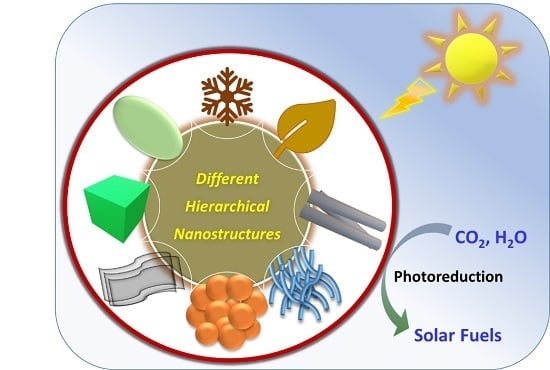

Hierarchical Nanostructured Photocatalysts for CO2 Photoreduction

Abstract

:1. Introduction

2. CO2 Photoreduction Mechanism

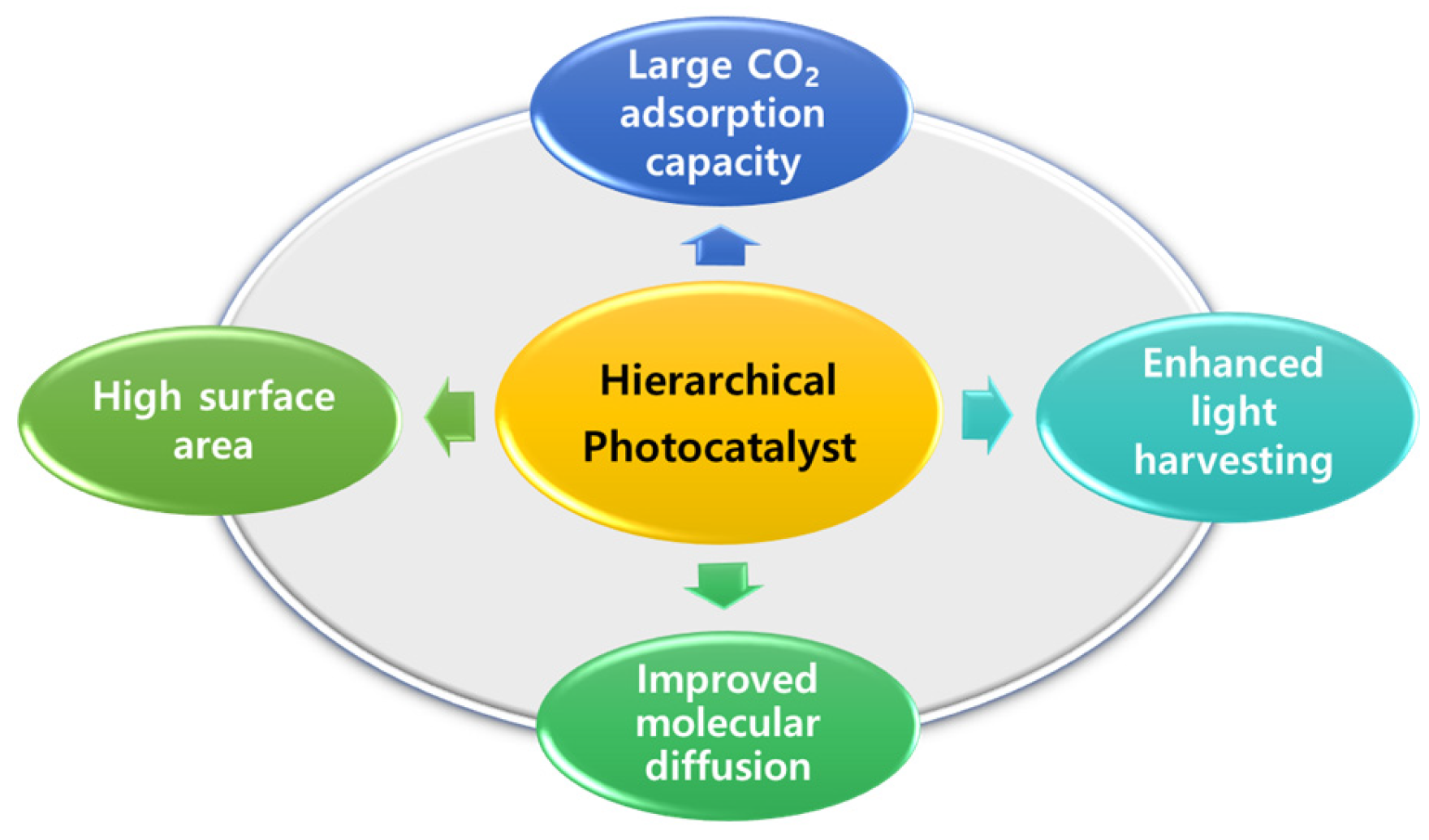

3. Benefits of Hierarchical Nanostructures in Photocatalysis

4. Hierarchical Nanostructured Photocatalysts for CO2 Reduction

4.1. Hierarchical Nanostructures with Leaf-Like Morphology

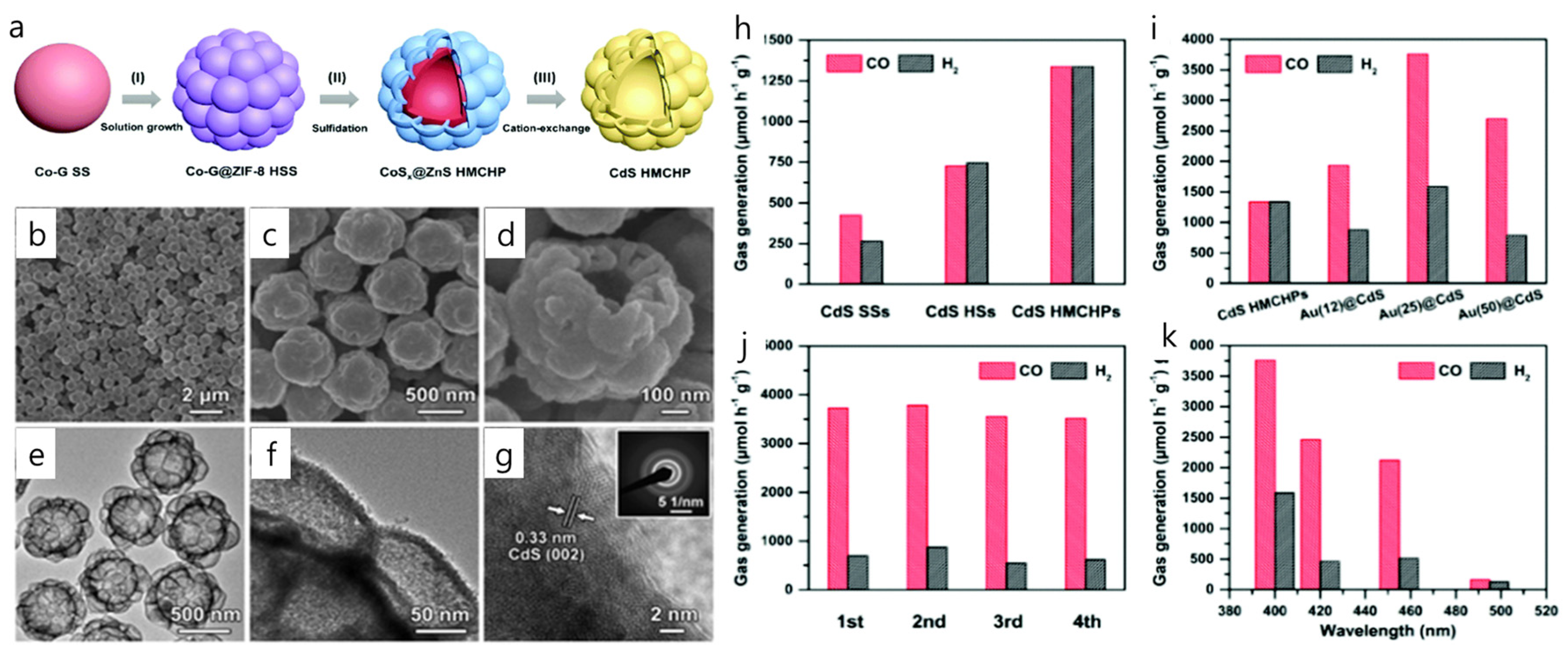

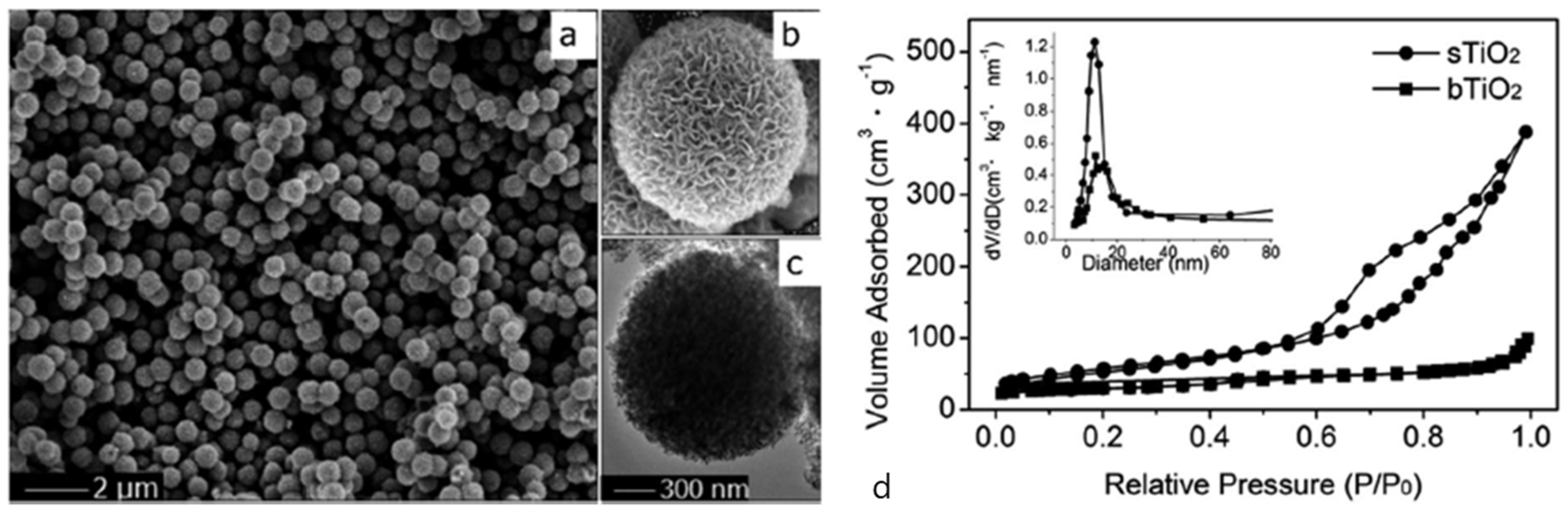

4.2. Hierarchical Nanosphere Morphologies

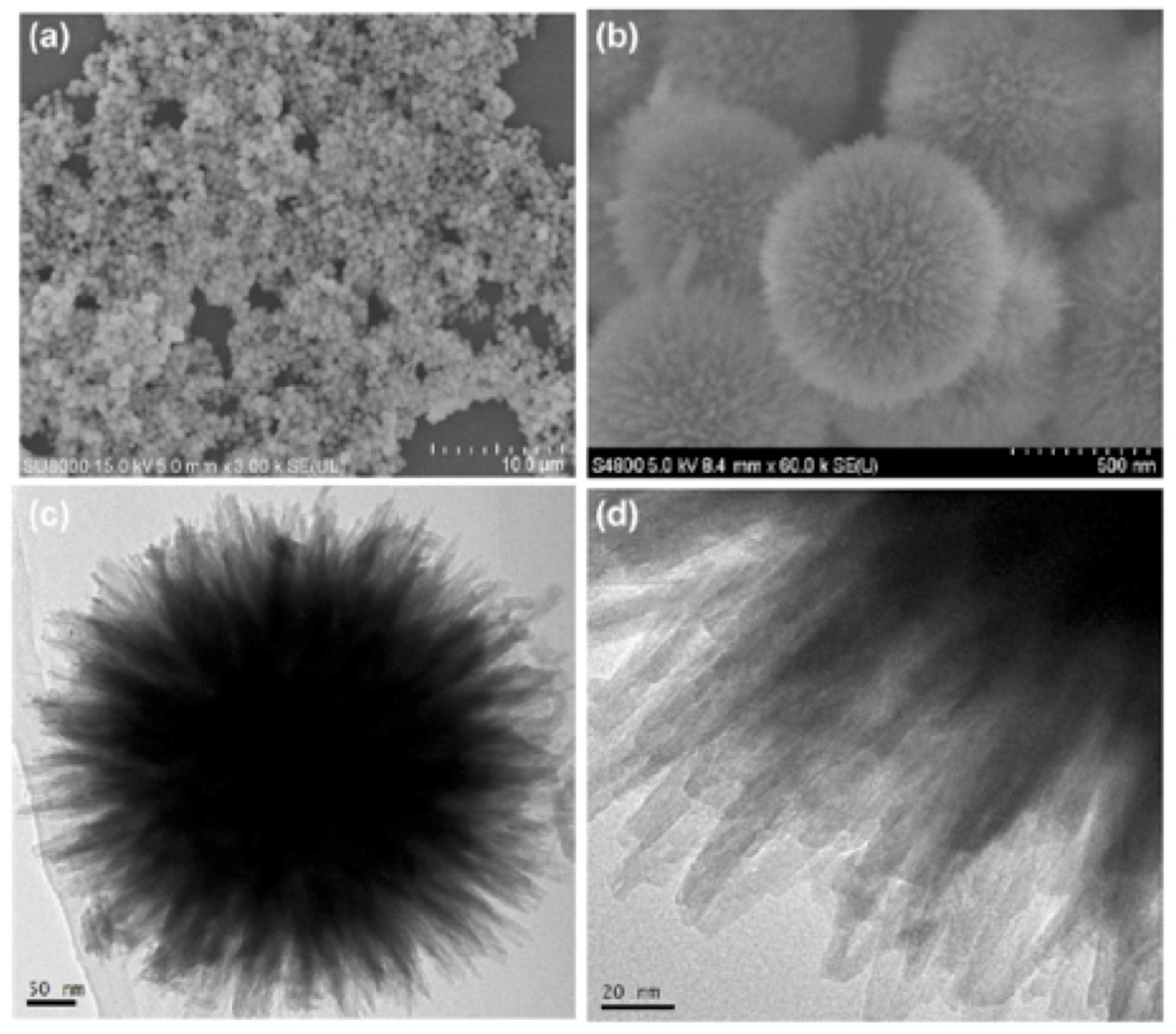

