Study on Graphene/CNC-Coated Bamboo Pulp Fabric Preparation of Fabrics with Thermal Conductivity

Abstract

1. Introduction

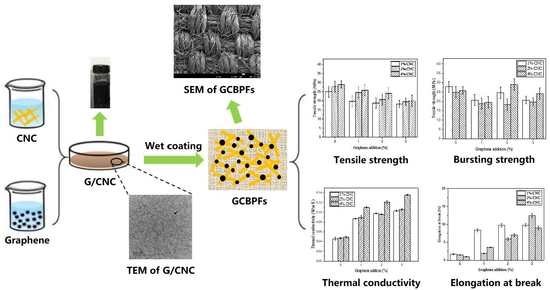

2. Experimental Section

2.1. Materials

2.2. Preparation of Coating Solution

2.3. Coating Procedure

2.4. Characterizations

3. Results and Discussion

3.1. Viscosity of G/CNC Solution

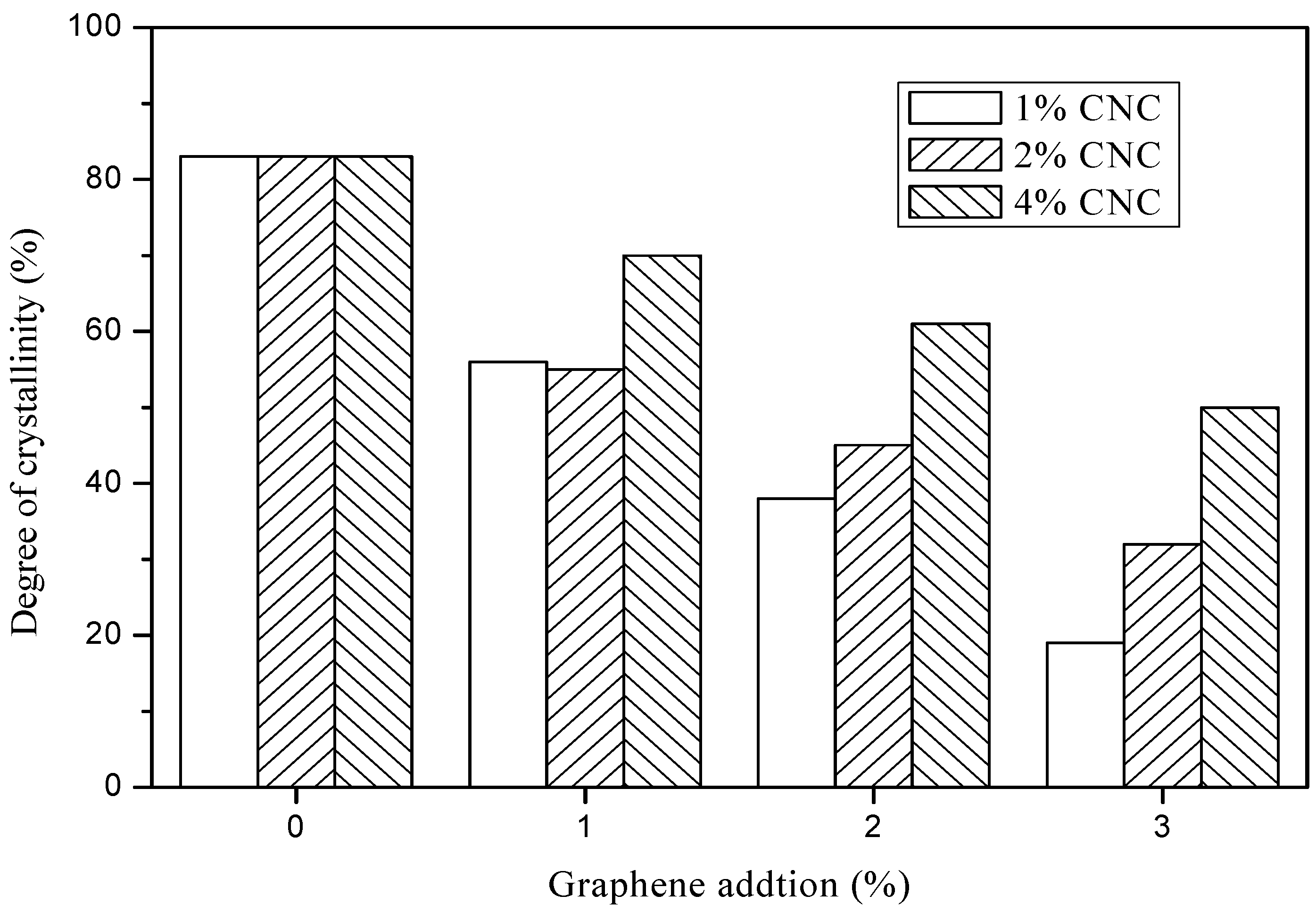

3.2. XRD Analysis

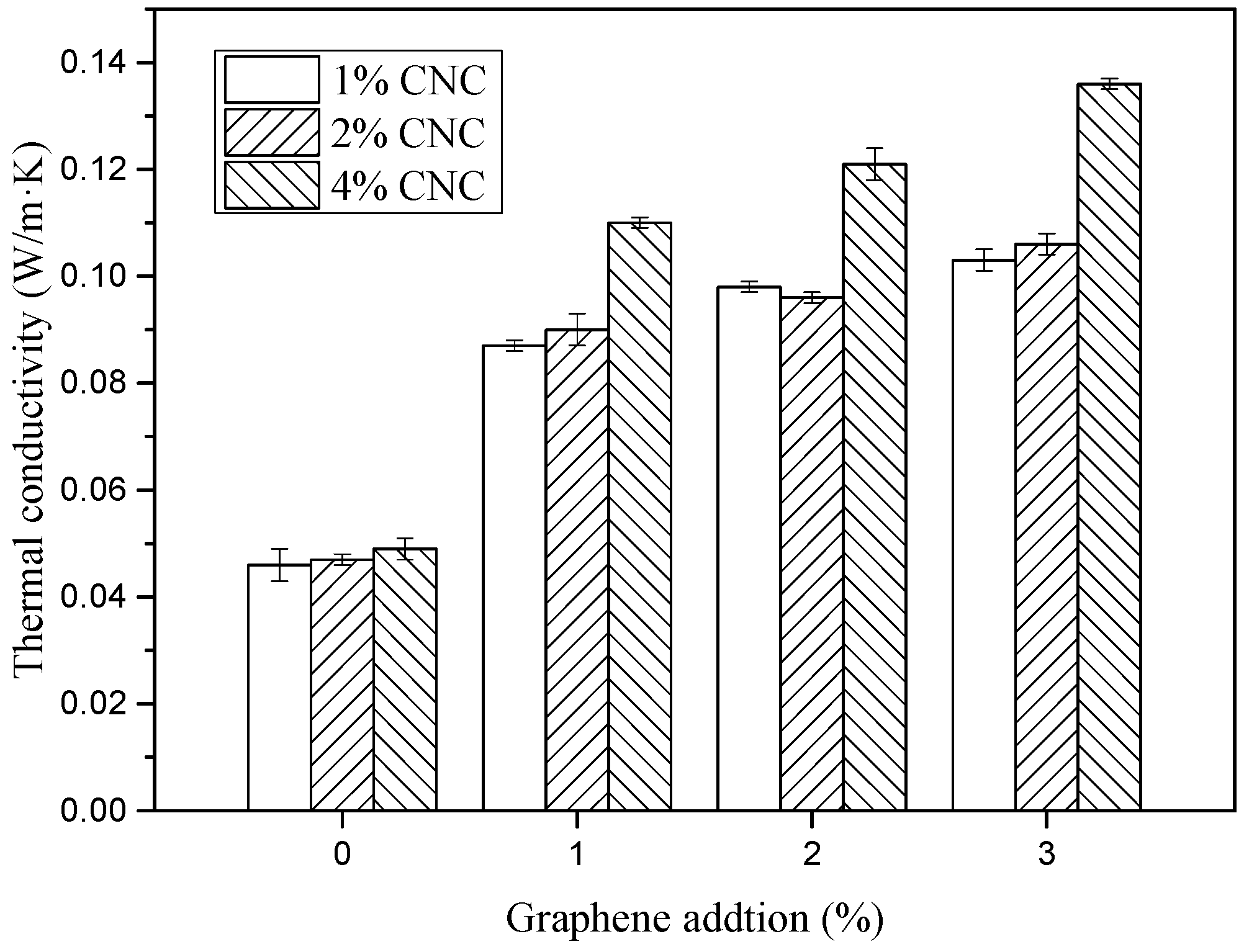

3.3. Thermal Conductivity

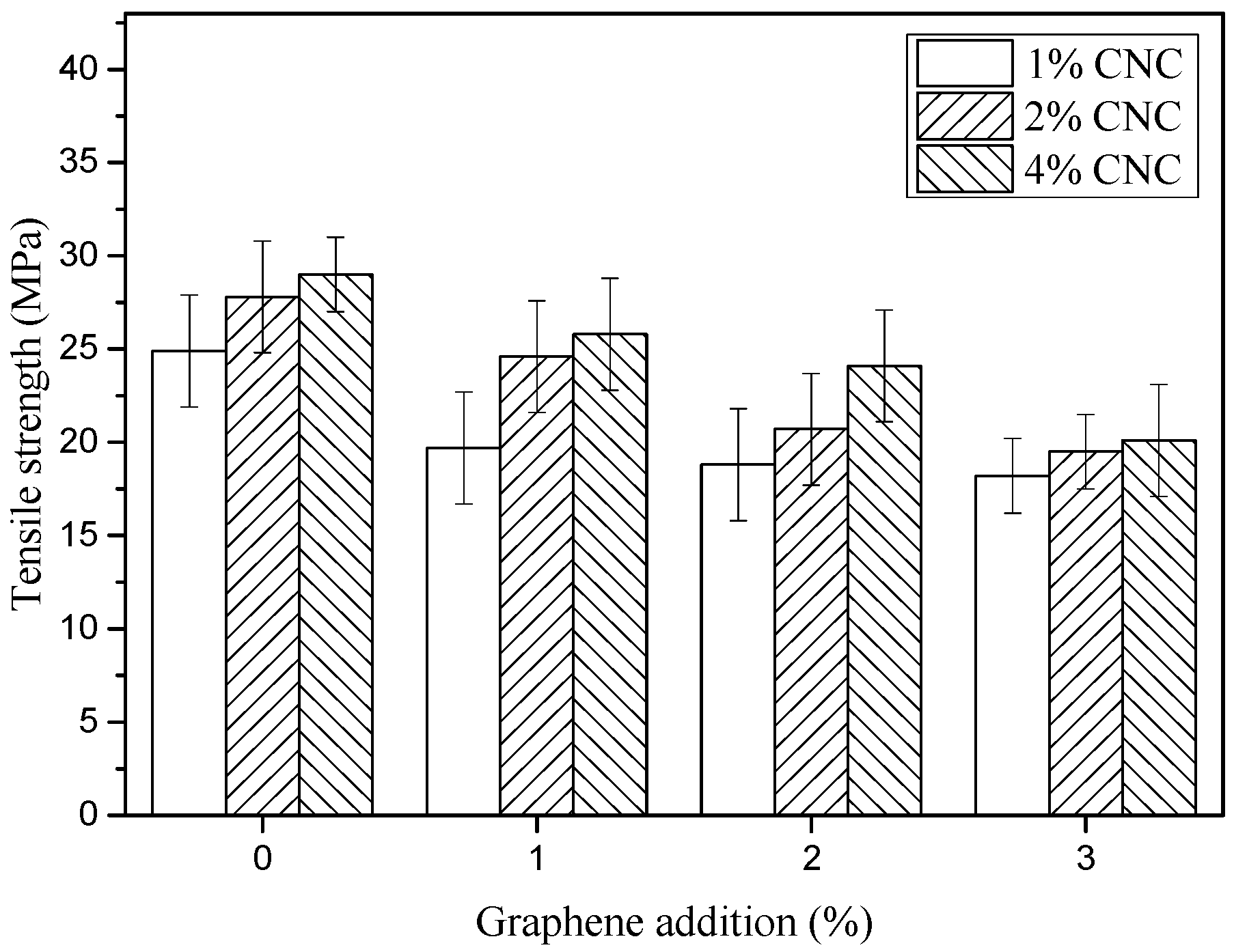

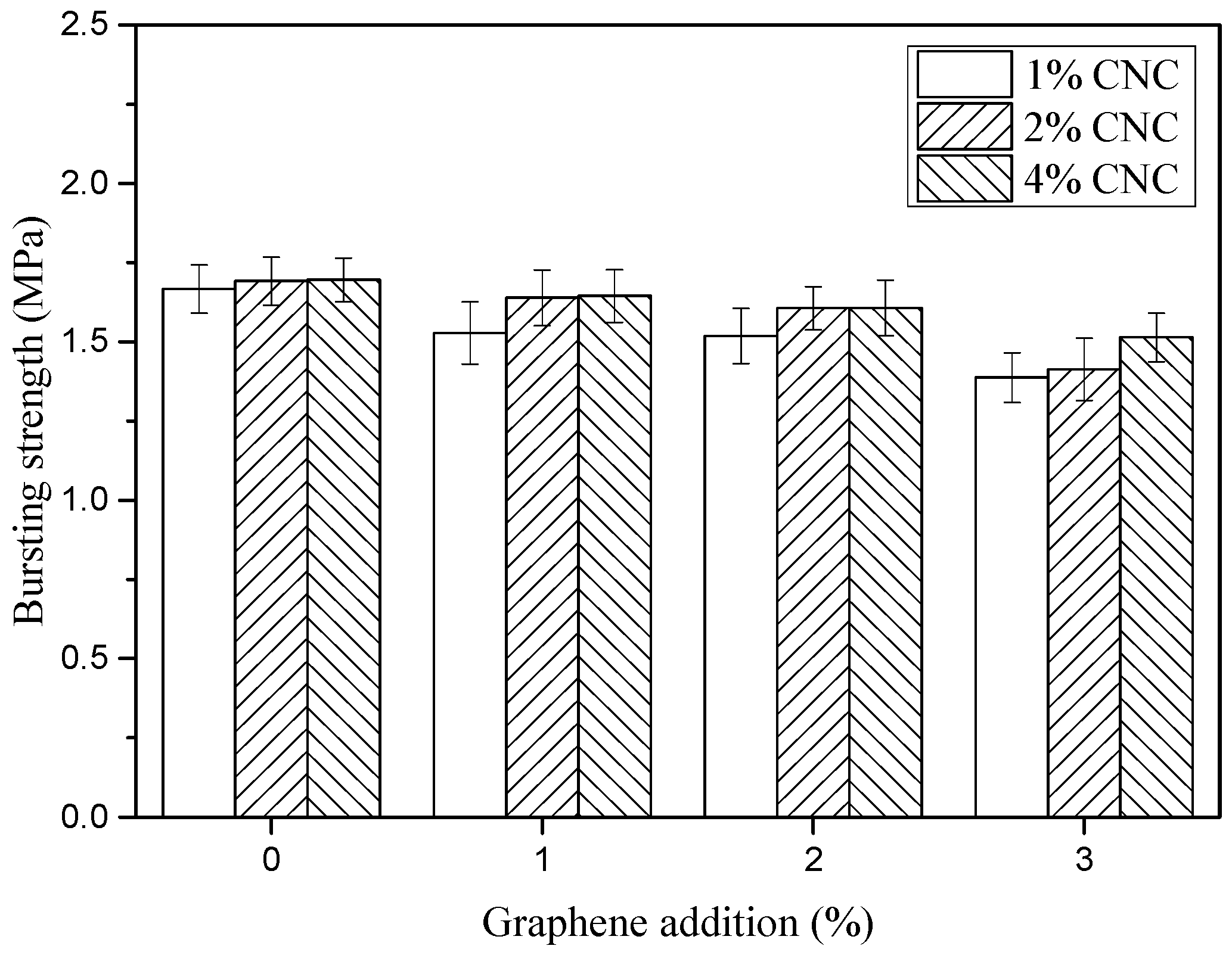

3.4. Tensile and Bursting Properties

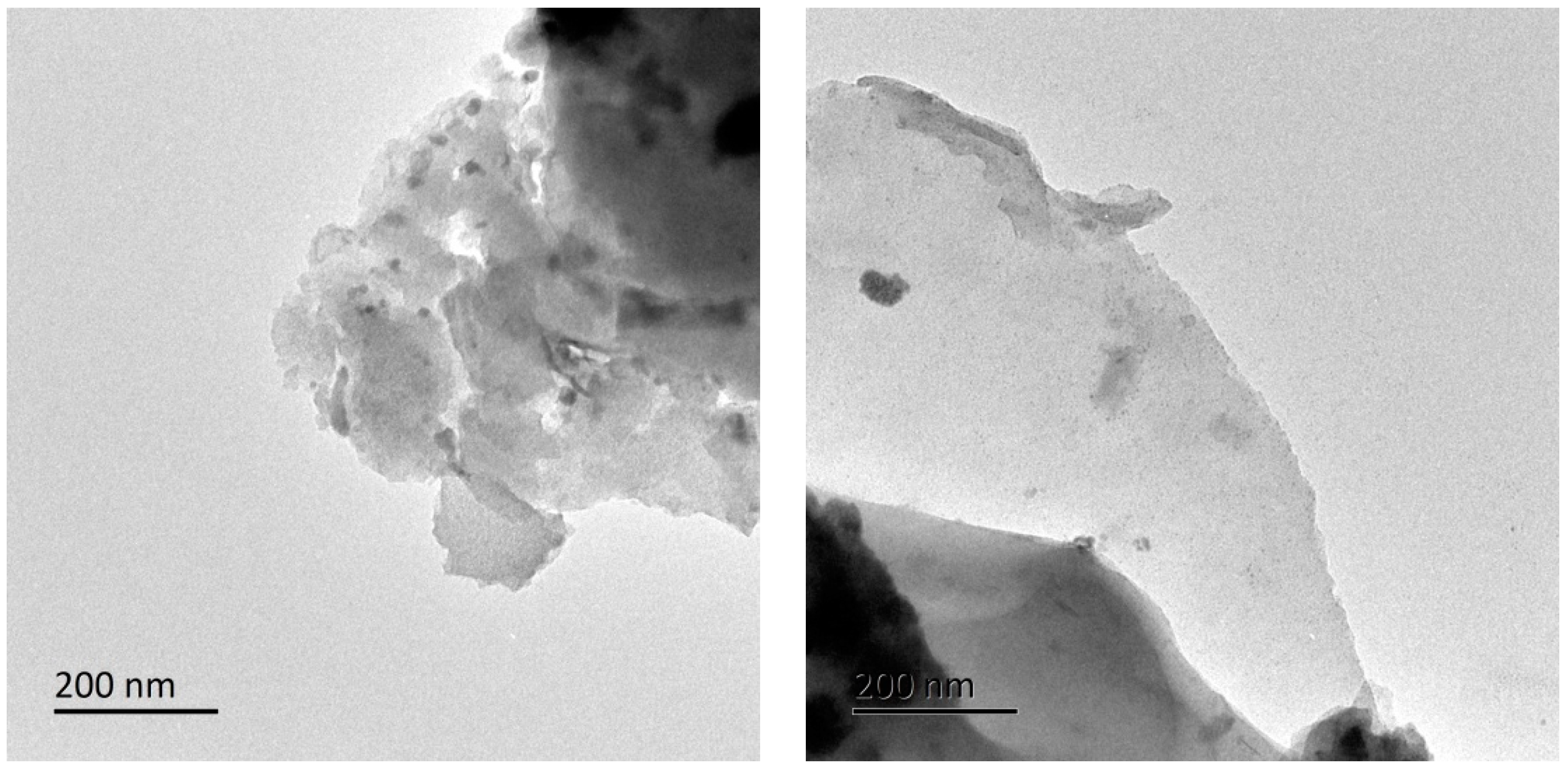

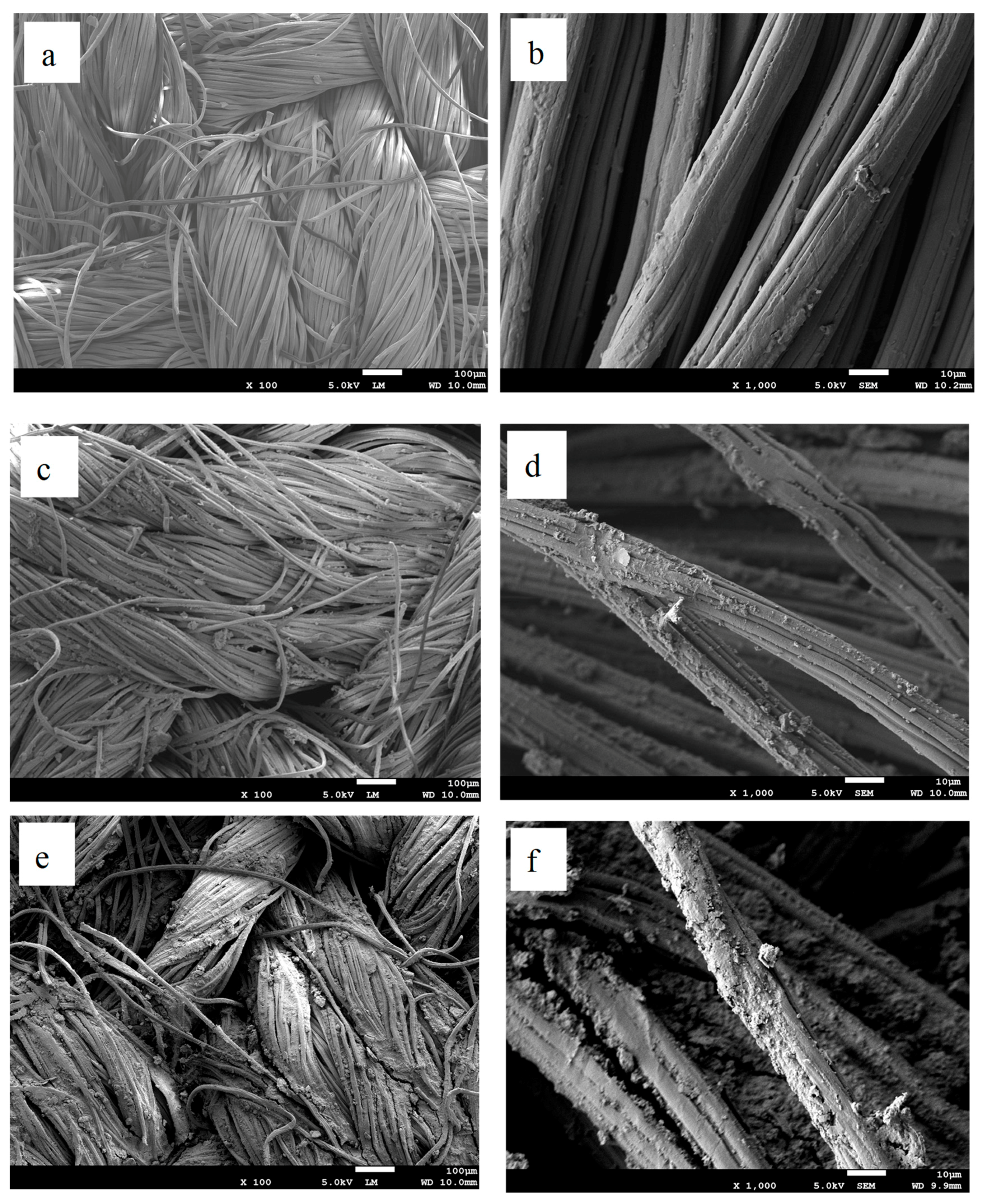

