Tandem Neural Network Based Design of Acoustic Metamaterials for Low-Frequency Vibration Reduction in Automobiles

Abstract

1. Introduction

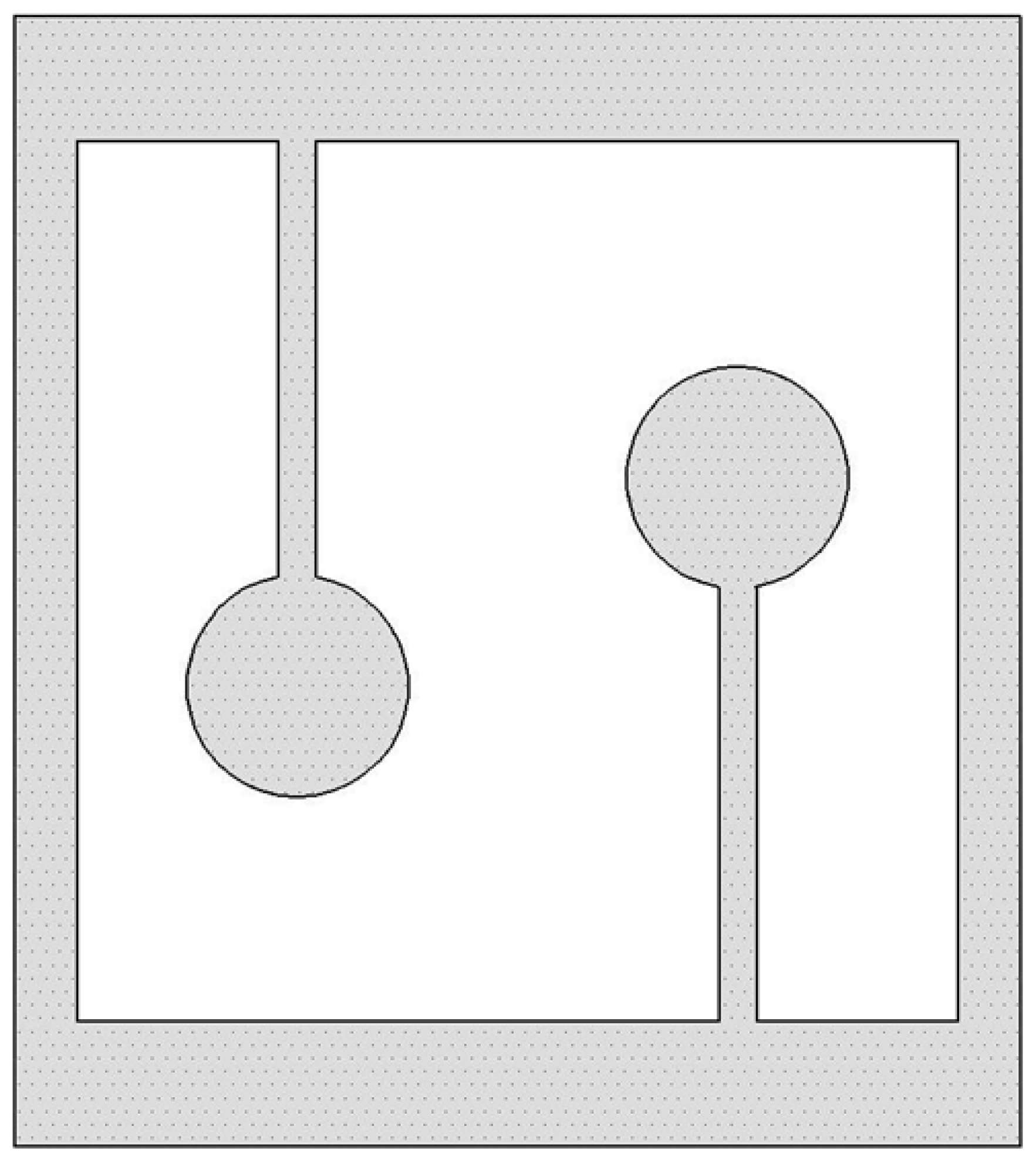

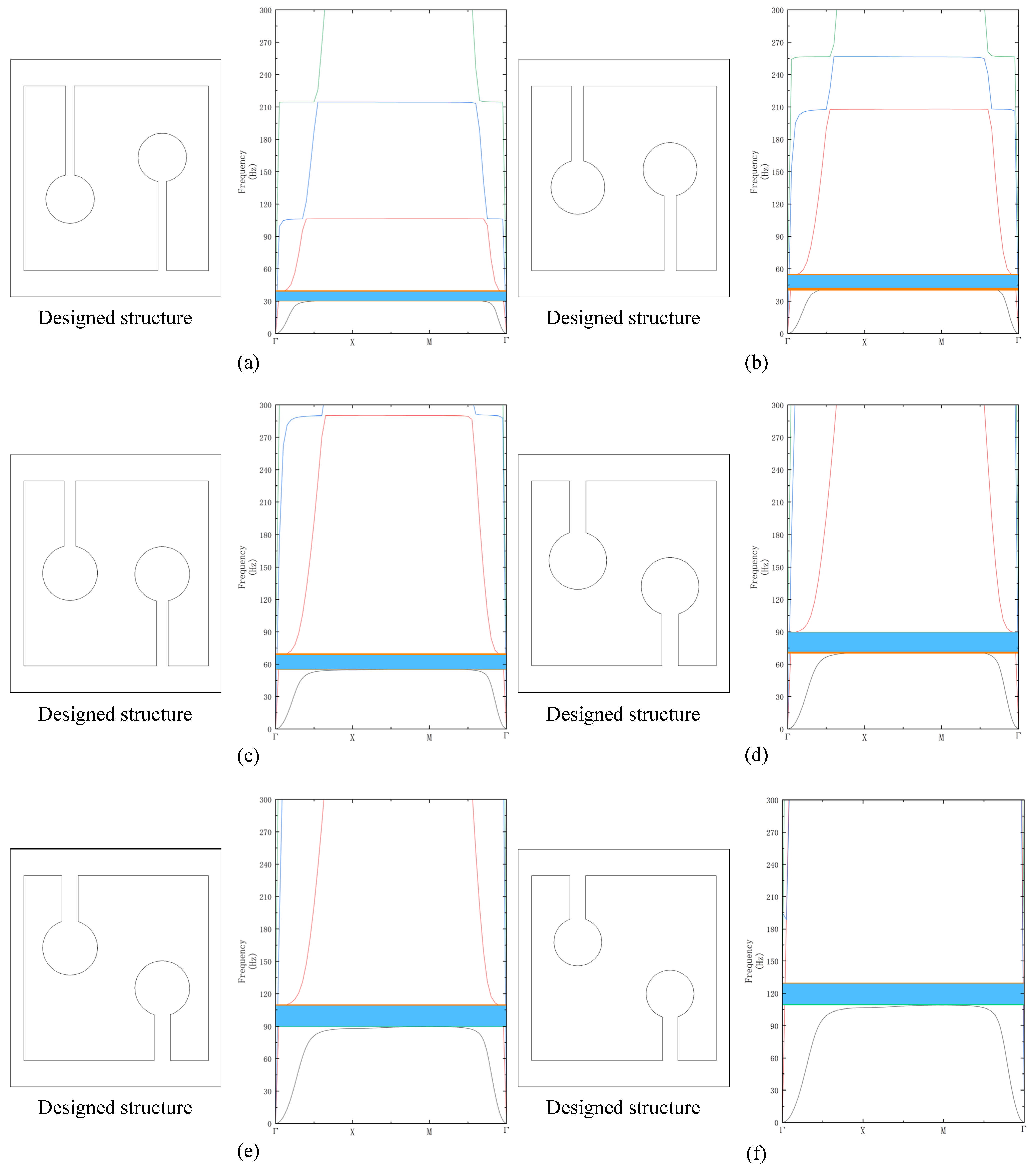

2. Parametric Modeling and Sample Set of AMMs

2.1. Basic Unit Structure of AMMs

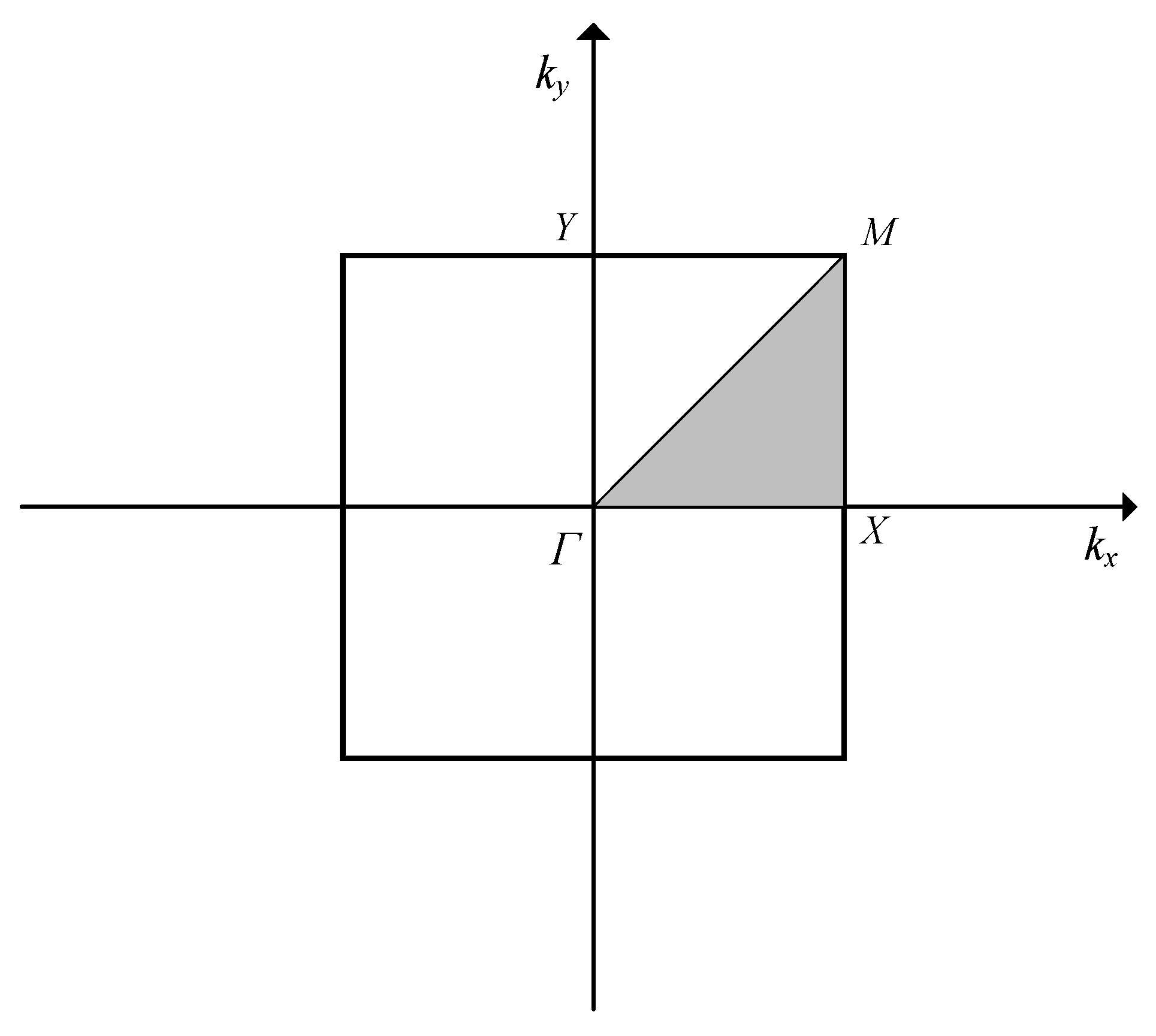

2.2. Bandgap Solution of AMMs

2.3. Dataset of AMMs with Different Design Parameters

3. AMMs Design Method Based on TNN

3.1. The Framework of TNN for AMMs

3.1.1. Forward Pretraining Network

3.1.2. Inverse Design Network

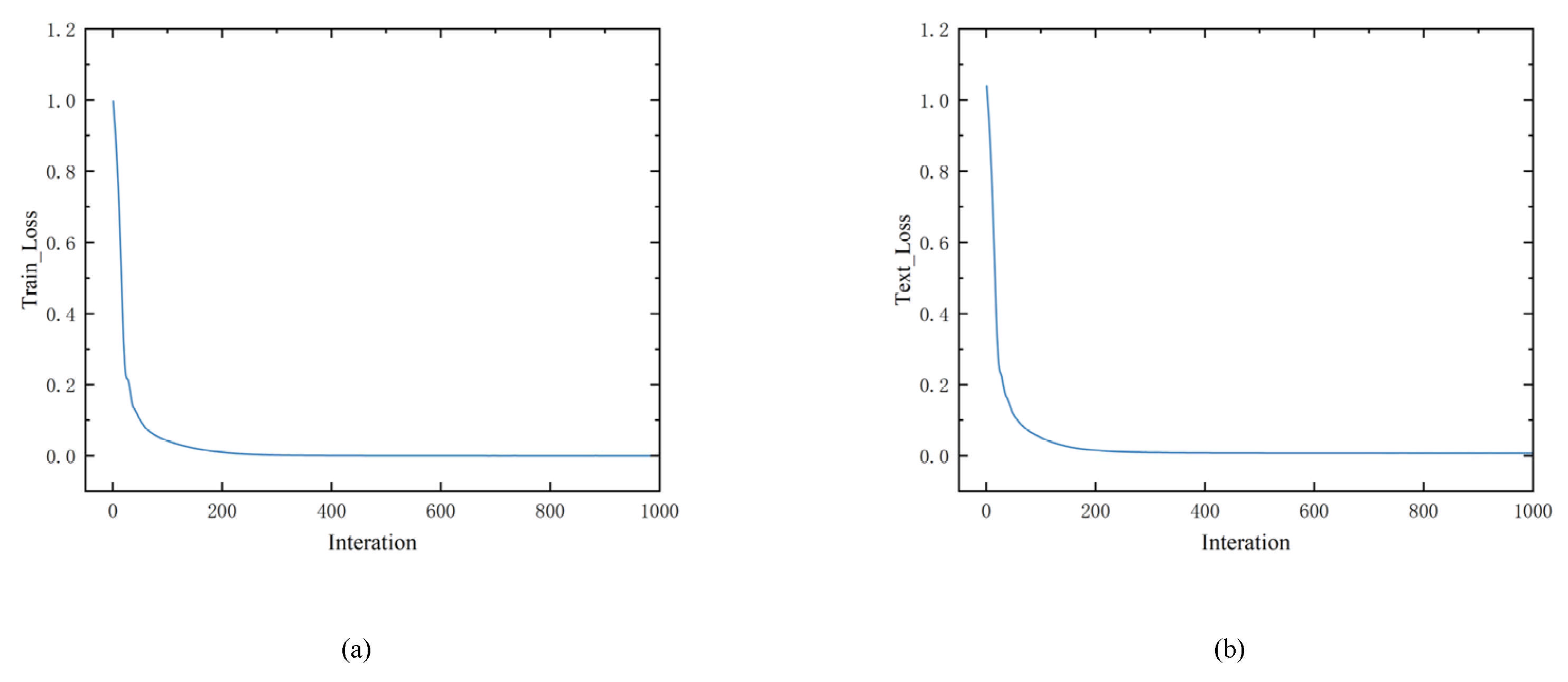

3.2. Forward and Inverse Design Results Through the TNN

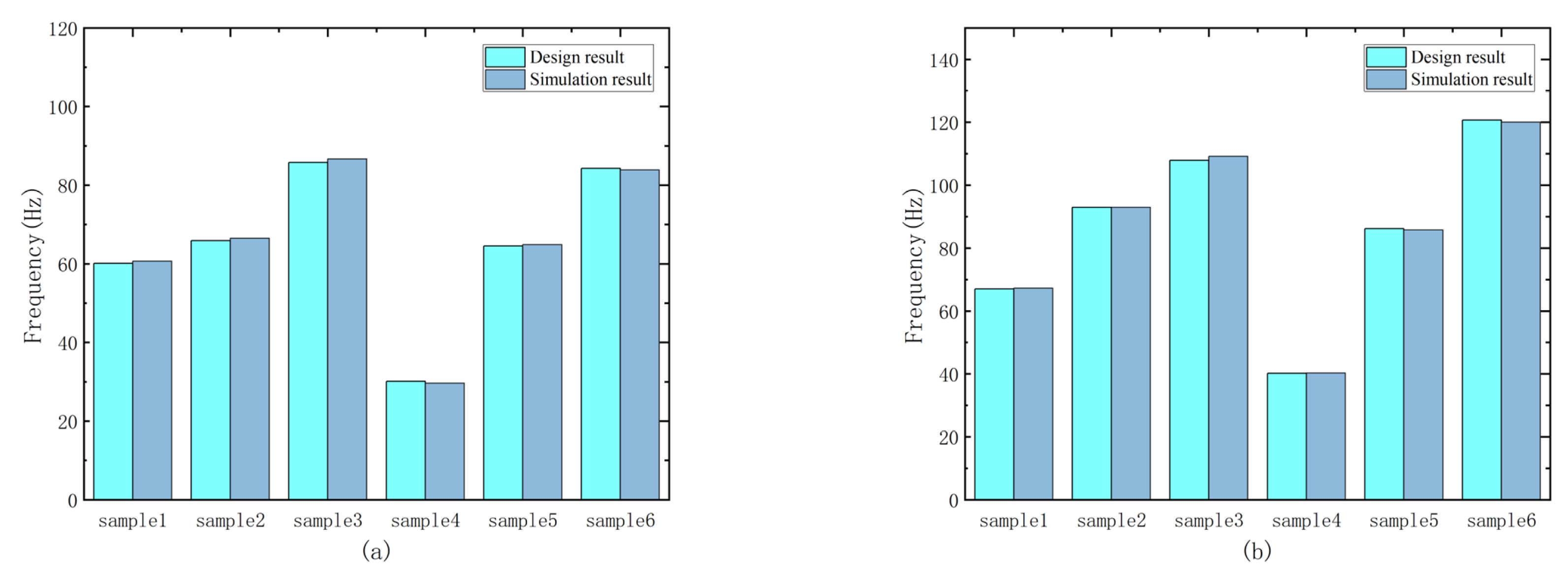

3.2.1. Forward Design of Bandgap Range Based on Design Parameters

