Microstructure and Mechanical Properties of Carbon/Carbon Composites Infiltrated with Ti–6Al–4V Titanium Alloy

Abstract

1. Introduction

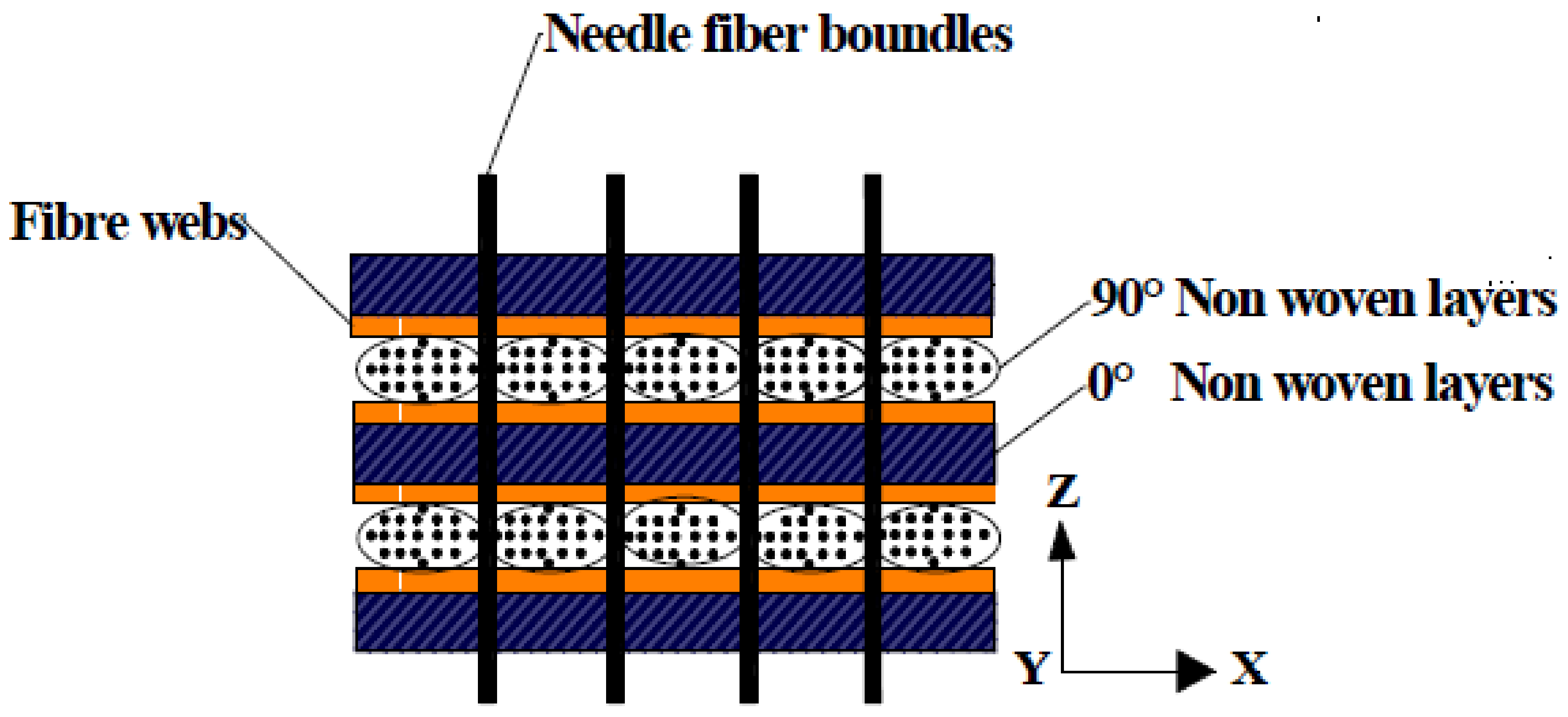

2. Experimental Procedure

3. Results and Discussion

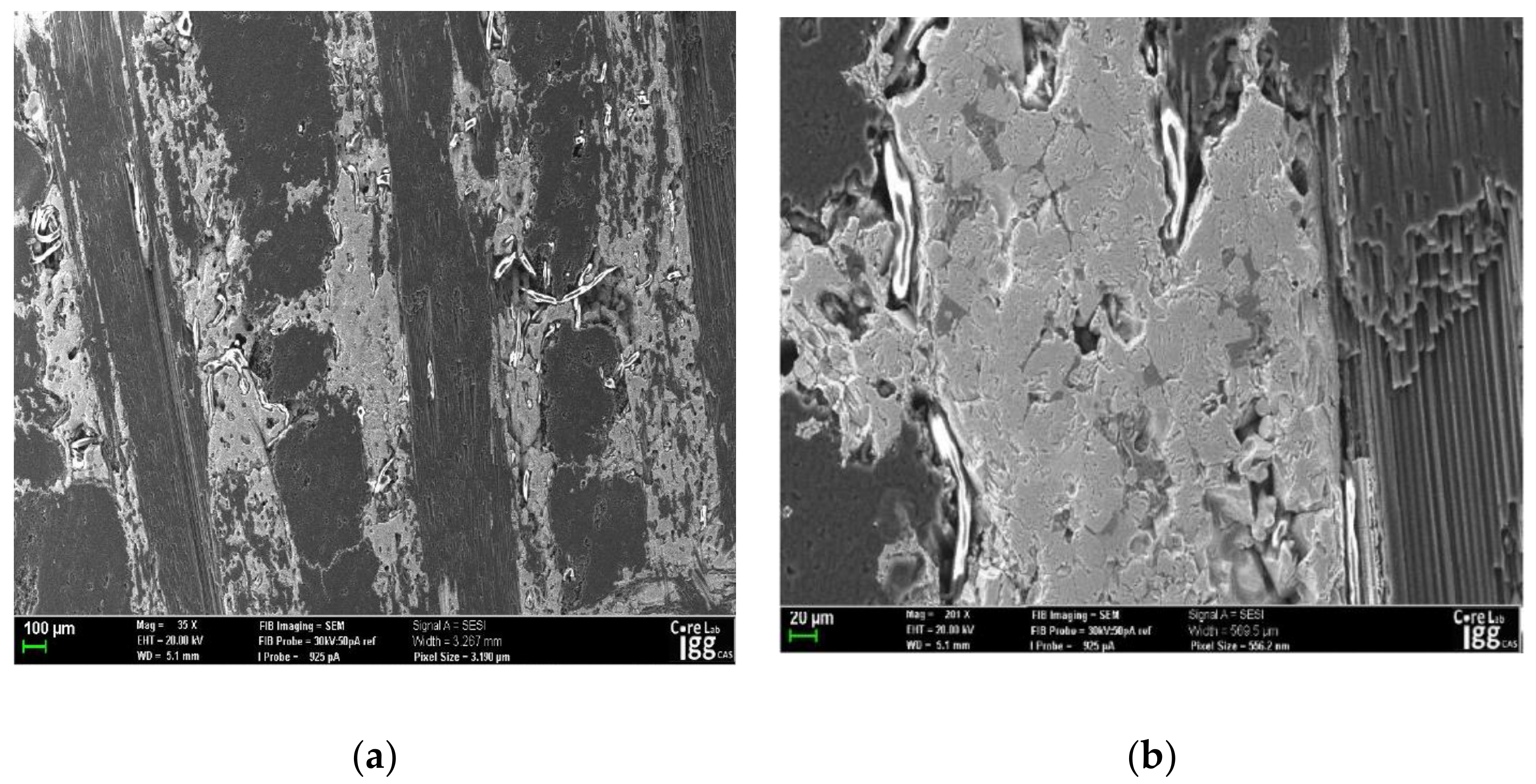

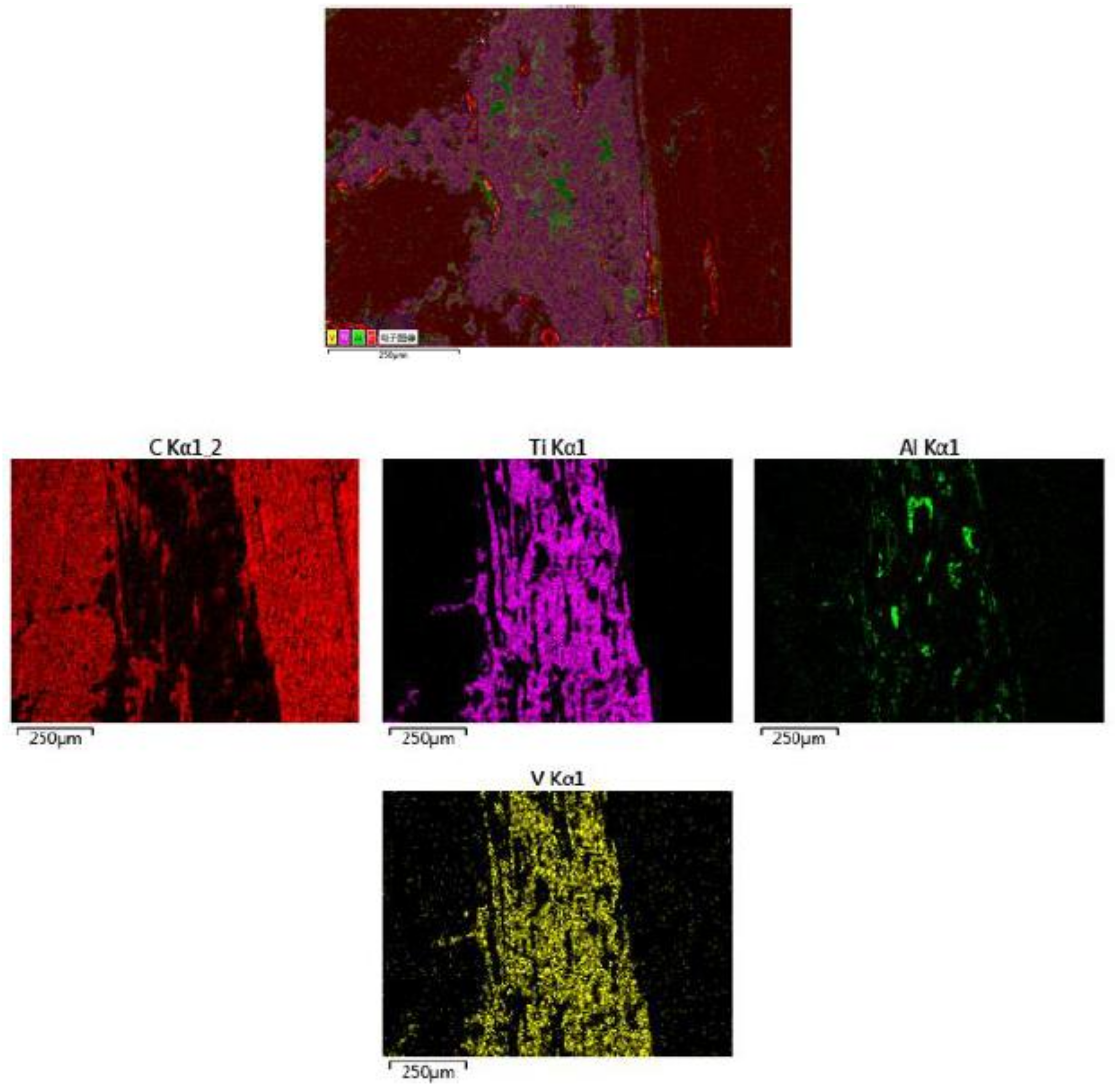

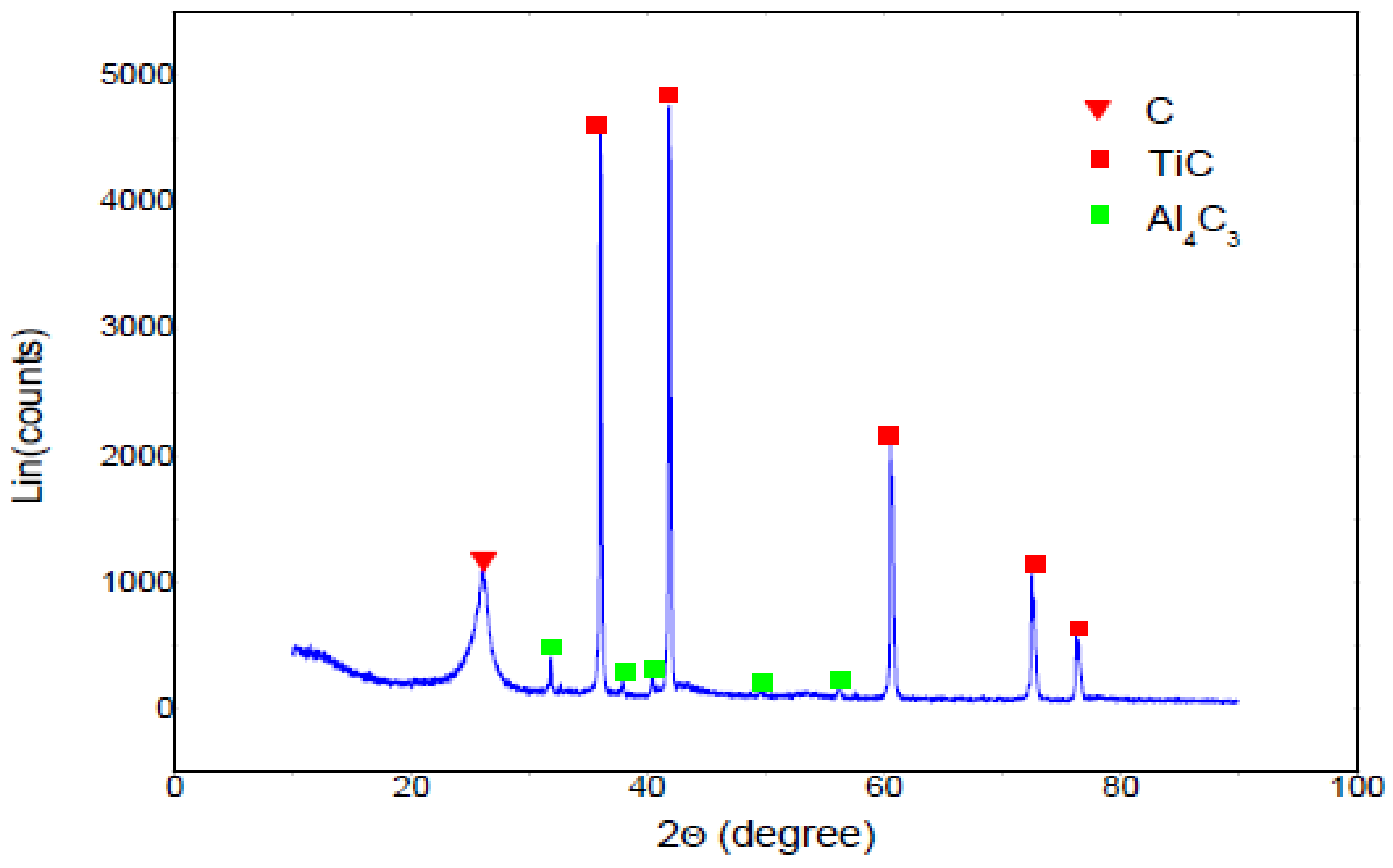

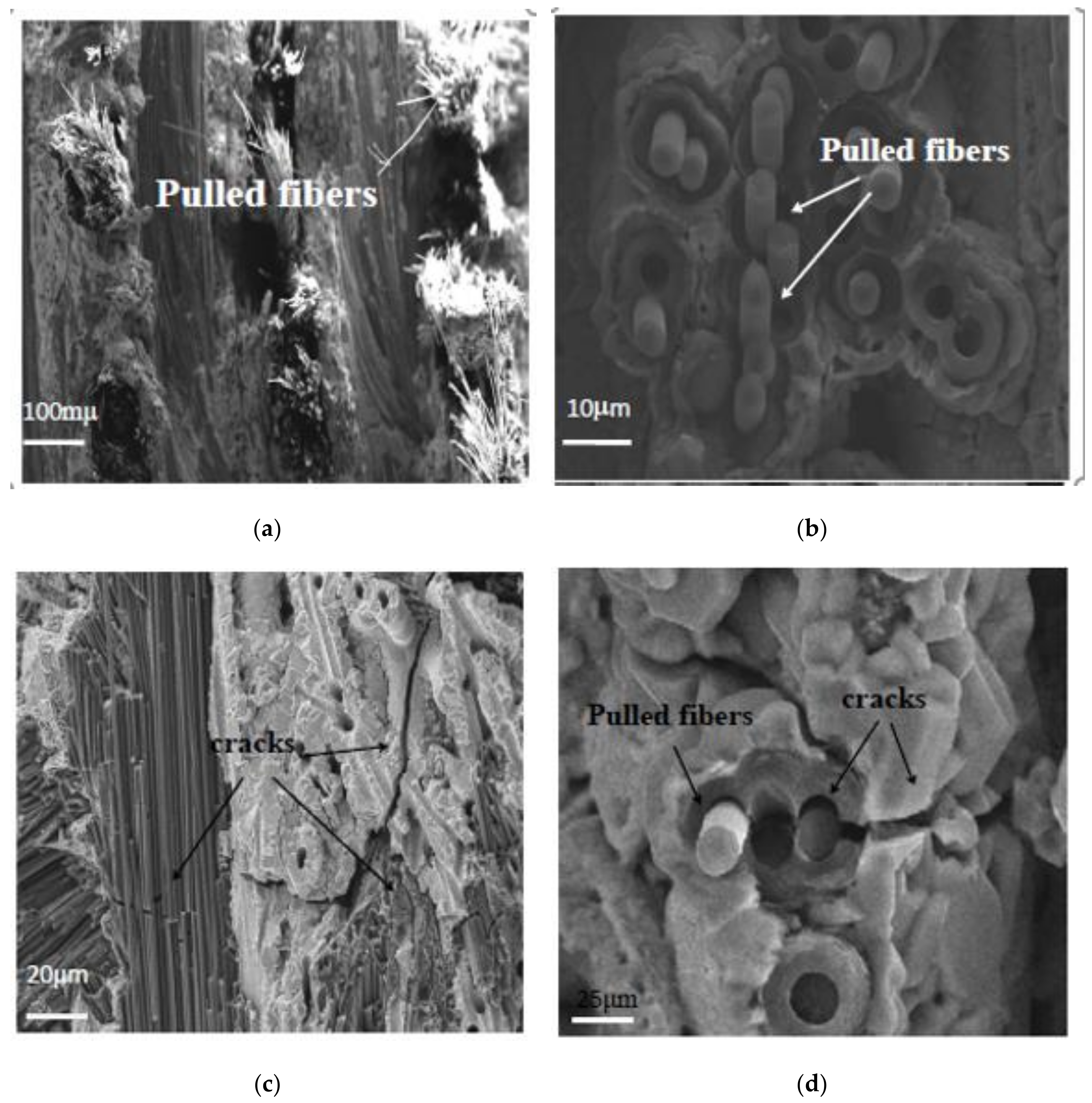

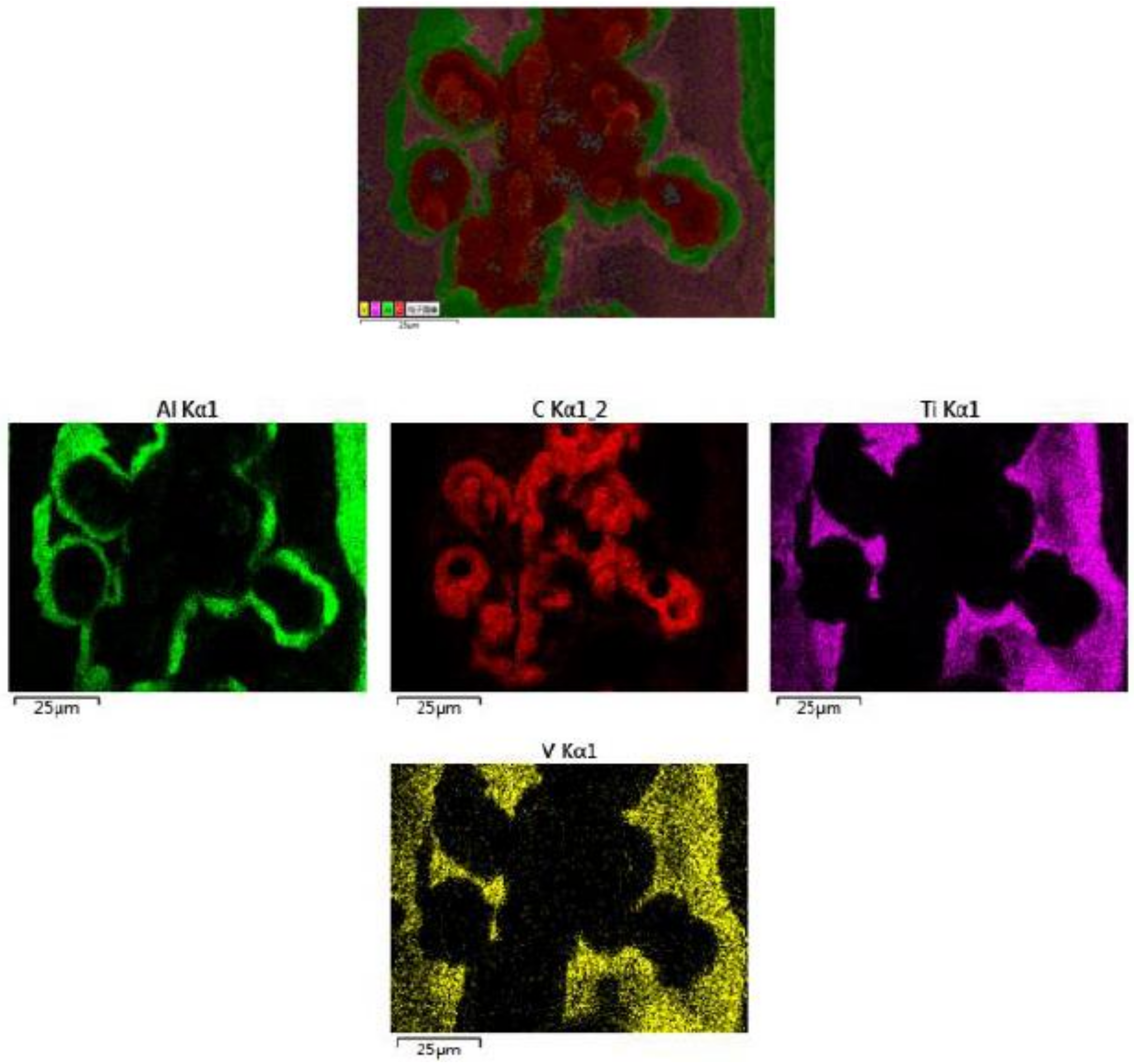

