Improvement of the Rubbing Fastness of Cotton Fiber in Indigo/Silicon Non-Aqueous Dyeing Systems

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Indigo Dyeing of Cotton Fiber

2.3. Fixing Method

2.4. Softening Finishing Method

2.5. Color Measurement

2.6. Rubbing Fastness

2.7. Friction Coefficient Analysis of Cotton Fiber

2.8. Scanning Electron Microscope Analysis (SEM)

3. Results and Discussion

3.1. Dyeing Performance of Indigo in Silicon Non-Aqueous Dyeing System

3.2. Influence of Temperature on the Indigo Dyeing Performance

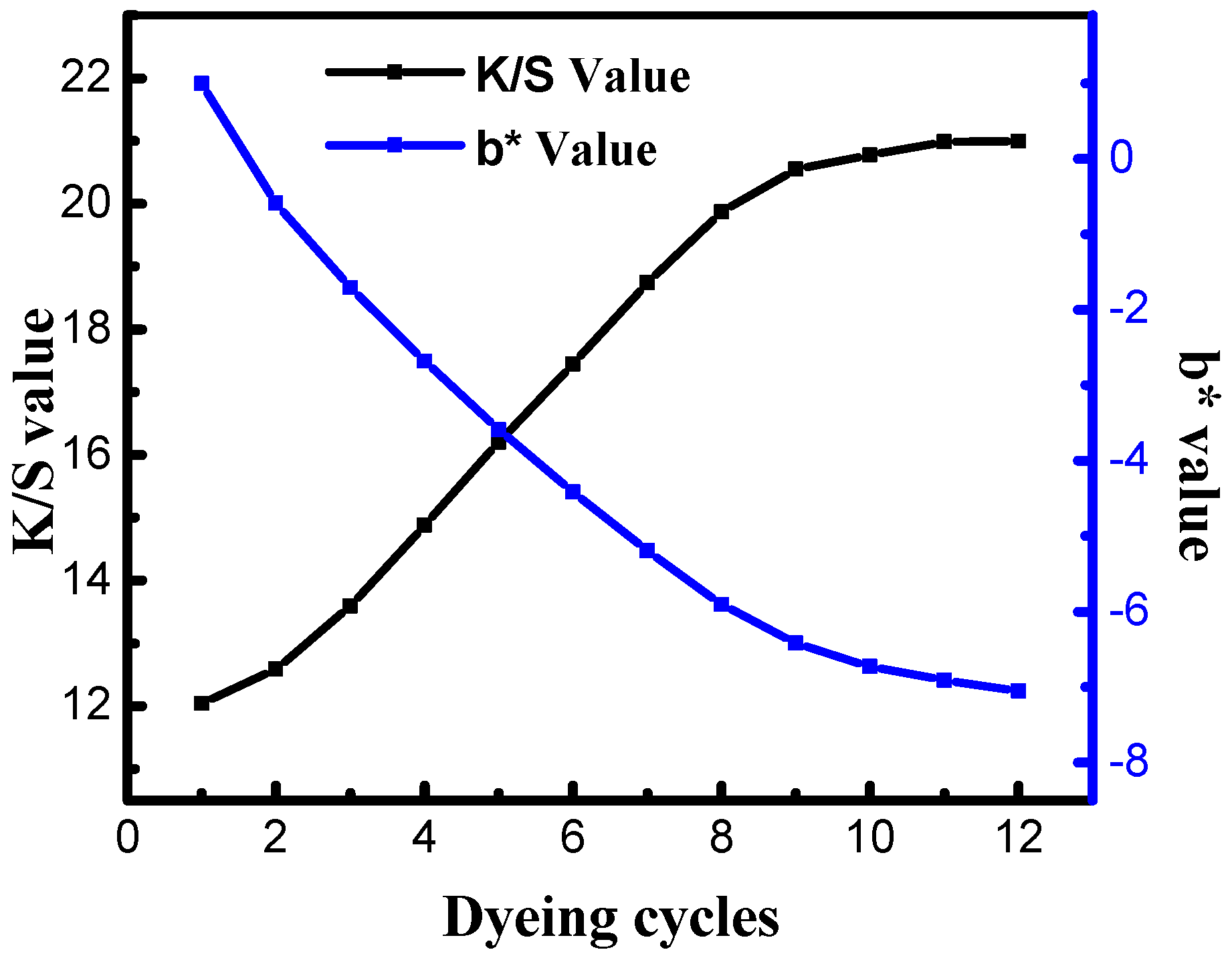

3.3. Influence of Dyeing Cycles on the Indigo Dyeing Performance in Silicon Non-Aqueous Medium Dyeing System

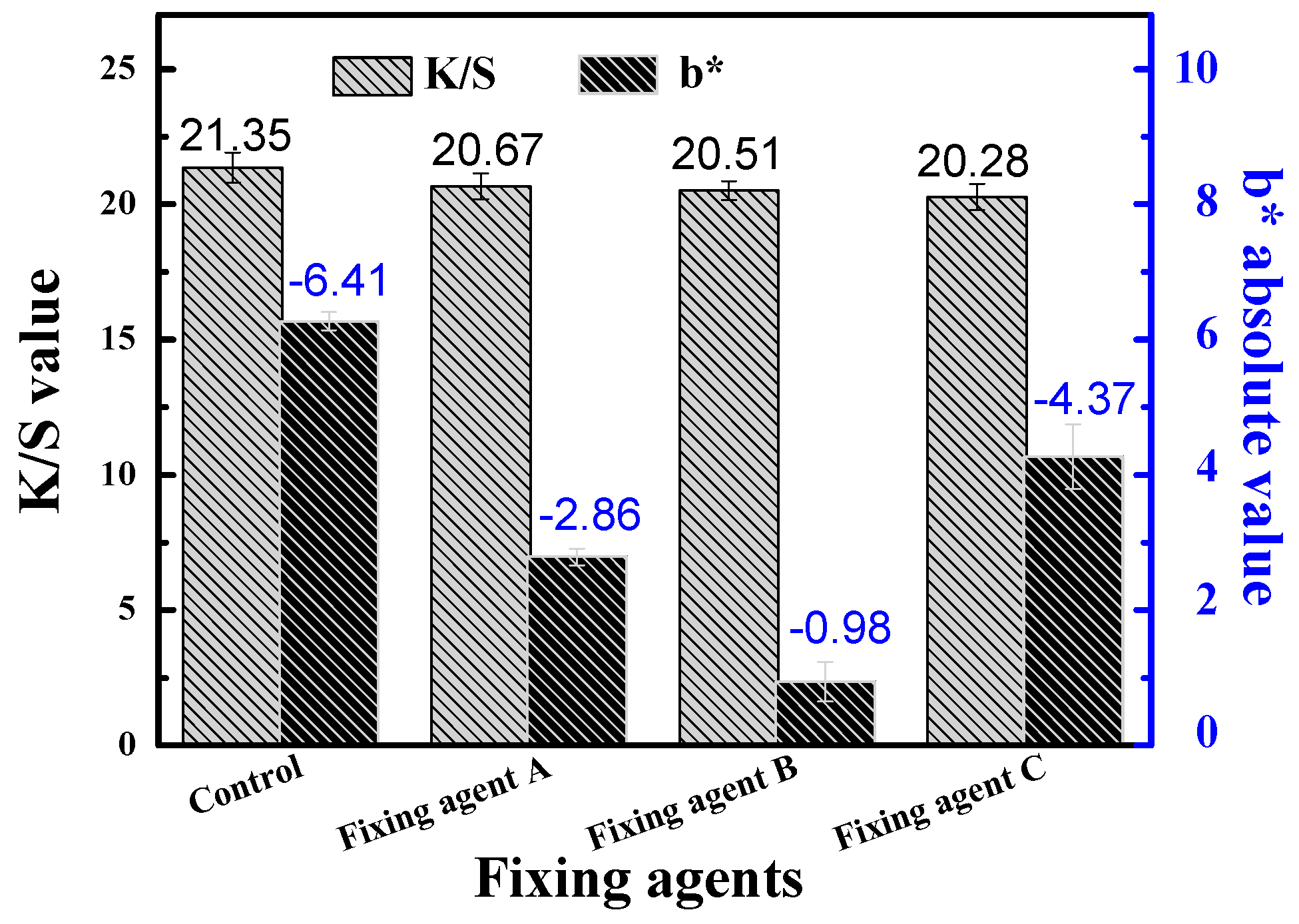

3.4. Effect of Fixing Finishing on the Rubbing Fastness of Dyed Cotton Fiber