3.2.2. Inverse Design of Design Parameters Based on Bandgap Range

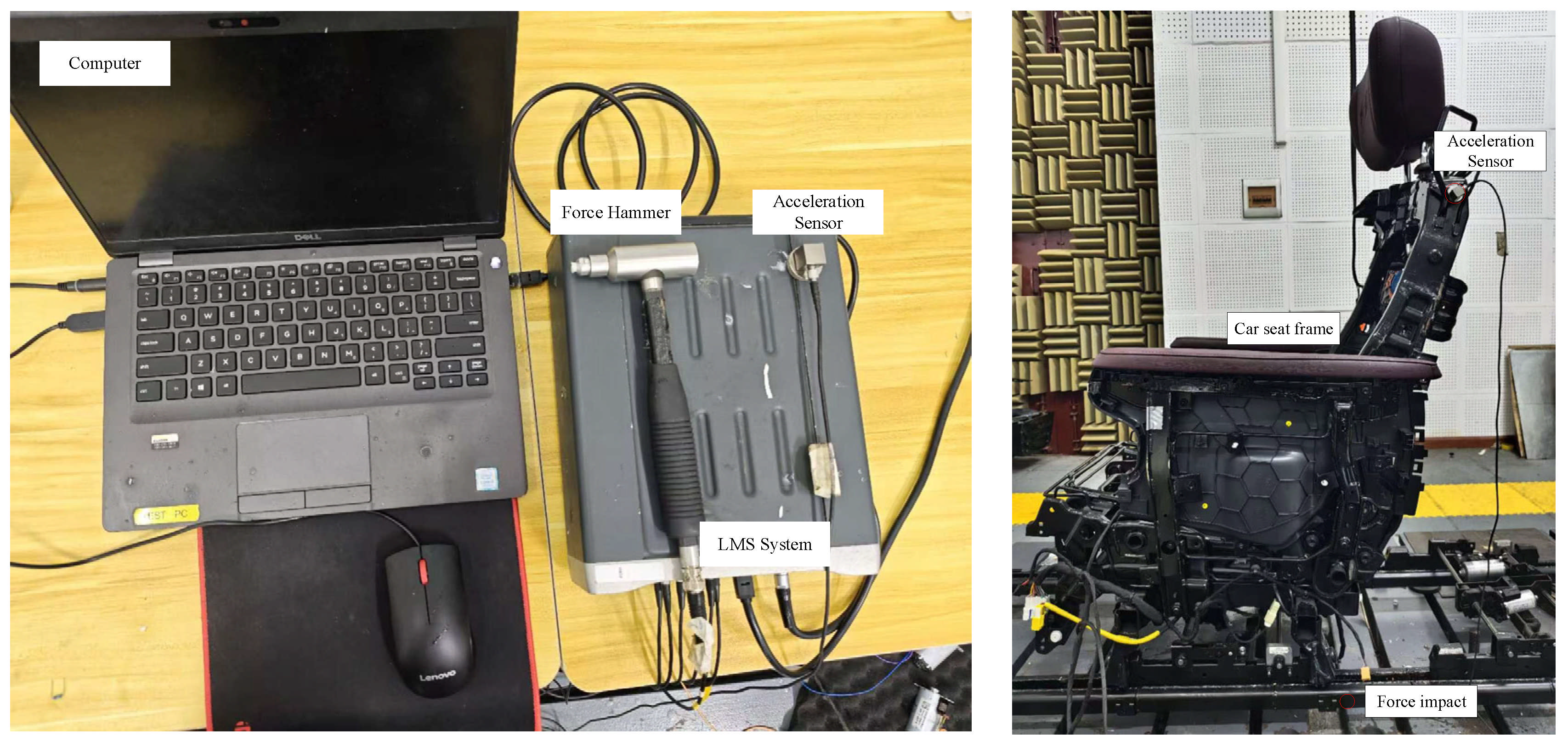

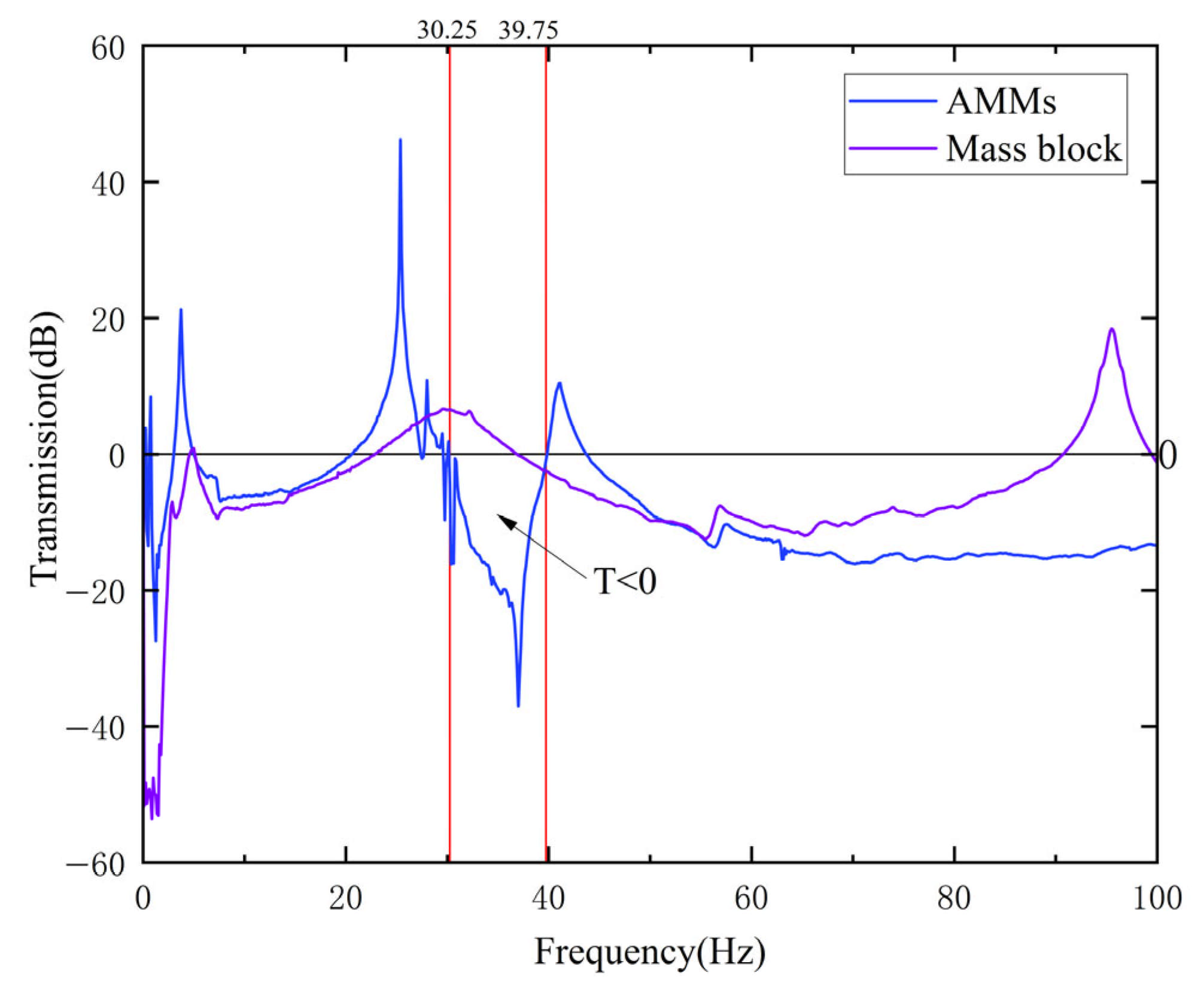

4. Experimental Verification

5. Conclusions

- (1)

- We propose a method to introduce TNN to design AMMs, which can accurately express the mutual mapping relationship between AMMs design parameters and bandgap range. In addition, the forward prediction network in this method can quickly and accurately output the predicted bandgap according to the given design parameters, and the inverse design network can output the design parameters of AMMs according to our desired bandgap range.

- (2)

- We applied this method to the vibration reduction of automobile structures, and designed AMMs for low-frequency vibration