The Influence of Hydrothermal Aging on the Dynamic Friction Model of Rubber Seals

Abstract

1. Introduction

2. Dynamic Friction Model of the Cylinder

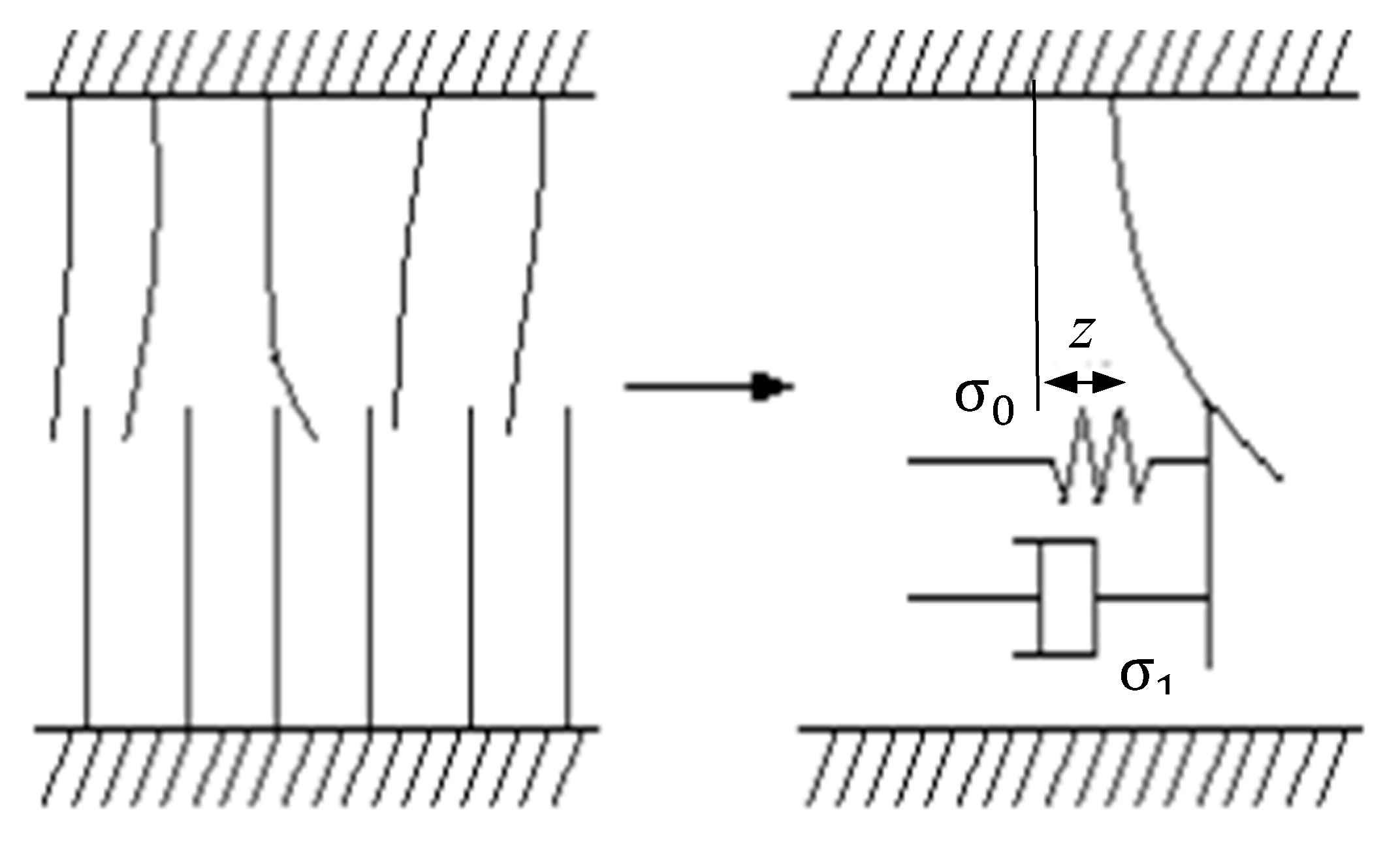

2.1. LuGre Model

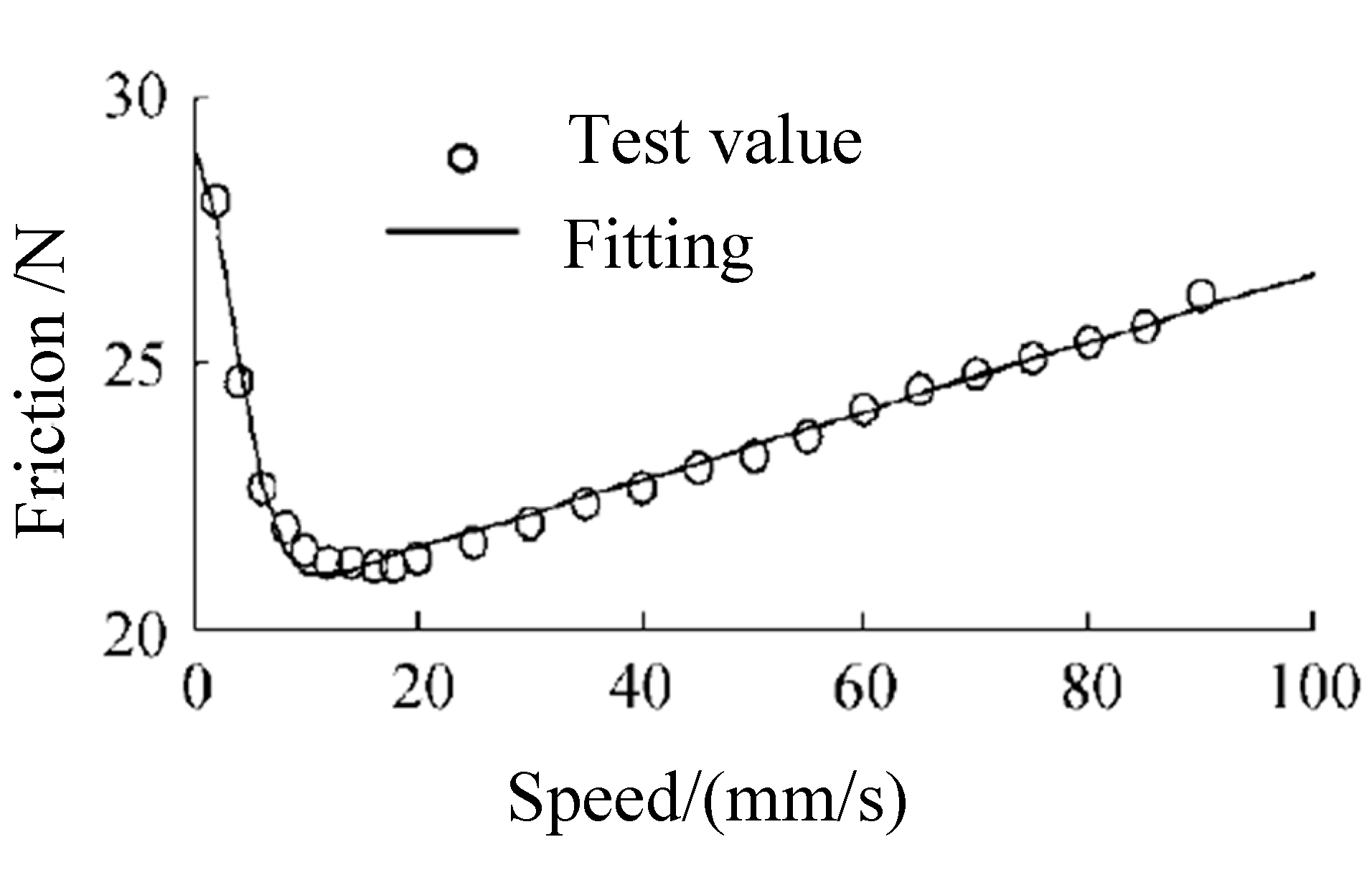

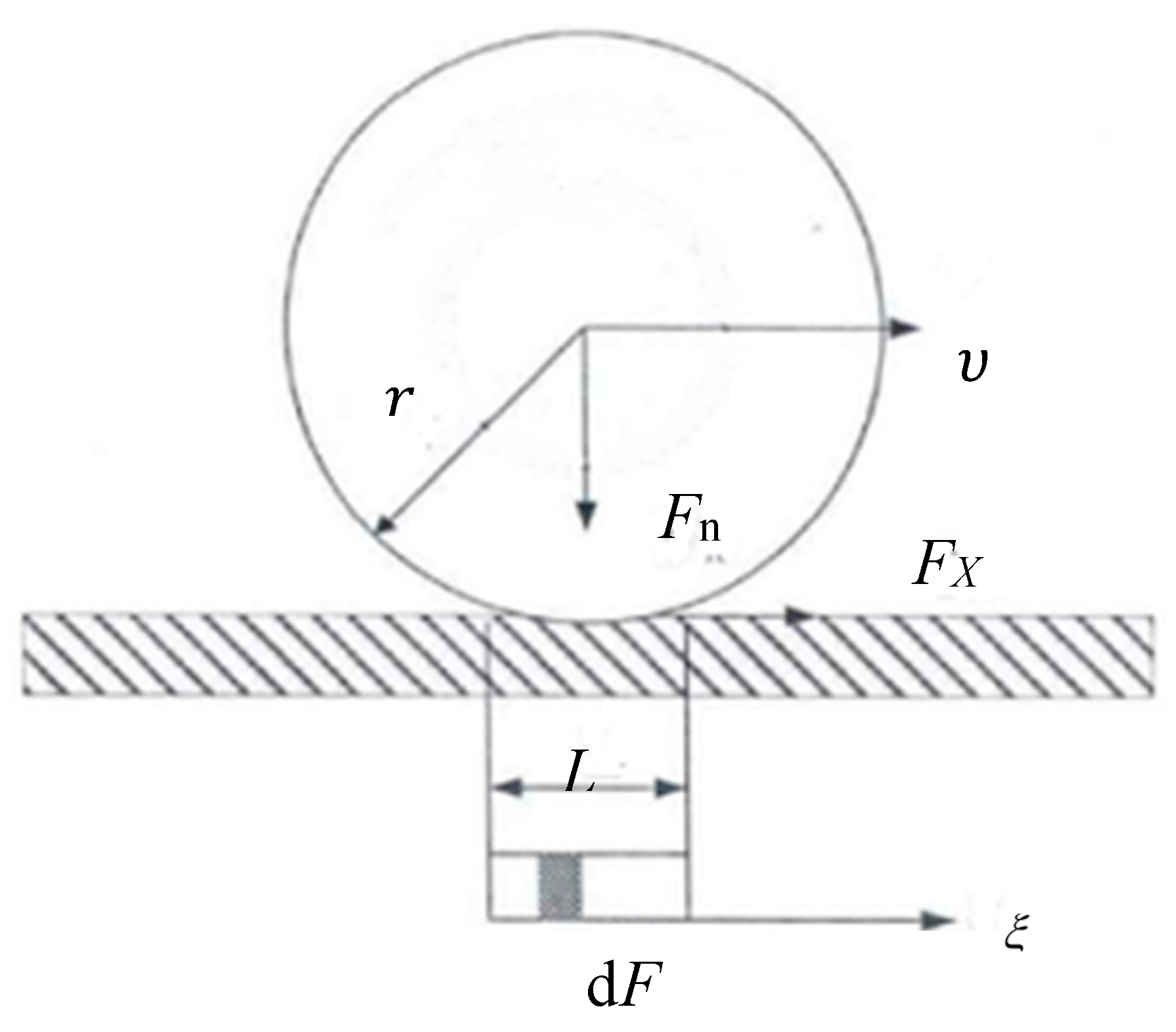

2.2. Improved Friction Model

- (1)

- Although the load is not uniformly distributed on the whole contact surface, different load distribution equations can be selected according to the contact states of different sealing rings and cylinders.

- (2)

- The sliding velocity between each element and the friction surface is the same, and its velocity is equal to v.

