Effect of Strain on Transformation Diagrams of 100Cr6 Steel

Abstract

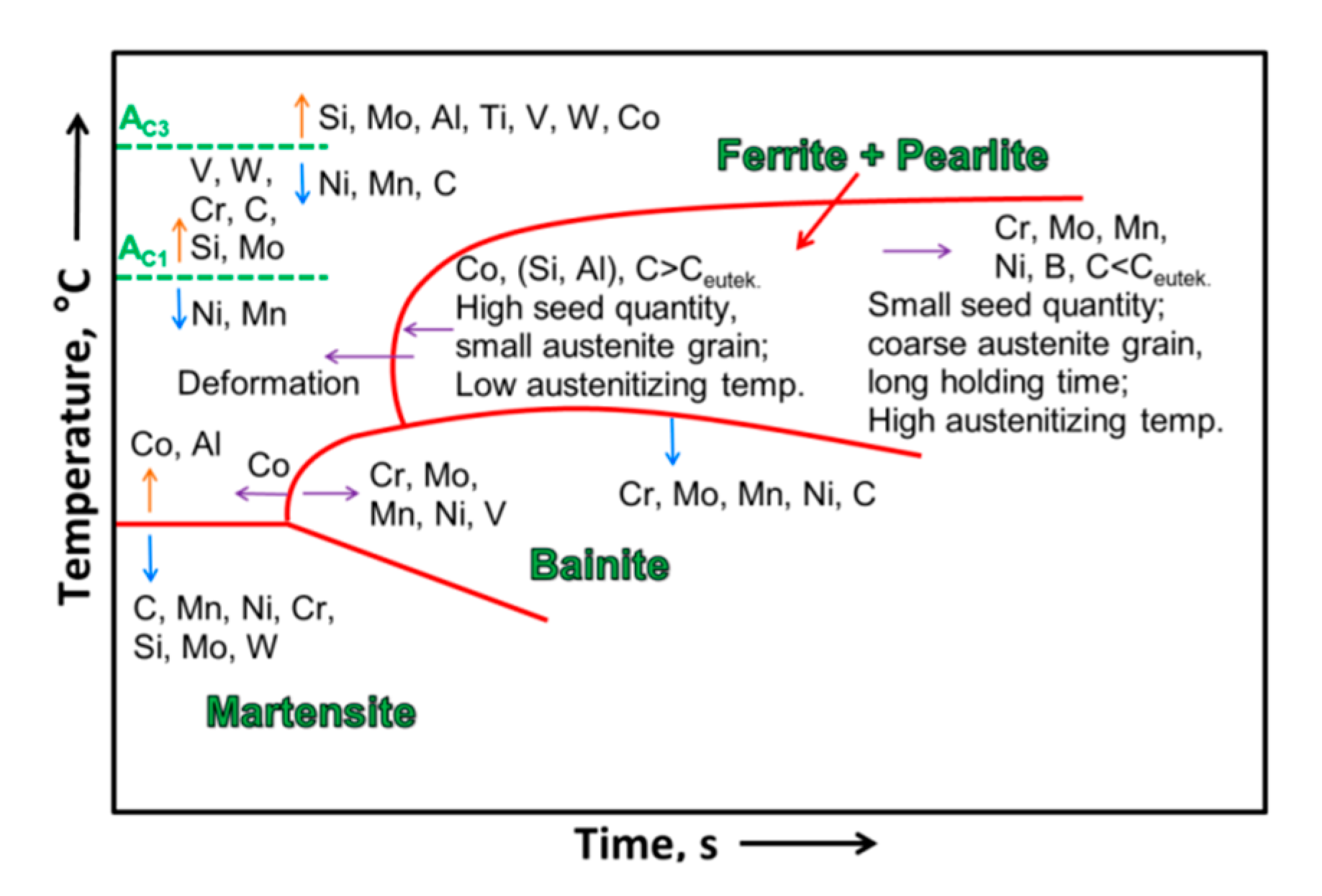

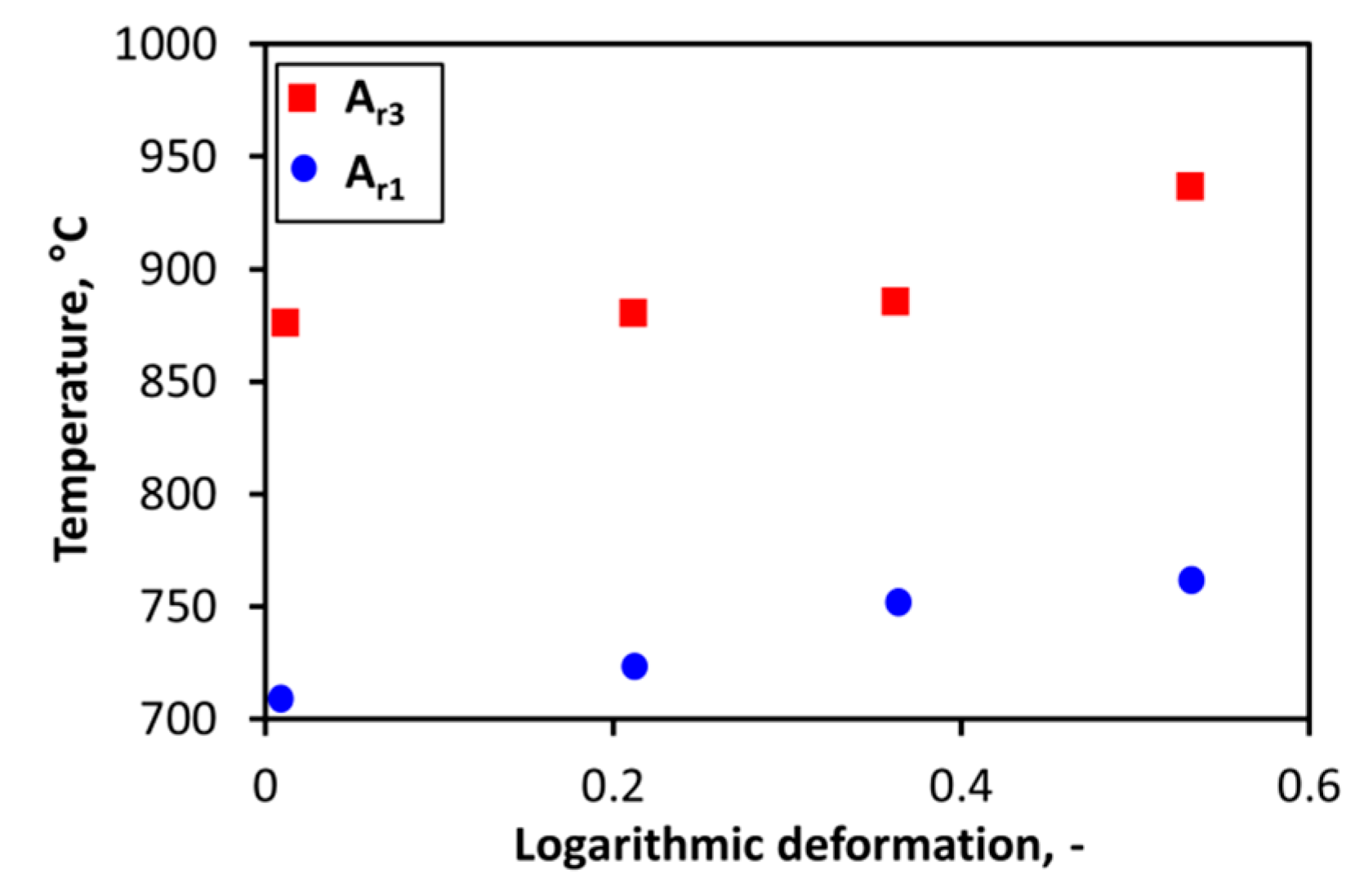

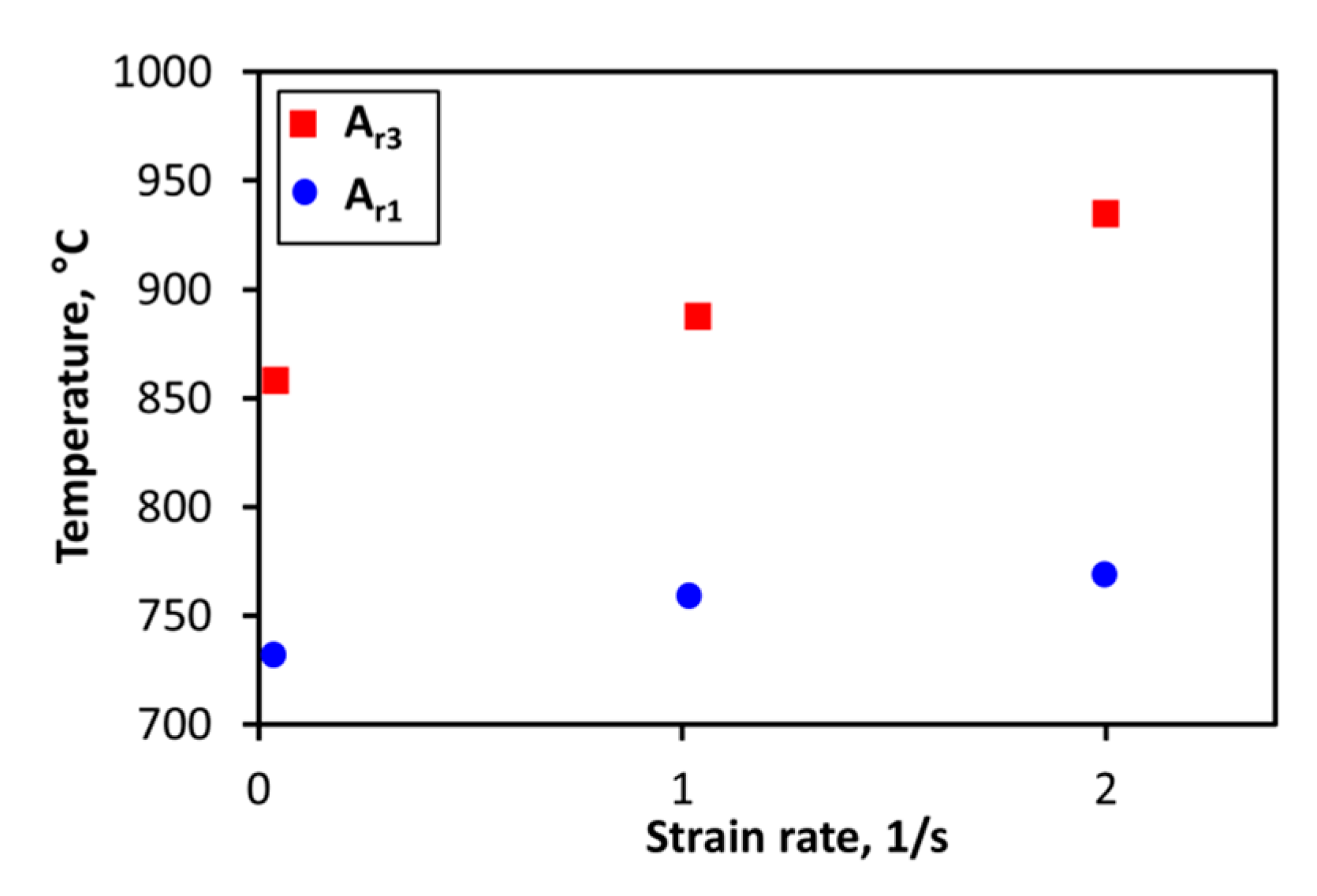

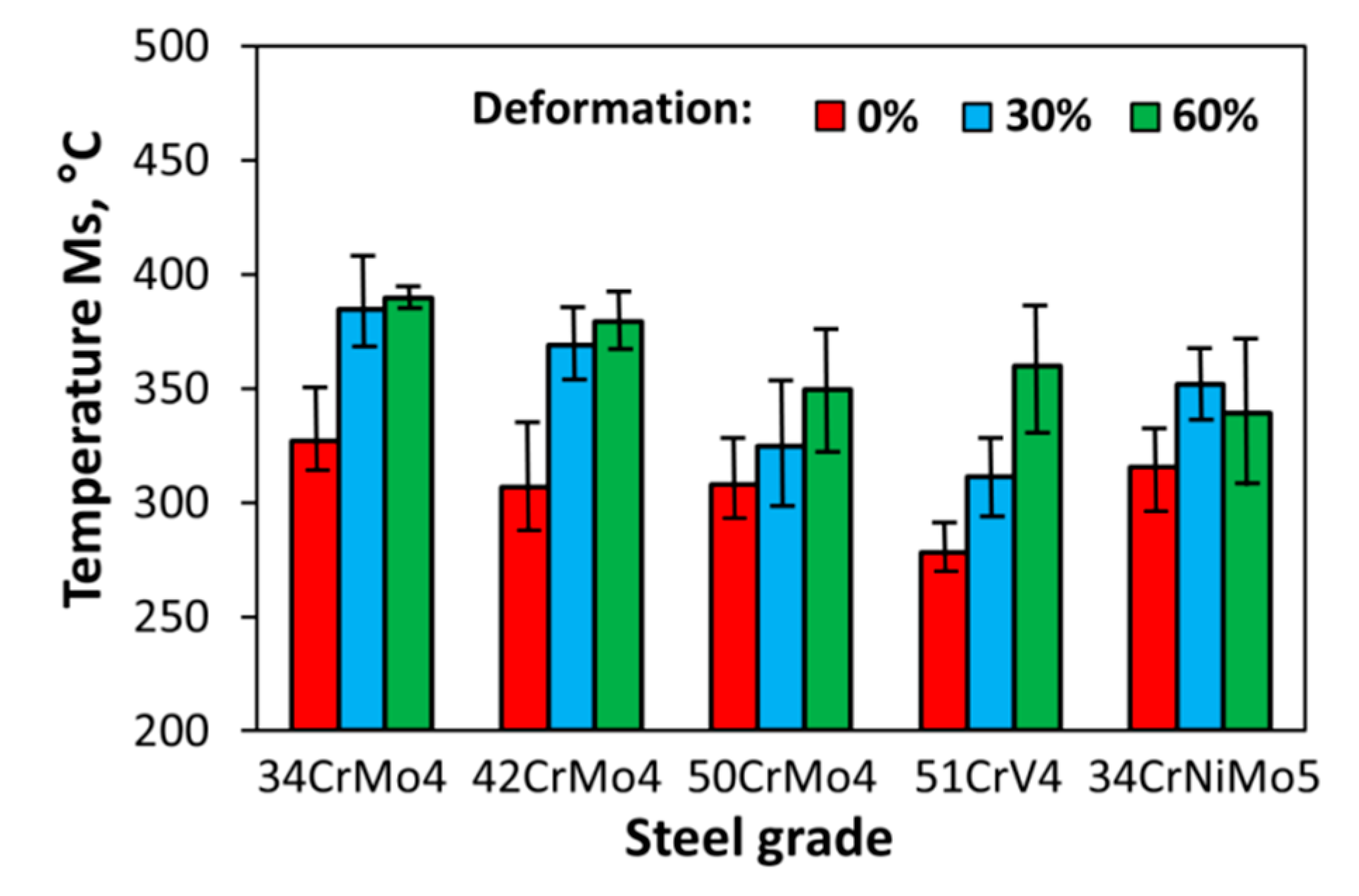

1. Introduction

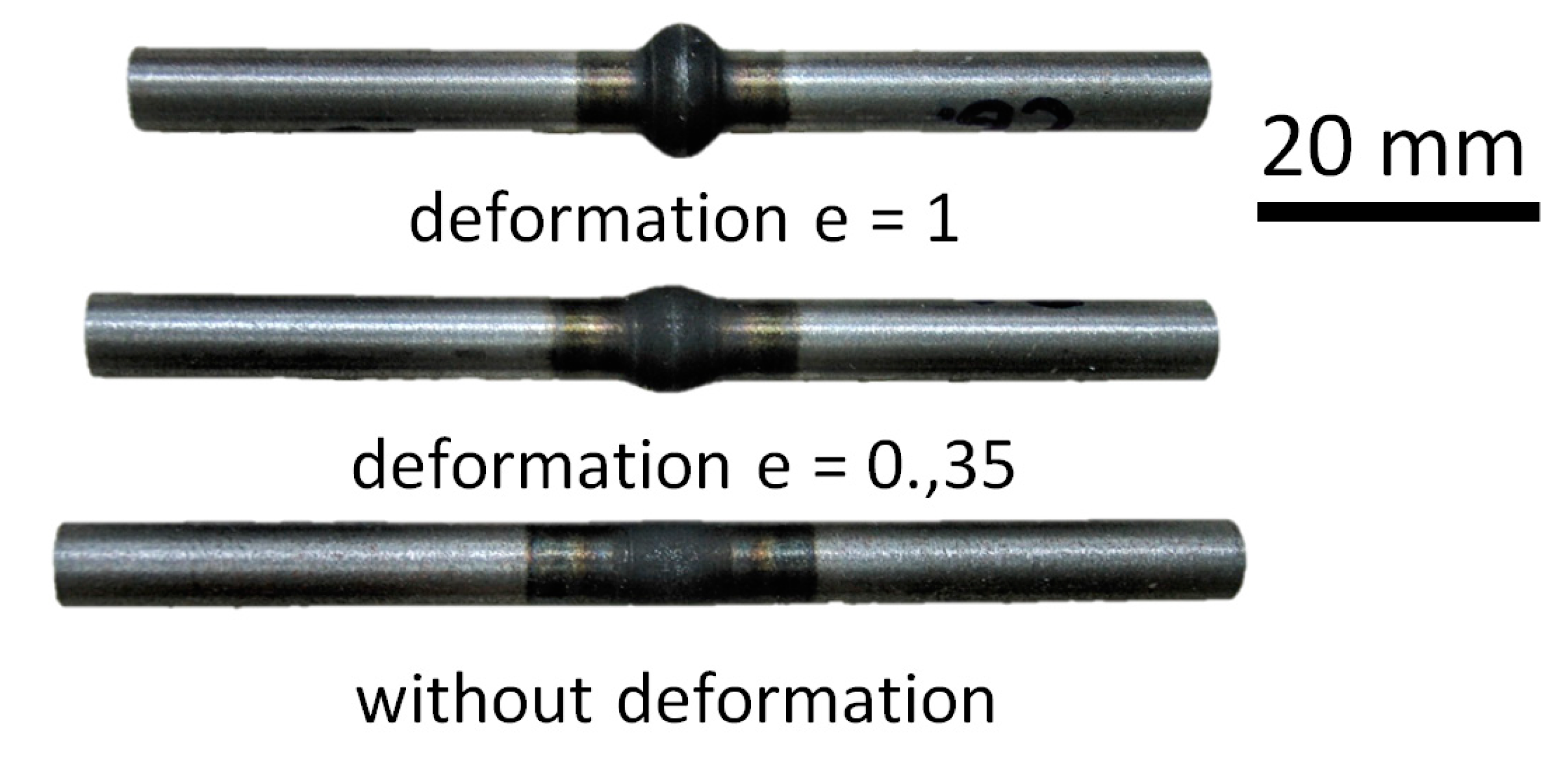

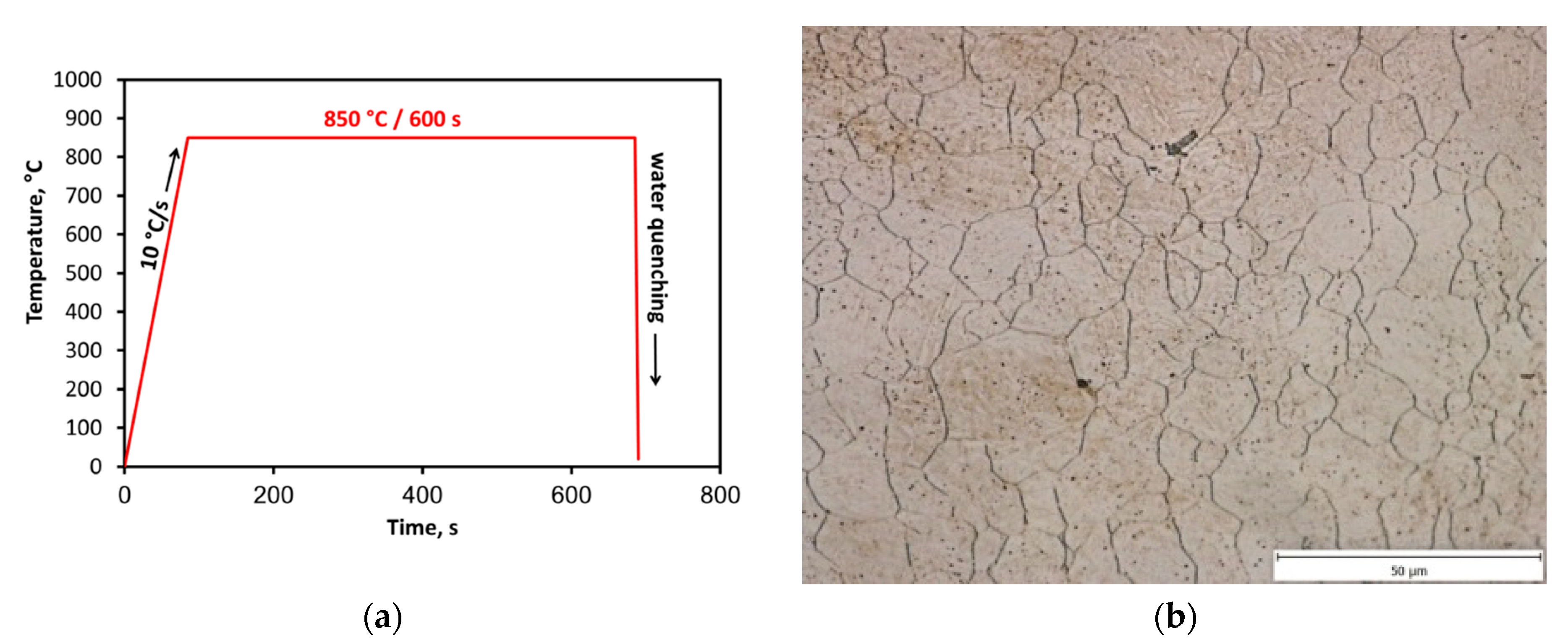

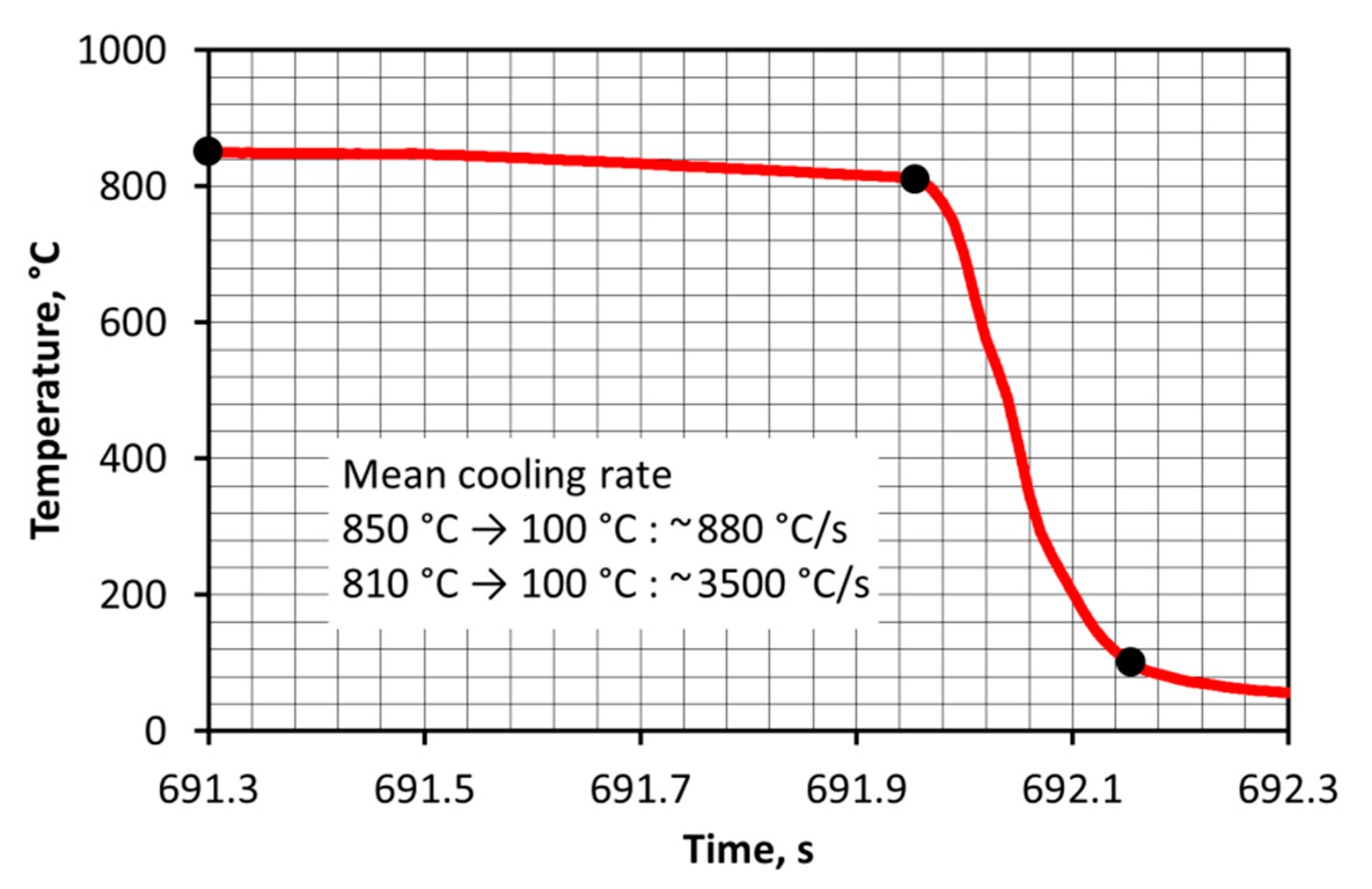

2. Materials and Methods

3. Results and Discussion

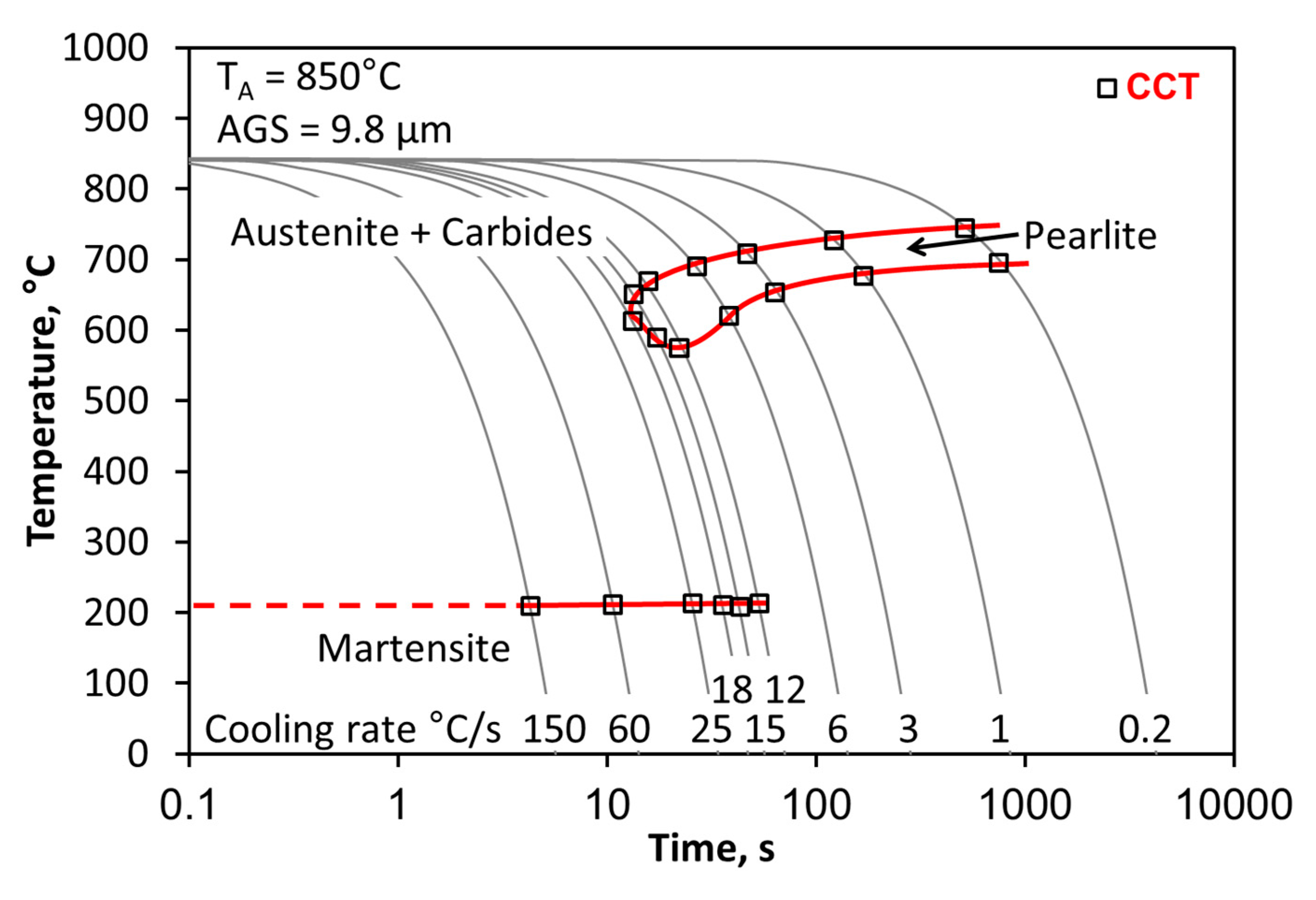

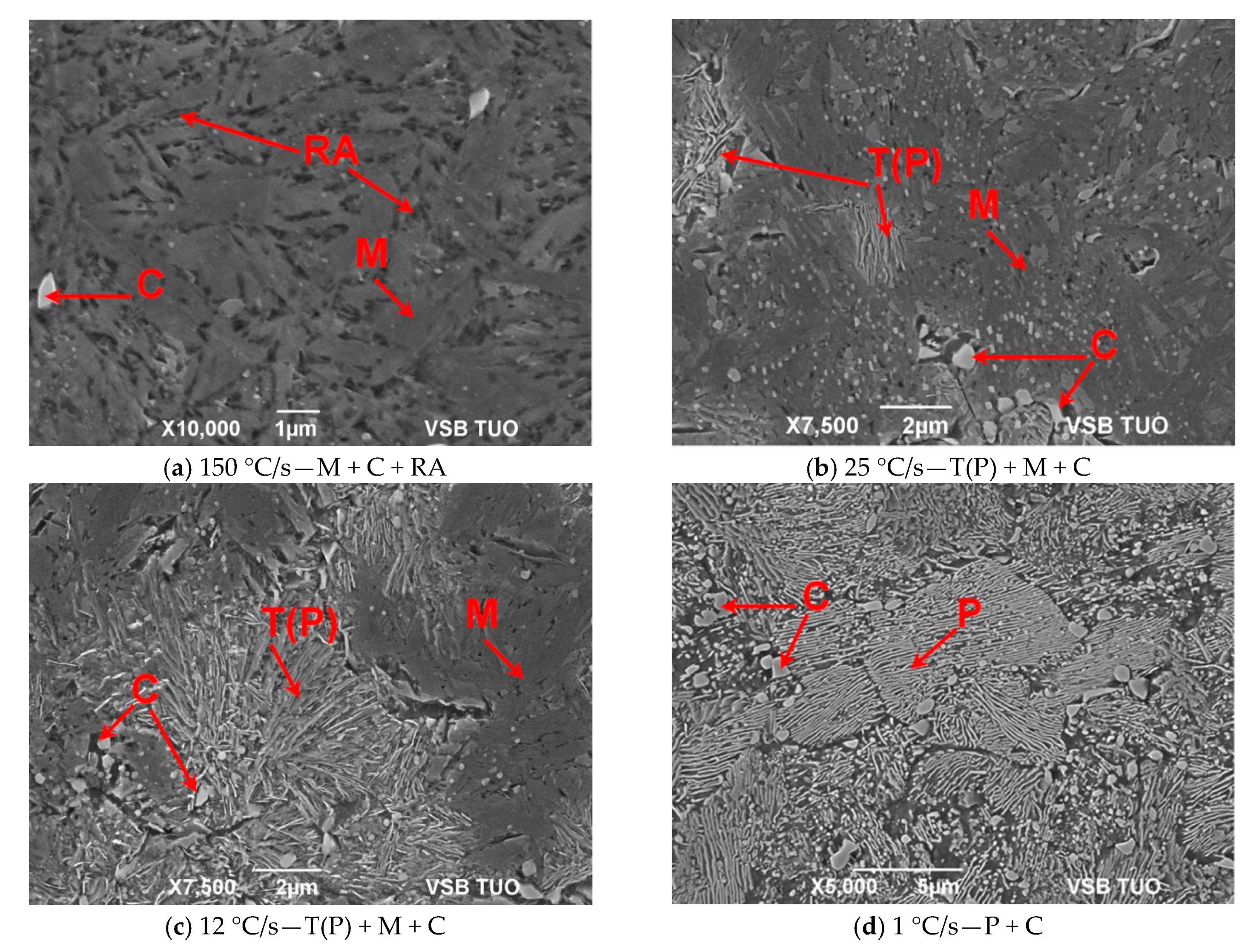

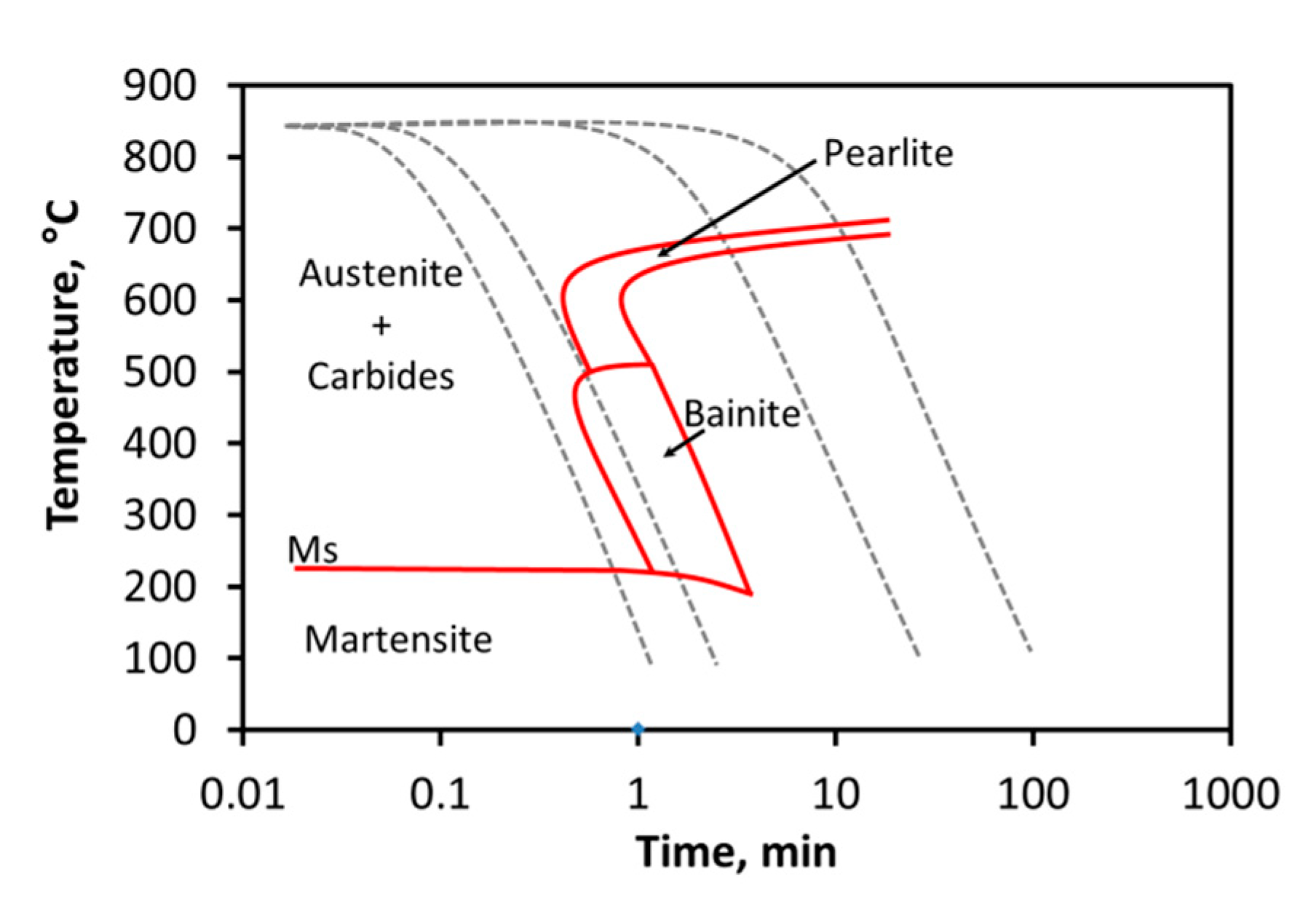

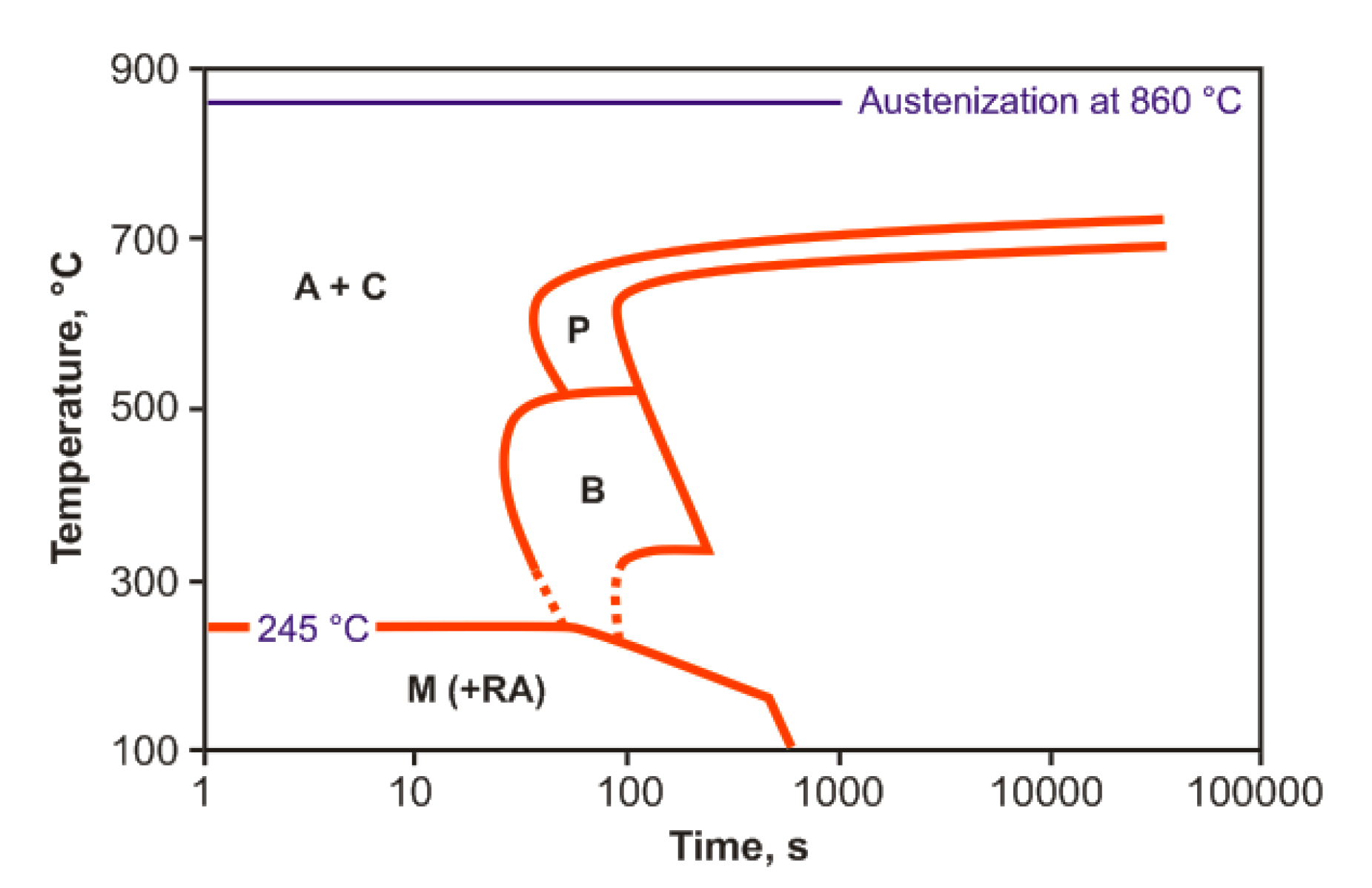

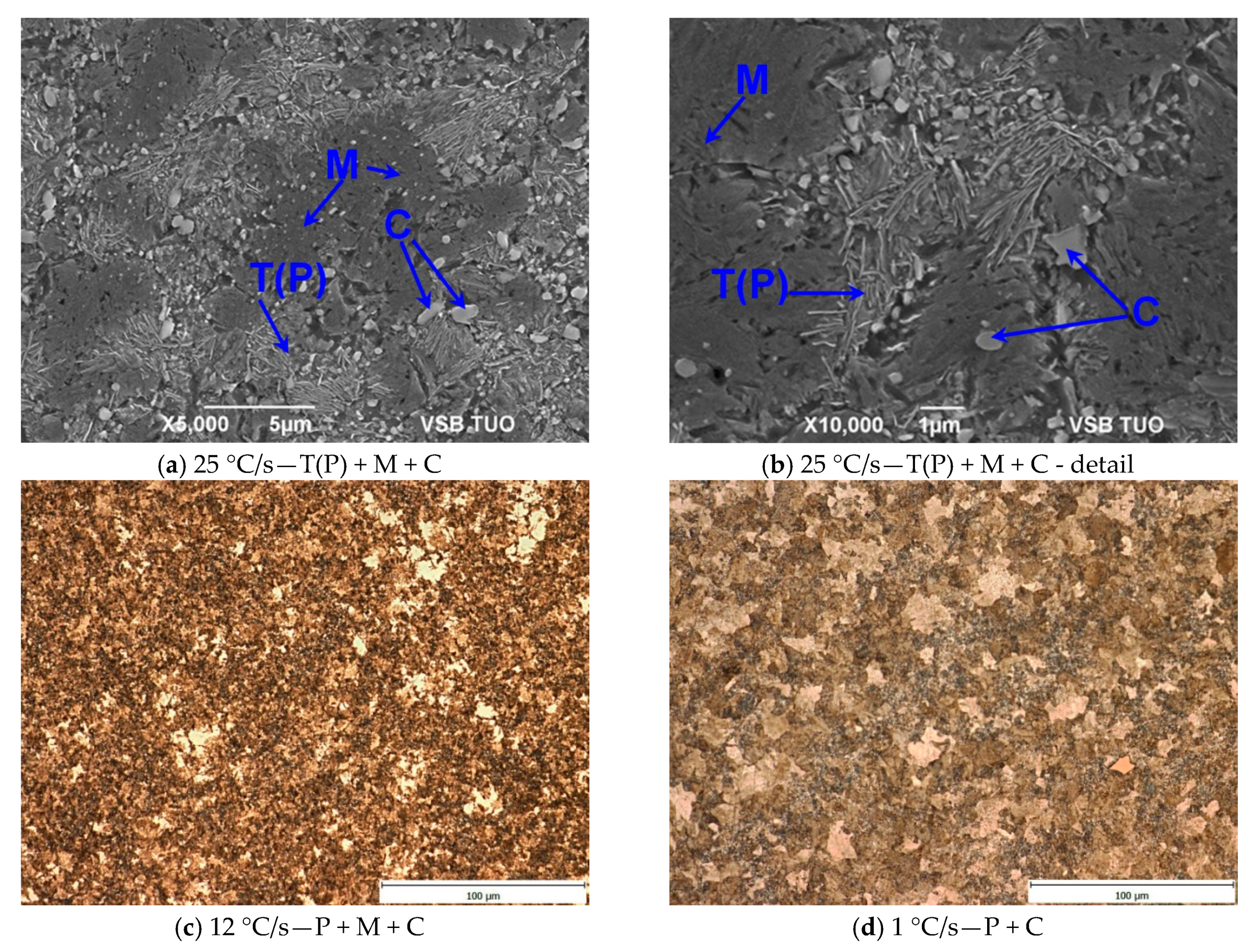

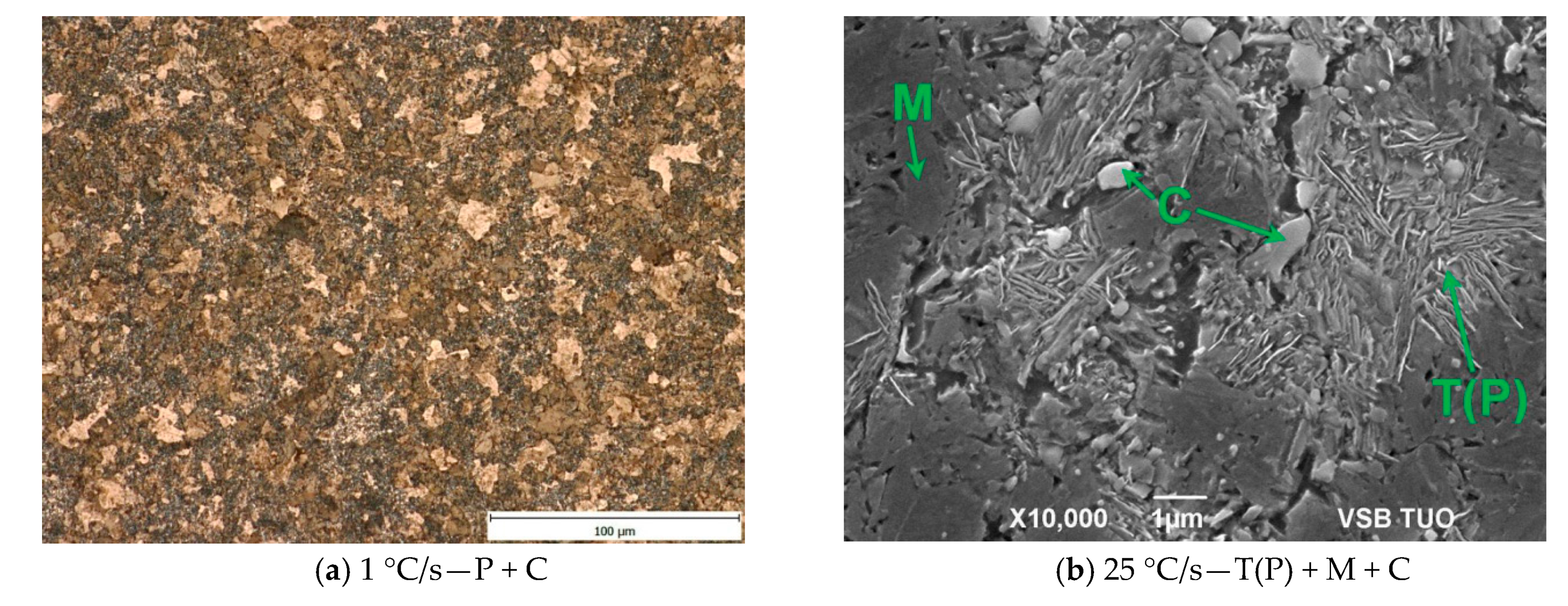

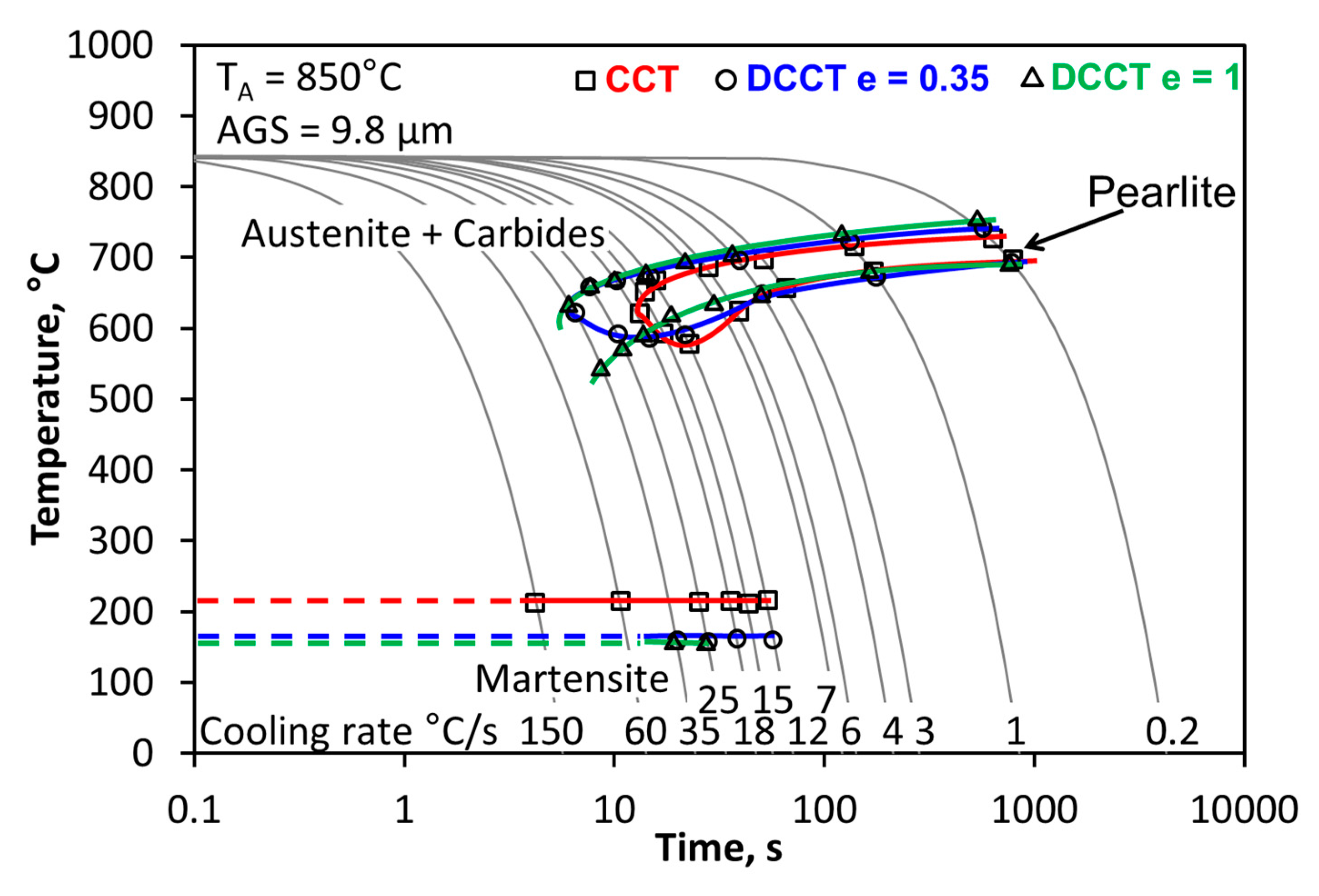

3.1. CCT Diagram

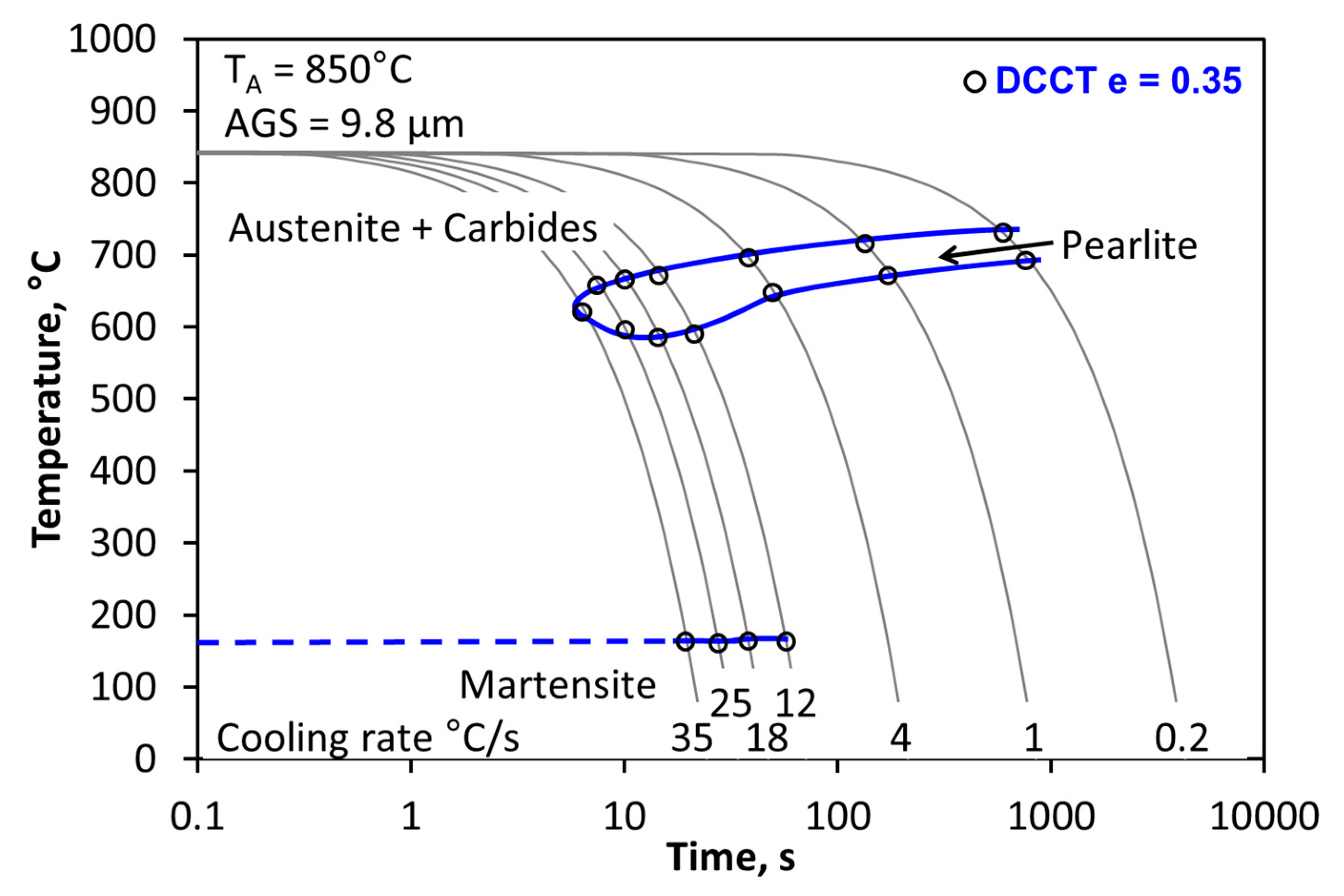

3.2. DCCT Diagram—Deformation e = 0.35

