Thermal Stability of the Ultra-Fine-Grained Structure and Mechanical Properties of AlSi7MgCu0.5 Alloy Processed by Equal Channel Angular Pressing at Room Temperature

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Material

2.2. Material Processing

2.3. Experimental Setup

3. Results

3.1. Microstructure, Substructure, and Phase Analysis

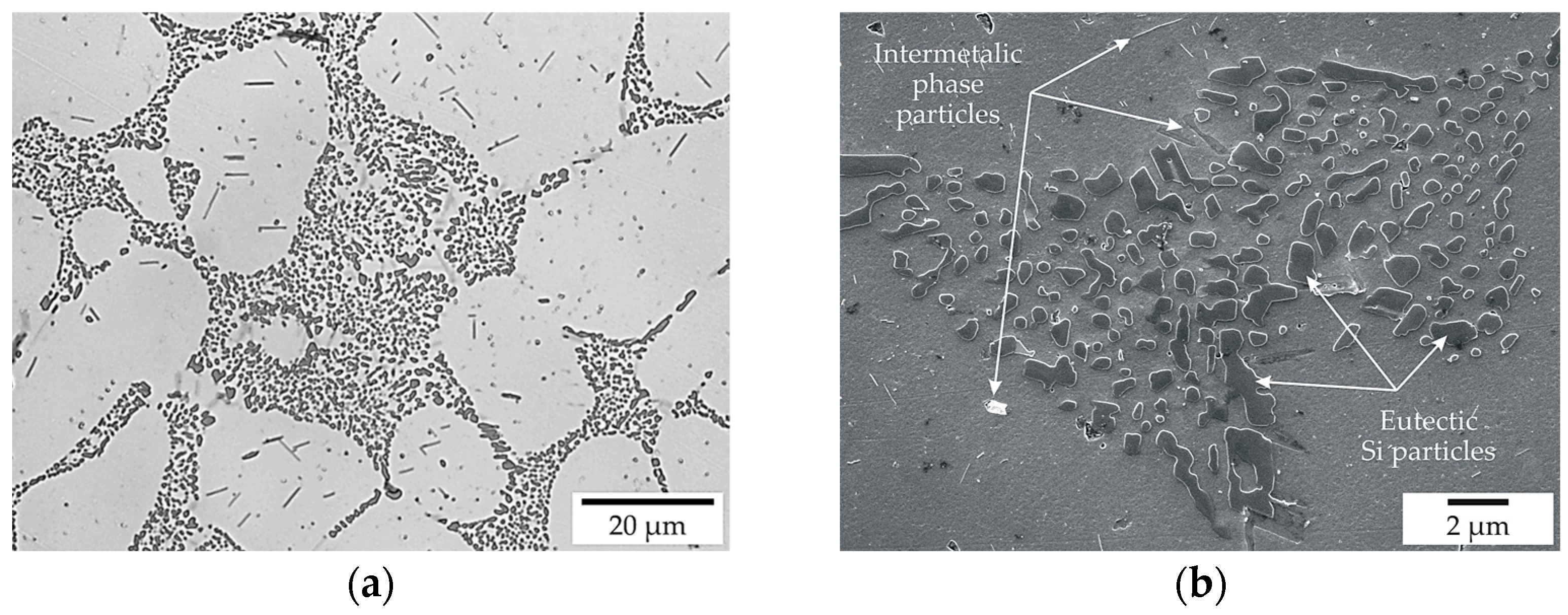

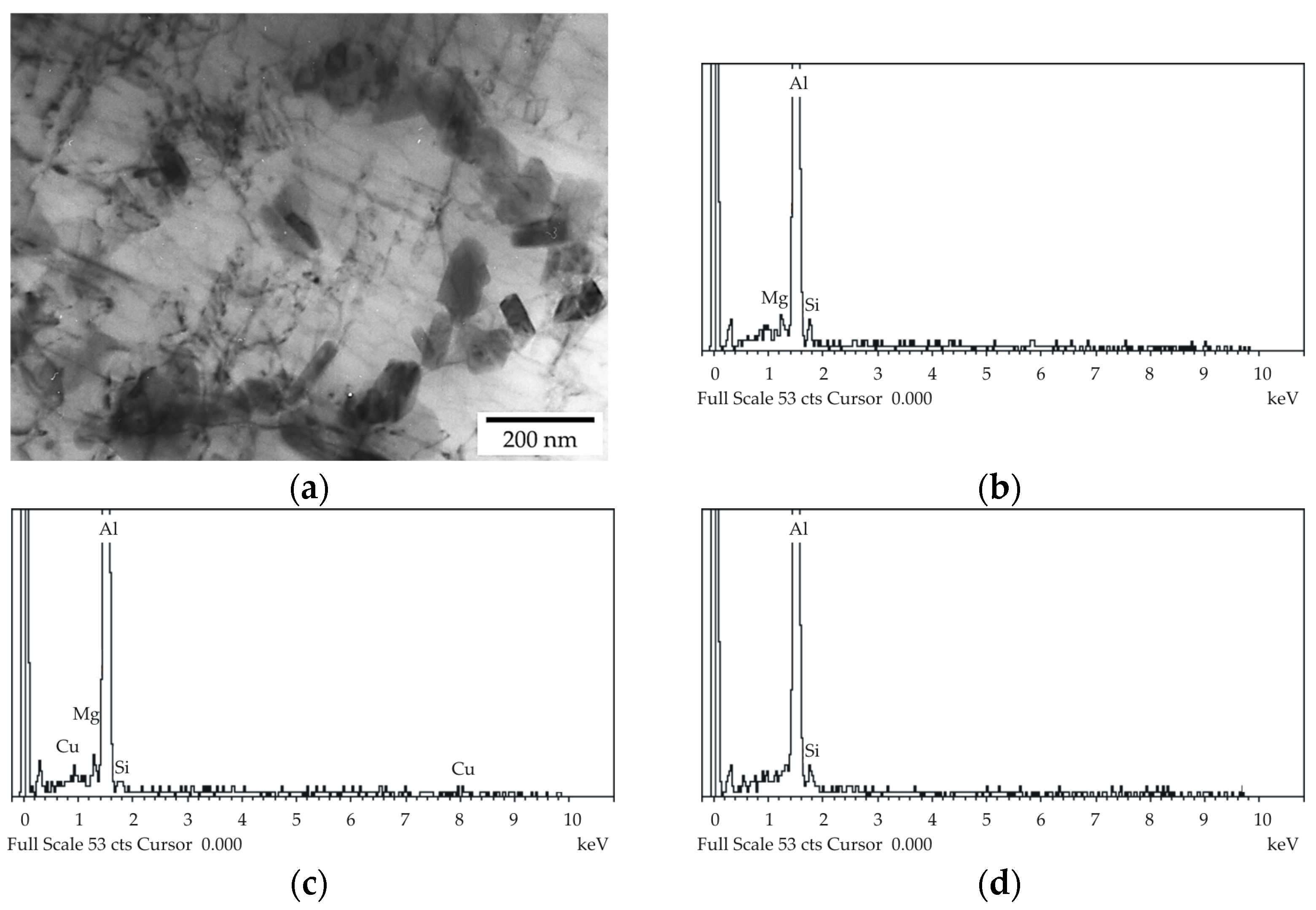

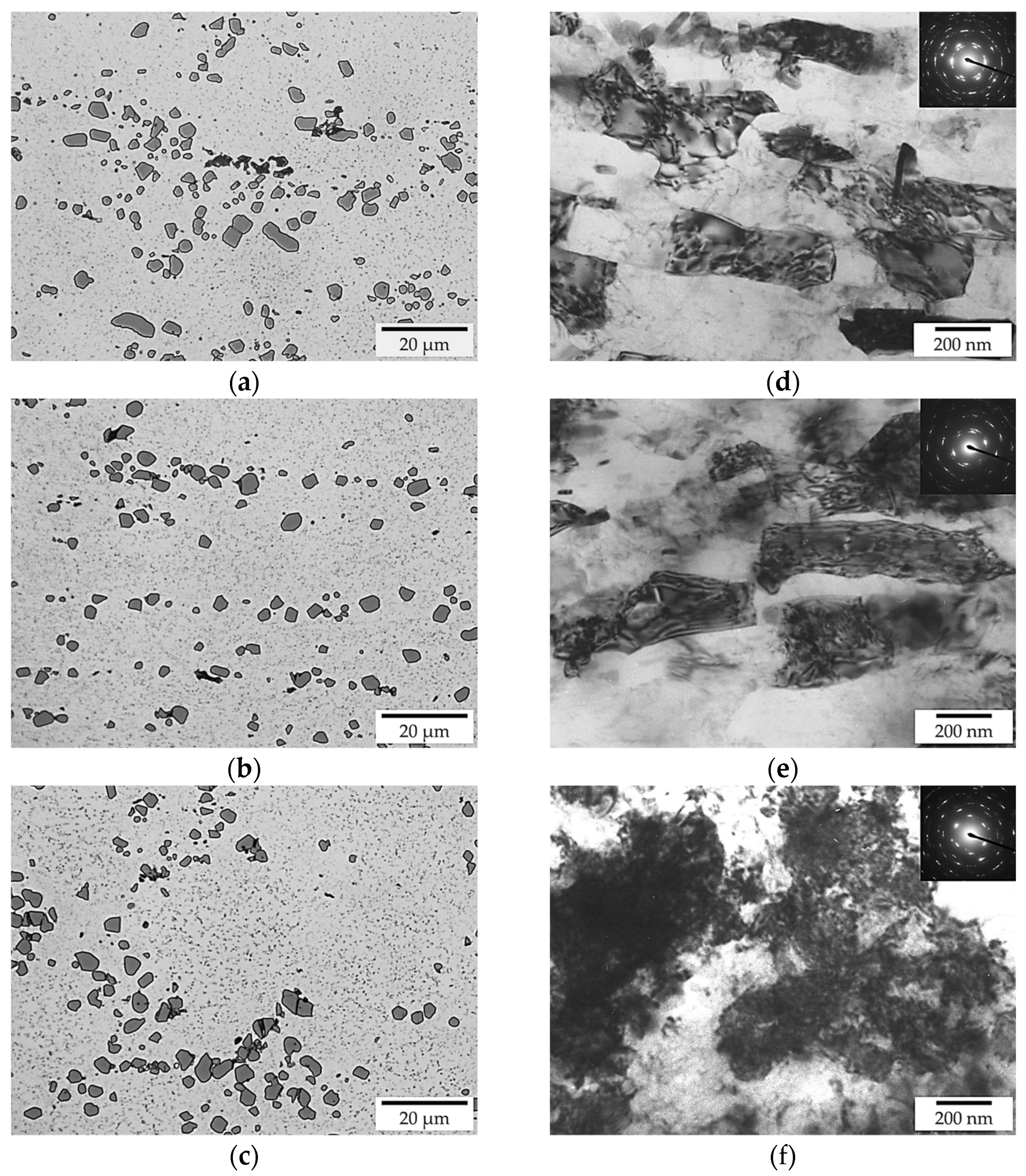

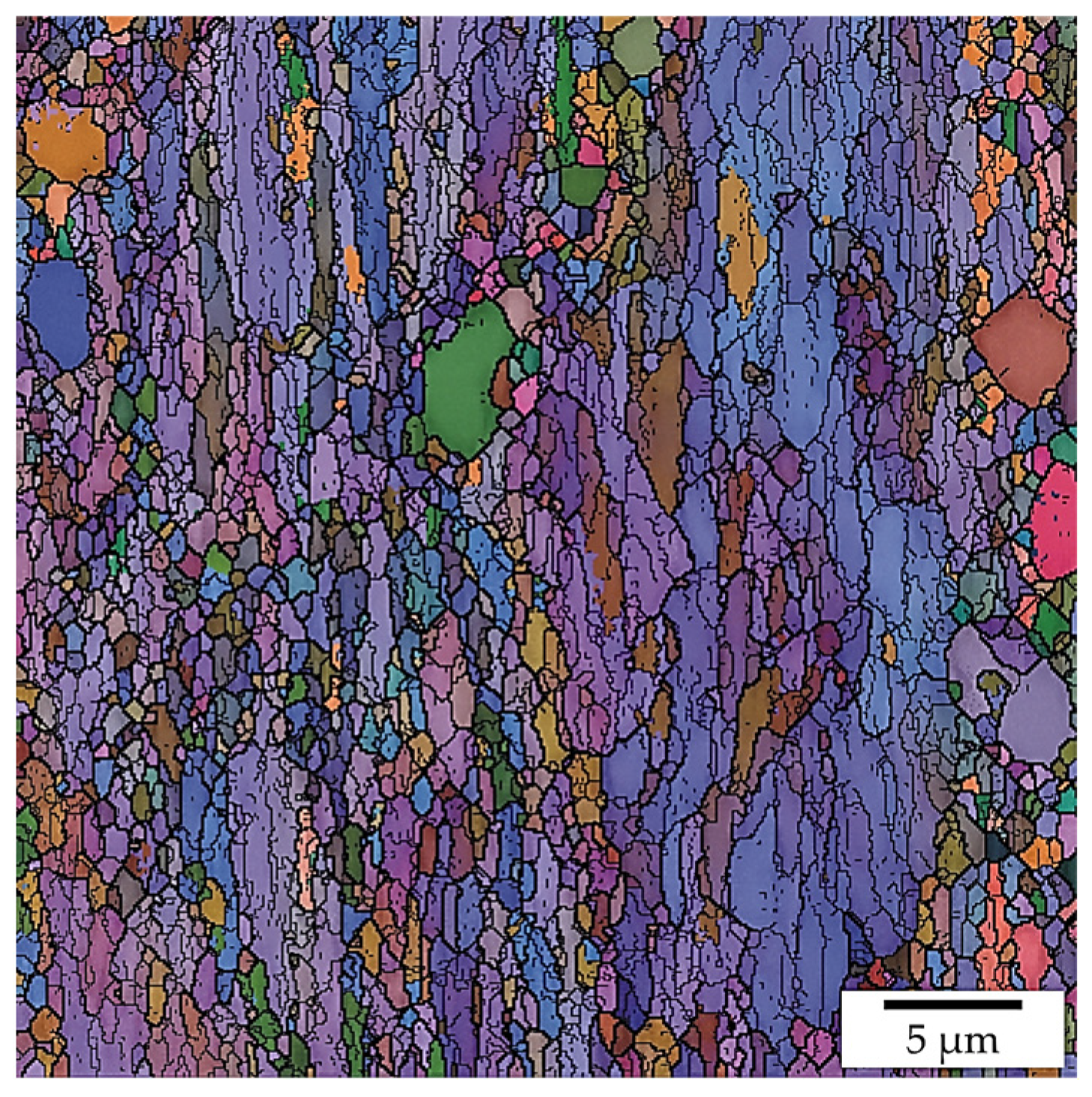

3.1.1. Microstructure and Substructure of AlSi7MgCu0.5 Alloy

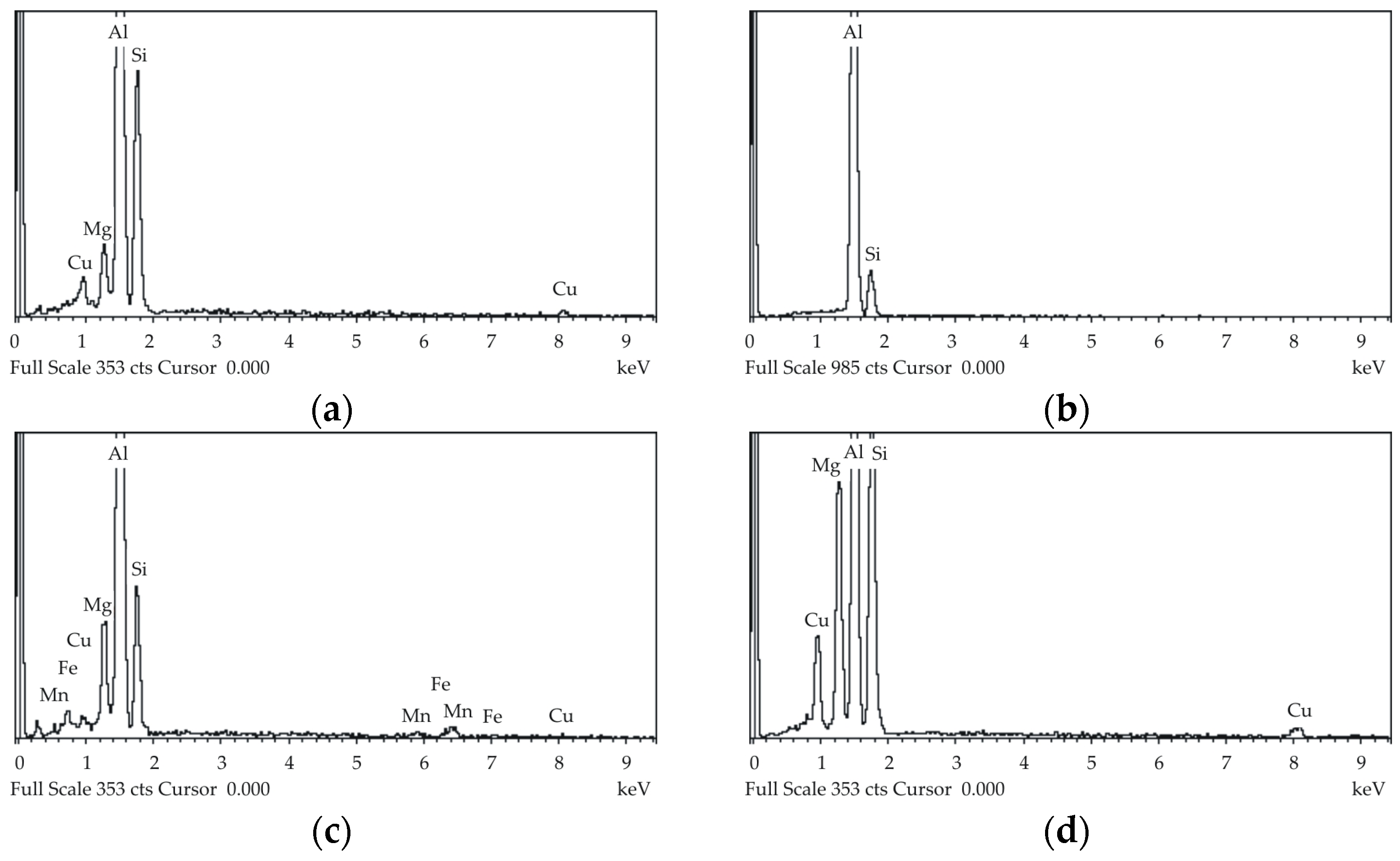

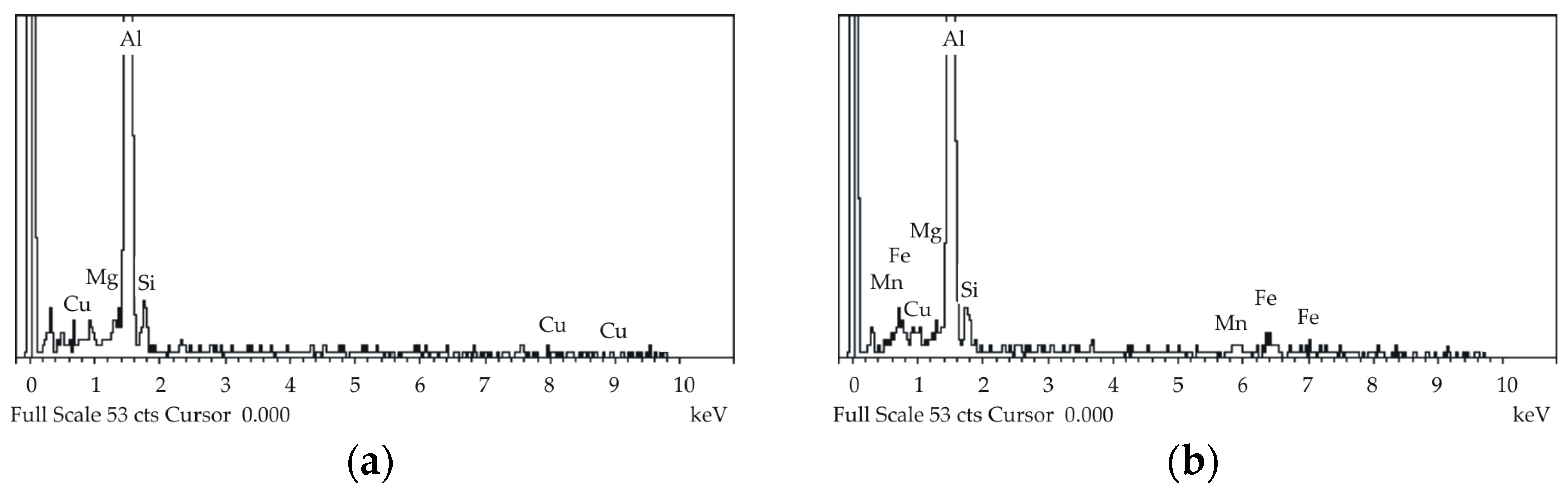

3.1.2. Phase Analysis of AlSi7MgCu0.5 Alloy

3.2. Mechanical Properties

3.2.1. Hardness Measurements

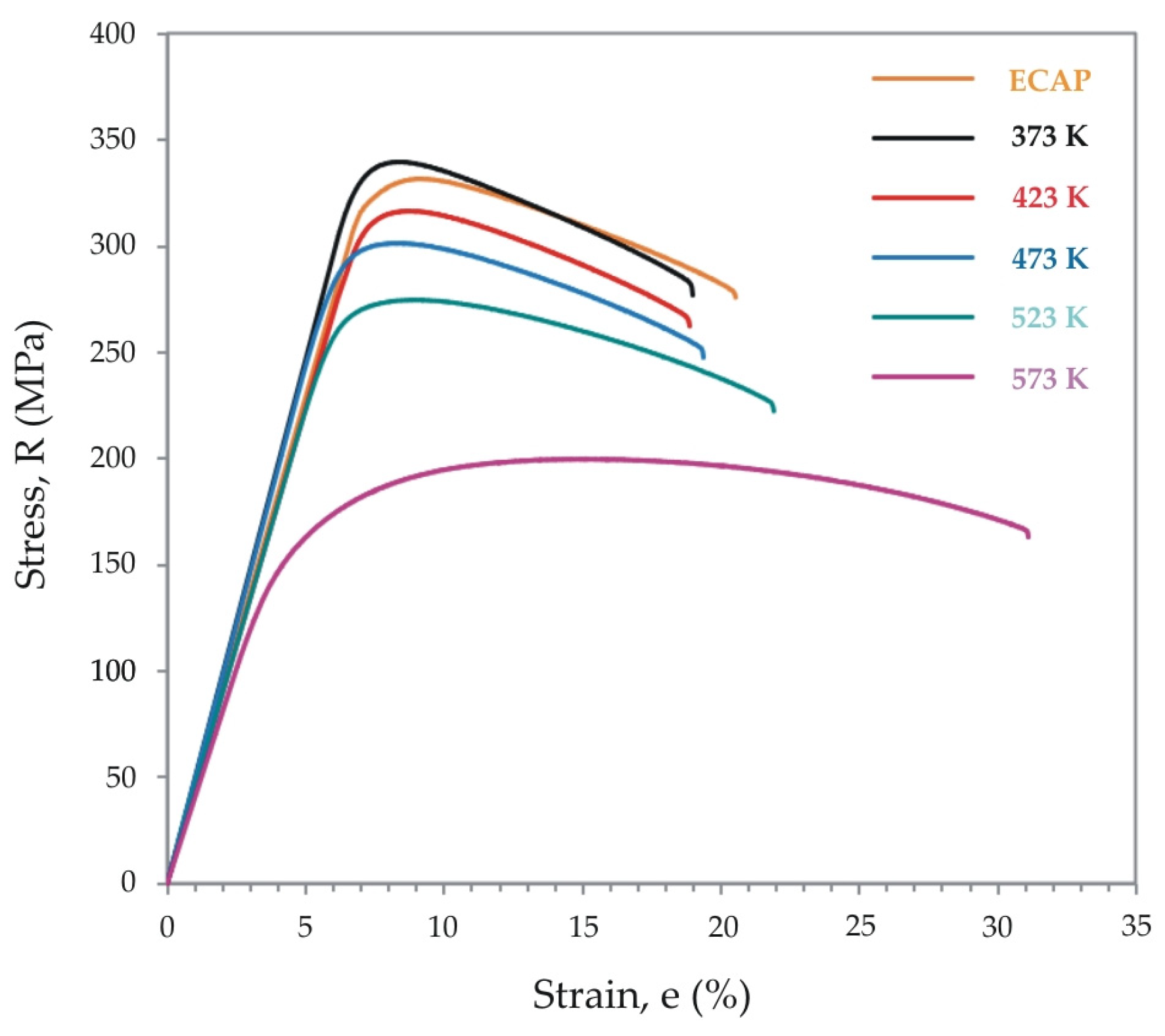

3.2.2. Tensile Testing

3.2.3. Impact Toughness Testing

4. Discussion