3.1. Density and Microstructure

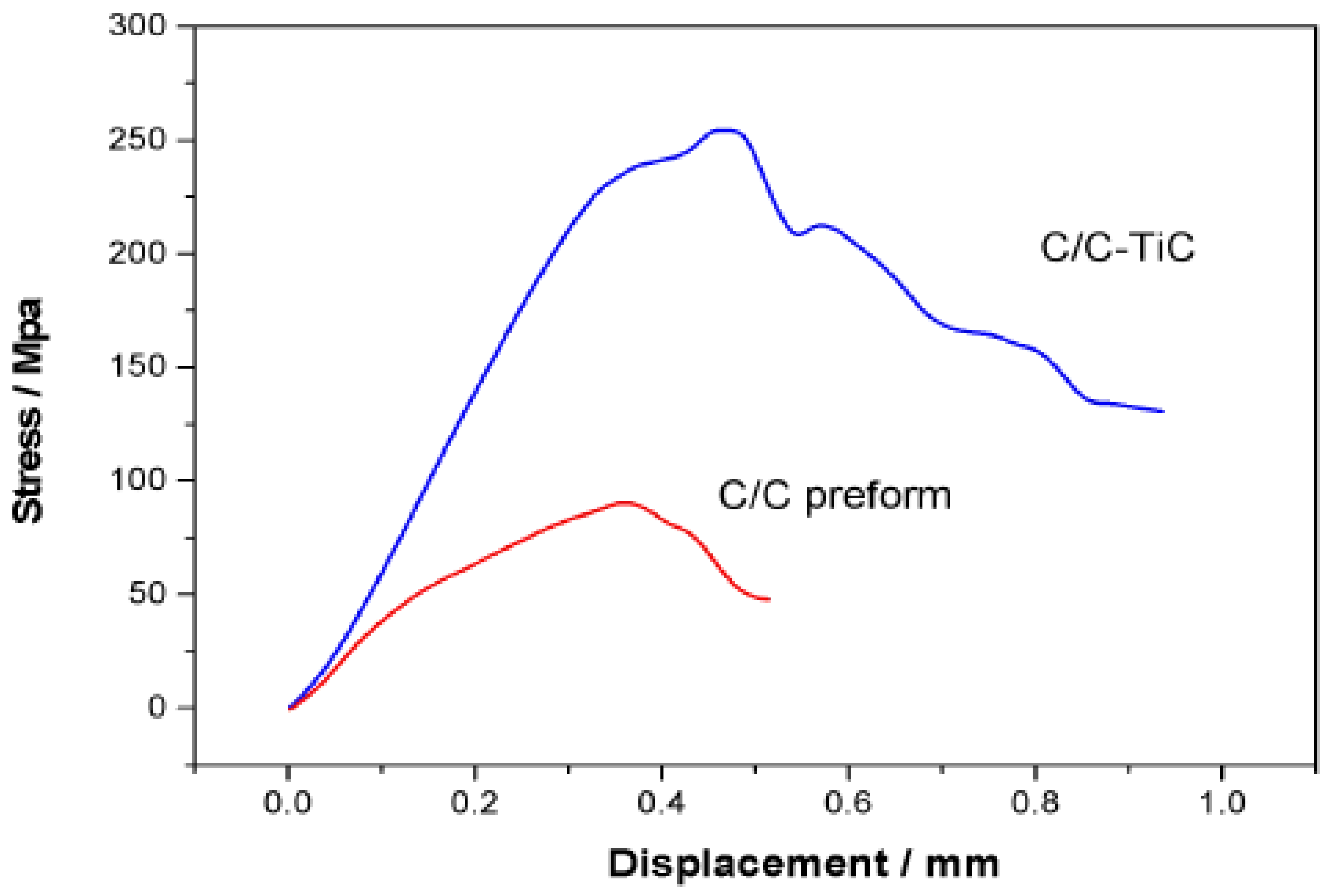

3.2. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Naslain, R.; Pailler, R.; Bourrat, X.; Bertarnd, S.; Lamouroux, L. Synthesis of highly tailored ceramic matrix composites by pressure-pulsed CVI. Solid State Ionics 2001, 541, 141–144. [Google Scholar] [CrossRef]

- Sato, K.; Tezuka, A.; Funayama, O.; Isoda, T.; Terada, Y.; Kato, S.; Iwata, M. Fabrication and