Accurate Estimation of Brittle Fracture Toughness Deterioration in Steel Structures Subjected to Large Complicated Prestrains

Abstract

:1. Introduction

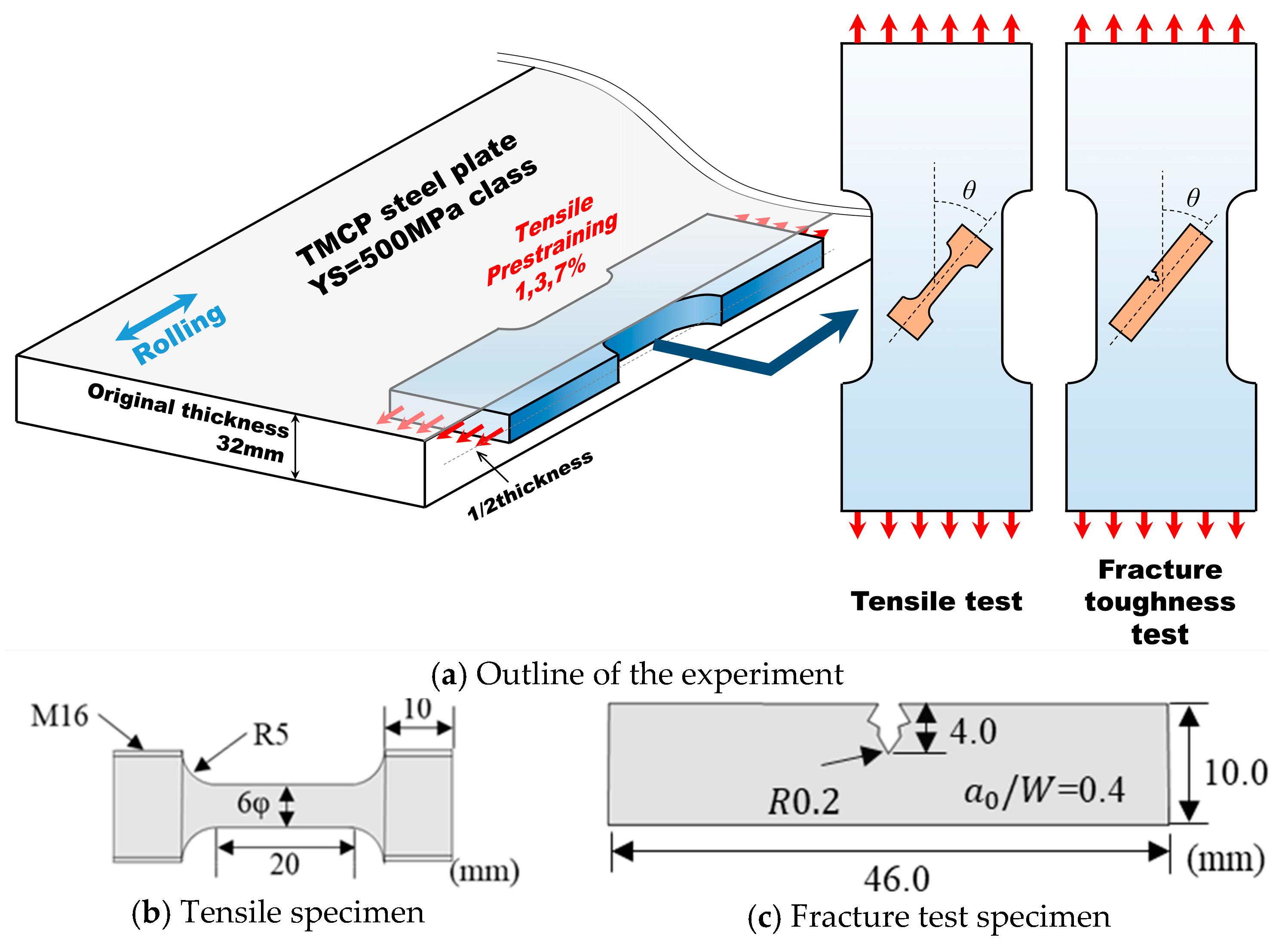

2. Experiment

2.1. Preparation of Testing and Prestraining

