Crack-Free High-Composition (>35%) Thick-Barrier (>30 nm) AlGaN/AlN/GaN High-Electron-Mobility Transistor on Sapphire with Low Sheet Resistance (<250 Ω/□)

Abstract

1. Introduction

2. Experimental Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shen, L.; Palacios, T.; Poblenz, C.; Corrion, A.; Chakraborty, A.; Fichtenbaum, N.; Keller, S.; DenBaars, S.P.; Speck, J.S.; Mishra, U.K. Unpassivated High Power Deeply Recessed GaN HEMTs with Fluorine-Plasma Surface Treatment. IEEE Electron Device Lett. 2006, 27, 214–216. [Google Scholar] [CrossRef]

- Higashiwaki, M.; Mimura, T.; Matsui, T. AlGaN/GaN Heterostructure Field-Effect Transistors on 4H-SiC Substrates with Current-Gain Cutoff Frequency of 190 GHz. Appl. Phys. Express 2008, 1, 021103. [Google Scholar] [CrossRef]

- Wright, A.; Nelson, J.M. Consistent Structural Properties for AlN, GaN, and InN. Phys. Rev. B 1995, 51, 7866–7869. [Google Scholar] [CrossRef]

- Polyakov, V.M.; Cimalla, V.; Lebedev, V.; Köhler, K.; Müller, S.; Waltereit, P.; Ambacher, O. Impact of al Content on Transport Properties of Two-Dimensional Electron Gas in GaN/AlxGa1−XN/GaN Heterostructures. Appl. Phys. Lett. 2010, 97, 142112. [Google Scholar] [CrossRef]

- Ahmadi, E.; Keller, S.; Mishra, U.K. Model to Explain the Behavior of 2DEG Mobility with Respect to Charge Density in N-Polar and Ga-Polar AlGaN-GaN Heterostructures. J. Appl. Phys. 2016, 120, 115302. [Google Scholar] [CrossRef]

- Yamada, A.; Junya, Y.; Nakamura, N.; Kotani, J. Low-Sheet-Resistance High-Electron-Mobility Transistor Structures with Strain-Controlled High-Al-Composition AlGaN Barrier Grown by MOVPE. J. Cryst. Growth 2021, 560, 126046. [Google Scholar] [CrossRef]

- Wang, X.; Hu, G.; Ma, Z.; Ran, J.; Wang, C.; Xiao, H.; Tang, J.; Li, J.; Wang, J.; Zeng, Y.; et al. AlGaN/AlN/GaN/SiC HEMT Structure with High Mobility GaN Thin Layer as Channel Grown by MOCVD. J. Cryst. Growth 2007, 298, 835–839. [Google Scholar] [CrossRef]

- Gaska, R.; Yang, J.; Andrei, O.; Chen, Q.Y.; Ijaz Khan, M.; Orlov, A.; Snider, G.L.; Shur, M. Electron Transport in AlGaN–GaN Heterostructures Grown on 6H–SiC Substrates. Appl. Phys. Lett. 1998, 72, 707–709. [Google Scholar] [CrossRef]

- Melton, W.A.; Pankove, J.I. GaN Growth on Sapphire. J. Cryst. Growth 1997, 178, 168–173. [Google Scholar] [CrossRef]

- O’Hanlon, T.J.; Zhu, T.; Massabuau, F.; Oliver, R.A. Dislocations at Coalescence Boundaries in Heteroepitaxial GaN/Sapphire Studied after the Epitaxial Layer Has Completely Coalesced. Ultramicroscopy 2021, 231, 113258. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, K.; Orlov, A.O.; Xing, H.G.; Jena, D. Very Low Sheet Resistance and Shubnikov–De-Haas Oscillations in Two-Dimensional Electron Gases at Ultrathin Binary AlN/GaN Heterojunctions. Appl. Phys. Lett. 2008, 92, 152112. [Google Scholar] [CrossRef]

- Palacios, T.; Suh, C.-S.; Chakraborty, A.; Keller, S.; DenBaars, S.P.; Mishra, U.K. High-Performance E-Mode AlGaN/GaN HEMTs. IEEE Electron Device Lett. 2006, 27, 428–430. [Google Scholar] [CrossRef]

- Ding, G.-J.; Guo, L.; Zhang, X.; Chen, Y.; Xu, P.; Jia, H.; Zhou, J.; Chen, H. Characterization of Different-Al-Content AlGaN/GaN Heterostructures on Sapphire. Sci. China Phys. Mech. Astron. 2010, 53, 49–53. [Google Scholar] [CrossRef]

- Palacios, T.; Chakraborty, A.; Rajan, S.; Poblenz, C.; Keller, S.; DenBaars, S.P.; Speck, J.S.; Mishra, U.K. High-Power AlGaN/GaN HEMTs for Ka-Band Applications. IEEE Electron Device Lett. 2005, 26, 781–783. [Google Scholar] [CrossRef]

- Gutierrez, P.; Tomas, A. Optimization of the High Frequency Performance of Nitride-Based Transistors—Order No. 3206406; University of California: Santa Barbara, CA, USA, 2006. [Google Scholar]

- Xiao, M.; Ma, Y.; Cheng, K.; Liu, K.; Xie, A.; Beam, E.; Cao, Y.; Zhang, Y. 3.3 KV Multi-Channel AlGaN/GaN Schottky Barrier Diodes with P-GaN Termination. IEEE Electron Device Lett. 2020, 41, 1177–1180. [Google Scholar] [CrossRef]

- Nela, L.; Erine, C.; Ma, J.; Yildirim, H.K.; van Erp, R.; Peng, X.; Cheng, K.; Matioli, E. High-Performance Enhancement-Mode AlGaN/GaN Multi-Channel Power Transistors. In Proceedings of the 2021 33rd International Symposium on Power Semiconductor Devices and ICs (ISPSD), Nagoya, Japan, 30 May–3 June 2021; pp. 143–146. [Google Scholar] [CrossRef]

