Abstract

This work demonstrates how the addition of few-layer graphene (FLG) influences the processability and mechanical properties of the mixed polyolefin waste stream (R-(PE/PP)). Three different types of compounds were investigated: (1) R-(PE/PP) with FLG; (2) blends of R-(PE/PP) with prime polyethylene (PE) or polypropylene (PP) or PP copolymer; and (3) R-(PE/PP) with both the prime polymer and FLG. The processability was assessed by measuring the torque during melt extrusion, the melt flow index (MFI), and viscosity of the compounds. Investigations of the processability and mechanical properties of the composites indicate that the presence of FLG can reinforce the composites without hindering the processability, an unusual but desired feature of rigid fillers. A maximum increase in tensile strength by 9%, flexural strength by 23%, but a reduction in impact strength were observed for the compounds containing R-(PE/PP), 4 wt.% FLG, and 9 wt.% prime PP. The addition of FLG concentrations higher than 4 wt.% in R-(PE/PP), however, resulted in higher tensile and flexural properties while preserving the impact strength. Remarkably, the addition of 10 wt.% FLG increased the impact strength of the composite by 9%. This increase in impact strength is attributed to the dominant resistance of the rigid FLG particles to crack propagation.

1. Introduction

Over the recent years, polymer materials have demonstrated a promising role in household as well as industrial applications. Consequently, plastic waste accumulation is soaring. According to a survey by Deloitte [1], over 11 Mt of plastics were wasted in Canada during 2016 only, and only 9% was recycled; around 4% was incinerated for energy recovery and 87% was dumped into the environment. The estimated loss was CAD 7.8 billion for Canada.

Polyolefins (different types of polyethylene (PE) and polypropylene (PP)) are widely used in packaging materials [2] and are heavily present in post-consumer plastic residues. However, because they have comparable densities, they cannot be easily separated using standard techniques available in most sorting facilities. The most straightforward solution to recycle them consists of blending them and using them as is. However, this is quite problematic as PE and PP are thermodynamically immiscible with each other, resulting in a material with weak mechanical properties. Hence, this type of mixed plastic waste is often directed to incineration and landfills [3]. Therefore, improving the properties of mixed polyolefin waste streams is highly desired to enable the recycling of a huge portion of polymer waste.

In general, the mechanical recycling of plastic waste involves mixing with a rigid filler, prime polymer, or both [4]. In this regard, several investigations have been reported on the influence of adding different copolymers [5,6,7,8], solid particles [9,10,11,12], and combinations of copolymers and solid particles [6,12,13,14] on the mechanical properties of prime polyolefin mixtures. However, these studies cannot be, necessarily, applied to mixed polyolefin waste due to many uncertainties such as polymer aging, presence of impurities, varied molecular structure, and molecular weight. Hence, more research work on the improvement of the mechanical properties of a mixed polyolefin waste stream is needed. A few studies are available on the upgrade of mixed polyolefin waste streams [15,16,17,18], involving a copolymer and a few rigid fillers. These additives in PE/PP blends mostly increase the impact strength (impact toughness) and elongation at break (tensile toughness or ductility), but deteriorate the strength and modulus (stiffness) compared to the unfilled blends. Generally, impact modifying copolymers increase toughness but hinder the strength of the original material. Unlike copolymers, inorganic rigid fillers act as stress concentrators and mostly increase stiffness and strength but reduce toughness. Therefore, different dosages of mechanically strong fillers and/or impact modifying copolymers need to be explored to obtain a better balance of stiffness, strength, and toughness in the composite.

Concomitantly, graphene is a 2D carbonaceous filler with lightweight and excellent mechanical strength. Moreover, commercially available few-layer graphene (FLG), mass-produced from natural graphite by a mechanochemical exfoliation process, allows for an economically viable use of graphene at an industrial scale. Although there have been several reports on the effect of adding modified and unmodified graphene on electrical properties [19,20,21,22,23,24], only a few have focused on the mechanical properties [19,25] of prime PE/PP blends. Furthermore, the effect of the addition of FLG to improve the properties of a mixed polyolefin waste stream, to our knowledge, has not been investigated. Therefore, this study was conducted to analyze the potential of commercially available FLG, which is less expensive than lab-grade graphene, to improve the properties of a mixed polyolefin waste stream.

In this work, a mixed polyolefin waste stream (designated as R-(PE/PP) mixture was melt blended with either FLG alone, a prime polymer alone (PE, PP homopolymer, or PP copolymer), or FLG in combination with a prime polymer. To prepare the composites containing R-(PE/PP) and FLG, the FLG concentration was varied from 1 to 10 wt.%. To prepare the blends of R-(PE/PP), FLG, and each of the three prime polymers, only a 4 wt.% loading was selected. Torque during extrusion, melt flow index (MFI), and viscosity of the samples were measured to evaluate the influence of adding FLG on the processability of the composites. In addition, the tensile, flexural, and impact properties of the composites of R-(PE/PP) containing FLG and/or the prime polymers were evaluated. Finally, the influence of adding FLG on the microstructure, and subsequently, the mechanical properties of the composites were investigated by scanning electron microscopy (SEM).

2. Materials and Methods

2.1. Materials

FLG powder (GrapheneBlack 3X) from NanoXplore Inc., Montreal, QC, Canada, produced through a water-based environmentally friendly mechano-chemical exfoliation process was used in this work. The average thickness of FLG is 6–10 atomic layers and the lateral primary particle size is 1 to 2 µm. Loose clusters of primary particles form secondary particles. The average lateral size of secondary particles is around 30 μm.

A R-(PE/PP) mixture sourced from a local recycler in Quebec was selected for this work. According to the supplier’s information, the mixture contains around 30 to 40 wt.% PP with less than 5 wt.% contamination (dye, ink, or pigment, etc.). Differential scanning calorimetry (DSC) analysis of the R-(PE/PP) samples (Figure S1, provided in the Supplementary Materials) indirectly confirmed the composition to be about PE/PP-60/40.

Masterbatches loaded with 30 wt.% FLG in three different prime polymers (PE homopolymer, PP homopolymer, and PP copolymer), provided by NanoXplore Inc., Montreal, QC, Canada, were used in this work. In addition, a masterbatch obtained by adding 20 wt.% FLG to the R-(PE/PP) was also prepared and used.

The specifications of the masterbatch polymers used in the present work are summarized in Table 1.

Table 1.

Identification, MFI, and density of the polymers used in this work.

2.2. Processing

Three types of composites were obtained:

Type 1: R-(PE/PP)/FLG composites by blending the R-(PE/PP) with the R-(PE/PP)/FLG masterbatch to analyze the individual effect of adding FLG.

Type 2: R-(PE/PP)/prime polymer compounds by mixing the R-(PE/PP) with the prime polymer (PE, PP homopolymer, and PP copolymer) to analyze the effect of adding only the prime polymer.

Type 3: R-(PE/PP)/prime polymer/FLG composites by mixing the R-(PE/PP) with the prime polymer/FLG masterbatch to investigate the combined effect of adding the prime polymer and FLG.

All of the samples were processed in a HAAKE twin-screw extruder, (Rheomex OS PTW16/40) at 150 rpm, and 200 °C in all zones. Table 2 summarizes the nomenclature and corresponding compositions of the samples.

Table 2.

Sample nomenclature and respective composition of the samples.

In the case of the Type 3 composites, 4 wt.% concentration of FLG was selected for further investigation. This choice was based on the performance of Type 1 composites, which, after the addition of 4 wt.% FLG, started to exhibit observable differences in the mechanical properties of the composites. Therefore, 87 wt.% R-(PE/PP) was blended with the 13 wt.% prime polymer/FLG masterbatch, resulting in Type 3 composites with 4 wt.% FLG. The final composition resulted in the R-(PE/PP)/prime polymer/FLG = 87/9/4.

2.3. Characterizations

2.3.1. Melt Flow Index (MFI)

A melt flow index (MFI) tester (manufactured by International Equipments, Mumbai, India) was used to estimate the MFI of the samples according to ASTM D1238.

2.3.2. Rheological Properties

A capillary rheometer (model: Instron SR20) was used to measure the viscosity of the samples at 200 °C at a shear rate varying from 50 s−1 to 1000 s−1. This range was selected because it includes the shear rate that the polymer undergoes during the extrusion or injection processes. The length and diameter of the capillary were 40 mm and 1 mm, respectively, resulting in an L/D ratio of 40.

