Microstructure, Texture, and Strength Development during High-Pressure Torsion of CrMnFeCoNi High-Entropy Alloy

Abstract

1. Introduction

2. Experimental

3. Results

4. Discussion

4.1. Microstructure Development

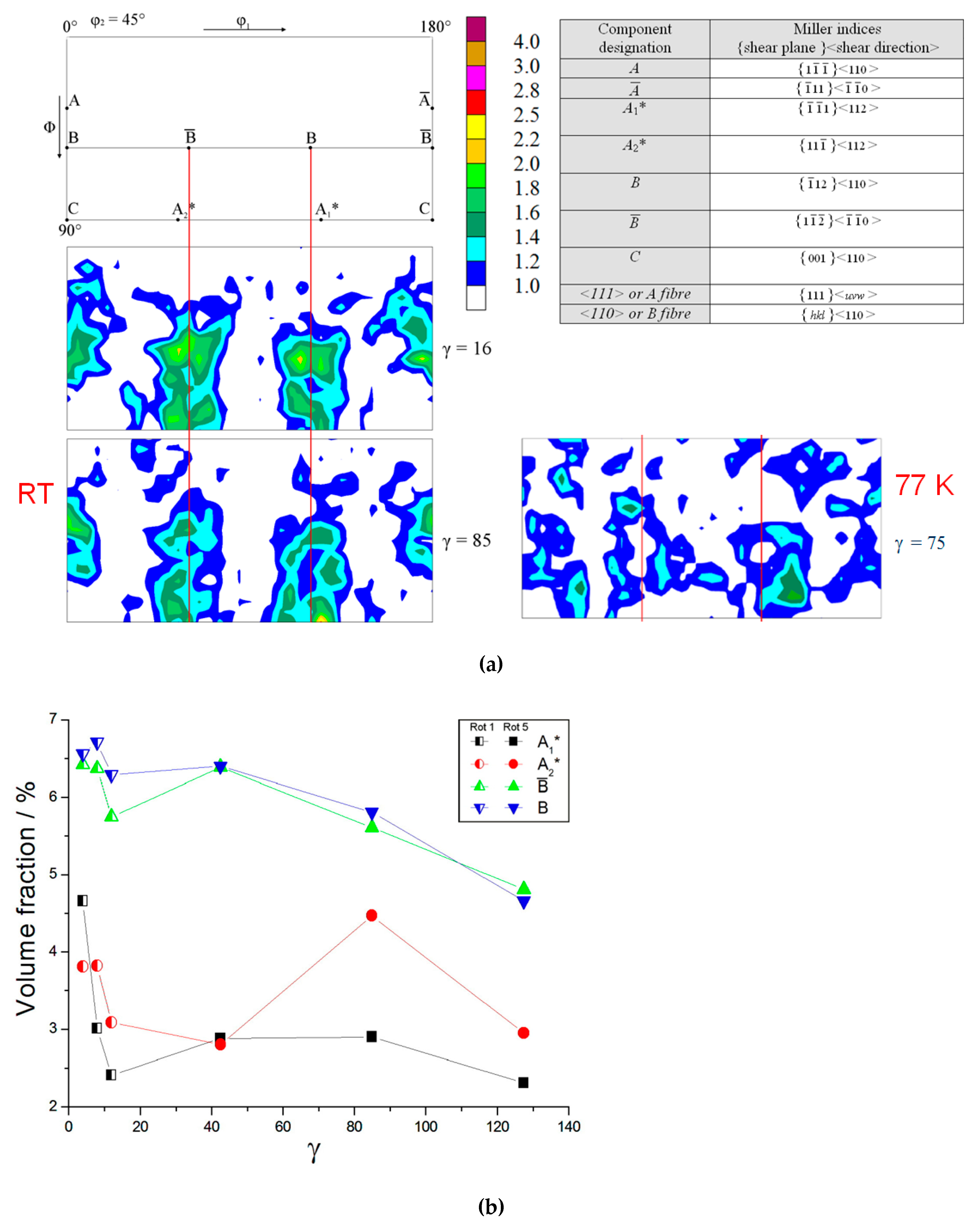

4.2. Texture Formation

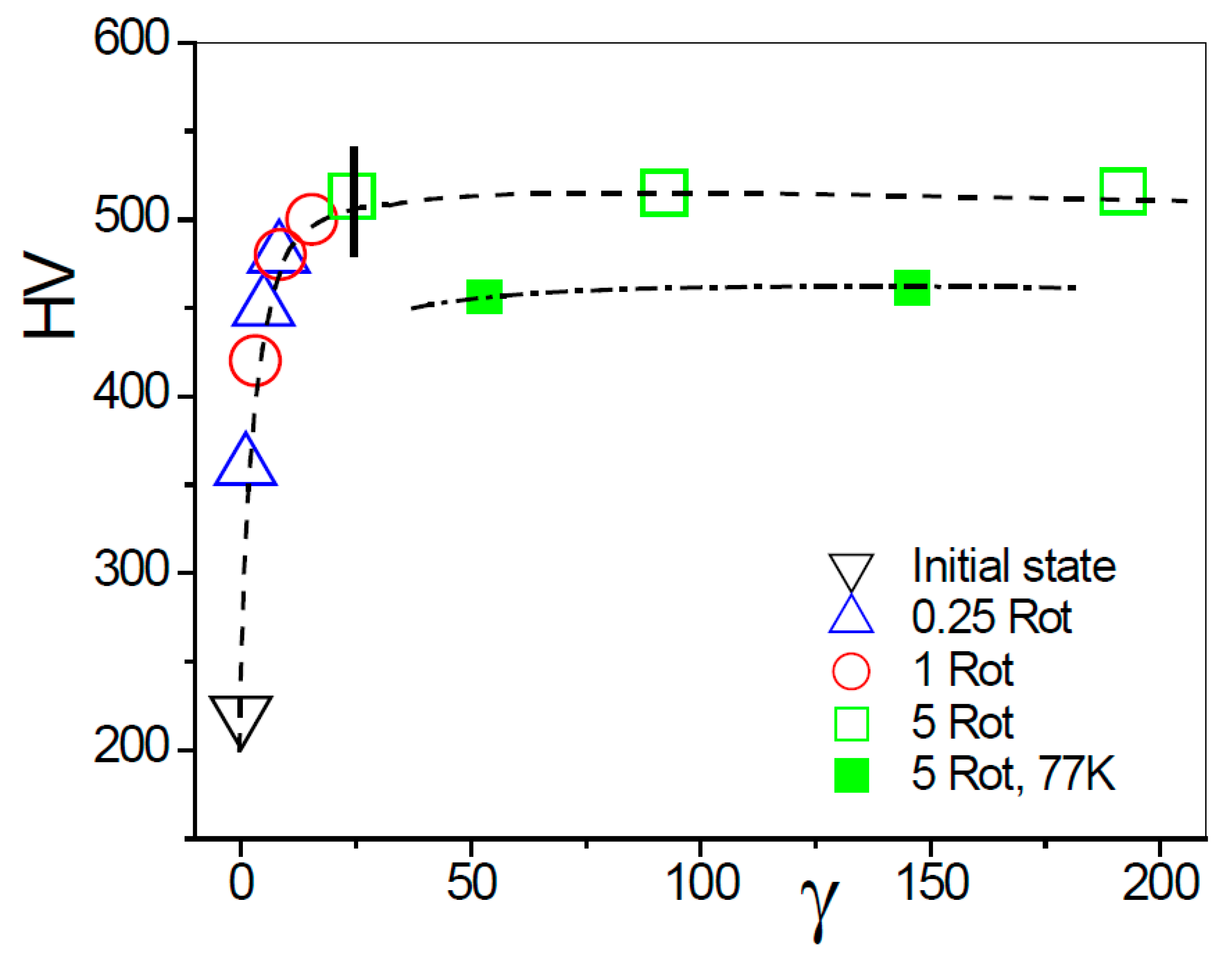

4.3. Strength Development

5. Conclusions

- (1)

