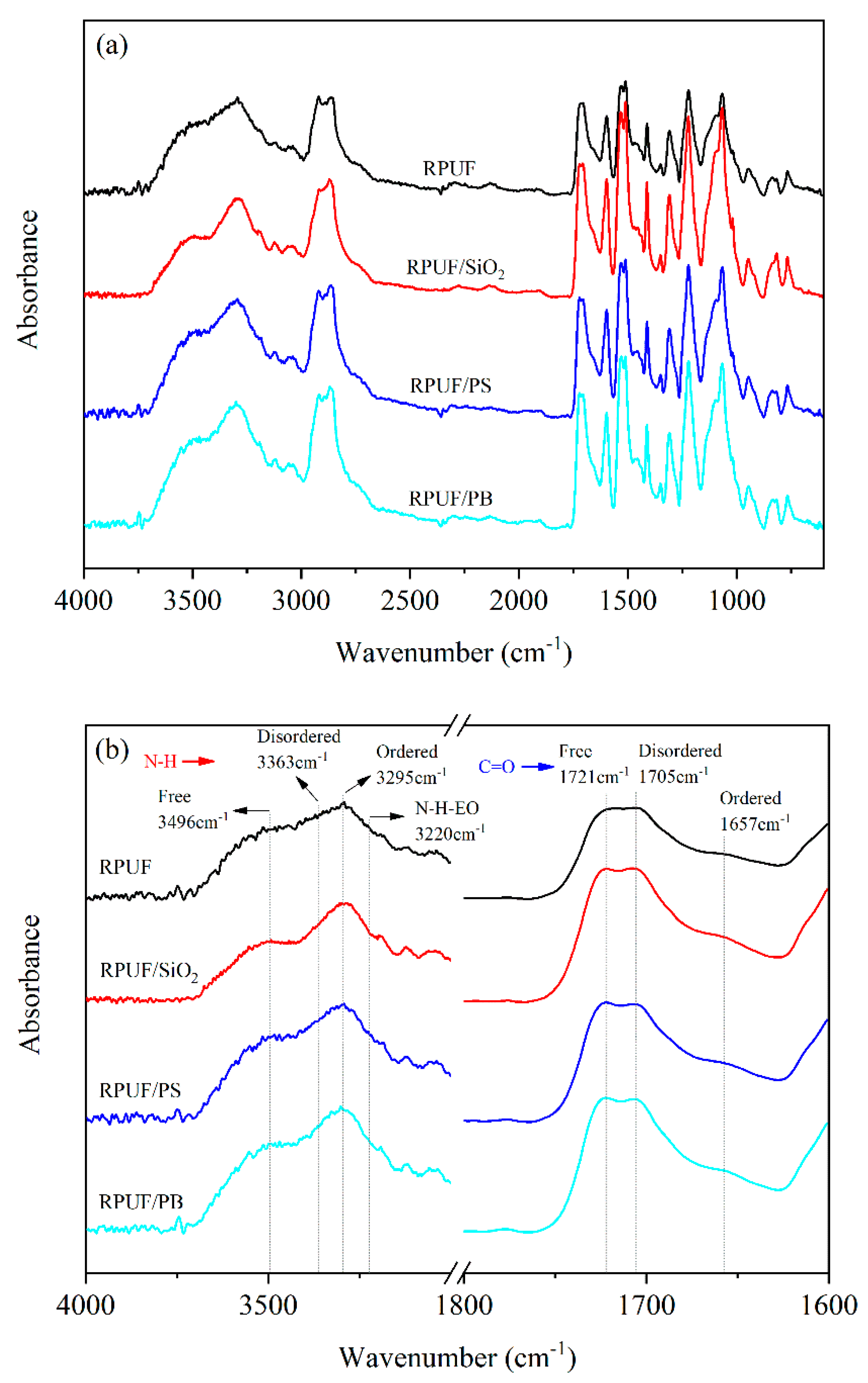

3.2. Hydrogen Bonding States from ATR-FTIR

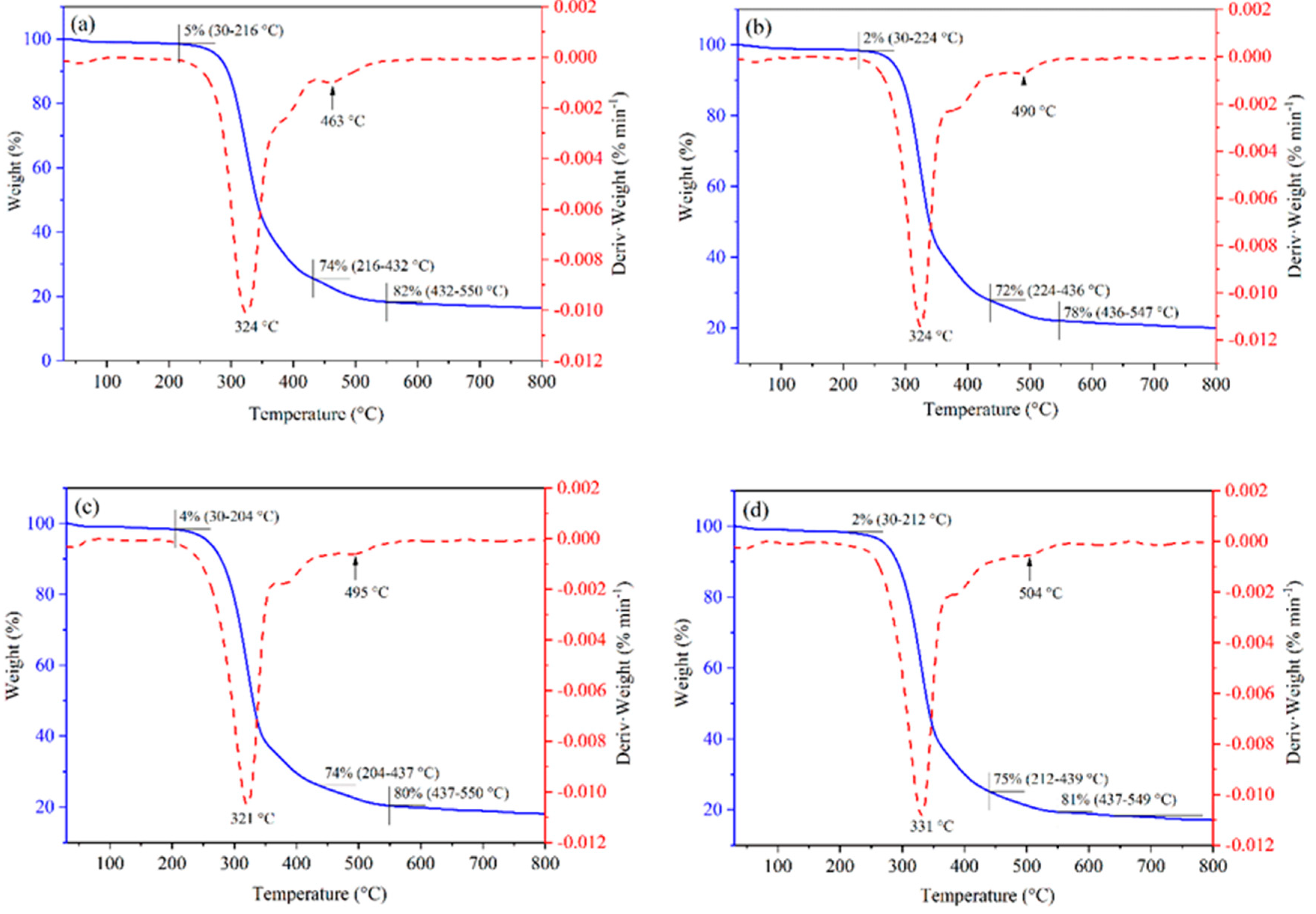

3.3. Thermal Behavior

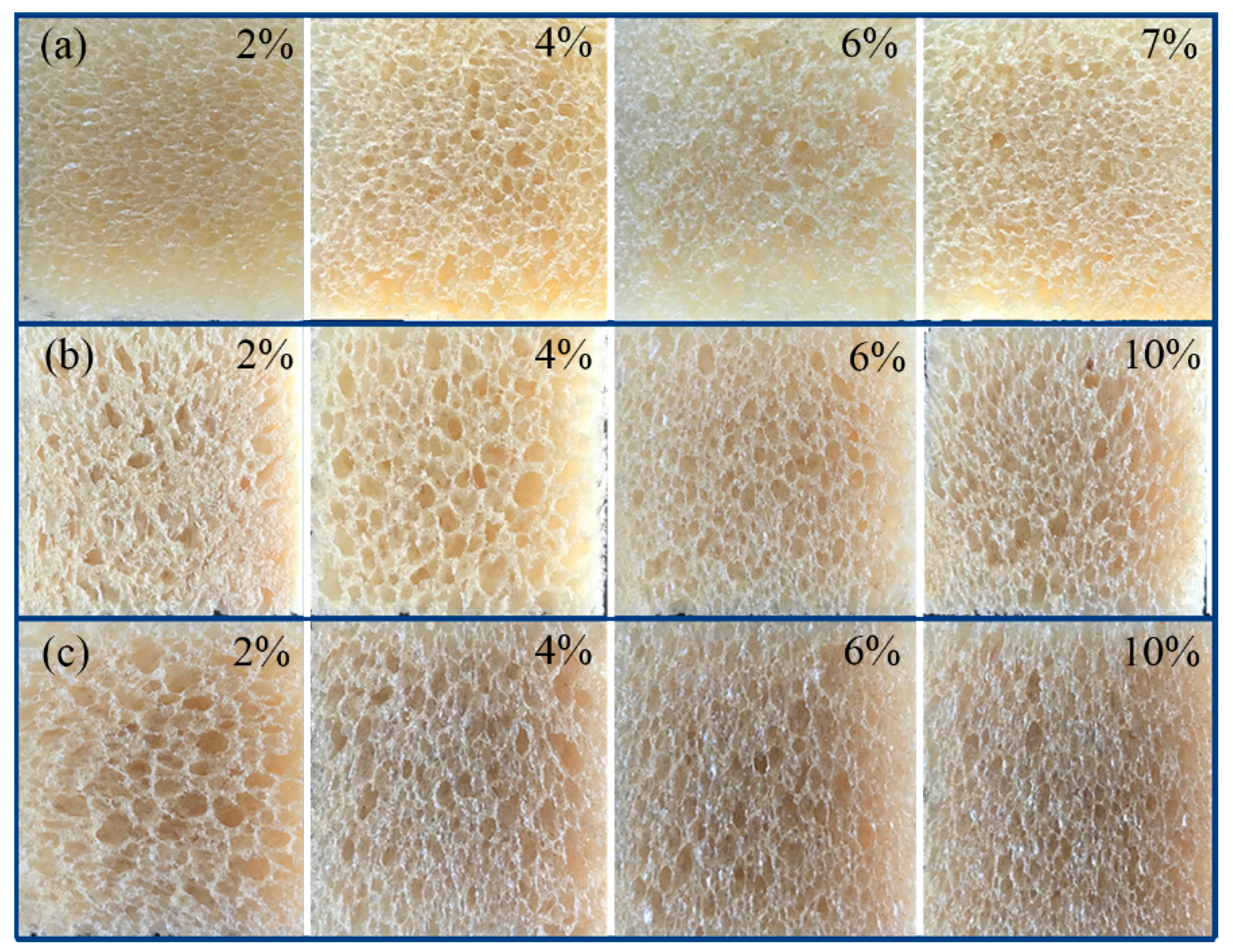

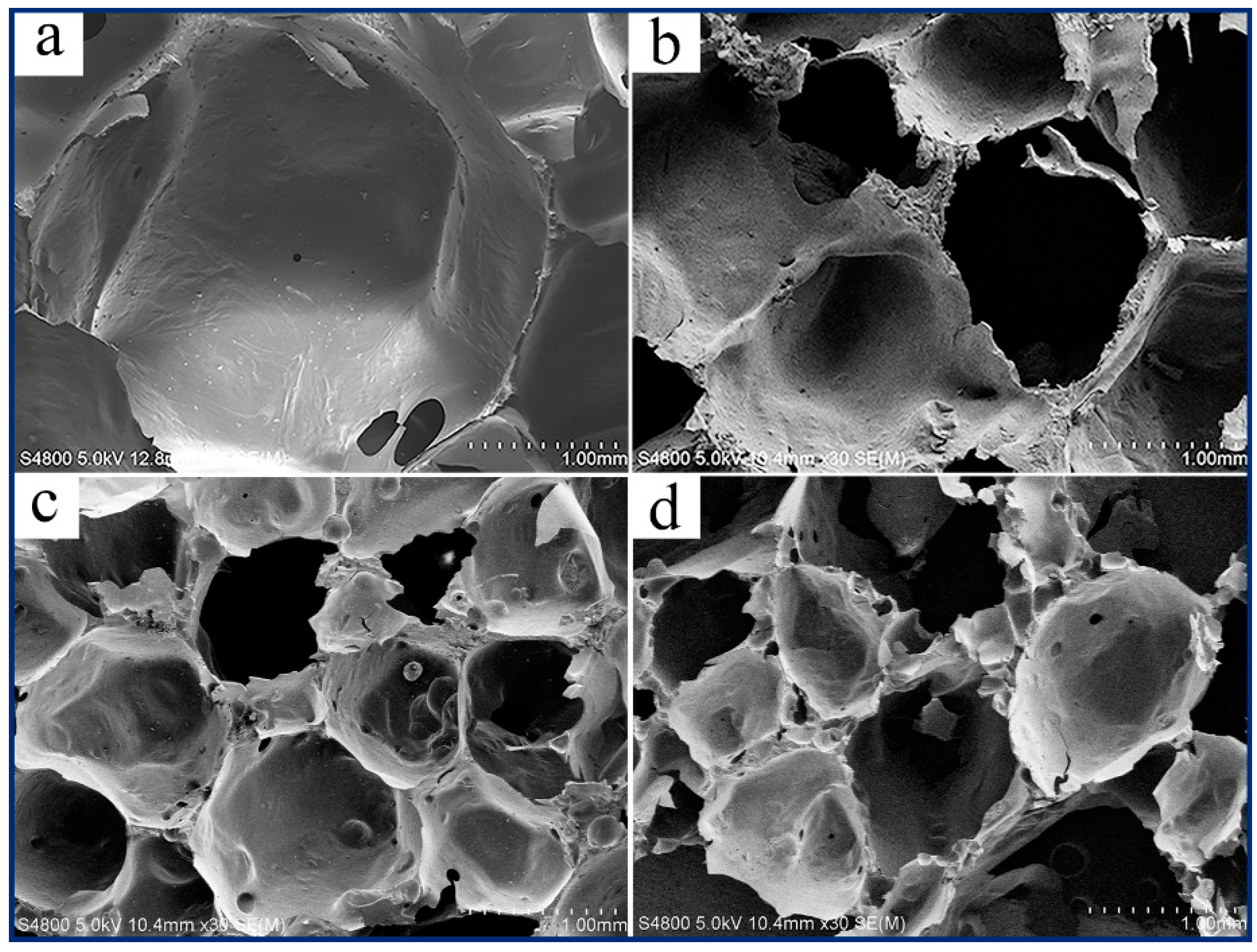

3.4. Morphology Investigation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- The G20 Seoul Summit Leaders’ Declaration. Available online: http://www.g20.utoronto.ca/ (accessed on 5 November 2019).

- Hwang, B.-G.; Zhao, X.; See, Y.L.; Zhong, Y. Addressing Risks in Green Retrofit Projects: The Case of Singapore. Proj. Manag. J. 2015, 46, 76–89. [Google Scholar] [CrossRef]

- Ravindu, S.; Rameezdeen, R.; Zuo, J.; Zhou, Z.; Chandratilake, R. Indoor environment quality of green buildings: Case study of an LEED platinum certified factory in a warm humid tropical climate. Build. Environ. 2015, 84, 105–113. [Google Scholar] [CrossRef]

- Roetzel, A.; Tsangrassoulis, A.; Dietrich, U. Impact of building design and occupancy on office comfort and energy performance in different climates. Build. Environ. 2014, 71, 165–175. [Google Scholar] [CrossRef]