pressure testing of a gas-turbine component manufactured by a pre ceramic–polymer-impregnation method. Compos. Sci. Technol. 1999, 59, 853–859. [Google Scholar] [CrossRef]

- Kohyama, A.; Kotani, M.; Katoh, Y.; Nakayasu, T.; Sato, M.; Yamamura, T.; Okamura, K. High performance SiC/SiC composites by improved PIP processing with new precursor polymers. J. Nucl. Mater. 2000, 283, 565–569. [Google Scholar] [CrossRef]

- Jiang, S.Z.; Xiong, X.; Chen, Z.K.; Xiao, P.; Huang, B.Y. Influence factors of C/C–SiC dual matrix composites prepared by reactive melt infiltration. Mater. Des. 2009, 30, 3738–3742. [Google Scholar]

- Einset, E.O. Analysis of reactive melt infiltration in the processing of ceramics and ceramic composites. Chem. Eng. Sci. 1998, 53, 1027–1039. [Google Scholar] [CrossRef]

- Storms, E.K. The Refractory Carbides; Academic Press: New York, NY, USA, 1967. [Google Scholar]

- Lengauer, W. Handbook of Ceramic Hard Materials; Riedel, R., Ed.; WileyVCH: New York, NY, USA, 2003; pp. 202–203, 234–235, 238. [Google Scholar]

- Vallauri, D.; Adrian, I.C.A.; Chrysanthou, A. TiC–TiB2 composites: A review of phase relationships, processing and properties. J. Eur. Ceram. Soc. 2008, 28, 1697–1713. [Google Scholar] [CrossRef]

- Song, G.M.; Wu, Y.; Li, Q. Elevated temperature strength and thermal shock behavior of hot-pressed carbon fiber reinforced TiC composites. J. Eur. Ceram. Soc. 2002, 22, 559–566. [Google Scholar] [CrossRef]

- Song, G.M.; Li, Q.; Wen, G.W.; Zhou, Y. Enhanced Microwave Absorption of SiO2-Coated Fe0.65Co0.35 Flakes at a Wide Frequency Band (1–18 GHz). Mater. Sci. Eng. A 2002, 326, 240–246. [Google Scholar] [CrossRef]

- Rossignol, J.Y.; Quenisset, J.M.; Naslain, R. Mechanical behaviour in compression loading of 2D-composite materials made of carbon fabrics and a ceramic matrix. Composites 1987, 18, 135–144. [Google Scholar] [CrossRef]

- Tong, Y.G. A low cost fabrication route for continuous carbon fiber reinforced TiC based ceramic matrix composites. J. Mater. Sci. Eng. A 2012, 556, 980–983. [Google Scholar] [CrossRef]

- Trantina, G.G.; Mehan, R.L. High-temperature time-dependent strength of an Si/SiC composite. J. Am. Ceram. Soc. 1977, 3, 177–178. [Google Scholar] [CrossRef]