of automobile seats and bonded them to the seat back frame. Finally, the experimental results show that the maximum vibration amplitude is attenuated by 27.3% when single AMMs are pasted, and 63.6% when multiple AMMs are pasted.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Y.; Zhang, H. Band gap mechanism and vibration attenuation characteristics of the quasi-one-dimensional tetra-chiral metamaterial. Eur. J. Mech.-A/Solids 2022, 92, 104478. [Google Scholar] [CrossRef]

- Wen, Z.; Jin, Y.; Gao, P.; Zhuang, X.; Rabczuk, T.; Djafari-Rouhani, B. Topological cavities in phononic plates for robust energy harvesting. Mech. Syst. Signal Process. 2022, 162, 108047. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, X.; Mao, Y.; Zhu, Y.Y.; Yang, Z.; Chan, C.T.; Sheng, P. Locally Resonant Sonic Materials. Science 2000, 289, 1734–1736. [Google Scholar] [CrossRef]

- Lu, M.-H.; Feng, L.; Chen, Y.-F. Phononic crystals and acoustic metamaterials. Mater. Today 2009, 12, 34–42. [Google Scholar] [CrossRef]

- Arjunan, A.; Baroutaji, A.; Robinson, J.; Vance, A.; Arafat, A. Acoustic metamaterials for sound absorption and insulation in buildings. Build. Environ. 2024, 251, 111250. [Google Scholar] [CrossRef]

- Wen, G.; Zhang, S.; Wang, H.; Wang, Z.-P.; He, J.; Chen, Z.; Liu, J.; Xie, Y.M. Origami-based acoustic metamaterial for tunable and broadband sound attenuation. Int. J. Mech. Sci. 2023, 239, 107872. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, X.; Liu, Z.Y.; Fan, Q.; Lin, T.R. A study of low frequency sound insulation