- Jiang, H.; Zhu, R.; Lyu, Q.; Lau, K.M. High-Voltage P-GaN HEMTs with OFF-State Blocking Capability after Gate Breakdown. IEEE Electron Device Lett. 2019, 40, 530–533. [Google Scholar] [CrossRef]

- Jiang, H.; Lyu, Q.; Zhu, R.; Xiang, P.; Cheng, K.; Lau, K.M. 1300 v Normally-off P-GaN Gate HEMTs on Si with High ON-State Drain Current. IEEE Trans. Electron Devices 2021, 68, 653–657. [Google Scholar] [CrossRef]

- Posthuma, N.; You, S.; Stoffels, S.; Wellekens, D.; Liang, H.; Zhao, M.; De Jaeger, B.; Geens, K.; Ronchi, N.; Decoutere, S.; et al. An Industry-Ready 200 Mm P-GaN E-Mode GaN-On-Si Power Technology. In Proceedings of the 2018 IEEE 30th International Symposium on Power Semiconductor Devices and ICs (ISPSD), Chicago, IL, USA, 13–17 May 2018. [Google Scholar] [CrossRef]

- Lee, J.-H.; Ju, J.J.; Atmaca, G.; Kim, J.-G.; Kang, S.-H.; Lee, Y.S.; Lee, S.-H.; Lim, J.-W.; Kwon, H.-S.; Lisesivdin, S.B.; et al. High Figure-of-Merit (V2BR/RON) AlGaN/GaN Power HEMT With Periodically C-Doped GaN Buffer and AlGaN Back Barrier. IEEE J. Electron Devices Soc. 2018, 6, 1179–1186. [Google Scholar] [CrossRef]

- Bahat-Treidel, E.; Brunner, F.; Hilt, O.; Cho, E.J.; Würfl, J.; Tränkle, G. AlGaN/GaN/GaN:C Back-Barrier HFETs With Breakdown Voltage of Over 1 kV and Low RON × A. IEEE Trans. Electron Devices 2010, 57, 3050–3058. [Google Scholar] [CrossRef]

- Hao, J.; Xing, Y.; Fu, K.; Zhang, P.; Song, L.; Chen, F.; Yang, T.; Deng, X.; Zhang, S.; Zhang, B. Influence of Channel/Back-Barrier Thickness on the Breakdown of AlGaN/GaN MIS-HEMTs. J. Semicond. 2018, 39, 094003. [Google Scholar] [CrossRef]

- Wang, H.Y.; Chiu, H.C.; Hsu, W.C.; Liu, C.M.; Chuang, C.Y.; Liu, J.Z.; Huang, Y.L. The Impact of AlxGa1−xN Back Barrier in AlGaN/GaN High Electron Mobility Transistors (HEMTs) on Six-Inch MCZ Si Substrate. Coatings 2020, 10, 570. [Google Scholar] [CrossRef]

- Einfeldt, S.; Kirchner, V.; Heinke, H.; Dießelberg, M.; Figge, S.; Vogeler, K.; Hommel, D. Strain Relaxation in AlGaN under Tensile Plane Stress. J. Appl. Phys. 2000, 88, 7029–7036. [Google Scholar] [CrossRef]

- Wang, C.; Wang, X.; Hu, G.; Wang, J.; Xiao, H.; Li, J. The Effect of AlN Growth Time on the Electrical Properties of Al0.38Ga0.62N/AlN/GaN HEMT Structures. J. Cryst. Growth 2006, 289, 415–418. [Google Scholar] [CrossRef]

- Wang, C.; Wang, X.; Hu, G.; Wang, J.; Li, J.; Wang, Z. Influence of AlN Interfacial Layer on Electrical Properties of High-Al-Content Al0.45Ga0.55N/GaN HEMT Structure. Appl. Surf. Sci. 2006, 253, 762–765. [Google Scholar] [CrossRef]

- Heikman, S.; Keller, S.; DenBaars, S.P.; Mishra, U.K. Growth of Fe Doped Semi-Insulating GaN by Metalorganic Chemical Vapor Deposition. Appl. Phys. Lett. 2002, 81, 439–441. [Google Scholar] [CrossRef]

- Heikman, S.; Keller, S.; Mates, T.; DenBaars, S.P.; Mishra, U.K. Growth and Characteristics of Fe-Doped GaN. J. Cryst. Growth 2003, 248, 513–517. [Google Scholar] [CrossRef]

- Saxler, A.; Walker, D.; Kung, P.; Zhang, X.; Manijeh, R.; Solomon, J.S.; Mitchel, W.C.; Vydyanath, H.R. Comparison of Trimethylgallium and Triethylgallium for the Growth of GaN. Appl. Phys. Lett. 1997, 71, 3272–3274. [Google Scholar] [CrossRef][Green Version]

- Kwang, H.S.; Dong, J.K.; Moon, Y.-T.; Park, S.-J. Characteristics of GaN Grown by Metalorganic Chemical Vapor Deposition Using Trimethylgallium and Triethylgallium. J. Cryst. Growth 2001, 233, 439–445. [Google Scholar] [CrossRef]

- Hospodková, A.; František, H.; Tomáš, H.; Zuzana, G.; Hubik, P.; Hývl, M.; Pangrác, J.; Dominec, F.; Košutová, T. Electron Transport Properties in High Electron Mobility Transistor Structures Improved by V-Pit Formation on the AlGaN/GaN Interface. ACS Appl. Mater. Interfaces 2023, 15, 19646–19652. [Google Scholar] [CrossRef]

- Stringfellow, G.B. Novel Precursors for Organometallic Vapor Phase Epitaxy. J. Cryst. Growth 1993, 128, 503–510. [Google Scholar] [CrossRef]

- Panalytical AMASS, 1.0, Malvern Panalytical B.V.: Almelo, The Netherlands, 2018.