5. Conclusions

- (1)

- Post-ECAP annealing was employed to evaluate the thermal stability of the strain- and precipitation-hardened UFG structure and the resulting mechanical properties. With increasing annealing temperature, a progressive growth in the average grain and/or subgrain size of the solid solution occurred primarily due to recovery and recrystallization processes. The UFG structure remained stable up to 523 K, with grain or subgrain sizes maintained below 1 μm. Annealing at 573 K triggered discontinuous recrystallization, resulting in a bimodal grain structure: near eutectic Si particles, equiaxed grains formed (~5 μm), while more distant regions retained elongated deformed grains or subgrains (~0.5 μm width, ~1.5 μm length). Furthermore, the volume fraction of the Q-Al5Mg8Si6Cu2 phase increased gradually with annealing temperature.

- (2)

- Substructural transformations induced by annealing led to corresponding changes in mechanical behavior. As the annealing temperature increased, the alloy exhibited a gradual reduction in strength and an increase in ductility, consistent with ongoing recovery and recrystallization. An exception was observed at 373 K, where a slight increase (~10 MPa) in yield strength (Rp0.2) and ultimate tensile strength (Rm) was recorded, likely due to additional precipitation hardening. Since no significant deterioration in mechanical properties was observed up to 423 K, the ECAP-processed alloy can be considered thermally stable up to this temperature. Discontinuous recrystallization at 573 K led to a marked decline in strength and a recovery of ductility to levels comparable with the pre-ECAP-treated state.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| EBSD | electron backscatter diffraction |