3.5. Morphology of Coated Bamboo Pulp Fabrics

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pérez, L.L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Soytas, U.; Sari, R. Energy consumption and GDP: Causality relationship in G-7 countries and emerging markets. Energy Econ. 2003, 25, 33–37. [Google Scholar] [CrossRef]

- Hsu, P.C.; Song, A.Y.; Catrysse, P.B.; Liu, C.; Peng, Y.; Xie, J.; Fan, S.; Cui, Y. Radiative human body cooling by nanoporous polyethylene textile. Science 2016, 353, 1019–1023. [Google Scholar] [CrossRef] [PubMed]

- Gao, T.; Yang, Z.; Chen, C.; Li, Y.; Fu, K.; Dai, J.; Hitz, E.M.; Xie, H.; Liu, B.; Song, J.; et al. Three-dimensional printed thermal regulation textiles. ACS Nano 2017, 11, 11513–11520. [Google Scholar] [CrossRef] [PubMed]

- Etheridge, M.A.; Wall, V.J.; Vernon, R.H. The role of the fluid phase during regional metamorphism and deformation. J. Metamorph. Geol. 2010, 1, 205–226. [Google Scholar] [CrossRef]

- Huang, C.; Juan He Du, L.; Min, D.; Yong, Q. Structural characterization of the lignins from the green and yellow bamboo of bamboo culm (Phyllostachys pubescens). J. Wood Chem. Technol. 2016, 36, 157–172. [Google Scholar] [CrossRef]

- Ming, L.; Wood, J.R.; Cathles, L.M. Prediction of thermal conductivity in reservoir rocks using fabric theory. J. Appl. Geophys. 1994, 32, 321–334. [Google Scholar]