- Wolfson, A.; Litvak, G.; Dlugy, C.; Shotland, Y.; Tavor, D. Employing crude glycerol from biodiesel production as an alternative green reaction medium. Ind. Crops Prod. 2009, 30, 78–81. [Google Scholar] [CrossRef]

- Sricharoenchaikul, V.; Atong, D. Fuel Gas Generation from Thermochemical Conversion of Crude Glycerol Mixed with Biomass Wastes. Energy Procedia 2012, 14, 1286–1291. [Google Scholar] [CrossRef]

- Briga-Sá, A.; Nascimento, D.; Teixeira, N.; Pinto, J.; Caldeira, F.; Varum, H.; Paiva, A. Textile waste as an alternative thermal insulation building material solution. Constr. Build. Mater. 2013, 38, 155–160. [Google Scholar] [CrossRef]

- Rajput, D.; Bhagade, S.S.; Raut, S.P.; Ralegaonkar, R.V.; Mandavgane, S.A. Reuse of cotton and recycle paper mill waste as building material. Constr. Build. Mater. 2012, 34, 470–475. [Google Scholar] [CrossRef]

- Liu, H.; Jiang, G.; Zhuang, H.; Wang, K. Distribution, utilization structure and potential of biomass resources in rural China: With special references of crop residues. Renew. Sustain. Energy Rev. 2008, 12, 1402–1418. [Google Scholar] [CrossRef]

- Sung, G.; Kim, J.W.; Kim, J.H. Fabrication of polyurethane composite foams with magnesium hydroxide filler for improved sound absorption. J. Ind. Eng. Chem. 2016, 44, 99–104. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, C.; Ren, L.; Ichchou, M.; Galland, M.A.; Bareille, O. Influences of rice hull in polyurethane foam on its sound absorption characteristics. Polym. Compos. 2013, 34, 1847–1855. [Google Scholar] [CrossRef]

- Tiuc, A.E.; Vermeşan, H.; Gabor, T.; Vasile, O. Improved Sound Absorption Properties of Polyurethane Foam Mixed with Textile Waste. Energy Procedia 2016, 85, 559–565. [Google Scholar] [CrossRef]

- Luo, F.; Wu, K.; Lu, M. Enhanced thermal stability and flame retardancy of polyurethane foam composites with polybenzoxazine modified ammonium polyphosphates. RSC Adv. 2016, 6, 13418–13425. [Google Scholar] [CrossRef]

- Shimizu, T.; Koshiro, S.; Yamada, Y.; Tada, K. Effect of cell structure on oil absorption of highly oil absorptive polyurethane foam for on-site use. J. Appl. Polym. Sci. 1997, 65, 179–186. [Google Scholar] [CrossRef]

- Zhou, X.; Zhang, Z.; Xu, X.; Men, X.; Zhu, X. Facile Fabrication of Superhydrophobic Sponge with Selective Absorption and Collection of Oil from Water. Ind. Eng. Chem. Res. 2013, 52, 9411–9416. [Google Scholar] [CrossRef]

- Kurańska, M.; Prociak, A. The influence of rapeseed oil-based polyols on the foaming process of rigid polyurethane foams. Ind. Crops Prod. 2016, 89, 182–187. [Google Scholar] [CrossRef]

- Kairytė, A.; Vėjelis, S. Evaluation of forming mixture composition impact on properties of water blown rigid polyurethane (PUR) foam from rapeseed oil polyol. Ind. Crops Prod. 2015, 66, 210–215. [Google Scholar] [CrossRef]

- Bähr, M.; Mülhaupt, R. Linseed and soybean oil-based polyurethanes prepared via the non-isocyanate route and catalytic carbon dioxide conversion. Green Chem. 2012, 14, 483–489. [Google Scholar] [CrossRef]

- Zhang, G.; Wu, Y.; Chen, W.; Han, D.; Lin, X.; Xu, G.; Zhang, Q. Open-Cell Rigid Polyurethane Foams from Peanut Shell-Derived Polyols Prepared under Different Post-Processing Conditions. Polymers 2019, 11, 1392. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, Q.; Wu, Y.; Zhang, H.; Cao, J.; Han, D. Effect of auxiliary blowing agents on properties of rigid polyurethane foams based on liquefied products from peanut shell. J. Appl. Polym. Sci. 2017, 134, 45582. [Google Scholar] [CrossRef]