2.3. Effect of Model Parameters

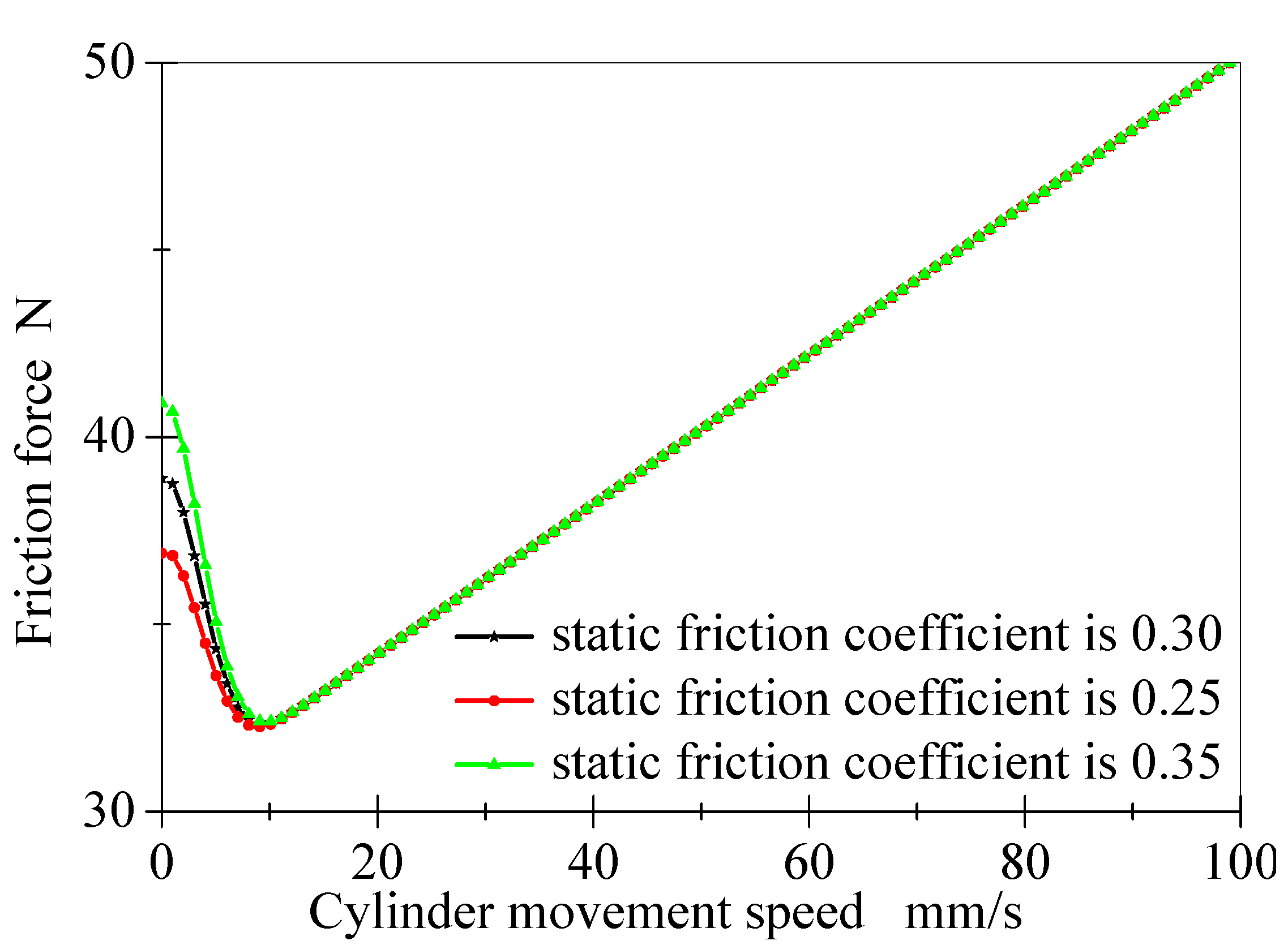

2.3.1. Static Friction Coefficient

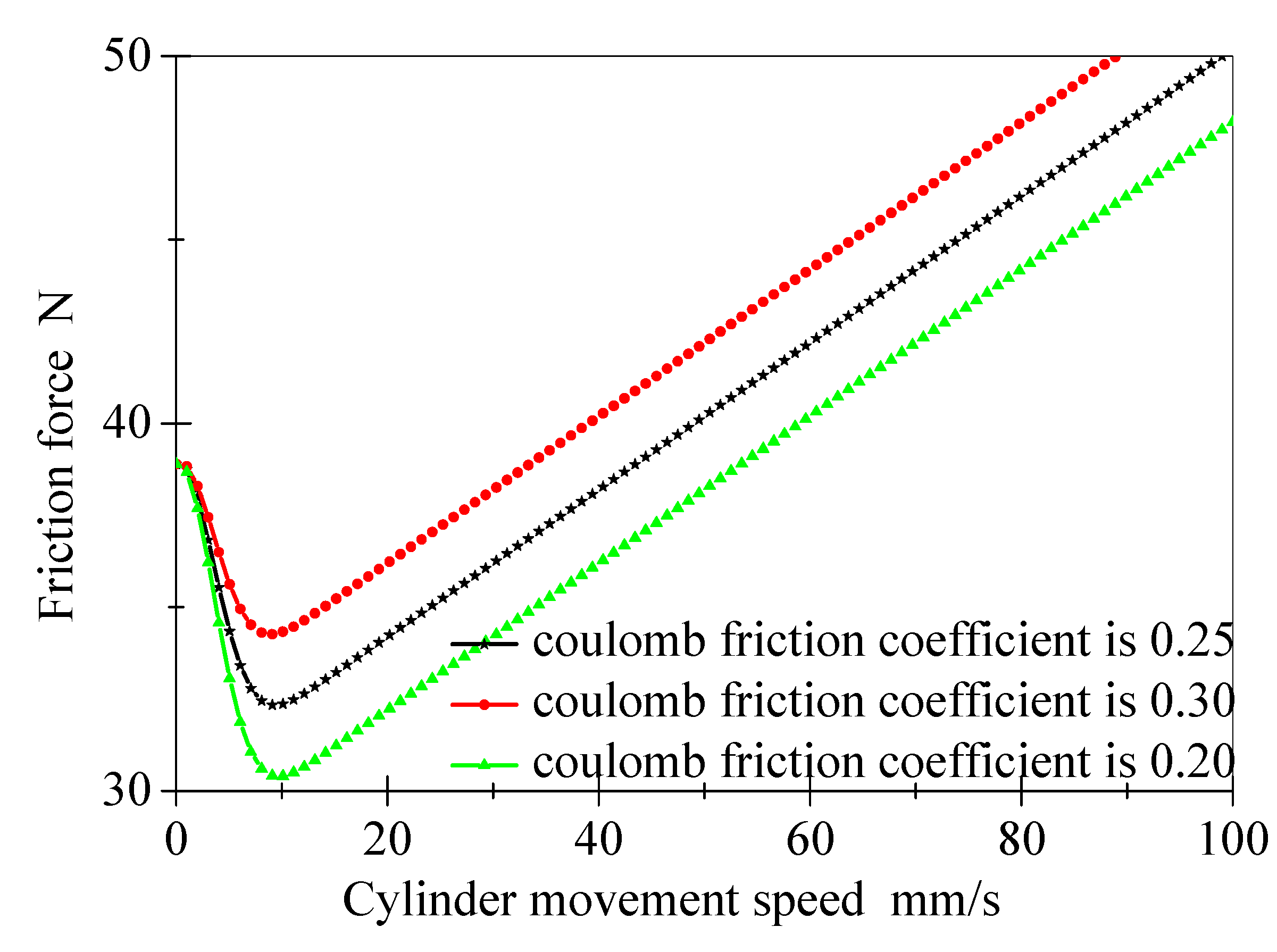

2.3.2. Coulomb Friction Coefficient

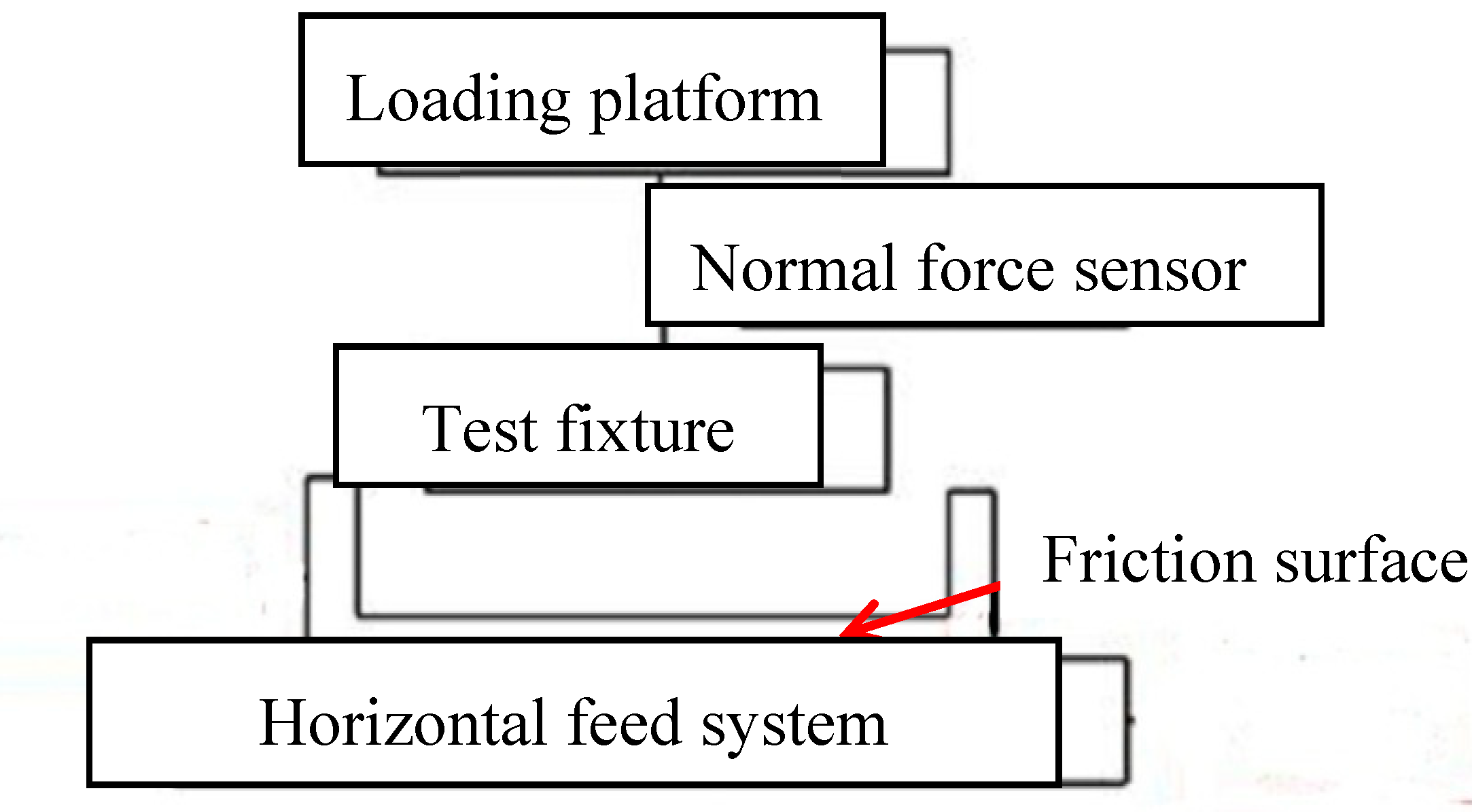

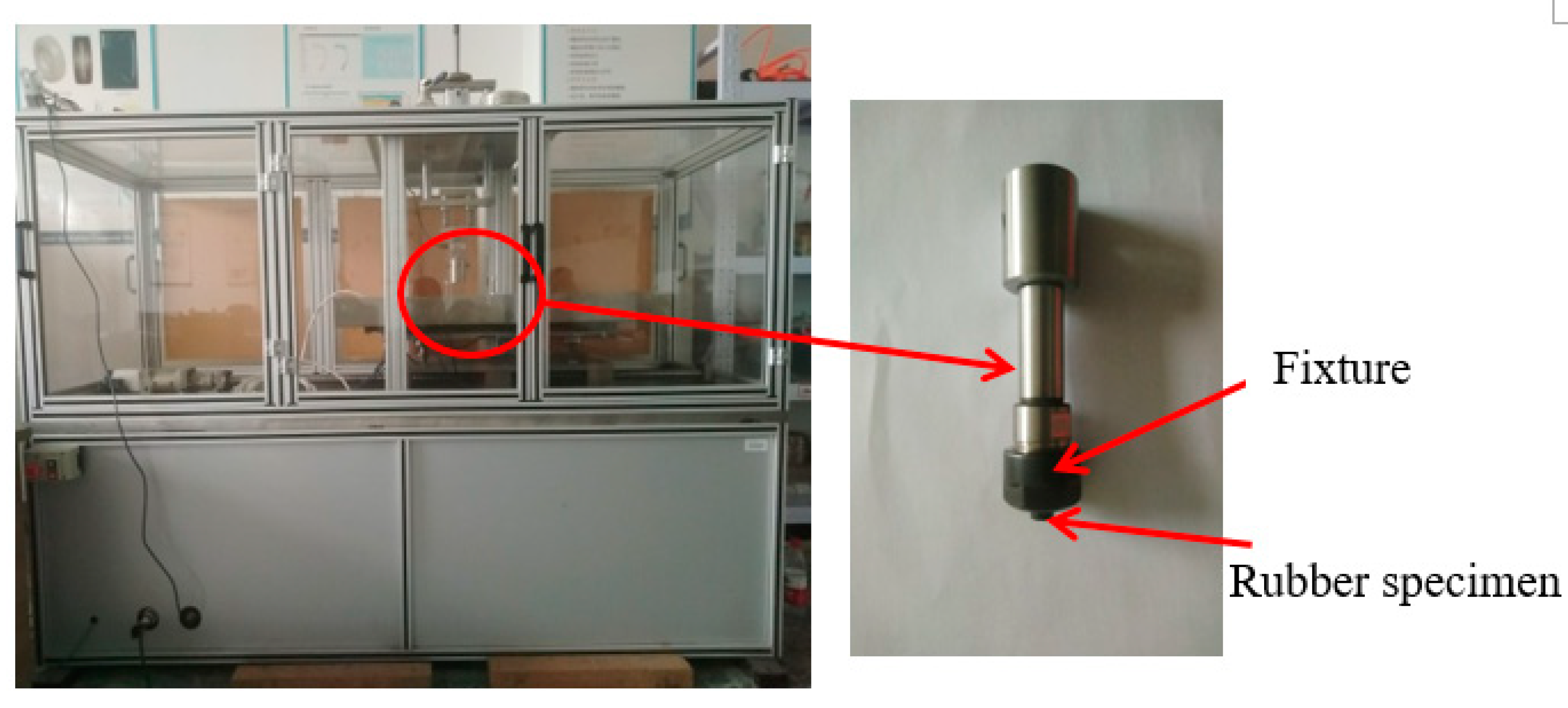

3. Experimental Setup

3.1. Friction Test

3.2. Hydrothermal Aging Test

4. Result and Discussion

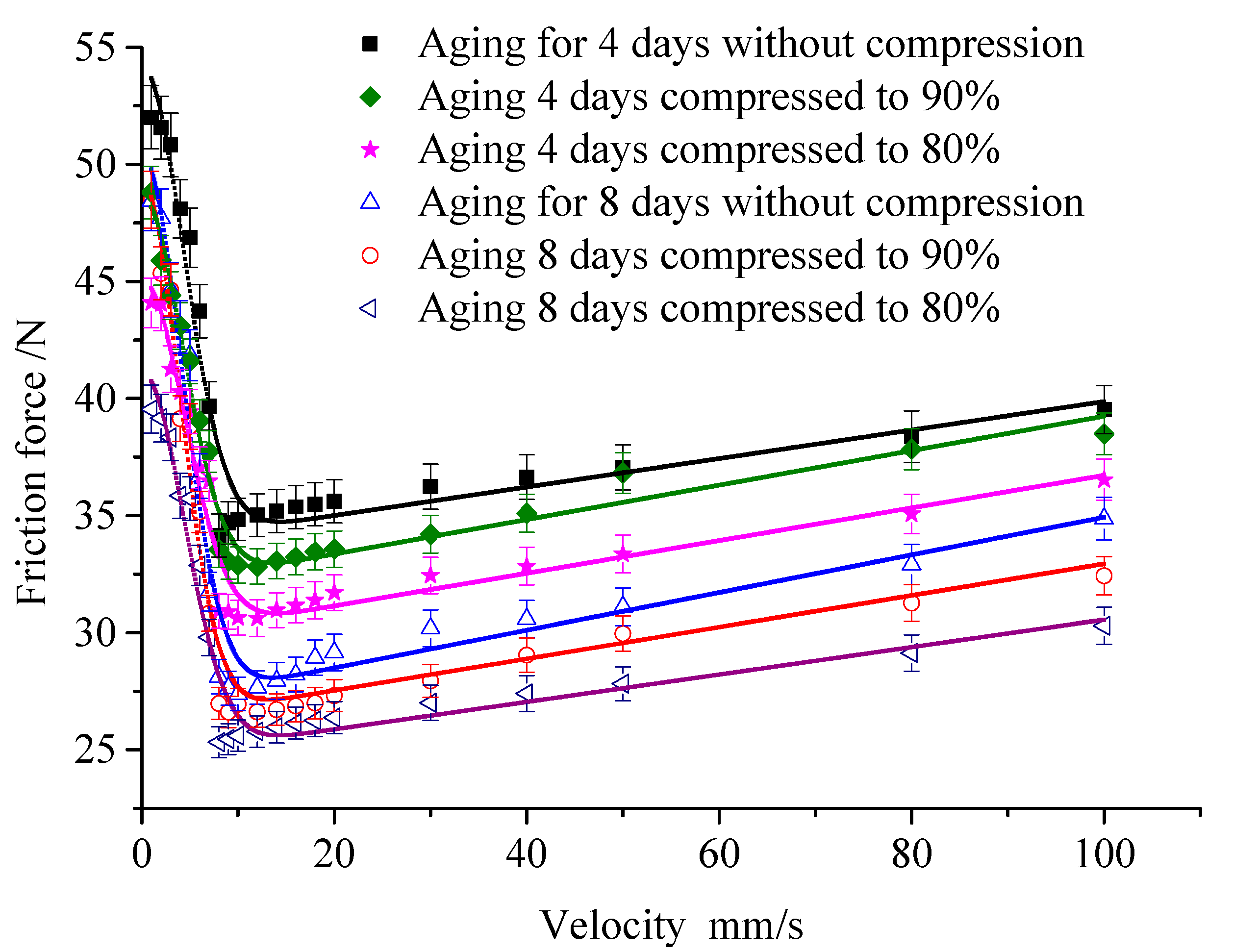

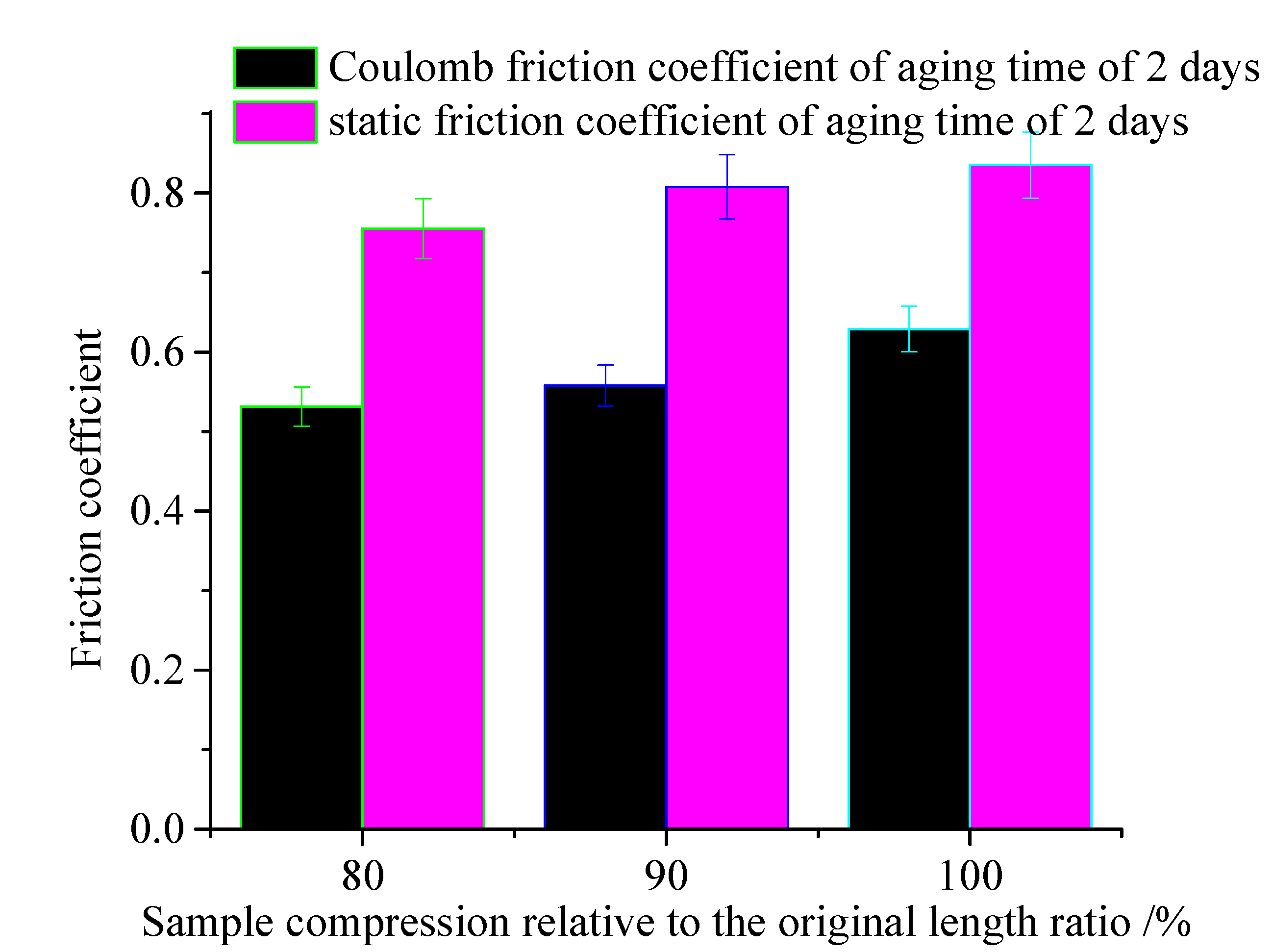

4.1. Compression Ratio

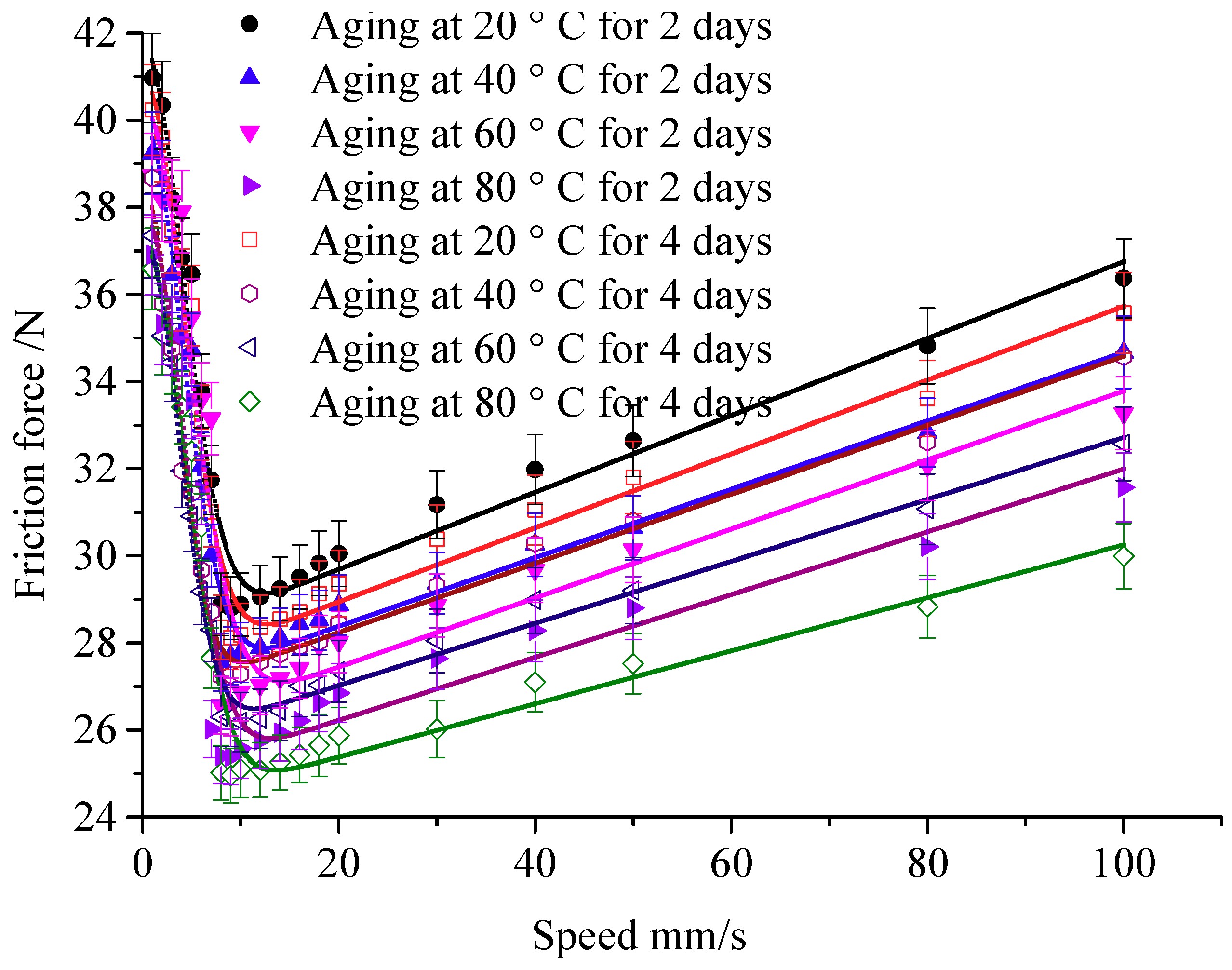

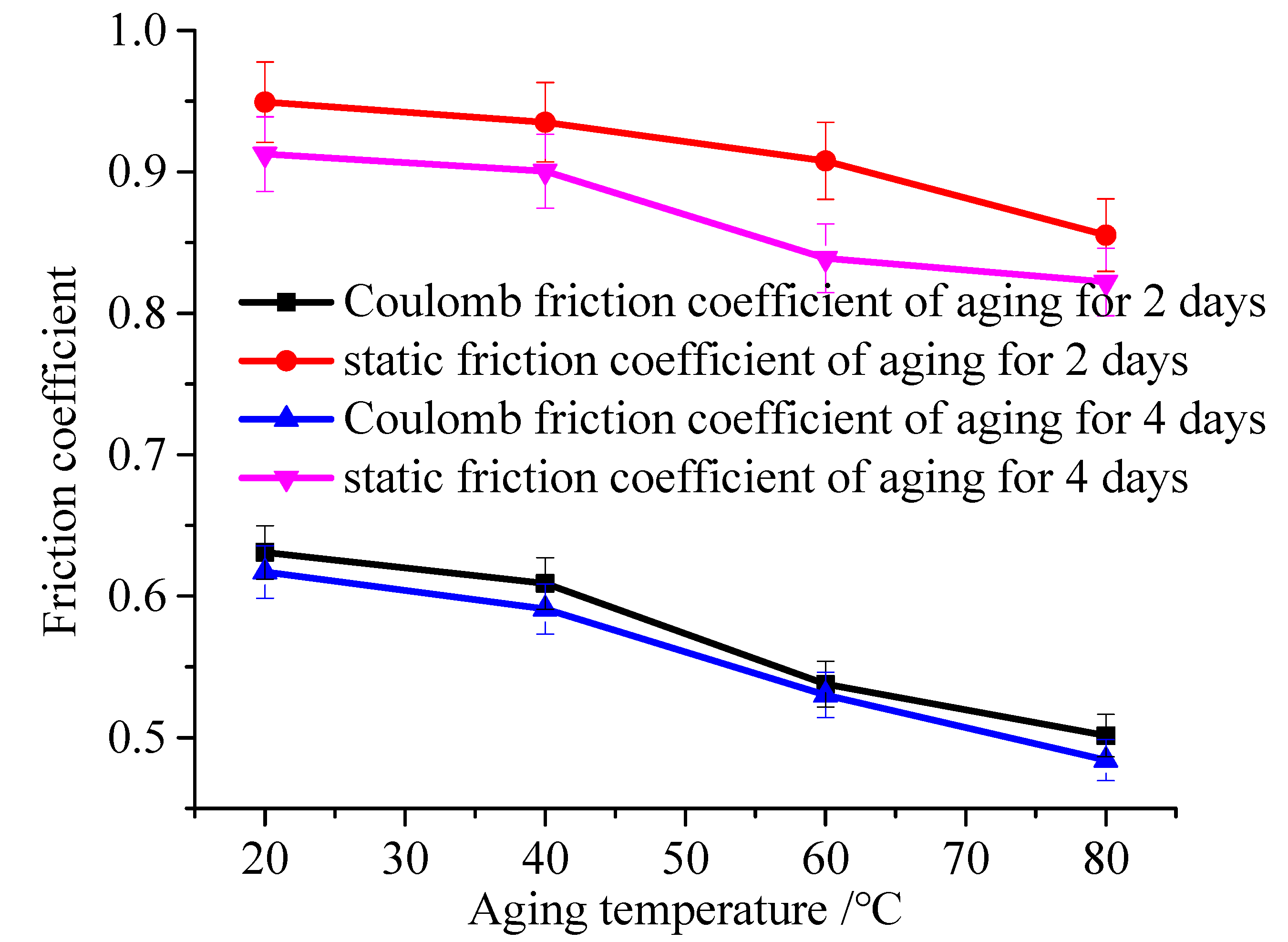

4.2. Temperature

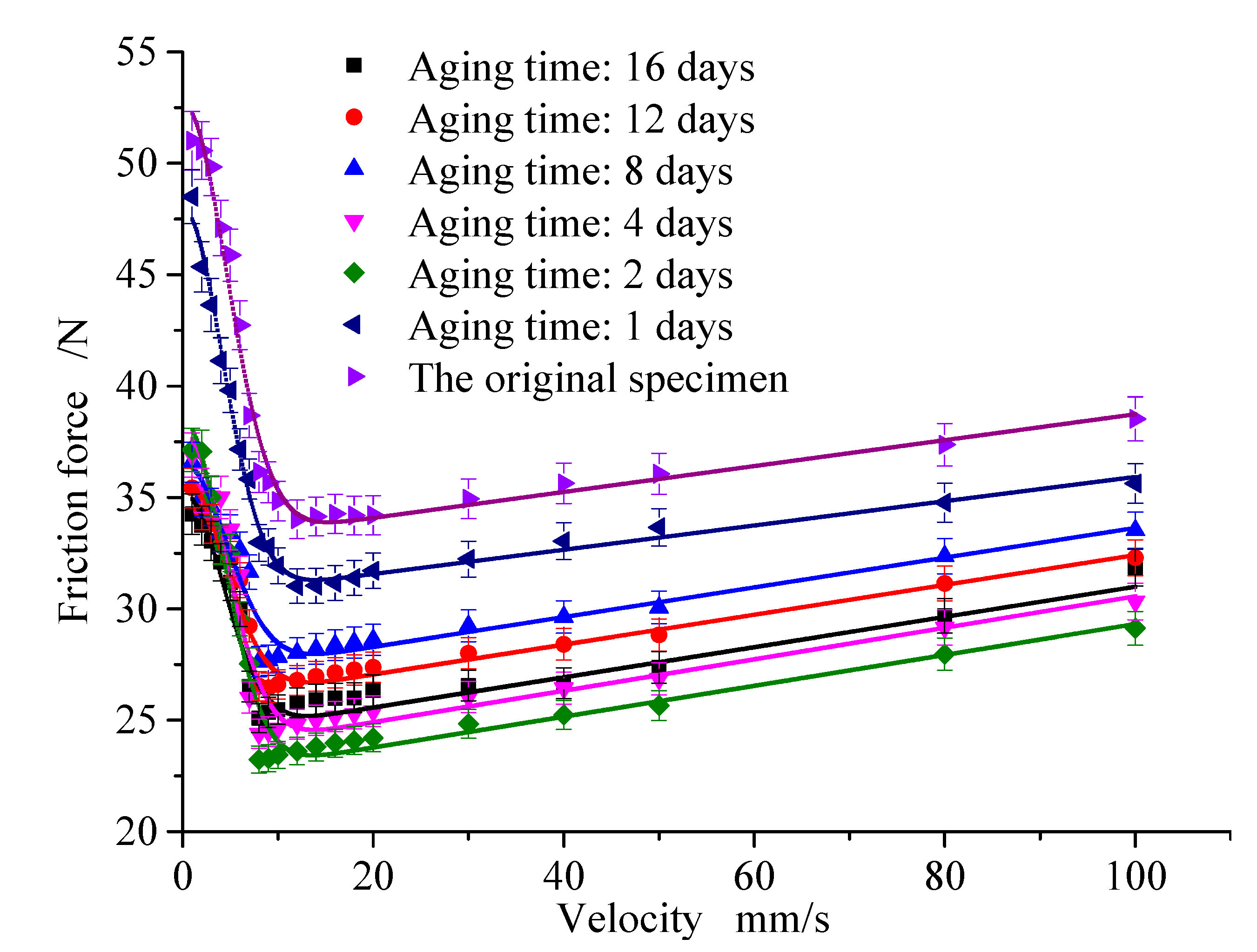

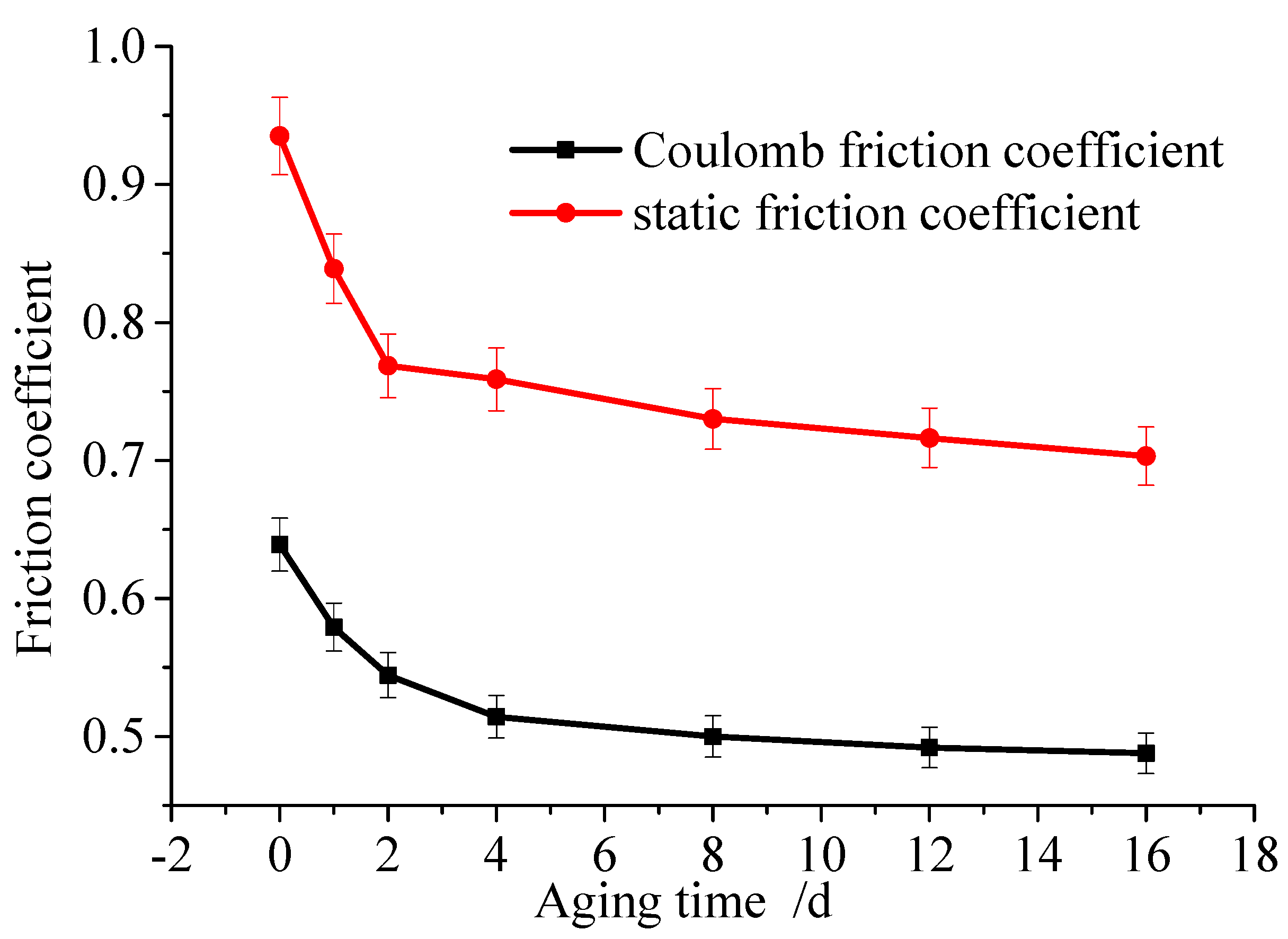

4.3. Aging Time

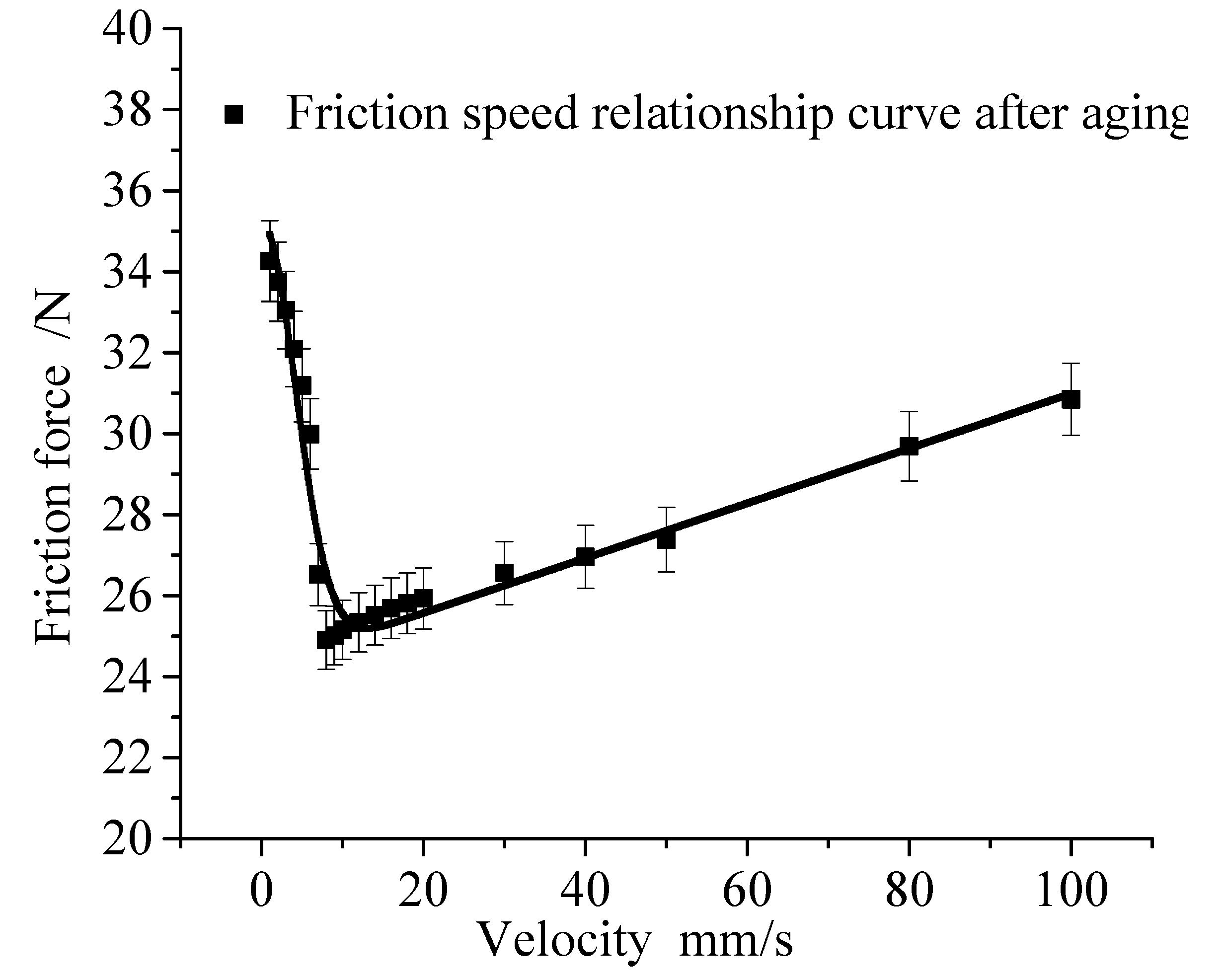

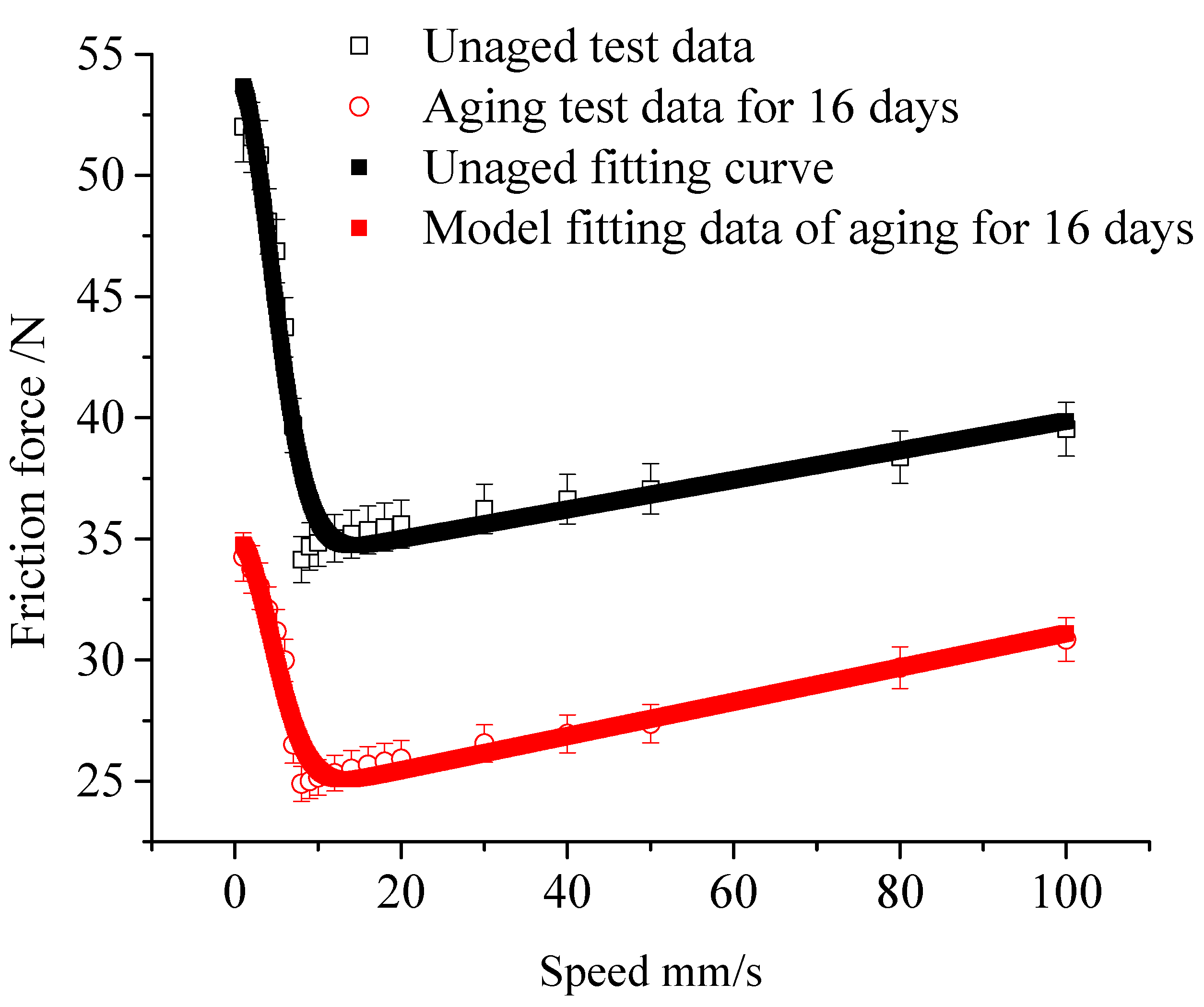

4.4. Effect of Aging on Friction Model

5. Conclusions

- (1)

- The steady friction model of the cylinder is developed based on the LuGre model. Results show that the model can well describe the friction process of the cylinder in the aging process.