| ECAP | equal channel angular pressing |

| EDX | energy dispersive X-ray |

| LM | light microscopy |

| SAED | selected area electron diffraction |

| SE | secondary electron |

| SEM | scanning electron microscopy |

| SPD | severe plastic deformation |

| TEM | transmission electron microscopy |

| UFG | ultra-fine-grained |

| XRD | X-ray diffraction |

References

- Zhou, P.; Wang, D.; Nagaumi, H.; Wang, R.; Zhang, X.; Li, X.; Zhang, H.; Zhang, B. Microstructural Evolution and Mechanical Properties of Al-Si-Mg-Cu Cast Alloys with Different Cu Contents. Metals 2023, 13, 98. [Google Scholar] [CrossRef]

- Choi, S.; Kim, Y.; Kim, Y.; Kang, C. Effects of alloying elements on mechanical and thermal characteristics of Al-6wt-%Si-0.4wt-%Mg–(Cu) foundry alloys. Mater. Sci. Technol. 2019, 35, 1365–1371. [Google Scholar] [CrossRef]

- Chen, B.; Dong, L.; Hu, B.; Liu, Z. The Effect of Cu Addition on the Precipitation Sequence in the Al-Si-Mg-Cr Alloy. Materials 2022, 15, 8221. [Google Scholar] [CrossRef]

- Segal, V.M.; Reznikov, V.I.; Drobyshevskiy, A.E.; Kopylov, V.I. Plastic Working of Metals by Simple Shear. Metally 1981, 1, 99–105. [Google Scholar]

- Hall, E.O. The deformation and ageing of mild steel: III Discussion of results. Proc. Phys. Soc. Lond. B 1951, 64, 747–753. [Google Scholar] [CrossRef]

- Petch, N.J. The cleavage strength of polycrystals. J. Iron Steel Inst. 1953, 174, 25–28. [Google Scholar]

- Rahmawaty, R.; Dharma, S.; Razak, A.; Sarjianto, S.; Bahri, N.; Sutrisno, J.; Suherman, S.; Abdullah, I.; Silalahi, A.R.S. The Effect of Process Route on the Mechanical Properties and Microstructure Aluminum Al-Si-Cu-Mg-Mn Alloys. Defect Diffus. Forum 2020, 402, 67–72. [Google Scholar] [CrossRef]