2.3.3. Mechanical Properties

An MTS Alliance RF/200 tensile test device was used to study the tensile and flexural properties of the samples. Tensile properties were studied according to ASTM D638 at a crosshead speed of 50 mm/min to measure the tensile strength, tensile modulus, and elongation at break, at room temperature. Flexural strength and modulus were analyzed according to ASTM D790 with a 0.1 (mm/mm)/min outer fiber strain rate (Z). For each case, a 10 kN load cell was used.

An impact strength tester device (manufactured by International Equipments, Mumbai, India) was used to measure the notched impact strength of the samples. The impact strength was evaluated according to ASTM D256. A motorized notch cutter (manufactured by International Equipments, Mumbai, India) was used to make notches in the samples.

At least five specimens of each composite were tested at room temperature to report the tensile, flexural, and impact properties. The average value is reported along with the standard deviation.

2.3.4. Morphological Characterization

A SEM S3600-N Hitachi (Model: MEB-3600-N) was used to obtain scanning electron microscope (SEM) images of the samples’ fractured surface. The FLG powder was attached to the double-sided carbon tape without any gold coating to obtain the SEM image. To obtain the SEM images of the composites, the samples were cryo-fractured to analyze the morphology. In addition, a few samples were fractured by applying an impact load. A Gold Sputter Coater (Model: K550X) was used to coat the surface of the compounds before taking the SEM images.

3. Results and Discussions

3.1. Rheological Properties

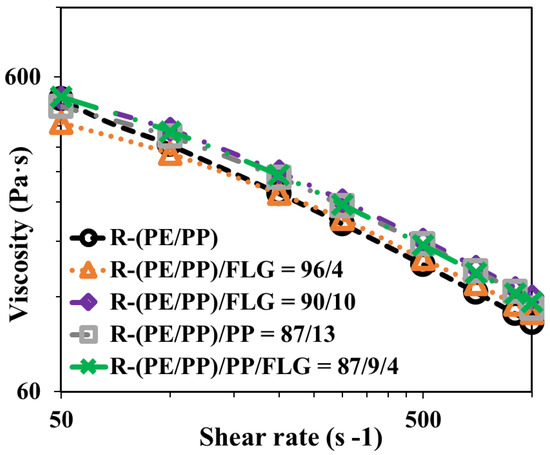

The MFI values (Figure S2, provided in the Supplementary Materials) of the neat R-(PE/PP) and FLG-filled composites (Type 1 and Type 3) were found to be independent of the studied additive concentrations and types. Similarly, the applied torque during extrusion remained at 48 ± 1 Nm, irrespective of the FLG concentration in the composites. Both observations indicate that unlike other solid particles [26,27], which adversely affect the processability and flow properties of the polymeric materials, FLG had very little or no effect on the flow behavior of the R-(PE/PP) when added up to 10 wt.%.

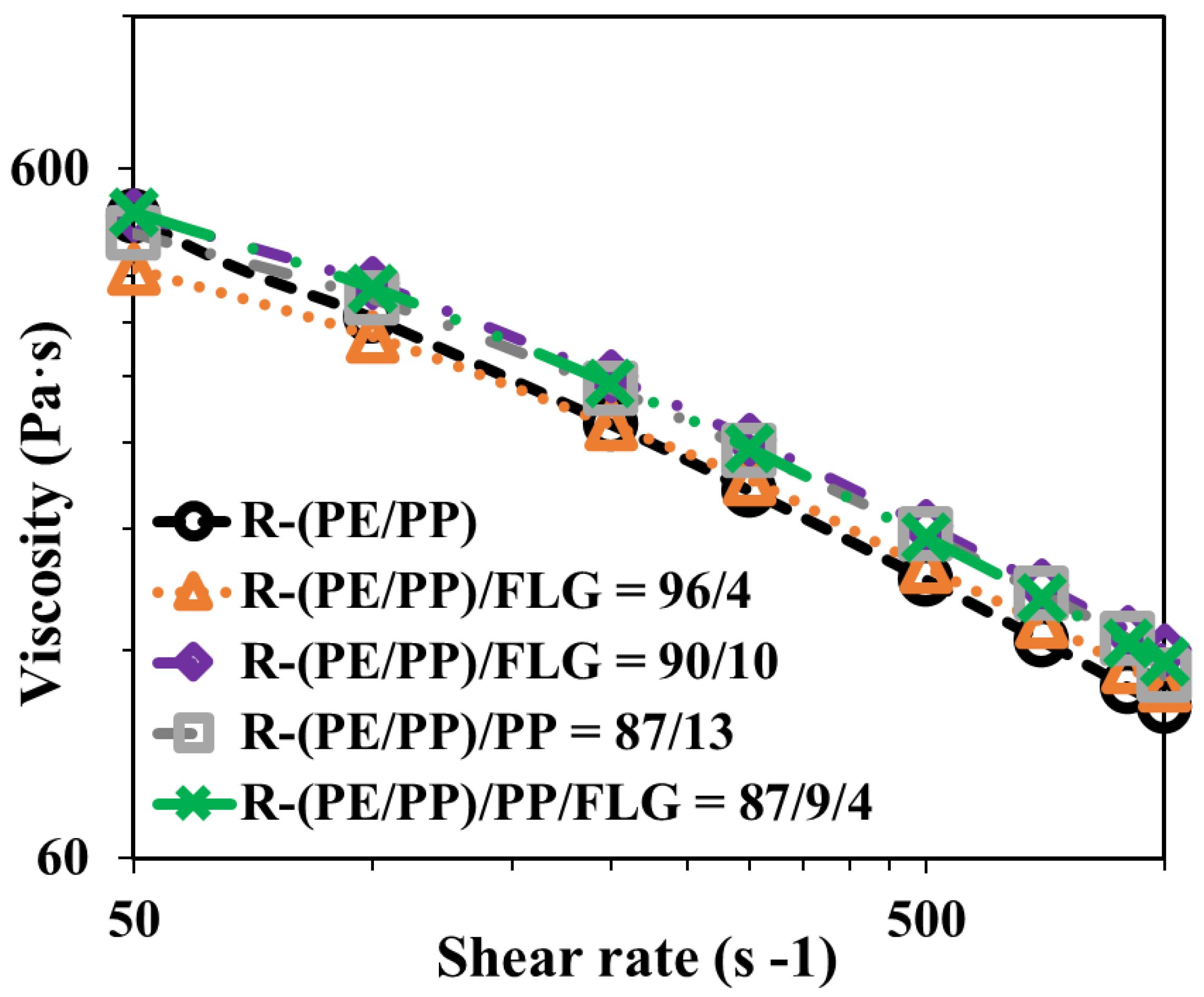

Furthermore, Figure 1 shows the viscosity as a function of shear rate at 200 °C (processing temperature) for a few of the studied compounds. It can be seen that the viscosity of the materials was not affected by the addition of graphene. This can be attributed to the lubrication effect of FLG [28]. Similar findings were reported by the co-authors in a previous study regarding prime high density polyethylene (HDPE)/recycled HDPE/FLG blend composites [4]. Another study [28] reported similar results for HDPE/graphite composites.

Figure 1.

Apparent viscosity of the neat R-(PE/PP) and the additive (FLG, prime polymer) filled R-(PE/PP) samples at 200 °C as a function of shear rate.