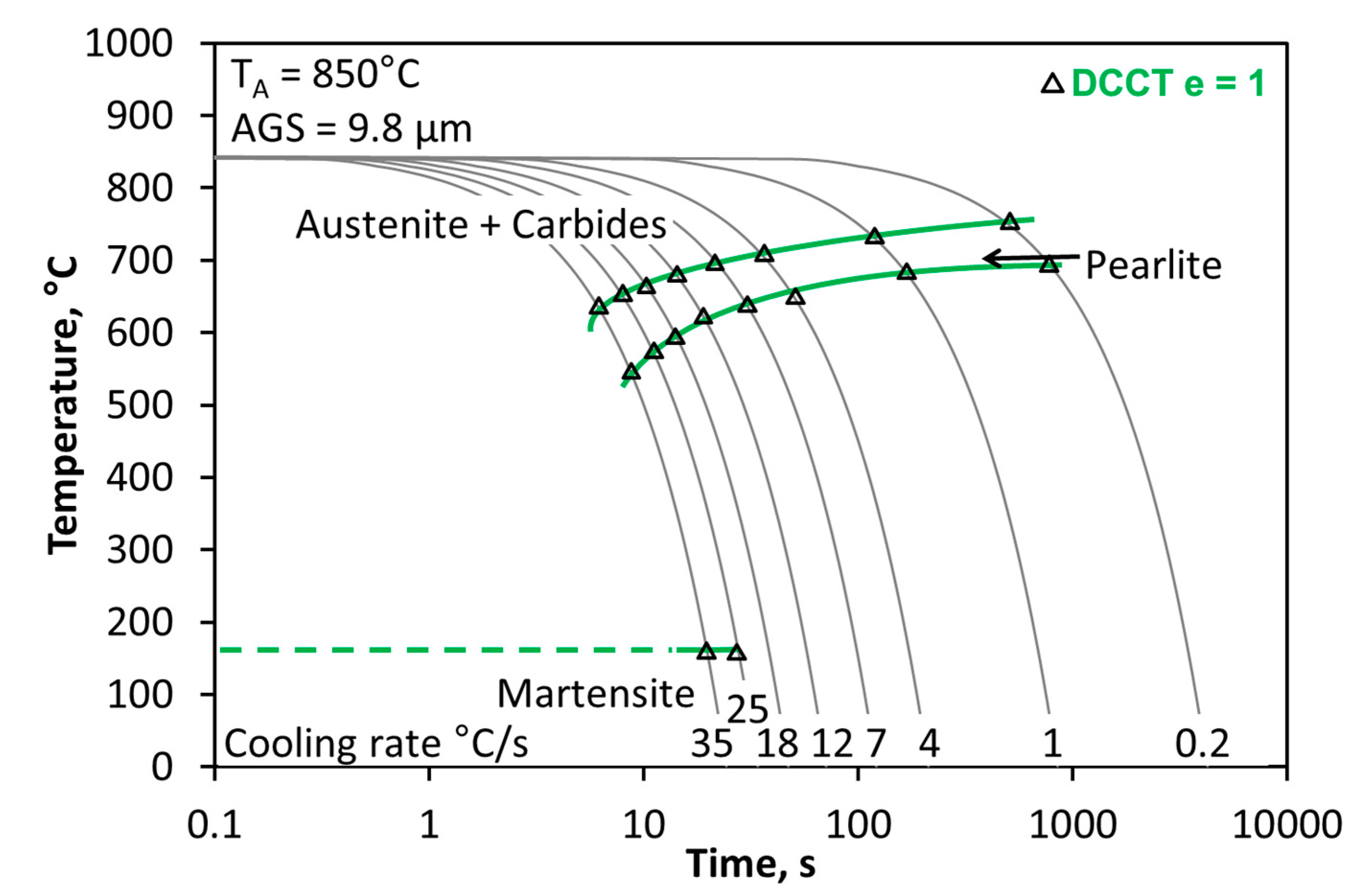

3.3. DCCT Diagram—Deformation e = 1

3.4. Comparison of the (D)CCT Diagrams

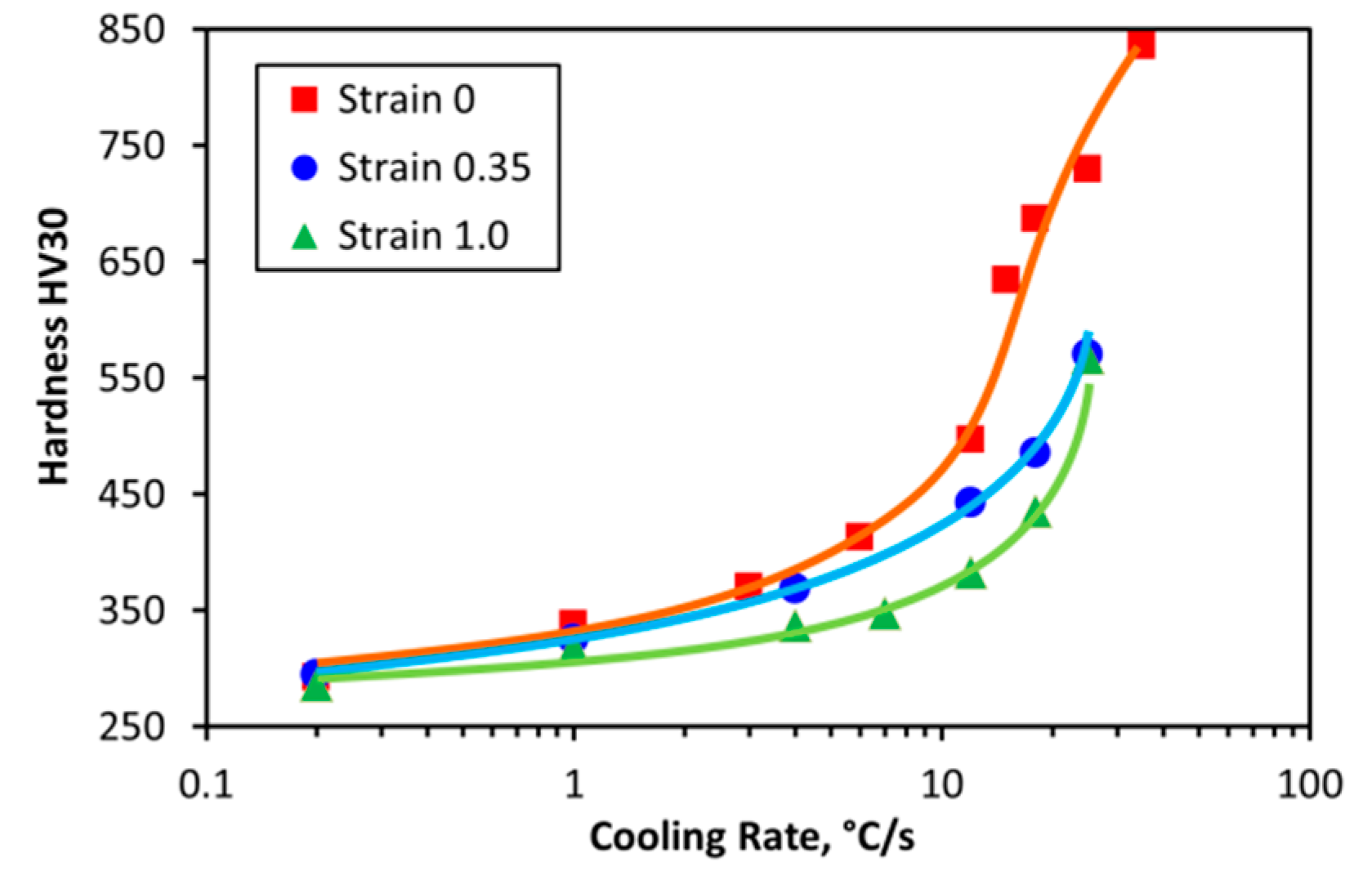

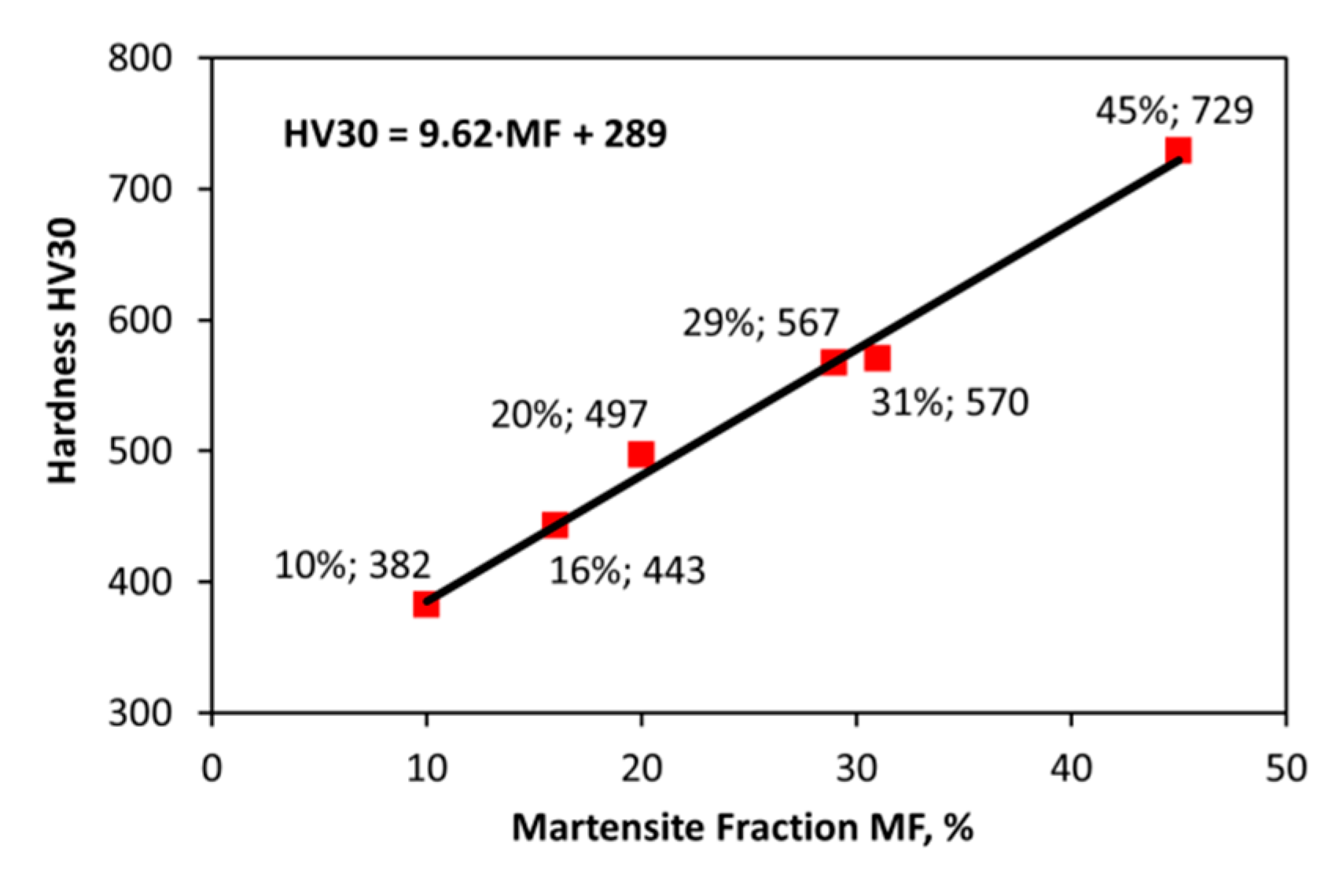

3.5. Comparison of the Hardness HV30

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Verlinden, B.; Driver, J.; Samajdar, I.; Doherty, R.D. Thermo-Mechanical Processing of Metallic Materials, 1st ed.; Elsevier: Oxford, UK, 2007; 528p. [Google Scholar]

- Kawulok, R.; Schindler, I.; Kawulok, P.; Rusz, S.; Opela, P.; Kliber, J.; Solowski, Z.; Čmiel, K.M.; Podolinsky, P.; Mališ, M.; et al. Transformation kinetics of selected steel grades after plastic deformation. Metalurgija 2016, 55, 357–360. [Google Scholar]

- Timoshenkov, A. Influence of Deformation on Phase Transformation and Precipitation of Steels for Oil Country Tubular Goods. Steel Res. Int. 2014, 6, 954–967. [Google Scholar] [CrossRef]

