Microstructure and Mechanical Properties of High-Speed Train Wheels: A Study of the Rim and Web

Abstract

1. Introduction

2. Methods

2.1. Background

2.2. Materials

2.3. Experimental Methods

3. Results

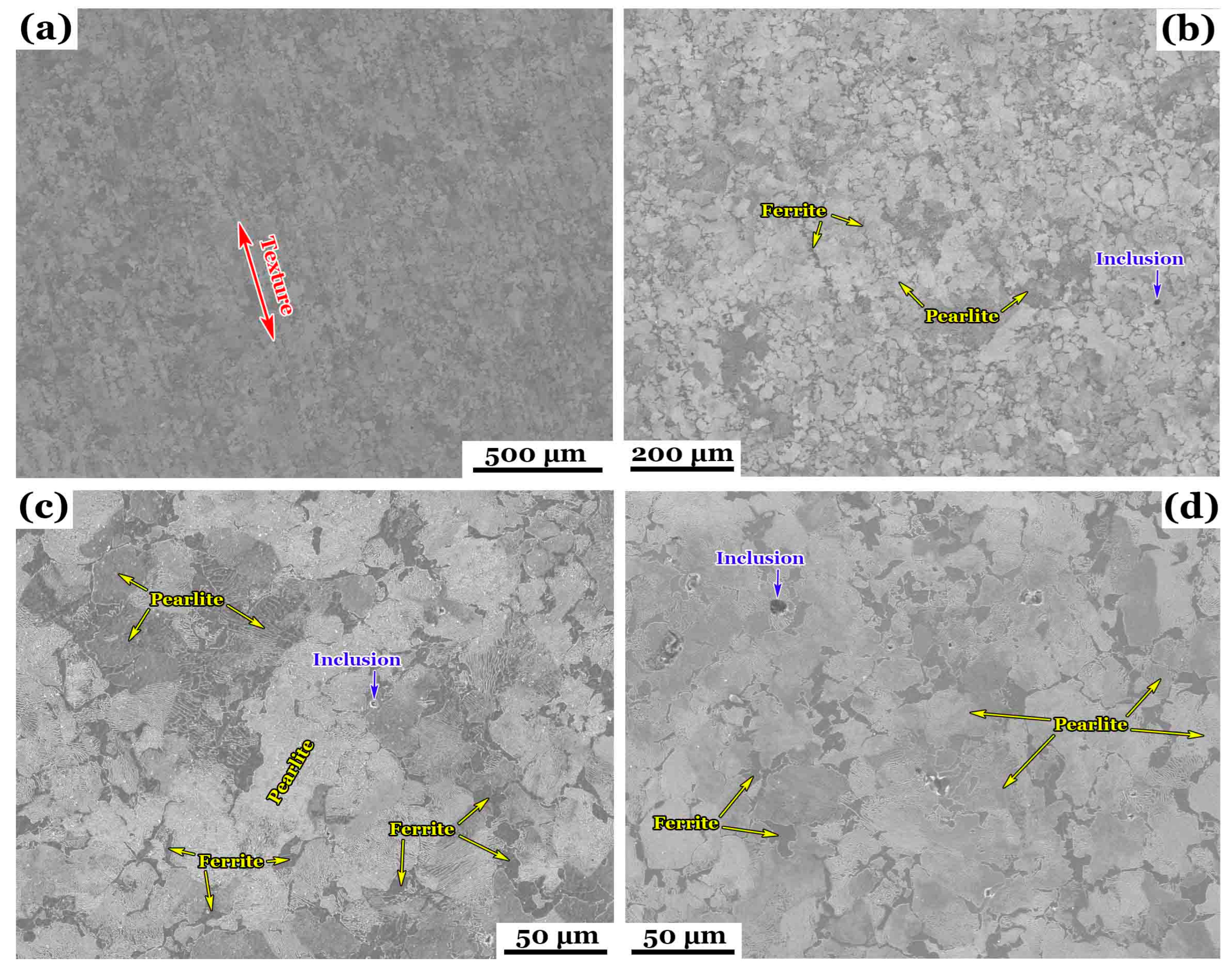

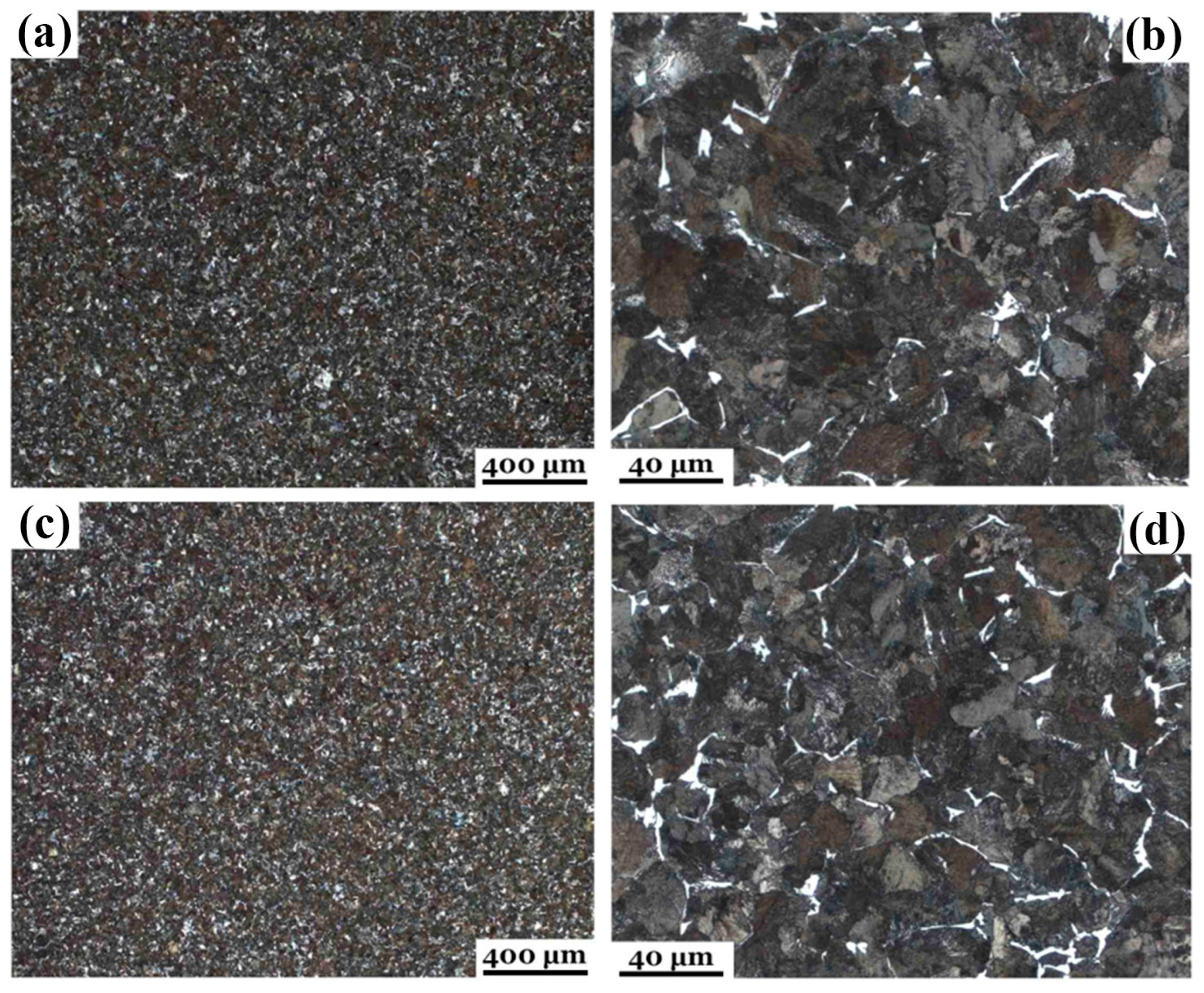

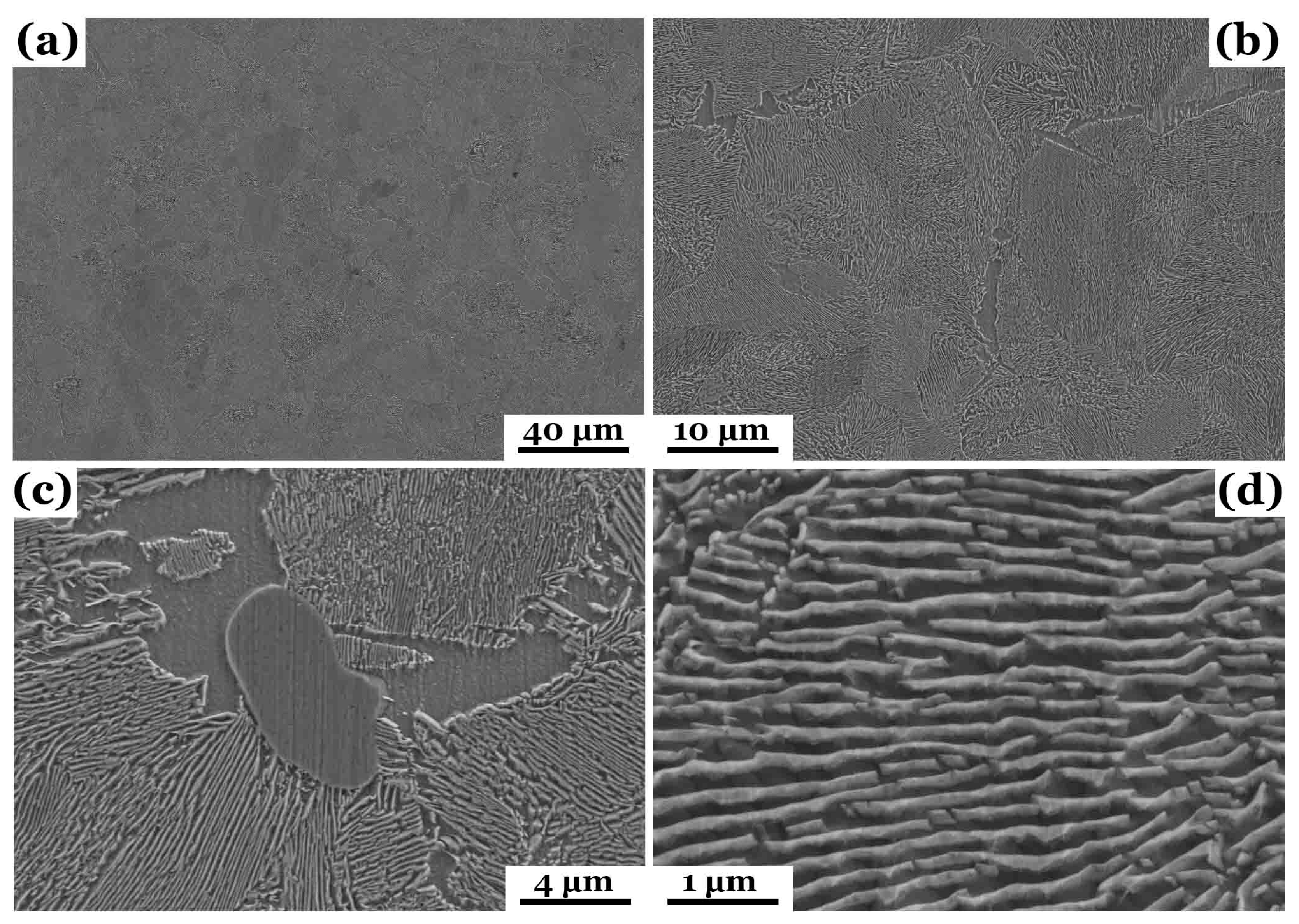

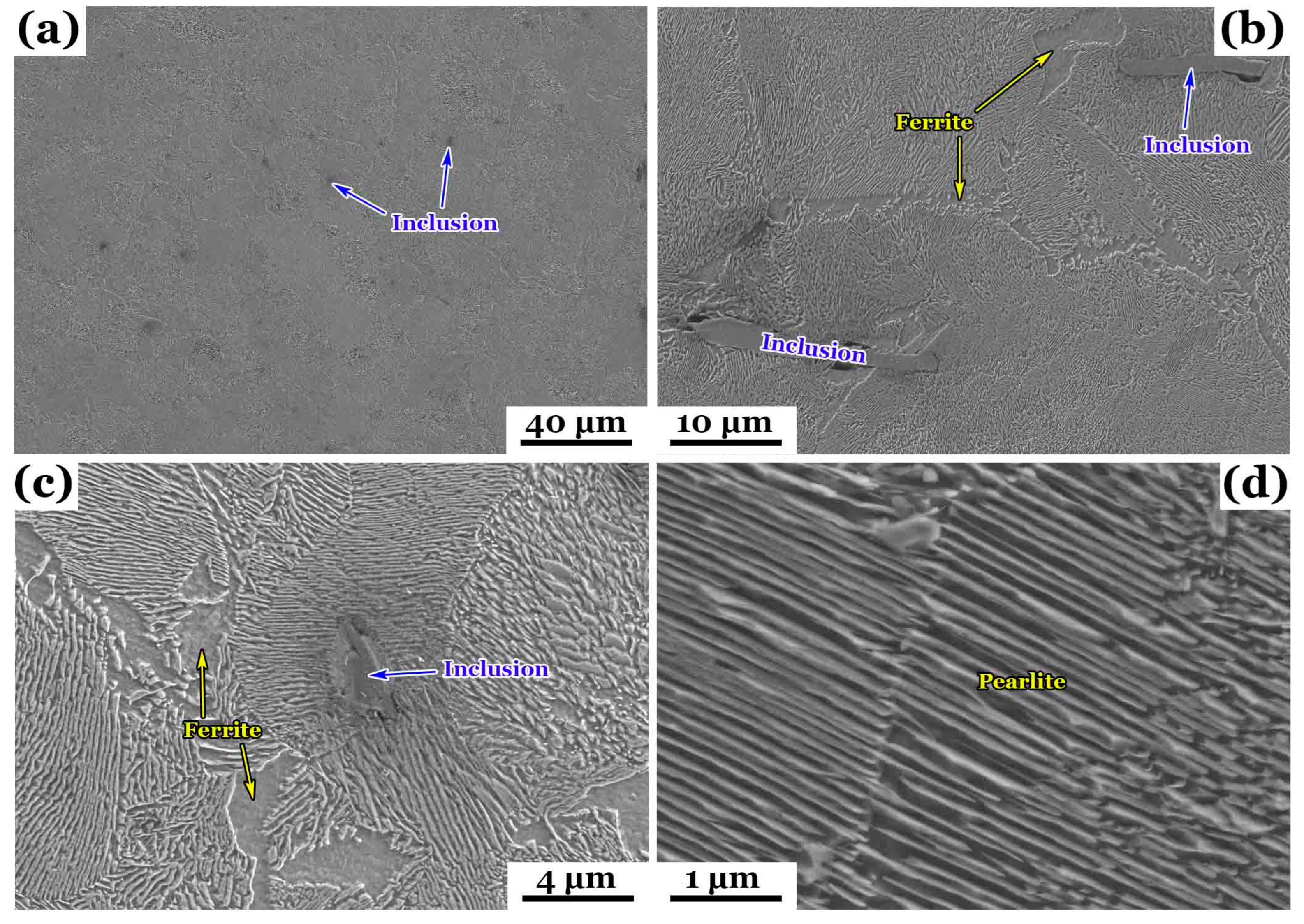

3.1. Microstructure Observations