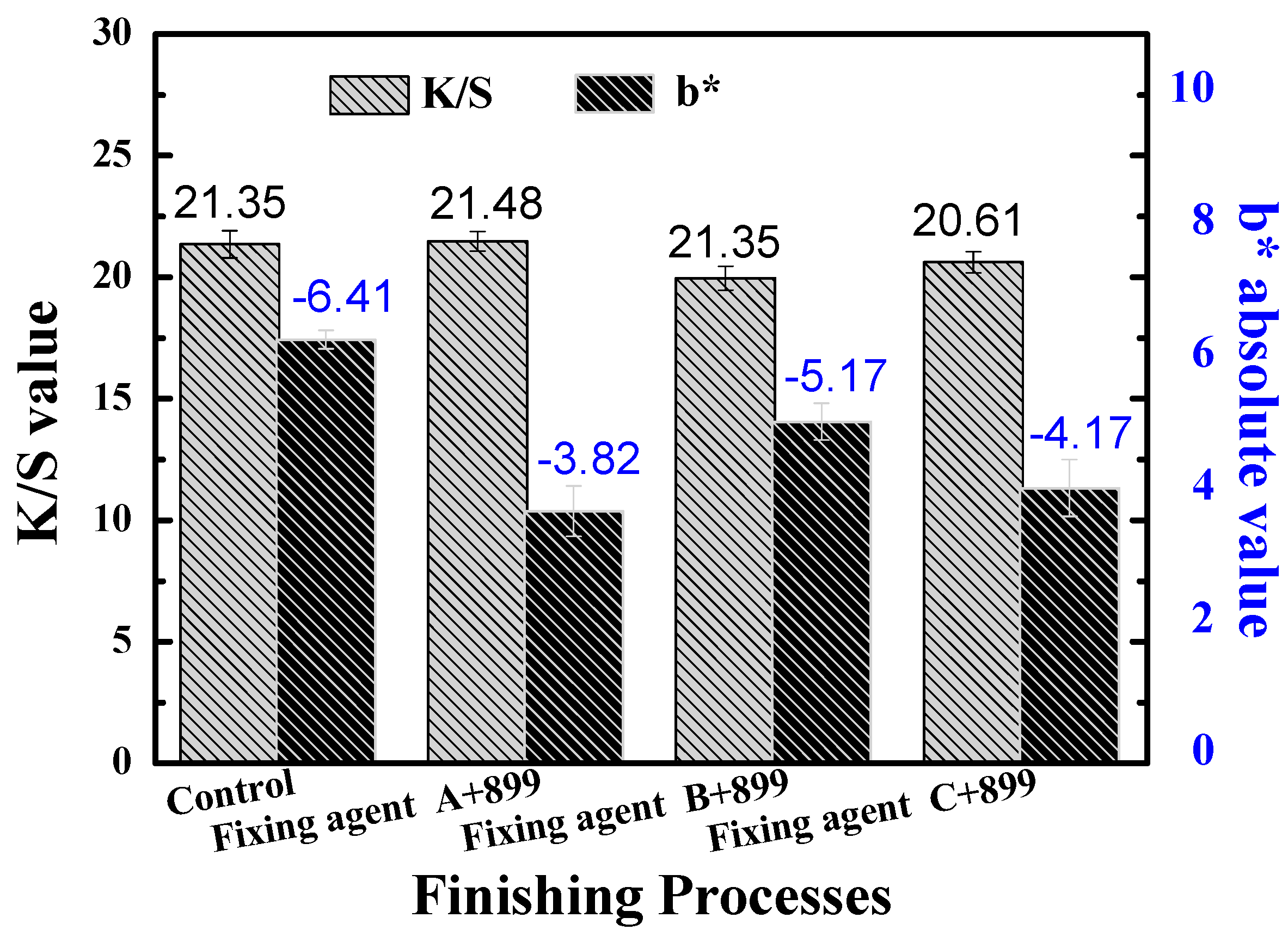

3.5. Effect of Soften Finishing on the Rubbing Fastness of Dyed Cotton Fiber

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Heikinheimo, L.; Buchert, J.; Miettinen-Oinonen, A.; Suominen, P. Treating denim fabrics with Trichoderma reesei cellulases. Text. Res. J. 2000, 70, 969–973. [Google Scholar] [CrossRef]