- Furukawa, M.; Iwahashi, Y.; Horita, Z.; Nemoto, M.; Langdon, T.G. The shearing characteristics associated with equal-channel angular pressing. Mater. Sci. Eng. A 1998, 257, 328–332. [Google Scholar] [CrossRef]

- Wang, J.; Iwahashi, Y.; Horita, Z.; Furukawa, M.; Nemoto, M.; Valiev, R.Z.; Langdon, T.G. An investigation of microstructural stability in an Al-Mg alloy with submicrometer grain size. Acta Mater. 1996, 44, 2973–2982. [Google Scholar] [CrossRef]

- Garcia-Infanta, J.M.; Swaminathan, S.; Zhilyaev, A.P.; Carreño, F.; Ruano, O.A.; McNelley, T.R. Microstructural development during equal channel angular pressing of hypo-eutectic Al–Si casting alloy by different processing routes. Mater. Sci. Eng. A 2008, 485, 160–175. [Google Scholar] [CrossRef]

- Gutierrez Urrutia, I.; Muñoz Morris, M.A.; Morris, D.G. Effects of ECAP processing on discontinuous dynamic recrystallization. Acta Mater. 2007, 55, 1319–1330. [Google Scholar] [CrossRef]

- Ma, A.; Takagi, M.; Saito, N.; Iwata, H.; Nishida, Y.; Suzuki, K.; Shigematsu, I. Tensile properties of an Al–11 mass%Si alloy at elevated temperatures processed by rotary-die equal-channel angular pressing. Mater. Sci. Eng. A 2005, 408, 147–153. [Google Scholar] [CrossRef]

- Ma, A.; Suzuki, K.; Nishida, Y.; Saito, N.; Shigematsu, I.; Takagi, M.; Iwata, H.; Watazu, A.; Imura, T. Impact toughness of an ultrafine-grained Al–11mass%Si alloy processed by rotary-die equal-channel angular pressing. Acta Mater. 2005, 53, 211–220. [Google Scholar] [CrossRef]

- Ma, A.; Saito, N.; Takagi, M.; Nishida, Y.; Iwata, H.; Suzuki, K.; Shigematsu, I.; Watazu, A. Effect of severe plastic deformation on tensile properties of a cast Al–11 mass% Si alloy. Mater. Sci. Eng. A 2005, 395, 70–76. [Google Scholar] [CrossRef]

- Kim, J.C.; Nishida, Y.; Arima, H.; Ando, T. Microstructure of Al–Si–Mg alloy processed by rotary-die equal channel angular pressing. Mater. Lett. 2003, 57, 1689–1695. [Google Scholar] [CrossRef]

- Gutierrez Urrutia, I.; Muñoz Morris, M.A.; Puertas, I.; Luis, C.; Morris, D.G. Influence of processing temperature and die angle on the grain microstructure produced by severe deformation of an Al–7% Si alloy. Mater. Sci. Eng. A 2008, 475, 268–278. [Google Scholar] [CrossRef]

- Cepeda Jiménez, C.M.; Garcia Infanta, J.M.; Zhilyaev, A.P.; Ruano, O.A.; Carreño, F. Influence of the supersaturated silicon solid solution concentration on the effectiveness of severe plastic deformation processing in Al–7 wt.% Si casting alloy. Mater. Sci. Eng. A 2011, 528, 7938–7947. [Google Scholar] [CrossRef]

- Moradi, M.; Nili Ahmadabadi, M.; Heidarian, B. Improvement of mechanical properties of AL (A356) cast alloy processed by ECAP with different heat treatments. Int. J. Mater. Forming 2009, 2, 85–88. [Google Scholar] [CrossRef]

- Szczygiel, P.; Roven, H.J.; Reiso, O. On the effect of severe plastic deformation on recycled experimental aluminium alloys: Nanostructures, particle break up and properties. Mater. Sci. Eng. A 2005, 410–411, 261–264. [Google Scholar] [CrossRef]

- Garcia-Infanta, J.M.; Zhilyaev, A.P.; Capeda-Jiménez, C.M.; Ruano, O.A.; Careno, F. Effect of the deformation path on the ductility of a hypoeutectic Al–Si casting alloy subjected to equal-channel angular pressing by routes A, BA, BC and C. Scr. Mater. 2008, 58, 138–141. [Google Scholar] [CrossRef]

- Swaminathan, S.; Garcia-Infanta, J.M.; McNelley, T.R.; Ruano, O.A.; Carreño, F. Severe plastic deformation of an as-cast hypoeutectic Al–Si alloy. J. Mater. Sci. 2008, 43, 7501–7506. [Google Scholar] [CrossRef][Green Version]

- Nishida, Y.; Arima, H.; Kim, J.C.; Ando, T. Rotary-die equal-channel angular pressing of an Al–7 mass% Si–0.35 mass% Mg alloy. Scr. Mater. 2001, 45, 261–266. [Google Scholar] [CrossRef]

- Matvija, M.; Fujda, M.; Milkovič, O.; Vojtko, M.; Kočiško, R.; Glogovský, M. Microstructure Changes and Improvement in the Mechanical Properties of As-Cast AlSi7MgCu0.5 Alloy Induced by the Heat Treatment and ECAP Technique at Room Temperature. Adv. Mater. Sci. Eng. 2018, 2018, 5697986. [Google Scholar] [CrossRef]

- Dippel, A.-C.; Liermann, H.-P.; Delitz, J.T.; Walter, P.; Schulte Schrepping, H.; Seeck, O.H.; Franz, H. Beamline P02.1 at PETRA III for high resolution and high energy powder diffraction. J. Synchrotron Radiat. 2015, 22, 675–687. [Google Scholar] [CrossRef]

- Franz, H.; Leupold, O.; Rohlsberger, R.; Roth, S.; Seeck, O.; Spengler, J.; Strempfer, J.; Tischer, M.; Viefhaus, J.; Weckert, E.; et al. Technical Report: PETRA III: DESY’s New High Brilliance Third Generation Synchrotron Radiation Source. Synchrotron Radiat. News 2006, 19, 25–29. [Google Scholar] [CrossRef]