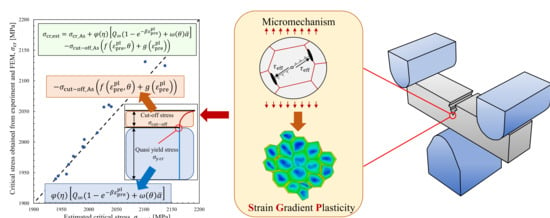

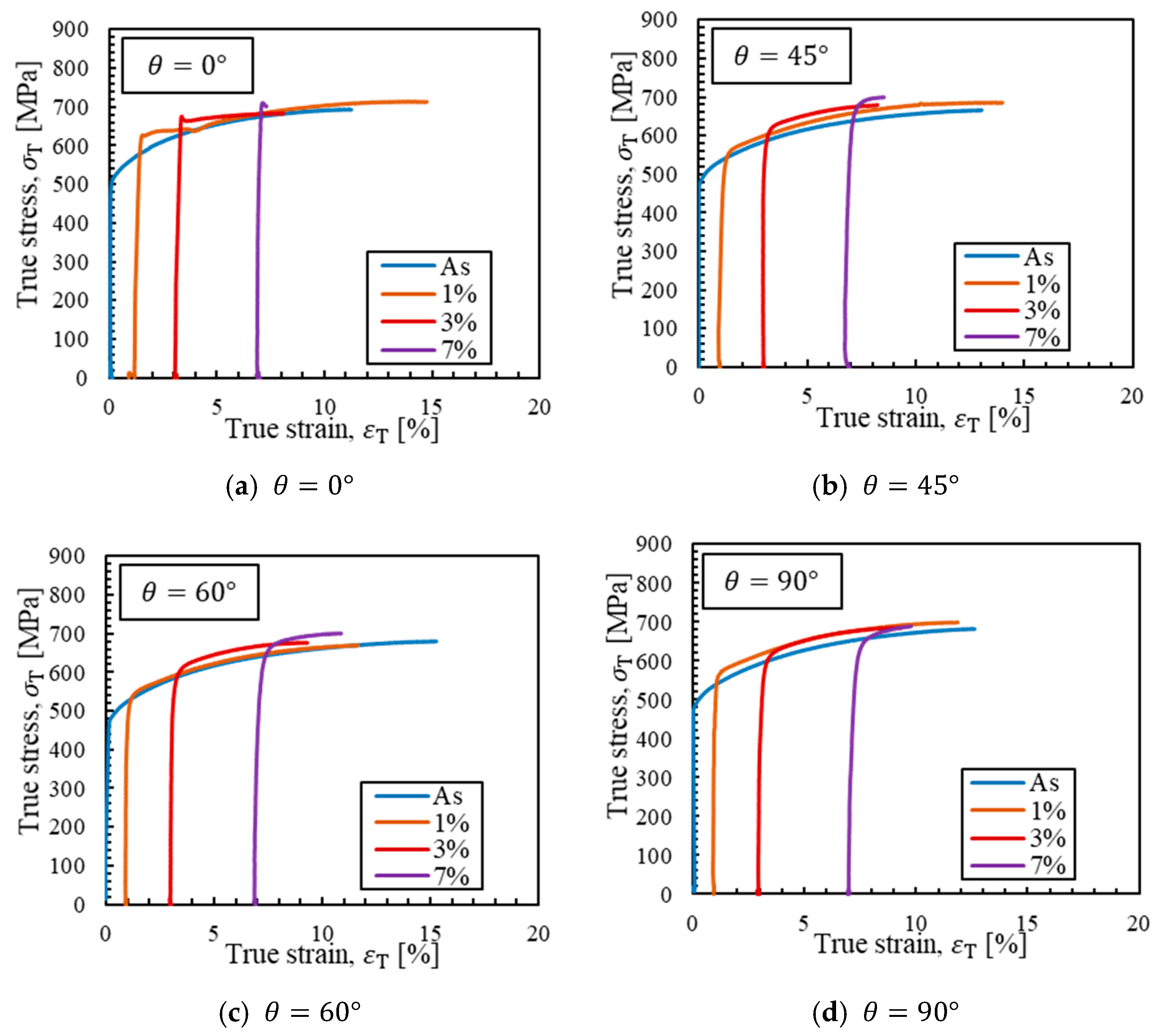

2.2. Tensile Tests

2.3. Fracture Test

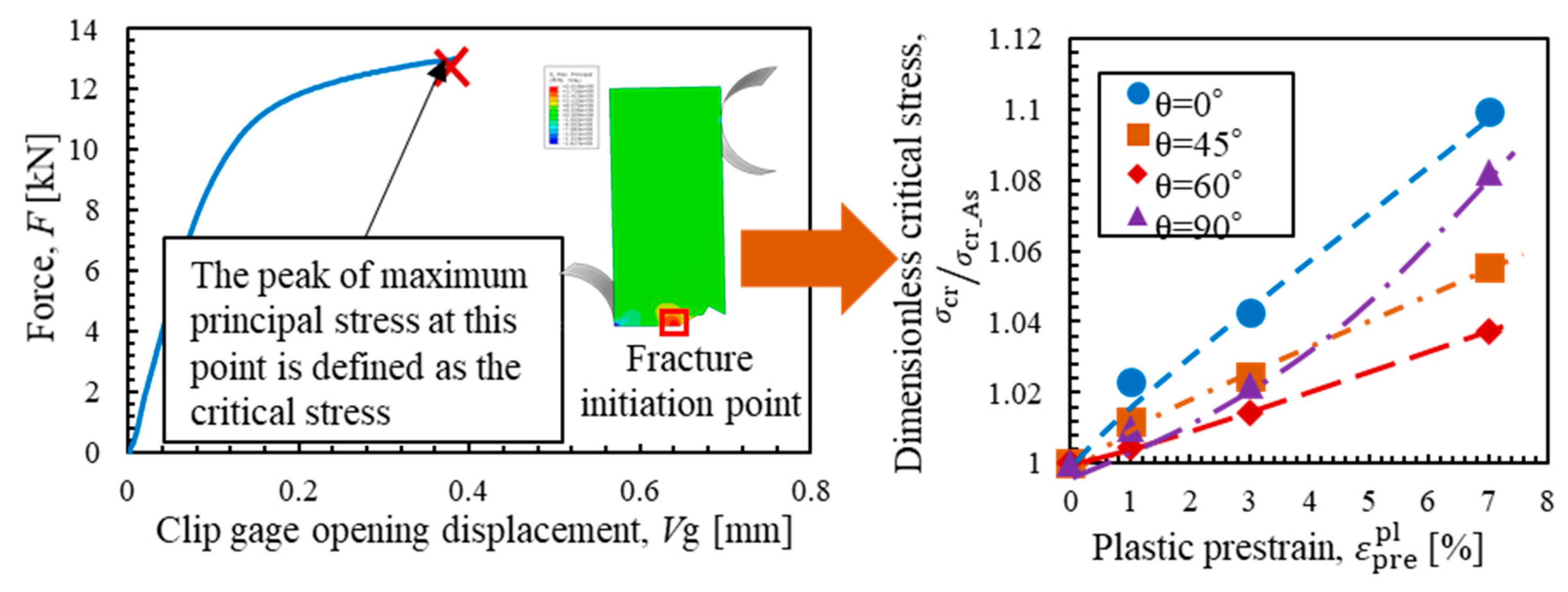

3. Calculation of Critical Stress