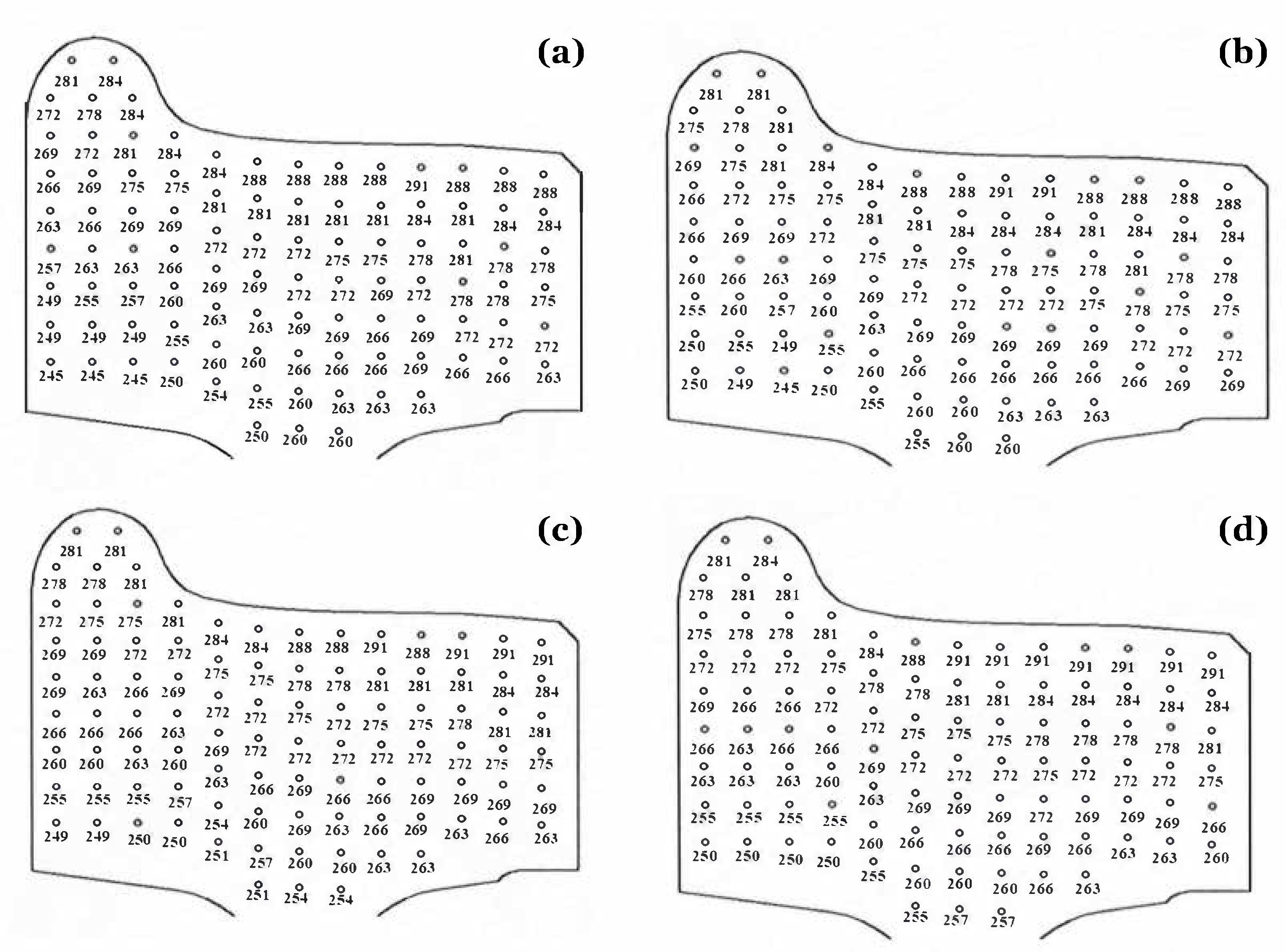

3.2. Microhardness

3.3. Tensile Properties

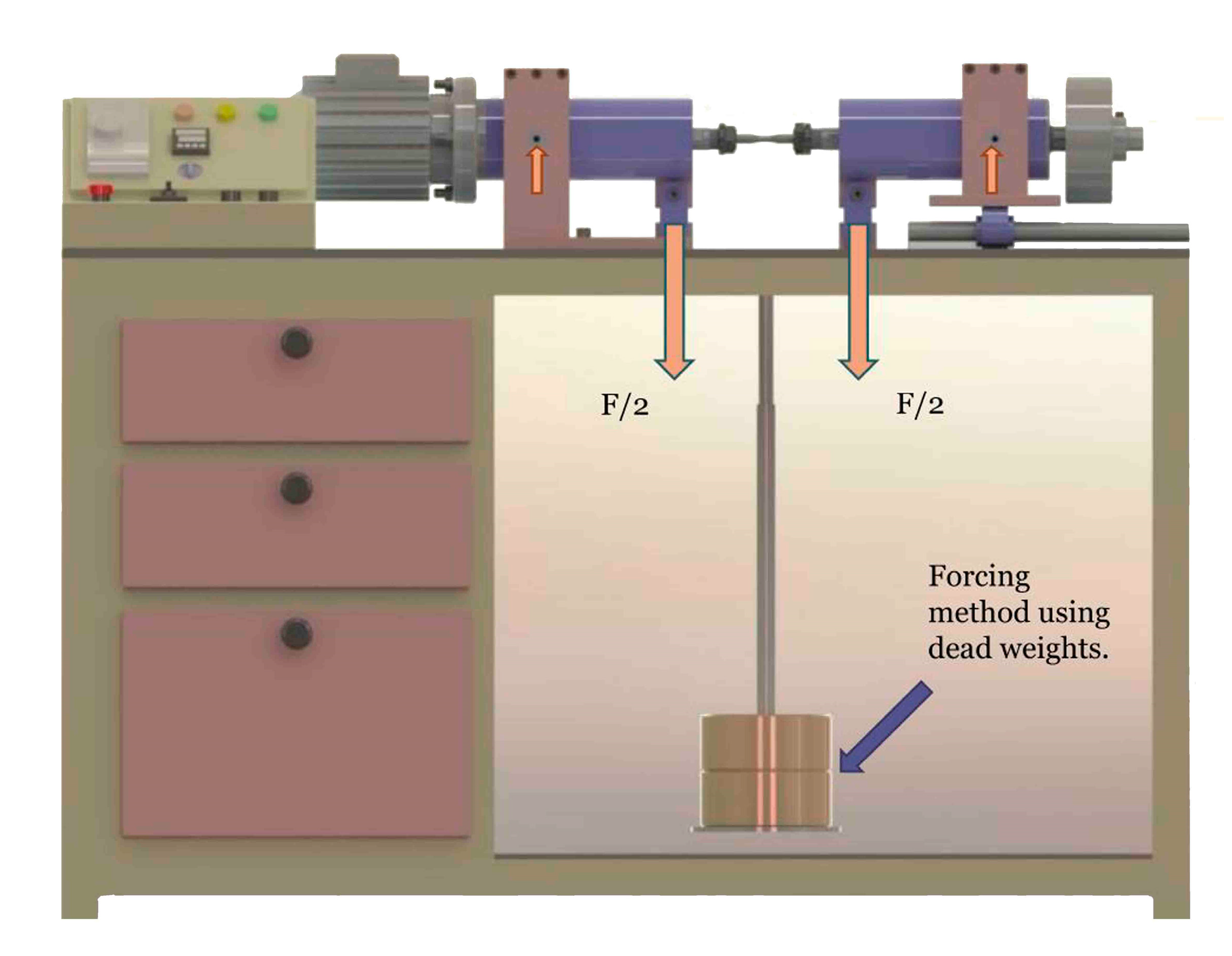

3.4. Low-Cycle and High-Cycle Fatigue

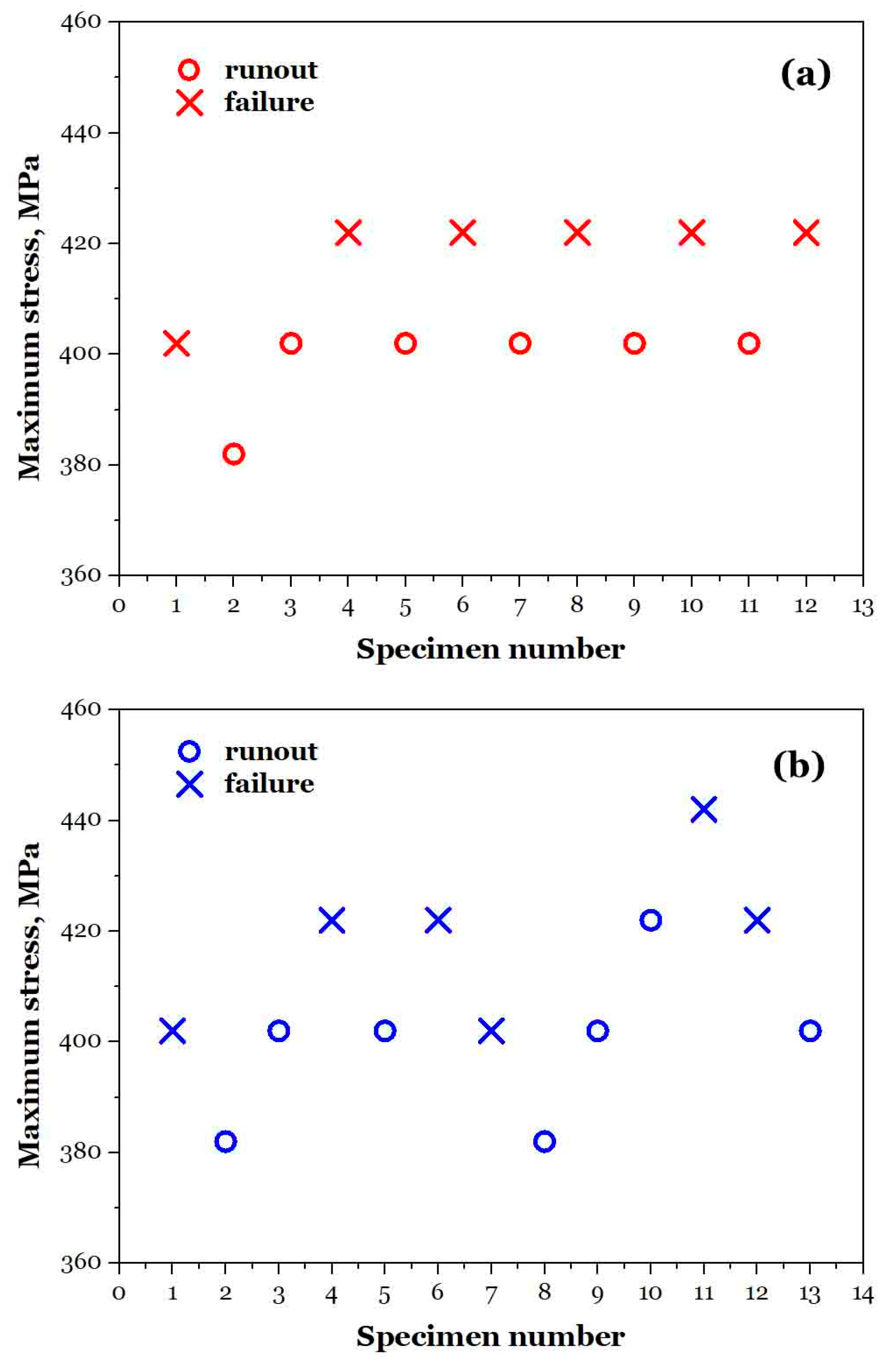

3.5. Estimating Fatigue Limit by Staircases

3.6. Engineering Implications and Limitations

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leboeuf, M. High Speed Rail—Fast Track to Sustainable Mobility; International Union of Railways: Paris, France, 2018. [Google Scholar]

- High-Speed Rail: Definition, History, Technology, Development, & Facts. Available online: https://www.britannica.com/technology/high-speed-rail (accessed on 6 April 2025).