- (2)

- The influence of aging temperatures, time, and compression conditions on the friction force have been revealed. The friction coefficient decreases with the increasement of aging temperature, aging time, and compression. The effect on static friction coefficient is larger than that of the Coulomb friction coefficient.

- (3)

- The effect of aging on the cylinder friction model parameters has been investigated. The parameters of the Coulomb friction coefficient and static friction coefficient have been fitted.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Morris, N.; Mohammadpour, M.; Rahmani, R.; Johns-Rahnejat, P.M.; Rahnejat, H.; Dowson, D. Effect of Cylinder Deactivation on Tribological Performance of Piston Compression Ring and Connecting Rod Bearing. Tribol. Int. 2018, 120, 243–254. [Google Scholar] [CrossRef]

- Al-Zughaibi, A.I. Experimental and analytical investigations of friction at lubricant bearings in passive suspension systems. Nonlinear Dyn. 2018, 94, 1227–1242. [Google Scholar] [CrossRef]

- Tiwari, A.; Dorogin, L.; Tahir, M.; Stöckelhuber, K.W.; Heinrich, G.; Espallargas, N.; Persson, B.N.J. Rubber contact mechanics: Adhesion, friction and leakage of seals. Soft Matter 2017, 13, 9103–9121. [Google Scholar] [CrossRef] [PubMed]

- Scaraggi, A.P.A.; Angerhausen, M.; Dorogin, J.; Murrenhoff, L.; Persson, B.N.J. Influence of anisotropic surface roughness on lubricated rubber friction: Extended theory and an application to hydraulic seals. Wear 2018, 410, 43–62. [Google Scholar] [CrossRef]

- Rouzic, J.L.; Perret-Liaudet, J.; Guibert, M. Friction-Induced Vibration by Stribeck’s Law: Application to Wiper Blade Squeal Noise. Tribol. Lett. 2013, 49, 563–572. [Google Scholar] [CrossRef]

- Popov, V.L.; Voll, L.; Kusche, S.; Li, Q.; Rozhkova, S.V. Generalized master curve procedure for elastomer friction taking into account dependencies on velocity, temperature and normal force. Tribol. Int. 2018, 120, 376–380. [Google Scholar] [CrossRef]