3.1. Simulation of the Prestraining Process

3.2. Simulation of the Fracture Test

4. Mechanism of Change in Critical Stress

4.1. Analysis of the Macroscopic Model

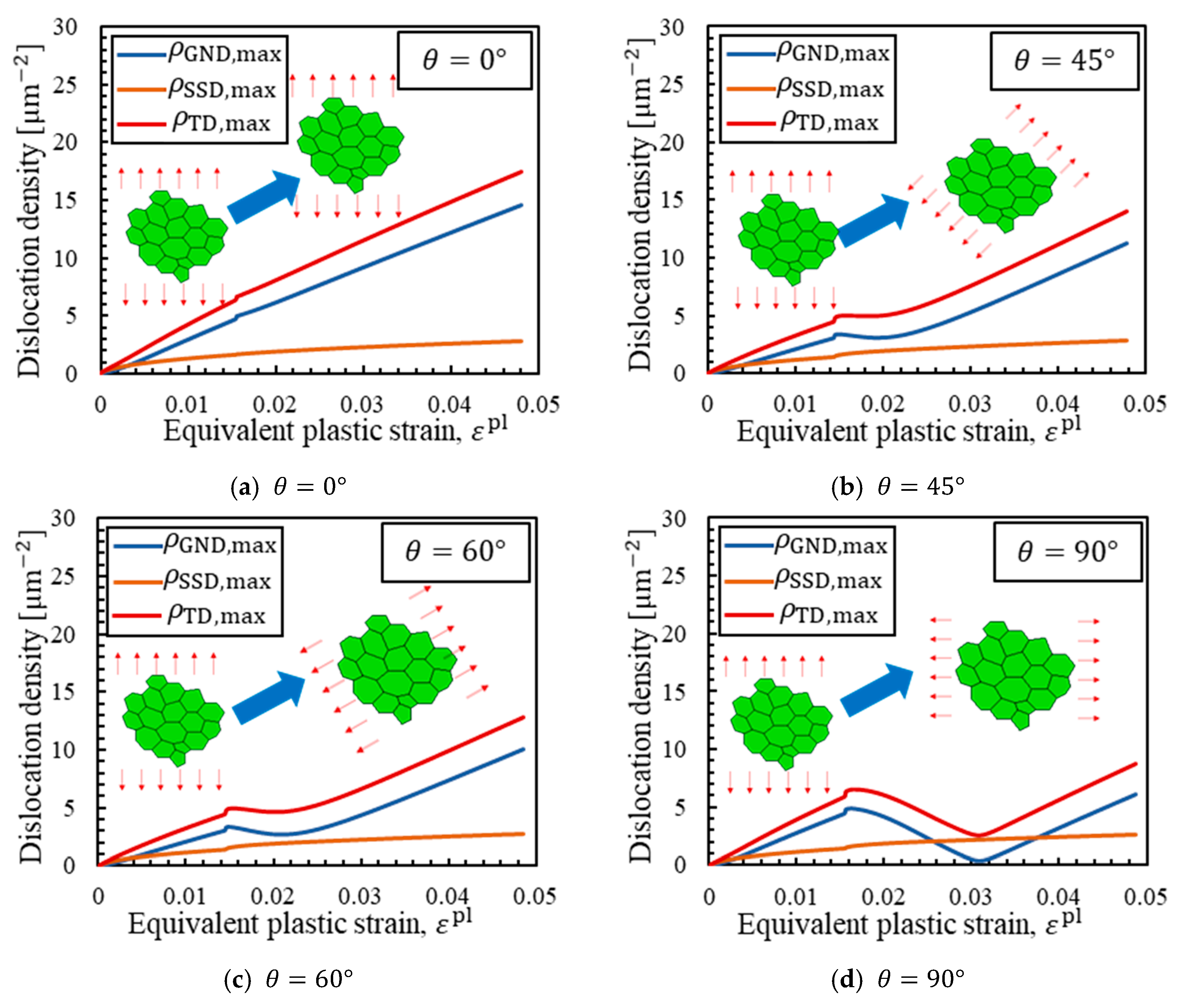

4.2. Analysis of the Crystal Plasticity Model