- Glossary: High-Speed Rail. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Glossary:High-speed_rail (accessed on 6 April 2025).

- High-Speed Rail. Available online: https://en.wikipedia.org/wiki/High-speed_rail (accessed on 6 April 2025).

- Ollivier, G.; Bullock, R.; Jin, Y.; Zhou, N. High-Speed Railways in China: A Look at Traffic; World bank: Washington, DC, USA, 2014. [Google Scholar]

- TB 10621-2014; Code for Design of High Speed Railway. National Railway Administration: Beijing, China, 2014. (In Chinese)

- The State Council Information Office of the People’s Republic of China. Development of China’s Transport; State Council Information Office: Beijing, China, 2016. (In Chinese)

- International Union of Railways. High-Speed Lines in the World; International Union of Railways: Paris, France, 2024. [Google Scholar]

- TB/T 2817-2018; Solid Forged and Rolled Wheels for Railway Wagon Applications. National Railway Administration: Beijing, China, 2018. (In Chinese)

- EN 13262; Railway applications—Wheelsets and Bogies—Wheels—Product Requirements. CEN: Brussels, Belgium, 2020.

- TB/T 3469-2016; Solid Forged and Rolled Wheels for Locomotive. National Railway Administration: Beijing, China, 2016. (In Chinese)

- EN 13979-1; Railway applications—Wheelsets and bogies—Monobloc Wheels—Technical approval procedure—Part 1: Forged and Rolled Wheels. CEN: Brussels, Belgium, 2023.

- Meyers, M.A.; Chawla, K.K. Mechanical Behavior of Materials, 2nd ed.; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- Dowling, N.E. Mechanical Behavior of Materials: Engineering Methods for Deformation, Fracture, and Fatigue, 4th ed.; Pearson: Boston, MA, USA, 2013. [Google Scholar]

- Hertzberg, R.W.; Vinci, R.P.; Hertzberg, J.L. Deformation and Fracture Mechanics of Engineering Materials, 6th ed.; Wiley: Oxford, UK, 2020. [Google Scholar]

- Pan, X.; Qian, G.; Hong, Y. Nanograin formation in dimple ridges due to local severe-plastic-deformation during ductile fracture. Scr. Mater. 2021, 194, 11363. [Google Scholar] [CrossRef]

- Xu, S.; Pan, S.; Li, Z.; Li, S.; He, X.; Pan, X. Anisotropic tensile behavior and fracture characteristics of an additively manufactured nickel alloy without and with a heat treatment of solution aging. Mater. Sci. Eng. A 2025, 927, 148015. [Google Scholar] [CrossRef]

- Suresh, S. Fatigue of Materials, 2nd ed.; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Murakami, Y. Metal Fatigue: Effect of Small Defects and Nonmetallic Inclusions; Elsevier: Oxford, UK, 2002. [Google Scholar]

- Schijve, J. Fatigue of Structures and Materials, 2nd ed.; Springer: Dordrecht, Germany, 2009. [Google Scholar]

- Pan, X.; Su, H.; Sun, C.; Hong, Y. The behavior of crack initiation and early growth in high-cycle and very-high-cycle fatigue regimes for a titanium alloy. Int. J. Fatigue 2018, 115, 67–78. [Google Scholar] [CrossRef]

- Pan, X.; Hong, Y. High-cycle and very-high-cycle fatigue behaviour of a titanium alloy with equiaxed microstructure under different mean stresses. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 1950–1964. [Google Scholar] [CrossRef]

- Sun, C.; Song, Q.; Zhou, L.; Pan, X. Characteristic of interior crack initiation and early growth for high cycle and very high cycle fatigue of a martensitic stainless steel. Mater. Sci. Eng. A 2019, 758, 112–120. [Google Scholar] [CrossRef]

- Chang, Y.; Zheng, L.; Pan, X.; Hong, Y. Further investigation on microstructure refinement of internal crack initiation region in VHCF regime of high-strength steels. Frat. Ed Integrità Strutturale 2019, 13, 1–11. [Google Scholar] [CrossRef]

- Chang, Y.; Pan, X.; Zheng, L.; Hong, Y. Microstructure refinement and grain size distribution in crack initiation region of very-high-cycle fatigue regime for high-strength alloys. Int. J. Fatigue 2020, 134, 105473. [Google Scholar] [CrossRef]

- Pan, X.; Xu, S.; Qian, G.; Nikitin, A.; Shanyavskiy, A.; Palin-Luc, T.; Hong, Y. The mechanism of internal fatigue-crack initiation and early growth in a titanium alloy with lamellar and equiaxed microstructure. Mater. Sci. Eng. A 2020, 798, 140110. [Google Scholar] [CrossRef]

- Liu, L.; Ma, Y.; Liu, S.; Wang, S. The fatigue behaviors of a medium-carbon pearlitic wheel-steel with elongated sulfides in high-cycle and very-high-cycle regimes. Materials 2021, 14, 4318. [Google Scholar] [CrossRef] [PubMed]

- Cong, T.; Qian, G.; Zhang, G.; Wu, S.; Pan, X.; Du, L.; Liu, X. Effects of inclusion size and stress ratio on the very-high-cycle fatigue behavior of pearlitic steel. Int. J. Fatigue 2021, 142, 105958. [Google Scholar] [CrossRef]

- Zhou, H.; Suzuki, Y.; Kinefuchi, M.; Shibanuma, K. Applicability of the multiscale model for predicting fatigue strength to short and long crack problems. ISIJ Int. 2022, 62, 2126–2131. [Google Scholar] [CrossRef]