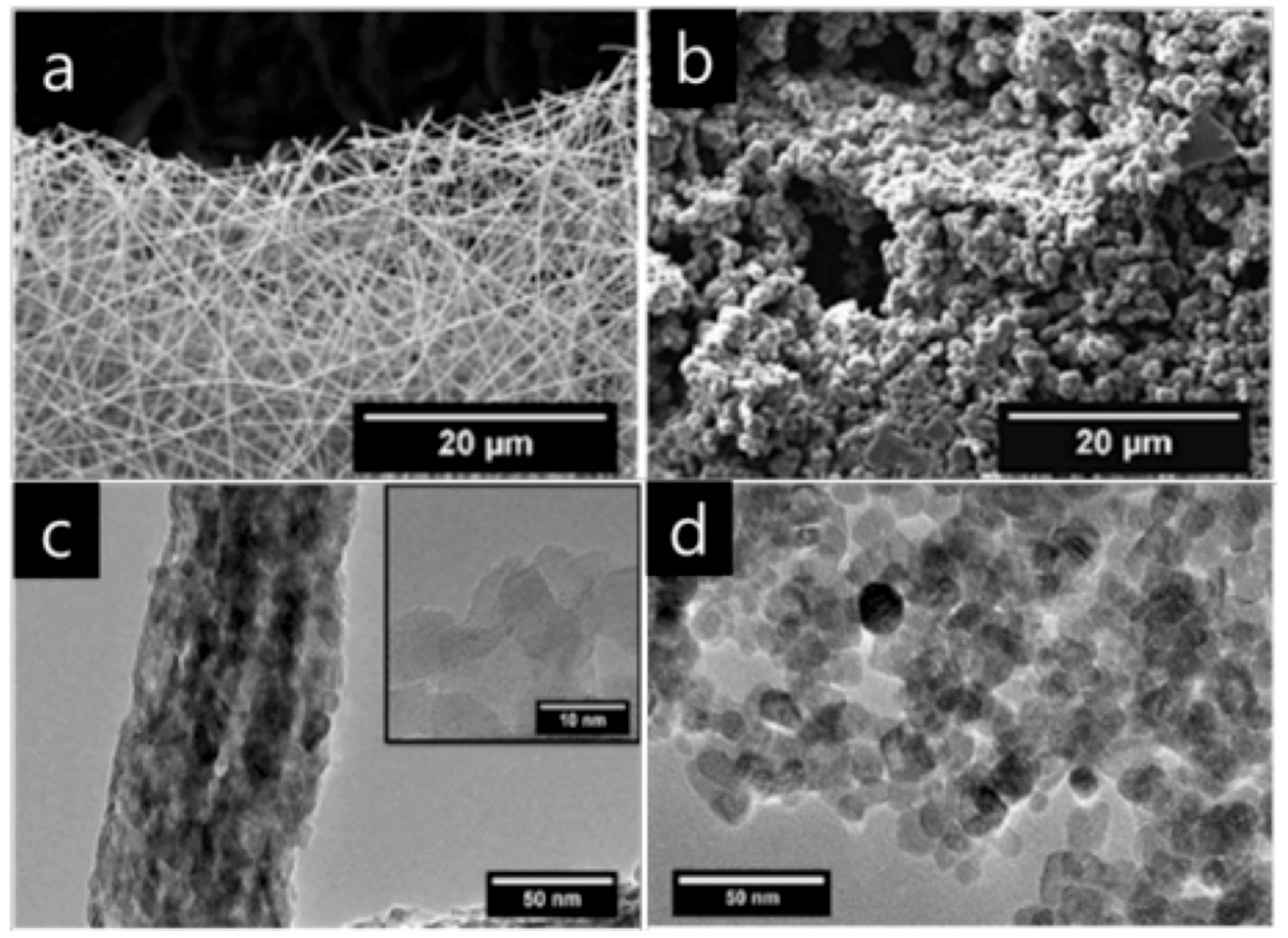

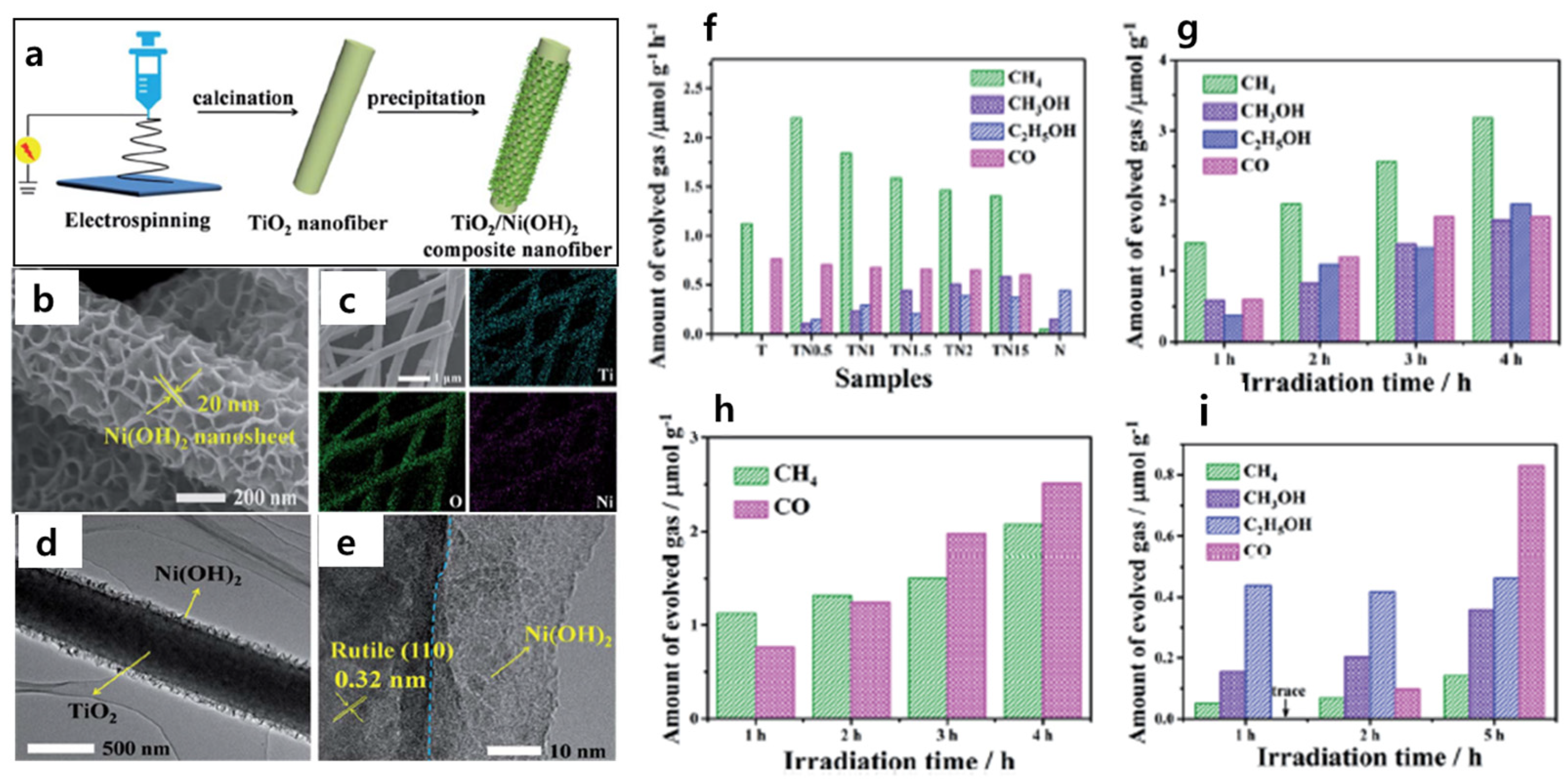

4.3. Fiber-Like Hierarchical Materials

4.4. Hierarchical Tube/Rod Morphologies

4.5. Sheet-Like Hierarchical Materials

4.6. Hierarchical Nanoboxes

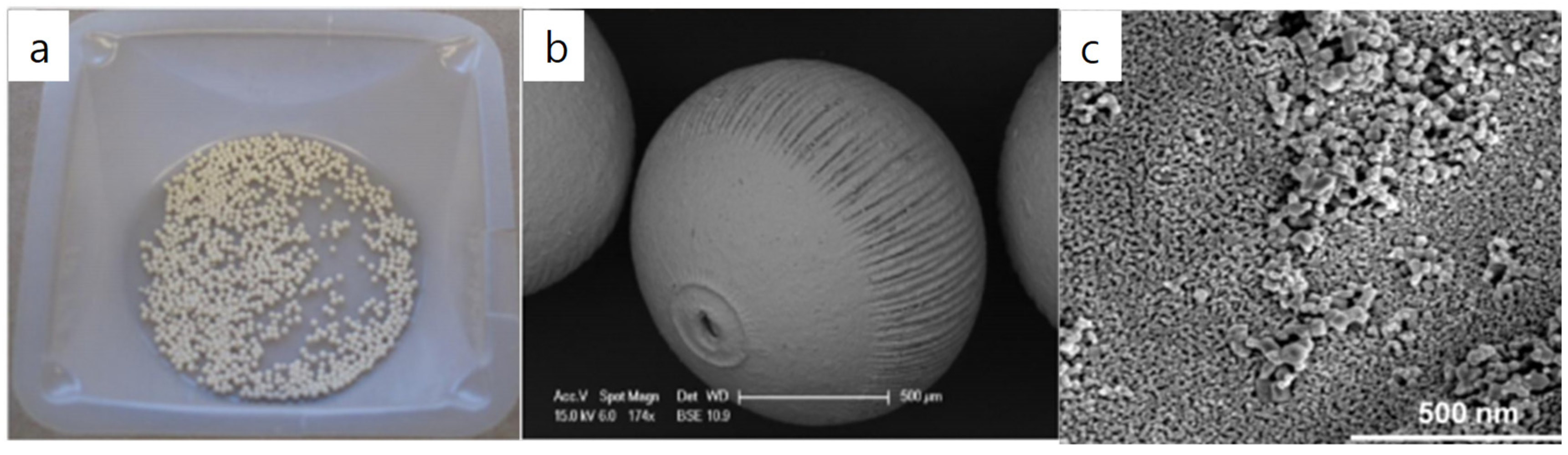

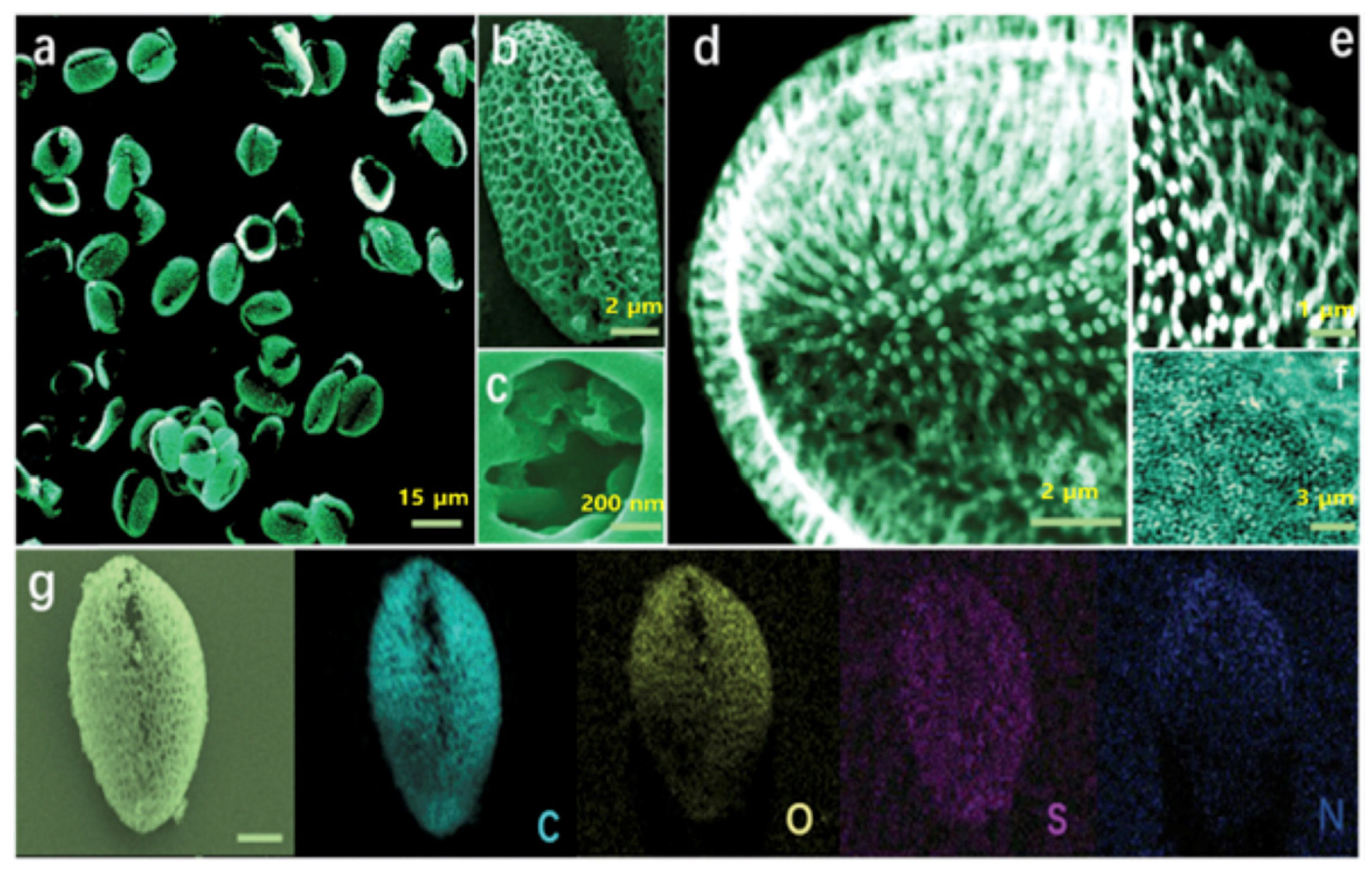

4.7. Hierarchical Natural Photocatalysts

5. Summary and Outlook

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Jiang, Z.; Xiao, T.; Kuznetsov, V.L.; Edwards, P.P. Turning carbon dioxide into fuel. Philos. Trans. Ser. A Math. Phys. Eng. Sci. 2010, 368, 3343–3364. [Google Scholar] [CrossRef]