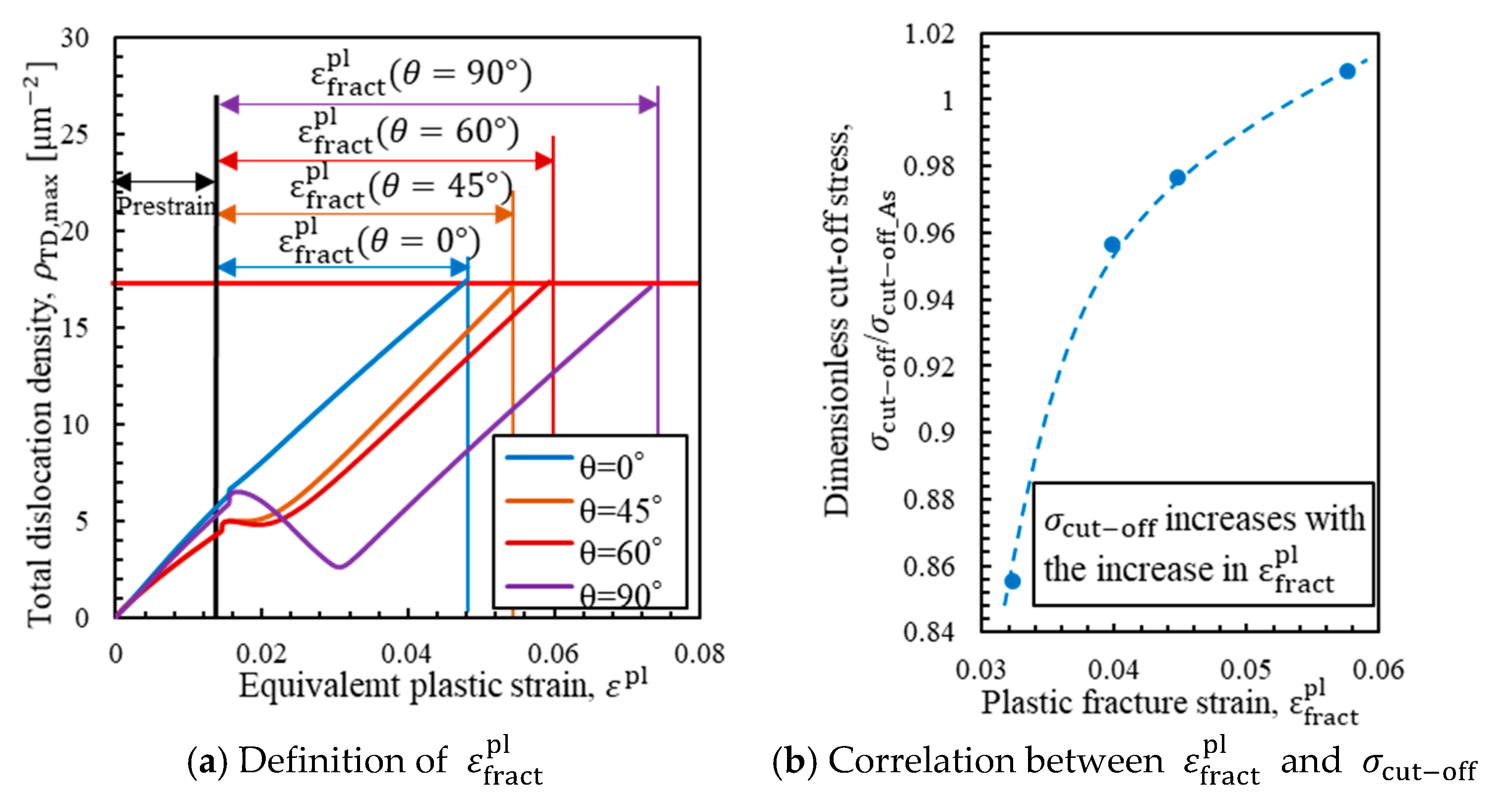

5. Formulation of Critical Stress Change from Various Prestrains

6. Conclusions

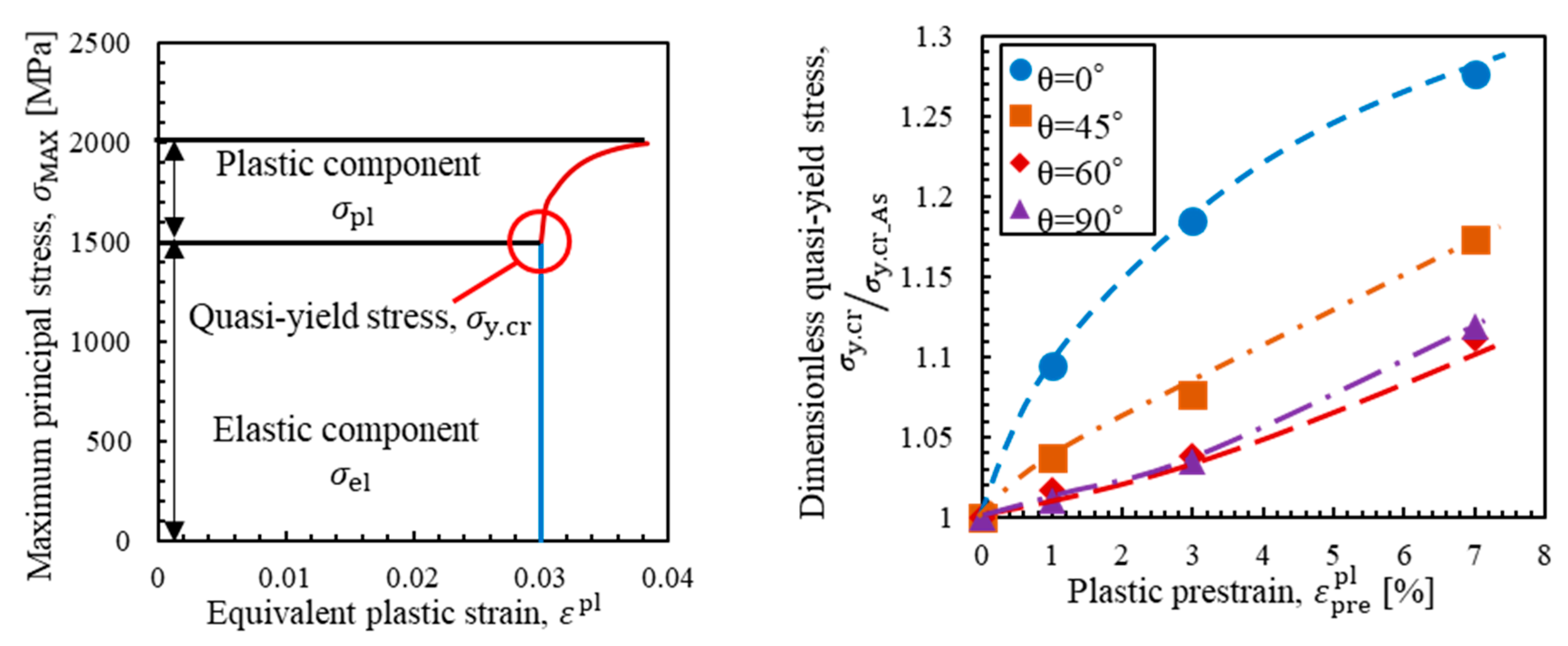

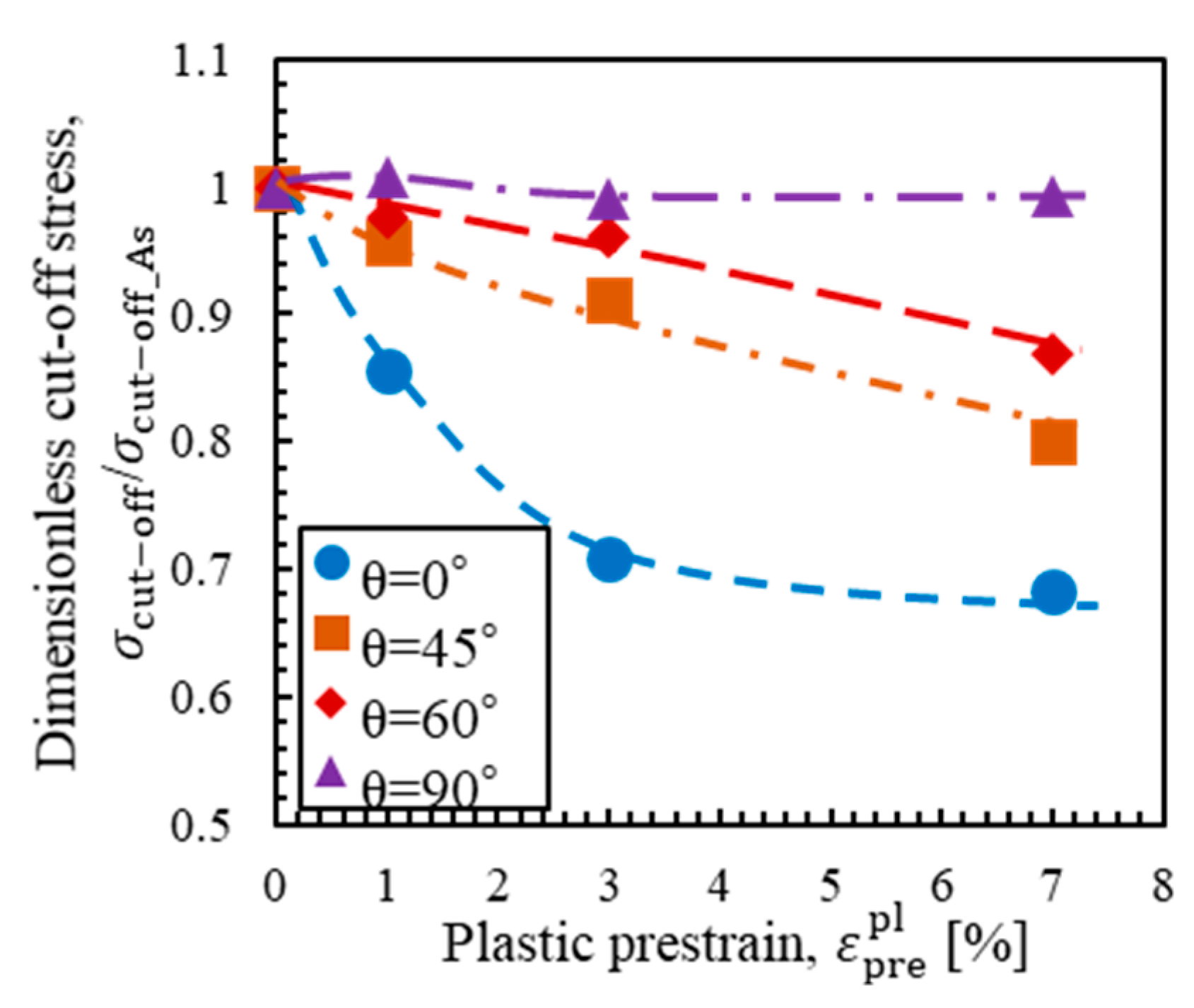

