Binder-Free Two-Dimensional Few-Layer Titanium Carbide MXene Ink for High-Performance Symmetric Supercapacitor Device Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials Required

2.2. Preparation of MXene

2.2.1. MXene Etching and Delimitations

2.2.2. Preparation of MXene Suspension and Ink Formulation

2.2.3. Material Characterization

2.2.4. Electrode Preparation and Coatings

3. Results

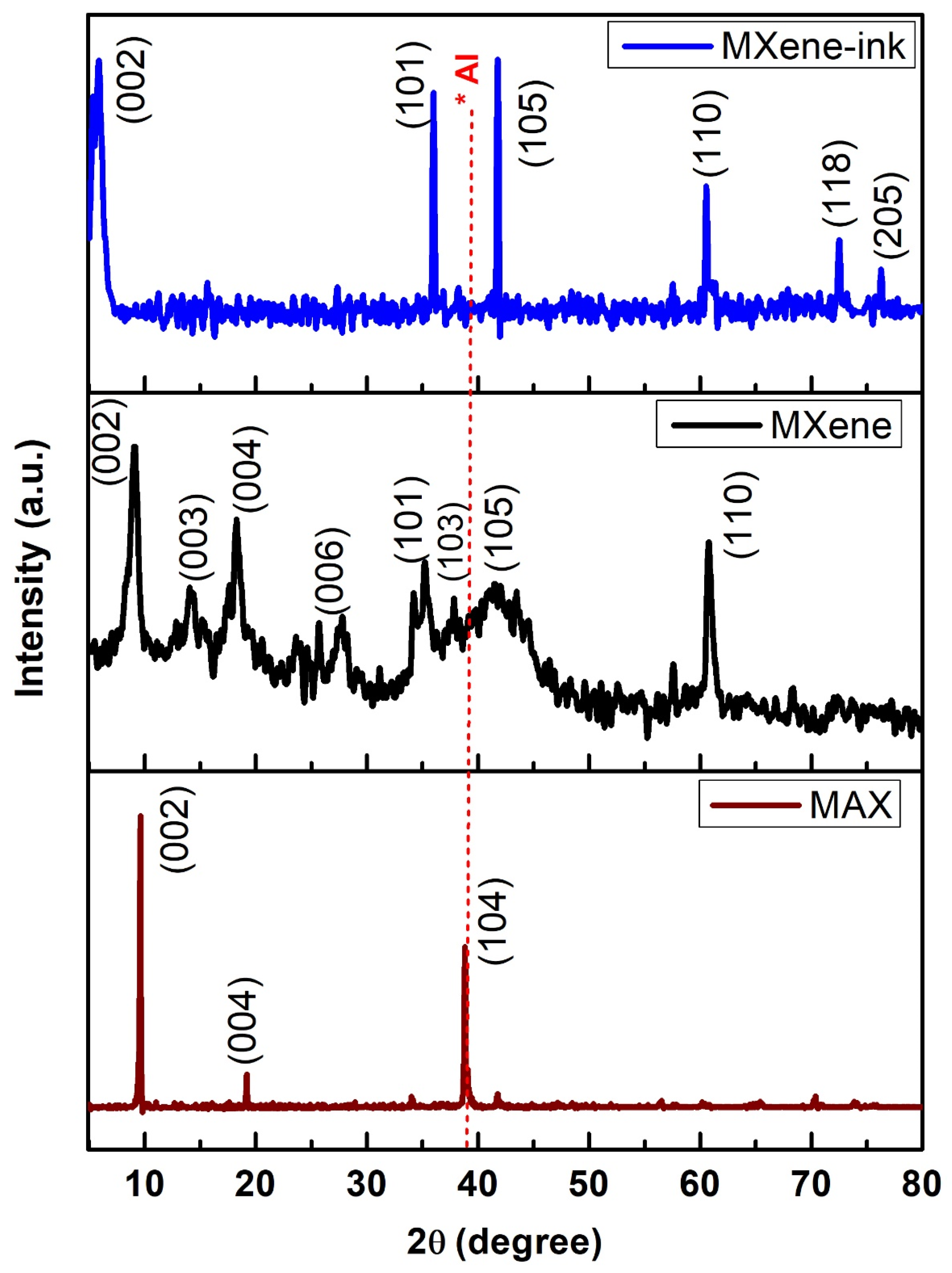

3.1. XRD Analysis

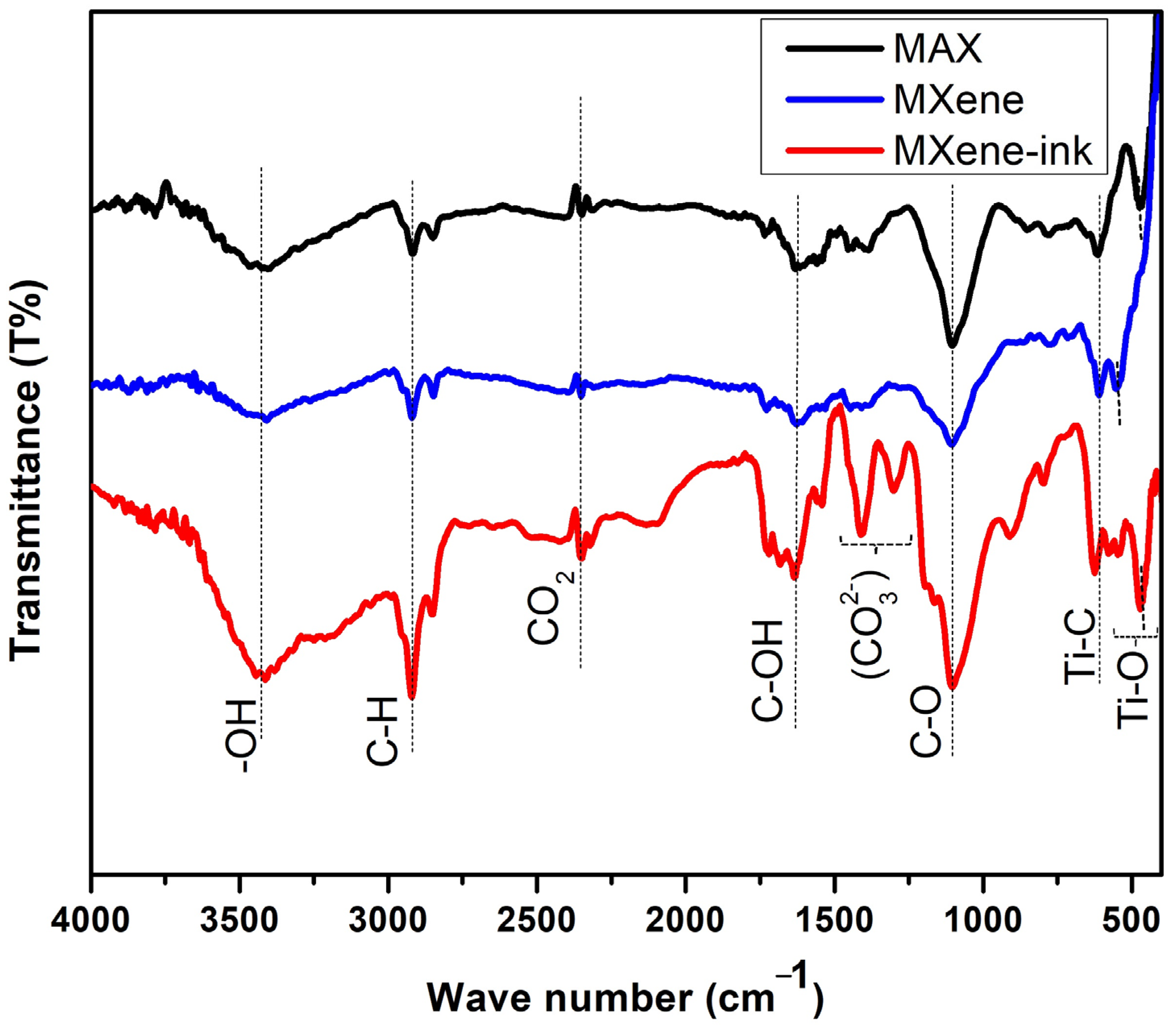

3.2. FT-IR Functional Group Analysis

3.3. FE-SEM Analysis

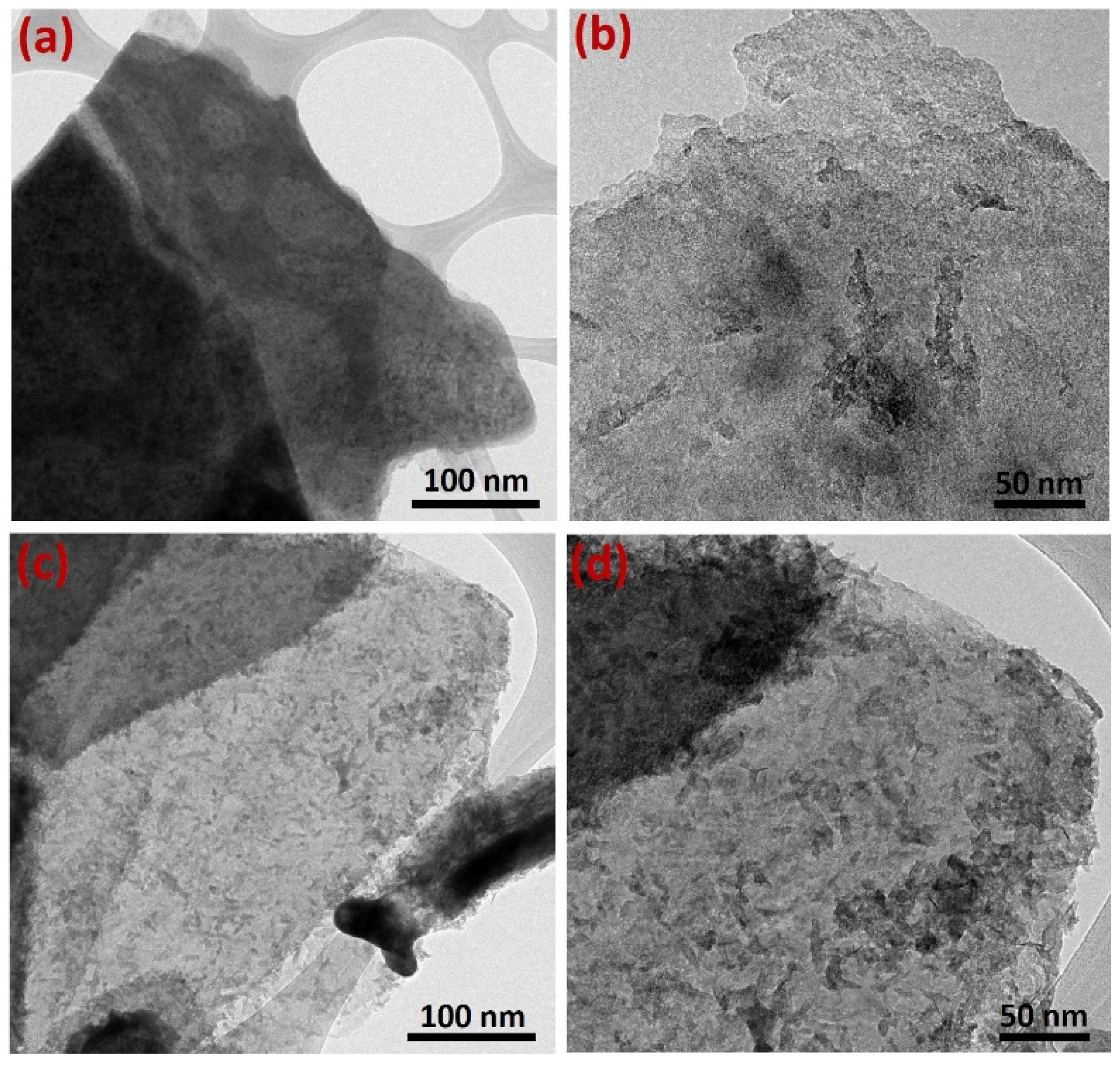

3.4. FE-TEM Analysis

