Design of GaN-Based Laser Diode Structures with Nonuniform Doping Distribution in a p-AlGaN Cladding Layer for High-Efficiency Operation

Abstract

1. Introduction

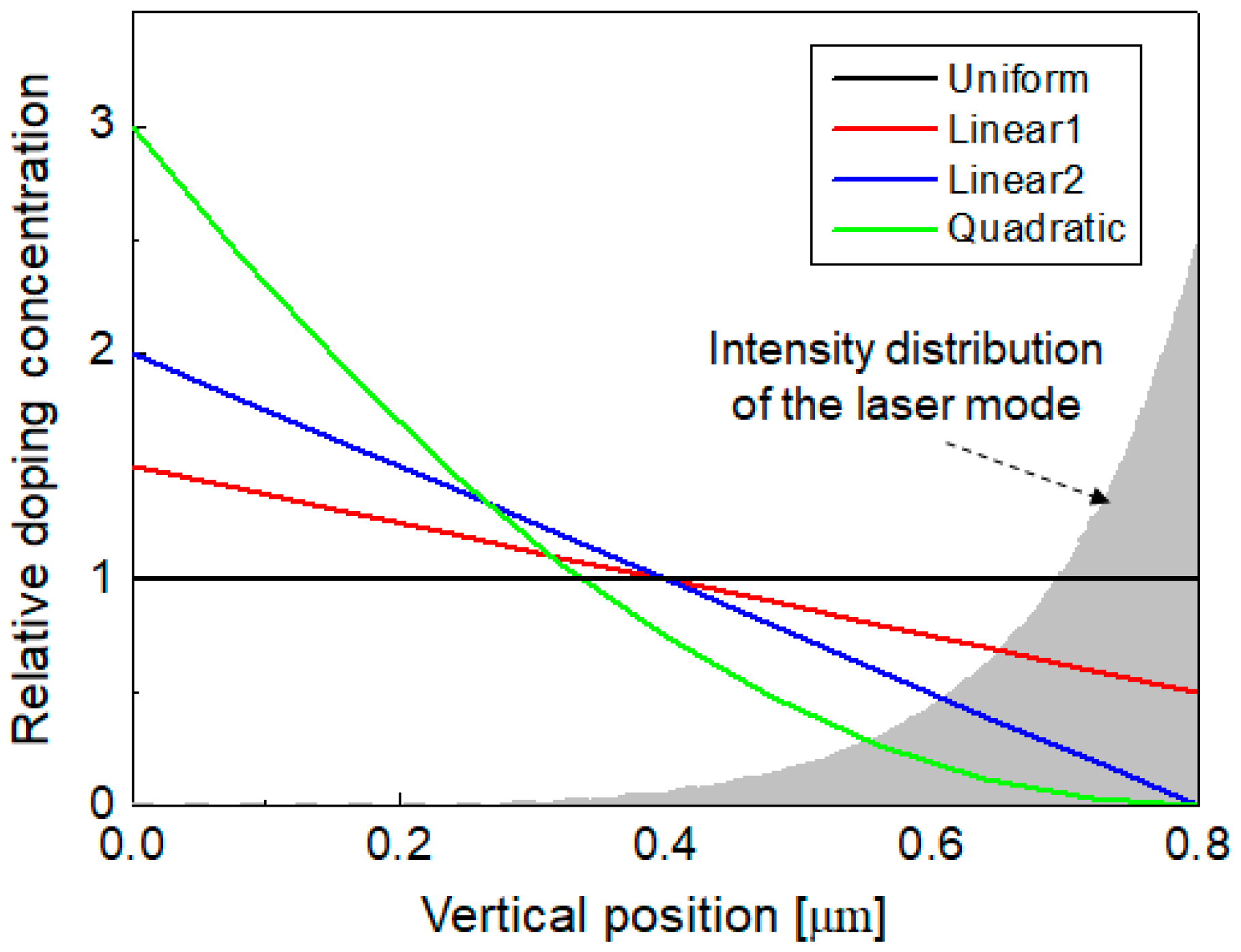

2. Simulation Structure and Methods

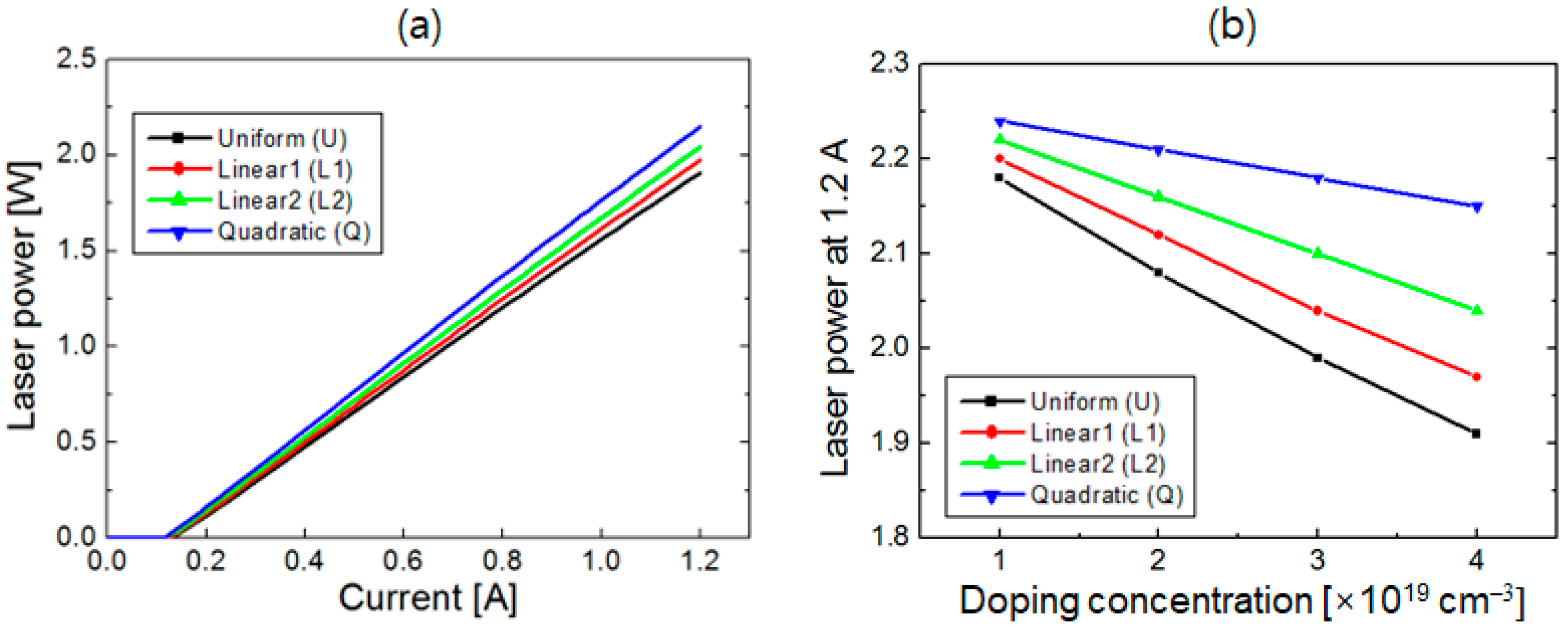

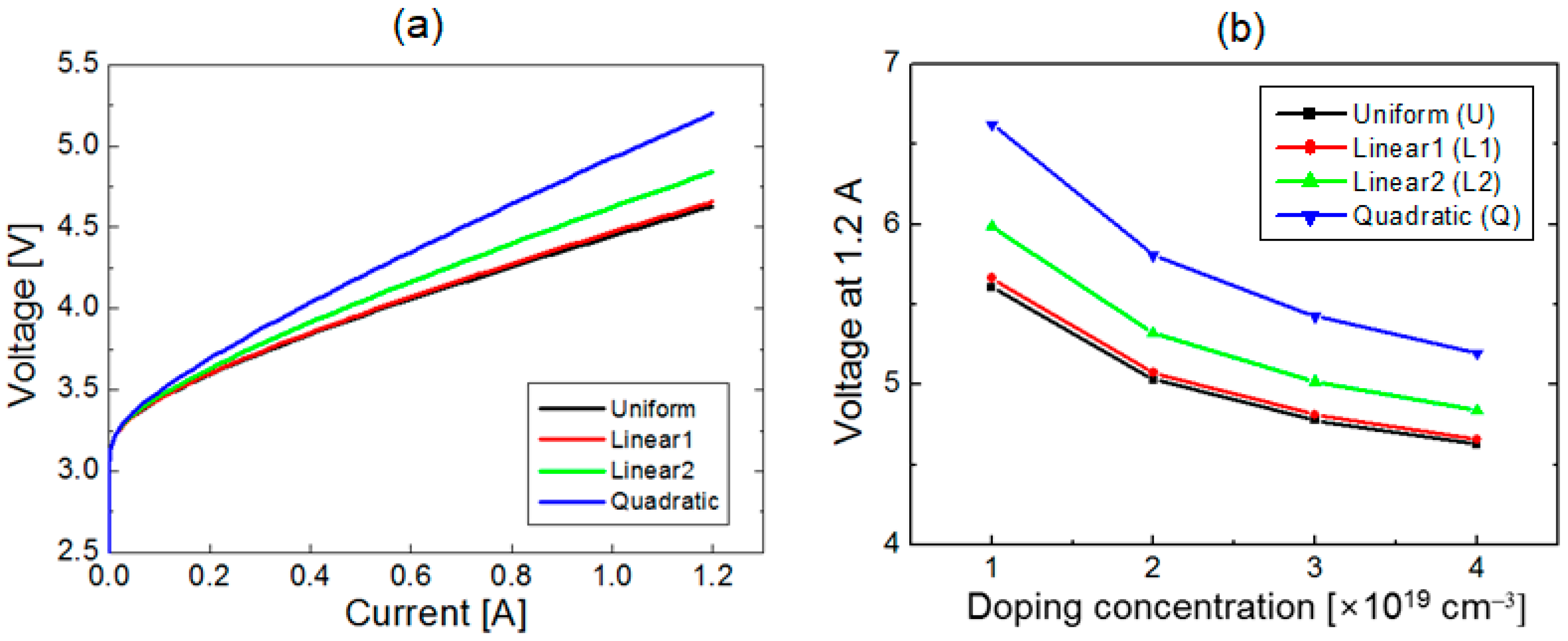

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ponce, F.A.; Bour, D.P. Nitride-based semiconductors for blue and green light-emitting devices. Nature 1997, 386, 351–359. [Google Scholar] [CrossRef]

