Dislocation Reaction Mechanism for Enhanced Strain Hardening in Crystal Nano-Indentations

Abstract

1. Introduction

2. Nano-, Micro- and Macro-Indentations on AP

3. Experimental and Simulated Nano-Indentation Hardness of α-Iron Crystals

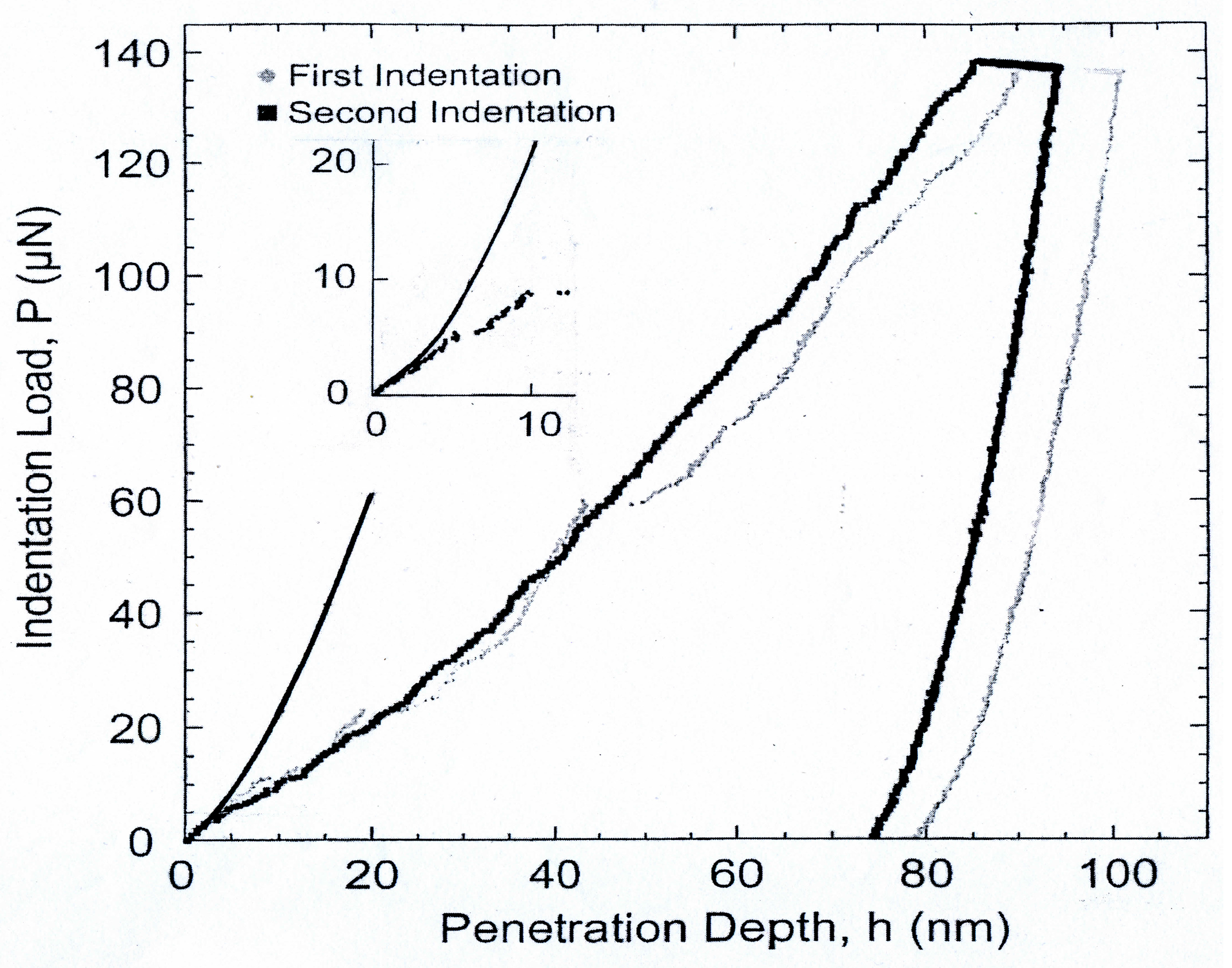

3.1. Comparison of Hertzian Elastic Loading Behaviors

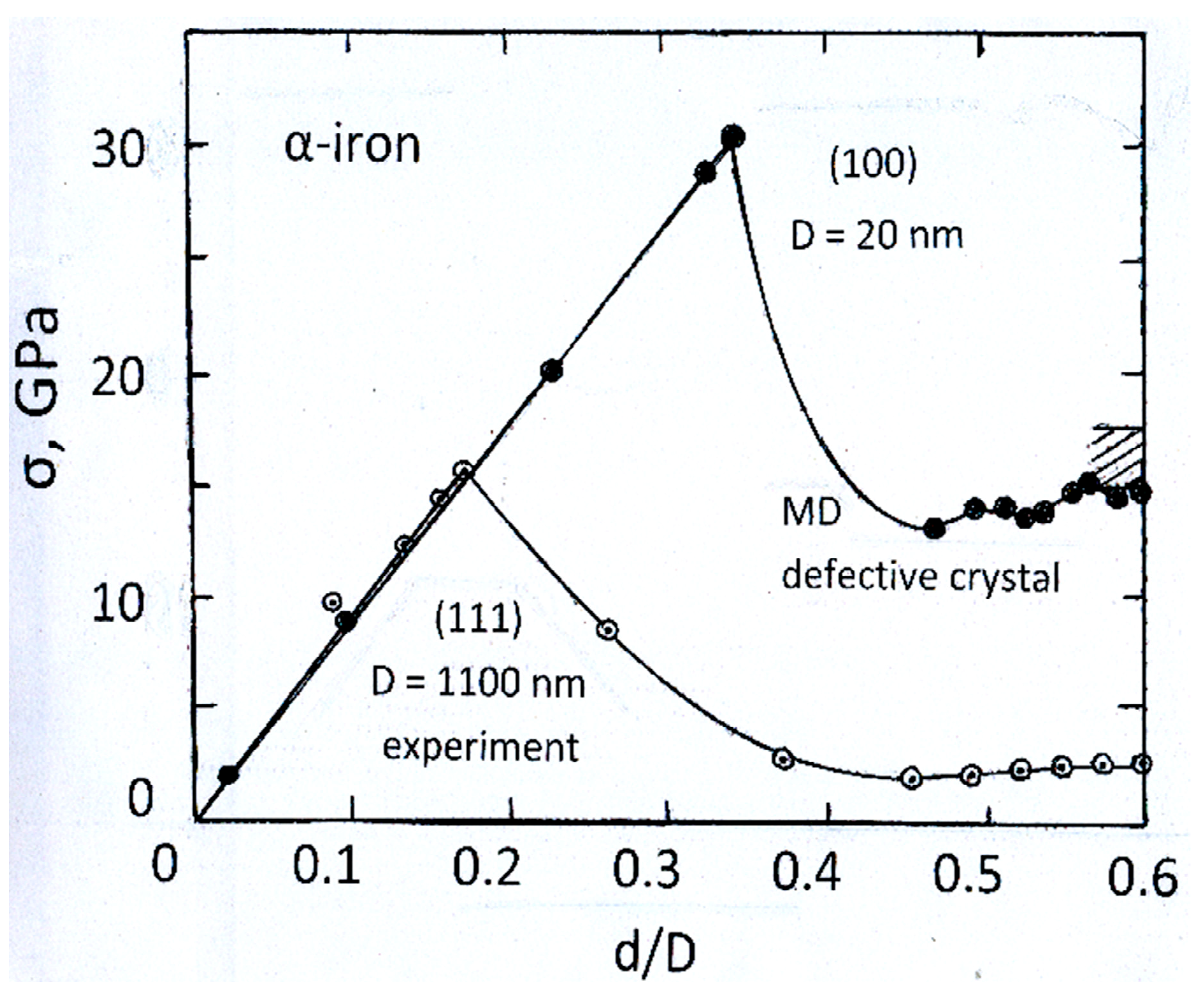

3.2. Plastic Yielding and Strain Hardening

4. Discussion

5. Summary

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Armstrong, R.W.; Elban, W.L. Exceptional crystal strain hardening determined over macro- to micro- to nano-size scales in continuous spherical indentation tests. Mater. Sci. Eng. A 2019, 757, 95–100. [Google Scholar] [CrossRef]

- Armstrong, R.W.; Wu, C.C. Lattice mis-orientation and displaced volume for micro-hardness indentations in MgO crystals. J. Am. Ceram. Soc. 1978, 61, 102–106. [Google Scholar] [CrossRef]

- Armstrong, R.W.; Elban, W.L. Tungsten (111) crystal strain hardening in nano-indentations. Int. J. Refract. Met. Hard Mater. 2019. [Google Scholar] [CrossRef]

- Cottrell, A.H. Theory of brittle fracture in steel and similar metals. Trans. TMS-AIME 1958, 212, 1089–1127. [Google Scholar]

- Alhafez, I.A.; Ruestes, C.J.; Bringa, E.M.; Urbassek, H.M. Influence of pre-existing plasticity on nano-indentation—An atomistic analysis of the dislocation fields produced. J. Mech. Phys. Solids 2019, 132, 103674. [Google Scholar] [CrossRef]

