Influence of Processing Temperature and Strain Rate on the Microstructure and Mechanical Properties of Magnesium Alloys Processed by Single-Pass Differential Speed Rolling

Abstract

1. Introduction

2. Materials and Methods

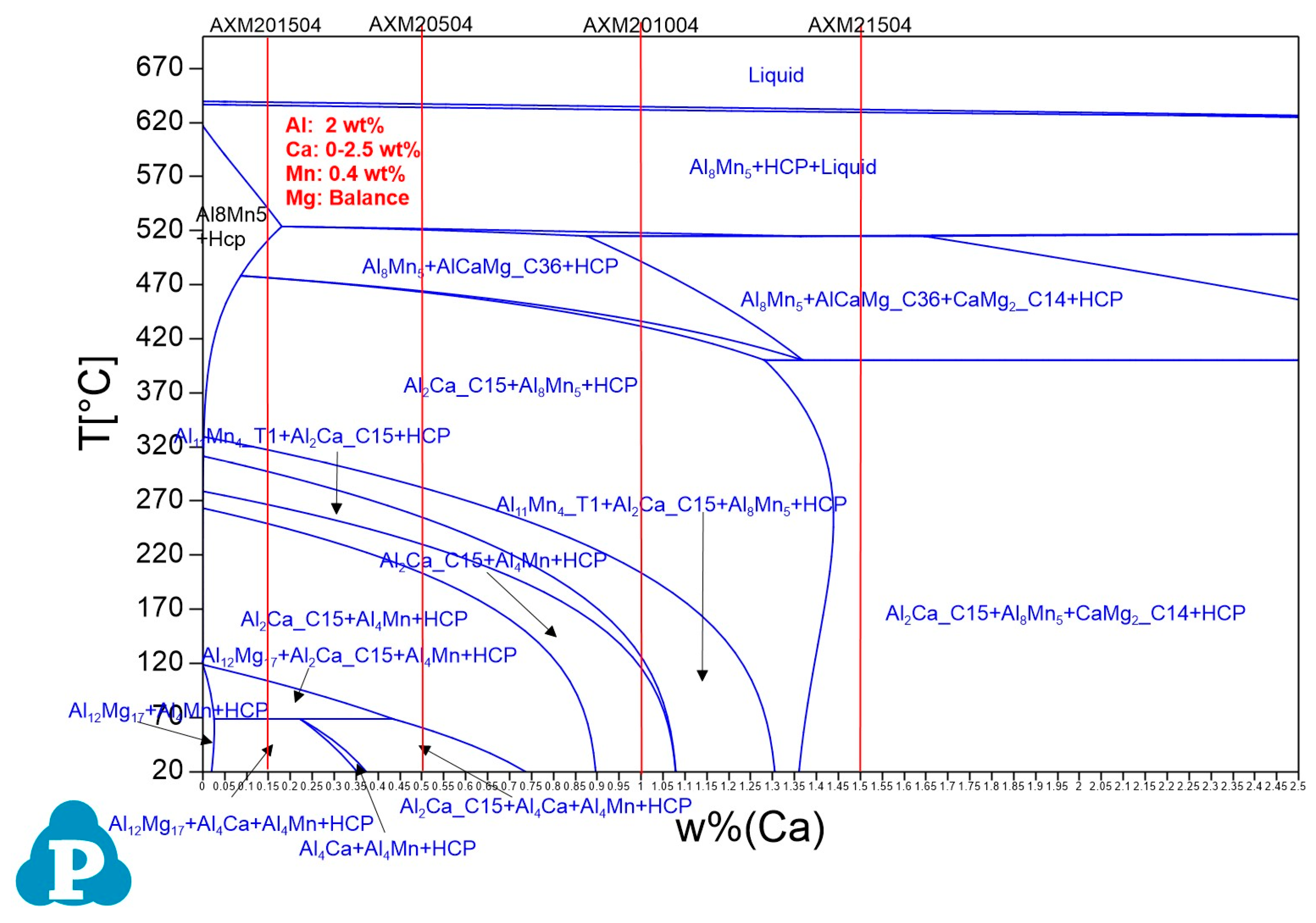

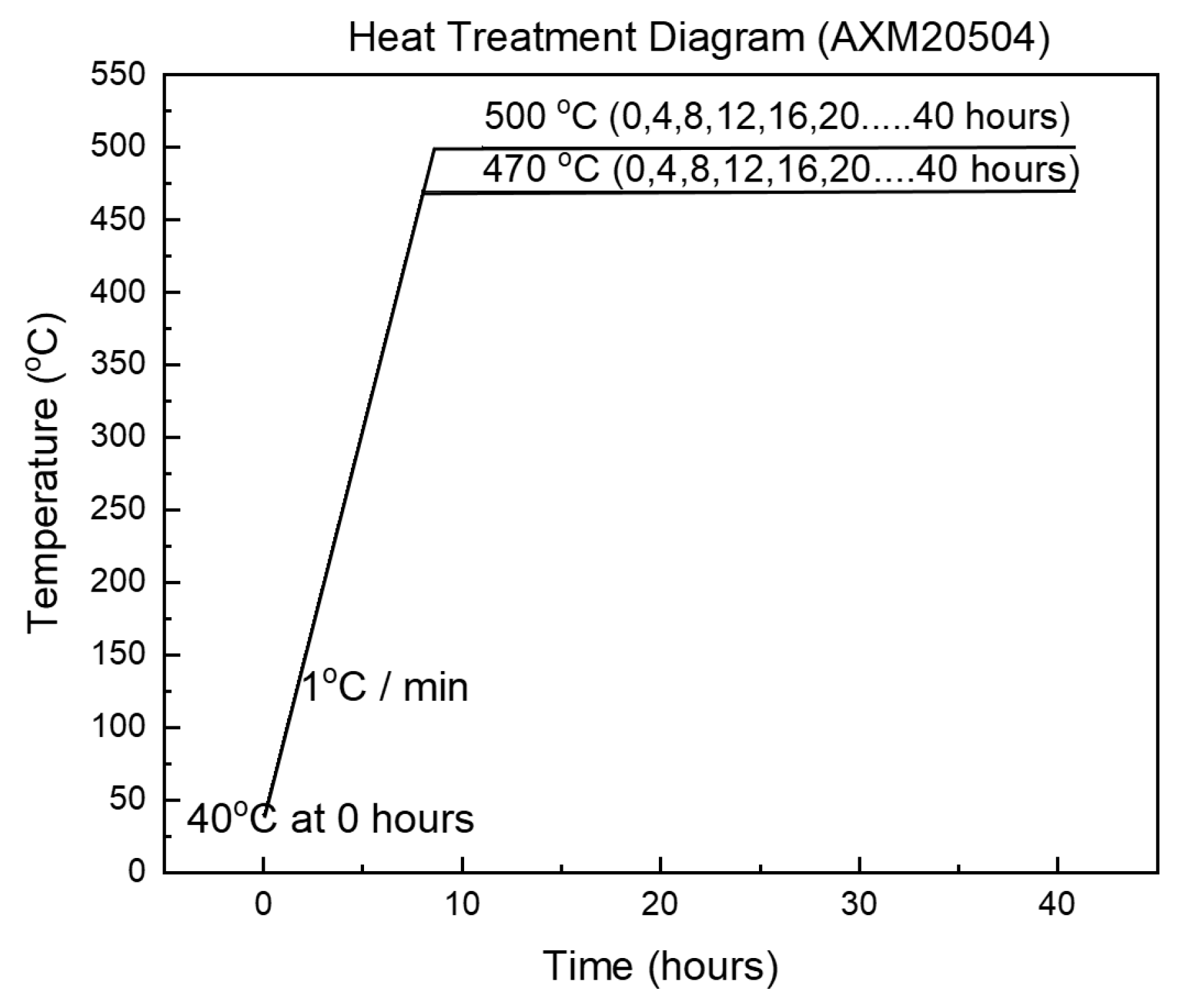