3.2. Mechanical Properties

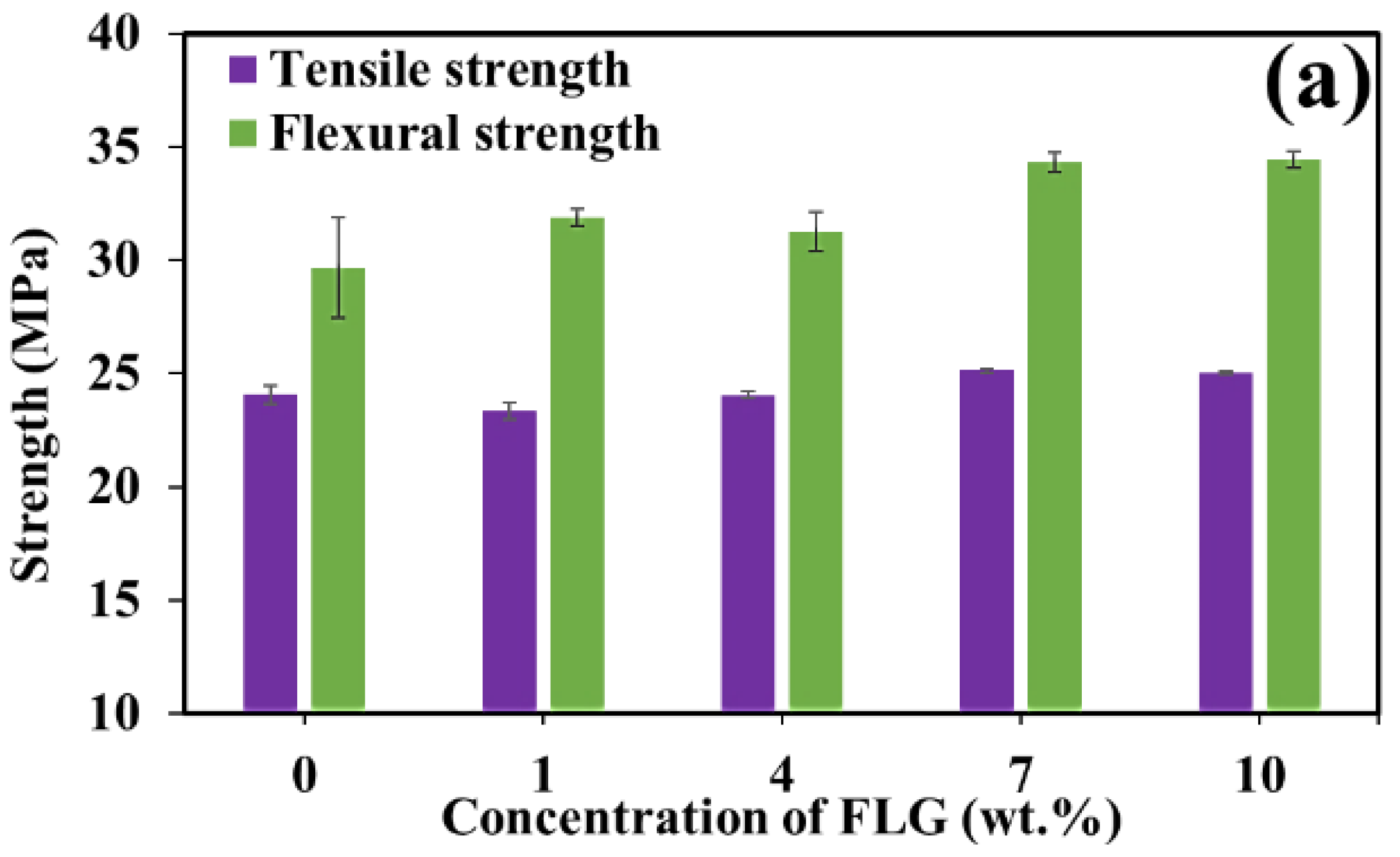

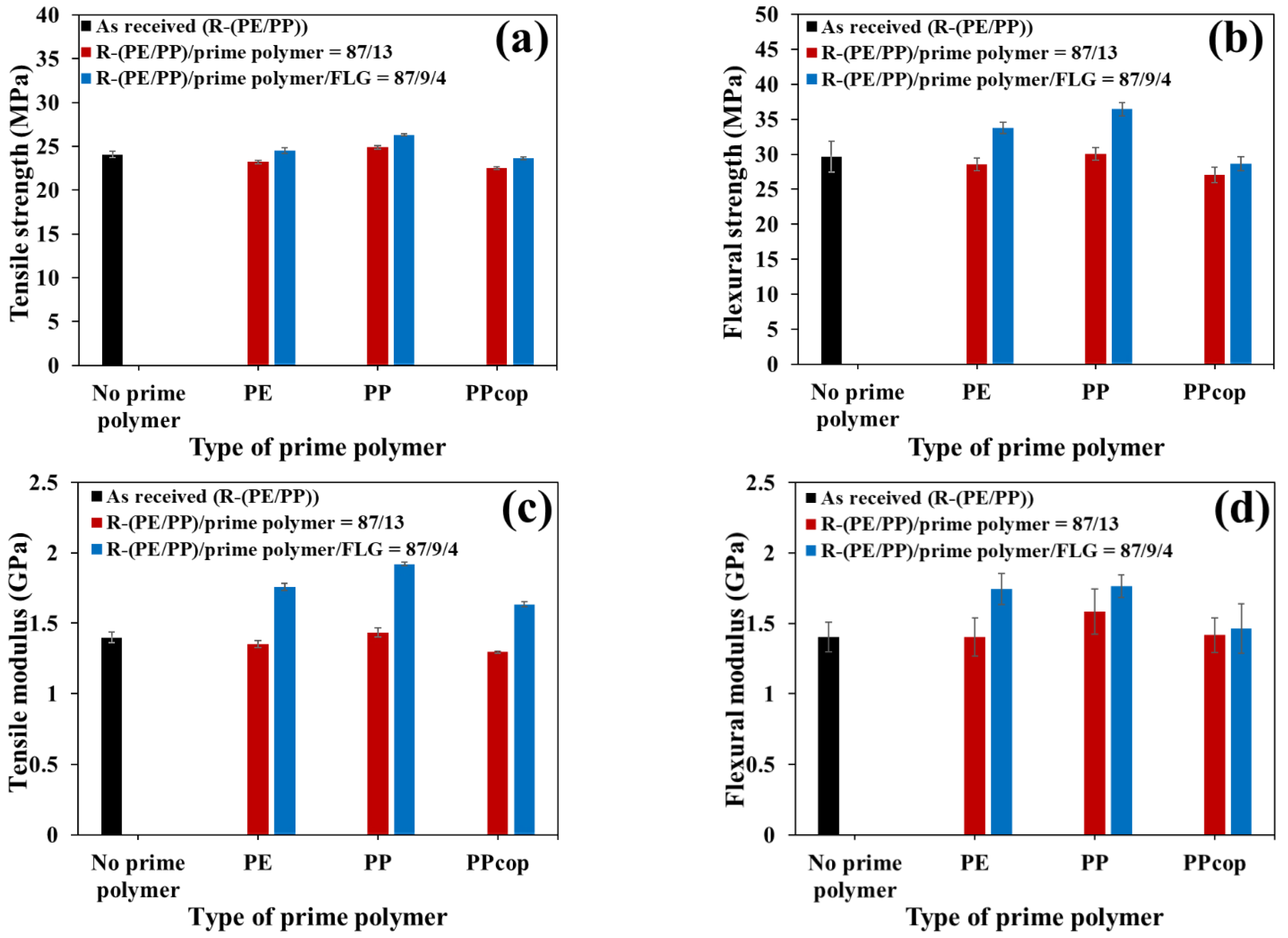

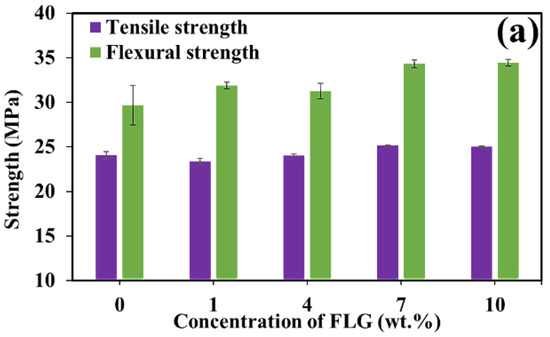

The tensile and flexural properties of the R-(PE/PP)/FLG composites (Type 1) as a function of FLG concentration were investigated. Figure 2a shows the tensile and flexural strengths, and Figure 2b shows the tensile and flexural moduli of the studied compounds. Figure 2c displays their impact strength, and Figure 2d indicates their tensile toughness and elongation at break.

Figure 2.

(a) Tensile strength and flexural strength, (b) tensile modulus and flexural modulus and (c) impact strength, and (d) tensile toughness and elongation at break of the R-(PE/PP)/FLG composites as a function of FLG concentration.

From Figure 2a,b, it can be observed that the presence of FLG resulted in an increase in the strength and modulus (stiffness) of the composites when compared to the one of the unfilled R-(PE/PP). The most significant increases in the tensile, flexural, and impact properties were observed for the R-(PE/PP)/FLG = 90/10 composite. These increases in strength and stiffness can be attributed to the reinforcement effect of the FLG particles in the R-(PE/PP). Previously, a similar reinforcing behavior of carbon fiber [9], glass beads [10], short glass fiber [11], and wood flour [29] in a controlled PE/PP blend system has been reported in the literature.

As illustrated in Figure 2c, the addition of 1 wt.% FLG resulted in a reduced impact strength while 4 and 7 wt.% FLG did not reduce the impact strength of the composites. However, an increase in the impact strength was observed in the R-(PE/PP)/FLG = 90/10 composite. This unusual trend in the impact strength by the addition of rigid fillers has only been reported in a few studies, and was attributed to the resistance of the rigid filler particles to crack propagation throughout the composite [30].