- Murayama, M.; Nakayama, Y.; Yamazaki, K.; Hoshina, Y.; Watanabe, H.; Fuutagawa, N.; Kawanishi, H.; Uemura, T.; Narui, H. Watt-class green (530 nm) and blue (465 nm) laser diodes. Phys. Status Solidi A 2018, 215, 1700513. [Google Scholar] [CrossRef]

- Nakatsu, Y.; Nagao, Y.; Hirao, T.; Hara, Y.; Masui, S.; Yamamoto, T.; Nagahama, S. Blue and green InGaN semiconductor lasers as light sources for displays. Proc. SPIE 2020, 11280, 81–87. [Google Scholar]

- Wierer, J.J.; Tsao, J.Y.; Sizov, D.S. Comparison between blue lasers and light-emitting diodes for future solid-state lighting. Laser Photonics Rev. 2013, 7, 963–993. [Google Scholar] [CrossRef]

- Ryu, H.Y.; Kim, D.H. High-brightness phosphor-conversion white light source using InGaN blue laser diode. J. Opt. Soc. Korea 2010, 14, 415–419. [Google Scholar] [CrossRef]

- Sui, P.; Lin, H.; Lin, Y.; Lin, S.; Huang, J.; Xu, J.; Cheng, Y.; Wang, Y. Toward high-power-density laser-driven lighting: Enhancing heat dissipation in phosphor-in-glass film by introducing h-BN. Opt. Lett. 2022, 47, 3455–3458. [Google Scholar] [CrossRef] [PubMed]