2.1. Materials Preparation (Casting and Heat Treatment)

2.2. Design of the Rolling Process

2.3. Microstructural Characterization

2.4. Mechanical Testing

3. Results

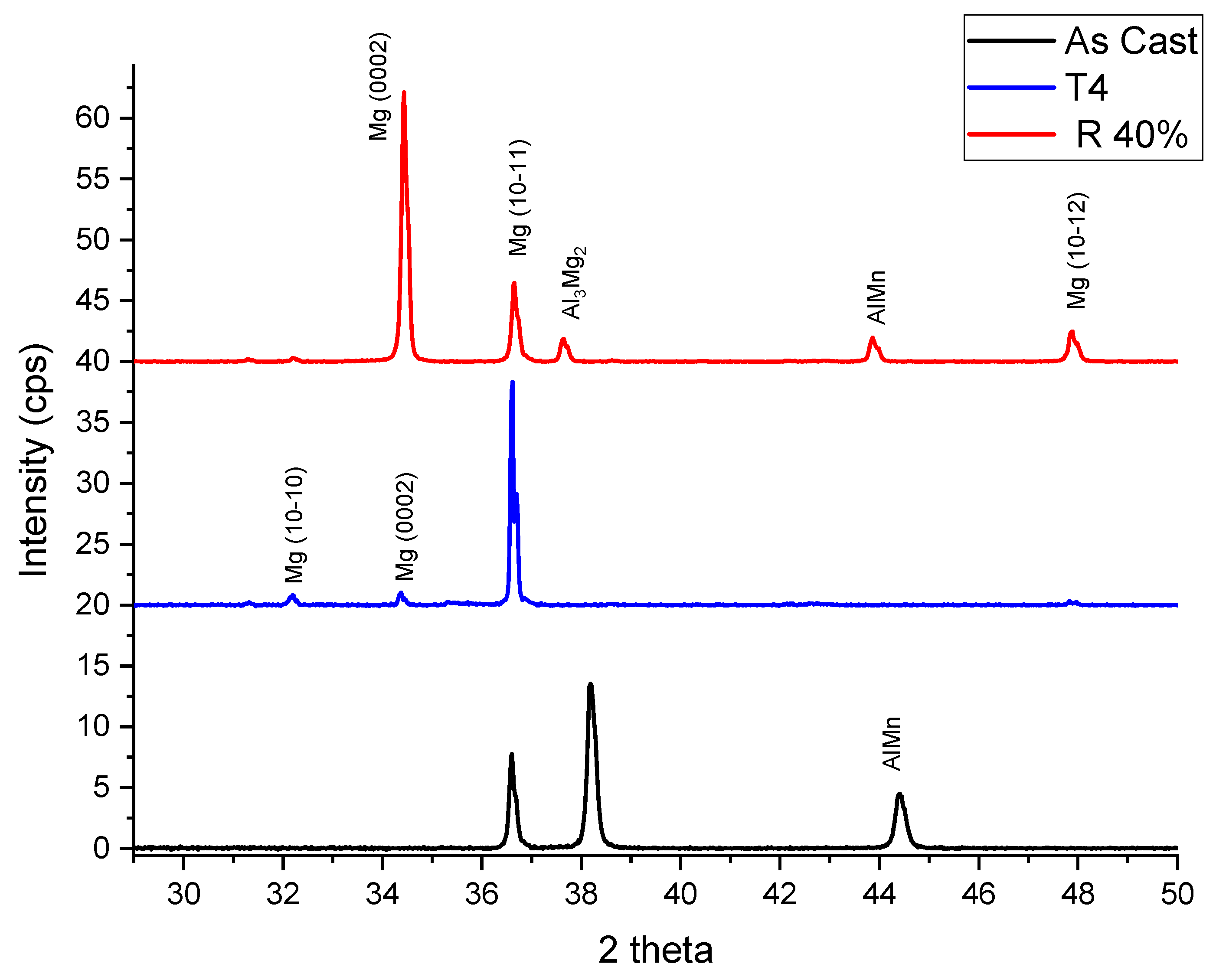

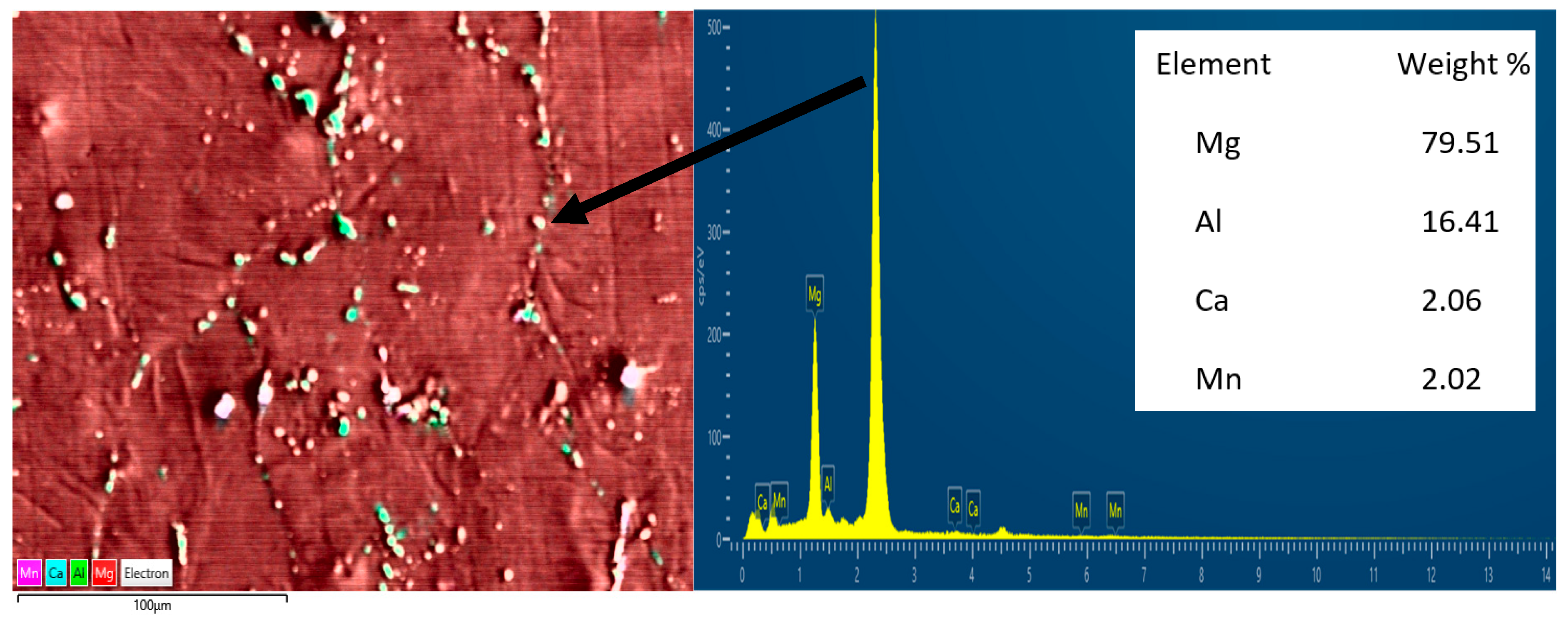

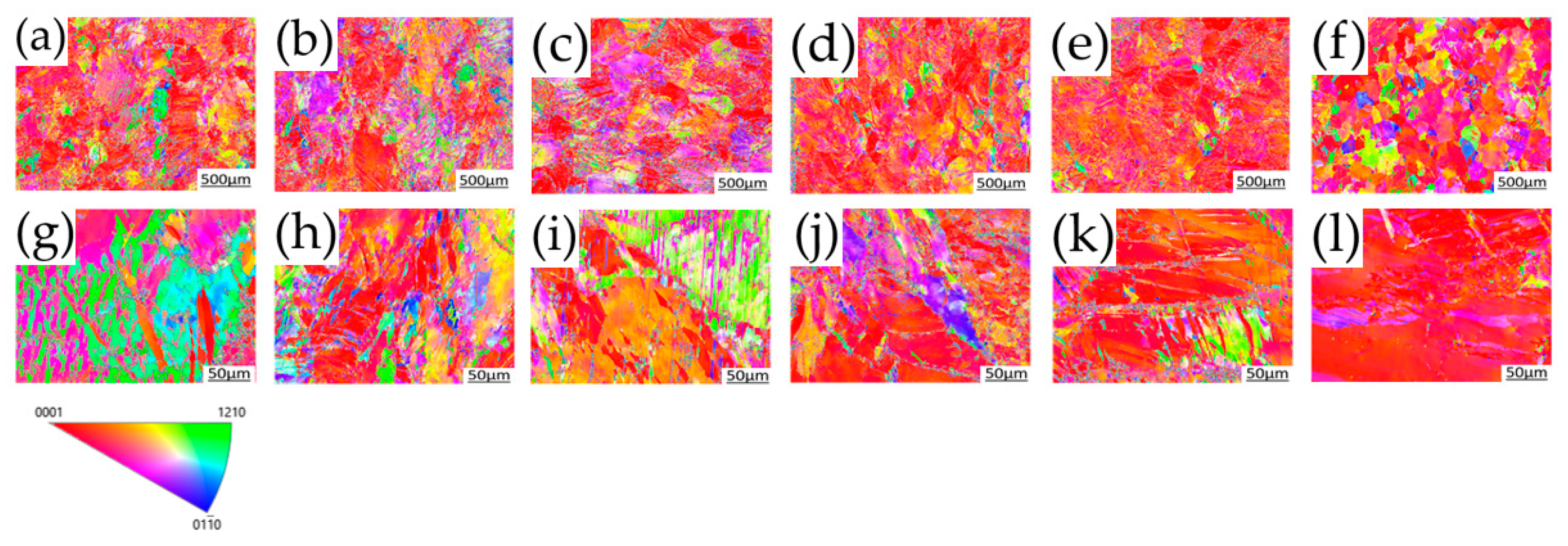

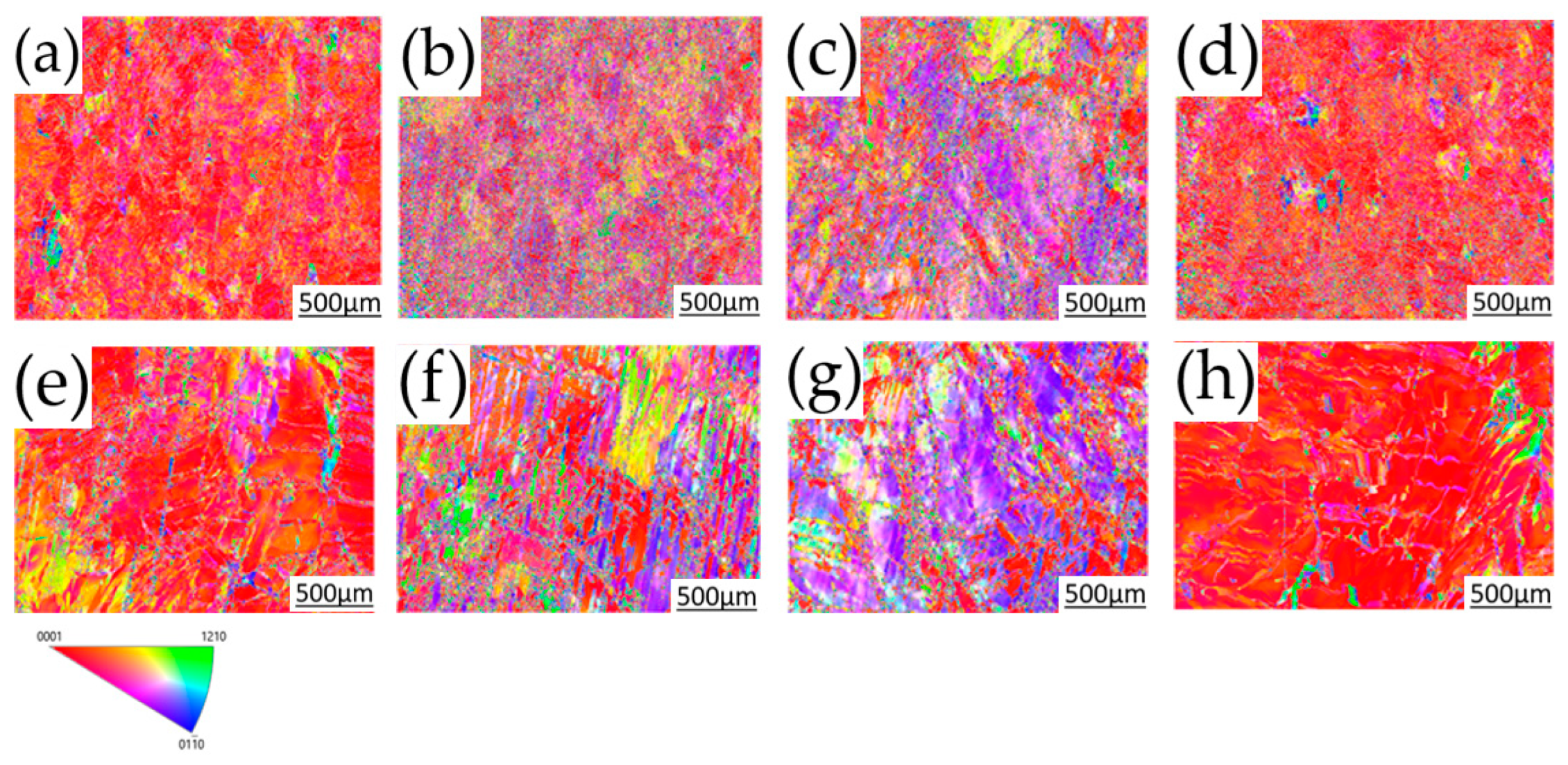