- Panalytical X’pert Epitaxy, 4. Panalytical X’pert Epitaxy, 4.5a, Malvern Panalytical B.V.: Almelo, The Netherlands, 2018.

- Li, X.; Bergsten, J.; Nilsson, D.; Örjan, D.; Pedersen, H.; Niklas, R.; Janzén, E.; Forsberg, U. Carbon Doped GaN Buffer Layer Using Propane for High Electron Mobility Transistor Applications: Growth and Device Results. Appl. Phys. Lett. 2015, 107, 262105. [Google Scholar] [CrossRef]

- Zanato, D.; Gokden, S.; Balkan, N.; Ridley, B.K.; Schaff, W.J. The Effect of Interface-Roughness and Dislocation Scattering on Low Temperature Mobility of 2D Electron Gas in GaN/AlGaN. Semicond. Sci. Technol. 2004, 19, 427–432. [Google Scholar] [CrossRef]

- Liu, J.P.; Ryou, J.-H.; Yoo, D.; Zhang, Y.; Limb, J.; Horne, C.A.; Shen, S.-C.; Dupuis, R.D.; Hanser, A.; Preble, E.A.; et al. III-Nitride Heterostructure Field-Effect Transistors Grown on Semi-Insulating GaN Substrate without Regrowth Interface Charge. Appl. Phys. Lett. 2008, 92, 133513. [Google Scholar] [CrossRef]

- Arteev, D.S.; Sakharov, A.V.; Lundin, W.V.; Zavarin, E.E.; Nikolaev, A.E.; Tsatsulnikov, A.F.; Ustinov, V.M. Scattering Analysis of AlGaN/AlN/GaN Heterostructures with Fe-Doped GaN Buffer. Materials 2022, 15, 8945. [Google Scholar] [CrossRef]

- Bergsten, J.; Chen, J.-T.; Gustafsson, S.; Malmros, A.; Forsberg, U.; Thorsell, M.; Janzén, E.; Rorsman, N. Performance Enhancement of Microwave GaN HEMTs without an AlN-Exclusion Layer Using an Optimized AlGaN/GaN Interface Growth Process. IEEE Trans. Electron Devices 2016, 63, 333–338. [Google Scholar] [CrossRef]

- Hu, W.; Ma, B.; Li, D.; Narukawa, M.; Miyake, H.; Hiramatsu, K. Mobility Enhancement of 2DEG in MOVPE-Grown AlGaN/AlN/GaN HEMT Structure Using Vicinal (0 0 0 1) Sapphire. Superlattices Microstruct. 2009, 46, 812–816. [Google Scholar] [CrossRef]

- Aggerstam, T.; Lourdudoss, S.; Radamson, H.H.; Sjödin, M.; Lorenzini, P.; Look, D.C. Investigation of the Interface Properties of MOVPE Grown AlGaN/GaN High Electron Mobility Transistor (HEMT) Structures on Sapphire. Thin Solid Film. 2006, 515, 705–707. [Google Scholar] [CrossRef]

- Miyoshi, M.; Egawa, T.; Ishikawa, H. Study on Mobility Enhancement in MOVPE-Grown AlGaN/AlN/GaN HEMT Structures Using a Thin AlN Interfacial Layer. Solid-State Electron. 2006, 50, 1515–1521. [Google Scholar] [CrossRef]

- Wang, X.L.; Wang, C.M.; Hu, G.X.; Wang, J.X.; Chen, T.S.; Jiao, G.; Li, J.P.; Zeng, Y.P.; Li, J.M. Improved DC and RF Performance of AlGaN/GaN HEMTs Grown by MOCVD on Sapphire Substrates. Solid-State Electron. 2005, 49, 1387–1390. [Google Scholar] [CrossRef]

- Elsass, C.R.; Poblenz, C.; Heying, B.; Fini, P.; Petroff, P.M.; DenBaars, S.P.; Mishra, U.K.; Speck, J.S.; Saxler, A.; Elhamrib, S.; et al. Influence of Growth Temperature and Thickness of AlGaN Caps on Electron Transport in AlGaN/GaN Heterostructures Grown by Plasma-Assisted Molecular Beam Epitaxy. Jpn. J. Appl. Phys. 2001, 40, 6235. [Google Scholar] [CrossRef]

- Keller, S.L.; Parish, G.; Fini, P.T.; Heikman, S.; Chen, C.; Zhang, N.; DenBaars, S.P.; Mishra, U.K.; Wu, Y. Metalorganic Chemical Vapor Deposition of High Mobility AlGaN/GaN Heterostructures. J. Appl. Phys. 1999, 86, 5850–5857. [Google Scholar] [CrossRef]

- Gustafsson, S.; Chen, T., Jr.; Bergsten, J.; Forsberg, U.; Thorsell, M.; Janzen, E.; Rorsman, N. Dispersive Effects in Microwave AlGaN/AlN/GaN HEMTs with Carbon-Doped Buffer. IEEE Trans. Electron Devices 2015, 62, 2162–2169. [Google Scholar] [CrossRef]

- Kumar, V.; Lu, W.; Schwindt, R.; Kuliev, A.; Simin, G.; Yang, J.; Khan, M.A.; Adesida, I. AlGaN/GaN HEMTs on SiC with F/Sub T/ of over 120 GHz. IEEE Electron Device Lett. 2002, 23, 455–457. [Google Scholar] [CrossRef]

- Yuen, Y.W.; Chiu, Y.-S.; Luong, T.-T.; Lin, T.-M.; Yen, T.H.; Lin, Y.C.; Chang, E.Y. Growth and Fabrication of AlGaN/GaN HEMT on SiC Substrate. In Proceedings of the 10th IEEE International Conference on Semiconductor Electronics (ICSE), Kuala Lumpur, Malaysia, 19–21 September 2012; pp. 729–732. [Google Scholar] [CrossRef]