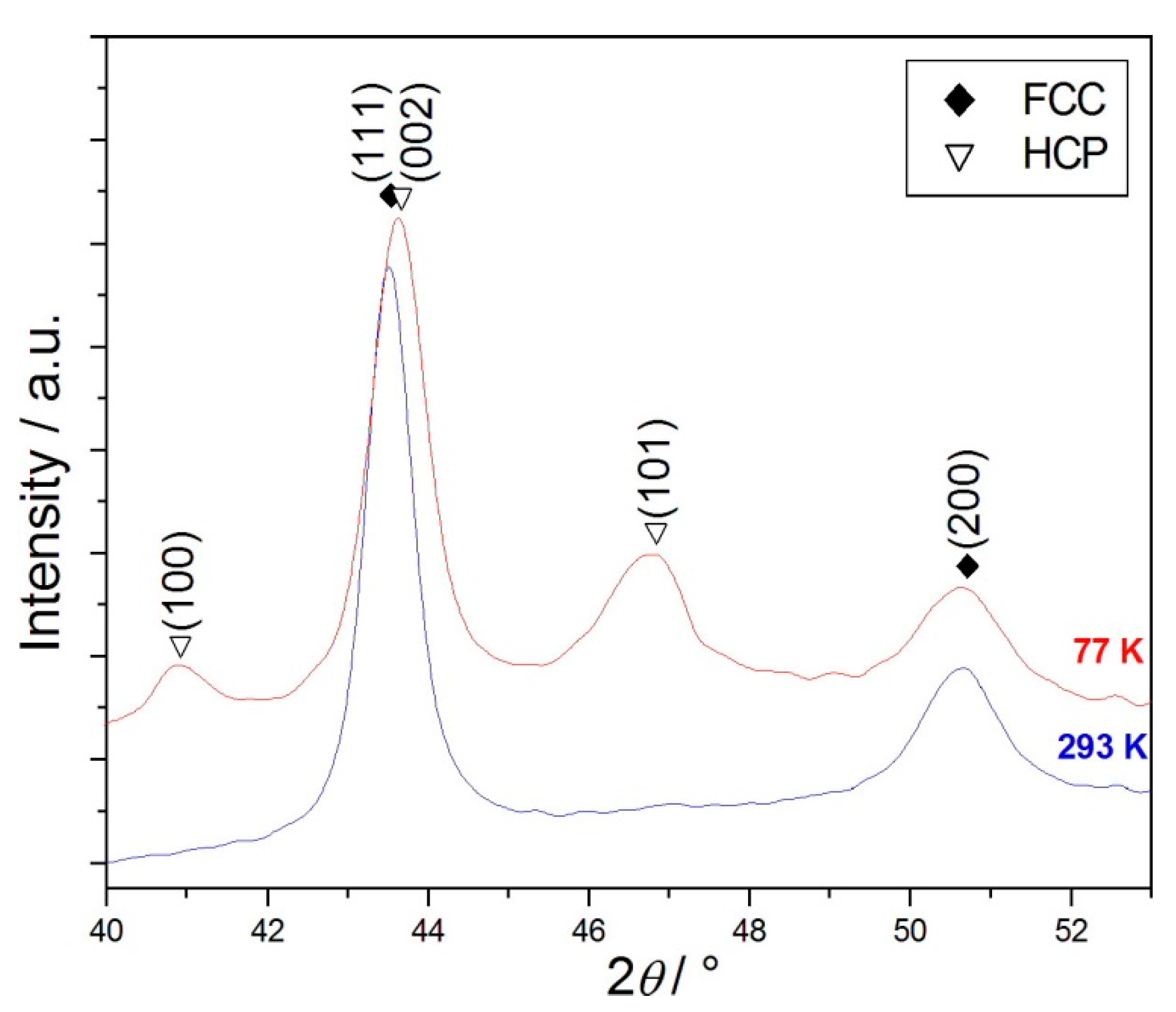

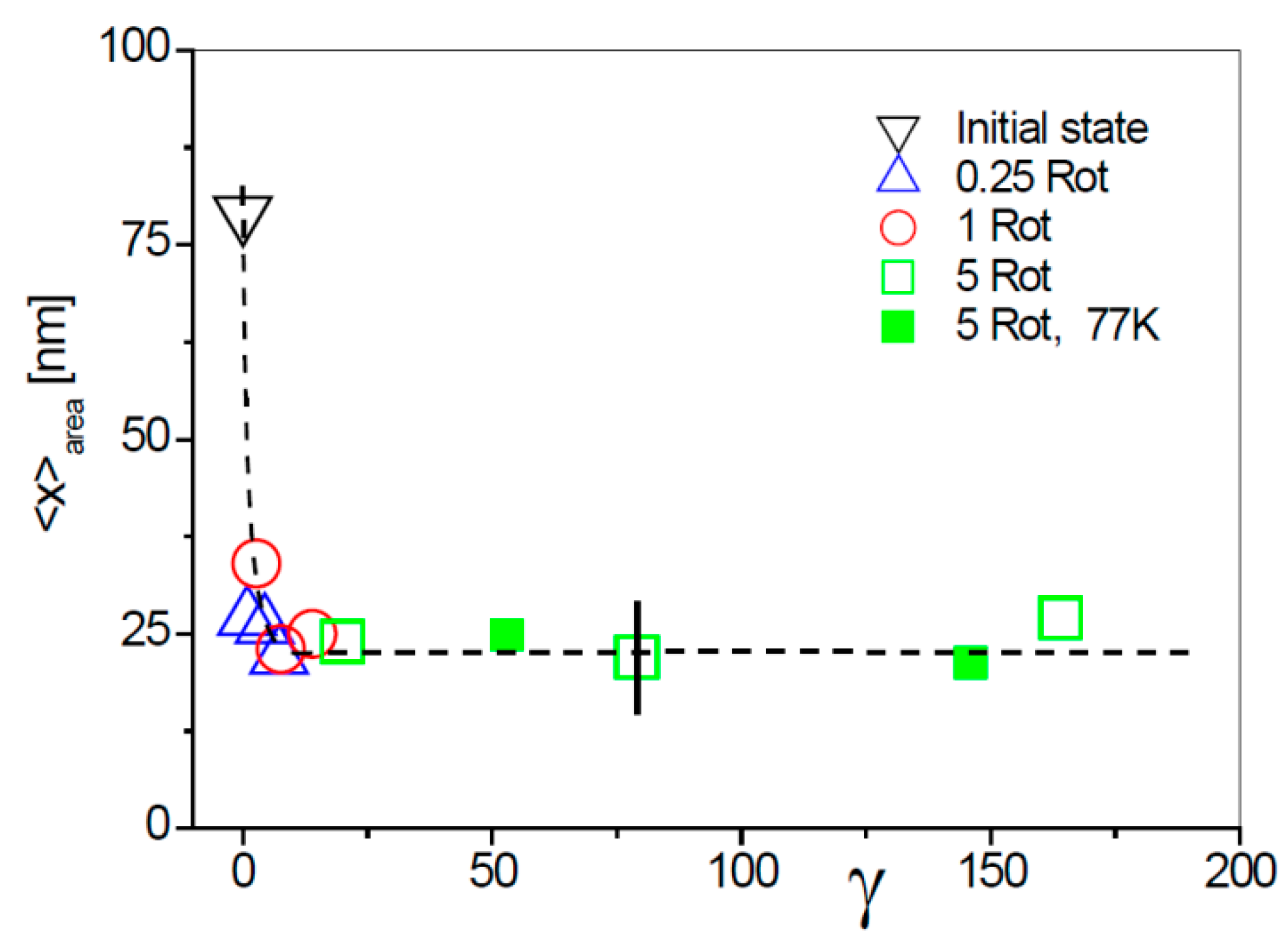

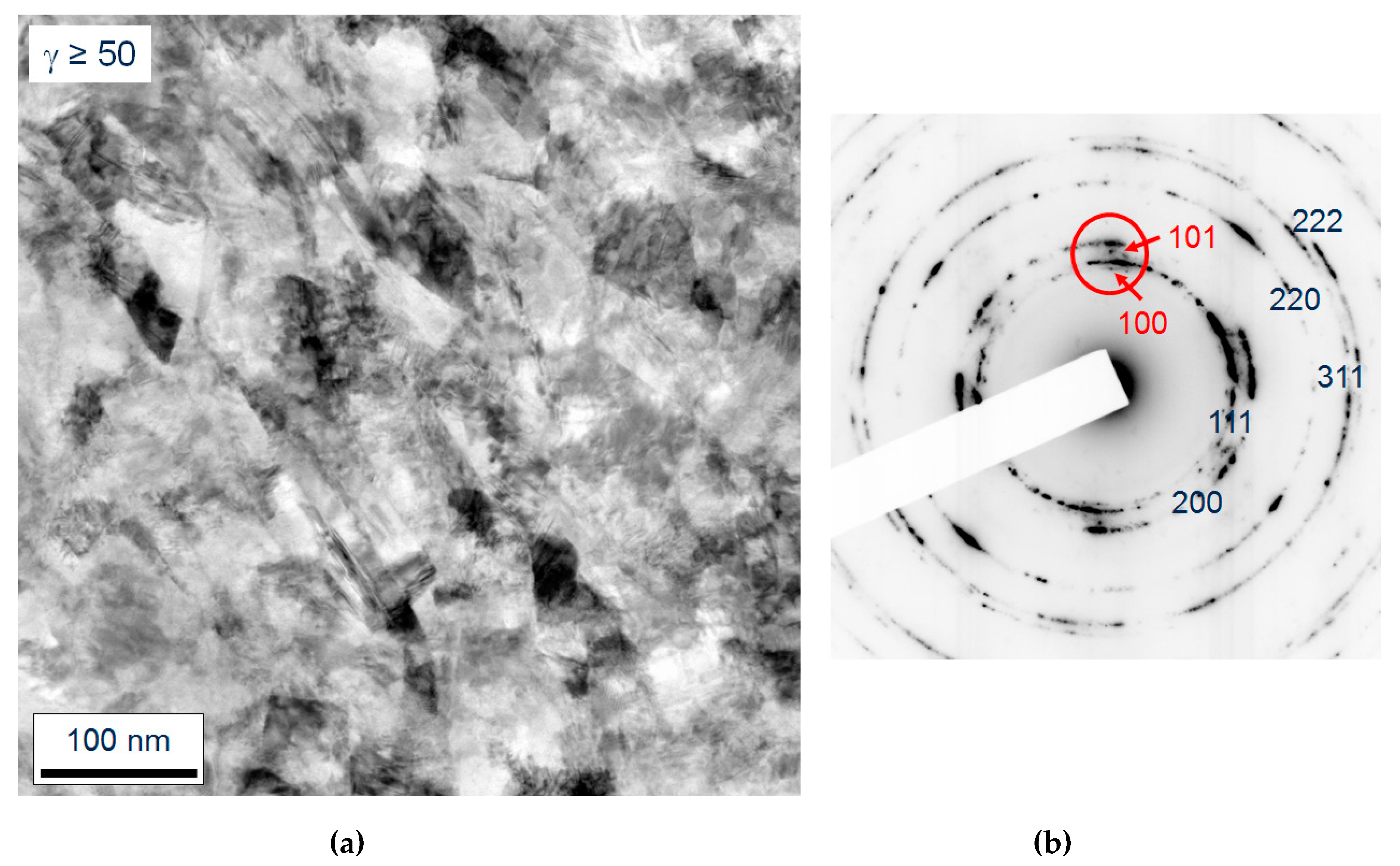

- HPT at RT and LNT leads to strong grain refinement of this HEA. Severe mechanical twinning at RT and martensitic phase transformation from FCC to HCP structure at LNT in addition to dislocation slip may cause this.