Both elongation at break and tensile toughness of the FLG-filled composites decreased as the FLG concentration increased, as can be seen in Figure 2d. This is a common effect of the addition of rigid fillers and has been reported in the literature [12,31].

It is worth noting that the increase in the FLG loading yielded the opposite effect on the tensile toughness and impact resistance of the Type 1 composites. Possible reasons explaining this difference are presented in the Discussion section.

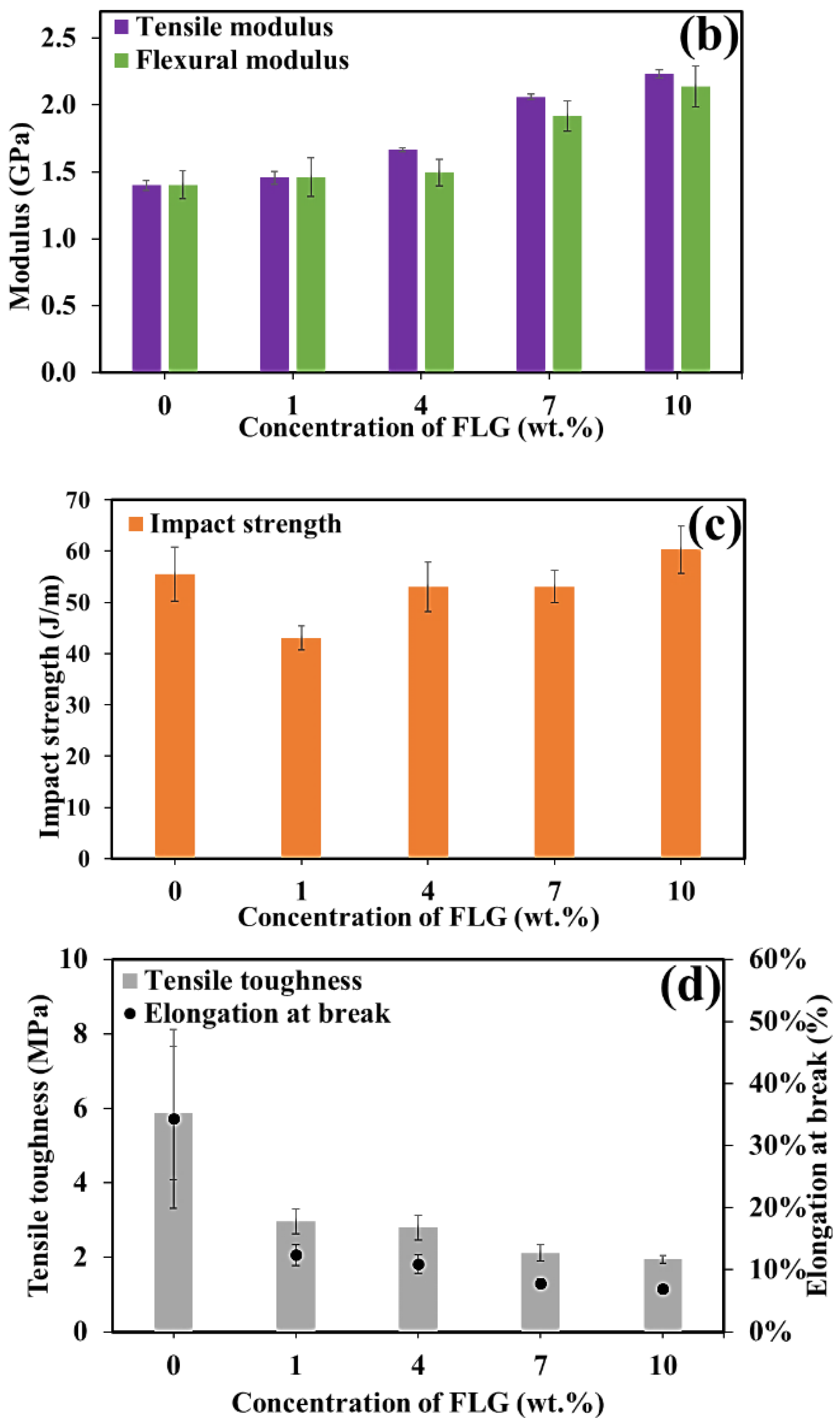

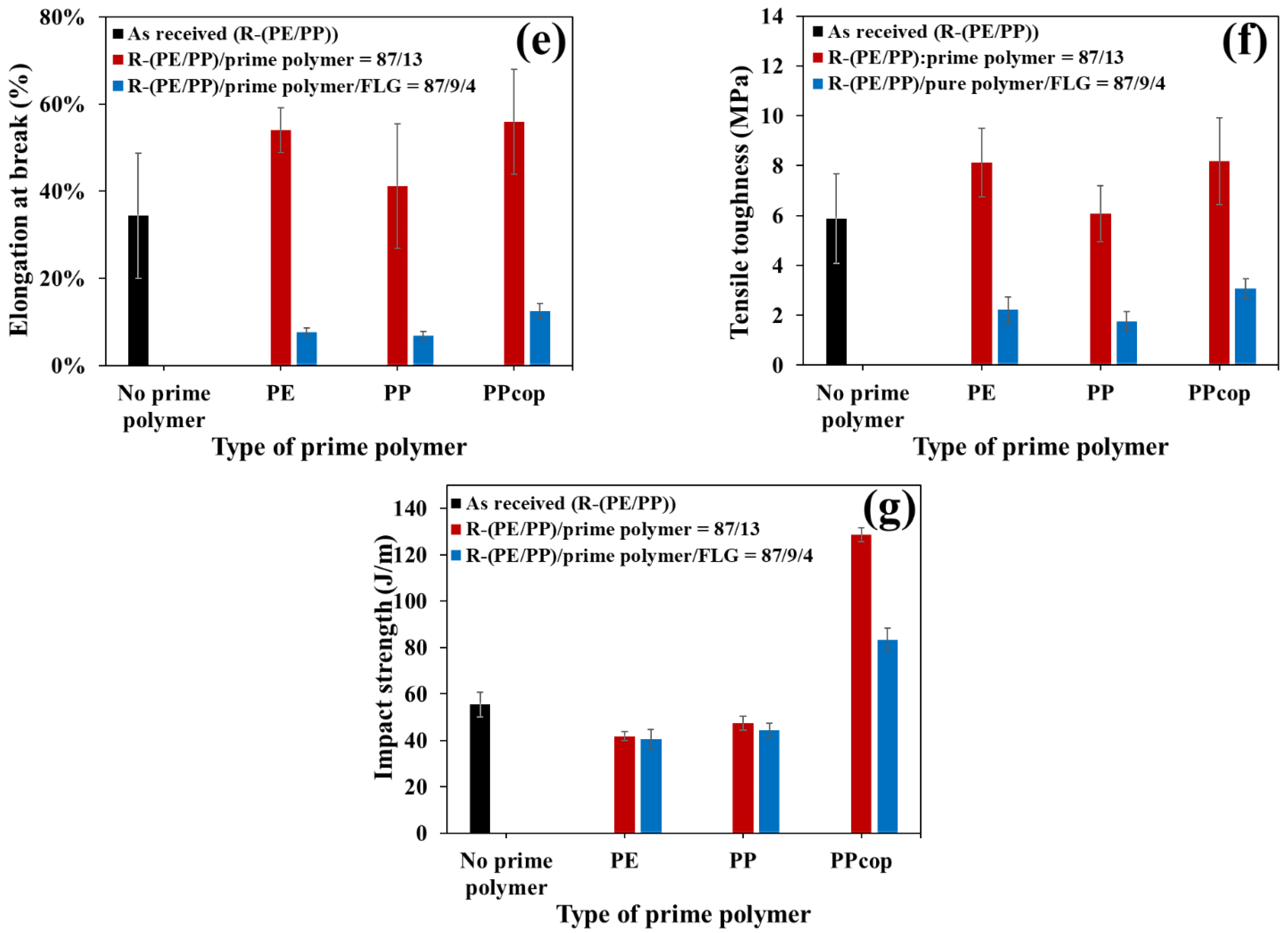

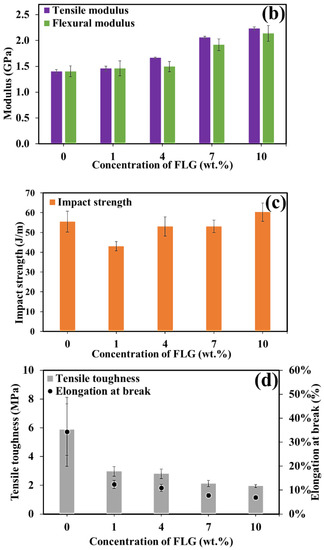

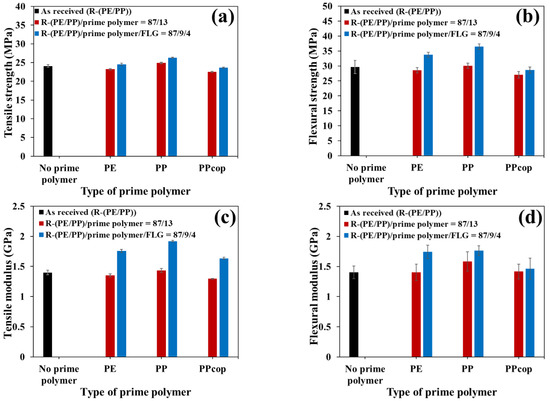

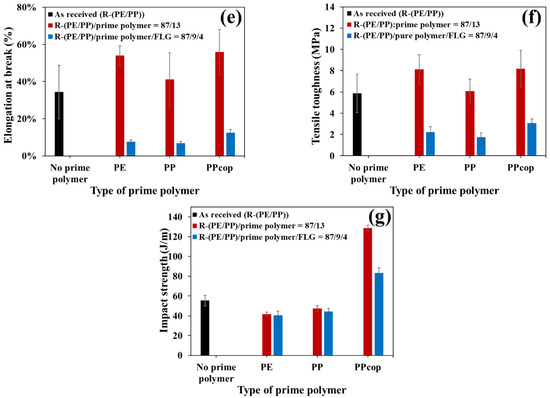

Mechanical properties of the Type 2 (R-(PE/PP)/prime polymer = 87/13) and Type 3 (R-(PE/PP)/prime polymer/FLG = 87/9/4) composites are summarized in Figure 3. The tensile strength, flexural strength, tensile modulus, flexural modulus, elongation at break, tensile toughness (estimated by the calculating the area underneath the stress–strain curve), and impact strength are, respectively, presented in Figure 3a–g, as a function of the type of prime polymer present in the Type 2 and Type 3 composites.

Figure 3.