mechanism of a perforated plate-type acoustic metamaterial. J. Sound Vib. 2023, 558, 117775. [Google Scholar] [CrossRef]

- Deng, S.; Hu, H.; Qi, Z.; Wu, Y.; Ding, W. An Electrically Tunable Spiral Acoustic Metastructure for Reducing In-Vehicle Noise with Varying Excitation Frequencies. J. Vib. Eng. Technol. 2025, 13, 322. [Google Scholar] [CrossRef]

- Wu, Y.; Yan, W.; Wen, G.; He, Y.; Deng, S.; Ding, W. Design and Application of a Lightweight Plate-Type Acoustic Metamaterial for Vehicle Interior Low-Frequency Noise Reduction. Crystals 2024, 14, 957. [Google Scholar] [CrossRef]

- Lu, K.; Zhou, G.; Gao, N.; Li, L.; Lei, H.; Yu, M. Flexural vibration bandgaps of the multiple local resonance elastic metamaterial plates with irregular resonators. Appl. Acoust. 2020, 159, 107115. [Google Scholar] [CrossRef]

- Yoon, J.Y.; Lim, S.; Yoo, J.; Park, N.-C. Vibration reduction of cables with pendulum-type elastic metamaterials. Int. J. Mech. Sci. 2022, 220, 107169. [Google Scholar] [CrossRef]

- Lu, Z.-Q.; Zhao, L.; Ding, H.; Chen, L.-Q. A dual-functional metamaterial for integrated vibration isolation and energy harvesting. J. Sound Vib. 2021, 509, 116251. [Google Scholar] [CrossRef]

- Ma, T.-X.; Fan, Q.-S.; Li, Z.-Y.; Zhang, C.; Wang, Y.-S. Flexural wave energy harvesting by multi-mode elastic metamaterial cavities. Extreme Mech. Lett. 2020, 41, 101073. [Google Scholar] [CrossRef]

- Assouar, B.; Liang, B.; Wu, Y.; Li, Y.; Cheng, J.-C.; Jing, Y. Acoustic metasurfaces. Nat. Rev. Mater. 2018, 3, 460–472. [Google Scholar] [CrossRef]