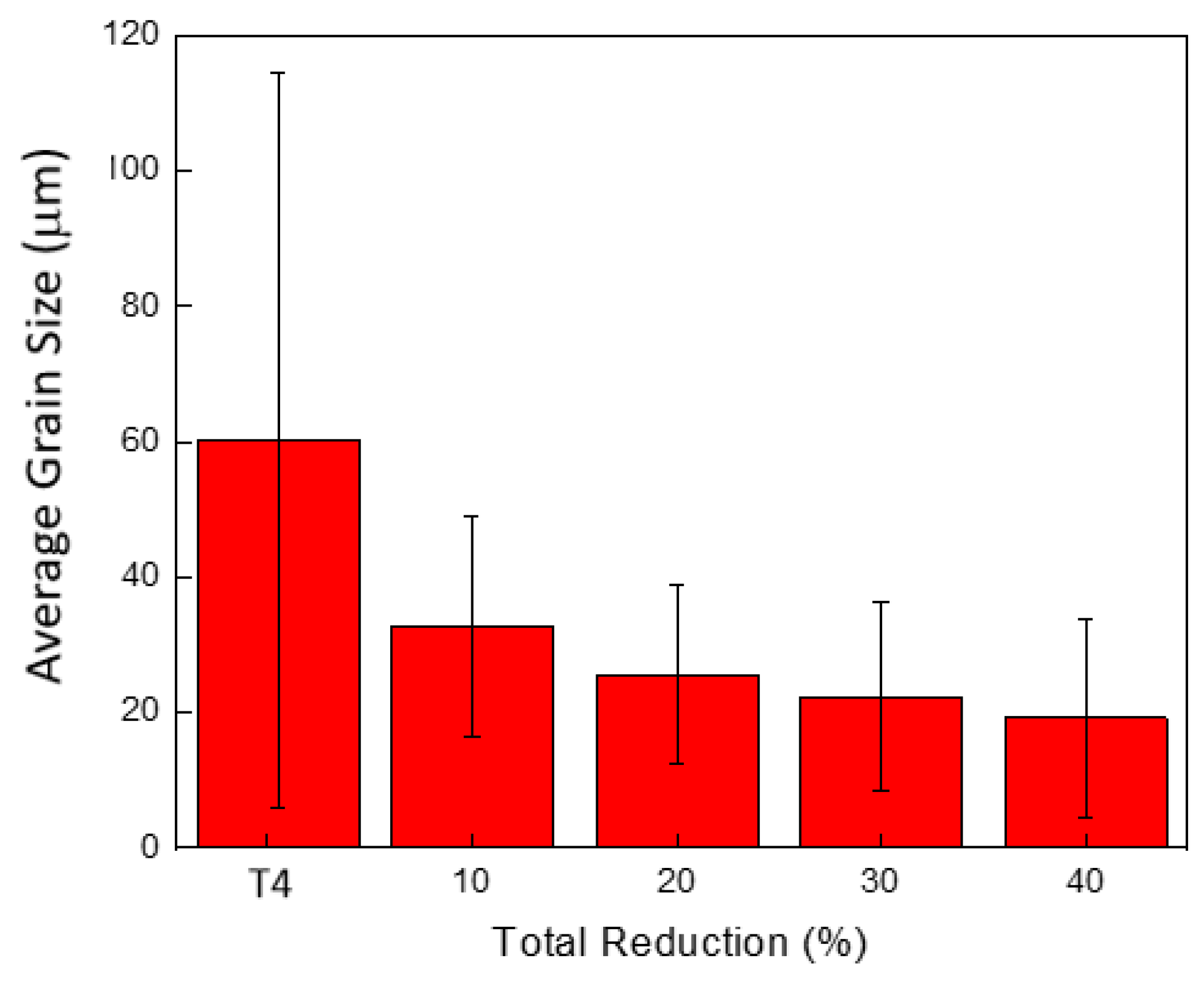

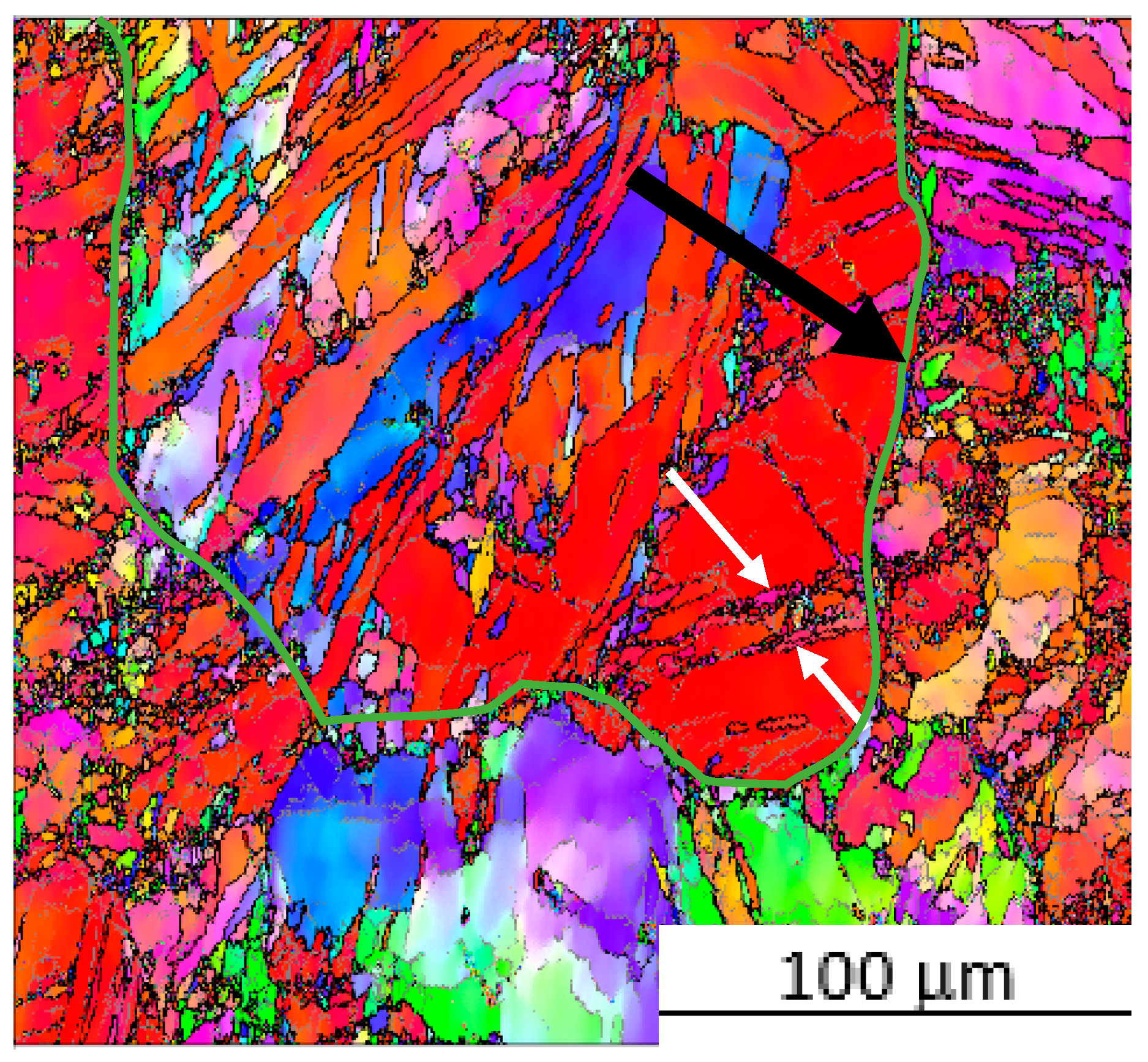

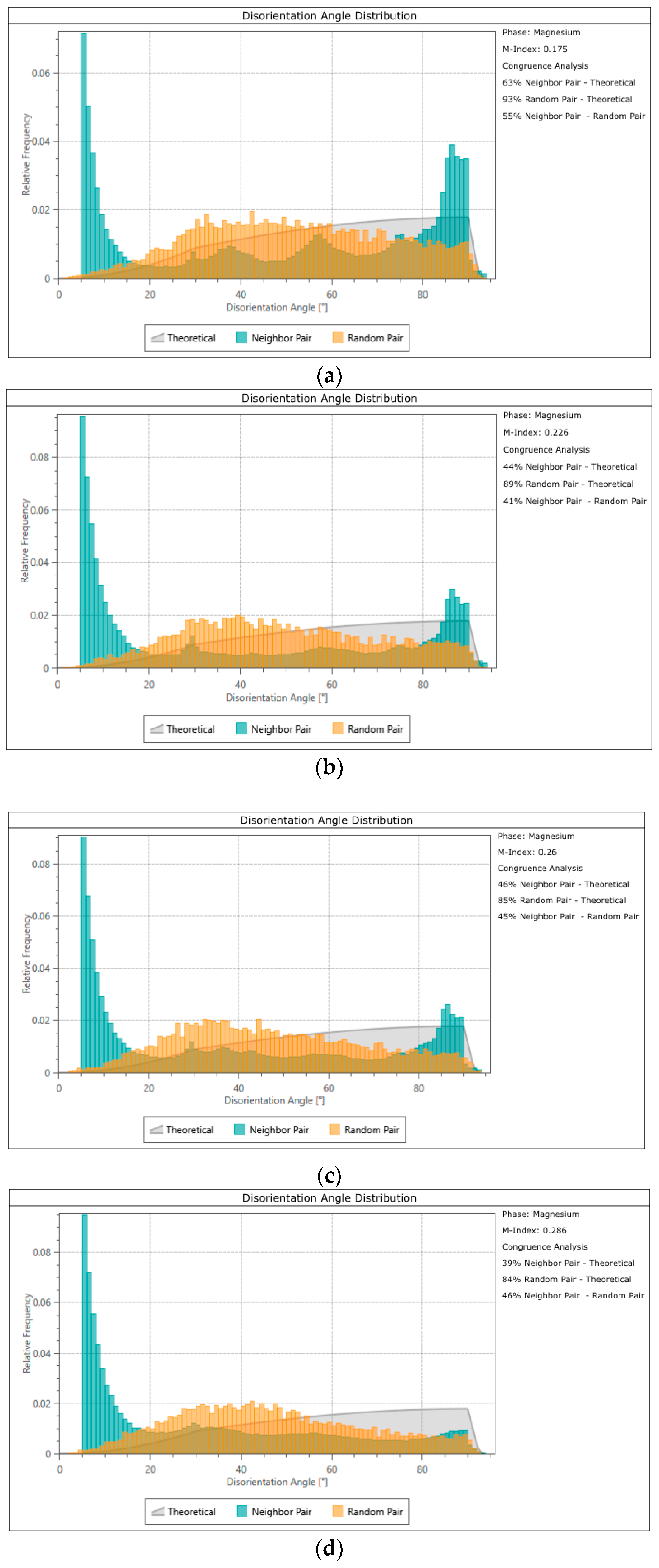

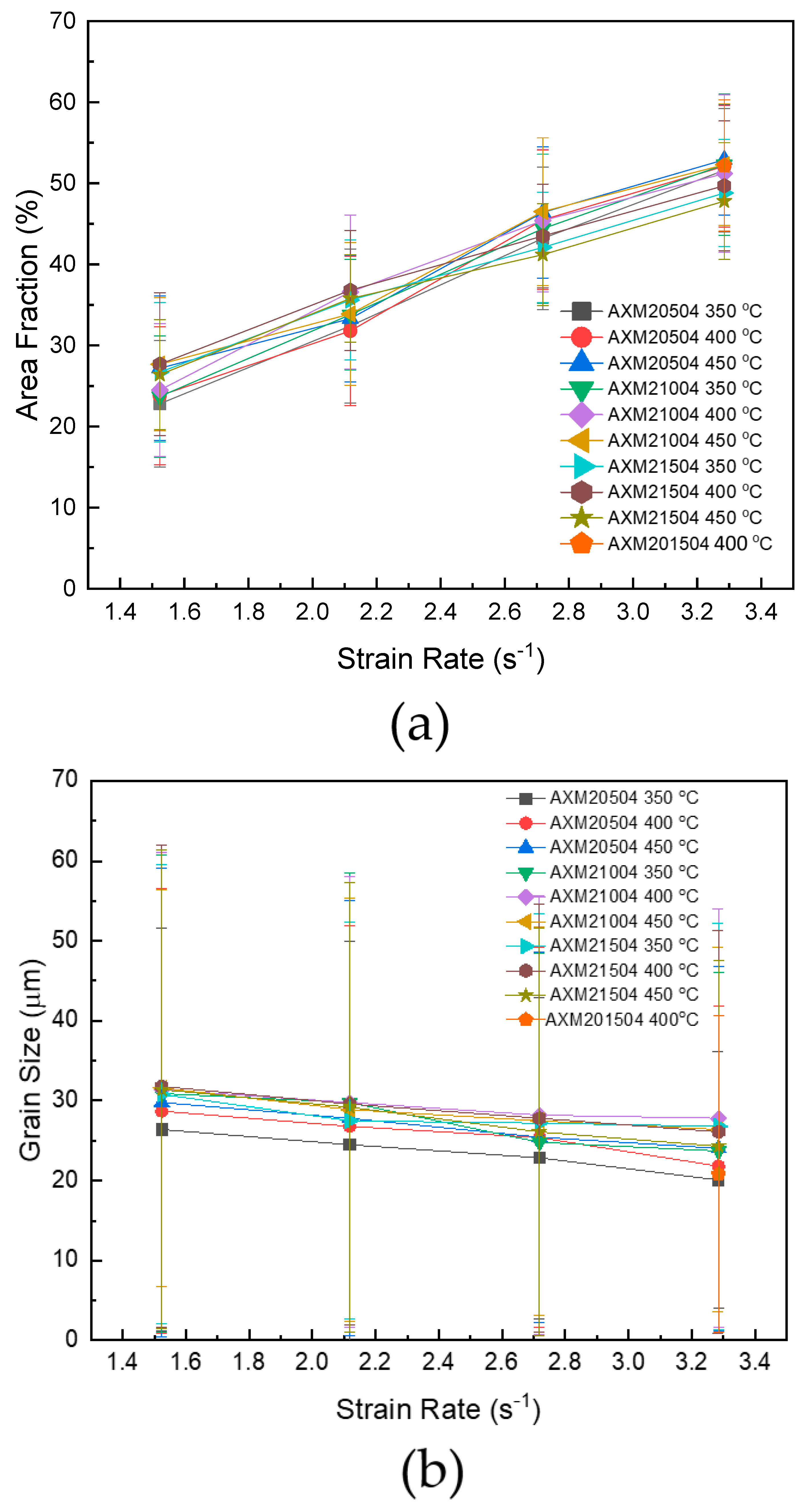

3.1. Microstructure of AXM Alloys

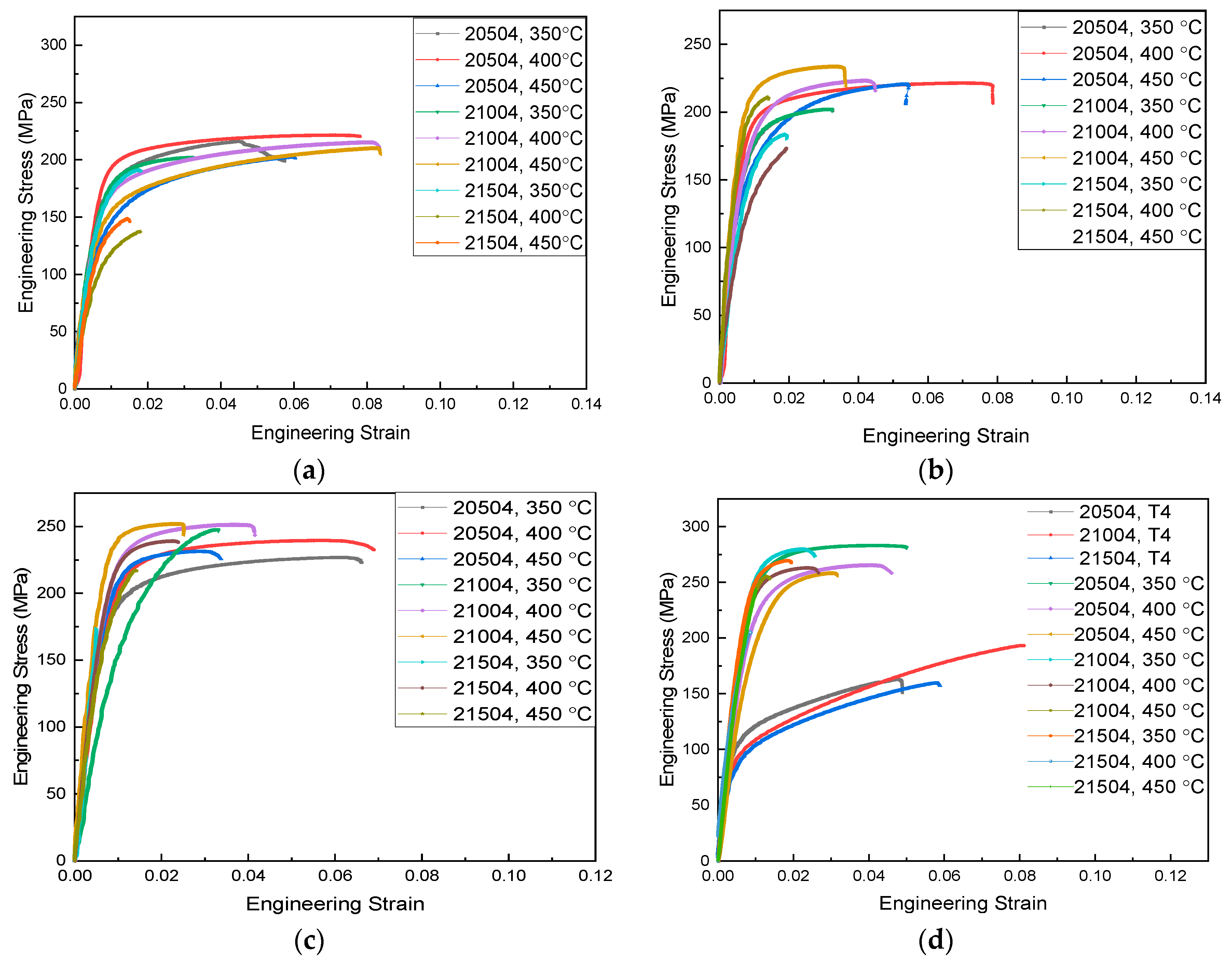

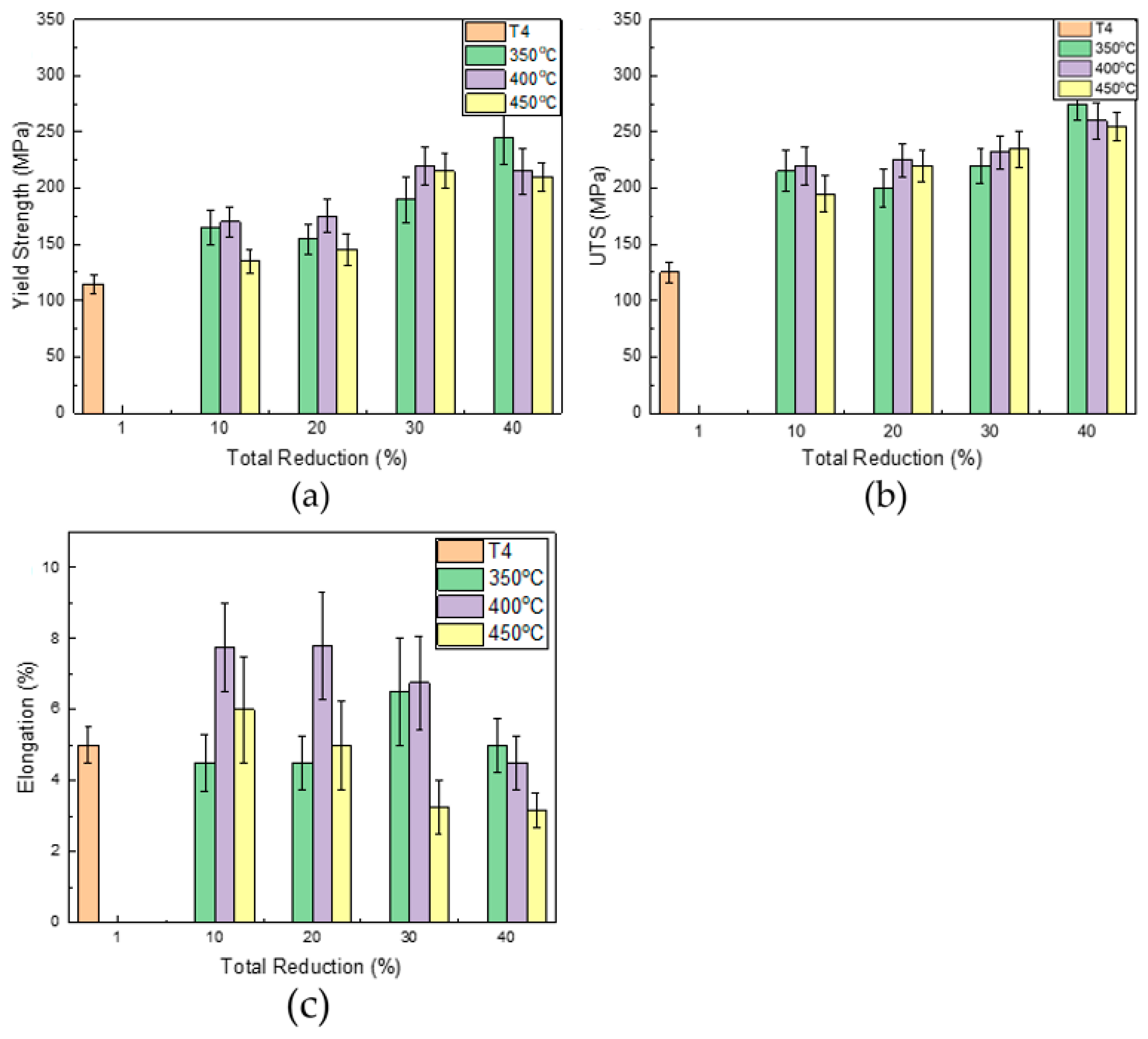

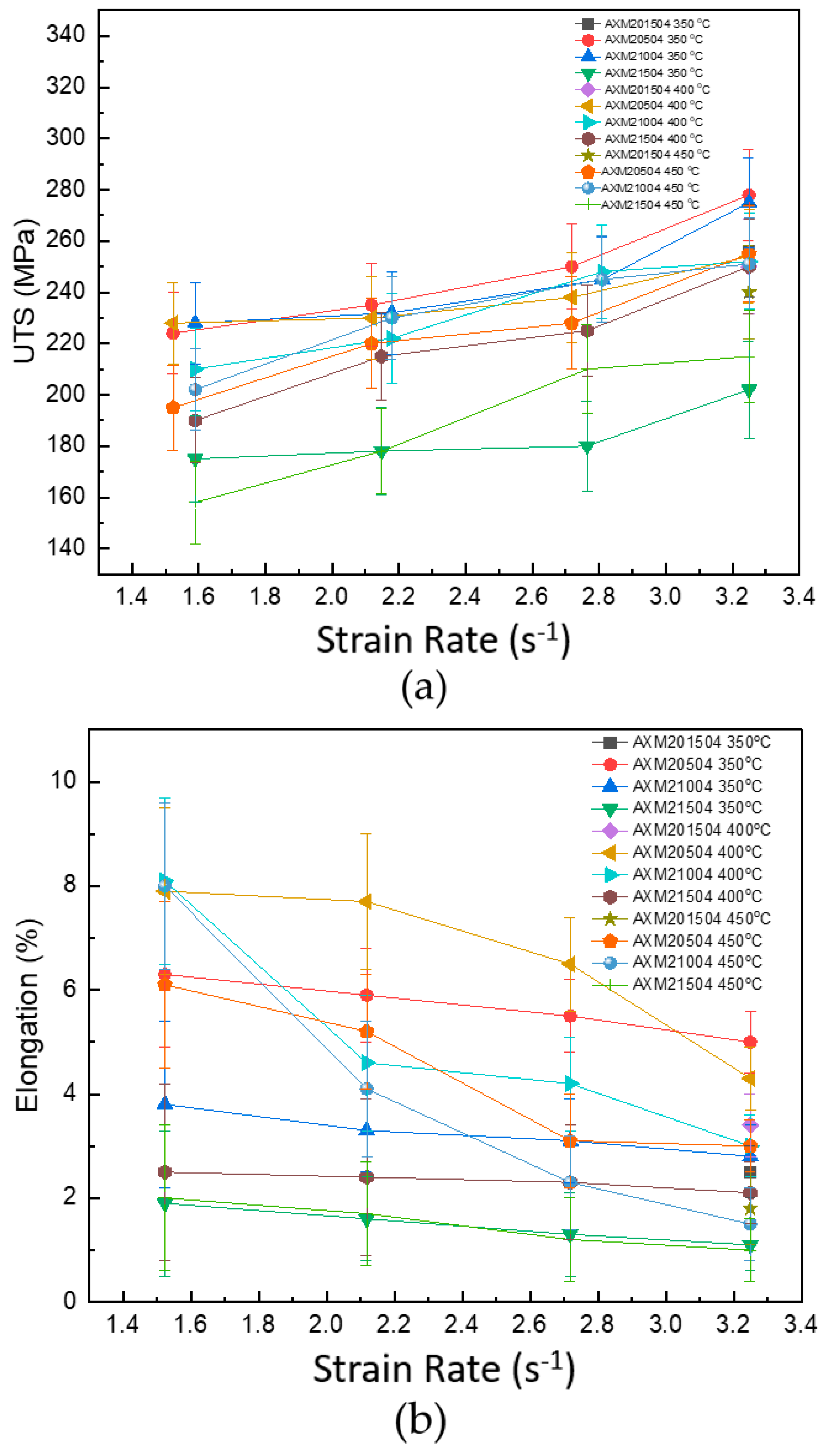

3.2. Mechanical Properties

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yan, H.; Xu, S.W.; Chen, R.S.; Kamado, S.; Honma, T.; Han, E.H. Twins, shear bands and recrystallization of a Mg-2.0%Zn-0.8%Gd alloy during rolling. Scripta Mater. 2011, 64, 141–144. [Google Scholar] [CrossRef]

- Yin, S.; Duan, W.; Liu, W.; Wu, L.; Yu, J.; Zhao, Z.; Liu, M.; Wang, P.; Cui, J.; Zhang, Z. Influence of specific second phases on corrosion behaviors of Mg-Zn-Gd-Zr alloys. Corros. Sci. 2019, 166, 108419. [Google Scholar] [CrossRef]

- Sameer, M.D.; Birru, A.K. Mechanical and metallurgical properties of friction stir welded dissimilar joints of AZ91 magnesium alloy and AA 6082-T6 aluminium alloy. J. Magnes. Alloys 2019, 7, 264–271. [Google Scholar]

- WChen, Z.; Zhang, W.C.; Zhang, L.X.; Wang, E.D. Property improvements in finegrained Mg-Zn-Zr alloy sheets produced by temperature-step-down multi-pass rolling. J. Alloys Compd. 2015, 646, 195–203. [Google Scholar]