- Persson, B.N.J.; Albohr, O.; Mancosu, F.; Peveri, V.; Samoilov, V.N.; Sivebaek, I.M. On the nature of the static friction, kinetic friction and creep. Wear 2003, 254, 835–851. [Google Scholar] [CrossRef]

- Zabala, B.; Igartua, A.; Fernández, X.; Priestner, C.; Nevshupa, R. Friction and wear of a piston ring/cylinder liner at the top dead centre: Experimental study and modelling. Tribol. Int. 2016, 106, 23–33. [Google Scholar] [CrossRef]

- Grabon, W.; Pawlus, P.; Wos, S.; Koszela, W.; Wieczorowski, M. Effects of cylinder liner surface topography on friction and wear of liner-ring system at low temperature. Tribol. Int. 2018, 121, 148–160. [Google Scholar] [CrossRef]

- Karnopp, D. Computer Simulation of Stick-Slip Friction in Mechanical Dynamic Systems. ASME J. Dyn. Syst. Meas. Control 1985, 107, 100–107. [Google Scholar] [CrossRef]

- Canudas, W.C.; Olsson, H.; Astrom, K.J.; Lischinsky, P. A new model for control of systems with friction. IEEE Trans. Autom. Control 1995, 40, 419–425. [Google Scholar] [CrossRef]

- Dahl, P. A Solid Friction Model; Technical Report; Aerospace Corporation: El Segundo, CA, USA, 1968. [Google Scholar]

- Carneiro, J.F.; Almeida, F.G.D. LuGre Friction Model: Application to a Pneumatic Actuated System. Lect. Notes Electr. Eng. 2015, 321, 459–468. [Google Scholar]

- Saha, A.; Wahi, P.; Wiercigroch, M.; Stefański, A. A modified lugre friction model for an accurate prediction of friction force in the pure sliding regime. Int. J. Non-Linear Mech. 2015, 80, 122–131. [Google Scholar] [CrossRef]

- Khayati, K.; Bigras, P.; Dessaint, L.A. Lugre model-based friction compensation and positioning control for a pneumatic actuator using multi-objective output-feedback control via lmi optimization. Mechatronics 2009, 19, 535–547. [Google Scholar] [CrossRef]