- Che, J.; Cagin, T.; Goddard, W.A.I. Thermal conductivity of carbon nanotubes. Nanotechnology 2000, 11, 2083–2085. [Google Scholar] [CrossRef]

- Zalba, B.; Marín, J.M.; Cabeza, L.F.; Mehling, H. Review on thermal energy storage with phase change: materials, heat transfer analysis and applications. Appl. Therm. Eng. 2003, 23, 251–283. [Google Scholar] [CrossRef]

- Majumdar, A.; Mal, P.; Ghosh, A.; Banerjee, D. Multi-objective optimization of air permeability and thermal conductivity of knitted fabrics with desired ultraviolet protection. J. Text. Inst. 2016, 108, 7. [Google Scholar] [CrossRef]

- Rezaei, B.; Askari, M.; Shoushtari, A.M.; Malek, R.A.M. The effect of diameter on the thermal properties of the modeled shape-stabilized phase change nanofibers (PCNs). J. Therm. Anal. Calorim. 2014, 118, 1619–1629. [Google Scholar] [CrossRef]

- Yang, A.; Cai, L.; Zhang, R.; Wang, J.; Hsu, P.C.; Wang, H.; Zhou, G.; Xu, J.; Cui, Y. Thermal Management in Nanofiber-Based Face Mask. Nano Lett. 2017, 17, 3506–3510. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.; Lin, W.; Lai, C.; Li, X.; Jin, Y.; Yong, Q. Coupling the post-extraction process to remove residual lignin and alter the recalcitrant structures for improving the enzymatic digestibility of acid-pretreated bamboo residues. Bioresour. Technol. 2019, 258, 121355. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.; He, J.; Wang, Y.; Min, D.; Yong, Q. Associating cooking additives with sodium hydroxide to pretreat bamboo residues for improving the enzymatic saccharification and monosaccharides production. Bioresour. Technol. 2015, 193, 142–149. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Ge Cheng, H.; Tian, G.; Zheng, L.; Feng, X. Structures of bamboo fiber for textiles. Text. Res. J. 2010, 80, 334–343. [Google Scholar] [CrossRef]

- Zhang, G.; Lin, H.; Morikawa, H.; Miura, M. In-situ growth of ZnO particles on bamboo pulp fabric and its anti-UV property. Fibers Polym. 2013, 14, 1803–1807. [Google Scholar] [CrossRef]

- Qin, Z.Y.; Chen, Y.; Zhang, P.; Zhang, G.; Liu, Y. Structure and properties of Cu (II) complex bamboo pulp fabrics. J. Appl. Polym. Sci. 2010, 117, 1843–1850. [Google Scholar] [CrossRef]