- Zhou, H.; Li, P.; Liu, J.; Chen, Z.; Liu, L.; Dontsova, D.; Yan, R.; Fan, T.; Zhang, D.; Ye, J. Biomimetic polymeric semiconductor based hybrid nanosystems for artificial photosynthesis towards solar fuels generation via CO2 reduction. Nano Energy 2016, 25, 128–135. [Google Scholar] [CrossRef]

- Tan, L.-L.; Ong, W.-J.; Chai, S.-P.; Mohamed, A.R. Visible-light-activated oxygen-rich TiO2 as next generation photocatalyst: Importance of annealing temperature on the photoactivity toward reduction of carbon dioxide. Chem. Eng. J. 2016, 283, 1254–1263. [Google Scholar] [CrossRef]

- Shi, Z.; Yang, H.; Gao, P.; Li, X.; Zhong, L.; Wang, H.; Liu, H.; Wei, W.; Sun, Y. Direct conversion of CO2 to long-chain hydrocarbon fuels over K–promoted CoCu/TiO2 catalysts. Catal. Today 2018, 311, 65–73. [Google Scholar] [CrossRef]

- Qamar, S.; Lei, F.; Liang, L.; Gao, S.; Liu, K.; Sun, Y.; Ni, W.; Xie, Y. Ultrathin TiO2 flakes optimizing solar light driven CO2 reduction. Nano Energy 2016, 26, 692–698. [Google Scholar] [CrossRef]

- Olah, G.A.; Goeppert, A.; Prakash, G.K.S. Chemical recycling of carbon dioxide to methanol and dimethyl