(a) Tensile strength, (b) flexural strength, (c) tensile modulus, (d) flexural modulus, (e) elongation at break, (f) tensile toughness, and (g) impact strength of the Type 2 and Type 3 samples as a function of the type of the used prime polymer. The properties of the as received R-(PE/PP) are presented by the black bars as a baseline.

As observed in Figure 3a–d, the Type 3 composite containing both the prime polymer (PE or PP) and FLG presented higher tensile and flexural properties than that of the neat R-(PE/PP) and respective Type 2 samples. For example, with 4 wt.% FLG and 9 wt.% PP, the flexural strength of Type 3 was 21% higher than the corresponding one of the Type 2 composite with 13 wt.% PP.

However, the Type 2 composites showed a higher elongation at break, tensile toughness, and impact strength than the corresponding ones of Type 3. A substantial increase in the impact strength and ductility was observed in the Type 2 composite containing the PP copolymer. Precisely, the addition of the impact-modifying PP copolymer resulted in a sharp increase in the fracture toughness by 132% for Type 2 and by 50% for Type 3 when compared to the neat R-(PE/PP). A similar effect resulting from the addition of copolymers has been reported [5,6,7,8].

3.3. Morphology

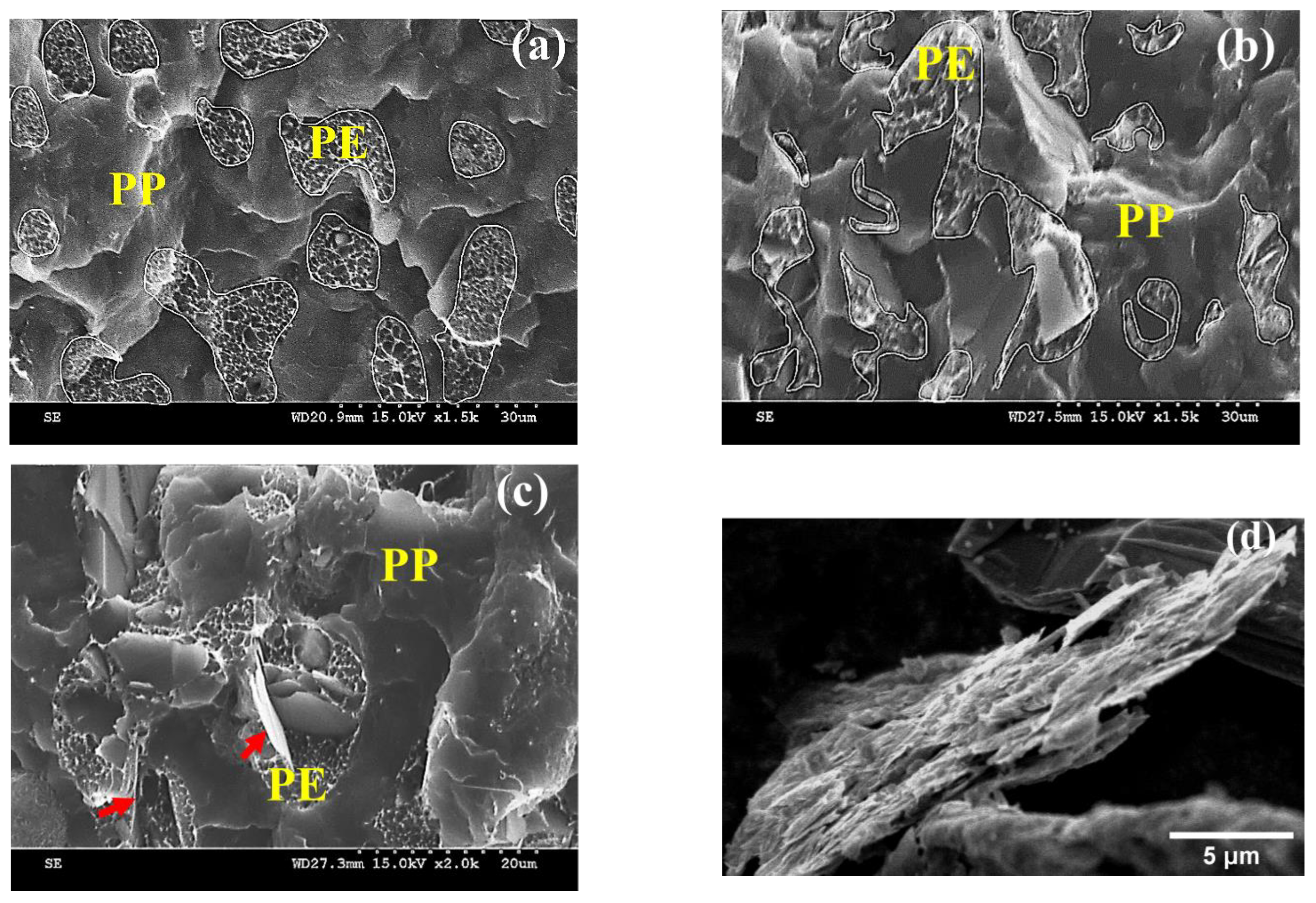

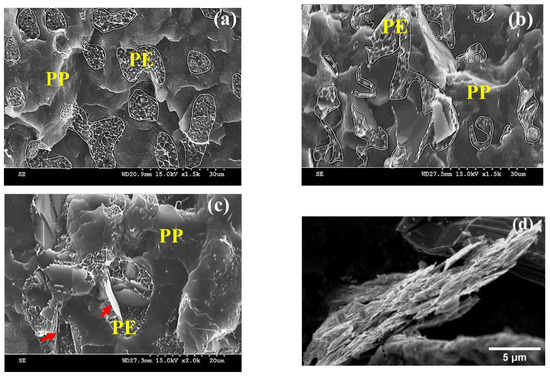

Figure 4 shows the SEM images of the cryo-fractured surface of (a) R-(PE/PP), (b) and (c) R-(PE/PP)/FLG = 96/4 and (d) FLG powder.

Figure 4.