- Totten, G.; Xie, L.; Funatani, K. Modeling and Simulation for Material Selection and Mechanical Design; Marcel Dekker: Basel, Switzerland, 2004; 166p. [Google Scholar]

- Kruglova, A.A.; Orlov, V.V. Effect of hot plastic deformation in the austenite interval on structure formation in low-alloyed—Carbon steels. Met. Sci. Heat Treat. 2007, 12, 556–560. [Google Scholar] [CrossRef]

- Kawulok, R.; Schindler, I.; Kawulok, P.; Rusz, S.; Opěla, P.; Solowski, Z.; Čmiel, K.M. Effect of deformation on the CCT diagram of steel 32CrB4. Metalurgija 2015, 54, 473–476. [Google Scholar]

- Grajcar, A.; Kuziak, R.; Zalecki, W. Designing of cooling conditions for Si-Al microalloyed TRIP steel on the basis of DCCT diagrams. J. Achiev. Mater. Manuf. Eng. 2011, 45, 115–124. [Google Scholar]

- QForm Heat Treatment Process Analysis Software, for Forging. Available online: https://www.indiamart.com/proddetail/heat-treatment-6322730912.html (accessed on 25 February 2019).

- Jagiełło, A.; Trzaska, J.; Dobrzañski, L.A. Computer Software for modelling CCT Diagrams. Czas. Technol. Mech. 2008, 105, 87–94. [Google Scholar]

- Domański, T.; Piekarska, W.; Kubiak, M.; Saternus, Z. Determination of the final microstructure during processingcarbon steel hardening. Procedia Eng. 2016, 136, 77–81. [Google Scholar] [CrossRef][Green Version]

- Kawulok, R.; Schindler, I.; Mizera, J.; Kawulok, P.; Rusz, S.; Opěla, P.; Podolinsky, P.; Čmiel, K.M. Transformation diagrams of selected steel grades with consideration of deformation effect. Arch. Metall. Mater. 2018, 63, 55–60. [Google Scholar]

