The Microstructure of Yellow River Ice in the Freezing Period

Abstract

:1. Introduction

2. Materials and Methods

2.1. Yellow River Ice Materials Preparation

2.2. Preparation of Ice Crystal Slices

2.3. Observation Method for Ice Crystals

3. Results

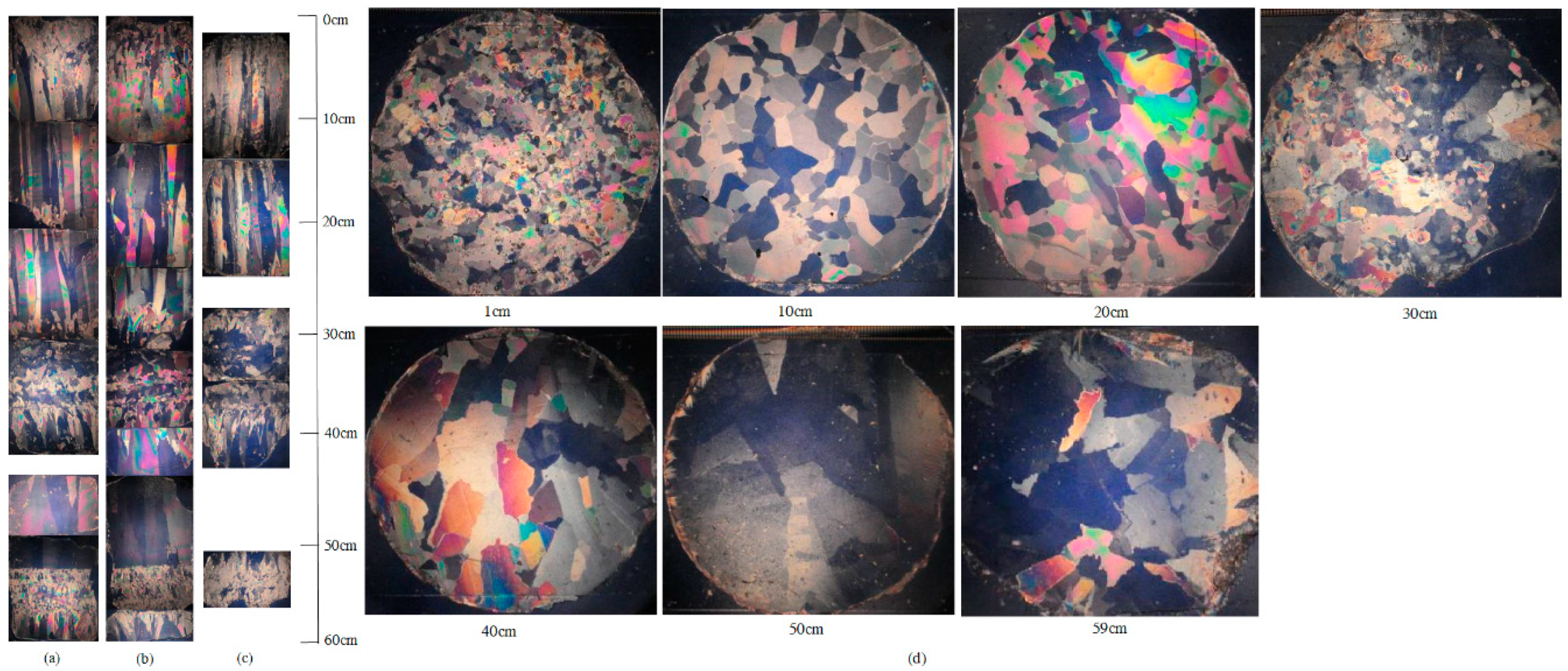

3.1. Ice Microstructure

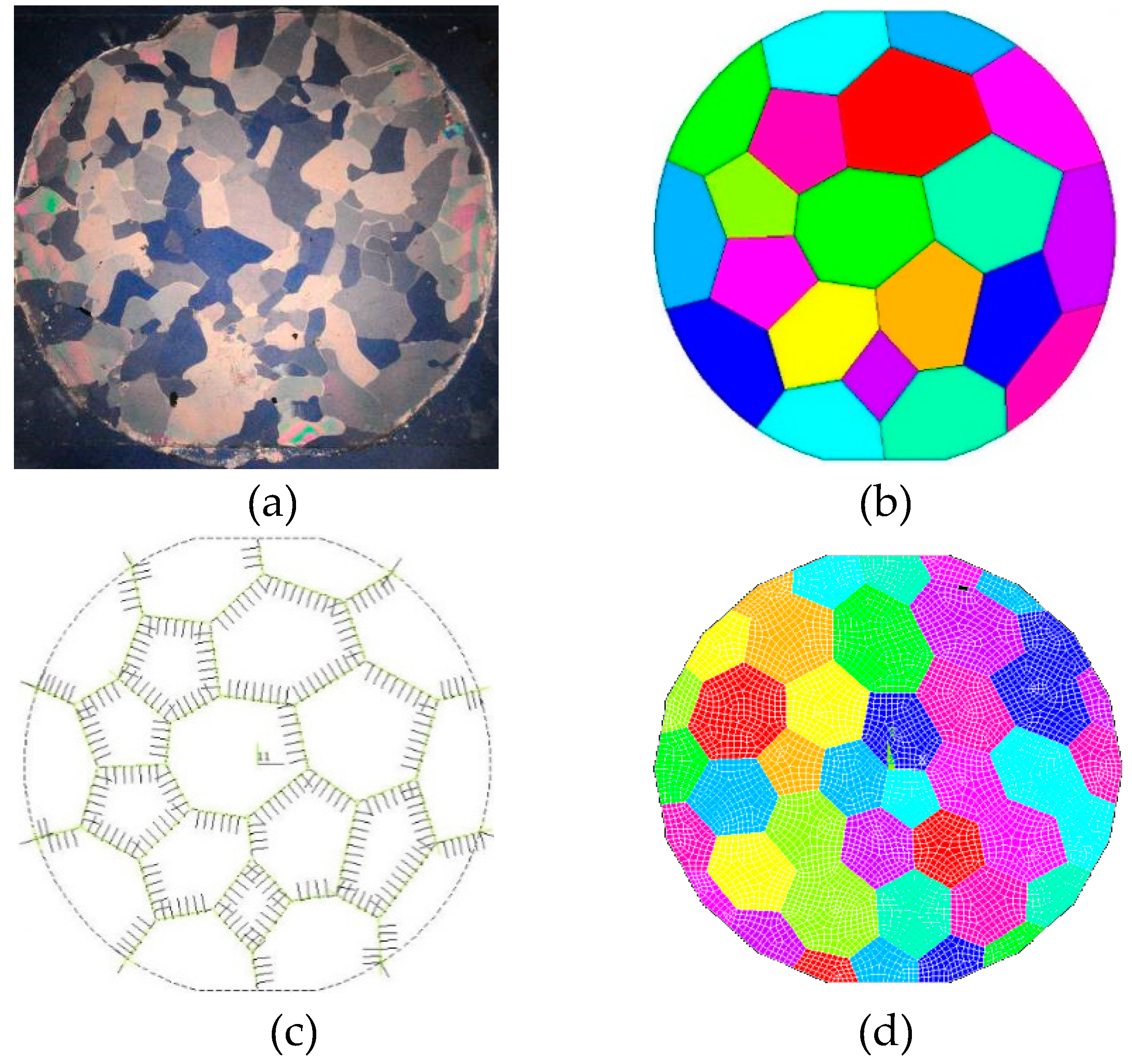

3.2. Ice Crystal Shape and Size

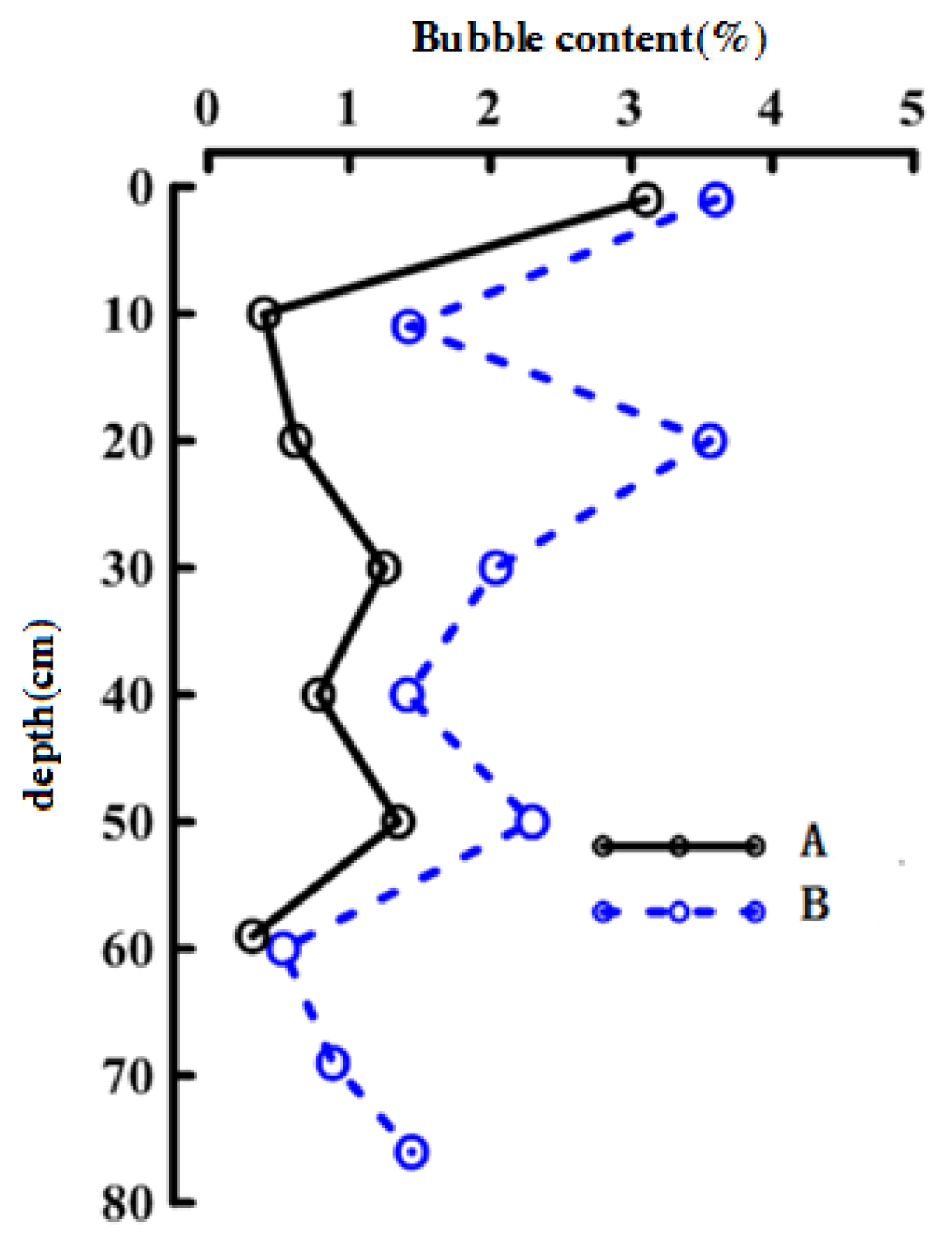

3.3. Initial Defects in Ice Crystals

4. Discussion

4.1. Ice Microstructure Changes in Different Locations

4.2. Granular Ice Crystals and Columnar Ice Crystals

