High Reflectivity AlN/Al1−xInxN Distributed Bragg Reflectors across the UV Regions by Sputtering

Abstract

:1. Introduction

2. Materials and Methods

2.1. Deposition of the AlN and AlInN Thin Films

2.2. Growth of the AlN/Al1−xInxN Distributed Bragg Reflectors (DBRs)

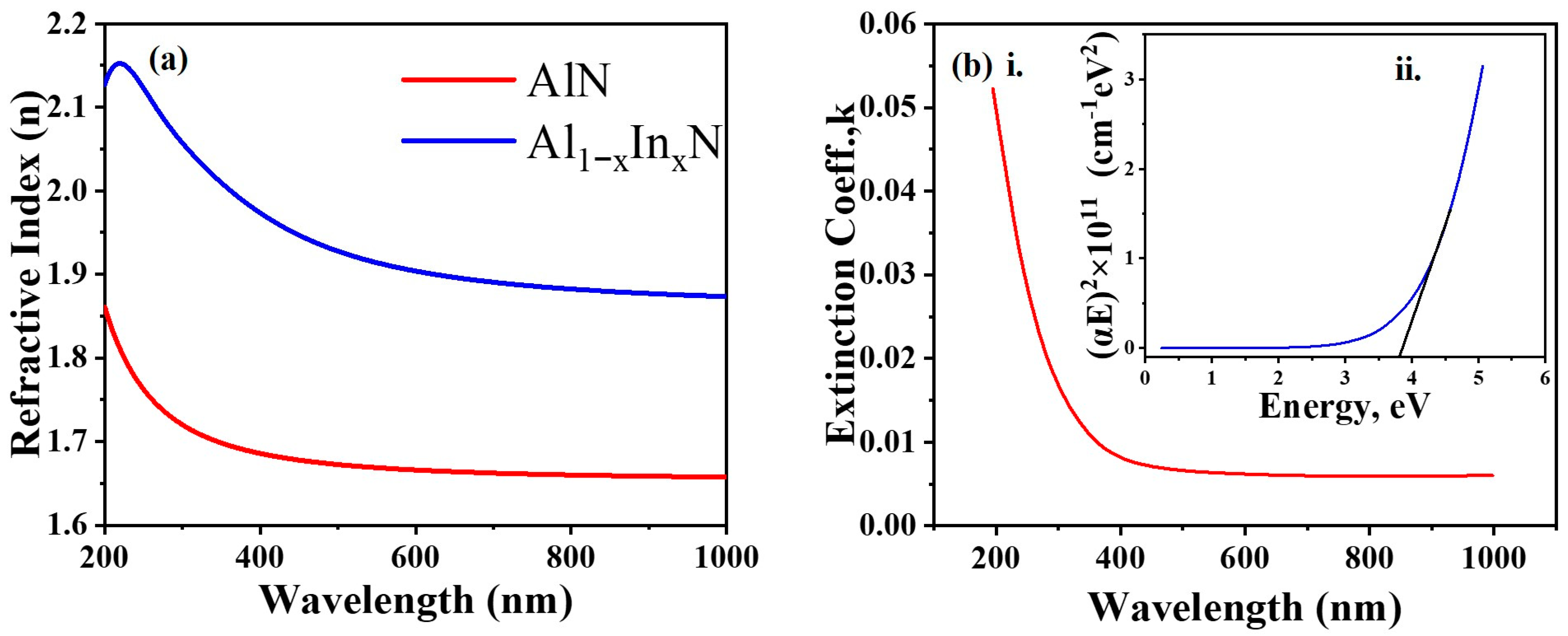

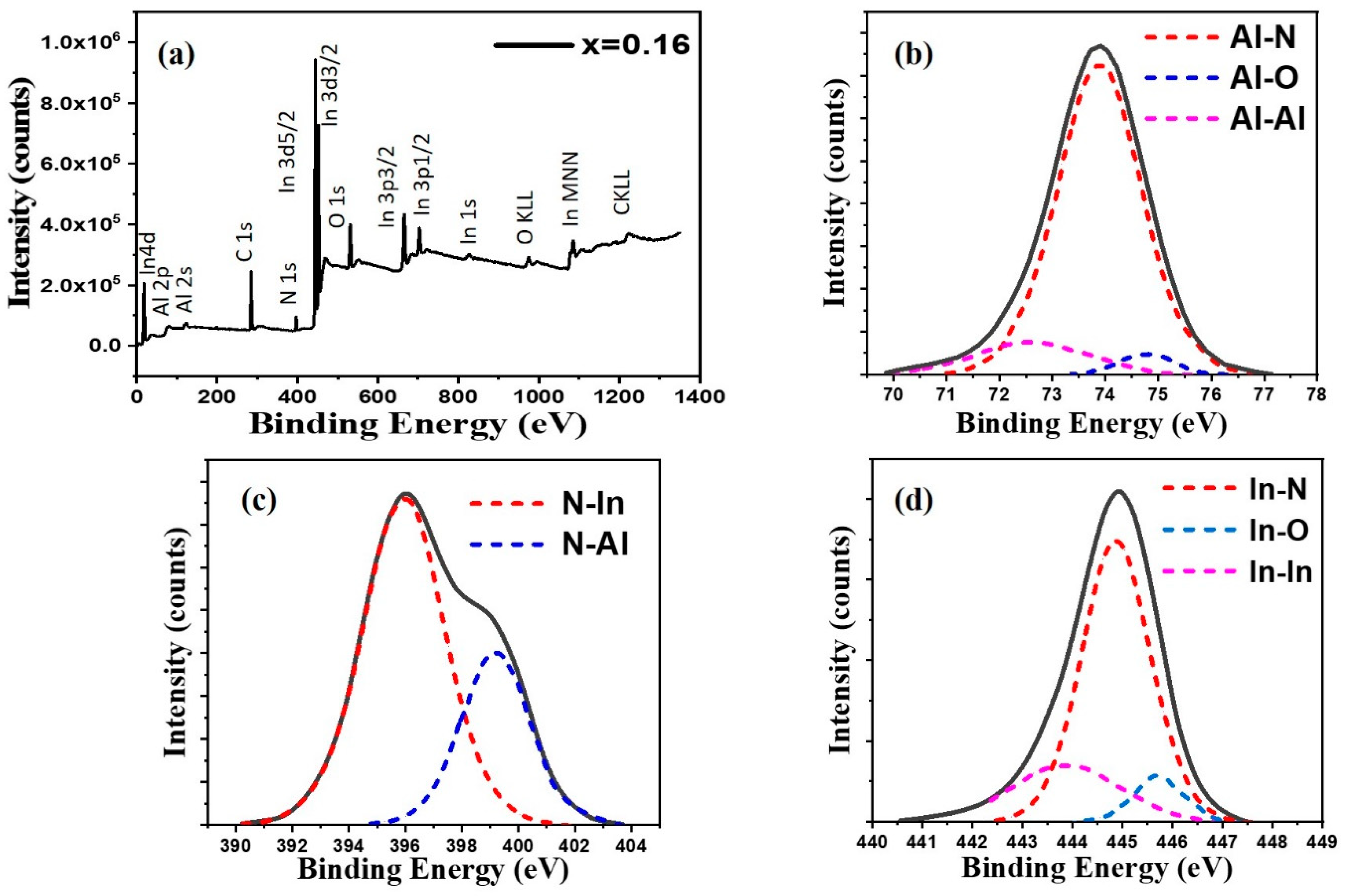

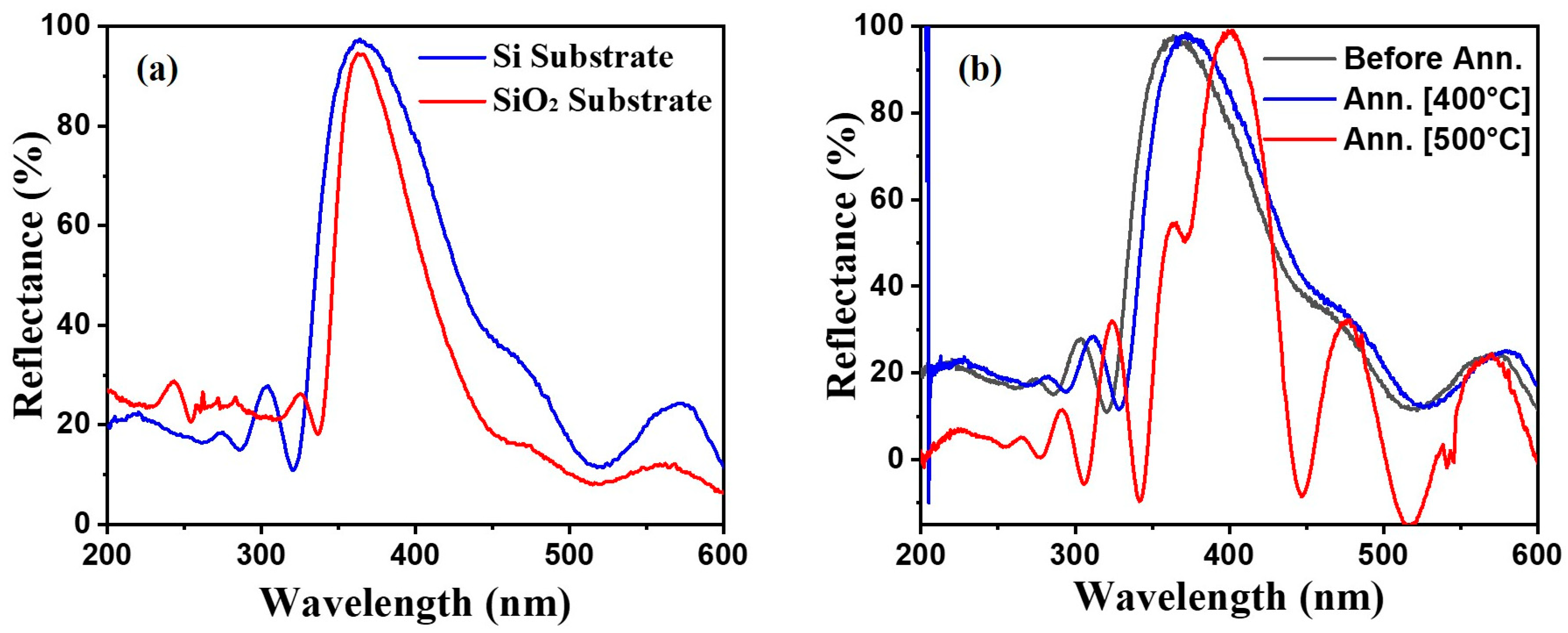

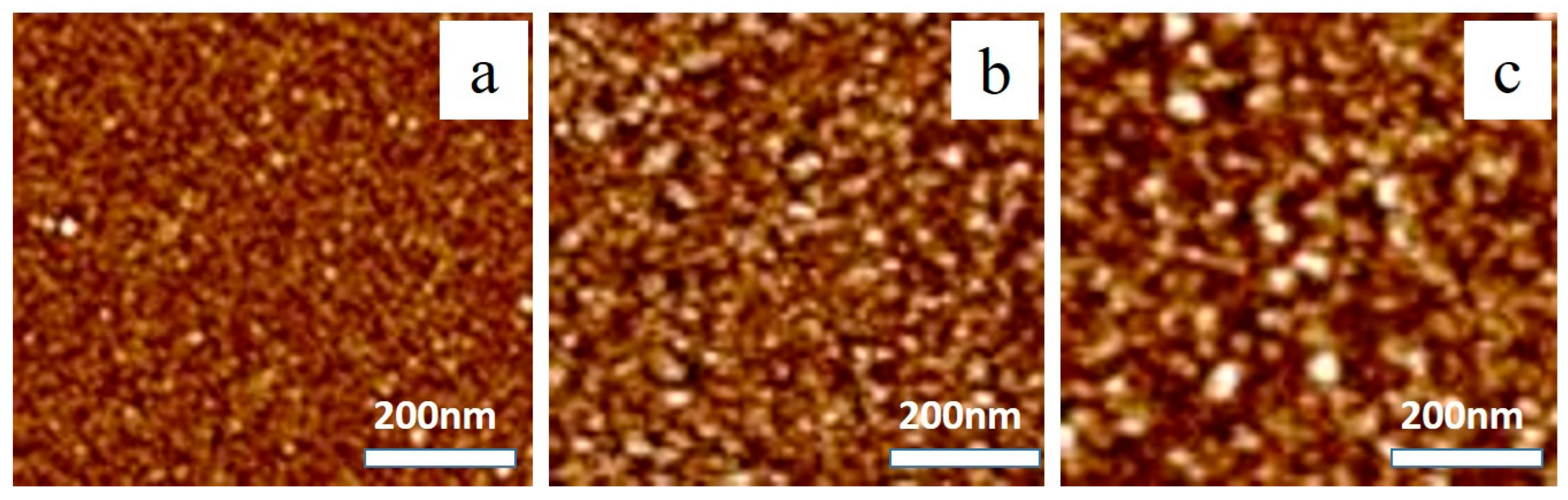

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bhattacharyya, A.; Iyer, S.; Iliopoulos, E.; Sampath, A.; Cabalu, J.; Moustakas, T.; Friel, I. High reflectivity and crack-free AlGaN/AlN ultraviolet distributed Bragg reflectors. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Processing Meas. Phenom. 2002, 20, 1229–1233. [Google Scholar] [CrossRef]