- Xie, H.J.; Wu, X.C.; Min, Y.A. Influence of Chemical Composition on Phase Transformation Temperature and Thermal Expansion Coefficient of Hot Work Die Steel. J. Iron Steel Res. Int. 2008, 15, 56–61. [Google Scholar] [CrossRef]

- Calvo, J.; Jung, I.H.; Elwazri, A.M.; Bai, D.; Yue, S. Influence of the chemical composition on transformation behaviour of low carbon microalloyed steels. J. Mater. Sci. Eng. A 2009, 520, 90–96. [Google Scholar] [CrossRef]

- Liu, S.K.; Yang, L.; Zhu, D.G.; Zhang, J. The Influence of the Alloying Elements upon the Transformation Kinetics and Morphologies of Ferrite Plates in Alloy Steels. Metall. Mater. Trans. A 1994, 25, 1991–2000. [Google Scholar] [CrossRef]

- Mun, D.J.; Shin, E.J.; Choi, Y.W.; Lee, S.J.; Koo, Y.M. Effects of cooling rate, austenitizing temperature and austenite deformation on the transformation behavior of high-strength boron steel. Mater. Sci. Eng. A 2012, 545, 214–224. [Google Scholar] [CrossRef]

- Zhizhong, H. The Handbook of Steel and Its Heat Treatment Curve; Defence Industry Press: Beijing, China, 1987. [Google Scholar]

- Aranda, M.; Kim, B.; Rementeria, R.; Capdevila, C.; García de Andrés, C. Effect of prior austenit grain size to pearlite transformation in a hypoeuctectoid Fe-C-Mn steel. Metall. Mater. Trans. A 2014, 4, 1778–1786. [Google Scholar] [CrossRef]

- Kawulok, P.; Podolinsky, P.; Kajzar, P.; Schindler, I.; Kawulok, R.; Ševčák, V.; Opěla, P. The influence of deformation and austenitization temperature on the kinetics of phase transformations during cooling of high-carbon steel. Arch. Metall. Mater. 2018, 63, 1743–1748. [Google Scholar]

- Kawulok, P.; Schindler, I.; Mizera, J.; Kawulok, R.; Rusz, S.; Opěla, P.; Olszar, M.; Čmiel, K.M. The influence of a cooling rate on the evolution of microstructure and hardness of the steel 27MnCrB5. Arch. Metall. Mater. 2018, 63, 907–914. [Google Scholar]

- Kawulok, R.; Kawulok, P.; Schindler, I.; Opěla, P.; Rusz, S.; Ševčák, V.; Solowski, Z. Study of the effect of deformation on transformation diagrams of two low-alloy manganese-chromium steels. Arch. Metall. Mater. 2018, 63, 1735–1741. [Google Scholar]

- Grajcar, A.; Zalecki, W.; Skrzypczyk, P.; Kilarski, A.; Kowalski, A.; Kołodziej, S. Dilatometric study of phase transformations in advanced high-strength bainitic steel. J. Therm. Anal. Calorim. 2014, 118, 739–748. [Google Scholar] [CrossRef]

- Grajcar, A.; Morawiec, M.; Zalecki, W. Austenite decomposition and precipitation behavior of plastically deformed low-Si microalloyed steel. Metals 2018, 8, 1028. [Google Scholar] [CrossRef]