ether: From greenhouse gas to renewable, environmentally carbon neutral fuels and synthetic hydrocarbons. J. Org. Chem. 2008, 74, 487–498. [Google Scholar] [CrossRef] [PubMed]

- Low, J.; Cheng, B.; Yu, J. Surface modification and enhanced photocatalytic CO2 reduction performance of TiO2: A review. Appl. Surf. Sci. 2017, 392, 658–686. [Google Scholar] [CrossRef]

- Cuéllar-Franca, R.M.; Azapagic, A. Carbon capture, storage and utilisation technologies: A critical analysis and comparison of their life cycle environmental impacts. J. CO2 Util. 2015, 9, 82–102. [Google Scholar] [CrossRef]

- Baldoví, H.G.; Neaţu, S.; Khan, A.; Asiri, A.M.; Kosa, S.A.; Garcia, H. Understanding the origin of the photocatalytic CO2 reduction by Au-and Cu-loaded TiO2: A microsecond transient absorption spectroscopy study. J. Phys. Chem. C 2015, 119, 6819–6827. [Google Scholar] [CrossRef]

- Sorcar, S.; Thompson, J.; Hwang, Y.; Park, Y.H.; Majima, T.; Grimes, C.A.; Durrant, J.R.; In, S.-I. High-rate solar-light photoconversion of CO2 to fuel: Controllable transformation from C1 to C2 products. Energy Environ. Sci. 2018, 11, 3183–3193. [Google Scholar] [CrossRef]

