The Microalloying Effect of Ce on the Mechanical Properties of Medium Entropy Bulk Metallic Glass Composites

Abstract

:1. Introduction

2. Materials and Methods

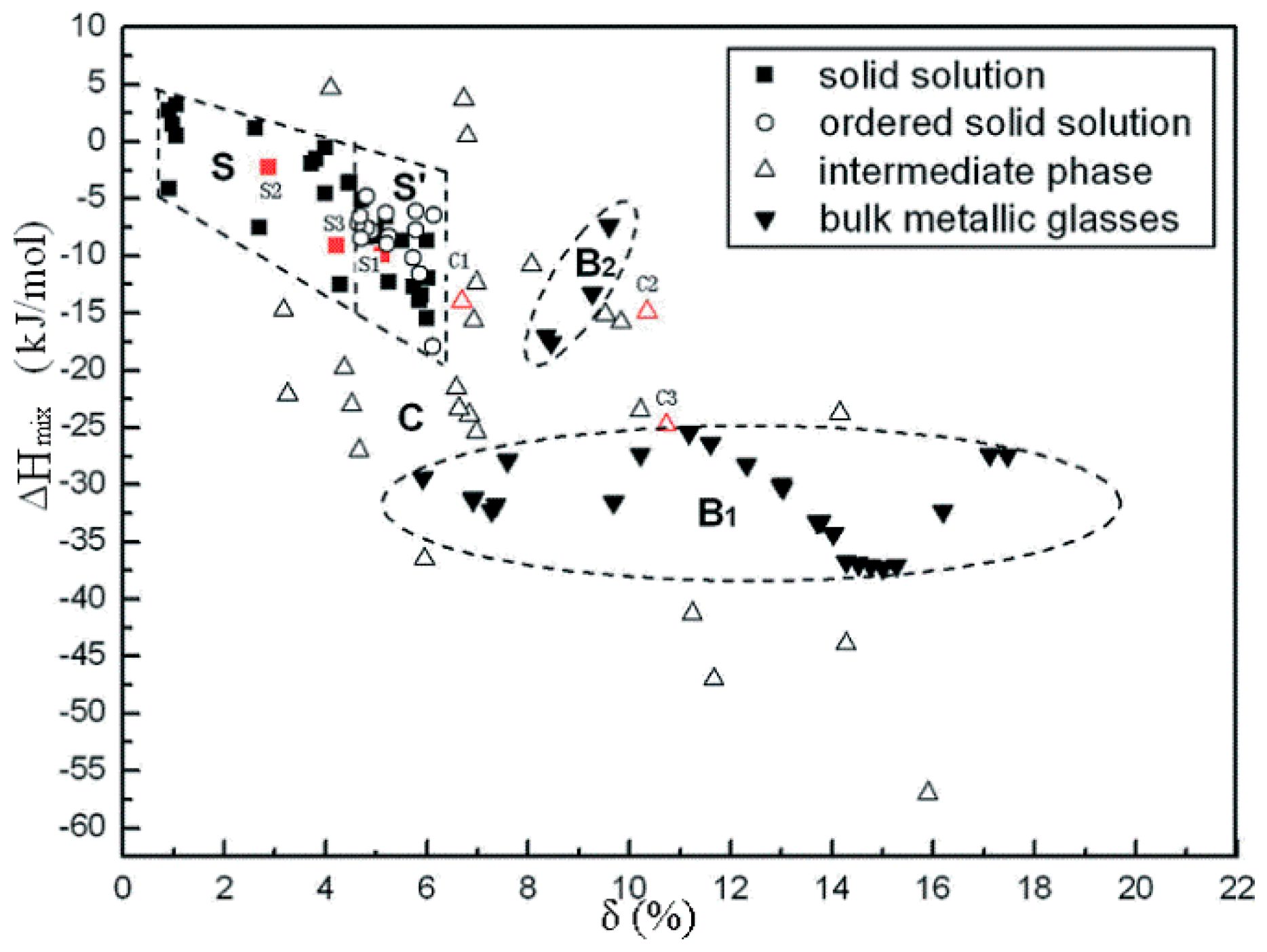

3. Results and Discussion

3.1. Microstructure of the Fe-Based and Ti-Based TRIP BMGCs

3.2. Mechanical Behaviors of the Fe-Based and Ti-Based TRIP BMGCs

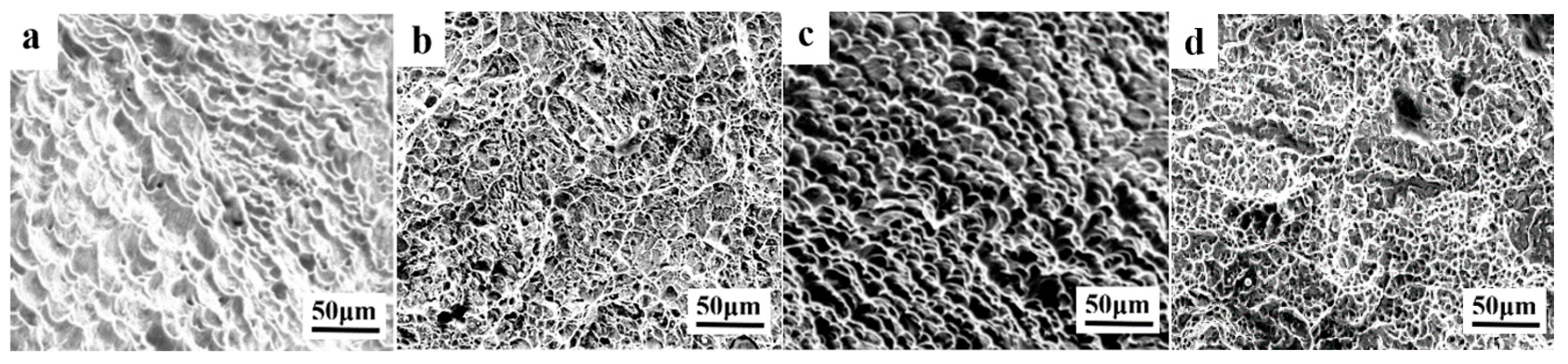

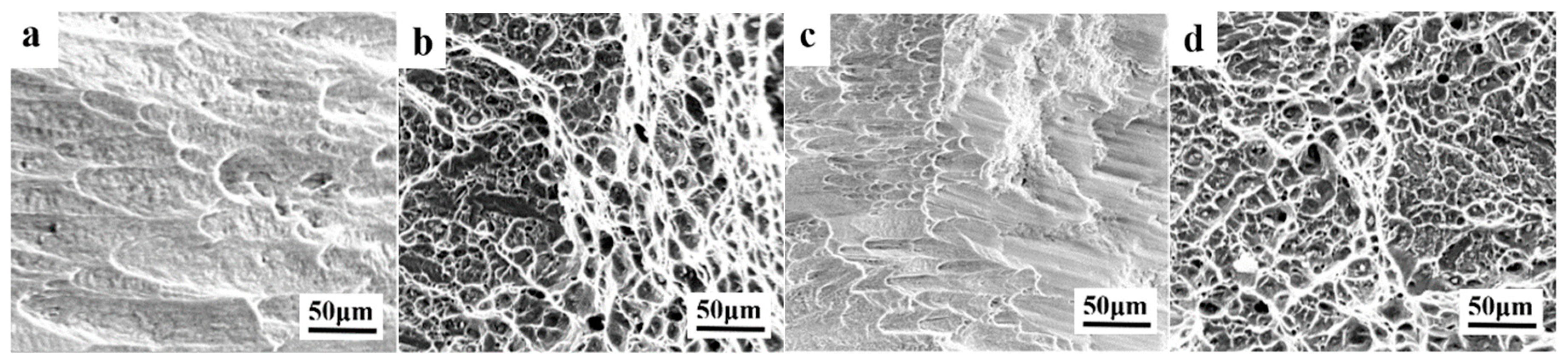

3.3. Fracture Morphology of the Fe-Based and Ti-Based TRIP BMGCs

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Qiao, J.C.; Wang, Q.; Pelletier, J.M.; Kato, H.; Casalini, R.; Crespo, D.; Pineda, E.; Yao, Y.; Yang, Y. Structural heterogeneities and mechanical behavior of amorphous alloys. Prog. Mater. Sci. 2019, 104, 250. [Google Scholar] [CrossRef]

- Wang, W.H. Bulk metallic glasses with functional physical properties. Adv. Mater. 2009, 21, 4524. [Google Scholar] [CrossRef]

- Qiao, J.W.; Jia, H.L.; Liaw, P.K. Metallic glass matrix composites. Mater. Sci. Eng. R Rep. 2016, 100, 1–69. [Google Scholar] [CrossRef] [Green Version]