- Xie, J.; Zhai, X.; Hse, C.Y.; Shupe, T.F.; Pan, H. Polyols from Microwave Liquefied Bagasse and Its Application to Rigid Polyurethane Foam. Materials 2015, 8, 8496–8509. [Google Scholar] [CrossRef]

- Şerban, D.A.; Weissenborn, O.; Geller, S.; Marşavina, L.; Gude, M. Evaluation of the mechanical and morphological properties of long fibre reinforced polyurethane rigid foams. Polym. Test. 2016, 49, 121–127. [Google Scholar] [CrossRef]

- Akkoyun, M.; Suvaci, E. Effects of TiO2, ZnO, and Fe3O4 nanofillers on rheological behavior, microstructure, and reaction kinetics of rigid polyurethane foams. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Yakushin, V.; Bel’kova, L.; Sevastyanova, I. Properties of rigid polyurethane foams filled with glass microspheres. Mech. Compos. Mater. 2012, 48, 579–586. [Google Scholar] [CrossRef]

- Yakushin, V.; Stirna, U.; Bel’kova, L.; Deme, L.; Sevastyanova, I. Properties of rigid polyurethane foams filled with milled carbon fibers. Mech. Compos. Mater. 2011, 46, 679–688. [Google Scholar] [CrossRef]

- Mukherji, A.; Mishra, S. Effect of Sizes of Nano Ca3(PO4)2 on Mechanical and Thermal Properties of Polyurethane Foam Composites. Polym. Plast. Technol. Eng. 2007, 46, 675–681. [Google Scholar] [CrossRef]

- Ekici, B.; Kentli, A.; Küçük, H. Improving Sound Absorption Property of Polyurethane Foams by Adding Tea-Leaf Fibers. Arch. Acoust. 2012, 37, 515–520. [Google Scholar] [CrossRef]

- Athanasopoulos, N.; Baltopoulos, A.; Matzakou, M.; Vavouliotis, A.; Kostopoulos, V. Electrical conductivity of polyurethane/MWCNT nanocomposite foams. Polym. Compos. 2012, 33, 1302–1312. [Google Scholar] [CrossRef]

- Gama, N.V.; Silva, R.; Mohseni, F.; Davarpanah, A.; Amaral, V.S.; Ferreira, A.; Barros-Timmons, A. Enhancement of physical and reaction to fire properties of crude glycerol polyurethane foams filled with expanded graphite. Polym. Test. 2018, 69, 199–207. [Google Scholar] [CrossRef]

- Tarakcılar, A.R. The effects of intumescent flame retardant including ammonium polyphosphate/pentaerythritol and fly ash fillers on the physicomechanical properties of rigid polyurethane foams. J. Appl. Polym. Sci. 2011, 120, 2095–2102. [Google Scholar] [CrossRef]

- Wolska, A.; Goździkiewicz, M.; Ryszkowska, J. Thermal and mechanical behaviour of flexible polyurethane foams modified with graphite and phosphorous fillers. J. Mater. Sci. 2012, 47, 5627–5634. [Google Scholar] [CrossRef]

- Wang, X.; Shi, Y.; Liu, Y.; Wang, Q. Recycling of waste melamine formaldehyde foam as flame-retardant filler for polyurethane foam. J. Polym. Res. 2019, 26. [Google Scholar] [CrossRef]

- Yao, Y.Y.; Tian, H.F.; Yuan, L.; Wu, Q.X.; Xiang, A.M. Improved mechanical, thermal, and flame-resistant properties of polyurethane-imide foams via expandable graphite modification. J. Appl. Polym. Sci. 2018, 136, 46990. [Google Scholar] [CrossRef]

- Zhou, W.; Bo, C.; Jia, P.; Zhou, Y.; Zhang, M. Effects of Tung Oil-Based Polyols on the Thermal Stability, Flame Retardancy, and Mechanical Properties of Rigid Polyurethane Foam. Polymers 2018, 11, 45. [Google Scholar] [CrossRef]