- (2)

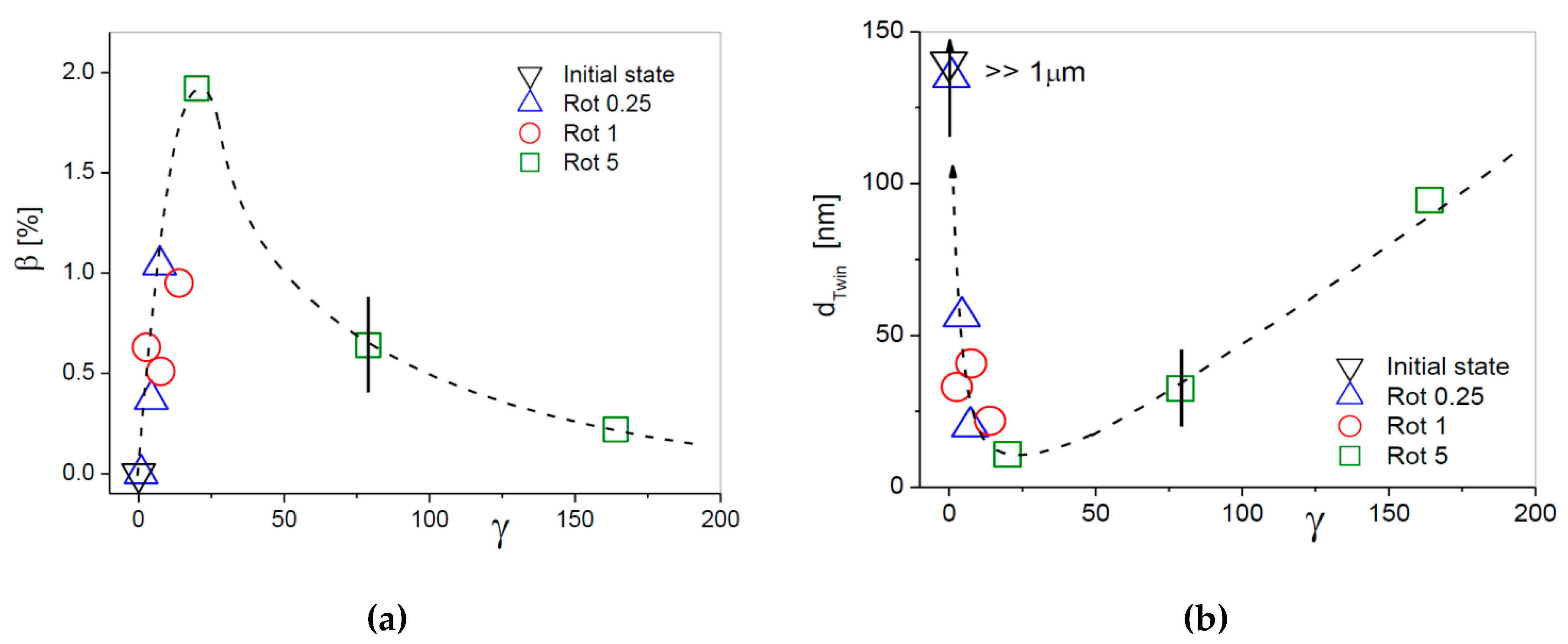

- Correlated with a steady-state grain size in the nano range is a high remnant dislocation density. These dislocations are predominantly screw-type and show a weak dipole character due to a wide dissociation into Shockley partials. HPT at LNT leads to an inhomogeneous microstructure with a lower dislocation density compared to HPT at RT.

- (3)

- The weak texture developed at RT is a dominant brass-type shear texture indicating that the deformation during SPD mainly occurs by partial dislocation slip accompanied by twinning and grain boundary sliding. Due to an inhomogeneous deformation at LNT coupled with phase transformation the texture becomes almost random.