- Pazarlioğlu, N.K.; Sariişik, M.; Telefoncu, A. Treating denim fabrics with immobilized commercial cellulases. Process Biochem. 2005, 40, 767–771. [Google Scholar] [CrossRef]

- Ghoranneviss, M.; Moazzenchi, B.; Shahidi, S.; Anvari, A.; Rashidi, A. Decolorization of denim fabrics with cold plasmas in the presence of magnetic fields. Plasma Process. Polym. 2006, 3, 316–321. [Google Scholar] [CrossRef]

- Meksi, N.; Ticha, M.B.; Kechida, M.; Kechida, M.; Mhenni, M.F. Using of ecofriendly α-hydroxycarbonyls as reducing agents to replace sodium dithionite in indigo dyeing processes. J. Clean. Prod. 2012, 24, 149–158. [Google Scholar] [CrossRef]

- Yao, J.; Liu, X. Optimization of indigo dyeing system on cotton fabrics. Text. Res. J. 2013, 39, 840–845. [Google Scholar]

- Etters, J.N. Advances in indigo dyeing: Implications for the dyer, apparel manufacturer and environment. Text. Chem. Color. 1995, 27, 17–22. [Google Scholar]

- Cole, G.S. Cole’s Encyclopedia of Dry Goods: A Reference Book for the Wholesale and Retail Dry Goods Trade of the United States, Containing a Descriptive List of All the Standard Fabrics, Garments, and Related Articles of Merchandise… with a History of Cotton, Silk, Wool, Flax, Jute, Ramie, Hemp and Other Commercial Fibers, and a Full Description of the Processes of Carding, Spinning, Weaving, Bleaching, Dyeing and Printing; Root Newspaper Association of America: Chicago, IL, USA; New York, NY, USA, 1900. [Google Scholar]

- Venkatraman, P.D.; Liauw, C.M. Use of a carbon dioxide laser for environmentally beneficial generation of distressed/faded effects on indigo dyed denim fabric: Evaluation of colour change, fibre morphology, degradation and textile properties. Opt. Laser Technol. 2019, 111, 701–713. [Google Scholar] [CrossRef]

- Mcqueen, R.H.; Batcheller, J.C.; Moran, L.J.; Zhang, H.; Hooper, P.M. Reducing laundering frequency to prolong the life of denim jeans. Int. J. Consum. Stud. 2017, 41, 36–45. [Google Scholar] [CrossRef]

- Xin, J.H.; Chong, C.L.; Tu, T. Colour variation in the dyeing of denim yarn with indigo. Color. Technol. 2000, 116, 260–265. [Google Scholar] [CrossRef]

- Surita, S.C.; Tansel, B. Emergence and fate of cyclic volatile polydimethylsiloxanes (D4, D5) in municipal waste streams: Release mechanisms, partitioning and persistence in air, water, soil and sediments. Sci. Total Environ. 2014, 468, 46–52. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Y.; Dou, H.; Pei, L. Influence of Ethylene Oxide Content in Nonionic Surfactant to the Hydrolysis of Reactive Dye in Silicone Non-Aqueous Dyeing System. Polymers 2018, 10, 1158. [Google Scholar] [CrossRef]

- Pei, L.; Liu, J.; Wang, J. Study of Dichlorotriazine Reactive Dye Hydrolysis in Siloxane Reverse Micro-emulsion. J. Clean. Prod. 2017, 165, 994–1004. [Google Scholar] [CrossRef]

- Miao, H.; Liu, J.; Li, Y.; Fu, C.; Zhang, Y. Study on hydrolysis kinetics of reactive dyes in dye/D5 suspending system. Text. Res. J. 2013, 34, 77–82. [Google Scholar]