- Zou, L.H.; Wali, N.; Yang, J.M. Microstructural Characterization of a Cf/ZrC Composite Manufactured by Reactive Melt Infiltration. Int. J. Appl. Ceram. Technol. 2011, 8, 329–341. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, A.; Devi, R.; Shukla, A.; Gupta, A. Capillary infiltration studies of liquids into 3D-stitched C-C preforms: Part A: Internal pore characterization by solvent infiltration, mercury porosimetry, and permeability studies. J. Eur. Ceram. Soc. 2009, 29, 2651–2657. [Google Scholar] [CrossRef]

- Einset, E.O. Microstructural Characterization of a Cf/ZrC Composite Manufactured by Reactive Melt Infiltration. Chem. Eng. Sci. 1998, 53, 1027–1039. [Google Scholar] [CrossRef]

- Zhu, Y.Z.; Huang, Z.R.; Dong, S.M.; Yuan, M.; Jiang, D.L. Fabricating 2.5D SiCf/SiC composite using polycarbosilane/SiC/Al mixture for matrix derivation. J. Am. Ceram. Soc. 2007, 90, 969–972. [Google Scholar] [CrossRef]

- Xiao, P.; Lu, Y.H.; Liu, Y.Z.; Li, Z.; Fang, H.C.; Zhou, W.; Almeida, R.S.; Li, Y. Microstructure and properties of Cu-Ti alloy infiltrated chopped Cf reinforced ceramics composites. J. Ceram. Int. 2017, 43, 16628–16637. [Google Scholar] [CrossRef]

- Li, Y.; Xiao, P.; Zhou, W.; Luo, H.; Li, Z. Microstructure and properties of plain-weave carbon fabric reinforced ceramic composites containing Cu-Si alloy. J. Compos. Part B Eng. 2018, 145, 129–135. [Google Scholar] [CrossRef]

- Tong, Y.; Zhu, W.; Bai, S.; Hu, Y.; Xie, X.; Li, Y. Thermal shock resistance of continuous carbon fiber reinforced ZrC based ultra-high temperature ceramic composites prepared via Zr-Si alloyed melt infiltration. J. Ceram. Int. 2018, 44, 16577–16582. [Google Scholar] [CrossRef]

- GB 6569-1986; China Building Materials Academy: Beijing, China, 1986.

- Liu, Y.S.; Chen, L.F.; Zhang, L.T.; Yang, W.B.; Zhou, S.T.; Zhang, W.H. Fracture behavior and mechanism of 2D C/SiC–BCx composite at room temperature. Mater. Sci. Eng. A 2011, 528, 1436–1441. [Google Scholar] [CrossRef]

- Zhao, G.L. In situ synthesis of TiC-VC particles reinforced Fe-based MMC coatings produced by laser cladding. J. Shandong Univ. (Eng. Sci.) 2008, 38, 6–17. [Google Scholar]

- Yang, J.; Ilegbusi, O.J. Kinetics of silicon-metal alloy infiltration into porous carbon. Compos. A 2000, 31, 617–625. [Google Scholar] [CrossRef]

- Jha, N.K.; Reinoso, J.; Dehghani, H.; Merodio, J. A computational model for fiber-reinforced composites: Hyperelastic constitutive formulation including residual stresses and damage. Comput. Mech. 2019, 63, 931–948. [Google Scholar] [CrossRef]

- Merodio, J.; Haughton, D. Bifurcation of thick-walled cylindrical shells and the mechanical response of arterial tissue affected by Marfan’s syndrome. Mech. Res. Commun. 2010, 37, 1–6. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ni, Y.; Luo, R. Microstructure and Mechanical Properties of Carbon/Carbon Composites Infiltrated with Ti–6Al–4V Titanium Alloy. Crystals 2020, 10, 29. https://doi.org/10.3390/cryst10010029

Ni Y, Luo R. Microstructure and Mechanical Properties of Carbon/Carbon Composites Infiltrated with Ti–6Al–4V Titanium Alloy. Crystals. 2020; 10(1):29. https://doi.org/10.3390/cryst10010029

Chicago/Turabian StyleNi, Yuanlin, and Ruiying Luo. 2020. "Microstructure and Mechanical Properties of Carbon/Carbon Composites Infiltrated with Ti–6Al–4V Titanium Alloy" Crystals 10, no. 1: 29. https://doi.org/10.3390/cryst10010029

APA StyleNi, Y., & Luo, R. (2020). Microstructure and Mechanical Properties of Carbon/Carbon Composites Infiltrated with Ti–6Al–4V Titanium Alloy. Crystals, 10(1), 29. https://doi.org/10.3390/cryst10010029