- Hao, Y.; Yang, L.; Ma, X.; Ma, J.; Cao, M.; Pan, C.; Wang, C.; Zhang, J. High-Performance Microwave Gate-Recessed AlGaN/AlN/GaN MOS-HEMT with 73% Power-Added Efficiency. IEEE Electron Device Lett. 2011, 32, 626–628. [Google Scholar] [CrossRef]

- Shen, L.; Heikman, S.; Moran, B.; Coffie, R.; Zhang, N.-Q.; Buttari, D.; Smorchkova, I.P.; Keller, S.; DenBaars, S.P.; Mishra, U.K. AlGaN/AlN/GaN High-Power Microwave HEMT. IEEE Electron Device Lett. 2001, 22, 457–459. [Google Scholar] [CrossRef]

- Yusuke, K.; Ozaki, S.; Okamoto, N.; Hara, N.; Takao, O. Low-Resistance and Low-Thermal-Budget Ohmic Contact by Introducing Periodic Microstructures for AlGaN/AlN/GaN HEMTs. IEEE Trans. Electron Devices 2022, 69, 3073–3078. [Google Scholar] [CrossRef]

- Palacios, T.; Chakraborty, A.; Heikman, S.; Keller, S.; DenBaars, S.P.; Mishra, U.K. AlGaN/GaN High Electron Mobility Transistors with InGaN Back-Barriers. IEEE Electron Device Lett. 2006, 27, 13–15. [Google Scholar] [CrossRef]

- Gong, J.-M.; Wang, Q.; Yan, J.-D.; Liu, F.-Q.; Feng, C.; Wang, X.-L.; Wang, Z.-G. Comparison of GaN/AlGaN/AlN/GaN HEMTs Grown on Sapphire with Fe-Modulation-Doped and Unintentionally Doped GaN Buffer: Material Growth and Device Fabrication. Chin. Phys. Lett. 2016, 33, 117303. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, Y.; Song, K.; Xing, C.; Yang, L.; Wang, D.; Yu, H.; Xiang, X.; Gao, N.; Xu, G.; et al. Demonstration of AlGaN/GaN HEMTs on Vicinal Sapphire Substrates with Large Misoriented Angles. Appl. Phys. Lett. 2021, 119, 072104. [Google Scholar] [CrossRef]

- Mahaboob, I.; Yakimov, M.M.; Hogan, K.; Rocco, E.; Tozier, S.; Shahedipour-Sandvik, F. Dynamic Control of AlGaN/GaN HEMT Characteristics by Implementation of a P-GaN Body-Diode-Based Back-Gate. IEEE J. Electron Devices Soc. 2019, 7, 581–588. [Google Scholar] [CrossRef]

- Wang, X.; Wang, C.; Hu, G.; Wang, J.; Li, J. Room Temperature Mobility above 2100 cm2/vs in Al0.3Ga0.7N/AlN/GaN Heterostructures Grown on Sapphire Substrates by MOCVD. Phys. Status Solidi C 2006, 3, 607–610. [Google Scholar] [CrossRef]

- Miyoshi, M.; Imanishi, A.; Egawa, T.; Ishikawa, H.; Asai, K.; Shibata, T.; Tanaka, M.; Oda, O. DC Characteristics in High-Quality AlGaN/AlN/GaN High-Electron-Mobility Transistors Grown on AlN/Sapphire Templates. Jpn. J. Appl. Phys. 2005, 44, 6490–6494. [Google Scholar] [CrossRef]

- Cai, Y.; Zhou, Y.; Chen, K.J.; Lau, K.M. High-Performance Enhancement-Mode AlGaN/GaN HEMTs Using Fluoride-Based Plasma Treatment. IEEE Electron Device Lett. 2005, 26, 435–437. [Google Scholar] [CrossRef]

- Li, H.; Keller, S.; DenBaars, S.P.; Mishra, U.K. Improved Properties of High-Al-Composition AlGaN/GaN High Electron Mobility Transistor Structures with Thin GaN Cap Layers. Jpn. J. Appl. Phys. 2014, 53, 095504. [Google Scholar] [CrossRef]

- Zhang, K.; Chen, X.; Mi, M.; Zhao, S.; Chen, Y.; Zhang, J.; Ma, X.; Hao, Y. Enhancement-Mode AlGaN/GaN HEMTs with Thin and High al Composition Barrier Layers Using O2 Plasma Implantation. Phys. Status Solidi A 2014, 212, 1081–1085. [Google Scholar] [CrossRef]

- Cheng, J.; Yang, X.; Sang, L.; Guo, L.; Hu, A.; Xu, F.; Tang, N.; Wang, X.; Shen, B. High Mobility AlGaN/GaN Heterostructures Grown on Si Substrates Using a Large Lattice-Mismatch Induced Stress Control Technology. Appl. Phys. Lett. 2015, 106, 142106. [Google Scholar] [CrossRef]

- Ubukata, A.; Yano, Y.; Shimamura, H.; Yamaguchi, A.; Tabuchi, T.; Matsumoto, K. High-Growth-Rate AlGaN Buffer Layers and Atmospheric-Pressure Growth of Low-Carbon GaN for AlGaN/GaN HEMT on the 6-in.-Diameter Si Substrate Metal-Organic Vapor Phase Epitaxy System. J. Cryst. Growth 2013, 370, 269–272. [Google Scholar] [CrossRef]

- Zhang, J.; He, L.; Li, L.; Ni, Y.; Que, T.; Liu, Z.; Wang, W.; Zheng, J.; Huang, Y.; Chen, J.; et al. High-Mobility Normally off Al2O3/AlGaN/GaN MISFET with Damage-Free Recessed-Gate Structure. IEEE Electron Device Lett. 2018, 39, 1720–1723. [Google Scholar] [CrossRef]