- Nürnberger, F.; Grydin, O.; Schaper, M.; Bach, F.W.; Koczurkiewicz, B.; Milenin, A. Microstructure transformations in tempering steels during continuous cooling from hot forging temperatures. Steel Res. Int. 2010, 81, 224–233. [Google Scholar] [CrossRef]

- Jandová, D.; Vadovicová, L. Influence of deformation on austenite decomposition of steel 0.5C-1Cr-0.8Mn-0.3Si. In Metal; TANGER: Ostrava, Czech Republic, 2004. [Google Scholar]

- Khlestov, V.M.; Konopleva, E.V.; McQueen, H.J. Effects of deformation and heating temperature on the austenite transformation to pearlite in high alloy tool steels. Mater. Sci. Technol. 2002, 18, 54–60. [Google Scholar] [CrossRef]

- Yin, S.B.; Sun, X.J.; Liu, Q.Y.; Zhang, Z.B. Influence of Deformation on Transformation of Low-Carbon and High Nb-Containing Steel during Continuous Cooling. J. Iron Steel Res. Int. 2010, 17, 43–47. [Google Scholar] [CrossRef]

- Opiela, M.; Zalecki, W.; Grajcar, A. Influence of plastic deformation on CCT-diagrams of new-developed microalloyed steel. J. Achiev. Mater. Manuf. Eng. 2012, 51, 78–89. [Google Scholar]

- Mohamadizadeh, A.; Zarei-Hanzaki, A.; Heshmati-Manesh, S.; Imandoust, A. The effect of strain induced ferrite transformation on the microstructural evolutions and mechanical properties of aTRIP-assisted steel. Mater. Sci. Eng. A 2014, 607, 621–629. [Google Scholar] [CrossRef]

- Du, L.X.; Yi, H.L.; Ding, H.; Liu, X.H.; Wang, G.D. Effects of Deformation on Bainite Transformation During Continuous Cooling of Low Carbon Steels. J. Iron Steel Res. 2006, 13, 37–39. [Google Scholar] [CrossRef]

- Nadeiri, M. Influence of Hot Plastic Deformation and Cooling Rate on Martenzite and Bainite Start Temperatures in 22MnB5 steel. Mater. Sci. Eng. 2012, 30, 24–29. [Google Scholar]

- Rusz, S.; Schindler, I.; Kawulok, P.; Kawulok, R.; Opěla, P.; Kliber, J.; Solowski, Z. Phase transformation and cooling curves of the mild steel influenced by previous hot rolling. Metalurgija 2016, 55, 655–658. [Google Scholar]

- Yamamoto, S. Effects of austenite Grain Size and Deformation in the Unrecrystallized Austenite Region on Bainite Transformation Behavior and Microstructure. ISIJ Int. 1995, 15, 1020–1026. [Google Scholar] [CrossRef]

- Kawata, H.; Fujiwara, K.; Takahashi, M. Effect of Carbon Content on Bainite Transformation Start Temperature in Low Carbon Fe–9Ni–C Alloys. ISIJ Int. 2017, 57, 1866–1873. [Google Scholar] [CrossRef]

- Liu, Z.; Yao, K.F.; Liu, Z. Quantitative research on effects of stresses and strains on bainitic transformation kinetics and transformation plasticity. Mater. Sci. Technol. 2000, 16, 643–647. [Google Scholar] [CrossRef]

- Xu, Y.; Xu, G.; Mao, X.; Zhao, G.; Bao, S. Method to Evaluate the Kinetics of Bainite Transformation in Low-Temperature Nanobainitic Steel Using Thermal Dilatation Curve Analysis. Metals 2017, 7, 330. [Google Scholar] [CrossRef]

- He, B.B.; Xu, W.; Huang, M.X. Increase of martensite start temperature after small deformation of austenite. Mater. Sci. Eng. A 2014, 609, 141–146. [Google Scholar] [CrossRef]

- Trzaska, J.; Dobrzañski, L.A. Modelling of CCT diagrams for engineering and constructional steels. J. Mater. Process. Technol. 2007, 192–193, 504–510. [Google Scholar] [CrossRef]

- Vermeulen, W.; Zwaag, S.; Morris, P.; Weijer, T. Prediction of the continuous cooling transformation diagram of some selected steels using artificial neural networks. Mater. Technol. 1997, 68, 72–79. [Google Scholar] [CrossRef]

- Motyčka, P.; Kövér, M. Evaluation methods of dilatometer curves of phase transformations. In Comat; Tanger Ltd.: Pilsen, Czech Republic, 2012; p. 1237. [Google Scholar]

- Qiu, C.; Zwaag, S. Dilatation measurements of plain carbon steels and their thermodynamic analysis. Steel Res. Int. 1997, 68, 32–38. [Google Scholar] [CrossRef]

- Rożniata, E.; Dziurka, R. The Phase transformations in hypoeutectoid steels Mn-Cr-Ni. Arch. Metall. Mater. 2015, 60, 497–502. [Google Scholar] [CrossRef]

- OVAKO—Material Data Sheet of Steel Grade 100Cr6. Available online: https://steelnavigator.ovako.com/steel-grades/100cr6/ (accessed on 25 February 2019).

- IMS—Data Sheet of 100Cr6 Steel—Normativa di Riferimento UNI 3097. Available online: https://www.ims.it/files/100Cr6.pdf (accessed on 20 February 2019).

- Durand-Chare, M. Microstructure of Steels and Cast Irons, 1st ed.; Springer: Berlin, Germany, 2004; pp. 297–304. [Google Scholar]

- Schindler, I.; Kawulok, P. Application possibilities of the plastometer Gleeble 3800 with simulation model Hydrawedge II at the VŠB-TU Ostrava. Hut. Listy 2013, 66, 85–90. [Google Scholar]

- Mandziej, S.T. Physical simulation of metallurgical processes. Mater. Technol. 2010, 44, 105–119. [Google Scholar]

- Alvarez, W.S. Microstructural Degradation of Bearing Steels. Ph.D. Thesis, Department of Materials Science and Metallurgy, University of Cambridge, Cambridge, UK, December 2014. [Google Scholar]

- AUSA—SPECIAL STEELS—Material data sheet of Steel grade 100Cr6. Available online: https://www.ausasteel.com/fichas/Bearing-Steel-100Cr6-AUSA.pdf (accessed on 14 October 2019).

- Glazunov, A. On the structure of troostite. Collect. Czech. Chem. Commun. 1933, 5, 76–83. [Google Scholar] [CrossRef]

- Müştak, O. Characterization of SAE 52100 Bearing Steel for Finite Element Simulation of through-Hardening Proces. Master’s Thesis, Master of Science in Metallurgical and Materials Engineering Department, Middle East Technical University, Ankara, Turkey, September 2014. [Google Scholar]

- Bhadeshia, H.K.D.H. Steels for bearings. Prog. Mater. Sci. 2012, 57, 268–435. [Google Scholar] [CrossRef]

- Ellerman, A.; Scholtes, B. The strength differential effect in different heat treatment conditions of the steels 42CrMoS4 and 100Cr6. Mater. Sci. Eng. A 2015, 620, 262–272. [Google Scholar] [CrossRef]

- Perez, M.; Sidoroff, C.; Vincent, A.; Esnouf, C. Microstructural evolution of martensitic 100Cr6 bearing steel during tempering: From thermoelectric power measurements to the prediction of dimensional changes. Acta Mater. 2009, 57, 3170–3181. [Google Scholar] [CrossRef]

- Ryttberg, K.; Wedel, M.K.; Recina, V.; Dahlman, P.; Nyborg, L. The effect of cold ring rolling on the evolution of microstructure and texture in 100Cr6 steel. Mater. Sci. Eng. A 2010, 527, 2431–2436. [Google Scholar] [CrossRef]

- Nikravesh, M.; Naderi, M.; Akbari, G.H. Influence of hot plastic deformation and cooling rate on martensite and bainite start temperatures in 22MnB5 steel. Mater. Sci. Eng. A 2012, 540, 24–29. [Google Scholar] [CrossRef]

- Maalekian, M.; Lendinez, M.L.; Kozeschnik, E.; Brantner, H.P.; Cerjak, H. Effect of hot plastic deformation of austenite on the transformation characteristics of eutectoid carbon steel under fast heating and cooling conditions. Mater. Sci. Eng. A 2007, 454–455, 446–452. [Google Scholar] [CrossRef]

- Wang, H.-Z.; Yang, P.; Mao, W.-M.; Lu, F.-Y. Effect of hot deformation of austenite on martensitic transformation in high manganese steel. J. Alloys Compd. 2013, 558, 26–33. [Google Scholar] [CrossRef]

- Mola, J.; Ren, M. On the hardness of high carbon ferrous martensite. IOP Conf. Ser. Mater. Sci. Eng. 2018, 373, 012004. [Google Scholar] [CrossRef]

- Xu, X.; Zwaag, S.; Xu, W. The effect of martensite volume fraction on the scratch and abrasion resistence of a ferrite-martensite dual phase steel. Wear 2016, 348–349, 80–88. [Google Scholar]

| C | Mn | Si | P | S | Cr |

|---|---|---|---|---|---|

| 0.994 | 0.38 | 0.324 | 0.011 | 0.001 | 1.45 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kawulok, R.; Schindler, I.; Sojka, J.; Kawulok, P.; Opěla, P.; Pindor, L.; Grycz, E.; Rusz, S.; Ševčák, V. Effect of Strain on Transformation Diagrams of 100Cr6 Steel. Crystals 2020, 10, 326. https://doi.org/10.3390/cryst10040326

Kawulok R, Schindler I, Sojka J, Kawulok P, Opěla P, Pindor L, Grycz E, Rusz S, Ševčák V. Effect of Strain on Transformation Diagrams of 100Cr6 Steel. Crystals. 2020; 10(4):326. https://doi.org/10.3390/cryst10040326

Chicago/Turabian StyleKawulok, Rostislav, Ivo Schindler, Jaroslav Sojka, Petr Kawulok, Petr Opěla, Lukáš Pindor, Eduard Grycz, Stanislav Rusz, and Vojtěch Ševčák. 2020. "Effect of Strain on Transformation Diagrams of 100Cr6 Steel" Crystals 10, no. 4: 326. https://doi.org/10.3390/cryst10040326

APA StyleKawulok, R., Schindler, I., Sojka, J., Kawulok, P., Opěla, P., Pindor, L., Grycz, E., Rusz, S., & Ševčák, V. (2020). Effect of Strain on Transformation Diagrams of 100Cr6 Steel. Crystals, 10(4), 326. https://doi.org/10.3390/cryst10040326