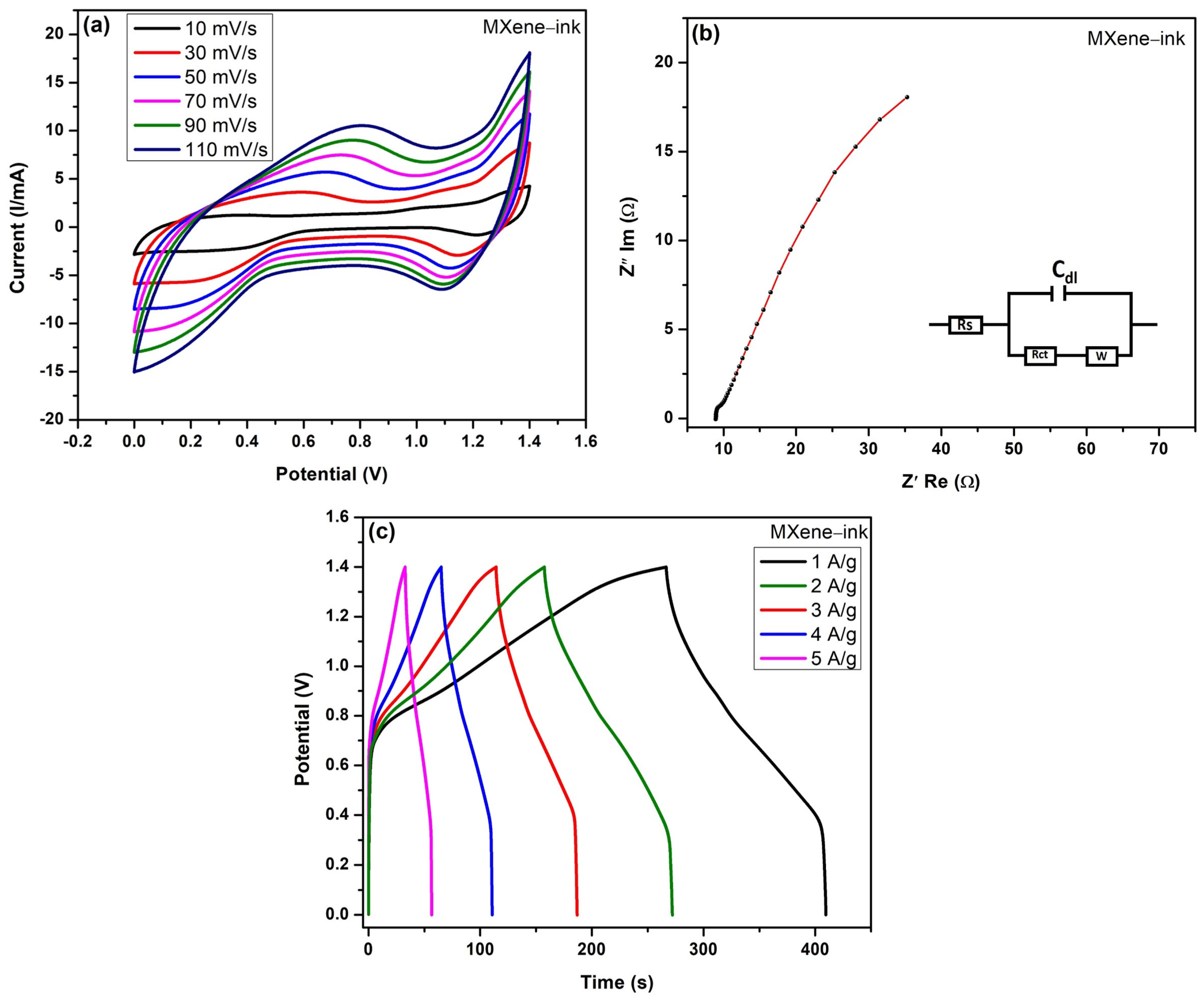

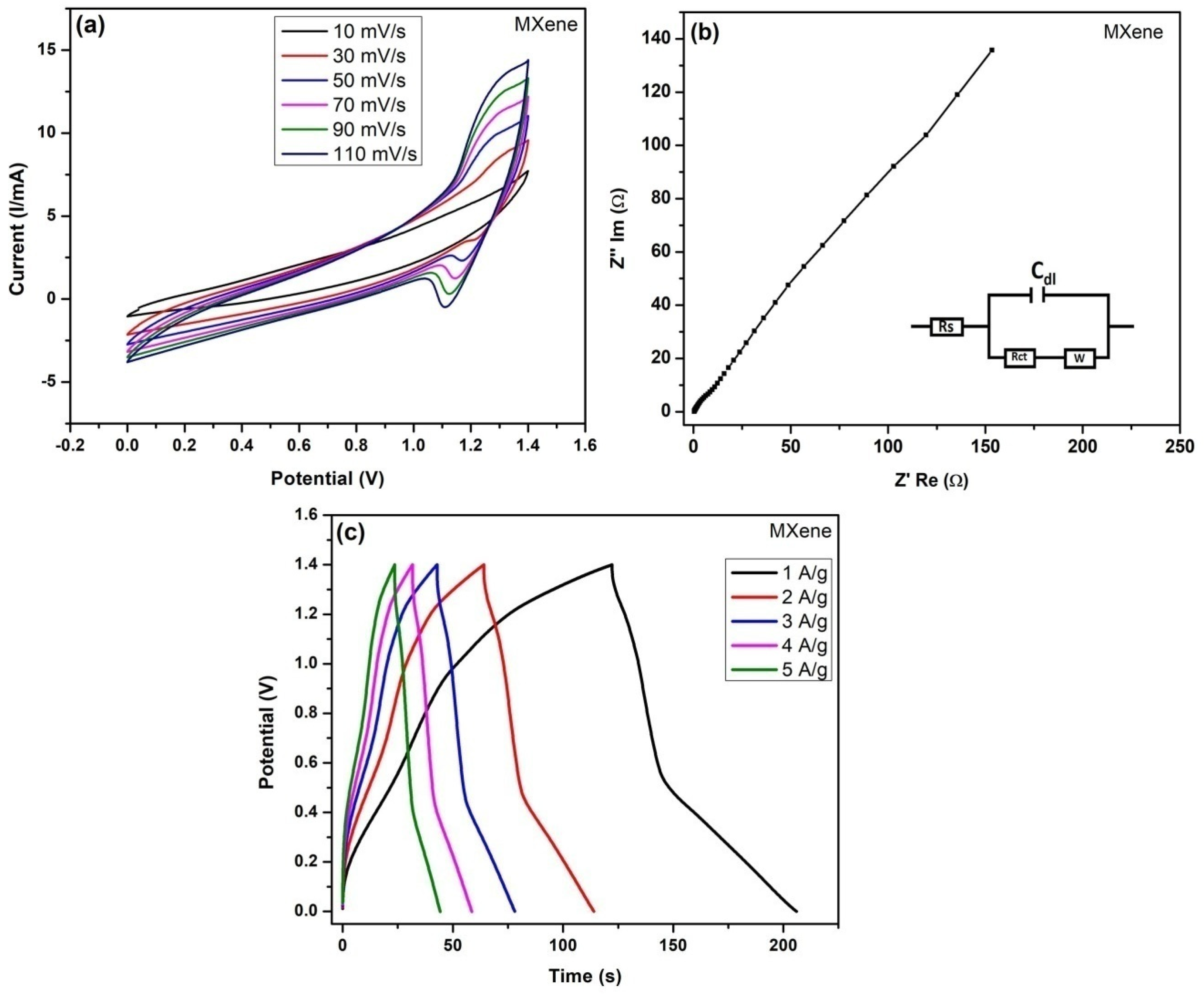

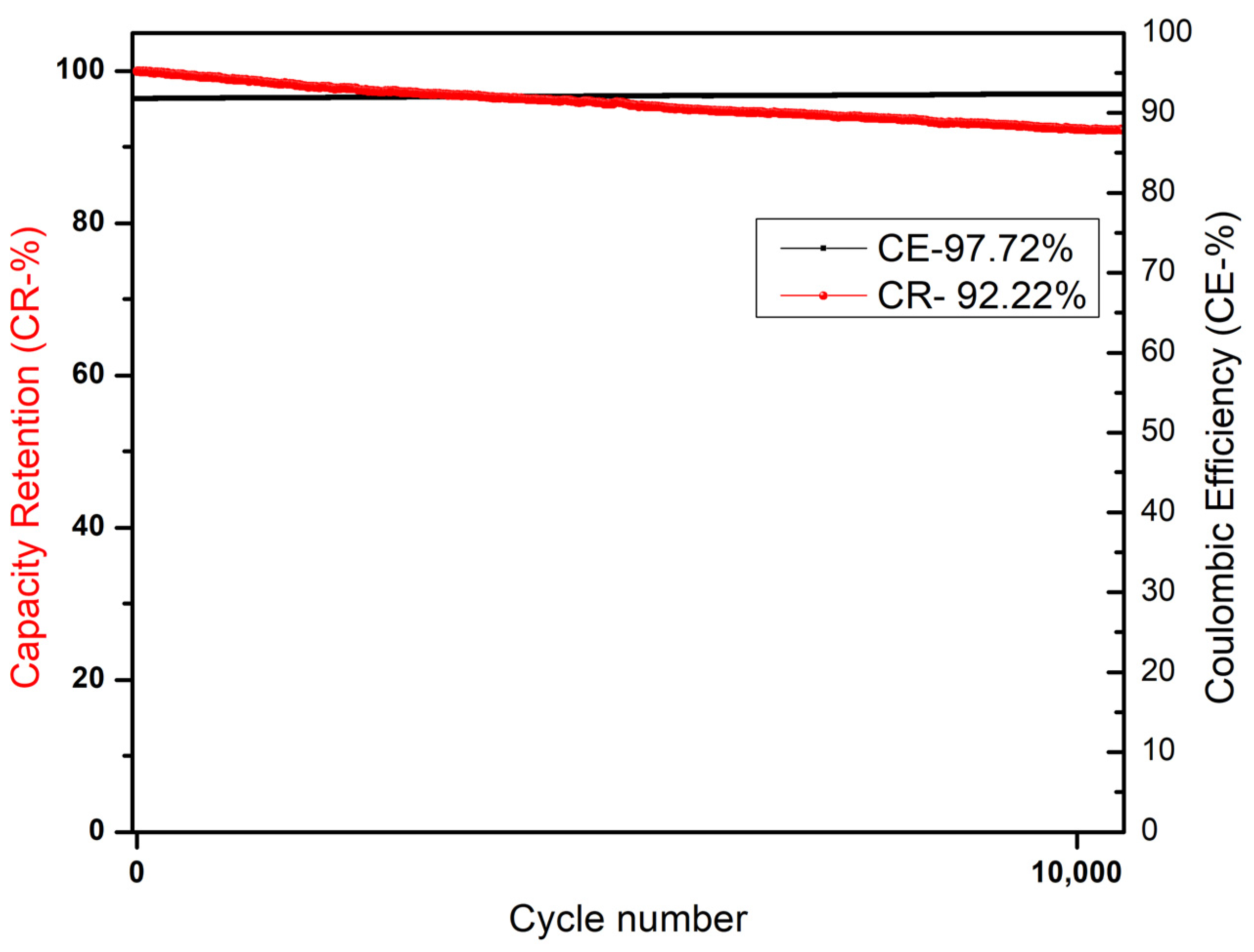

3.5. Electrochemical Symmetric Device Performance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Naguib, M.; Kurtoglu, M.; Presser, V.; Lu, J.; Niu, J.; Heon, M.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Barsoum, Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. Adv. Mater. 2011, 23, 4248–4253. [Google Scholar] [CrossRef] [PubMed]

- Barsoum, M.W. MAX Phases: Properties of Machinable Ternary Carbides and Nitrides; Wiley: Hoboken, NJ, USA, 2013. [Google Scholar]