- Bouzid-Driad, S.; Maher, H.; Defrance, N.; Hoel, V.; De Jaeger, J.-C.; Renvoise, M.; Frijlink, P. AlGaN/GaN HEMTs on Silicon Substrate with 206-GHz FMax. IEEE Electron Device Lett. 2013, 34, 36–38. [Google Scholar] [CrossRef]

- Latrach, S.; Frayssinet, E.; Defrance, N.; Chenot, S.; Cordier, Y.; Gaquière, C.; Maaref, H. Trap States Analysis in AlGaN/AlN/GaN and InAlN/AlN/GaN High Electron Mobility Transistors. Curr. Appl. Phys. 2017, 17, 1601–1608. [Google Scholar] [CrossRef]

- Xu, X.; Zhong, J.; So, H.; Norvilas, A.; Sommerhalter, C.; Senesky, D.G.; Tang, M. Wafer-Level MOCVD Growth of AlGaN/GaN-On-Si HEMT Structures with Ultra-High Room Temperature 2DEG Mobility. AIP Adv. 2016, 6, 115016. [Google Scholar] [CrossRef]

- Chu, J.; Wang, Q.; Jiang, L.; Feng, C.; Li, W.; Liu, H.; Xiao, H.; Wang, X. Room Temperature 2DEG Mobility above 2350 cm2/V·s in AlGaN/GaN HEMT Grown on GaN Substrate. J. Electron. Mater. 2021, 50, 2630–2636. [Google Scholar] [CrossRef]

- Yu, H.; Alian, A.; Peralagu, U.; Zhao, M.; Waldron, N.; Parvais, B.; Collaert, N. Surface State Spectrum of AlGaN/AlN/GaN Extracted from Static Equilibrium Electrostatics. IEEE Trans. Electron Devices 2021, 68, 5559–5564. [Google Scholar] [CrossRef]

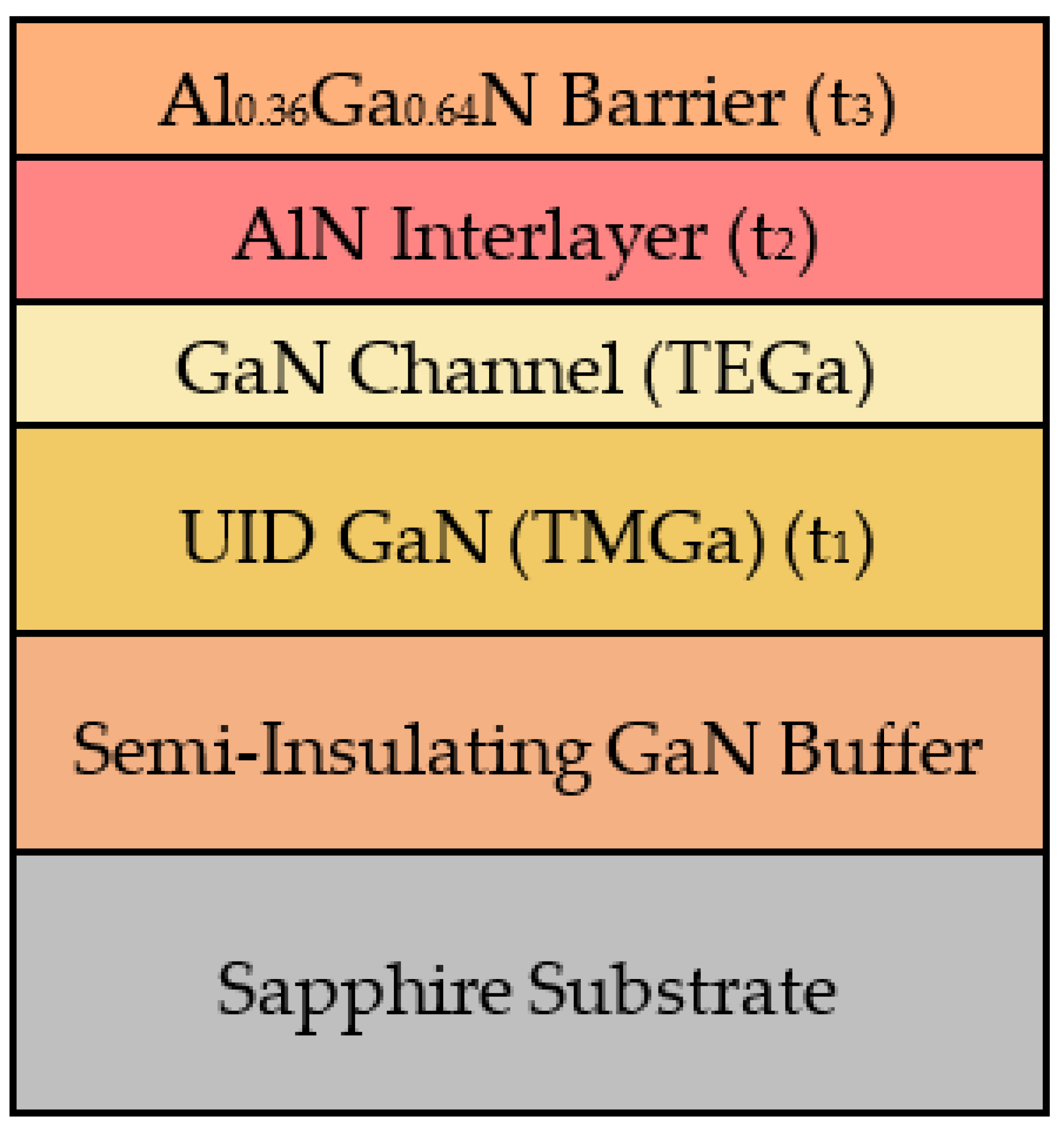

| Sample No. | UID-GaN Thickness (nm) (t1) | AlN Thickness (nm) (t2) | Al0.36Ga0.64N Thickness (nm) (t3) | Deposition Temperature (°C) |