- Nakata, T.; Xu, C.; Ajima, R.; Shimizu, K.; Hanaki, S.; Sasaki, T.; Ma, L.; Hono, K.; Kamado, S. Strong and ductile age-hardening Mg-Al-Ca-Mn alloy that can be extruded as fast as aluminum alloys. Acta Mater. 2017, 130, 261–270. [Google Scholar] [CrossRef]

- Wang, P.; Guo, E.; Wang, X.; Kang, H.; Chen, Z.; Cao, Z.; Wang, T. The influence of Sc addition on microstructure and tensile mechanical properties of Mg-4.5Sn-5Zn alloys. J. Magnes. Alloys 2019, 7, 456–465. [Google Scholar] [CrossRef]

- Wei, J.; Chen, J.; Yan, H.; Su, B.; Pan, X. Effects of minor Ca addition on microstructure and mechanical properties of the Mg-4.5Zn-4.5Sn-2Al-based alloy system. J. Alloys Compd. 2013, 548, 52–59. [Google Scholar] [CrossRef]

- She, J.; Peng, P.; Xiao, L.; Tang, A.; Wang, Y.; Pan, F. Development of high strength and ductility in Mg-2Zn extruded alloy by high content Mn-alloying. Mater. Sci. Eng. A 2019, 765, 138203. [Google Scholar] [CrossRef]

- Huang, H.; Liu, H.; Wang, C.; Sun, J.; Bai, J.; Xue, F.; Jiang, J.; Ma, A. Potential of multipass ECAP on improving the mechanical properties of a high-calcium-content MgAl-Ca-Mn alloy. J. Magnes. Alloys 2019, 7, 617–627. [Google Scholar] [CrossRef]

- Li, Z.T.; Qiao, X.G.; Xu, C.; Kamado, S.; Zheng, M.Y.; Luo, A.A. Ultrahigh strength Mg-Al-Ca-Mn extrusion alloys with various aluminum contents. J. Alloys Compd. 2019, 792, 130–141. [Google Scholar] [CrossRef]

- Wang, H.; Yu, Z.; Zhang, L.; Liu, C.; Zha, M.; Wang, C.; Jiang, Q. Achieving high strength and high ductility in magnesium alloy using hard-plate rolling (HPR) process. Sci. Rep. 2015, 5, 17100. [Google Scholar] [CrossRef] [PubMed]

- Bian, M.Z.; Sasaki, T.T.; Suh, B.C.; Nakata, T.; Kamado, S.; Hono, K. A heat-treatable Mg-Al-Ca-Mn-Zn sheet alloy with good room temperature formability. Scr. Mater. 2017, 138, 151–155. [Google Scholar] [CrossRef]

- Wang, Y.; Kang, S.B.; Cho, J. Microstructure and mechanical properties of Mg-Al-Mn-Ca alloy sheet produced by twin roll casting and sequential warm rolling. J. Alloys Compd. 2011, 509, 704–711. [Google Scholar] [CrossRef]

- Gong, X.; Li, H.; Kang, S.B.; Cho, J.H.; Li, S. Microstructure and mechanical properties of twin-roll cast Mg-4.5Al-1.0Zn sheets processed by differential speed rolling. Mater. Des. 2010, 31, 1581–1587. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Hashemi, R.; Tayyebi, M.; Bayati, A. Investigation of mechanical properties, formability, and anisotropy of dual phase Mg-7Li-1Zn. Mater. Res. Express 2019, 6, 096543. [Google Scholar] [CrossRef]

- Huang, H.; Tang, Z.; Tian, Y.; Jia, G.; Niu, J.; Zhang, H.; Pei, J.; Yuan, G.; Ding, W. Effects of cyclic extrusion and compression parameters on microstructure and mechanical properties of Mg-1.50Zn-0.25Gd alloy. Mater. Des. 2015, 86, 788–796. [Google Scholar] [CrossRef]

- Peng, P.; She, J.; Tang, A.; Zhang, J.; Zhou, S.; Xiong, X.; Pan, F. Novel continuous forging extrusion in a one-step extrusion process for bulk ultrafine magnesium alloy. Mater. Sci. Eng. A 2019, 764, 138144. [Google Scholar] [CrossRef]

- Torbati-Sarraf, S.; Mahmudi, R. Microstructure and mechanical properties of extruded and ECAPed AZ31 Mg alloy, grain refined with Al-Ti-C master alloy. Mater. Sci. Eng. A 2010, 527, 3515–3520. [Google Scholar] [CrossRef]

- Kang, J.-W.; Sun, X.-F.; Deng, K.-K.; Xu, F.-J.; Zhang, X.; Bai, Y. High strength Mg-9Al serial alloy processed by slow extrusion. Mater. Sci. Eng. A 2017, 697, 211–216. [Google Scholar] [CrossRef]

- Chen, C.; Chen, J.; Yan, H.; Su, B.; Song, M.; Zhu, S. Dynamic precipitation, microstructure and mechanical properties of Mg-5Zn-1Mn alloy sheets prepared by high strain-rate rolling. Mater. Des. 2016, 100, 58–66. [Google Scholar] [CrossRef]

- Zubair, M.; Sandlöbes, S.; Wollenweber, M.; Kusche, C.; Hildebrandt, W.; Broeckmann, C.; Korte-Kerzel, S. On the role of Laves phases on the mechanical properties of Mg-Al-Ca alloys. Mater. Sci. Eng. A 2019, 756, 272–283. [Google Scholar] [CrossRef]

- Kammer, C. Magnesium-Taschenbuch; Aluminium-Verlag: Düsseldorf, Germany, 2000. [Google Scholar]

- Avedesian, M.M.; Baker, H. ASM Specialty Handbook: Magnesium and Magnesium Alloys; ASM International: Almere, The Netherlands, 1999. [Google Scholar]

- Lee, Y.C.; Dahle, A.K.; StJohn, D.H. Grain refinement of magnesium. In Essential Readings in Magnesium Technology; Mathaudhu, S.N., Luo, A.A., Neelameggham, N.R., Nyberg, E.A., Sillekens, W.H., Eds.; Springer International Publishing: Basel, Switzerland, 2016; pp. 247–254. [Google Scholar]

- Zuo, Y.B.; Fu, X.; Mou, D.; Zhu, Q.F.; Li, L.; Cui, J.Z. Study on the role of Ca in the grain refinement of Mg–Ca binary alloys. Mater. Res. Innov. 2015, 19, S1-94–S1-97. [Google Scholar] [CrossRef]

- Esmaily, M.; Svensson, J.E.; Fajardo, S.; Birbilis, N.; Frankel, G.S.; Virtanen, S.; Arrabal, R.; Thomas, S.; Johansson, L.G. Fundamentals and advances in magnesium alloy corrosion. Prog. Mater. Sci. 2017, 89, 92–193. [Google Scholar] [CrossRef]

- Cihova, M.; Schäublin, R.; Hauser, L.; Gerstl, S.; Simson, C.; Uggowitzer, P.; Löffler, J. Rational design of a lean magnesium-based alloy with high age-hardening response. Acta Mater. 2018, 158, 214–229. [Google Scholar] [CrossRef]

- Gneiger, S.; Papenberg, N.P.; Arnoldt, A.R.; Schlögl, C.M.; Fehlbier, M. Investigations of High-Strength Mg-Al-Ca-Mn Alloys with a Broad Range of Ca + Al Contents. Materials 2021, 14, 5439. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Zhu, C.; Lin, Z.; Jin, C.; Kamado, S.; Oh-Ishi, K.; Qin, Y. Dynamic microstructure evolution and mechanical properties of dilute Mg-Al-Ca-Mn alloy during hot rolling. J. Mater. Sci. Technol. 2022, 129, 1–14. [Google Scholar] [CrossRef]

- Wang, W.; Chen, W.; Zhang, W.; Cui, G.; Wang, E. Effect of deformation temperature on texture and mechanical properties of ZK60 magnesium alloy sheet rolled by multi-pass lowered-temperature rolling. Mater. Sci. Eng. A 2018, 712, 608–615. [Google Scholar] [CrossRef]

- Hale, C.; Xu, Z.; Sankar, J. Optimization of Mechanical Properties in Magnesium-Zinc Alloys. In Proceedings of the TMS 2021, Virtual, 15–18 March 2021; pp. 1–16. [Google Scholar]