SEM images of (a) neat R-(PE/PP), (b,c) R-(PE/PP)/FLG = 96/4, and (d) FLG powder; in (a,b), the domain of the PE phase is marked by a white outline and in (c), the localization of FLG in the PE phase is marked by the red arrow to guide the readers’ eyes.

In Figure 4a,b, two different phases are visible. The rough phase corresponds to PE and the smooth phase to PP. PP has a much higher glass transition temperature than PE. During cryo-fracturing, PP dips below its glass transition temperature much easier than the case for PE. Consequently, the PE undergoes ductile fracture while the PP undergoes brittle fracture [18]. Although PE was the major component of the mixed polyolefin waste stream of this work, the area of the PE phase domain was smaller than that of the PP phase. In the case of an immiscible polymer blend, the morphology is directly dependent on the viscosity ratio of the constituting polymer components at the processing conditions. In the PE/PP immiscible blend systems, PP can form the matrix of the blend morphology with minor weight contribution, if the viscosity of PP is less than that of PE. A similar observation of creating a matrix by the minor component of the blend has been reported in the literature [18]. The authors showed this observation in the case of a PE/PP-65/35 blend where the viscosity of PE was 500 Pa·s and the viscosity of PP was 300 Pa·s.

Moreover, Figure 4c indicates the localization of FLG in the PE phase, which was similar to the observations by other authors [23]. The SEM image of the FLG powder on carbon tape is provided in Figure 4d as a reference and for the purpose of comparison. The preferential localization of FLG in the PE phase is attributed to lower interfacial tension between PE and graphene than that of PP and graphene [32]. Moreover, it is observed that the addition of FLG resulted in a finer or elongated domain size of the PE phase in the R-(PE/PP)/FLG = 96/4 composite compared to that of the neat R-(PE/PP). A similar refinement of morphology in the presence of FLG has been reported by other authors [4].

3.4. Discussion

As shown in Figure 1, the viscosity of the FLG-filled composites remained independent of the loading of FLG. The observed torque during extrusion and the MFI values (provided in Figure S2 of Supplementary Materials) also support this finding. Therefore, it can be stated that FLG loadings up to 10 wt.% do not affect the processability of the composites. This may be the outcome of commensurable contacts of filler agglomerates, which maintain both the slippage and mobility of the molten polymer chain in the filled composites, similar to the unfilled compound (i.e., lubricant effect) [28].

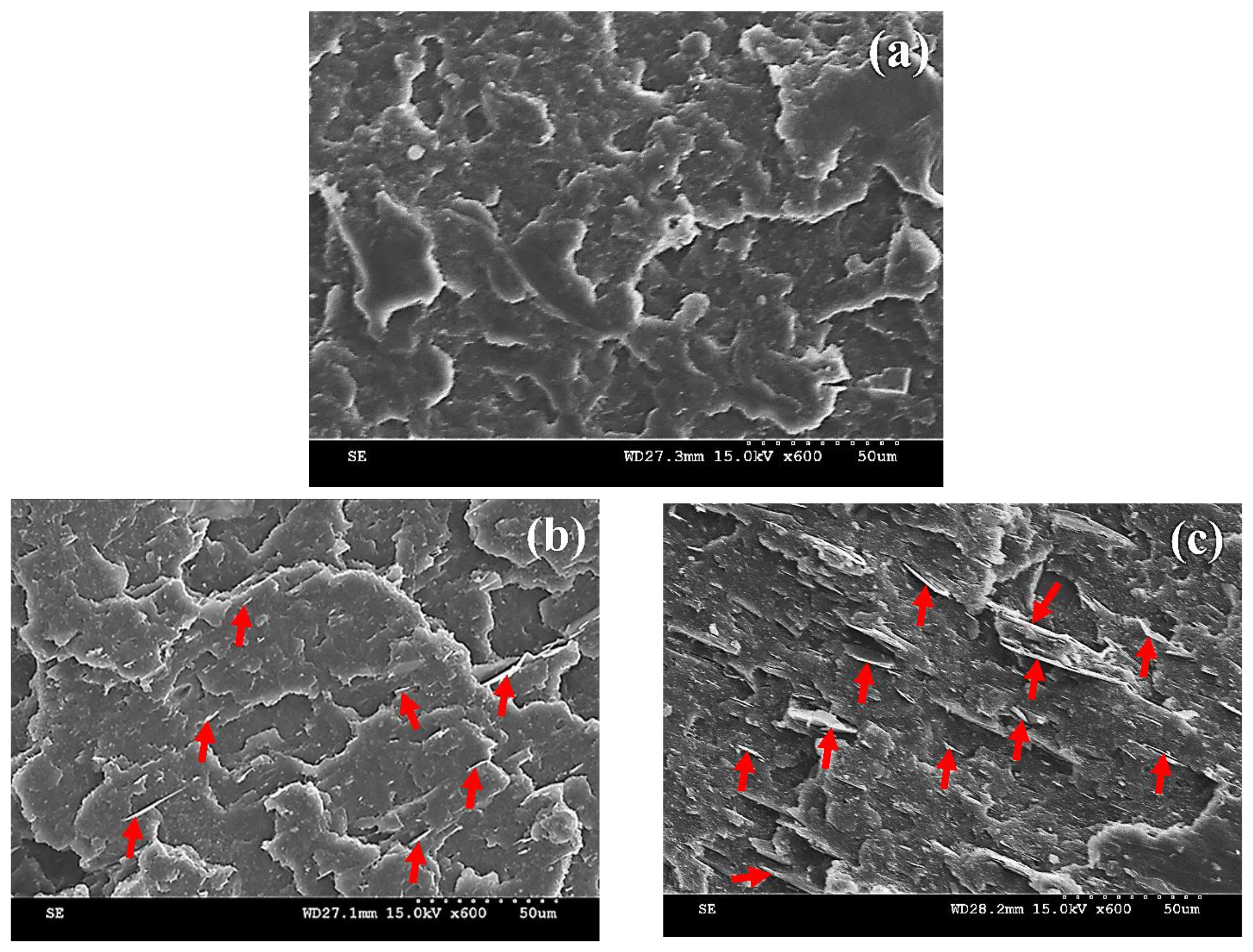

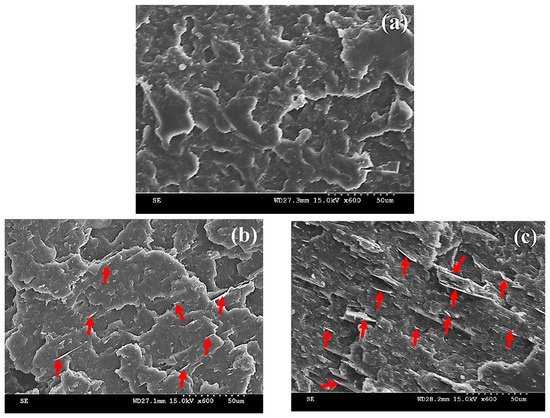

It was observed that in the Type 1 composites, higher loadings of FLG increased both the tensile and flexural strength and modulus of the composites. This is attributed to the reinforcing effect of strong solid particles [9,11,29] such as FLG. Furthermore, decreasing trends of both elongation at break and tensile toughness were observed at increasing concentrations of FLG. In contrast, the impact strength (fracture toughness) behavior as a function of FLG loading showed a different trend. Low (1 wt.%), medium (4 and 7 wt.%), and high loadings (10 wt.%) of FLG resulted in reduced, similar, and increased impact strength, respectively, compared to the one of neat R-(PE/PP). In particular, the R-(PE/PP)/FLG = 90/10 composites showed an increase in the fracture toughness but a decrease in elongation at break and tensile toughness. In homogeneous or single-phased materials, both impact toughness and tensile toughness follow a similar trend of variation. More complicated trends might be at play in heterogeneous or multiphase composite systems. In fact, the elongation at break of a polymer composite depends mostly on the extent of the polymer chains’ mobility while the impact strength depends on the rate of crack propagation throughout the compound. Solid particles reinforcing the polymer composites may have a positive or negative effect on the impact strength by acting either as defect centers [33] or crack resisting points [30], depending on their strength and stiffness. In other words, the overall impact strength of the solid particle filled blend composites is the outcome of the competition between the negative effect of a filler as a defect center and the positive effect of the crack resistance of the filler. A higher impact strength of the composite can be achieved if the loading of the rigid filler is within an optimum concentration range where the crack propagation resistance of the filler is the dominant factor. In this work, the reduction in the impact strength of the R-(PE/PP)/FLG = 99/1 composite indicates that 1 wt.% FLG was not within the desired optimum concentration range to overcome the negative effect of fillers as defect centers in the composite. On the other hand, the increased impact strength of the R-(PE/PP)/FLG = 90/10 composite suggests that 10 wt.% FLG was adequate and within the optimum concentration range to increase the resistance to crack propagation, and to overcome the negative effect of FLG as a defect center, on the impact toughness of the composite. For reference, the SEM images of the fractured surfaces of the neat R-(PE/PP), R-(PE/PP)/FLG = 96/4, and R-(PE/PP)/FLG = 90/10 composites are shown in Figure 5a–c, respectively.