- Zhou, H.; Liu, Z.; Kinefuchi, M.; Shibanuma, K. Multiscale modelling strategy for predicting fatigue lives and limits of steels based on a generalised evaluation method of grain boundaries effects. Int. J. Fatigue 2022, 158, 106749. [Google Scholar] [CrossRef]

- Zhou, Y.; Sun, J.; Pan, X.; Qian, G.; Hong, Y. Microstructure evolution and very-high-cycle fatigue crack initiation behavior of a structural steel with two loading intermittence modes. Int. J. Fatigue 2022, 161, 106904. [Google Scholar] [CrossRef]

- Chen, Z.; Bao, H.; Dai, Y.; Liu, Y. Numerical prediction based on XFEM for mixed-mode crack growth path and fatigue life under cyclic overload. Int. J. Fatigue 2022, 162, 106943. [Google Scholar] [CrossRef]

- Chen, Z.; Dai, Y.; Liu, Y. Numerical study on high-cycle fatigue crack growth of sinusoidal interface based on cyclic cohesive zone model. Int. J. Fatigue 2023, 174, 107748. [Google Scholar] [CrossRef]

- Chen, Z.; Dai, Y.; Liu, Y. Life prediction of corrosion-fatigue based on a new crack growth rate model with damage and the extended finite element method. Eng. Fract. Mech. 2023, 289, 109445. [Google Scholar] [CrossRef]

- Zhou, H.; Suzuki, Y.; Kinefuchi, M.; Schmauder, S.; Dogahe, K.; Shibanuma, K. Bridging strategy between microscopic and macroscopic crack growth simulations to predict fatigue strength of steels. Int. J. Fatigue 2023, 168, 107386. [Google Scholar] [CrossRef]

- Zhou, H.; Liu, Z.; Kikuchi, S.; Shibanuma, K. Analysis of fatigue performance of austenitic stainless steels with bimodal harmonic structures based on multiscale model simulations. Mater. Des. 2023, 226, 111657. [Google Scholar] [CrossRef]

- Hong, Y.; Hu, Y.; Zhao, A. Effects of loading frequency on fatigue behavior of metallic materials—A literature review. Fatigue Fract. Eng. Mater. Struct. 2023, 46, 3077–3098. [Google Scholar] [CrossRef]

- Pan, X.; Su, H.; Liu, X.; Hong, Y. Multi-scale fatigue failure features of titanium alloys with equiaxed or bimodal microstructures from low-cycle to very-high-cycle loading numbers. Mater. Sci. Eng. A 2024, 890, 145906. [Google Scholar] [CrossRef]

- Pan, X.; Xu, S.; Nikitin, A.; Shanyavskiy, A.; Palin-Luc, T.; Hong, Y. Crack initiation induced nanograins and facets of a titanium alloy with lamellar and equiaxed microstructure in very-high-cycle fatigue. Mater. Lett. 2024, 357, 135769. [Google Scholar] [CrossRef]

- Chen, Z.; Dai, Y.; Liu, Y. Crack propagation simulation and overload fatigue life prediction via enhanced physics-informed neural networks. Int. J. Fatigue 2024, 186, 108382. [Google Scholar] [CrossRef]

- Chen, Z.; Dai, Y.; Liu, Y. Structural fatigue crack propagation simulation and life prediction based on improved XFEM-VCCT. Eng. Fract. Mech. 2024, 310, 110519. [Google Scholar] [CrossRef]

- Romano, L.; Maglio, M.; Bruni, S. Transient wheel-rail rolling contact theories. Tribol. Int. 2023, 186, 108600. [Google Scholar] [CrossRef]

- Shao, Z.; Zou, Q.; Zhu, Y.; Zhang, P.; Wang, B.; Xu, Z.; Gu, X.; Wang, Q.; Zhang, Z. Effect of alloy elements on the rolling contact fatigue performance of wheel steel. Mater. Sci. Eng. A 2024, 913, 147085. [Google Scholar] [CrossRef]

- Bai, Z.; Zhou, J.; Lin, Y.; Li, J.; Ma, C.; Shen, M. Effects of intermittent airflow on rolling contact damage characteristics of wheel steels in a low-temperature environment: Airflow humidity. Wear 2025, 572–573, 206025. [Google Scholar] [CrossRef]

- Li, Z.; Han, J.; Yang, Z.; Li, W. Analyzing the mechanisms of thermal fatigue and phase change of steel used in brake discs. Eng. Fail. Anal. 2015, 57, 202–218. [Google Scholar] [CrossRef]

- Hong, H.; Kim, M.; Lee, H.; Jeong, N.; Moon, H.; Lee, E.; Kim, H.; Suh, M.; Chung, J.; Lee, J. The thermo-mechanical behavior of brake discs for high-speed railway vehicles. J. Mech. Sci. Technol. 2019, 33, 1711–1721. [Google Scholar] [CrossRef]

- Yang, Z.; Fang, D.; Sun, M.; Wang, Y.; Li, Z. Experimental and simulation investigation of the thermal crack formation mechanism on the friction surface of SiCp/A356 brake discs. Eng. Fail. Anal. 2025, 171, 109341. [Google Scholar] [CrossRef]

- True, H.; Christiansen, L.E.; Plesner, A.L.; Ammitzbøll, A.L.; Dahl, B.J. On the problem of the dynamical reactions of a rolling wheelset to real track irregularities. Railw. Eng. Sci. 2023, 31, 1–19. [Google Scholar] [CrossRef]

- Lu, K. Gradient nanostructured materials. Acta Metall. Sin. 2015, 51, 1–10. (In Chinese) [Google Scholar]