- Lucca, D.A.; Klopfstein, M.J.; Mejia, O.R.; Rossettini, L.; DeLuca, L.T. Investigation of ammonium perchlorate by nano-indentation. Mater. Sci. Technol. 2006, 22, 396–401. [Google Scholar] [CrossRef]

- Elban, W.L.; Armstrong, R.W. Plastic anisotropy and cracking at hardness impressions in single crystal ammonium perchlorate. Acta Mater. 1998, 46, 6041–6052. [Google Scholar] [CrossRef]

- Elban, W.L.; Sandusky, H.W.; Beard, B.C.; Glancy, B.C. Microstructural basis for enhanced shock-induced chemistry in single crystal ammonium perchlorate. J. Propuls. Power 1995, 11, 24–31. [Google Scholar] [CrossRef]

- Liu, B.; Wang, X.-J.; Bu, X.Y. First principles investigations of structural, electronic and elastic properties of ammonium perchlorate under high pressures. Acta Phys. Sin. 2016, 65, 126102. [Google Scholar] [CrossRef]

- Ramaswamy, A.L.; Shin, H.; Armstrong, R.W.; Lee, C.H. Nano-second and pico-second laser-induced cracking and ignition of single crystals of ammonium perchlorate. J. Mater. Sci. 1996, 31, 6035–6042. [Google Scholar] [CrossRef]

- Araki, S.; Mashima, K.; Masumura, T.; Tsuchiyama, T.; Takaki, S.; Ohmura, T. Effect of grain boundary segregation of carbon on critical grain boundary strength of ferritic steel. Scr. Mater. 2019, 169, 38–41. [Google Scholar] [CrossRef]

- Cantara, A.M.; Zecevic, M.; Eghtesad, A.; Poulin, C.M.; Knezevic, M. Predicting elastic anisotropy of dual-phase steels based on crystal mechanics and microstructure. Int. J. Mech. Sci. 2019, 151, 639–649. [Google Scholar] [CrossRef]

- Diehl, M.; Niehuesbernd, J.; Bruder, E. Quantifying the contribution of crystallographic texture and grain morphology on the elastic and plastic anisotropy of bcc steel. Metals 2019, 9, 1252. [Google Scholar] [CrossRef]

- Dub, S.N.; Lim, Y.Y.; Chaudhri, M.M. Nano-hardness of high purity Cu (111) single crystals: The effect of indenter load and prior plastic strain. J. Appl. Phys. 2010, 107, 043510. [Google Scholar] [CrossRef]

- Ruestes, C.J.; Stukowski, A.; Tang, Y.; Tramontina, D.R.; Erhart, P.; Remington, B.A.; Urbassek, H.M.; Meyers, M.A.; Bringa, E.M. Atomic simulation of tantalum nano-indentation: Effects of indenter diameter, penetration velocity, and interatomic potentials on defect mechanisms and evolution. Mater. Sci. Eng. A 2014, 613, 390–403. [Google Scholar] [CrossRef]

- Goel, S.; Cross, G.; Stukowski, A.; Gamsjäger, E.; Beake, B.; Agrawal, A. Designing nano-indentation simulation studies by appropriate indenter choices: Case study on single crystal tungsten. Comput. Mater. Sci. 2018, 152, 196–210. [Google Scholar] [CrossRef]

- Vlassak, J.J.; Nix, W.D. Indentation modulus of elastically anisotropic half spaces. Philos. Mag. A 1993, 67, 1045–1056. [Google Scholar] [CrossRef]

- Hirth, J.P.; Lothe, J. Theory of Dislocations, 1st ed.; McGraw-Hill Book Co.: New York, NY, USA, 1968; pp. 761–762. [Google Scholar]

- Filippov, P.; Koch, U. Nano-indentation of aluminum single crystals: Experimental study on influencing factors. Materials 2019, 12, 3688. [Google Scholar] [CrossRef]

- Lu, C.; Gao, Y.; Michal, G.; Deng, G.; Huynh, N.N.; Zhu, H.; Liu, X.; Tieu, A.K. Experiment and molecular dynamics simulation of nano-indentation of body-centered cubic iron. J. Nanosci. Nanotechnol. 2009, 9, 7307–7313. [Google Scholar] [CrossRef]

- Kositski, R.; Mordehai, D. Role of dislocation pile-ups in nucleation-controlled size-dependent strength of Fe nano-wires. Acta Mater. 2017, 136, 190–201. [Google Scholar] [CrossRef]