- Sun, Y.H.; Sun, Y.; Wu, C.Q.; Sepehri, N. Stability analysis of a controlled mechanical system with parametric uncertainties in lugre friction model. Int. J. Control 2017, 91, 770–784. [Google Scholar] [CrossRef]

- Jeon, J.; Bramley, A.N. A friction model for microforming. Int. J. Adv. Manuf. Technol. 2007, 33, 125–129. [Google Scholar] [CrossRef]

- Schindele, D.; Aschemann, H. Adaptive friction compensation based on the LuGre model for a pneumatic rodless cylinder. In Proceedings of the 35th Annual Conference of IEEE Industrial Electronics, Porto, Portugal, 3–5 November 2009; pp. 1432–1437. [Google Scholar]

- Yanada, H.; Sekikawa, Y. Modeling of dynamic behaviors of friction. Mechatronics 2008, 18, 330–339. [Google Scholar] [CrossRef]

- Tan, W.; Li, X.; Qiu, Z.; Xiang, H.; Zhang, C. Adaptive Sliding Friction Compensation Method Based on Modified LuGre Model. J. Tianjin Univ. 2015, 48, 463–467. [Google Scholar]

- Guan, H.; Duan, C.G.; Lu, P.P. The Friction Model of Dynamic-Wheel Model Based on LuGre Model. Appl. Mech. Mater. 2014, 556, 4288–4292. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Luo, H.; Li, H.; Su, B.; Wang, Y.; Li, Z. The Influence of Hydrothermal Aging on the Dynamic Friction Model of Rubber Seals. Polymers 2020, 12, 102. https://doi.org/10.3390/polym12010102

Wu J, Luo H, Li H, Su B, Wang Y, Li Z. The Influence of Hydrothermal Aging on the Dynamic Friction Model of Rubber Seals. Polymers. 2020; 12(1):102. https://doi.org/10.3390/polym12010102

Chicago/Turabian StyleWu, Jian, Hang Luo, Haohao Li, Benlong Su, Youshan Wang, and Zhe Li. 2020. "The Influence of Hydrothermal Aging on the Dynamic Friction Model of Rubber Seals" Polymers 12, no. 1: 102. https://doi.org/10.3390/polym12010102

APA StyleWu, J., Luo, H., Li, H., Su, B., Wang, Y., & Li, Z. (2020). The Influence of Hydrothermal Aging on the Dynamic Friction Model of Rubber Seals. Polymers, 12(1), 102. https://doi.org/10.3390/polym12010102