- Watson, S.; Tan, M.; Najda, S.P.; Perlin, P.; Leszczynski, M.; Targowaski, G.; Grzanka, S.; Kelly, A.E. Visible light communications using a directly modulated 422 nm GaN laser diode. Opt. Lett. 2013, 38, 3792–3794. [Google Scholar] [CrossRef]

- Lee, C.; Zhang, C.; Cantore, M.; Farrell, R.M.; Oh, S.H.; Margalith, T.; Speck, J.S.; Nakamura, S.; Bowers, J.E.; DenBaars, S.P. 4 Gbps direct modulation of 450 nm GaN laser for high-speed visible light communication. Opt. Express 2015, 23, 16232–16237. [Google Scholar] [CrossRef]

- Wu, T.C.; Chi, Y.C.; Wang, H.Y.; Tsai, C.T.; Lin, G.R. Blue laser diode enables underwater communication at 12.4 Gbps. Sci. Rep. 2017, 7, 40480. [Google Scholar] [CrossRef]

- Wang, H.; Kawahito, Y.; Yoshida, R.; Nakashima, Y.; Shiokawa, K. Development of a high-power blue laser (445 nm) for material processing. Opt. Lett. 2017, 42, 2151–2154. [Google Scholar] [CrossRef]

- Baumann, M.; Balck, A.; Malchus, J.; Chacko, R.V.; Marfels, S.; Witte, U.; Dinakaran, D.; Ocylok, S.; Weinbach, M.; Bachert, C. 1000 W blue fiber-coupled diode laser emitting at 450 nm. Proc. SPIE 2019, 10900, 10–21. [Google Scholar]

- Hagino, H.; Kawaguchi, M.; Nozaki, S.; Mochida, A.; Kano, T.; Takigawa, S.; Katayama, T.; Tanaka, T. High-power InGaN laser array with advanced lateral-corrugated waveguides. IEEE J. Quantum Electron. 2021, 57, 2600107. [Google Scholar] [CrossRef]

- Hatakeyama, K.; Tanahashi, Y.; Konishi, R.; Nakagaki, M.; Okuno, R.; Sugiyama, T.; Shibuya, S.; Okada, A.; Hayamizu, N. High-power and high-luminance blue laser module using GaN-based laser diodes. Proc. SPIE 2024, 12867, 74–80. [Google Scholar]

- Zhong, Z.; Lu, S.; Li, J.; Lin, W.; Huang, K.; Li, S.; Cai, D.; Kang, J. Design and fabrication of high power InGaN blue laser diode over 8 W. Opt. Laser Technol. 2021, 139, 106985. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, J.; Liang, F.; Chen, P.; Liu, Z.; Zhao, D. Low threshold current density and high power InGaN-based blue-violet laser diode with an asymmetric waveguide structure. Opt. Express 2023, 31, 7839–7849. [Google Scholar] [CrossRef] [PubMed]

- Piprek, J. Comparative efficiency analysis of GaN-based light-emitting diodes and laser diodes. Appl. Phys. Lett. 2016, 109, 021104. [Google Scholar] [CrossRef]

- Piprek, J. Analysis of efficiency limitations in high-power InGaN/GaN laser diodes. Opt. Quantum Electron. 2016, 48, 471. [Google Scholar] [CrossRef]

- Onwukaeme, C.; Ryu, H.Y. Investigation of the optimum Mg doping concentration in p-type-doped layers of InGaN blue laser diode structures. Crystals 2021, 11, 1335. [Google Scholar] [CrossRef]

- Aktas, M.; Kafar, A.; Stanczyk, S.; Marona, L.; Schiavon, D.; Grzanka, S.; Wisniewski, P.; Perlin, P. Optimization of p-clading layer utilizing polarization doping for blue-violet InGaN laser diodes. Opt. Laser Technol. 2024, 177, 111144. [Google Scholar] [CrossRef]

- Schubert, E.F. Light-Emitting Diodes, 2nd ed.; Cambridge University Press: Cambridge, UK, 2006; pp. 145–149. [Google Scholar]