- Araki, S.; Fuji, K.; Akama, D.; Tsuchiyama, T.; Takaki, S.; Ohmura, T.; Takahashi, J. Effect of low temperature aging on Hall-Petch coefficient in ferritic steels containing a small amount of carbon and nitrogen. ISIJ Int. 2018, 58, 1920–1926. [Google Scholar] [CrossRef]

- Purcek, G.; Saray, O.; Karaman, I.; Maier, H.J. High strength and high ductility of ultrafine-grained interstitial-free steel produced by ECAE and annealing. Metal. Mater. Trans. A 2012, 43A, 1884–1894. [Google Scholar] [CrossRef]

- Rogne, B.R.S.; Thaulow, C. Strengthening mechanisms of iron micro-pillars. Philos. Mag. A 2015, 95, 1814–1828. [Google Scholar] [CrossRef]

- Li, Y.; Raabe, D.; Herbig, M.; Choi, P.-P.; Goto, S.; Kostka, A.; Yarita, H.; Borchers, C.; Kirchheim, R. Segregation stabilizes nano-crystalline bulk steel with near theoretical strength. Phys. Rev. Lett. 2014, 113, 106104. [Google Scholar] [CrossRef]

- Armstrong, R.W. Crystal engineering for mechanical strength at nano-scale dimensions. Crystal 2017, 7, 315. [Google Scholar] [CrossRef]

- Shahbeyk, S.; Voyiadjis, G.Z.; Habibi, V.; Astaneh, S.H.; Yaghoobi, M. Review of size effects during micro-pillar compression test: Experiments and atomistic simulations. Crystal 2019, 9, 591. [Google Scholar] [CrossRef]

- Zhao, K.; Mayer, A.E.; He, J.; Zhang, Z. Dislocation-based plasticity in the case of nano-indentation. Int. J. Mech. Sci. 2018, 148, 158–173. [Google Scholar] [CrossRef]

| Reference | Crystal | D Nm | σe GPa | σpop-in GPa | (d/D)pop-in | (Δσc/Δεc) GPa | εc |

|---|---|---|---|---|---|---|---|

| Araki et al. [11] | (111) | 1100 | 15.6 | 1.98 | 0.45 | 6.04 | 0.11 |

| Lu et al. [20] | (111) | 200 | 37.4 | 8.80 | 0.60 | 39 | 0.15 |

| Alhafez et al. [5] | (111) | 20 | 30.45 | 14.0 | 0.34 | 23.6 | 0.11 |

| Kositski and Mordehai [21] | (110) | 10 | 37.4 | 19.6 | 0.44 | 17.1 | 0.18 |

| Reference | Condition | σε GPa | *D, ℓ, d Nm | εi | Δσc/Δεc GPa | σε GPa |

|---|---|---|---|---|---|---|

| Araki et al. [5] | (111) Nano-indent | (σp/3): 0.66 | D: 1100 | εc: 0.11 | 6.04 | 0.95 |

| Araki et al. [22] | Bulk Tension | σt: 0.25 | ℓ: 1600 | εt: 0.11 | 0.20 | 0.28 |

| Purcek et al. [23] | ECAP Tension | σt: 0.69 | ℓ: 240 | εt: 0.009 | 4.14 | 0.79 |

| Rogne and Thaulow [24] | Micro-pillar Compression | σc: 1.9 | d: 150 | εc: 0.05 | 25 | 2.75 |

| Li et al. [25] | Drawn Wire Tension | σt: 6.5 | ℓ: 9 | εt: 0.095 | 74 | 6.5 |

| Kositski and Mordehai [21] | MD Nano-wire Compression | σc: 7.5 | d: 5 | εc: 0.10 | 105 | 18 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Armstrong, R.W.; Elban, W.L. Dislocation Reaction Mechanism for Enhanced Strain Hardening in Crystal Nano-Indentations. Crystals 2020, 10, 9. https://doi.org/10.3390/cryst10010009

Armstrong RW, Elban WL. Dislocation Reaction Mechanism for Enhanced Strain Hardening in Crystal Nano-Indentations. Crystals. 2020; 10(1):9. https://doi.org/10.3390/cryst10010009

Chicago/Turabian StyleArmstrong, Ronald W., and Wayne L. Elban. 2020. "Dislocation Reaction Mechanism for Enhanced Strain Hardening in Crystal Nano-Indentations" Crystals 10, no. 1: 9. https://doi.org/10.3390/cryst10010009

APA StyleArmstrong, R. W., & Elban, W. L. (2020). Dislocation Reaction Mechanism for Enhanced Strain Hardening in Crystal Nano-Indentations. Crystals, 10(1), 9. https://doi.org/10.3390/cryst10010009