Figure 5.

SEM images of the fractured surface of the (a) neat R-(PE/PP), (b) R-(PE/PP)/FLG = 96/4, and (c) R-(PE/PP)/FLG = 90/10. The arrows indicate a few of the FLGs, visible on the fractured surface of the R-(PE/PP)/FLG composites.

It can be seen in Figure 5b,c that more FLG was visible in the R-(PE/PP)/FLG = 90/10 composite than in the R-(PE/PP)/FLG = 96/4 composite. In other words, R-(PE/PP)/FLG-90/10 (shown in Figure 5c) had more impact crack resisting sites than the neat R-(PE/PP) and R-(PE/PP)/FLG = 96/4 (as can be seen in Figure 5b)). This phenomenon resulted in a higher impact strength for the R-(PE/PP)/FLG = 90/10 composite. However, the polymer chain mobility or slippage of the polymer chains in the solid state was restricted by strong and rigid FLG, which reduced the elongation at break of R-(PE/PP)/FLG = 90/10. Simultaneous increment in the impact toughness and reduction in the tensile toughness in the same composite was also observed by Antimo et al. [25] in a PE/PP-90/10 composite with 4 wt.% graphene derivatives.

Based on the analysis of the plots in Figure 2 and Figure 3, it can be concluded that R-(PE/PP)/FLG = 90/10, R-(PE/PP)/PP/FLG = 87/9/4, and R-(PE/PP)/PPcopolymer = 87/13 compounds have shown significant improvement in different properties compared to that of the unmodified R-(PE/PP). Table 3 shows the variation in the mechanical properties of the best performing samples in this work.

Table 3.

Mechanical property variation (%) in compounds showing a significant change in properties compared to the neat R-(PE/PP).

Further analysis of the data presented in Table 3 suggests that, if the target application requires an overall increase in the strength, stiffness, and fracture toughness in the mixed polyolefin waste stream, then the addition of a higher loading of FLG is recommended. Since any reprocessing step or inclusion of any additive (fillers or nanofillers) will increase the cost of R-(PE/PP), the addition of a higher loading of FLG will increase the price of the R-(PE/PP)/FLG composite. However, it is worth mentioning that an industrial grade FLG was used in this work, which is more cost effective than other grades of carbon based nanofillers such as carbon nanotubes (CNT). In addition, FLG has the potential to reduce the photodegradation of polymer composites [34]. Therefore, it is expected that FLG-filled composites feature a higher strength and durability compared to those of the unmodified mixed polyolefin waste stream, at a cost of the added FLG. Finally, the presented approach is intended to recover mixed plastic waste streams that have little or no value at the base and are otherwise landfilled. For superior impact and tensile toughness, the strategy of the mixing of R-(PE/PP) with a copolymer would be more useful. For applications requiring higher strength and stiffness and less sensitivity to toughness, compounds containing both prime PP and FLG would be interesting.

4. Conclusions

We investigated the influence of adding FLG on the processability and mechanical properties of mixed polyolefin waste streams. FLG alone, the prime polymer (PE, PP, or PP copolymer) alone, and FLG in combination with different prime polymers were melt blended with the R-(PE/PP). MFI, effective torque during extrusion, and viscosity of the FLG-filled composites remained unchanged for concentrations of FLG up to 10 wt.%. Moreover, it was shown that the addition of 4 wt.% FLG in combination with prime PP increased the tensile strength by 9%, the tensile modulus by 37%, the flexural strength by 23%, and the flexural modulus by 34%, but reduced the impact strength by 20% compared to the respective properties of the neat R-(PE/PP). However, the addition of 10 wt.% of FLG increased the tensile strength by 4%, tensile modulus by 60%, flexural strength by 16%, flexural modulus by 46%, and the impact strength by 9% compared to that of the neat R-(PE/PP). This desired increase in the tensile and flexural properties is attributed to the reinforcing effect of FLG. The increase in the impact strength of R-(PE/PP)/FLG with a higher loading (10 wt.%) of FLG was attributed to the resistance effect of strong FLG particles to impact crack propagation.

Based on the experimental and morphological observations, this work reports that FLG enables the processability of R-(PE/PP) while improving the mechanical properties of FLG-filled R-(PE/PP) composites. This work outlines the possibility of channeling a mixed polyolefin waste stream back to various regular applications with more strength, without altering the processability. FLG-reinforced R-(PE/PP) composites can be used in outdoor furniture and in the construction industry. As a result, the demand for virgin polymers could be reduced, which would be a big step toward the protection of biodiversity and a reduction in harmful gas emissions. Moreover, this study suggests a useful application of commercially produced FLG.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/cryst13020358/s1, Figure S1: DSC analysis of unfilled R-(PE/PP), Figure S2: MFI of (a) R-(PE/PP)/FLG composites as a function of the concentration of FLG and (b) R-(PE/PP)/prime polymer/FLG composites as a function of the type of prime polymer.

Author Contributions

Conceptualization, S.M.N.S., E.H., G.G., E.D., N.M. and N.R.D.; Methodology, S.M.N.S., E.H., E.D. and N.R.D.; Validation, S.M.N.S., E.H., G.G., E.D., N.M. and N.R.D.; Formal analysis, S.M.N.S., E.H., G.G., E.D., N.M. and N.R.D.; Investigation, S.M.N.S., E.H., E.D. and N.R.D.; Resources, E.H., G.G., E.D., N.M. and N.R.D.; Writing—original draft, S.M.N.S.; Writing—review & editing, E.H., G.G., E.D., N.M. and N.R.D.; Visualization, S.M.N.S., E.H., E.D. and N.R.D.; Supervision, E.H., G.G., E.D., N.M. and N.R.D.; Project administration, E.H., G.G., E.D., N.M. and N.R.D.; Funding acquisition, S.M.N.S., E.D. and N.R.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by NanoXplore Inc.; Natural Sciences and Engineering Research Council (grant number CRDPJ 538482—18); PRIMA Quebec (grant number R18-46-001); Fonds de Recherche du Québec-Nature et Technologies (grant number 318813). The APC was funded by discounts from Editorial Office, MDPI and IOAP of Ecole de Technologie Superieure (ETS) Montreal.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The author confirms that the data supporting the reported results can be found within the article and its Supporting Materials. Raw data that supports the findings of this work can be inquired to the corresponding authors, upon reasonable request.

Acknowledgments

The authors would like to thank Mazen Samara for his helpful feedback to improve the language of this paper, Laure Castagna for preparing a few samples during her internship, and Jose Carlos Ferreira Junior for the help in obtaining the SEM image of the FLG powder.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Petigny, J.; Ménigault, C.; Luisce, T.; Harscoët, E.; David, A.; Mitsios, A.; Laberge, M.; Lysenko, D.; Moore, P.; Dimoff, A.; et al. Economic Study of the Canadian Plastic Industry, Markets and Waste: Summary Report to Environment and Climate Change Canada. 2019, pp. 1–43. Available online: https://publications.gc.ca/site/eng/9.871296/publication.html (accessed on 30 January 2023).