- (4)

- The strength of the nanocrystalline HEA is mainly controlled by dislocation–dislocation interaction. For the material HPT-deformed at LNT with a lower dislocation density there is an additional contribution from HCP lamellae which act as further dislocation barriers.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Notice of Copyright

References

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equi atomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Otto, F.; Yang, Y.; Bei, H.; George, E.P. Relative effects of enthalpy and entropy on the phase stability of equiatomic high-entropy alloys. Acta Mater. 2013, 61, 2628–2638. [Google Scholar] [CrossRef]

- Schuh, B.; Mendez-Martin, F.; Völker, B.; George, E.P.; Clemens, H.; Pippan, R.; Hohenwarter, A. Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCrFeMnNi high-entropy alloy after severe plastic deformation. Acta Mater. 2015, 96, 258–268. [Google Scholar] [CrossRef]

- Otto, F.; Dlouhy, A.; Pradeep, K.G.; Kubenova, M.; Raabe, D.; Eggeler, G.; George, E.P. Decomposition of the single-phase high-entropy alloy CrMnFeCoNi after prolonged anneals at intermediate temperatures. Acta Mater. 2016, 112, 40–52. [Google Scholar] [CrossRef]

- Pickering, E.J.; Munoz-Moreno, R.; Stone, H.J.; Jones, N.G. Precipitation in the equiatomic high-entropy alloy CrMnFeCoNi. Scr. Mater. 2016, 113, 106–109. [Google Scholar] [CrossRef]

- Zhang, F.; Lou, H.; Cheng, B.; Zeng, Z.; Zeng, Q. High-pressure induced phase transitions in high-entropy alloys: A review. Entropy 2019, 21, 239. [Google Scholar] [CrossRef]

- Huang, S.; Li, W.; Lu, S.; Tian, F.; Shen, J.; Holmström, E.; Vitos, L. Temperature dependent stacking fault energy of FeCrCoNiMn high entropy alloy. Scr. Mater. 2015, 108, 44–47. [Google Scholar] [CrossRef]

- Ma, D.; Grabowski, B.; Körmann, F.; Neugebauer, J.; Raabe, D. Ab initio thermodynamics of the CoCrFeMnNi high entropy alloy: Importance of entropy contributions beyond the configurational one. Acta Mater. 2015, 100, 90–97. [Google Scholar] [CrossRef]

- Zhao, S.; Stocks, G.M.; Zhang, Y. Stacking fault energies of face-centered cubic concentrated solid solution alloys. Acta Mater. 2017, 134, 334–345. [Google Scholar] [CrossRef]

- George, E.P.; Curtin, W.A.; Tasan, C.C. High entropy alloys: A focused review of mechanical properties and deformation mechanisms. Acta Mater. 2020, 188, 435–474. [Google Scholar] [CrossRef]

- Sathiaraj, G.D.; Pukenas, A.; Skrotzki, W. Texture formation in face-centered cubic high-entropy alloys. J. Alloy. Compd. 2020, 826, 15183. [Google Scholar] [CrossRef]

- Skrotzki, W.; Pukenas, A.; Joni, B.; Odor, E.; Ungar, T.; Hohenwarter, A.; Pippan, R.; George, E.P. Microstructure and texture evolution during severe plastic deformation of CrMnFeCoNi high-entropy alloy. IOP Conf. Ser. Mater. Sci. Eng. 2017, 194, 012028. [Google Scholar] [CrossRef]

- Pippan, R.; Scheriau, S.; Hohenwarter, A.; Hafok, M. Advantages and limitations of HPT: A review. Mater. Sci. Forum 2008, 584–586, 16–21. [Google Scholar] [CrossRef]

- Ungar, T.; Ott, S.; Sanders, P.G.; Borbely, A.; Weertman, J.R. Dislocations, grain size and planar faults in nanostructured copper determined by high resolution X-ray diffraction and a new procedure of peak profile analysis. Acta Mater. 1998, 46, 3693–3699. [Google Scholar] [CrossRef]

- Ribarik, G.; Joni, B.; Ungar, T. Global optimum of microstructure parameters in the CMWP line-profile-analysis method by combining Marquardt-Levenberg and Monte-Carlo procedures. J. Mater. Sci. Technol. 2019, 35, 1508–1514. [Google Scholar] [CrossRef]

- Multex Manual; Multex 3; Bruker AXS GmbH: Karlsruhe, Germany, 2008.

- Pawlik, K. Determination of the orientation distribution function from pole figures in arbitrarily defined cells. Phys. Stat. Sol. B 1986, 134, 477–483. [Google Scholar] [CrossRef]

- Bunge, H.-J. Zur Darstellung allgemeiner Texturen. Z. Met. 1965, 56, 872–874. [Google Scholar]

- Toth, L.S.; Molinari, A. Tuning a self consistent viscoplastic model by finite element results—I. Modeling. Acta Metall. Mater. 1994, 42, 2453–2458. [Google Scholar] [CrossRef]

- Miao, J.; Slone, C.E.; Smith, T.M.; Niu, C.; Bei, H.; Ghazisaeidi, M.; Pharr, G.M.; Mills, M.J. The evolution of the deformation substructure in a Ni-Co-Cr equiatomic solid solution alloy. Acta Mater. 2017, 132, 35–48. [Google Scholar] [CrossRef]

- Lin, Q.; Liu, J.; An, X.; Wang, H.; Zhang, Y.; Liao, X. Cryogenic-deformation-induced phase transformation in an FeCoCrNi high-entropy alloy. Mater. Res. Lett. 2018, 6, 236–243. [Google Scholar] [CrossRef]