- Marszewski, M.; Cao, S.; Yu, J.; Jaroniec, M. Semiconductor-based photocatalytic CO2 conversion. Mater. Horiz. 2015, 2, 261–278. [Google Scholar] [CrossRef]

- Li, K.; An, X.; Park, K.H.; Khraisheh, M.; Tang, J. A critical review of CO2 photoconversion: Catalysts and reactors. Catal. Today 2014, 224, 3–12. [Google Scholar] [CrossRef]

- Taheri Najafabadi, A. CO2 chemical conversion to useful products: An engineering insight to the latest advances toward sustainability. Int. J. Energy Res. 2013, 37, 485–499. [Google Scholar] [CrossRef]

- Shi, J.; Jiang, Y.; Jiang, Z.; Wang, X.; Wang, X.; Zhang, S.; Han, P.; Yang, C. Enzymatic conversion of carbon dioxide. Chem. Soc. Rev. 2015, 44, 5981–6000. [Google Scholar] [CrossRef]

- Qiao, J.; Liu, Y.; Hong, F.; Zhang, J. A review of catalysts for the electroreduction of carbon dioxide to produce low-carbon fuels. Chem. Soc. Rev. 2014, 43, 631–675. [Google Scholar] [CrossRef]

- Qu, Y.; Duan, X. Progress, challenge and perspective of heterogeneous photocatalysts. Chem. Soc. Rev. 2013, 42, 2568–2580. [Google Scholar] [CrossRef] [PubMed]

- Oh, Y.; Hu, X. Organic molecules as mediators and catalysts for photocatalytic and electrocatalytic CO2 reduction. Chem. Soc. Rev. 2013, 42, 2253–2261. [Google Scholar] [CrossRef]

- Berardi, S.; Drouet, S.; Francas, L.; Gimbert-Suriñach, C.; Guttentag, M.; Richmond, C.; Stoll, T.; Llobet, A. Molecular artificial photosynthesis. Chem. Soc. Rev. 2014, 43, 7501–7519. [Google Scholar] [CrossRef] [PubMed]

- Chueh, W.C.; Falter, C.; Abbott, M.; Scipio, D.; Furler, P.; Haile, S.M.; Steinfeld, A. High-flux solar-driven thermochemical dissociation of CO2 and H2O using nonstoichiometric ceria. Science 2010, 330, 1797–1801. [Google Scholar] [CrossRef] [PubMed]

- Kauffman, D.R.; Thakkar, J.; Siva, R.; Matranga, C.; Ohodnicki, P.R.; Zeng, C.; Jin, R. Efficient electrochemical CO2 conversion powered by renewable energy. ACS Appl. Mater. Interfaces 2015, 7, 15626–15632. [Google Scholar] [CrossRef]

- Costentin, C.; Robert, M.; Savéant, J.-M. Catalysis of the electrochemical reduction of carbon dioxide. Chem. Soc. Rev. 2013, 42, 2423–2436. [Google Scholar] [CrossRef]

- Benson, E.E.; Kubiak, C.P.; Sathrum, A.J.; Smieja, J.M. Electrocatalytic and homogeneous approaches to conversion of CO2 to liquid fuels. Chem. Soc. Rev. 2009, 38, 89–99. [Google Scholar] [CrossRef] [PubMed]

- Ganesh, I. Electrochemical conversion of carbon dioxide into renewable fuel chemicals—The role of nanomaterials and the commercialization. Renew. Sustain. Energy Rev. 2016, 59, 1269–1297. [Google Scholar] [CrossRef]

- Olajire, A.A. A review of mineral carbonation technology in sequestration of CO2. J. Pet. Sci. Eng. 2013, 109, 364–392. [Google Scholar] [CrossRef]

- Walter, M.G.; Warren, E.L.; McKone, J.R.; Boettcher, S.W.; Mi, Q.; Santori, E.A.; Lewis, N.S. Solar water splitting cells. Chem. Rev. 2010, 110, 6446–6473. [Google Scholar] [CrossRef]

- Meng, A.; Wu, S.; Cheng, B.; Yu, J.; Xu, J. Hierarchical TiO2/Ni(OH)2 composite fibers with enhanced photocatalytic CO2 reduction performance. J. Mater. Chem. A 2018, 6, 4729–4736. [Google Scholar] [CrossRef]

- Fang, W.; Xing, M.; Zhang, J. Modifications on reduced titanium dioxide photocatalysts: A review. J. Photochem. Photobiol. C Photochem. Rev. 2017, 32, 21–39. [Google Scholar] [CrossRef]

- Inoue, T.; Fujishima, A.; Konishi, S.; Honda, K. Photoelectrocatalytic reduction of carbon dioxide in aqueous suspensions of semiconductor powders. Nature 1979, 277, 637–638. [Google Scholar] [CrossRef]

- Nikokavoura, A.; Trapalis, C. Alternative photocatalysts to TiO2 for the photocatalytic reduction of CO2. Appl. Surf. Sci. 2017, 391, 149–174. [Google Scholar] [CrossRef]

- Yu, J.; Wang, K.; Xiao, W.; Cheng, B. Photocatalytic reduction of CO2 into hydrocarbon solar fuels over gC3N4–Pt nanocomposite photocatalysts. Phys. Chem. Chem. Phys. 2014, 16, 11492–11501. [Google Scholar] [CrossRef] [PubMed]