- Majumdar, A.; Mukhopadhyay, S.; Yadav, R. Thermal properties of knitted fabrics made from cotton and regenerated bamboo cellulosic fibres. Int. J. Therm. Sci. 2010, 49, 2042–2048. [Google Scholar] [CrossRef]

- Xu, Y.; Lu, Z.; Tang, R. Structure and thermal properties of bamboo viscose, tencel and conventional viscose fiber. J. Therm. Anal. Calorim. 2007, 89, 197–201. [Google Scholar] [CrossRef]

- Mondal, S. Phase change materials for smart textiles—An overview. Appl. Therm. Eng. 2008, 28, 1536–1550. [Google Scholar] [CrossRef]

- Maity, S.; Chatterjee, A.; Singh, B.; Pal, S.A. Polypyrrole based electro-conductive textiles for heat generation. J. Text. Inst. Proc. Abstr. 2014, 105, 887–893. [Google Scholar] [CrossRef]

- Bashir, T.; Skrifvars, M.; Persson, N.K. Production of highly conductive textile viscose yarns by chemical vapor deposition technique: A route to continuous process. Polym. Adv. Technol. 2011, 22, 2214–2221. [Google Scholar] [CrossRef]

- Jang, J.; Park, H.C.; Lee, H.S.; Khil, M.S.; Kim, S.Y. Electrically and thermally conductive carbon fibre fabric reinforced polymer composites based on nanocarbons and an in-situ polymerizable cyclic oligoester. Sci. Rep. 2018, 8, 7659. [Google Scholar] [CrossRef] [PubMed]

- Cai, G.; Xu, Z.; Yang, M.; Tang, B.; Wang, X. Functionalization of cotton fabrics through thermal reduction of graphene oxide. Appl. Surf. Sci. 2017, 393, 441–448. [Google Scholar] [CrossRef]

- Zhang, J.; Li, B.C.; Wu, L.; Wang, A.Q. Facile preparation of durable and robust superhydrophobic textiles by dip coating in nanocomposite solution of organosilanes. Chem. Commun. 2013, 49, 11509–11511. [Google Scholar] [CrossRef] [PubMed]

- Yue, P.; Wang, S.; Li, X.; Ge, M. Preparation of polyaniline/Ag composite conductive fabric via one-step oxidation-reduction reaction. J. Text. Res. 2014, 60, 33–42. [Google Scholar]

- Yu, S.; Park, B.I.; Park, C.; Hong, S.M.; Han, T.H.; Koo, C.M. RTA-treated carbon fiber/copper core/shell hybrid for thermally conductive composites. ACS Appl. Mater. Interfaces 2014, 6, 7498–7503. [Google Scholar] [CrossRef] [PubMed]

- Mengal, N.; Sahito, I.A.; Arbab, A.A.; Sun, K.C.; Qadir, M.B.; Memon, A.A. Fabrication of a flexible and conductive lyocell fabric decorated with graphene nanosheets as a stable electrode material. Carbohydr. Polym. 2016, 152, 19–25. [Google Scholar] [CrossRef] [PubMed]

- Kongahge, D.; Foroughi, J.; Gambhir, S.; Spinks, G.M.; Wallace, G.G. Fabrication of a graphene coated nonwoven textile for industrial applications. RSC Adv. 2016, 6, 73203–73209. [Google Scholar] [CrossRef]

- Gan, L.; Shang, S.; Yuen, C.W.M.; Jiang, S.X. Graphene nanoribbon coated flexible and conductive cotton fabric. Compos. Sci. Technol. 2015, 117, 208–214. [Google Scholar] [CrossRef]

- Zhang, L.; Tang, P.; Zhang, W.; Xu, M.; Wang, Y. Effect of chitosan as a dispersant on collagen-hydroxyapatite composite matrices. Tissue Eng. Part C Methods 2010, 16, 71–79. [Google Scholar] [CrossRef] [PubMed]

- Posudievsky, O.Y.; Khazieieva, O.A.; Cherepanov, V.V.; Koshechko, V.G.; Pokhodenko, V.D. High yield of graphene by dispersant-free liquid exfoliation of mechanochemically delaminated graphite. J. Nanoparticle Res. 2013, 15, 2046. [Google Scholar] [CrossRef]

- Bin, W.U.; Yang, X. Molecular Simulation of Electrolyte-Induced Interfacial Interaction between SDS/Graphene Assemblies. J. Phys. Chem. C 2013, 117, 23216–23223. [Google Scholar]

- Lotya, M.; King, P.J.; Khan, U.; De, S.; Coleman, J.N. High-concentration, surfactant-stabilized graphene dispersions. ACS Nano 2010, 4, 3155–3162. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Wang, S.; Zhou, D.; Zhang, Y.; Wang, X.; Yang, R. Biodegradable polyvinyl alcohol nanocomposites made from rice straw fibrils: Mechanical and thermal properties. J. Comp. Mater. 2013, 47, 1449–1459. [Google Scholar] [CrossRef]