- Javni, I.; Zhang, W.; Karajkov, V.; Petrovic, Z.S.; Divjakovic, V. Effect of Nano-and Micro-Silica Fillers on Polyurethane Foam Properties. J. Cell. Plast. 2016, 38, 229–239. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Strzelec, K.; Kairytė, A.; Vaitkus, S. Composites of rigid polyurethane foams and silica powder filler enhanced with ionic liquid. Polym. Test. 2019, 75, 12–25. [Google Scholar] [CrossRef]

- Kairytė, A.; Kizinievič, O.; Kizinievič, V.; Kremensas, A. Synthesis of biomass-derived bottom waste ash based rigid biopolyurethane composite foams: Rheological behaviour, structure and performance characteristics. Compos. Part A: Appl. Sci. Manuf. 2019, 117, 193–201. [Google Scholar] [CrossRef]

- Bolcu, C.; Vlase, G.; Vlase, T.; Albu, P.; Doca, N.; Şisu, E. Thermal behavior of some polyurethanes reticulated by aminated maltose. J. Therm. Anal. Calorim. 2013, 113, 1409–1414. [Google Scholar] [CrossRef]

- Vander Schuur, M.; Noordover, B.; Gaymans, R.J. Polyurethane elastomers with amide chain extenders of uniform length. Polymer 2006, 47, 1091–1100. [Google Scholar] [CrossRef]

- Yu, T.L.; Lin, T.L.; Tsai, Y.M.; Liu, W.J. Morphology of polyurethanes with triol monomer crosslinked on hard segments. J. Polym. Sci. Part B Polym. Phys. 1999, 37, 2673–2681. [Google Scholar] [CrossRef]

- Sormana, J.L.; Meredith, J.C. High-Throughput Discovery of Structure—Mechanical Property Relationships for Segmented Poly(urethane—urea)s. Macromolecules 2004, 37, 2186–2195. [Google Scholar] [CrossRef]

- Hernandez, R.; Weksler, J.; Padsalgikar, A.; Runt, J. Microstructural Organization of Three-Phase Polydimethylsiloxane-Based Segmented Polyurethanes. Macromolecules 2007, 40, 5441–5449. [Google Scholar] [CrossRef]

- Chattopadhyay, D.K.; Webster, D.C. Thermal stability and flame retardancy of polyurethanes. Prog. Polym. Sci. 2009, 34, 1068–1133. [Google Scholar] [CrossRef]

- Petrović, Z.S.; Zavargo, Z.; Flyn, J.H.; Macknight, W.J. Thermal Degradation of Segmented Polyurethanes. J. Appl. Polym. Sci. 1994, 51, 1087–1095. [Google Scholar] [CrossRef]

- Levchik, S.V.; Weil, E.D. Thermal decomposition, combustion and flame-retardancy of epoxy resins? A review of the recent literature. Polym. Int. 2004, 53, 1901–1929. [Google Scholar] [CrossRef]

- Kong, X.; Narine, S.S. Physical properties of polyurethane plastic sheets produced from polyols from canola oil. Biomacromolecules 2007, 8, 2203–2209. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Lin, X.; Chen, W.; Zhang, H.; Han, D. Modification of Rigid Polyurethane Foams with the Addition of Nano-SiO2 or Lignocellulosic Biomass. Polymers 2020, 12, 107. https://doi.org/10.3390/polym12010107

Zhang Q, Lin X, Chen W, Zhang H, Han D. Modification of Rigid Polyurethane Foams with the Addition of Nano-SiO2 or Lignocellulosic Biomass. Polymers. 2020; 12(1):107. https://doi.org/10.3390/polym12010107

Chicago/Turabian StyleZhang, Qinqin, Xiaoqi Lin, Weisheng Chen, Heng Zhang, and Dezhi Han. 2020. "Modification of Rigid Polyurethane Foams with the Addition of Nano-SiO2 or Lignocellulosic Biomass" Polymers 12, no. 1: 107. https://doi.org/10.3390/polym12010107

APA StyleZhang, Q., Lin, X., Chen, W., Zhang, H., & Han, D. (2020). Modification of Rigid Polyurethane Foams with the Addition of Nano-SiO2 or Lignocellulosic Biomass. Polymers, 12(1), 107. https://doi.org/10.3390/polym12010107