- Jubinville, D.; Esmizadeh, E.; Saikrishnan, S.; Tzoganakis, C.; Mekonnen, T. A comprehensive review of global production and recycling methods of polyolefin (PO) based products and their post-recycling applications. Sustain. Mater. Technol. 2020, 25, e00188. [Google Scholar] [CrossRef]

- Maris, J.; Bourdon, S.; Brossard, J.-M.; Cauret, L.; Fontaine, L.; Montembault, V. Mechanical recycling: Compatibilization of mixed thermoplastic wastes. Polym. Degrad. Stab. 2018, 147, 245–266. [Google Scholar] [CrossRef]

- Diallo, A.K.; Helal, E.; Gutiérrez, G.; Madinehei, M.; David, E.; Demarquette, N.; Moghimian, N. Graphene: A multifunctional additive for sustainability. Sustain. Mater. Technol. 2022, 33, e00487. [Google Scholar] [CrossRef]

- Vranjes, N.; Rek, V. Effect of EPDM on Morphology, Mechanical Properties, Crystallization Behavior and Viscoelastic Properties of iPP+HDPE Blends. Macromol. Symp. 2007, 258, 90–100. [Google Scholar] [CrossRef]

- Parameswaranpillai, J.; Parambil, H.P.; Sanjay, M.R.; Siengchin, S. Polypropylene/high-density polyethylene based blends and nanocomposites with improved toughness. Mater. Res. Express 2019, 6, 075334. [Google Scholar] [CrossRef]

- Blom, H.; Teh, J.; Rudin, A. I-PP/HDPE blends. III. Characterization and compatibilization at lower i-PP contents. J. Appl. Polym. Sci. 1996, 61, 959–968. [Google Scholar] [CrossRef]

- Yang, M.; Wang, K.; Ye, L.; Mai, Y.-W.; Wu, J. Low density polyethylene-polypropylene blends: Part 2—Strengthening and toughening with copolymer. Plast. Rubber Compos. 2003, 32, 27–31. [Google Scholar] [CrossRef]

- Hsieh, C.-T.; Pan, Y.-J.; Lin, J.-H. Polypropylene/high-density polyethylene/carbon fiber composites: Manufacturing techniques, mechanical properties, and electromagnetic interference shielding effectiveness. Fibers Polym. 2017, 18, 155–161. [Google Scholar] [CrossRef]

- Qiu, G.-X.; Raue, F.; Ehrenstein, G.W. Mechanical properties and morphologies of PP/mPE/filler composites. J. Appl. Polym. Sci. 2002, 83, 3029–3035. [Google Scholar] [CrossRef]

- Ramos, M.A.; Belmontes, F.A. Polypropylene/low density polyethylene blends with short glass fibers. II: Effect of compounding method on mechanical properties. Polym. Compos. 1991, 12, 1–6. [Google Scholar] [CrossRef]

- Ghasemi, F.A.; Daneshpayeh, S.; Ghasemi, I. Multi-response optimization of impact strength and elongation at break of nanocomposites based on polypropylene/polyethylene binary polymer matrix in the presence of titanium dioxide nanofiller. J. Elastomers Plast. 2017, 49, 633–649. [Google Scholar] [CrossRef]

- Parameswaranpillai, J.; Elamon, R.; Sanjay, M.R.; Siengchin, S. Synergistic effects of ethylene propylene diene copolymer and carbon nanofiber on the thermo-mechanical properties of polypropylene/high-density polyethylene composites. Mater. Res. Express 2019, 6, 085302. [Google Scholar] [CrossRef]

- Mofokeng, T.G.; Ray, S.S.; Ojijo, V. Structure-property relationship in PP/LDPE blend composites: The role of nanoclay localization. J. Appl. Polym. Sci. 2018, 135, 46193. [Google Scholar] [CrossRef]

- Fang, C.; Nie, L.; Liu, S.; Yu, R.; An, N.; Li, S. Characterization of polypropylene–polyethylene blends made of waste materials with compatibilizer and nano-filler. Compos. Part B Eng. 2013, 55, 498–505. [Google Scholar] [CrossRef]

- Karaagac, E.; Koch, T.; Archodoulaki, V.-M. The effect of PP contamination in recycled high-density polyethylene (rPE-HD) from post-consumer bottle waste and their compatibilization with olefin block copolymer (OBC). Waste Manag. 2021, 119, 285–294. [Google Scholar] [CrossRef]

- Najafi, S.K.; Hamidinia, E.; Tajvidi, M. Mechanical properties of composites from sawdust and recycled plastics. J. Appl. Polym. Sci. 2006, 100, 3641–3645. [Google Scholar] [CrossRef]

- Kazemi, Y.; Kakroodi, A.R.; Rodrigue, D. Compatibilization efficiency in post-consumer recycled polyethylene/polypropylene blends: Effect of contamination. Polym. Eng. Sci. 2015, 55, 2368–2376. [Google Scholar] [CrossRef]

- Al-Saleh, M.H. Electrical, EMI shielding and tensile properties of PP/PE blends filled with GNP:CNT hybrid nanofiller. Synth. Met. 2016, 217, 322–330. [Google Scholar] [CrossRef]

- Du, B.X.; Hou, Z.H.; Li, J.; Li, Z.L. Effect of graphene nanoplatelets on space charge and breakdown strength of PP/ULDPE blends for HVDC cable insulation. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 2405–2412. [Google Scholar] [CrossRef]

- Wei, Z.; Hou, Y.; Jiang, C.; Liu, H.; Chen, X.; Zhang, A.; Liu, Y. Graphene Enhanced Electrical Properties of Polyethylene Blends for High-Voltage Insulation. Electron. Mater. Lett. 2019, 15, 582–594. [Google Scholar] [CrossRef]

- Mun, S.C.; Kim, M.J.; Cobos, M.; Gu, L.; Macosko, C.W. Strategies for interfacial localization of graphene/polyethylene-based cocontinuous blends for electrical percolation. AIChE J. 2019, 65, e16579. [Google Scholar] [CrossRef]

- Tu, C.; Nagata, K.; Yan, S. Morphology and electrical conductivity of polyethylene/polypropylene blend filled with thermally reduced graphene oxide and surfactant exfoliated graphene. Polym. Compos. 2017, 38, 2098–2105. [Google Scholar] [CrossRef]

- Tu, C.; Nagata, K.; Yan, S. Dependence of Electrical Conductivity on Phase Morphology for Graphene Selectively Located at the Interface of Polypropylene/Polyethylene Composites. Nanomaterials 2022, 12, 509. [Google Scholar] [CrossRef] [PubMed]

- Graziano, A.; Garcia, C.; Jaffer, S.; Tjong, J.; Sain, M. Novel functional graphene and its thermodynamic interfacial localization in biphasic polyolefin systems for advanced lightweight applications. Compos. Sci. Technol. 2020, 188, 321–329. [Google Scholar] [CrossRef]

- Lago, E.D.; Cagnin, E.; Boaretti, C.; Roso, M.; Lorenzetti, A.; Modesti, M. Influence of Different Carbon-Based Fillers on Electrical and Mechanical Properties of a PC/ABS Blend. Polymers 2020, 12, 29. [Google Scholar] [CrossRef]

- Koodehi, A.V.; Koohi, A.D. Optimization of Thermal Stability of High-Density Polyethylene Composite Using Antioxidant, Carbon Black and Nanoclay Addition by a Central Composite Design Method: X-ray Diffraction and Rheological Characterization. J. Macromol. Sci. Part B 2018, 57, 660–678. [Google Scholar] [CrossRef]

- Ferreira, E.H.C.; Andrade, R.J.E.; Fechine, G.J.M. The “Superlubricity State” of Carbonaceous Fillers on Polyethylene-Based Composites in a Molten State. Macromolecules 2019, 52, 9620–9631. [Google Scholar] [CrossRef]

- Feng, Y.; Yuan, Z.; Sun, H.; He, H.; Zhang, G. Toughening and reinforcing wood flour/polypropylene composites with high molecular weight polyethylene under elongation flow. Compos. Sci. Technol. 2020, 200, 108395. [Google Scholar] [CrossRef]

- Juan, L. Simultaneous Improvement in the Tensile and Impact Strength of Polypropylene Reinforced by Graphene. J. Nanomater. 2020, 2020, 7840802. [Google Scholar] [CrossRef]

- Batista, N.L.; Helal, E.; Kurusu, R.S.; Moghimian, N.; David, E.; Demarquette, N.R.; Hubert, P. Mass-produced graphene—HDPE nanocomposites: Thermal, rheological, electrical, and mechanical properties. Polym. Eng. Sci. 2019, 59, 675–682. [Google Scholar] [CrossRef]

- Tu, C.; Nagata, K.; Yan, S. Influence of melt-mixing processing sequence on electrical conductivity of polyethylene/polypropylene blends filled with graphene. Polym. Bull. 2017, 74, 1237–1252. [Google Scholar] [CrossRef]

- Dikobe, D.; Luyt, A. Thermal and mechanical properties of PP/HDPE/wood powder and MAPP/HDPE/wood powder polymer blend composites. Thermochim. Acta 2017, 654, 40–50. [Google Scholar] [CrossRef]

- Karimi, S.; Helal, E.; Gutierrez, G.; Moghimian, N.; Madinehei, M.; David, E.; Samara, M.; Demarquette, N. A Review on Graphene’s Light Stabilizing Effects for Reduced Photodegradation of Polymers. Crystals 2021, 11, 3. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).