4.3. Microstructure Model of Yellow River Ice

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cole, D.M. Effect of grain size on the internal fracturing of polycrystalline ice. Cold Reg. Res. Eng. Lab. Hanover Nh Rep. 1986, 4, 35–40. [Google Scholar]

- Cole, D.M. Crack nucleation in polycrystalline ice. Cold Reg. Sci. Technol. 1988, 15, 79–87. [Google Scholar] [CrossRef]

- Liu, F.P.; Baker, I.; Dudley, M. Dislocation-grain boundary interaction in ice under creep conditions. Int. Assoc. Hydraul. Res. Ice Symp. 1994, 1, 484–494. [Google Scholar]

- Baker, I.; Liu, F.; Dudley, M.; Black, D. In-situ synchrotron X-ray topographic studies of polycrystalline ice. Int. Assoc. Hydraul. Res. Ice Symp. 1994, 1, 416–425. [Google Scholar]

- Baker, I.; Cullen, D. SEM/EDS observations of impurities in polar ice: Artifacts or not? J. Glaciol. 2003, 49, 184–190. [Google Scholar] [CrossRef]

- Iliescu, D.; Baker, I. The structure and mechanical properties of river and lake ice. Cold Reg. Sci. Technol. 2007, 48, 202–217. [Google Scholar] [CrossRef]

- Currier, J.H.; Schulson, E.M. The tensile strength of ice as a function of grain size. Acta Metall. 1983, 30, 1511–1514. [Google Scholar] [CrossRef]