- Li, D.; Li, X.; Liu, J.; Wang, L.; Shao, J. Indigo dye/D5 system for cotton fiber dyeing. Dyeing. Finish. 2016, 4, 9–13. [Google Scholar]

- Miettinen-Oinonen, A.; Suominen, P. Enhanced production of trichoderma reesei endoglucanases and use of the new cellulase preparations in producing the stonewashed effect on denim fabric. Appl. Environ. Microbiol. 2002, 68, 3956–3964. [Google Scholar] [CrossRef]

- Campbell, B.; Inkumsah, S.E.; Tandoh, W.C. The fastness of indigo and topped indigo dyeings on wool cloth. Color. Technol. 2010, 80, 583–587. [Google Scholar] [CrossRef]

- Zarkogianni, M.; Mikropoulou, E.; Varella, E.; Tsatsaroni, E. Colour and fastness of natural dyes: Revival of traditional dyeing techniques. Color. Technol. 2011, 127, 18–27. [Google Scholar] [CrossRef]

- Son, Y.A.; Hong, J.P.; Kim, T.K. An approach to the dyeing of polyester fiber using indigo and its extended wash fastness properties. Dyes Pigment. 2004, 61, 263–272. [Google Scholar] [CrossRef]

- Fang, K.; Shu, D.; Liu, X.; Cai, Y.; An, F.; Zhang, X. Reactive pad-steam dyeing of cotton fabric modified with cationic P (St-BA-VBT) nanospheres. Polymers 2018, 10, 564. [Google Scholar] [CrossRef]

- Colorfastness to Crocking: AATCC Crockmeter Method. AATCC Test Method 8-2007. Available online: www. max.book118.com (accessed on 3 February 2019).

- Gebert, B.; Saus, W.; Knittel, D.; Buschmann, H.J.; Schollmeyer, E. Dyeing natural fibers with disperse dyes in supercritical carbon dioxide. Text. Res. J. 1994, 64, 371–374. [Google Scholar] [CrossRef]

- Mantanis, G.I.; Young, R.A.; Rowell, R.M. Swelling of compressed cellulose fiber webs in organic liquids. Cellulose 1995, 2, 1–22. [Google Scholar]

- Gusakov, A.V.; Sinitsyn, A.P.; Markov, A.V.; Sinitsyna, O.A.; Ankudimova, N.V.; Berlin, A.G. Study of protein adsorption on indigo particles confirms the existence of enzyme–indigo interaction sites in cellulase molecules. J. Biotechnol. 2001, 87, 83–90. [Google Scholar] [CrossRef]

- Meksi, N.; Kechida, M.; Mhenni, F. Cotton dyeing by indigo with the borohydride process: Effect of some experimental conditions on indigo reduction and dyeing quality. Chem. Eng. J. 2007, 131, 187–193. [Google Scholar] [CrossRef]

- Radetić, M.; Jovančić, P.; Puač, N.; Petrović, Z.L.; Šaponjić, Z. Plasma-induced decolorization of indigo-dyed denim fabrics related to mechanical properties and fiber surface morphology. Text. Res. J. 2009, 79, 558–565. [Google Scholar] [CrossRef]

- Correia, M.S.; Miranda, A.S.; Oliveira, M.C.; Capela, C.A.; Pouzada, A.S. Analysis of friction in the ejection of thermoplastic mouldings. Int. J. Adv. Manuf. Technol. 2012, 59, 977–986. [Google Scholar] [CrossRef]

- Jeevarathinam, A.S.; Pai, N.; Huang, K.; Hariri, A.; Wang, J.; Bai, Y.; Jokerst, J.V.; Wang, L.; Hancock, T.; Keys, S.; et al. A cellulose-based photoacoustic sensor to measure heparin concentration and activity in human blood samples. Biosens. Bioelectron. 2019, 126, 831–837. [Google Scholar] [CrossRef]

- Teidelt, E.; Starcevic, J.; Popov, V.L. Influence of ultrasonic oscillation on static and sliding friction. Tribol. Lett. 2012, 48, 51–62. [Google Scholar] [CrossRef]