- Podolskiy, A.V.; Shapovalov, Y.O.; Tabachnikova, E.D.; Tortika, A.S.; Tikhonovsky, M.A.; Joni, B.; Odor, E.; Ungar, T.; Maier, S.; Rentenberger, C.; et al. Anomalous evolution of strength and microstructure of high-entropy alloy CoCrFeNiMn after high-pressure torsion at 300 and 77 K. Adv. Eng. Mater. 2020, 22, 1900752. [Google Scholar] [CrossRef]

- Heczel, A.; Kawasaki, M.; Labar, J.L.; Jang, J.; Langdon, T.G.; Gubicza, J. Defect structure and hardness in nanocrystalline CoCrFeMnNi high-entropy alloy processed by high-pressure torsion. J. Alloy. Compd. 2017, 711, 143–154. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Stepanov, N.; Ivanisenko, Y.; Shaysultanov, D.; Yurchenko, N.; Klimova, M.; Salishchev, G. Evolution of microstructure and mechanical properties of a CoCrFeMnNi high-entropy alloy during high-pressure torsion at room and cryogenic temperatures. Metals 2018, 8, 123. [Google Scholar] [CrossRef]

- Okamoto, N.L.; Fujimoto, S.; Kambara, Y.; Kawamura, M.; Chen, Z.M.; Matsunshita, H.; Tanaka, K.; Inui, H.; George, E.P. Size effect, critical resolved shear stress, stacking fault energy, and solid solution strengthening in the CrMnFeCoNi high-entropy alloy. Sci. Rep. 2016, 6, 35836. [Google Scholar] [CrossRef] [PubMed]

- Yeh, J.W. Physical metallurgy of high-entropy alloys. JOM 2015, 67, 2254–2261. [Google Scholar] [CrossRef]

- Wang, Y.B.; Liao, X.Z.; Zhao, Y.H.; Lavernia, E.J.; Ringer, S.P.; Horita, Z.; Langdon, T.G.; Zhu, Y.T. The role of stacking faults and twin boundaries in grain refinement of a Cu-Zn alloy processed by high-pressure torsion. Mater. Sci. Eng. A 2010, 527, 4959–4966. [Google Scholar] [CrossRef]

- Zhao, Y.; Toth, L.S.; Massion, R.; Skrotzki, W. Role of grain boundary sliding in texture evolution for nanoplasticity. Adv. Eng. Mater. 2017, 20, 1–9. [Google Scholar] [CrossRef]

- Toth, L.S.; Skrotzki, W.; Zhao, Y.; Pukenas, A.; Braun, C.; Birringer, R. Revealing grain boundary sliding from textures of a deformed nanocrystalline Pd-Au alloy. Materials 2018, 11, 190. [Google Scholar] [CrossRef]

- Wu, W.; Song, M.; Ni, S.; Wang, J.; Liu, Y.; Liu, B.; Liao, X. Dual mechanisms of grain refinement in a FeCoCrNi high-entropy alloy processed by high-pressure torsion. Sci. Rep. 2017, 7, 46720. [Google Scholar] [CrossRef]

- Edalati, K.; Cubero-Sesin, J.M.; Alhamidi, A.; Mohamed, I.F. Influence of severe plastic deformation at cryogenic temperature on grain refinement and softening of pure metals: Investigation using high-pressure torsion. Mater. Sci. Eng. A 2014, 613, 103–110. [Google Scholar] [CrossRef]

- Moon, J.; Qi, Y.; Tabachnikova, E.; Estrin, Y.; Choi, W.-M.; Joo, S.-H.; Lee, B.-J.; Podolskiy, A.; Tikhonovsky, M.; Kim, H.S. Microstructure and mechanical properties of high-entropy alloy Co20Cr26Fe20Mn20Ni14 processed by high-pressure torsion at 77 K and 300 K. Sci. Rep. 2018, 8, 11074. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Wu, Y.; Lou, H.B.; Zeng, Z.D.; Prakapenka, V.B.; Greenberg, E.; Yan, J.Y.; Okasinski, J.S.; Liu, X.J.; Liu, Y.; et al. Polymorphism in a high-entropy alloy. Nat. Commun. 2017, 8, 15687. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Lou, H.; Chen, S.; Chen, X.; Zeng, Z.; Yan, J.; Zhao, W.; Wu, Y.; Lu, Z.; Zeng, Q. Effects of non-hydrostaticity and grain size on pressure-induced phase transformation of the CoCrFeMnNi high-entropy alloy. J. Appl. Phys. 2018, 124, 115901. [Google Scholar] [CrossRef]

- Von Bergen, N.; Boehler, R. Effect of non-hydrostaticity on the—Transition in iron. High Press. Res. 1990, 6, 133–140. [Google Scholar]