- Yan, Q.; Zhang, X.; Li, J.; Hassan, E.B.; Wang, C.; Zhang, J.; Cai, Z. Catalytic conversion of Kraft lignin to bio-multilayer graphene materials under different atmospheres. J. Mater. Sci. 2018, 53, 8020. [Google Scholar] [CrossRef]

- Huang, C.; Chu, Q.; Xie, Y.; Li, X.; Jin, Y.; Min, D.; Yong, Q. Effect of kraft pulping pretreatment on the chemical composition, enzymatic digestibility, and sugar release of moso bamboo residues. Bioresources 2015, 10, 240–255. [Google Scholar] [CrossRef]

- Tondi, G.; Thevenon, M.F.; Mies, B.; Standfest, G.; Petutschnigg, A.; Wieland, S. Impregnation of Scots pine and beech with tannin solutions: Effect of viscosity and wood anatomy in wood infiltration. Wood Sci. Technol. 2013, 47, 615–626. [Google Scholar] [CrossRef]

- Montes, S.; Carrasco, P.M.; Ruiz, V.; Germán, C.; Odriozola, I. Synergistic reinforcement of poly(vinyl alcohol) nanocomposites with cellulose nanocrystal-stabilized graphene. Comp. Sci. Technol. 2015, 117, 26–31. [Google Scholar] [CrossRef]

- Carrasco, P.M.; Montes, S.; García, I.; Borghei, M.; Jiang, H.; Odriozola, I. High-concentration aqueous dispersions of graphene produced by exfoliation of graphite using cellulose nanocrystals. Carbon 2014, 70, 157–163. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, H.; Lin, X.; Chen, S.; Jiang, Z.; Wang, J.; Huang, J.; Zhang, F.; Li, H. Naked Au nanoparticles monodispersed onto multifunctional cellulose nanocrystals-graphene hybrid sheets: Towards efficient and sustainable heterogeneous catalysts. New J. Chem. 2018, 42, 2197–2203. [Google Scholar] [CrossRef]

- Tao, X. Preparation and Thermal Conductivity of Modified Wood Impregnated by Graphene; Nanjing Forestry University: Nanjing, China, 2019; p. 84. [Google Scholar]

- Abbas, A.; Zhao, Y.; Zhou, J.; Wang, X.; Lin, T. Improving thermal conductivity of cotton fabrics using composite coatings containing graphene, multiwall carbon nanotube or boron nitride fine particles. Fibers Polym. 2013, 14, 1641–1649. [Google Scholar] [CrossRef]

- Zhang, L.; Becton, M.; Wang, X. Mechanical analysis of graphene-based woven nano-fabric. Mater. Sci. Eng. A 2015, 620, 367–374. [Google Scholar] [CrossRef]

- Fernandes, M.; Souto, A.P.; Esteves, M.F.; Bonastre, J.; Cases, F. Plasma treatment of polyester fabrics to increase the adhesion of reduced graphene oxide. Synth. Metals 2015, 202, 110–122. [Google Scholar]

- Kim, H.; Lee, S. Characteristics of Electrical Heating Elements Coated with Graphene Nanocomposite on Polyester Fabric: Effect of Different Graphene Contents and Annealing Temperatures. Fibers Polym. 2018, 19, 965–976. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, F.; Lan, C.; Zhang, H.; Guan, J.; Zhang, F.; Fei, B.; Zhang, J. Study on Graphene/CNC-Coated Bamboo Pulp Fabric Preparation of Fabrics with Thermal Conductivity. Polymers 2019, 11, 1265. https://doi.org/10.3390/polym11081265

Yang F, Lan C, Zhang H, Guan J, Zhang F, Fei B, Zhang J. Study on Graphene/CNC-Coated Bamboo Pulp Fabric Preparation of Fabrics with Thermal Conductivity. Polymers. 2019; 11(8):1265. https://doi.org/10.3390/polym11081265

Chicago/Turabian StyleYang, Feng, Cuiqin Lan, Haiming Zhang, Jian Guan, Fan Zhang, Benhua Fei, and Jilei Zhang. 2019. "Study on Graphene/CNC-Coated Bamboo Pulp Fabric Preparation of Fabrics with Thermal Conductivity" Polymers 11, no. 8: 1265. https://doi.org/10.3390/polym11081265

APA StyleYang, F., Lan, C., Zhang, H., Guan, J., Zhang, F., Fei, B., & Zhang, J. (2019). Study on Graphene/CNC-Coated Bamboo Pulp Fabric Preparation of Fabrics with Thermal Conductivity. Polymers, 11(8), 1265. https://doi.org/10.3390/polym11081265