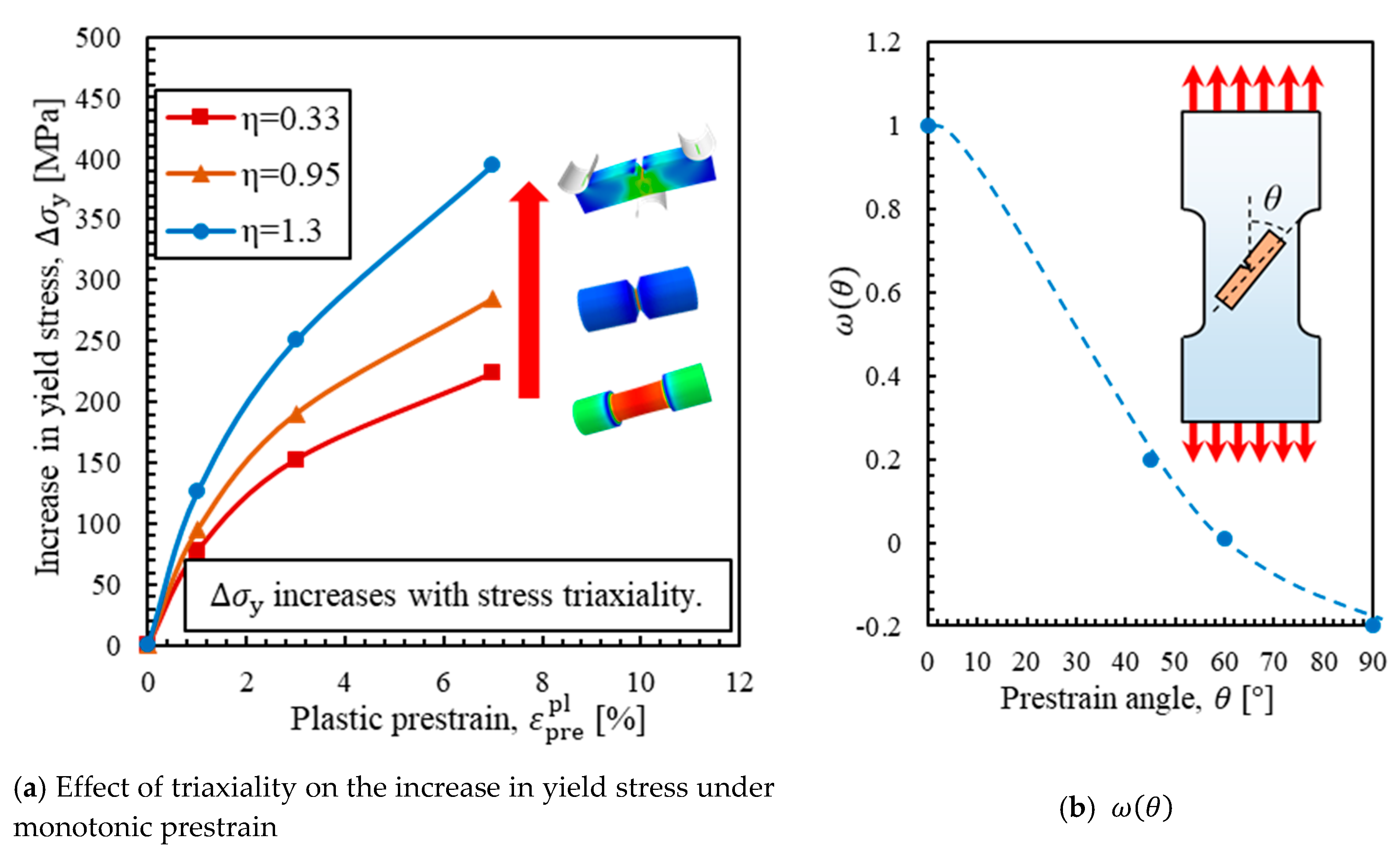

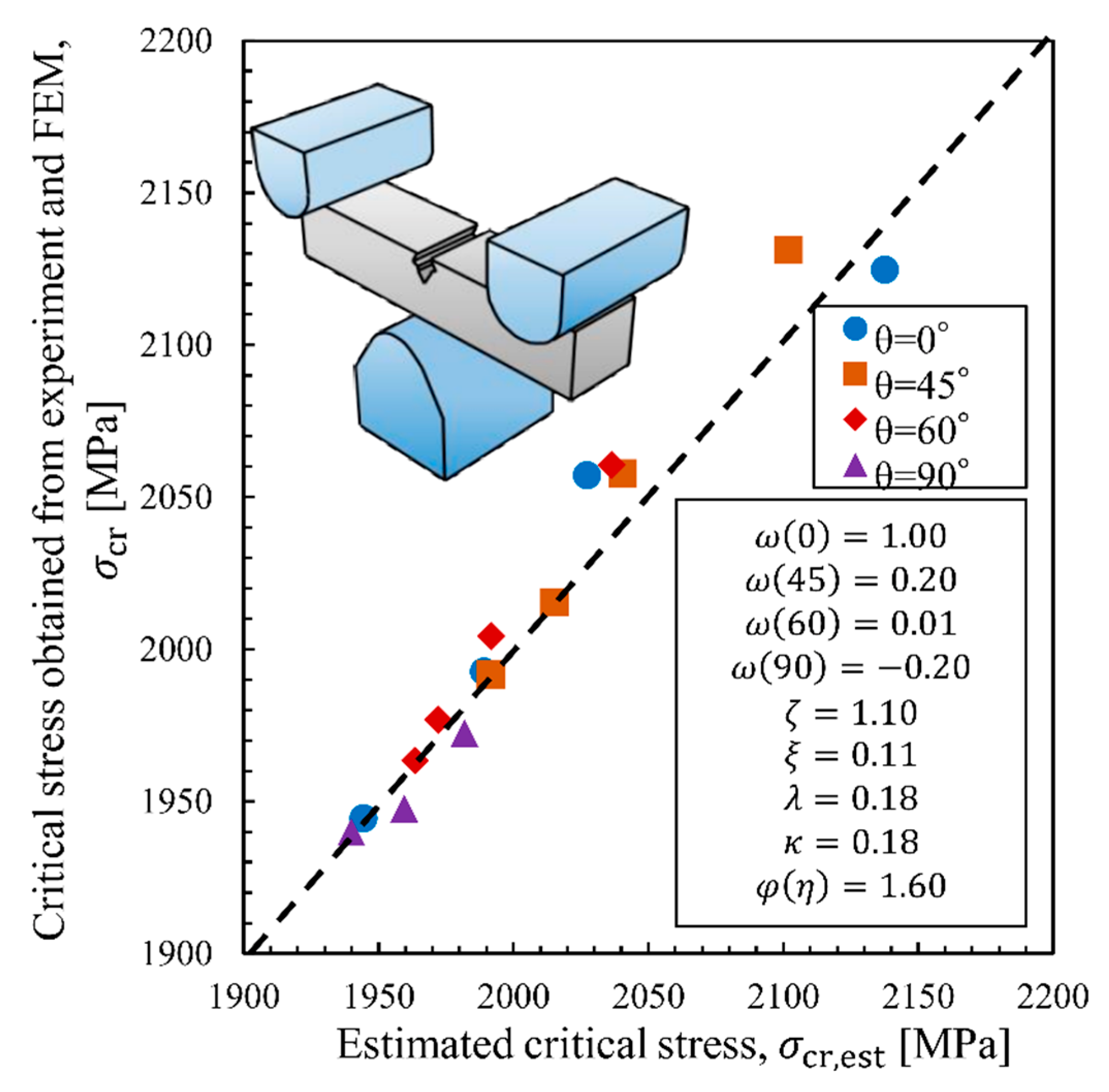

- It was verified that the critical stress increased due to the application of prestrain at any angle, and the ratio of this increase varied strongly with respect to the prestrain direction. This finding is different from Griffith’s equation or Smith’s model, in which the critical stress is determined only by the length of the microcrack or the thickness of the carbide particles and the remote stress.