- Davydov, V.Y.; Klochikhin, A.; Seisyan, R.; Emtsev, V.; Ivanov, S.; Bechstedt, F.; Furthmüller, J.; Harima, H.; Mudryi, A.; Aderhold, J. Absorption and emission of hexagonal InN. Evidence of narrow fundamental band gap. Phys. Status Solidi (B) 2002, 229, r1–r3. [Google Scholar] [CrossRef]

- Nakamura, S.; Senoh, M.; Nagahama, S.-I.; Iwasa, N.; Yamada, T.; Matsushita, T.; Kiyoku, H.; Sugimoto, Y. InGaN-based multi-quantum-well-structure laser diodes. Jpn. J. Appl. Phys. 1996, 35, L74. [Google Scholar] [CrossRef]

- Rubio, A.; Corkill, J.L.; Cohen, M.L.; Shirley, E.L.; Louie, S.G. Quasiparticle band structure of AlN and GaN. Phys. Rev. B 1993, 48, 11810. [Google Scholar] [CrossRef]

- Wright, A.F.; Nelson, J. Explicit treatment of the gallium 3d electrons in GaN using the plane-wave pseudopotential method. Phys. Rev. B 1994, 50, 2159. [Google Scholar] [CrossRef]

- Yim, W.; Stofko, E.; Zanzucchi, P.; Pankove, J.; Ettenberg, M.; Gilbert, S. Epitaxially grown AlN and its optical band gap. J. Appl. Phys. 1973, 44, 292–296. [Google Scholar] [CrossRef]

- Shen, L.; Cheng, T.; Wu, L.; Li, X.; Cui, Q. Synthesis and optical properties of aluminum nitride nanowires prepared by arc discharge method. J. Alloys Compd. 2008, 465, 562–566. [Google Scholar] [CrossRef]

- Davydov, V.Y.; Klochikhin, A.; Seisyan, R.; Emtsev, V.; Ivanov, S.; Bechstedt, F.J.; Furthmüller, H.; Harima, A.V.; Mudryi, J.; Aderhold, O.; et al. Graul. Phys. Status Solidi B 2002, 229, R1. [Google Scholar] [CrossRef]

- Rivera, C.; Pau, J.; Pereiro, J.; Muñoz, E. Properties of Schottky barrier photodiodes based on InGaN/GaN MQW structures. Superlattices Microstruct. 2004, 36, 849–857. [Google Scholar] [CrossRef]

- Chen, Z.; Sakai, Y.; Zhang, J.; Egawa, T.; Wu, J.; Miyake, H.; Hiramatsu, K. Effect of strain on quantum efficiency of InAlN-based solar-blind photodiodes. Appl. Phys. Lett. 2009, 95, 083504. [Google Scholar] [CrossRef]

- Gardner, N.; Müller, G.; Shen, Y.; Chen, G.; Watanabe, S.; Götz, W.; Krames, M. Blue-emitting InGaN–GaN double-heterostructure light-emitting diodes reaching maximum quantum efficiency above 200 A/cm2. Appl. Phys. Lett. 2007, 91, 243506. [Google Scholar] [CrossRef]