- Wang, S.; Liu, Y.; Liu, Y.; Hu, W. Effect of HF etching on titanium carbide (Ti3C2Tx) microstructure and its capacitive properties. Chem. Eng. J. 2023, 452, 139512. [Google Scholar] [CrossRef]

- Kvashina, T.; Uvarov, N.; Korchagin, M.; Krutskiy, Y.; Ukhina, A. Synthesis of MXene Ti3C2 by selective etching of MAX-phase Ti3AlC2. Mater. Today Proc. 2020, 31, 592–594. [Google Scholar] [CrossRef]

- Li, T.; Yao, L.; Liu, Q.; Gu, J.; Luo, R.; Li, J.; Yan, X.; Wang, W.; Liu, P.; Chen, B.; et al. Fluorine-Free Synthesis of High-Purity Ti3C2Tx (T = OH, O) via Alkali Treatment. Angew. Chem. Int. Ed. 2018, 57, 6115–6119. [Google Scholar] [CrossRef] [PubMed]

- Mashtalir, O.; Naguib, M.; Mochalin, V.N.; Dall’Agnese, Y.; Heon, M.; Barsoum, M.W.; Gogotsi, Y. Intercalation and delamination of layered carbides and carbonitrides. Nat. Commun. 2013, 4, 1716. [Google Scholar] [CrossRef] [PubMed]

- Anasori, B.; Lukatskaya, M.R.; Gogotsi, Y. 2D metal carbides and nitrides (MXenes) for energy storage. Nat. Rev. Mater. 2017, 2, 16098. [Google Scholar] [CrossRef]

- HTang, H.; Hu, Q.; Zheng, M.; Chi, Y.; Qin, X.; Pang, H.; Xu, Q. MXene–2D Layered Electrode Materials for Energy Storage. Prog. Nat. Sci. 2018, 28, 133–147. [Google Scholar]

- Ronchi, R.M.; Arantes, J.T.; Santos, S.F. Synthesis, structure, properties and applications of MXenes: Current status and perspectives. Ceram. Int. 2019, 45, 18167–18188. [Google Scholar] [CrossRef]

- Zhang, C.; Anasori, B.; Seral-Ascaso, A.; Park, S.H.; McEvoy, N.; Shmeliov, A.; Duesberg, G.S.; Coleman, J.N.; Gogotsi, Y.; Nicolosi, V. Transparent, flexible, and conductive 2D titanium carbide (MXene) films with high volumetric capacitance. Adv. Mater. 2017, 29, 1702678. [Google Scholar] [CrossRef]

- Jiang, X.; Kuklin, A.V.; Baev, A.; Ge, Y.; Ågren, H.; Zhang, H.; Prasad, P.N. Two-dimensional MXenes: From morphological to optical, electric, and magnetic properties and applications. Phys. Rep. 2020, 848, 1–58. [Google Scholar] [CrossRef]