- Kioupakis, E.; Rinke, P.; Van de Walle, C.G. Determination of internal loss in nitride lasers from first principles. Appl. Phys. Express 2010, 3, 082101. [Google Scholar] [CrossRef]

- Son, J.K.; Lee, S.N.; Paek, H.S.; Sakong, T.; Kim, H.K.; Park, Y.; Ryu, H.Y.; Nam, O.H.; Hwang, J.S.; Cho, Y.H. Measurement of optical loss variation on thickness of InGaN optical confinement layers of blue-violet-emitting laser diodes. J. Appl. Phys. 2008, 103, 103101. [Google Scholar] [CrossRef]

- Kioupakis, E.; Rinke, P.; Schleife, A.; Bechstedt, F.; Van de Walle, C.G. Free-carrier absorption in nitrides from first principles. Phys. Rev. B 2010, 82, 241201. [Google Scholar] [CrossRef]

- Chen, Y.; Jiang, D.; Zeng, C.; Xu, C.; Sun, H.; Hou, Y.; Zhou, M. Controlling GaN-based laser diode performance by variation of the Al content of an inserted AlGaN electron blocking layer. Nanomaterials 2024, 14, 449. [Google Scholar] [CrossRef]

- Uchida, S.; Takeya, M.; Ikeda, S.; Mizuno, T.; Fujimoto, T.; Matsumoto, O.; Goto, S.; Tojyo, T.; Ikeda, M. Recent progress in high-power blue-violet lasers. IEEE J. Sel. Top. Quantum Electron. 2023, 9, 1252. [Google Scholar] [CrossRef]

- Liang, F.; Zhao, D.; Jiang, D.; Liu, Z.; Zhu, J.; Chen, P.; Yang, J.; Liu, W.; Li, X.; Liu, S.; et al. New design of upper waveguide with unintentionally doped InGaN layer for InGaN-based laser diode. Opt. Laser Technol. 2017, 97, 284–289. [Google Scholar] [CrossRef]

- Chen, P.; Feng, M.X.; Jiang, D.S.; Zhao, D.G.; Liu, Z.S.; Li, L.; Wu, L.L.; Le, L.C.; Zhu, J.J.; Wang, H. Improvement of characteristics of InGaN-based laser diodes with undoped InGaN upper waveguide layer. J. Appl. Phys. 2012, 112, 113105. [Google Scholar] [CrossRef]

- Hou, Y.; Zhao, D.; Liang, F.; Liu, Z.; Yang, J.; Chen, P. Enhancing the efficiency of GaN-based laser diodes by the designing of a p-AlGaN cladding layer and an upper waveguide layer. Opt. Mater. Express 2021, 11, 1780. [Google Scholar] [CrossRef]

- Ryu, H.Y.; Ha, K.H.; Lee, S.N.; Choi, K.K.; Jang, T.; Son, J.K.; Chae, J.H.; Chae, S.H.; Paek, H.S.; Sung, Y.J.; et al. Single-mode blue-violet laser diodes with low beam divergence and high COD level. IEEE Photonics Technol. Lett. 2006, 18, 1001–1003. [Google Scholar] [CrossRef]

- Ryu, H.Y.; Ha, K.H.; Son, J.K.; Paek, H.S.; Sung, Y.J.; Kim, K.S.; Kim, H.K.; Park, Y.; Lee, S.N.; Nam, O.H. Comparison of output power of InGaN laser diodes for different Al compositions in the AlGaN n-cladding layer. J. Appl. Phys. 2009, 105, 103102. [Google Scholar] [CrossRef]

- LASTIP by Crosslight Software Inc. Burnaby Canada. Available online: http://crosslight.com (accessed on 1 January 2025).