- Tian, Z.; Shen, C.; Li, J.; Reit, E.; Gu, Y.; Fu, H.; Cummer, S.A.; Huang, T.J. Programmable Acoustic Metasurfaces. Adv. Funct. Mater. 2019, 29, 1808489. [Google Scholar] [CrossRef] [PubMed]

- Lv, P.; Yang, J.; Huo, C.; Pagliaroli, T. Predicting the ultrasonically suppressive behavior of acoustic metasurfaces. J. Sound Vib. 2022, 535, 117086. [Google Scholar] [CrossRef]

- Beli, D.; Arruda, J.; Ruzzene, M. Wave propagation in elastic metamaterial beams and plates with interconnected resonators. Int. J. Solids Struct. 2018, 139–140, 105–120. [Google Scholar] [CrossRef]

- Zhang, K.; Zhao, P.; Zhao, C.; Hong, F.; Deng, Z. Study on the mechanism of band gap and directional wave propagation of the auxetic chiral lattices. Compos. Struct. 2020, 238, 111952. [Google Scholar] [CrossRef]

- Wang, X.; Li, J.; Wang, Y.; Liu, Y. Active control of wave propagation direction of elastic metamaterial. Eur. J. Mech.-A/Solids 2025, 113, 105685. [Google Scholar] [CrossRef]

- He, P.; Zhang, Y.; Lv, Q.; Wang, Y.; Liu, Z. Research on the Vibration Damping Capabilities of Low-Frequency Bandgap Star-Quadrilateral-Coupled Acoustic Metamaterials. Arab. J. Sci. Eng. 2025, 1–17. [Google Scholar] [CrossRef]

- Li, L.; Hu, H.; Wu, X. Ultra-Low-Frequency Acoustic Black Hole Radial Elastic Metamaterials. Appl. Sci. 2023, 13, 11542. [Google Scholar] [CrossRef]

- Zhou, J. Tunable low-frequency wideband acoustic metamaterials with negative Poisson’s ratio and pre-compression. Int. J. Mech. Mater. Des. 2024, 20, 959–972. [Google Scholar] [CrossRef]

- Sanchez-Lengeling, B.; Aspuru-Guzik, A. Inverse molecular design using machine learning: Generative models for matter engineering. Science 2018, 361, 360–365. [Google Scholar] [CrossRef] [PubMed]

- Goh, G.B.; Hodas, N.O.; Vishnu, A. Deep learning for computational chemistry. J. Comput. Chem. 2017, 38, 1291–1307. [Google Scholar] [CrossRef] [PubMed]

- Baldi, P.; Sadowski, P.; Whiteson, D. Searching for exotic particles in high-energy physics with deep learning. Nat. Commun. 2014, 5, 4308. [Google Scholar] [CrossRef]

- Muhammad; Kennedy, J.; Lim, C. Machine learning and deep learning in phononic crystals and metamaterials—A review. Mater. Today Commun. 2022, 33, 104606. [Google Scholar] [CrossRef]

- Donda, K.; Brahmkhatri, P.; Zhu, Y.; Dey, B.; Slesarenko, V. Machine learning for inverse design of acoustic and elastic metamaterials. Curr. Opin. Solid State Mater. Sci. 2025, 35, 101218. [Google Scholar] [CrossRef]

- Guo, H.; Chen, W.; Wang, Y.; Ma, F.; Sun, P.; Yuan, T.; Xie, X. Parametric modeling and deep learning-based forward and inverse design for acoustic metamaterial plates. Mech. Adv. Mater. Struct. 2024, 31, 12986–12996. [Google Scholar] [CrossRef]

- Huang, J.; Chen, J.; Mai, H.; Wan, H.; Chen, R.; He, T. Performance prediction and inverse design of cylindrical plate-type acoustic metamaterials based on deep learning. Appl. Acoust. 2025, 234, 110633. [Google Scholar] [CrossRef]

- Jin, Y.; Zeng, S.; Wen, Z.; He, L.; Li, Y.; Li, Y. Deep-subwavelength lightweight metastructures for low-frequency vibration isolation. Mater. Des. 2022, 215, 110499. [Google Scholar] [CrossRef]

- He, L.; Wen, Z.; Jin, Y.; Torrent, D.; Zhuang, X.; Rabczuk, T. Inverse design of topological metaplates for flexural waves with machine learning. Mater. Des. 2021, 199, 109390. [Google Scholar] [CrossRef]

- Jiang, W.; Zhu, Y.; Yin, G.; Lu, H.; Xie, L.; Yin, M. Dispersion relation prediction and structure inverse design of elastic metamaterials via deep learning. Mater. Today Phys. 2022, 22, 100616. [Google Scholar] [CrossRef]

- Donda, K.; Zhu, Y.; Merkel, A.; Wan, S.; Assouar, B. Deep learning approach for designing acoustic absorbing metasurfaces with high degrees of freedom. Extreme Mech. Lett. 2022, 56, 101879. [Google Scholar] [CrossRef]