- Xu, J.; You, J.; Wang, L.; Wang, Z.; Zhang, H. MXenes serving aqueous supercapacitors: Preparation, energy storage mechanism and electrochemical performance enhancement. Sustain. Mater. Technol. 2022, 33, e00490. [Google Scholar] [CrossRef]

- Zhu, Q.; Li, J.; Simon, P.; Xu, B. Two-dimensional MXenes for electrochemical capacitor applications: Progress, challenges and perspectives. Energy Storage Mater. 2020, 35, 630–660. [Google Scholar] [CrossRef]

- Yoon, Y.; Lee, K.; Lee, H. Low-dimensional carbon and MXene-based electrochemical capacitor electrodes. Nanotechnology 2016, 27, 172001. [Google Scholar] [CrossRef]

- Tian, Y.; Yang, C.; Que, W.; Liu, X.; Yin, X.; Kong, L.B. Flexible and free-standing 2D titanium carbide film decorated with manganese oxide nanoparticles as a high volumetric capacity electrode for supercapacitor. J. Power Sources 2017, 359, 332–339. [Google Scholar] [CrossRef]

- Oyehan, T.A.; Salami, B.A.; Abdulrasheed, A.A.; Hambali, H.U.; Gbadamosi, A.; Valsami-Jones, E.; Saleh, T.A. MXenes: Synthesis, properties, and applications for sustainable energy and environment. Appl. Mater. Today 2023, 35, 101993. [Google Scholar] [CrossRef]

- Mojtabavi, M.; VahidMohammadi, A.; Ganeshan, K.; Hejazi, D.; Shahbazmohamadi, S.; Kar, S.; Van Duin, A.C.; Wanunu, M. Wafer-scale lateral self-assembly of mosaic Ti3C2Tx MXene monolayer films. ACS Nano 2021, 15, 625–636. [Google Scholar] [CrossRef]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–196. [Google Scholar] [CrossRef]

- Xu, M.; Liang, T.; Shi, M.; Chen, H. Graphene-like two-dimensional materials. Chem. Rev. 2013, 113, 3766–3798. [Google Scholar] [CrossRef]

- Kong, X.; Liu, Q.; Zhang, C.; Peng, Z.; Chen, Q. Elemental two-dimensional nanosheets beyond graphene. Chem. Soc. Rev. 2017, 46, 2127–2157. [Google Scholar] [CrossRef]

- Gogotsi, Y.; Anasori, B. The Rise of MXenes. ACS Nano 2019, 13, 8491–8494. [Google Scholar] [CrossRef]

- Li, J.; Ye, F.; Vaziri, S.; Muhammed, M.; Lemme, M.C.; Östling, M. Efficient inkjet printing of graphene. Adv. Mater. 2013, 25, 3985. [Google Scholar] [CrossRef]

- McManus, D.; Vranic, S.; Withers, F.; Sanchez-Romaguera, V.; Macucci, M.; Yang, H.; Sorrentino, R.; Parvez, K.; Son, S.K.; Iannaccone, G.; et al. Water-based and biocompatible 2D crystal inks for all-inkjet-printed heterostructures. Nat. Nanotechnol. 2017, 12, 343–350. [Google Scholar] [CrossRef] [PubMed]

- Hu, G.; Albrow-Owen, T.; Jin, X.; Ali, A.; Hu, Y.; Howe, R.C.; Shehzad, K.; Yang, Z.; Zhu, X.; Woodward, R.I.; et al. Black phosphorus ink formulation for inkjet printing of optoelectronics and photonics. Nat. Commun. 2017, 8, 278. [Google Scholar] [CrossRef]

- Zhang, C.; McKeon, L.; Kremer, M.P.; Park, S.-H.; Ronan, O.; Seral-Ascaso, A.; Barwich, S.; Coileáin, C.; McEvoy, N.; Nerl, H.C.; et al. Additive-free MXene inks and direct printing of micro-supercapacitors. Nat. Commun. 2019, 10, 1795. [Google Scholar]

- Quain, E.; Mathis, T.S.; Kurra, N.; Maleski, K.; Van Aken, K.L.; Alhabeb, M.; Alshareef, H.N.; Gogotsi, Y. Direct writing of additive-free MXene-in-water ink for electronics and energy storage. Adv. Mater. Technol. 2019, 4, 1800256. [Google Scholar] [CrossRef]

- Quain, E.; Mathis, T.S.; Kurra, N.; Maleski, K.; Van Aken, K.L.; Alhabeb, M.; Alshareef, H.N.; Gogotsi, Y. Ultra-high-rate pseudocapacitive energy storage in two-dimensional transition metal carbides. Nat. Energy 2017, 2, 17105. [Google Scholar]

- Zhang, C.; Kremer, M.P.; Seral-Ascaso, A.; Park, S.H.; McEvoy, N.; Anasori, B.; Gogotsi, Y.; Nicolosi, V. Stamping of flexible, coplanar micro-supercapacitors using MXene inks. Adv. Funct. Mater. 2018, 28, 1705506. [Google Scholar] [CrossRef]

- Couly, C.; Alhabeb, M.; Van Aken, K.L.; Kurra, N.; Gomes, L.; Navarro-Suárez, A.M.; Anasori, B.; Alshareef, H.N.; Gogotsi, Y. Asymmetric flexible MXene-reduced graphene oxide micro-supercapacitor. Adv. Electron. Mater. 2018, 4, 1700339. [Google Scholar] [CrossRef]