- Skinner, L.B.; Benmore, C.J.; Parise, J.B. Area detector corrections for high quality synchrotron X ray structure factor measurements. Nucl. Instrum. Methods Phys. Res. A 2012, 662, 61–70. [Google Scholar] [CrossRef]

- Bednarcik, J.; Gamcova, J.; Liermann, H.P. New Heating/Cooling Stage Available to Users at P02.1. In DESY Annual Report 2012; DESY: Hamburg, Germany, 2012. [Google Scholar]

- Hammersley, A.P.; Svensson, S.O.; Hanfland, M.; Fitch, A.N.; Hausermann, D. Two dimensional detector software: From real detector to idealised image or two theta scan. High Press. Res. 1996, 14, 235–248. [Google Scholar] [CrossRef]

- ISO 6507-1:2023; Metallic Materials—Vickers Hardness Test. Part 1: Test Method. International Organization for Standardization: Geneva, Switzerland, 2023.

- ISO 6892-1:2019; Metallic Materials—Tensile Testing. Part 1: Method of Test at Room Temperature. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 148-1:2016; Metallic Materials—Charpy Pendulum Impact Test. Part 1: Test Method. International Organization for Standardization: Geneva, Switzerland, 2016.

- Phragmen, G.J. The coarsening behavior of strengthening particles in an Al–Cu–Mg–Ag alloy during creep. J. Inst. Met. 1950, 77, 489–552. [Google Scholar] [CrossRef]

- Mondolfo, L.F. Aluminum Alloys: Structure and Properties; Butterworths: London, UK, 1976; pp. 806–841. ISBN 0 408 10827 6. [Google Scholar] [CrossRef]

- Farkoosh, A.R.; Javidani, M.; Hoseini, M.; Larouche, D.; Pekguleryuz, M. Phase formation in as-solidified and heat-treated Al–Si–Cu–Mg–Ni alloys: Thermodynamic assessment and experimental investigation for alloy design. J. Alloy. Compd. 2013, 551, 596–606. [Google Scholar] [CrossRef]

- Unterreiter, G.; Ludwig, A.; Wu, M. Numerical microstructure prediction for an aluminium casting and its experimental validation. China Foundry 2011, 8, 331–336. [Google Scholar]

- Nafisi, S.; Ghomashchi, R.; Vali, H. Eutectic nucleation in hypoeutectic Al-Si alloys. Mater. Charact. 2008, 59, 1466–1473. [Google Scholar] [CrossRef]

- Wang, L.; Makhlouf, M.; Apelian, D. Aluminium die casting alloys: Alloy composition, microstructure, and properties-performance relationships. Int. Mater. Rev. 1995, 40, 221–238. [Google Scholar] [CrossRef]

- Mohamed, A.M.A.; Samuel, F.H. Review on the Heat Treatment of Al Si Cu/Mg Casting Alloys. In Heat Treatment: Conventional and Novel Applications; Czerwinski, F., Ed.; InTech: Rijeka, Croatia, 2012; pp. 55–72. ISBN 978-953-51-0768-2. [Google Scholar] [CrossRef]

- Sjölander, E.; Seifeddine, S. The heat treatment of Al–Si–Cu–Mg casting alloys. J. Mater. Process. Technol. 2010, 210, 1249–1259. [Google Scholar] [CrossRef]

- Kearney, A.L. Properties of Cast Aluminum Alloys. In ASM Handbook: Properties and Selection: Nonferrous Alloys and Special Purpose Materials; ASM International Handbook Committee, Ed.; ASM International: Cleveland, OH, USA, 1990; Volume 2, pp. 569–666. ISBN 978-0-87170-378-1. [Google Scholar] [CrossRef]

- Colás, R.; Velasco, E.; Valtierra, S. Castings. In Handbook of Aluminum: Physical Metallurgy and Processes; Totten, G.E., Mackenzie, D.C., Eds.; Taylor & Francis Group: Boca Raton, FL, USA, 2003; Volume 1, pp. 591–641. ISBN 978-0-20391-259-1. [Google Scholar] [CrossRef]

- Tillová, E.; Panušková, M. Effect of solution treatment on intermetallic phases morphology in AlSi9Cu3 cast alloy. Metalurgija 2008, 47, 207–210. [Google Scholar]

- Wang, G.; Sun, Q.; Feng, L.; Hui, L.; Jing, C. Influence of Cu content on ageing behavior of AlSiMgCu cast alloys. Mater. Des. 2007, 28, 1001–1005. [Google Scholar] [CrossRef]

- Gupta, A.K.; Jena, A.K.; Chaturvedi, M.C. Insoluble phase in Al–1·52Cu–0·75Mg alloys containing silicon. Mater. Sci. Technol. 1987, 3, 1012–1018. [Google Scholar] [CrossRef]

- Dennis, J.; Bate, P.S.; Humphreys, F.J. Abnormal grain growth in Al–3.5Cu. Acta Mater. 2009, 57, 4539–4547. [Google Scholar] [CrossRef]

- Rofman, O.V.; BATE, P.S. Dynamic grain growth and particle coarsening in Al–3.5Cu. Acta Mater. 2010, 58, 2527–2534. [Google Scholar] [CrossRef]

- Fleck, N.A.; Muller, G.M.; Ashby, M.F.; Hutchinson, J.W. Strain gradient plasticity: Theory and experiment. Acta Metall. Mater. 1994, 42, 475–487. [Google Scholar] [CrossRef]

- Fujda, M.; Matvija, M.; Kvačkaj, T.; Milkovič, O.; Zubko, P.; Nagyová, K. Structure and properties of AlMgSi alloys after ECAP and post-ECAP ageing. Mater. Technol. 2012, 46, 465–469. [Google Scholar]