- Onwukaeme, C.; Ryu, H.Y. Optimum design of InGaN blue laser diodes with indium-tin-oxide and dielectric cladding layers. Nanomaterials 2024, 14, 1409. [Google Scholar] [CrossRef]

- Fiorentini, V.; Bernardini, F.; Ambacher, O. Evidence for nonlinear macroscopic polarization in III-V nitride alloy heterostructures. Appl. Phys. Lett. 2002, 80, 1204–1206. [Google Scholar] [CrossRef]

- Wang, W.; Li, D.; Liu, N.; Chen, Z.; Wang, L.; Liu, L.; Li, L.; Wan, C.; Chen, W.; Hu, X.; et al. Improvement of hole injection and electron overflow by a tapered AlGaN electron blocking layer in InGaN-based blue laser diodes. Appl. Phys. Lett. 2012, 100, 031105. [Google Scholar]

- Piprek, J. Semiconductor Optoelectronic Devices; Academic Press: London, UK, 2003; pp. 187–211. [Google Scholar]

- Bergmann, M.J.; Casey, H.C., Jr. Optical-field calculations for lossy multiple-layer AlxGa1−xN/InxGa1−xN laser diodes. J. Appl. Phys. 1998, 84, 1196–1203. [Google Scholar] [CrossRef]

- Laws, G.M.; Larkins, E.C.; Harrison, I.; Molloy, C.; Somerford, D. Improved refractive index formulas for the AlxGa1−xN and InyGa1−yN alloys. J. Appl. Phys. 2001, 89, 1108–1115. [Google Scholar] [CrossRef]

- Ryu, H.Y. Investigation into the anomalous temperature characteristics of InGaN double quantum well blue laser diodes using numerical simulation. Nanoscale Res. Lett. 2017, 12, 366. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Liang, P.; Ren, H.; Han, P. Enhanced efficiency in 808 nm GaAs laser power converters via gradient doping. AIP Adv. 2019, 9, 105206. [Google Scholar] [CrossRef]

- Jakiela, R.; Barcz, A. Diffusion and activation of Si implanted into GaAs. Vacuum 2003, 70, 97–101. [Google Scholar] [CrossRef]

- Chen, Y.; Wu, H.; Han, E.; Yue, G.; Chen, Z.; Wu, Z.; Wang, G.; Jiang, H. High hole concentration in p-type AlGaN by indium-surfactant-assisted Mg-delta doping. Appl. Phys. Lett. 2015, 106, 162102. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, X.; Dai, Q.; Zhao, J.; Fan, A.; Wang, S.; Cui, Y. High hole concentration in nonpolar a-plane p-AlGaN films with Mg-delta doping technique. Superlattice Microst. 2017, 109, 880–885. [Google Scholar] [CrossRef]

- Hertkorn, J.; Thapa, S.B.; Wunderer, T.; Scholz, F.; Wu, Z.H.; Wei, Q.Y.; Ponce, F.A.; Moram, M.A.; Humphreys, C.J.; Vierheilig, C.; et al. Highly conductive modulation doped composition graded p-AlGaN/(AlN)/GaN multiheterostructures grown by metalorganic vapor phase epitaxy. J. Appl. Phys. 2009, 106, 013720. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Onwukaeme, C.; Ryu, H.-Y. Design of GaN-Based Laser Diode Structures with Nonuniform Doping Distribution in a p-AlGaN Cladding Layer for High-Efficiency Operation. Crystals 2025, 15, 259. https://doi.org/10.3390/cryst15030259

Onwukaeme C, Ryu H-Y. Design of GaN-Based Laser Diode Structures with Nonuniform Doping Distribution in a p-AlGaN Cladding Layer for High-Efficiency Operation. Crystals. 2025; 15(3):259. https://doi.org/10.3390/cryst15030259

Chicago/Turabian StyleOnwukaeme, Chibuzo, and Han-Youl Ryu. 2025. "Design of GaN-Based Laser Diode Structures with Nonuniform Doping Distribution in a p-AlGaN Cladding Layer for High-Efficiency Operation" Crystals 15, no. 3: 259. https://doi.org/10.3390/cryst15030259

APA StyleOnwukaeme, C., & Ryu, H.-Y. (2025). Design of GaN-Based Laser Diode Structures with Nonuniform Doping Distribution in a p-AlGaN Cladding Layer for High-Efficiency Operation. Crystals, 15(3), 259. https://doi.org/10.3390/cryst15030259