- It was shown that the increase in critical stress can be separately explained by the increase in yield stress and the decrease in . Additionally, the decrease in represented the effect of embrittlement and strongly depended on the way dislocations were piled up. Using analysis based on the SGP theory, the change in was shown to be affected by piled-up dislocations that moved in the opposite direction during load reversal.

- The change in critical stress can be formulated based on the micromechanisms. The critical stress was calculated by the triaxiality of the fracture test and the amount and direction of prestrain. It was shown that critical stress can be estimated with high accuracy by giving appropriate parameters.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Griffith, A.A. The phenomena of rupture and flow in solid. Philos. Trans. Ser. A 1920, 221, 163–198. [Google Scholar]

- Inglis, C.E. Stresses in a Plate Due to the Presence of Cracks and Sharp Corners. Trans. Inst. Nav. Archit. 1913, 55, 219–241. [Google Scholar]

- Stroh, A. A theory of the fracture of metals. Adv. Phys. 1957, 6, 418–465. [Google Scholar] [CrossRef]

- Smith, E. The nucleation and growth of cleavage microcracks in mild steel. Phys. Basis Yield Fract. Conf. Proc. 1966, 1966, 36–46. [Google Scholar]

- Hall, E.O. The deformation and aging of mild steel. Proc. Phys. Soc. Sect. B 1951, 64, 747–753. [Google Scholar] [CrossRef]

- Petch, N.J. The Cleavage Strength of Polycrystals. J. Iron Steel Inst. 1953, 174, 25–28. [Google Scholar]

- Cottrell, A.H. Theory of brittle fracture in steel and similar metals. Trans. Metall. Soc. AIME 1959, 212, 192–201. [Google Scholar]

- Epstein, B. Statistical approach to brittle fracture. J. Appl. Phys. 1948, 19, 140–147. [Google Scholar] [CrossRef]

- Beremin, F.M. A local criterion for cleavage fracture of a nuclear pressure vessel steel. Metall. Trans. A 1983, 14, 2277–2287. [Google Scholar] [CrossRef]

- Bordet, S.R.; Karstensen, A.D.; Knowles, D.M.; Wiesner, C.S. A new statistical local criterion for cleavage fracture in steel. Part I: Model presentation. Eng. Fract. Mech. 2005, 72, 435–452. [Google Scholar] [CrossRef]

- Bordet, S.; Karstensen, A.; Knowles, D.; Wiesner, C. A new statistical local criterion for cleavage fracture in steel. Part II: Application to an offshore structural steel. Eng. Fract. Mech. 2005, 72, 453–474. [Google Scholar] [CrossRef]

- Lei, W.-S. A cumulative failure probability model for cleavage fracture in ferritic steels. Mech. Mater. 2016, 93, 184–198. [Google Scholar]

- Lei, W.-S. A discussion of “An engineering methodology for constraint corrections of elastic–plastic fracture toughness—Part II: Effects of specimen geometry and plastic strain on cleavage fracture predictions” by C. Ruggieri, R.G. Savioli, R.H. Dodds [Eng. Fract. Mech. 146 (2015) 185–209]. Eng. Fract. Mech. 2017, 178, 527–534. [Google Scholar] [CrossRef]

- McMahon, C.; Cohen, M. Initiation of cleavage in polycrystalline iron. Acta Met. 1965, 13, 591–604. [Google Scholar] [CrossRef]

- Gurland, J. Observations on the fracture of cementite particles in a spheroidized 1.05% c steel deformed at room temperature. Acta Met. 1972, 20, 735–741. [Google Scholar]

- Sukedai, E.; Hid, M. Effect of Tensile Pestrain on Ductile-Brittle Transition Temperture of Low Carbon Steel. Mater. Sci. Monogr. 1982, 15, 112–118. [Google Scholar]

- Miki, C.; Sasaki, E.; Kyuba, H.; Takenoi, I. Deterioration of Fracture Toughness of Steel by Effect of Tensile and Compressive Prestrain. J. JSCE 2000, 640, 165–175. [Google Scholar]

- Kosuge, H.; Kawabata, T.; Okita, T.; Murayama, H.; Takagi, S. Establishment of damage estimation rules for brittle fracture after cyclic plastic prestrain in steel. Mater. Des. 2020, 185, 108222. [Google Scholar] [CrossRef]

- Yoshinari, H.; Enami, K.; Koseki, T.; Shimanuki, H.; Aihara, S. Ductile and brittle fracture initiation behavior for compressively prestrained steel. J. Soc. Nav. Arch. Jpn. 2001, 2001, 559–567. [Google Scholar] [CrossRef]

- Bordet, S.R.; Tanguy, B.; Bugat, S.; Moinereau, D.; Pineau, A. Cleavage Fracture Micromechanisms Related to WPS Effect in RPV Steel. Fract. Nano Eng. Mater. Struct. 2008, 16, 835–836. [Google Scholar]

- Tagawa, T.; Itoh, A.; Miyata, T. Ouantitative prediction of embrittlement due to pre-strain for low carbon steels. Q. J. Jpn. Weld. Soc. 1996, 2, 429–434. [Google Scholar] [CrossRef]

- Nishioka, K.; Ichikawa, K. Progress in thermomechanical control of steel plates and their commercialization. Sci. Technol. Adv. Mater. 2012, 13, 023001. [Google Scholar] [CrossRef] [PubMed]

- International Organization for Standardization. Petroleum and Natural Gas Industries—Steel Pipe for Pipeline Transportation Systems; ISO 3183:2019; ISO: Geneva, Switzerland, 2019. [Google Scholar]