- Ghidiu, M.; Lukatskaya, M.R.; Zhao, M.Q.; Gogotsi, Y.; Barsoum, M.W. Conductive two-dimensional titanium carbide ‘clay’ with high volumetric capacitance. Nature 2014, 516, 78–81. [Google Scholar] [CrossRef]

- Orangi, J.; Hamade, F.; Davis, V.A.; Beidaghi, M. 3D printing of additive-free 2D Ti3C2Tx (MXene) ink for fabrication of micro-supercapacitors with ultra-high energy densities. ACS Nano 2019, 14, 640–650. [Google Scholar] [CrossRef]

- Abdolhosseinzadeh, S.; Schneider, R.; Verma, A.; Heier, J.; Nüesch, F.; Zhang, C. Turning trash into treasure: Additive free MXene sediment inks for screen-printed micro-supercapacitors. Adv. Mater. 2020, 32, 2000716. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Fan, Z.; Shao, Y.; Tian, Z.; Sun, J.; Liu, Z. Versatile N-doped MXene ink for printed electrochemical energy storage application. Adv. Energy Mater. 2019, 9, 1901839. [Google Scholar] [CrossRef]

- Huang, L.; Lin, Y.; Zeng, W.; Xu, C.; Chen, Z.; Wang, Q.; Zhou, H.; Yu, Q.; Zhao, B.; Ruan, L.; et al. Highly Transparent and Flexible Zn-Ti3C2TxMXene Hybrid Capacitors. Langmuir 2022, 38, 5968–5976. [Google Scholar] [CrossRef] [PubMed]

- Wen, D.; Wang, X.; Liu, L.; Hu, C.; Sun, C.; Wu, Y.; Zhao, Y.; Zhang, J.; Liu, X.; Ying, G. Inkjet Printing Transparent and Conductive MXene (Ti3C2Tx) Films: A Strategy for Flexible Energy Storage Devices. ACS Appl. Mater. Inter. 2021, 13, 17766–17780. [Google Scholar] [CrossRef]

- Guo, T.; Zhou, D.; Deng, S.; Jafarpour, M.; Avaro, J.; Neels, A.; Heier, J.; Zhang, C. Rational Design of Ti3C2Tx MXene Inks for Conductive, Transparent Films. ACS Nano 2023, 17, 3737–3749. [Google Scholar] [CrossRef]

- Tang, Q.; Zhou, Z.; Shen, P.W. Are MXenes promising anode materials for Li ion batteries? Computational studies on electronic properties and Li storage capability of Ti3C2 and Ti3C2X2 (X = F, OH) monolayer. J. Am. Chem. Soc. 2012, 134, 16909–16916. [Google Scholar] [CrossRef]

- Hu, M.; Zhang, H.; Hu, T.; Fan, B.; Wang, X.; Li, Z. Emerging 2D MXenes for supercapacitors: Status, challenges and prospects. Chem. Soc. Rev. 2020, 49, 6666–6693. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, Y.; Sun, H.; Zhou, J.; Yang, F.; Li, H.; Chen, H.; Chen, Y.; Liu, Z.; Qiu, Z.; et al. Progress and perspective: MXene and MXene-based nanomaterials for high-performance energy storage devices. Adv. Electron. Mater. 2021, 7, 2000967. [Google Scholar] [CrossRef]

- Wu, C.-W.; Unnikrishnan, B.; Chen, I.-W.P.; Harroun, S.G.; Chang, H.-T.; Huang, C.-C. Excellent oxidation resistive MXene aqueous ink for micro-supercapacitor application. Energy Storage Mater. 2020, 25, 563–571. [Google Scholar] [CrossRef]

- Yang, W.; Peng, D.; Kimura, H.; Zhang, X.; Sun, X.; Pashameah, R.A.; Alzahrani, E.; Wang, B.; Guo, Z.; Du, W.; et al. Honeycomb-like nitrogen-doped porous carbon decorated with Co3O4 nanoparticles forsuperior electrochemical performance pseudo-capacitive lithium storage and supercapacitors. Adv. Compos. Hybrid Mater. 2022, 5, 3146–3157. [Google Scholar] [CrossRef]

- Jiang, H.; Mu, Q.; Kimura, H.; Liu, R.; Yang, W.; Liu, L.; Du, W.; Hou, C. Advanced ferroferric oxide-based composites for lithium-ion battery: Recent developments and future perspectives. Prog. Nat. Sci. Mater. Int. 2024, 33, 743–753. [Google Scholar] [CrossRef]

- Du, W.; Wang, X.; Zhan, J.; Sun, X.; Kang, L.; Jiang, F.; Zhang, X.; Shao, Q.; Dong, M.; Liu, H.; et al. Biological cell template synthesis of nitrogen-doped porous hollow carbon spheres/MnO2 composites for high-performance asymmetric supercapacitors. Electrochim. Acta 2019, 296, 907–915. [Google Scholar] [CrossRef]

- Im, J.K.; Sohn, E.J.; Kim, S.; Jang, M.; Son, A.; Zoh, K.-D.; Yoon, Y. Review of MXene-based nanocomposites for photocatalysis. Chemosphere 2021, 270, 129478. [Google Scholar] [CrossRef]

- Wang, S.; Ma, J.; Zhu, S.; Cheng, J.; Qiao, Z.; Yang, J.; Liu, W. High temperature tribological properties of Ti3AlC2 ceramic against SiC under different atmospheres. Mater. Des. 2015, 67, 188–196. [Google Scholar] [CrossRef]