- Zhang, S.; Xie, J.; Jiang, Q.; Zhang, X.; Sun, C.; Hong, Y. Fatigue crack growth behavior in gradient microstructure of hardened surface layer for an axle steel. Mater. Sci. Eng. A 2017, 700, 66–74. [Google Scholar] [CrossRef]

- Pan, X.; Qian, G.; Wu, S.; Fu, Y.; Hong, Y. Internal crack characteristics in very-high-cycle fatigue of a gradient structured titanium alloy. Sci. Rep. 2020, 10, 4742. [Google Scholar] [CrossRef] [PubMed]

- Qian, G.; Jian, Z.; Pan, X.; Berto, F. In-situ investigation on fatigue behaviors of Ti-6Al-4V manufactured by selective laser melting. Int. J. Fatigue 2020, 133, 105424. [Google Scholar] [CrossRef]

- Qian, G.; Jian, Z.; Qian, Y.; Pan, X.; Ma, X.; Hong, Y. Very-high-cycle fatigue behavior of AlSi10Mg manufactured by selective laser melting: Effect of build orientation and mean stress. Int. J. Fatigue 2020, 138, 105696. [Google Scholar] [CrossRef]

- Du, L.; Pan, X.; Qian, G.; Zheng, L.; Hong, Y. Crack initiation mechanisms under two stress ratios up to very-high-cycle fatigue regime for a selective laser melted Ti-6Al-4V. Int. J. Fatigue 2021, 149, 106294. [Google Scholar] [CrossRef]

- Long, X.; Jia, Q.; Li, J.; Chong, K.; Du, L.; Pan, X.; Chang, C. Mechanical properties and parameter optimization of TC4 alloy by additive manufacturing. China Surf. Eng. 2022, 35, 215–223. (In Chinese) [Google Scholar]

- Tao, Z.; Wang, Z.; Pan, X.; Su, T.; Long, X.; Liu, B.; Tang, Q.; Ren, X.; Sun, C.; Qian, G.; et al. A new probabilistic control volume scheme to interpret specimen size effect on fatigue life of additively manufactured titanium alloys. Int. J. Fatigue 2024, 183, 108262. [Google Scholar] [CrossRef]

- Pan, X.; Du, L.; Qian, G.; Hong, Y. Microstructure features induced by fatigue crack initiation up to very-high-cycle regime for an additively manufactured aluminium alloy. J. Mater. Sci. Technol. 2024, 173, 247–260. [Google Scholar] [CrossRef]

- Pan, X.; Hong, Y. High-cycle and very-high-cycle fatigue of an additively manufactured aluminium alloy under axial cycling at ultrasonic and conventional frequencies. Int. J. Fatigue 2024, 185, 108363. [Google Scholar] [CrossRef]

- Du, L.; Pan, X.; Hong, Y. New insights into microstructure refinement in crack initiation region of very-high-cycle fatigue for SLM Ti-6Al-4V via precession electron diffraction. Materialia 2024, 33, 102008. [Google Scholar] [CrossRef]

- Gao, C.; Zhang, Y.; Jiang, J.; Fu, R.; Du, L.; Pan, X. Research viewpoint on performance enhancement for very-high-cycle fatigue of Ti-6Al-4V alloys via laser-based powder bed fusion. Crystals 2024, 14, 749. [Google Scholar] [CrossRef]

- GB/T 228.1-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Standardization Administration of China: Beijing, China, 2021.

| C | Si | Mn | P | S | Cr | Cu | Ni | Mo | V | Cr + Ni + Mo | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Required | ≤0.56 | ≤0.40 | ≤0.80 | ≤0.02 | ≤0.015 | ≤0.30 | ≤0.30 | ≤0.30 | ≤0.08 | ≤0.06 | ≤0.50 |

| Measured | 0.54 | 0.30 | 0.75 | 0.013 | 0.007 | 0.18 | 0.20 | 0.10 | 0.04 | 0.003 | 0.32 |

| The Wheel Rim | The Wheel Web | ||||||

|---|---|---|---|---|---|---|---|

| σu | σy | δf | ψf | σu | δf | ψf | |

| Required | 860~980 MPa | ≥540 MPa | ≥13% | – | 740~860 MPa | ≥16% | – |

| Measured | 929 ± 8 MPa | 602 ± 5 MPa | 17.0 ± 1.5% | 46.0 ± 1.2% | 779 ± 5 MPa | 21.0 ± 1.1% | 42.0 ± 1.2% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, C.; Zhang, Y.; Fan, T.; Wang, J.; Song, H.; Su, H. Microstructure and Mechanical Properties of High-Speed Train Wheels: A Study of the Rim and Web. Crystals 2025, 15, 677. https://doi.org/10.3390/cryst15080677

Gao C, Zhang Y, Fan T, Wang J, Song H, Su H. Microstructure and Mechanical Properties of High-Speed Train Wheels: A Study of the Rim and Web. Crystals. 2025; 15(8):677. https://doi.org/10.3390/cryst15080677

Chicago/Turabian StyleGao, Chun, Yuanyuan Zhang, Tao Fan, Jia Wang, Huajian Song, and Hang Su. 2025. "Microstructure and Mechanical Properties of High-Speed Train Wheels: A Study of the Rim and Web" Crystals 15, no. 8: 677. https://doi.org/10.3390/cryst15080677

APA StyleGao, C., Zhang, Y., Fan, T., Wang, J., Song, H., & Su, H. (2025). Microstructure and Mechanical Properties of High-Speed Train Wheels: A Study of the Rim and Web. Crystals, 15(8), 677. https://doi.org/10.3390/cryst15080677