|---|---|---|---|---|

| 1 | 200 | 0.7 | 21 | |

| 2 | 200 | 1.2 | 21 | |

| 3 | 1000 | 0.7 | 21 | 1210 |

| 4 | 1000 | 0.7 | 31 | |

| 5 | 1000 | 1.2 | 31 |

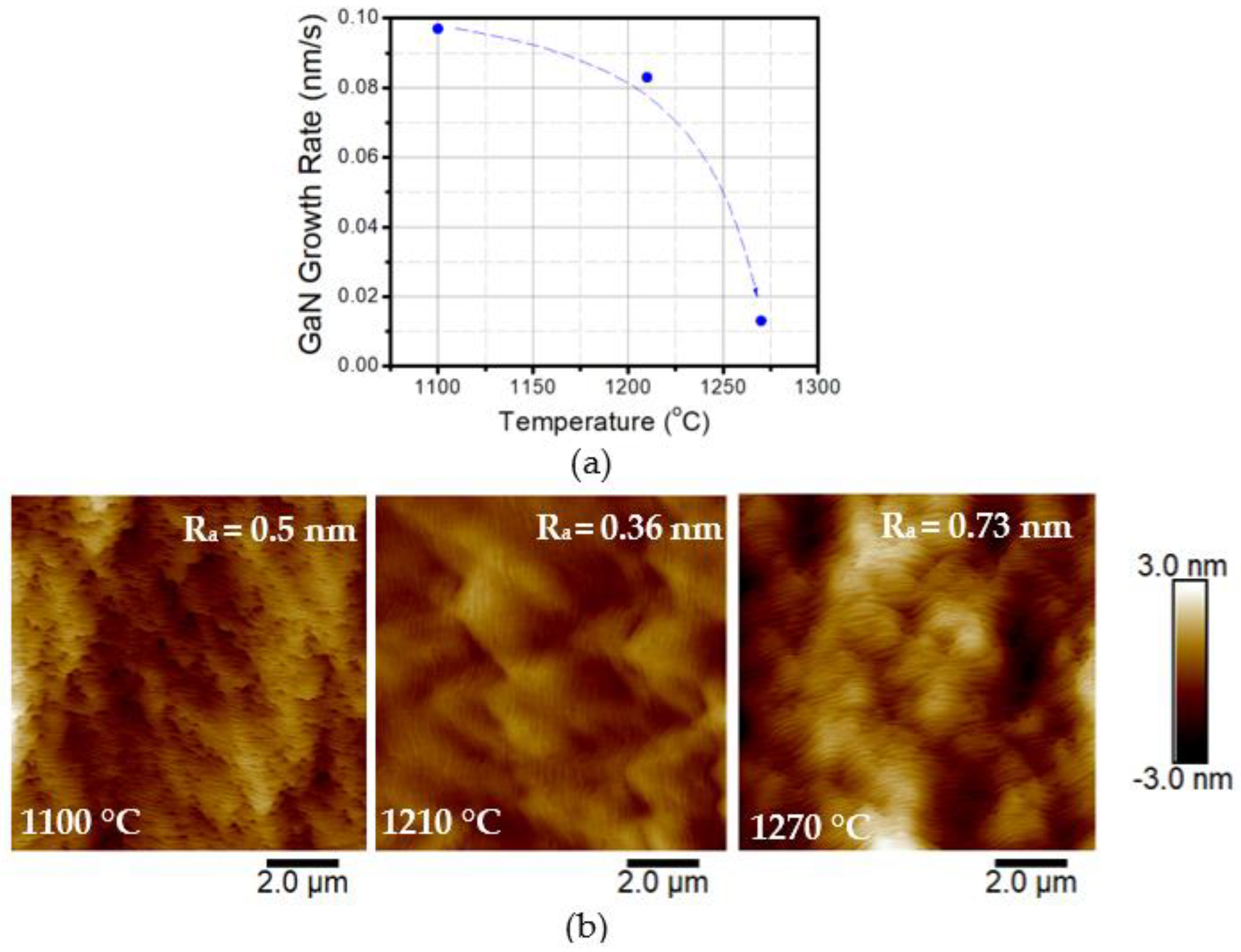

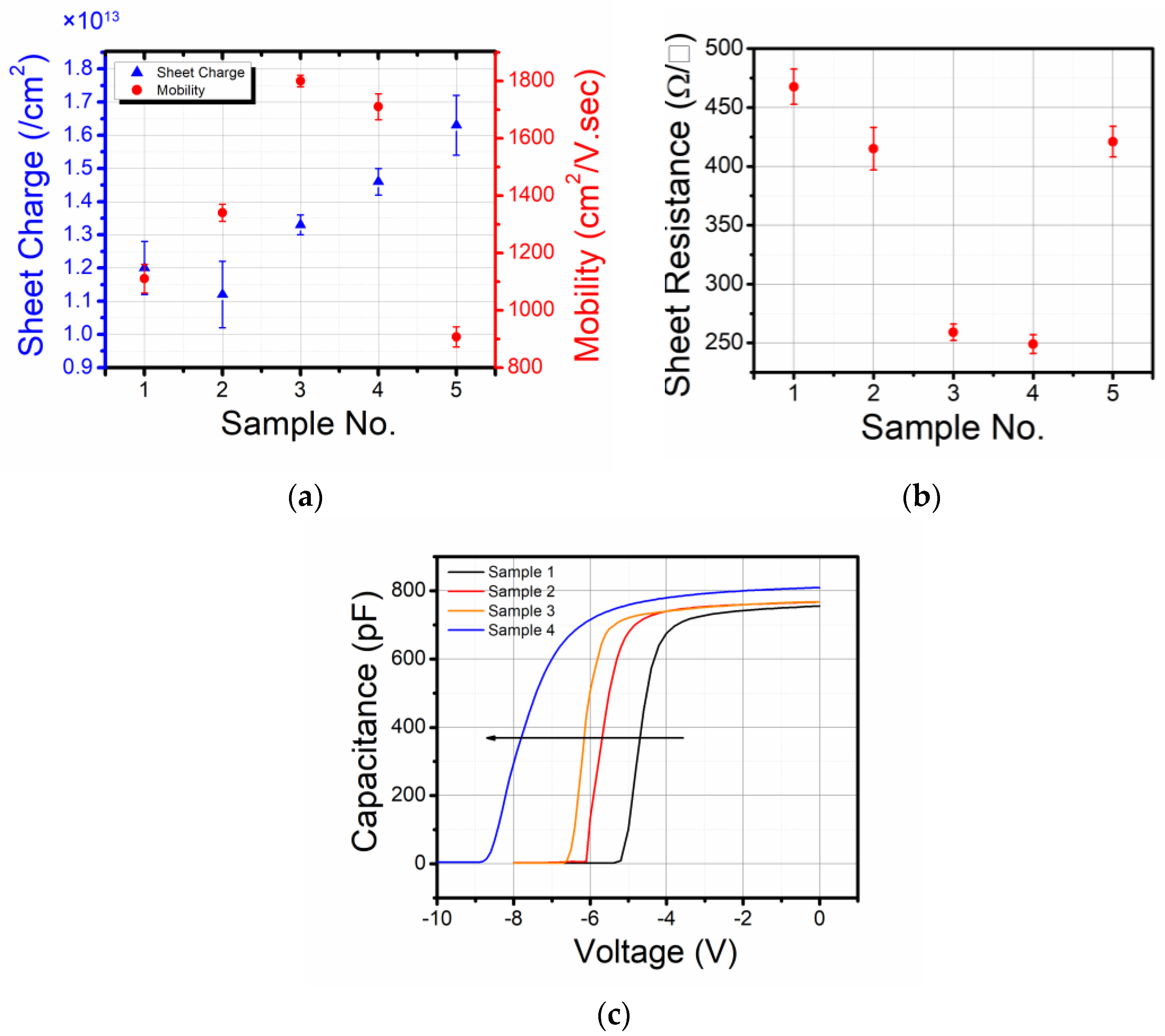

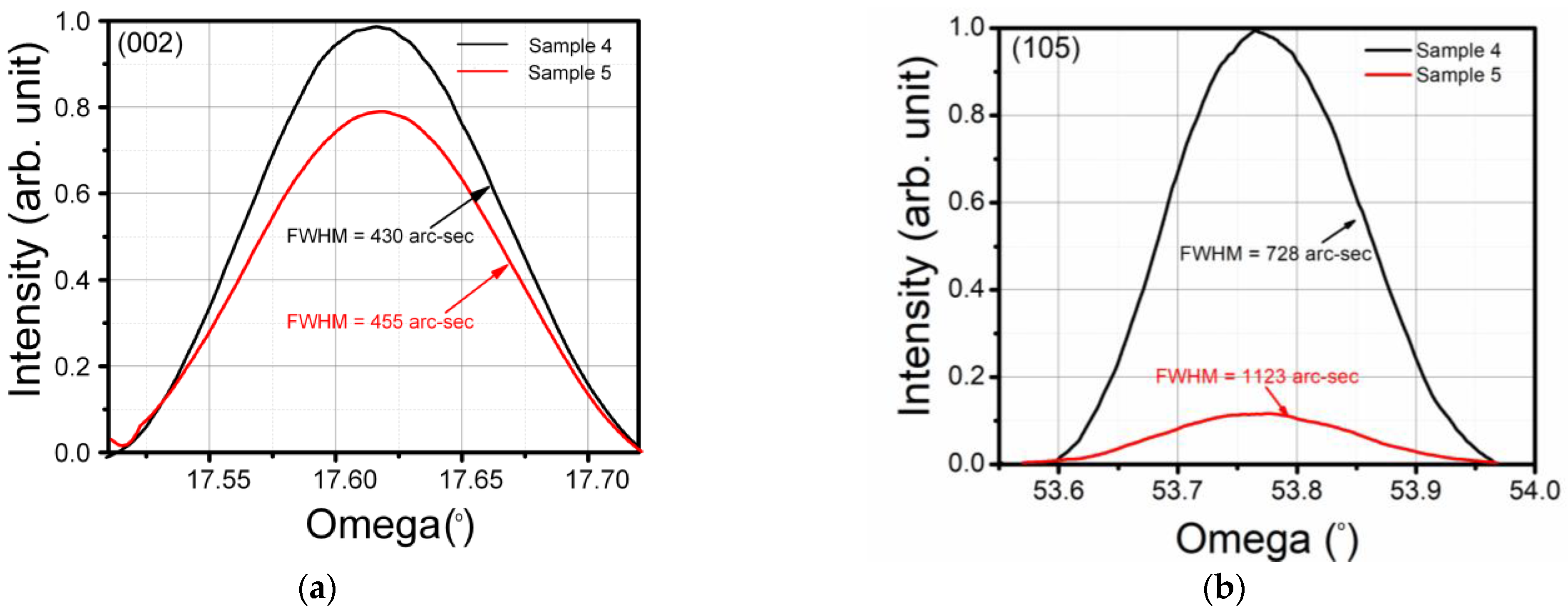

| Sample No. | Hall Measurement | Ra (nm) | |||

|---|---|---|---|---|---|

| ns (cm−2) × 1013 | μ (cm2/V·s) (300 K) | μ (cm2/V·s) (77 K) | RSH (Ω/□) | ||

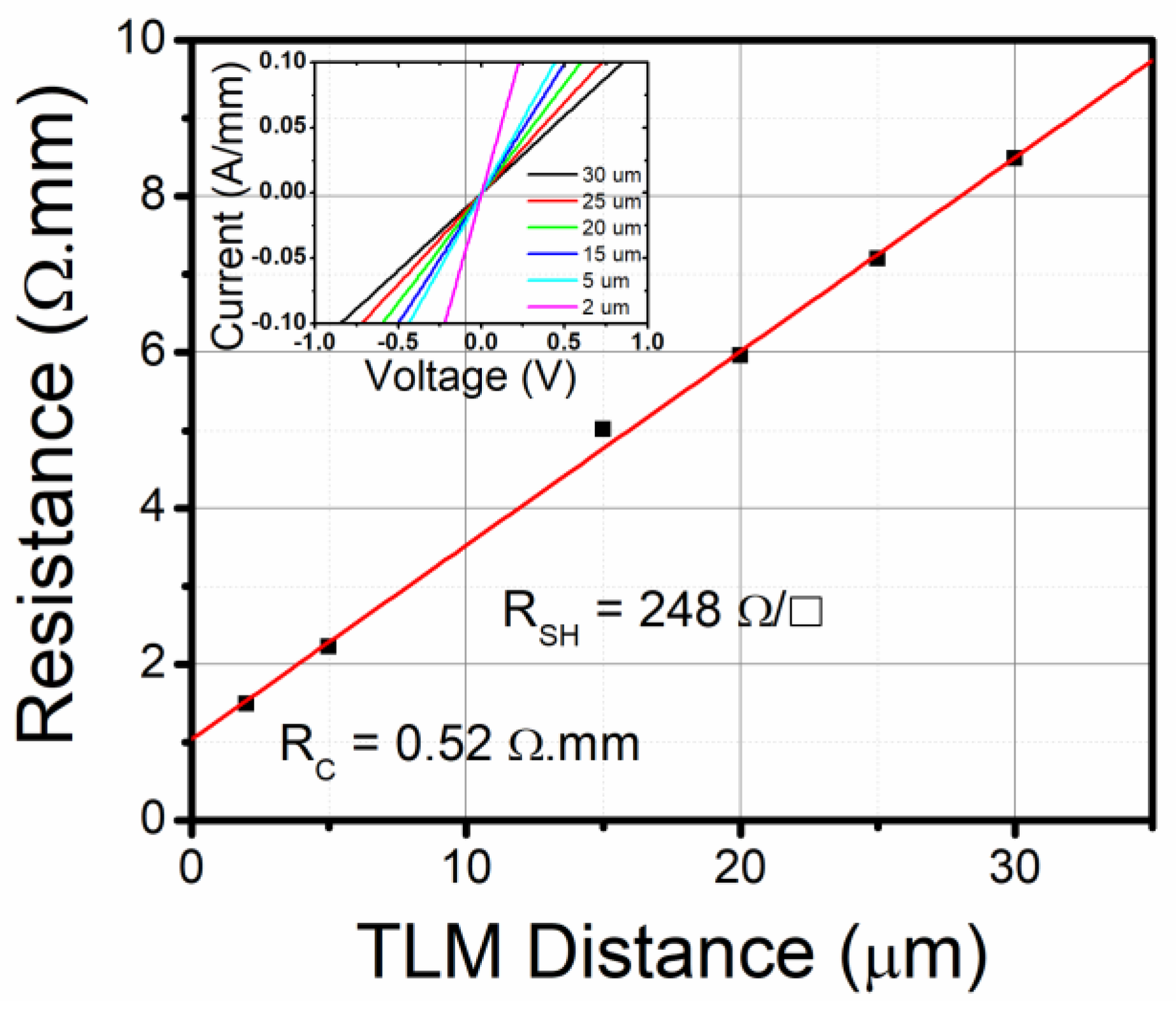

| 3 | 1.33 | 1800 | 8570 | 259 | 0.42 |

| 4 | 1.46 | 1710 | 7830 | 249 | 0.27 |

| 5 | 1.63 | 907 | 3840 | 421 | 0.