- Liu, C.-X.; Yu, G.-L.; Zhao, G.-Y. Neural networks for inverse design of phononic crystals. AIP Adv. 2019, 9, 085223. [Google Scholar] [CrossRef]

- Li, J.; Miao, Z.; Li, S.; Ma, Q. Inverse Design of Micro Phononic Beams Incorporating Size Effects via Tandem Neural Network. Materials 2023, 16, 1518. [Google Scholar] [CrossRef] [PubMed]

- Xiao, L.; Cao, Z.; Lu, H.; Cai, Y. Controllable and scalable gradient-driven optimization design for two-dimensional metamaterials based on deep learning. Compos. Struct. 2024, 337, 118072. [Google Scholar] [CrossRef]

- Zhou, H.; Chen, N.; Xia, B.; Man, X.; Liu, J. A data-driven inverse design framework for tunable phononic crystals. Eng. Struct. 2025, 327, 119599. [Google Scholar] [CrossRef]

- Mahesh, K.; Ranjith, S.K.; Mini, R.S. A deep autoencoder based approach for the inverse design of an acoustic-absorber. Eng. Comput. 2024, 40, 279–300. [Google Scholar] [CrossRef]

- Luo, C.; Ning, S.; Liu, Z.; Zhuang, Z. Interactive inverse design of layered phononic crystals based on reinforcement learning. Extrem. Mech. Lett. 2020, 36, 100651. [Google Scholar] [CrossRef]

- He, L.; Guo, H.; Jin, Y.; Zhuang, X.; Rabczuk, T.; Li, Y. Machine-learning-driven on-demand design of phononic beams. Sci. China Phys. Mech. Astron. 2022, 65, 214612. [Google Scholar] [CrossRef]

| Sample | a (mm) | b (mm) | r (mm) | m (g) | Network Output (Hz) | Simulation Result (Hz) | Error Rate (%) |

|---|---|---|---|---|---|---|---|

| 1 | 3.0 | 36.2 | 13.5 | 10.0 | 60.1–67.0 | 60.7–67.3 | 0.72% |

| 2 | 6.5 | 25.8 | 12.0 | 65.0 | 65.9–93.0 | 66.5–93.0 | 0.45% |

| 3 | 9.0 | 29.6 | 9.5 | 35.0 | 85.8–107.9 | 86.7–109.2 | 1.11% |

| 4 | 4.0 | 42.4 | 7.0 | 50.0 | 30.1–40.2 | 29.7–40.3 | 0.80% |

| 5 | 7.5 | 31.6 | 8.0 | 45.0 | 64.5–86.2 | 64.9–85.8 | 0.48% |

| 6 | 4.5 | 18.4 | 11.0 | 80.0 | 84.3–120.7 | 83.9–120.1 | 0.49% |

| Input Bandgap Range (Hz) | a (mm) | b (mm) | r (mm) | m (g) | Simulation Result (Hz) | Error Rate (%) |

|---|---|---|---|---|---|---|

| 30–40 | 3.2 | 42.9 | 9.2 | 35.0 | 30.6–38.9 | 2.38% |

| 40–55 | 4.6 | 38.4 | 10.2 | 35.2 | 42.6–54.1 | 4.06% |

| 55–70 | 5.2 | 34.8 | 10.4 | 30.9 | 55.3–68.6 | 1.27% |

| 70–90 | 6.2 | 30.1 | 11.0 | 33.1 | 71.8–89.6 | 1.51% |

| 90–110 | 6.2 | 27.3 | 10.4 | 28.0 | 89.7–108.9 | 0.67% |

| 110–130 | 6.0 | 25.1 | 9.1 | 23.7 | 109.0–129.2 | 0.76% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, J.; Wu, J.; Chen, X.; Zhang, X.; Li, S.; Song, Y.; Wu, J.; Xu, J.; Deng, S.; Wu, Y. Tandem Neural Network Based Design of Acoustic Metamaterials for Low-Frequency Vibration Reduction in Automobiles. Crystals 2025, 15, 676. https://doi.org/10.3390/cryst15080676

Deng J, Wu J, Chen X, Zhang X, Li S, Song Y, Wu J, Xu J, Deng S, Wu Y. Tandem Neural Network Based Design of Acoustic Metamaterials for Low-Frequency Vibration Reduction in Automobiles. Crystals. 2025; 15(8):676. https://doi.org/10.3390/cryst15080676

Chicago/Turabian StyleDeng, Jianjiao, Jiawei Wu, Xi Chen, Xinpeng Zhang, Shoukui Li, Yu Song, Jian Wu, Jing Xu, Shiqi Deng, and Yudong Wu. 2025. "Tandem Neural Network Based Design of Acoustic Metamaterials for Low-Frequency Vibration Reduction in Automobiles" Crystals 15, no. 8: 676. https://doi.org/10.3390/cryst15080676

APA StyleDeng, J., Wu, J., Chen, X., Zhang, X., Li, S., Song, Y., Wu, J., Xu, J., Deng, S., & Wu, Y. (2025). Tandem Neural Network Based Design of Acoustic Metamaterials for Low-Frequency Vibration Reduction in Automobiles. Crystals, 15(8), 676. https://doi.org/10.3390/cryst15080676