- Zhou, S.; Liu, X.; Yan, H.; Chen, Z.; Liu, Y.; Liu, S. Highly efficient GaN-based high-power flip-chip light-emitting diodes. Opt. Express 2019, 27, A669–A692. [Google Scholar] [CrossRef]

- Zhou, S.; Zheng, C.; Lv, J.; Gao, Y.; Wang, R.; Liu, S. GaN-based flip-chip LEDs with highly reflective ITO/DBR p-type and via hole-based n-type contacts for enhanced current spreading and light extraction. Opt. Laser Technol. 2017, 92, 95–100. [Google Scholar] [CrossRef] [Green Version]

- Ive, T.; Brandt, O.; Kostial, H.; Hesjedal, T.; Ramsteiner, M.; Ploog, K.H. Crack-free and conductive Si-doped AlN/GaN distributed Bragg reflectors grown on 6H-SiC (0001). Appl. Phys. Lett. 2004, 85, 1970–1972. [Google Scholar] [CrossRef] [Green Version]

- Carlin, J.-F.; Ilegems, M. High-quality AlInN for high index contrast Bragg mirrors lattice matched to GaN. Appl. Phys. Lett. 2003, 83, 668–670. [Google Scholar] [CrossRef]

- Detchprohm, T.; Liu, Y.-S.; Mehta, K.; Wang, S.; Xie, H.; Kao, T.-T.; Shen, S.-C.; Yoder, P.D.; Ponce, F.A.; Dupuis, R.D. Sub 250 nm deep-UV AlGaN/AlN distributed Bragg reflectors. Appl. Phys. Lett. 2017, 110, 011105. [Google Scholar] [CrossRef] [Green Version]

- Adolph, D.; Zamani, R.R.; Dick, K.A.; Ive, T. Hybrid ZnO/GaN distributed Bragg reflectors grown by plasma-assisted molecular beam epitaxy. APL Mater. 2016, 4, 086106. [Google Scholar] [CrossRef] [Green Version]

- Carlin, J.-F.; Dorsaz, J.; Feltin, E.; Butté, R.; Grandjean, N.; Ilegems, M.; Laügt, M. Crack-free fully epitaxial nitride microcavity using highly reflective AlInN/GaN Bragg mirrors. Appl. Phys. Lett. 2005, 86, 031107. [Google Scholar] [CrossRef]

- Kruse, C.; Dartsch, H.; Aschenbrenner, T.; Figge, S.; Hommel, D. Growth and characterization of nitride-based distributed Bragg reflectors. Phys. Status Solidi (B) 2011, 248, 1748–1755. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, Q.; Bai, Y.; Zhang, H.; Hu, P.; Li, Y.; Yun, F. Deep-UV hexagonal boron nitride (hBN)/BAlN distributed Bragg reflectors fabricated by RF-sputtering. Opt. Mater. Express 2021, 11, 180–188. [Google Scholar] [CrossRef]

- Tauc, J.; Grigorovici, R.; Vancu, A. Optical properties and electronic structure of amorphous germanium. Phys. Status Solidi (B) 1966, 15, 627–637. [Google Scholar] [CrossRef]

- Pankove, J. Transitions between band tails. In Optical Processes in Semiconductors; Dover: New York, NY, USA, 1975; pp. 43–46. [Google Scholar]

- Aschenbrenner, T.; Dartsch, H.; Kruse, C.; Anastasescu, M.; Stoica, M.; Gartner, M.; Pretorius, A.; Rosenauer, A.; Wagner, T.; Hommel, D. Optical and structural characterization of AlInN layers for optoelectronic applications. J. Appl. Phys. 2010, 108, 063533. [Google Scholar] [CrossRef]

- Wei, G.; Goto, Y.; Ohta, A.; Makihara, K.; Murakami, H.; Higashi, S.; Miyazaki, S. Handbook of X-ray Photoelectron Spectroscopy: A Reference Book of Standard Spectra for the Identification and Interpretation of XPS Data Handbook of X-ray Photoelectron Spectroscopy: A Reference Book of Standard Spectra for the Identification and Interpretation of XPS Data 240, 1993. IEICE Trans. Electron. 2011, 94, 699–704. [Google Scholar]

- Minj, A.; Cavalcoli, D.; Cavallini, A. Indium segregation in AlInN/AlN/GaN heterostructures. Appl. Phys. Lett. 2010, 97, 132114. [Google Scholar] [CrossRef]