- Xu, Z.; Hale, C.; Zhang, H.; Yarmolenko, S.; Sankar, J. Comparison of Single-Pass Differential Speed Rolling (DSR) and Conventional Rolling (CR) on the Microstructure and Mechanical Properties of Mg5Zn. Bentham Sci. 2023, 16, 431–442. [Google Scholar] [CrossRef]

- Guo, F.; Zhang, D.; Yang, X.; Jiang, L.; Chai, S.; Pan, F. Influence of rolling speed on microstructure and mechanical properties of AZ31 Mg alloy rolled by large strain hot rolling. Mater. Sci. Eng. A 2014, 607, 1631–1636. [Google Scholar] [CrossRef]

- Sun, H.-F.; Liang, S.-J.; Wang, E.-D. Mechanical properties and texture evolution during hot rolling of AZ31 magnesium alloy. Trans. Nonferrous Met. Soc. China 2009, 19, s349–s354. [Google Scholar] [CrossRef]

- Lee, J.; Kim, W.; Jeong, H. Microstructure and mechanical properties of Mg-Al-Zn alloy sheets severely deformed by asymmetrical rolling. Scr. Mater. 2007, 56, 309–312. [Google Scholar]

- Li, Z.T.; Zhang, X.D.; Zheng, M.Y.; Qiao, X.G.; Wu, K.; Xu, C.; Kamado, S. Effect of Ca/Al ratio on microstructures and mechanical properties of Mg-Al-Ca-Mn Alloys. Mater. Sci. Eng. A 2017, 682, 423–432. [Google Scholar] [CrossRef]

- Cao, W.; Chen, S.-L.; Zhang, F.; Wu, K.; Yang, Y.; Chang, Y.; Schmid-Fetzer, R.; Oates, W. PANDAT software with Pan-Engine, PanOptimizer and PanPrecipitation for multi-component phase diagram calculation and materials property simulation. Calphad 2009, 33, 328–342. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, Z.; Yarmolenko, S.; Kecskes, L.; Sankar, J. Evolution of microstructure and mechanical properties of Mg-6Al alloy processed by differential speed rolling upon post-annealing treatment. Metals 2021, 11, 926. [Google Scholar] [CrossRef]

- Chang, T.-C.; Wang, J.-Y.; Chia-Ming, O.; Lee, S. Grain refining of magnesium alloy AZ31 by rolling. J. Mater. Process. Technol. 2003, 140, 588–591. [Google Scholar] [CrossRef]

- Lu, L.; Liu, X.; Shi, D.; Ma, M.; Wang, Z. Effect of Twinning Behavior on Dynamic Recrystallization During Extrusion of AZ31 Mg Alloy. JOM 2019, 71, 1566–1573. [Google Scholar] [CrossRef]

- Niu, W.; Wang, D.; Wang, G.; Li, J. Recrystallization and Anisotropy of AZ31 Magnesium Alloy by Asynchronous Rolling. Metals 2023, 13, 1631. [Google Scholar] [CrossRef]

- Ko, Y.G.; Suharto, J.; Lee, J.S.; Park, B.H.; Shin, D.H. Effect of roll speed ratio on deformation characteristics of IF steel subjected to differential speed rolling. Met. Mater. Int. 2013, 19, 603–609. [Google Scholar] [CrossRef]

- Avramov, I. Kinetics of distribution of infections in networks. Physica A 2007, 379, 615–620. [Google Scholar] [CrossRef]

- Avrami, M. Kinetics of Phase Change 1. General Theory. J. Chem. Phys. 1939, 7, 1103–1112. [Google Scholar] [CrossRef]

- Avrami, M. Kinetics of Phase Change 11. Transformation-Time Relations for Random Distribution of Nuclei. J. Chem. Phys. 1940, 8, 212–224. [Google Scholar] [CrossRef]

- Avrami, M. Kinetics of Phase Change III. Granulation, Phase Change and Microstructure. J. Chem. Phys. 1941, 9, 177–184. [Google Scholar] [CrossRef]

- Jena, A.K.; Chaturvedi, M.C. Phase Transformations in Materials; Prentice Hall: Upper Saddle River, NJ, USA, 1992; pp. 243–247. [Google Scholar]

- Cahn, J.W. Transformation Kinetics During Continuous Cooling. Acta Met. 1956, 4, 572–575. [Google Scholar] [CrossRef]

- Goris, N.A.V.; Castañeda, A.R.S.; Ramirez-Torres, E.E.; Reyes, J.B.; Randez, L.; Cabrales, L.E.B.; Montijano, J.I. Correspondence Between Formulations of Avrami and Gompertz Equations for Untreated Tumor Growth Kinetics. Rev. Mex. De Fis. 2020, 66, 632–636. [Google Scholar] [CrossRef]

- Callister, W.D. Fundamentals of Materials Science and Engineering, 2nd ed.; Wiley & Sons: Hoboken, NJ, USA, 2004; p. 252. [Google Scholar]

- Li, J.C.M.; Chou, Y.T. The role of dislocations in the flow stress grain size relationships. Met. Trans. 1970, 1, 1145–1159. [Google Scholar] [CrossRef]

- Hughes, D.A.; Hansen, N. Deformation structures developing on fine scales. Philos. Mag. 2003, 83, 3871. [Google Scholar] [CrossRef]

- Wert, J.A. Microstructural Control in Aluminum Alloys: Deformation, Recovery, and Recrystallization; Metallurgical Society Inc.: Burlington, ON, Canada, 1986; pp. 67–70. [Google Scholar]

- Wang, C.; Kang, J.; Deng, K.; Nie, K.; Liang, W.; Li, W. Microstructure and mechanical properties of Mg-4Zn-xGd (x = 1, 0.5, 1, 2) alloys. JOM 2020, 8, 451–551. [Google Scholar] [CrossRef]

| Alloys | Wt% Mg | Wt% Al | Wt% Ca | Wt% Mn | Ca/Al wt |

|---|---|---|---|---|---|

| AXM201504 | 97.45 | 2.0 | 0.15 | 0.4 | 0.075 |

| AXM20504 | 97.1 | 2.0 | 0.5 | 0.4 | 0.25 |

| AXM21004 | 96.6 | 2.0 | 1.0 | 0.4 | 0.5 |

| AXM21504 | 96.1 | 2.0 | 1.5 | 0.4 | 0.75 |

| Sample Set | Reduction Rate (%) | Final Thickness (mm) |

|---|---|---|

| 1 | 10 | 3.56 ± 0.05 |

| 2 | 20 | 3.18 ± 0.09 |

| 3 | 30 | 2.78 ± 0.03 |

| 4 | 40 | 2.48 ± 0.06 |

| Reduction (%) | Low Angle GB (%) | High Angle GB (%) |

|---|---|---|

| 10 | 34.6 | 65.4 |

| 20 | 49.4 | 50.6 |

| 30 | 41.0 | 59.0 |

| 40 | 50.9 | 49.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hale, C.; Xu, Z.; Fialkova, S.; Rawles, J.; Sankar, J. Influence of Processing Temperature and Strain Rate on the Microstructure and Mechanical Properties of Magnesium Alloys Processed by Single-Pass Differential Speed Rolling. Crystals 2024, 14, 262. https://doi.org/10.3390/cryst14030262

Hale C, Xu Z, Fialkova S, Rawles J, Sankar J. Influence of Processing Temperature and Strain Rate on the Microstructure and Mechanical Properties of Magnesium Alloys Processed by Single-Pass Differential Speed Rolling. Crystals. 2024; 14(3):262. https://doi.org/10.3390/cryst14030262

Chicago/Turabian StyleHale, Christopher, Zhigang Xu, Svitlana Fialkova, Jessica Rawles, and Jagannathan Sankar. 2024. "Influence of Processing Temperature and Strain Rate on the Microstructure and Mechanical Properties of Magnesium Alloys Processed by Single-Pass Differential Speed Rolling" Crystals 14, no. 3: 262. https://doi.org/10.3390/cryst14030262

APA StyleHale, C., Xu, Z., Fialkova, S., Rawles, J., & Sankar, J. (2024). Influence of Processing Temperature and Strain Rate on the Microstructure and Mechanical Properties of Magnesium Alloys Processed by Single-Pass Differential Speed Rolling. Crystals, 14(3), 262. https://doi.org/10.3390/cryst14030262