- Kiran, N.U.; Deore, A.B.; More, M.A.; Late, D.J.; Rout, C.S.; Mane, P.; Chakraborty, B.; Besra, L.; Chatterjee, S. Comparative Study of Cold Electron Emission from 2D Ti3C2Tx MXene Nanosheets with Respect to Its Precursor Ti3SiC2 MAX Phase. ACS Appl. Electron. Mater. 2022, 4, 2656–2666. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, X.; Wang, J.; Deng, Q.; Li, M.; Du, S.; Han, Y.-H.; Lee, J.; Huang, Q. Facile preparation of in situ coated Ti3C2Tx/Ni0.5Zn0.5Fe2O4 composites and their electromagnetic performance. RSC Adv. 2017, 7, 24698–24708. [Google Scholar] [CrossRef]

- Li, X.; Zeng, Q. HRTEM analysis of the aggregate structure and ultrafine microporous characteristics of Xinjiang Zhundong coal under heat treatment. Sci. Rep. 2022, 12, 4994. [Google Scholar] [CrossRef]

- Chen, W.Y.; Jiang, X.; Lai, S.N.; Peroulis, D.; Stanciu, L. Nanohybrids of a MXene and transition metal dichalcogenide for selective detection of volatile organic compounds. Nat. Commun. 2020, 11, 1302. [Google Scholar] [CrossRef] [PubMed]

- Yin, Z.; Lu, Z.; Xu, Y.; Zhang, Y.; He, L.; Li, P.; Xiong, L.; Ding, L.; Wei, Y.; Wang, H. Supported MXene/GO Composite Membranes with Suppressed Swelling for Metal Ion Sieving. Membranes 2021, 11, 621. [Google Scholar] [CrossRef]

- Delekta, S.S.; Smith, A.D.; Li, J.; Östling, M. Inkjet printed highly transparent and flexible graphene micro-supercapacitors. Nanoscale 2017, 21, 6998–7005. [Google Scholar] [CrossRef]

- Xu, H.; Zhu, J.; Xu, M.; Lei, Z.; Hu, Q.; Jin, X. Flexible and alternately layered high electrochemical active electrode based on MXene, carboxymethylcellulose, and carbon nanotube for asymmetric micro-supercapacitors. J. Colloid Interface Sci. 2023, 645, 974–984. [Google Scholar] [CrossRef]

- Pan, Z.; Cao, F.; Hu, X.; Ji, X. A facile method for synthesizing CuS decorated Ti3C2 MXene with enhanced performance for asymmetric supercapacitors. J. Mater. Chem. A 2019, 7, 8984–8992. [Google Scholar] [CrossRef]

- Guo, J.; Zhao, Y.; Ma, T. Electrostatic self-assembly of 2D delaminated MXene (Ti3C2) onto Ni foam with superior electrochemical performance for supercapacitor. Electrochimica Acta. 2019, 305, 164–174. [Google Scholar] [CrossRef]

- Sun, L.; Song, G.; Sun, Y.; Fu, Q.; Pan, C. MXene/N-Doped Carbon Foam with Three-Dimensional Hollow Neuron-like Architecture for Freestanding, Highly Compressible All Solid-State Supercapacitors. ACS Appl. Mater. Interfaces 2020, 12, 44777–44788. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zhao, X.; Yan, X.; Xiao, Z.; Liu, C.; Zhang, Y.; Yang, X. Regulating Fast Anionic Redox for High-Voltage Aqueous Hydrogen-Ion-based Energy Storage. Angew. Chem. 2019, 131, 211–216. [Google Scholar] [CrossRef]

- Liu, H.; Hu, R.; Qi, J.; Sui, Y.; He, Y.; Meng, Q.; Wei, F.; Ren, Y.; Zhao, Y.; Wei, W. One-Step Synthesis of Nanostructured CoS2 Grown on Titanium Carbide MXene for High-Performance Asymmetrical Supercapacitors. Adv. Mater. Interfaces 2020, 7, 1901659. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thirumal, V.; Rajkumar, P.; Kim, J.-H.; Babu, B.; Yoo, K. Binder-Free Two-Dimensional Few-Layer Titanium Carbide MXene Ink for High-Performance Symmetric Supercapacitor Device Applications. Crystals 2024, 14, 261. https://doi.org/10.3390/cryst14030261

Thirumal V, Rajkumar P, Kim J-H, Babu B, Yoo K. Binder-Free Two-Dimensional Few-Layer Titanium Carbide MXene Ink for High-Performance Symmetric Supercapacitor Device Applications. Crystals. 2024; 14(3):261. https://doi.org/10.3390/cryst14030261

Chicago/Turabian StyleThirumal, Vediyappan, Palanisamy Rajkumar, Jin-Ho Kim, Bathula Babu, and Kisoo Yoo. 2024. "Binder-Free Two-Dimensional Few-Layer Titanium Carbide MXene Ink for High-Performance Symmetric Supercapacitor Device Applications" Crystals 14, no. 3: 261. https://doi.org/10.3390/cryst14030261

APA StyleThirumal, V., Rajkumar, P., Kim, J.-H., Babu, B., & Yoo, K. (2024). Binder-Free Two-Dimensional Few-Layer Titanium Carbide MXene Ink for High-Performance Symmetric Supercapacitor Device Applications. Crystals, 14(3), 261. https://doi.org/10.3390/cryst14030261