- Yang, X.-S.; Sun, S.; Ruan, H.-H.; Shi, S.-Q.; Zhang, T.Y. Shear and shuffling accomplishing polymorphic fcc γ→hcp ε→bct α martensitic phase transformation. Acta Mater. 2017, 136, 347–354. [Google Scholar] [CrossRef]

- Wu, S.W.; Wang, G.; Yi, J.; Jia, Y.D.; Hussain, I.; Zhai, Q.J.; Liaw, P.K. Strong grain-size effect on deformation twinning of an Al0.1CoCrFeNi high-entropy alloy. Mater. Res. Lett. 2017, 5, 276–283. [Google Scholar] [CrossRef]

- Skrotzki, W.; Eschke, A.; Joni, B.; Ungar, T.; Toth, L.S.; Ivanisenko, Y.; Kurmanaeva, L. New experimental insight into the mechanisms of nanoplasticity. Acta Mater. 2013, 61, 7271–7284. [Google Scholar] [CrossRef]

- Li, L.; Ungar, T.; Toth, L.S.; Skrotzki, W.; Wang, J.D.; Ren, J.; Choo, H.; Fogarassy, Z.; Zhou, X.Z.; Liaw, P.K. Shear-coupled grain growth and texture development in a nanocrystalline Ni-Fe alloy during cold rolling. Metall. Mat. Trans. A 2016, 47, 6632–6644. [Google Scholar] [CrossRef]

- Podolskiy, A.V.; Schafler, E.; Tabachnikova, E.D.; Tikhonovsky, M.A.; Zehetbauer, M.J. Thermally activated deformation of nanocrystalline and coarse grained CoCrFeNiMn high entropy alloy in the temperature range 4.2–350 K. Low Temp. Phys. 2018, 44, 1245–1253. [Google Scholar] [CrossRef]

- Scheriau, S.; Zhang, Z.; Kleber, S.; Pippan, R. Deformation mechanisms of modified 316L austenitic steel subjected to high pressure torsion. Mater. Sci. Eng. A 2011, 528, 2776–2786. [Google Scholar] [CrossRef]

- Chen, S.; Oh, H.S.; Gludovatz, B.; Kim, S.J.; Park, E.S.; Zhang, Z.; Ritchie, R.O.; Yu, Q. Real-time observations of TRIP-induced ultrahigh strain hardening in a dual-phase CrMnFeCoNi high-entropy alloy. Nat. Commun. 2020, 11, 826. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off. Nature 2016, 534, 227–231. [Google Scholar] [CrossRef] [PubMed]

- Asaro, R.S.; Suresh, S. Mechanistic models for the activation volume and rate sensitivity in metals with nanocrystalline grains and nano-scale twins. Acta Mater. 2005, 53, 3369–3382. [Google Scholar] [CrossRef]

- Seeger, A. Handbuch Der Physik; Springer: Berlin/Heidelberg, Germany, 1958; Volume VII/2. [Google Scholar]

- Patriarca, L.; Ojha, A.; Sehitoglu, H.; Chumlyakov, Y.I. Slip nucleation in single crystal FeNiCoCrMn high entropy alloy. Scr. Mater. 2016, 112, 54–57. [Google Scholar] [CrossRef]

- Renk, O.; Hohenwarter, A.; Eder, K.; Kormout, K.S.; Cernay, J.M.; Pippan, R. Increasing the strength of nanocrystalline steels by annealing: Is segregation necessary? Scr. Mater. 2015, 95, 27–30. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skrotzki, W.; Pukenas, A.; Odor, E.; Joni, B.; Ungar, T.; Völker, B.; Hohenwarter, A.; Pippan, R.; George, E.P. Microstructure, Texture, and Strength Development during High-Pressure Torsion of CrMnFeCoNi High-Entropy Alloy. Crystals 2020, 10, 336. https://doi.org/10.3390/cryst10040336

Skrotzki W, Pukenas A, Odor E, Joni B, Ungar T, Völker B, Hohenwarter A, Pippan R, George EP. Microstructure, Texture, and Strength Development during High-Pressure Torsion of CrMnFeCoNi High-Entropy Alloy. Crystals. 2020; 10(4):336. https://doi.org/10.3390/cryst10040336

Chicago/Turabian StyleSkrotzki, Werner, Aurimas Pukenas, Eva Odor, Bertalan Joni, Tamas Ungar, Bernhard Völker, Anton Hohenwarter, Reinhard Pippan, and Easo P. George. 2020. "Microstructure, Texture, and Strength Development during High-Pressure Torsion of CrMnFeCoNi High-Entropy Alloy" Crystals 10, no. 4: 336. https://doi.org/10.3390/cryst10040336

APA StyleSkrotzki, W., Pukenas, A., Odor, E., Joni, B., Ungar, T., Völker, B., Hohenwarter, A., Pippan, R., & George, E. P. (2020). Microstructure, Texture, and Strength Development during High-Pressure Torsion of CrMnFeCoNi High-Entropy Alloy. Crystals, 10(4), 336. https://doi.org/10.3390/cryst10040336