- Fu, X.; Maruyama, T.; Sotani, T.; Matsuyama, H. Effect of surface morphology on membrane fouling by humic acid with the use of cellulose acetate butyrate hollow fiber membranes. J. Membr. Sci. 2008, 320, 483–491. [Google Scholar] [CrossRef]

- Acharya, S.; Abidi, N.; Rajbhandari, R.; Meulewaeter, F. Chemical cationization of cotton fabric for improved dye uptake. Cellulose 2014, 21, 4693–4706. [Google Scholar] [CrossRef]

- Rao, W.H.; Xu, H.X.; Xu, Y.J.; Qi, M.; Liao, W.; Xu, S.; Wang, Y.Z. Persistently flame-retardant flexible polyurethane foams by a novel phosphorus-containing polyol. Chem. Eng. J. 2018, 343, 198–206. [Google Scholar] [CrossRef]

- Ibrahim, N.A.; Fahmy, H.M.; Hassan, T.M.; Mohamed, Z.E. Effect of cellulase treatment on the extent of post-finishing and dyeing of cotton fabrics. J. Mater. Process. Technol. 2005, 160, 99–106. [Google Scholar] [CrossRef]

- Jatoi, A.W.; Khatri, Z.; Ahmed, F.; Memon, M.H. Effect of Silicone Nano, Nano/Micro and Nano/Macro-Emulsion Softeners on Color Yield and Physical Characteristics of Dyed Cotton Fabric. J. Surfactants Deterg. 2015, 18, 205–211. [Google Scholar] [CrossRef]

| Dyeing System | Dyeing Cycle | K/S Value | Rubbing Fatness | L* | a* | b* (Cotton Fiber) |

|---|---|---|---|---|---|---|

| water | 12 | 20.10 | 3 | 20.79 | 2.84 | −10.64 |

| silicon | 1 | 25.94 | 2~3 | 17.39 | 2.34 | −14.92 |

| Control Sample | Dyed Cotton Fiber | Fixing Agent A | Fixing Agent B | Fixing Agent C | |

|---|---|---|---|---|---|

| fs | 57.20 | 65.51 | 63.74 | 61.31 | 63.86 |

| us | 0.0196 | 0.0224 | 0.0214 | 0.0212 | 0.0216 |

| fa | 52.72 | 60.57 | 57.59 | 56.31 | 59.03 |

| ua | 0.0163 | 0.0197 | 0.0191 | 0.0189 | 0.0194 |

| Sample | Dyed Cotton Fiber | Fixing Finishing | Fixing Finishing and Soften Finishing (899) | ||||

|---|---|---|---|---|---|---|---|

| Fixing Agent A | Fixing Agent B | Fixing Agent C | Fixing Agent A | Fixing Agent B | Fixing Agent C | ||

| Handle | rough | rough | soft | rough | soft | soft | soft |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, Y.; Pei, L.; Zhang, H.; Zhong, Q.; Wang, J. Improvement of the Rubbing Fastness of Cotton Fiber in Indigo/Silicon Non-Aqueous Dyeing Systems. Polymers 2019, 11, 1854. https://doi.org/10.3390/polym11111854

Luo Y, Pei L, Zhang H, Zhong Q, Wang J. Improvement of the Rubbing Fastness of Cotton Fiber in Indigo/Silicon Non-Aqueous Dyeing Systems. Polymers. 2019; 11(11):1854. https://doi.org/10.3390/polym11111854

Chicago/Turabian StyleLuo, Yuni, Liujun Pei, Hongjuan Zhang, Qi Zhong, and Jiping Wang. 2019. "Improvement of the Rubbing Fastness of Cotton Fiber in Indigo/Silicon Non-Aqueous Dyeing Systems" Polymers 11, no. 11: 1854. https://doi.org/10.3390/polym11111854

APA StyleLuo, Y., Pei, L., Zhang, H., Zhong, Q., & Wang, J. (2019). Improvement of the Rubbing Fastness of Cotton Fiber in Indigo/Silicon Non-Aqueous Dyeing Systems. Polymers, 11(11), 1854. https://doi.org/10.3390/polym11111854