- Schuh, C.A.; Hufnagel, T.C.; Ramamurty, U. Mechanical behavior of amorphous alloys. Acta Mater. 2007, 55, 4067. [Google Scholar] [CrossRef]

- Schroers, J. Processing of bulk metallic glass. Adv. Mater. 2010, 22, 1566. [Google Scholar] [CrossRef] [PubMed]

- Lazzara, G.; Cavallaro, G.; Panchal, A.; Fakhrullin, R.; Stavitskaya, A.; Vinokurov, V.; Lvov, Y. An assembly of organic-inorganic composites using halloysite clay nanotubes. Curr. Opin. Colloid Interface 2018, 35, 42–50. [Google Scholar] [CrossRef]

- Wu, Y.; Ma, D.; Li, Q.K.; Stoica, A.D.; Song, W.L.; Wang, H.; Liu, X.J.; Stoica, G.M.; Wang, G.Y.; An, K. Transformation-induced plasticity in bulk metallic glass composites evidenced by in-situ neutron diffraction. Acta Mater. 2017, 124, 478–488. [Google Scholar] [CrossRef]

- Pauly, S.; Das, J.; Bednarcik, J.; Mattern, N.; Kim, K.B.; Kim, D.H.; Eckert, J. Deformation-induced martensitic transformation in Cu-Zr-(Al,Ti) bulk metallic glass composites. Scr. Mater. 2009, 60, 431–434. [Google Scholar] [CrossRef]

- Wu, Y.; Xiao, Y.H.; Chen, G.L.; Liu, C.T.; Lu, Z.P. Bulk metallic glass composite with transformation-mediated work-hardening and ductility. Adv. Mater. 2010, 22, 2770. [Google Scholar] [CrossRef] [PubMed]

- Tian, X.; Zhang, K.; Tan, C.; Guo, E. Influence of doping tb on the mechanical properties and martensitic transformation of Ni-Mn-Sn magnetic shape memory alloys. Crystals 2018, 8, 247. [Google Scholar] [CrossRef]

- Yu, H.B.; Hu, J.; Xia, X.X.; Sun, B.A.; Li, X.X.; Wang, W.H.; Bai, H.Y. Stress-induced structural inhomogeneity and plasticity of bulk metallic glasses. Scr. Mater. 2009, 61, 640–643. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, H.; Wu, H.H.; Zhang, Z.Y.; Hui, X.D.; Chen, G.L.; Ma, D.; Wang, X.L.; Lu, Z.P. Formation of Cu-Zr-Al bulk metallic glass composites with improved tensile properties. Acta Mater. 2011, 59, 2928–2936. [Google Scholar] [CrossRef]

- Li, W.; Zhao, C. Microstructure and phase transformation analysis of Ni50−xTi50Lax shape memory alloys. Crystals 2018, 8, 345. [Google Scholar] [CrossRef]

- Park, J.M.; Park, J.S.; Na, J.H.; Kim, D.H.; Kim, D.H. Effect of Y addition on thermal stability and the glass forming ability in Fe-Nb-B-Si bulk glassy alloy. Mater. Sci. Eng. A 2006, 435, 425–428. [Google Scholar] [CrossRef]

- Zhang, J.; Tan, H.; Feng, Y.P. The effect of Y on glass forming ability. Scr. Mater. 2005, 53, 183. [Google Scholar] [CrossRef]

- Kariper, İ.A. The production of UV absorber amorphous Cerium sulfide thin film. Mater. Res. 2017, 20, 1345. [Google Scholar] [CrossRef]

- Gaskell, D.R. Introduction to the Thermodynamics of Materials, 3rd ed.; Taylor & Francis Ltd.: Washington, DC, USA, 2008; pp. 80–84. [Google Scholar]

- Swalin, R.A. Thermodynamics of Solids, 2nd ed.; Wiley: New York, NY, USA, 1972; pp. 35–41. [Google Scholar]

- Gao, M.C.; Yeh, J.W.; Liaw, P.K.; Zhang, Y. High-Entropy Alloys: Fundamentals and Applications, 1st ed.; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Takeuchi, A.; Inoue, A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater. Trans. 2005, 46, 2817–2829. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Y. Prediction of high-entropy stabilized solid-solution in multicomponent alloys. Mater. Chem. Phys. 2012, 132, 233–238. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, X.; Liaw, P.K. Alloy design and properties optimization of high-entropy alloys. JOM 2012, 64, 830–838. [Google Scholar] [CrossRef]