- Yang, X.; Xiao, H.; Cao, D.; Zhao, C.; Shen, L.; Ma, J. Fabrication, annealing, and regrowth of wafer-scale nanoporous GaN distributed Bragg reflectors. Scr. Mater. 2018, 156, 10–13. [Google Scholar] [CrossRef]

- Feng, I.-W.; Jin, S.; Li, J.; Lin, J.; Jiang, H. SiO2/TiO2 distributed Bragg reflector near 1.5 μm fabricated by e-beam evaporation. J. Vac. Sci. Technol. A Vac. Surf. Film. 2013, 31, 061514. [Google Scholar] [CrossRef]

- Feltin, E.; Carlin, J.-F.; Dorsaz, J.; Christmann, G.; Butté, R.; Laügt, M.; Ilegems, M.; Grandjean, N. Crack-free highly reflective AlInN/AlGaN Bragg mirrors for UV applications. Appl. Phys. Lett. 2006, 88, 051108. [Google Scholar] [CrossRef]

- Moudakir, T.; Gautier, S.; Suresh, S.; Abid, M.; El Gmili, Y.; Patriarche, G.; Pantzas, K.; Troadec, D.; Jacquet, J.; Genty, F. Suppression of crack generation in AlGaN/GaN distributed Bragg reflectors grown by MOVPE. J. Cryst. Growth 2013, 370, 12–15. [Google Scholar] [CrossRef]

| DBR 1 | DBR 2 | DBR3 | |

|---|---|---|---|

| Low index layer | AlN | AlN | AlN |

| High index layer | Al0.84In0.16N | Al0.84In0.16N | Al0.84In0.16N |

| Target Wavelength | 235 nm | 290 nm | 365 nm |

| No. of bilayers | 8 | 8 | 8 |

| Sputter Time | 20 min | 26 min | 34 min |

| Deposition temp. | 150 °C | 150 °C | 150 °C |

| Simulation layer thickness (nm) | dAlN = 26 | dAlN = 42 | dAlN = 53 |

| dAlInN = 32 | dAlInN = 34 | dAlInN = 46 |

| Material | Fabrication Method | Period | Wavelength (nm) | Thickness (High Index Material) | Thickness (Low Index Material) | Total Thickness | Reflectance (%) | Ref. |

|---|---|---|---|---|---|---|---|---|

| AlGaN/AlN | MBE | 29.5 | 340 | 35 nm | 39.5 nm | 2198 | 99 | [1] |

| AlInN/AlGaN | MOCVD | 35 | 343 | 32 nm | 36 nm | 2380 | 99.5 | [28] |

| AlGaN/AlN | MOCVD | 30.5 | 220–250 | - | - | 2196–2379 | 97 | [16] |

| AlGaN/GaN | MOCVD | 20 | 384 | 36 nm | 42 nm | 1560 | 90 | [29] |

| AlInN/AlN | R.F Sputtering | 8 | 235, 290,365 | 26 nm/34 nm/45 nm | 32 nm/42 nm/54 nm | 464, 608, 792 | 86.5, 97.7, 97.5 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frimpong-Manso, E.S.; Wang, L. High Reflectivity AlN/Al1−xInxN Distributed Bragg Reflectors across the UV Regions by Sputtering. Crystals 2022, 12, 162. https://doi.org/10.3390/cryst12020162

Frimpong-Manso ES, Wang L. High Reflectivity AlN/Al1−xInxN Distributed Bragg Reflectors across the UV Regions by Sputtering. Crystals. 2022; 12(2):162. https://doi.org/10.3390/cryst12020162

Chicago/Turabian StyleFrimpong-Manso, Ellen Serwaa, and Liancheng Wang. 2022. "High Reflectivity AlN/Al1−xInxN Distributed Bragg Reflectors across the UV Regions by Sputtering" Crystals 12, no. 2: 162. https://doi.org/10.3390/cryst12020162

APA StyleFrimpong-Manso, E. S., & Wang, L. (2022). High Reflectivity AlN/Al1−xInxN Distributed Bragg Reflectors across the UV Regions by Sputtering. Crystals, 12(2), 162. https://doi.org/10.3390/cryst12020162