- Thorsteinsson, T.; Kipfstuhl, J.; Miller, H. Microstructures and fabrics in the GRIP ice core. J. Geophys. Res. 1997, 102, 26583–26599. [Google Scholar] [CrossRef]

- Benjamin, R.; Markus, J.; Rainer, G. Under-ice turbulent microstructure and upper ocean vertical fluxes in the Makarov and Eurasian Basins, Arctic Ocean, During Late Spring and Late Summer/Autumn in 2015. In Proceedings of the EGU General Assembly Conference, Vienna, Austria, 23–28 April 2017; Volume 19. [Google Scholar]

- Yuan, L.; Sepp, K.; Maohuan, H. Ice microstructure and fabric of Guliya ice cap in Tibetan plateau, and comparisons with vostok3G-1, EPICA DML, and north GRIP. Crystals 2017, 7, 97. [Google Scholar]

- Li, Y.; Du, Z.; Cunde, X. Analyzing characteristically on ice fabric and microstructure of Miaoergou glacier top-flatted, East Tangshan. J. Glaciol. Geocryol. 2017, 39, 273–280. [Google Scholar]

- RM, L.; EJ, G.; RW, O. Metrics for interpreting the microstructure of sea ice using X-ray micro-computed tomography. Cold Reg. Sci. Technol. 2017, 138, 24–35. [Google Scholar]

- Wang, G.; Huang, W.; Li, Z.; Jia, Q. Observations on the inner structures of Hongqi-pao reservoir ice in daqing. J. Heilongjiang Hydraul. Eng. 2009, 12, 75–79. [Google Scholar]

- Li, Z.; Jia, Q.; Huang, W. Characteristics of ice crystals bubbles and densities of fresh ice in a reservoir. J. Hydraul. Eng. 2009, 40, 1333–1338. [Google Scholar]

- Pervier, M.A.; Pervier, H.; Hammond, D.W. Observation of microstructures of atmospheric ice using a new replica technique. Cold Reg. Sci. Technol. 2017, 140, 54–57. [Google Scholar] [CrossRef] [Green Version]

- Deng, Y.; Wang, J.; Xiao, Z. The selection of microscopic parameters in building fracture microscopic model of River Ice. Yellow River 2017, 10, 27–31. [Google Scholar]

- Zhang, Y.; Gao, G.; Deng, Y.; Li, Z.; Li, G.; Guo, W. Investigation on ice crystal density and sediment content in ice at different positions in Bayannaoer section of the Yellow River. Yellow River 2018, 11, 44–48. [Google Scholar]

- Lebensohn, R.; Montagnat, M.; Mansuy, P.; Duval, P.; Meysonnier, J.; Philip, A. Modeling viscoplastic behavior and heterogeneous intracrystalline deformation of columnar ice polycrystals. Acta Mater. 2009, 57, 1405–1415. [Google Scholar] [CrossRef]

- Montagnat, M.; Castelnau, O.; Bons, P.; Faria, S.; Gagliardini, O.; Gillet-Chaulet, F. Multiscale modeling of ice deformation behavior. J. Struct. Geol. 2014, 61, 78–108. [Google Scholar] [CrossRef]

- Suquet, P.; Moulinec, H.; Castelnau, O.; Montagnat, M.; Lahellec, N.; Grennerat, F. Multi-scale modeling of the mechanical behavior of polycrystalline ice under transient creep. Procedia IUTAM 2012, 3, 76–90. [Google Scholar] [CrossRef] [Green Version]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, Y.; Li, Z.; Wang, J.; Xu, L. The Microstructure of Yellow River Ice in the Freezing Period. Crystals 2019, 9, 484. https://doi.org/10.3390/cryst9090484

Deng Y, Li Z, Wang J, Xu L. The Microstructure of Yellow River Ice in the Freezing Period. Crystals. 2019; 9(9):484. https://doi.org/10.3390/cryst9090484

Chicago/Turabian StyleDeng, Yu, Zongkun Li, Juan Wang, and Lukai Xu. 2019. "The Microstructure of Yellow River Ice in the Freezing Period" Crystals 9, no. 9: 484. https://doi.org/10.3390/cryst9090484

APA StyleDeng, Y., Li, Z., Wang, J., & Xu, L. (2019). The Microstructure of Yellow River Ice in the Freezing Period. Crystals, 9(9), 484. https://doi.org/10.3390/cryst9090484