- Hansen, N. Boundary Strengthening over Five Length Scales. Adv. Eng. Mater. 2005, 7, 815–821. [Google Scholar] [CrossRef]

- Morris, D.G.; Gutierrez-Urrutia, I.; Munoz-Morris, M.A. Analysis of strengthening mechanisms in a severely-plastically-deformed Al–Mg–Si alloy with submicron grain size. J. Mater. Sci. 2007, 42, 1439–1443. [Google Scholar] [CrossRef]

- Mao, W. Recrystallization and Grain Growth. In Handbook of Aluminum: Physical Metallurgy and Processes; Totten, G.E., Mackenzie, D.S., Eds.; Taylor & Francis Group: Boca Raton, FL, USA, 2003; Volume 1, pp. 211–258. ISBN 978-0-20391-259-1. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Grain Growth Following Recrystallization. In Recrystallization and Related Annealing Phenomena, 2nd ed.; Humphreys, F.J., Hatherly, M., Eds.; Elsevier: Oxford, UK, 2004; pp. 333–378. ISBN 0 08 041884-8. [Google Scholar]

- Jazaeri, H.; Humphreys, F.J. The transition from discontinuous to continuous recrystallization in some aluminium alloys: I—the deformed state. Acta Mater. 2004, 52, 3251–3262. [Google Scholar] [CrossRef]

- Huang, W.; Liu, Z.; Lin, M.; Zhou, X.; Zhao, L.; Ning, A.; Zeng, S. Reprecipitation behavior in Al–Cu binary alloy after severe plastic deformation-induced dissolution of θ′ particles. Mater. Sci. Eng. A 2012, 546, 26–33. [Google Scholar] [CrossRef]

- Huang, W.; Liu, Z.; Xia, L.; Xia, P.; Zeng, S. Severe plastic deformation-induced dissolution of θ” particles in Al–Cu binary alloy and subsequent nature aging behavior. Mater. Sci. Eng. A 2012, 556, 801–806. [Google Scholar] [CrossRef]

- Furu, T.; Marthinsen, K.; Nes, E. Modelling recrystallisation. Mater. Sci. Technol. 1990, 6, 1093–1102. [Google Scholar] [CrossRef]

| Element | Si | Cu | Mg | Fe | Ti | Mn | Sr | Zn | Al |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | 6.49 | 0.45 | 0.38 | 0.11 | 0.11 | 0.08 | 0.03 | 0.01 | Bal. |

| Alloy State | Average Width (nm) | Average Length (nm) |

|---|---|---|

| ECAP-processed [23] | 200 | 650 |

| Post-ECAP-annealed at 373 K | 200 | 730 |

| Post-ECAP-annealed at 423 K | 290 | 900 |

| Post-ECAP-annealed at 473 K | 310 | 900 |

| Post-ECAP-annealed at 523 K | 330 | 960 |

| Post-ECAP-annealed at 573 K | 550 | 1600 |

| Alloy State | HV0.2 |

|---|---|

| As-cast [23] | 72.2 |

| Pre-ECAP heat-treated [23] | 69.9 |

| ECAP-processed [23] | 110.7 |

| Post-ECAP-annealed at 373 K | 110.7 |

| Post-ECAP-annealed at 423 K | 110.1 |

| Post-ECAP-annealed at 473 K | 102.1 |

| Post-ECAP-annealed at 523 K | 94.4 |

| Post-ECAP-annealed at 573 K | 67.6 |

| Alloy State | Rp0.2 [MPa] | Rm [MPa] | A [%] | Ag [%] | Z [%] |

|---|---|---|---|---|---|

| As-cast [23] | 127 | 219 | 10.1 | 8.9 | 14.6 |

| Pre-ECAP heat-treated [23] | 136 | 208 | 17.1 | 7.6 | 28.2 |

| ECAP-processed [23] | 319 | 332 | 14.5 | 1.8 | 21.5 |

| Post-ECAP-annealed at 373 K | 328 | 340 | 13.4 | 1.5 | 24.0 |

| Post-ECAP-annealed at 423 K | 304 | 317 | 13.1 | 1.6 | 20.4 |

| Post-ECAP-annealed at 473 K | 282 | 302 | 14.3 | 2.3 | 25.0 |

| Post-ECAP-annealed at 523 K | 255 | 275 | 16.9 | 2.9 | 27.8 |

| Post-ECAP-annealed at 573 K | 140 | 200 | 27.0 | 10.0 | 37.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matvija, M.; Fujda, M.; Milkovič, O.; Vojtko, M.; Gáborová, K. Thermal Stability of the Ultra-Fine-Grained Structure and Mechanical Properties of AlSi7MgCu0.5 Alloy Processed by Equal Channel Angular Pressing at Room Temperature. Crystals 2025, 15, 701. https://doi.org/10.3390/cryst15080701

Matvija M, Fujda M, Milkovič O, Vojtko M, Gáborová K. Thermal Stability of the Ultra-Fine-Grained Structure and Mechanical Properties of AlSi7MgCu0.5 Alloy Processed by Equal Channel Angular Pressing at Room Temperature. Crystals. 2025; 15(8):701. https://doi.org/10.3390/cryst15080701

Chicago/Turabian StyleMatvija, Miloš, Martin Fujda, Ondrej Milkovič, Marek Vojtko, and Katarína Gáborová. 2025. "Thermal Stability of the Ultra-Fine-Grained Structure and Mechanical Properties of AlSi7MgCu0.5 Alloy Processed by Equal Channel Angular Pressing at Room Temperature" Crystals 15, no. 8: 701. https://doi.org/10.3390/cryst15080701

APA StyleMatvija, M., Fujda, M., Milkovič, O., Vojtko, M., & Gáborová, K. (2025). Thermal Stability of the Ultra-Fine-Grained Structure and Mechanical Properties of AlSi7MgCu0.5 Alloy Processed by Equal Channel Angular Pressing at Room Temperature. Crystals, 15(8), 701. https://doi.org/10.3390/cryst15080701