- Yang, X.; Chen, S.Y.; Cotton, J.D.; Zhang, Y. Phase stability of low-density, multiprincipal component alloys containing aluminum, magnesium, and lithium. JOM 2014, 10, 2009–2020. [Google Scholar] [CrossRef]

- Zhang, Y.; Lu, Z.P.; Ma, S.G.; Liaw, P.K.; Tang, Z.; Cheng, Y.Q.; Gao, M.C. Guidelines in predicting phase formation of high-entropy alloys. MRS Commun. 2014, 4, 57–62. [Google Scholar] [CrossRef]

- Wang, W.H.; Dong, C.; Shek, C.H. Bulk metallic glasses. Mater. Sci. Eng. R Rep. 2004, 44, 45–89. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Y.J.; Lin, J.P.; Chen, G.L.; Liaw, P.K. Solid-solution phase formation rules for multi-component alloys. Adv. Eng. Mater. 2008, 10, 534–538. [Google Scholar] [CrossRef]

- Hwang, S.W.; Ji, J.H.; Lee, E.G.; Park, K.T. Tensile deformation of a duplex Fe-20Mn-9Al-0.6C steel having the reduced specific weight. Mater. Sci. Eng. A 2011, 528, 5196–5203. [Google Scholar] [CrossRef]

| Element | Fe | Mn | Si | Cr | C | Ti | Ni | Cu | Ce |

|---|---|---|---|---|---|---|---|---|---|

| Fe | 0 | −35 | −1 | −50 | 3 | ||||

| Mn | 0 | −45 | 2 | −66 | 1 | ||||

| Si | −35 | −45 | −37 | −39 | −73 | ||||

| Cr | −1 | 2 | −37 | −61 | 15 | ||||

| C | −50 | −66 | −39 | −61 | −116 | ||||

| Ti | −35 | −9 | 18 | ||||||

| Ni | −35 | 4 | −28 | ||||||

| Cu | −9 | 4 | −21 | ||||||

| Ce | 3 | 1 | −73 | 15 | −116 | 18 | −28 | −21 |

| Alloy | ΔSmix (J·mol−1·K−1) | ΔHmix (kJ·mol−1) | δ (%) |

|---|---|---|---|

| Fe65.4Mn14.3Si9.4Cr10C0.9 | 1.05R | −14.34 | 3.69 |

| Fe64.4Ce1.0Mn14.3Si9.4Cr10C0.9 | 1.08R | −14.43 | 5.62 |

| Ti40Ni40Cu20 | 1.06R | −23.72 | 7.01 |

| Ti39Ce1.0Ni40Cu20 | 1.10R | −24.12 | 7.85 |

| Element | Fe | Mn | Si | Cr | C | Ti | Ni | Cu |

|---|---|---|---|---|---|---|---|---|

| ψ | 1.43 | 1.38 | 1.36 | 1.43 | 2.12 | 1.26 | 1.47 | 1.42 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Zhao, P.; Li, W.; Kou, S.; Jiang, J.; Mao, X.; Yang, Z. The Microalloying Effect of Ce on the Mechanical Properties of Medium Entropy Bulk Metallic Glass Composites. Crystals 2019, 9, 483. https://doi.org/10.3390/cryst9090483

Zhao Y, Zhao P, Li W, Kou S, Jiang J, Mao X, Yang Z. The Microalloying Effect of Ce on the Mechanical Properties of Medium Entropy Bulk Metallic Glass Composites. Crystals. 2019; 9(9):483. https://doi.org/10.3390/cryst9090483

Chicago/Turabian StyleZhao, Yanchun, Pengbiao Zhao, Wensheng Li, Shengzhong Kou, Jianlong Jiang, Xuejing Mao, and Zhuang Yang. 2019. "The Microalloying Effect of Ce on the Mechanical Properties of Medium Entropy Bulk Metallic Glass Composites" Crystals 9, no. 9: 483. https://doi.org/10.3390/cryst9090483

APA StyleZhao, Y., Zhao, P., Li, W., Kou, S., Jiang, J., Mao, X., & Yang, Z. (2019). The Microalloying Effect of Ce on the Mechanical Properties of Medium Entropy Bulk Metallic Glass Composites. Crystals, 9(9), 483. https://doi.org/10.3390/cryst9090483