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mukhopadhyay, S.; Liu, C.; Chen, J.; Tahmidul Alam, M.; Sanyal, S.; Bai, R.; Wang, G.; Gupta, C.; Pasayat, S.S. Crack-Free High-Composition (>35%) Thick-Barrier (>30 nm) AlGaN/AlN/GaN High-Electron-Mobility Transistor on Sapphire with Low Sheet Resistance (<250 Ω/□). Crystals 2023, 13, 1456. https://doi.org/10.3390/cryst13101456

Mukhopadhyay S, Liu C, Chen J, Tahmidul Alam M, Sanyal S, Bai R, Wang G, Gupta C, Pasayat SS. Crack-Free High-Composition (>35%) Thick-Barrier (>30 nm) AlGaN/AlN/GaN High-Electron-Mobility Transistor on Sapphire with Low Sheet Resistance (<250 Ω/□). Crystals. 2023; 13(10):1456. https://doi.org/10.3390/cryst13101456

Chicago/Turabian StyleMukhopadhyay, Swarnav, Cheng Liu, Jiahao Chen, Md Tahmidul Alam, Surjava Sanyal, Ruixin Bai, Guangying Wang, Chirag Gupta, and Shubhra S. Pasayat. 2023. "Crack-Free High-Composition (>35%) Thick-Barrier (>30 nm) AlGaN/AlN/GaN High-Electron-Mobility Transistor on Sapphire with Low Sheet Resistance (<250 Ω/□)" Crystals 13, no. 10: 1456. https://doi.org/10.3390/cryst13101456

APA StyleMukhopadhyay, S., Liu, C., Chen, J., Tahmidul Alam, M., Sanyal, S., Bai, R., Wang, G., Gupta, C., & Pasayat, S. S. (2023). Crack-Free High-Composition (>35%) Thick-Barrier (>30 nm) AlGaN/AlN/GaN High-Electron-Mobility Transistor on Sapphire with Low Sheet Resistance (<250 Ω/□). Crystals, 13(10), 1456. https://doi.org/10.3390/cryst13101456