- The American Petroleum Institute (API). Steel Plates Produced by Thermo Mechanically Controlled Processing for Offshore Structures. In API Specification 2W, 6th ed.; API: Washington, DC, USA, 2019. [Google Scholar]

- ASTM International. Standard Specification for Steel Plates for Pressure Vessels, Produced by Thermo-Mechanical Control Process (TMCP); ASTM A841/A841M-17; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- International Association of Classification Societies. Normal and Higher Strength Hull Structural Steels; IACS W11, Rev.9; IACS: London, UK, 2017. [Google Scholar]

- The Japanese Iron and Steel Federation (JISF). TMCP Steel for Building (TMCP325, TMCP355); MDCR 0016-2016; JISF: Tokyo, Japan, 2016. [Google Scholar]

- The Japanese Iron and Steel Federation. Rolled Steel with 500N/mm2 Yield Strangth and 700N/mm2 Yield Strength for Welded Structure; MDCR 0014-2004; JISF: Tokyo, Japan, 2005. [Google Scholar]

- International Organization for Standardization. Metallic Materials—Unified Method of Test for the Determination of Quasistatic Fracture Toughness; ISO12135:2016; ISO: Geneva, Switzerland, 2016. [Google Scholar]

- Kawabata, T.; Tagawa, T.; Sakimoto, T.; Kayamori, Y.; Ohata, M.; Yamashita, Y.; Tamura, E.-I.; Yoshinari, H.; Aihara, S.; Minami, F.; et al. Proposal for a new CTOD calculation formula. Eng. Fract. Mech. 2016, 159, 16–34. [Google Scholar] [CrossRef]

- International Organization for Standardization. Metallic Materials—Method of Test for the Determination of Quasistatic Fracture Toughness of Welds; ISO15653:2018; ISO: Geneva, Switzerland, 2018. [Google Scholar]

- Chaboche, J.L. Constitutive equations for cyclic plasticity and cyclic viscoplasticity. Int. J. Plast. 1989, 5, 247–302. [Google Scholar] [CrossRef]

- Lemaitre, J.; Chaboche, J.L. Mechanics of Solid Materials; Cambridge University Press: Cambridge, UK, 1994; 584p, ISBN 0521477581/9780521477581. [Google Scholar]

- Abaqus, version 2018; Dassault Systèmes®: Vélizy-Villacoublay, France, 2018.

- Ashby, M.F. The deformation of plastically non-homogeneous materials. Philos. Mag. 1970, 21, 399–424. [Google Scholar] [CrossRef]

- Fleck, N.; Hutchinson, J. A phenomenological theory for strain gradient effects in plasticity. J. Mech. Phys. Solids 1993, 41, 1825–1857. [Google Scholar] [CrossRef]

- Fleck, N.; Muller, G.; Ashby, M.; Hutchinson, J. Strain gradient plasticity: Theory and experiment. Acta Met. Mater. 1994, 42, 475–487. [Google Scholar] [CrossRef]

- Fleck, N.A.; Hutchinson, J.W. A reformulation of strain gradient plasticity. J. Mech. Phys. Solids 2001, 49, 2245–2271. [Google Scholar] [CrossRef] [Green Version]

- Gudmundson, P. A unified treatment of strain gradient plasticity. J. Mech. Phys. Solids 2004, 52, 1379–1406. [Google Scholar] [CrossRef]

- Martínez-Pañeda, E.; Betegón, C. Modeling damage and fracture within strain-gradient plasticity. Int. J. Solids Struct. 2015, 59, 208–215. [Google Scholar] [CrossRef]

- Kitade, A.; Kawabata, T.; Kimura, S.; Takatani, H.; Kagehira, K.; Mitsuzumi, T. Clarification of micromechanism on Brittle Fracture Initiation Condition of TMCP Steel with MA as the trigger point. Procedia Struct. Integr. 2018, 13, 1845–1854. [Google Scholar] [CrossRef]

| Parameter | Value | Units |

|---|---|---|

| 500 | MPa | |

| E | 206 | GPa |

| YR | 0.806 | - |

| B | 10 | mm |

| W | 10 | mm |

| 4 | mm | |

| S | 80 | mm |

| z | −1.5 | mm |

| Parameter | Value | Units |

|---|---|---|

| 500 | MPa | |

| 200 | MPa | |

| 4.5 | - | |

| C | 10,000 | MPa |

| 81 | - |

| Parameter | Units | ||||

|---|---|---|---|---|---|

| 750 | 750 | 750 | 750 | MPa | |

| 500 | 600 | 500 | 550 | MPa | |

| 3 | 3 | 3 | 3 | - | |

| C | 5000 | 5000 | 5000 | 5000 | MPa |

| 81 | 81 | 81 | 81 | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kosuge, H.; Kawabata, T.; Okita, T.; Nako, H. Accurate Estimation of Brittle Fracture Toughness Deterioration in Steel Structures Subjected to Large Complicated Prestrains. Crystals 2020, 10, 867. https://doi.org/10.3390/cryst10100867

Kosuge H, Kawabata T, Okita T, Nako H. Accurate Estimation of Brittle Fracture Toughness Deterioration in Steel Structures Subjected to Large Complicated Prestrains. Crystals. 2020; 10(10):867. https://doi.org/10.3390/cryst10100867

Chicago/Turabian StyleKosuge, Hiroaki, Tomoya Kawabata, Taira Okita, and Hidenori Nako. 2020. "Accurate Estimation of Brittle Fracture Toughness Deterioration in Steel Structures Subjected to Large Complicated Prestrains" Crystals 10, no. 10: 867. https://doi.org/10.3390/cryst10100867

APA StyleKosuge, H., Kawabata, T., Okita, T., & Nako, H. (2020). Accurate Estimation of Brittle Fracture Toughness Deterioration in Steel Structures Subjected to Large Complicated Prestrains. Crystals, 10(10), 867. https://doi.org/10.3390/cryst10100867