- Reli, M.; Kobielusz, M.; Daniš, S.; Macyk, W.; Obalová, L.; Kuśtrowski, P.; Rokicińska, A.; Kočí, K. TiO2 Processed by pressurized hot solvents as a novel photocatalyst for photocatalytic reduction of carbon dioxide. Appl. Surf. Sci. 2017, 391, 282–287. [Google Scholar] [CrossRef]

- Yan, S.; Ouyang, S.; Xu, H.; Zhao, M.; Zhang, X.; Ye, J. Co-ZIF-9/TiO2 nanostructure for superior CO2 photoreduction activity. J. Mater. Chem. A 2016, 4, 15126–15133. [Google Scholar] [CrossRef]

- Yu, J.; Jin, J.; Cheng, B.; Jaroniec, M. A noble metal-free reduced graphene oxide–CdS nanorod composite for the enhanced visible-light photocatalytic reduction of CO2 to solar fuel. J. Mater. Chem. A 2014, 2, 3407–3416. [Google Scholar] [CrossRef]

- Meng, A.; Zhu, B.; Zhong, B.; Zhang, L.; Cheng, B. Direct Z-scheme TiO2/CdS hierarchical photocatalyst for enhanced photocatalytic H2-production activity. Appl. Surf. Sci. 2017, 422, 518–527. [Google Scholar] [CrossRef]

- Yu, W.; Zhang, J.; Peng, T. New insight into the enhanced photocatalytic activity of N-, C-and S-doped ZnO photocatalysts. Appl. Catal. B Environ. 2016, 181, 220–227. [Google Scholar] [CrossRef]

- Yu, W.; Chen, J.; Shang, T.; Chen, L.; Gu, L.; Peng, T. Direct Z-scheme g-C3N4/WO3 photocatalyst with atomically defined junction for H2 production. Appl. Catal. B Environ. 2017, 219, 693–704. [Google Scholar] [CrossRef]

- Akple, M.S.; Low, J.; Qin, Z.; Wageh, S.; Al-Ghamdi, A.A.; Yu, J.; Liu, S. Nitrogen-doped TiO2 microsheets with enhanced visible light photocatalytic activity for CO2 reduction. Chin. J. Catal. 2015, 36, 2127–2134. [Google Scholar] [CrossRef]

- Low, J.; Yu, J.; Ho, W. Graphene-based photocatalysts for CO2 reduction to solar fuel. J. Phys. Chem. Lett. 2015, 6, 4244–4251. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.; Razzaq, A.; Sorcar, S.; Park, Y.; Grimes, C.A.; In, S.-I. Hybrid mesoporous Cu2ZnSnS4 (CZTS)–TiO2 photocatalyst for efficient photocatalytic conversion of CO2 into CH4 under solar irradiation. RSC Adv. 2016, 6, 38964–38971. [Google Scholar] [CrossRef]

- Sorcar, S.; Hwang, Y.; Grimes, C.A.; In, S.-I. Highly enhanced and stable activity of defect-induced titania nanoparticles for solar light-driven CO2 reduction into CH4. Mater. Today 2017, 20, 507–515. [Google Scholar] [CrossRef]

- Tjandra, A.D.; Huang, J. Photocatalytic carbon dioxide reduction by photocatalyst innovation. Chin. Chem. Lett. 2018, 31, 734–746. [Google Scholar] [CrossRef]

- Grills, D.C.; Fujita, E. New directions for the photocatalytic reduction of CO2: Supramolecular, scCO2 or biphasic ionic liquid−scCO2 systems. J. Phys. Chem. Lett. 2010, 1, 2709–2718. [Google Scholar] [CrossRef]

- Liu, L.; Zhao, C.; Li, Y. Spontaneous dissociation of CO2 to CO on defective surface of Cu(I)/TiO2–x nanoparticles at room temperature. J. Phys. Chem. C 2012, 116, 7904–7912. [Google Scholar] [CrossRef]

- Corma, A.; Garcia, H. Photocatalytic reduction of CO2 for fuel production: Possibilities and challenges. J. Catal. 2013, 308, 168–175. [Google Scholar] [CrossRef]

- Sato, S.; Arai, T.; Morikawa, T. Toward solar-driven photocatalytic CO2 reduction using water as an electron donor. Inorg. Chem. 2015, 54, 5105–5113. [Google Scholar] [CrossRef]

- Anpo, M. Photocatalytic reduction of CO2 with H2O on highly dispersed Ti-oxide catalysts as a model of artificial photosynthesis. J. CO2 Util. 2013, 1, 8–17. [Google Scholar] [CrossRef]

- Li, K.; Peng, B.; Peng, T. Recent advances in heterogeneous photocatalytic CO2 conversion to solar fuels. ACS Catal. 2016, 6, 7485–7527. [Google Scholar] [CrossRef]

- Habisreutinger, S.N.; Schmidt-Mende, L.; Stolarczyk, J.K. Photocatalytic reduction of CO2 on TiO2 and other semiconductors. Angew. Chem. Int. Ed. 2013, 52, 7372–7408. [Google Scholar] [CrossRef]

- Xin, C.; Hu, M.; Wang, K.; Wang, X. Significant enhancement of photocatalytic reduction of CO2 with H2O over ZnO by the formation of basic zinc carbonate. Langmuir 2017, 33, 6667–6676. [Google Scholar] [CrossRef]

- Liu, X.; Ye, L.; Liu, S.; Li, Y.; Ji, X. Photocatalytic reduction of CO2 by ZnO micro/nanomaterials with different morphologies and ratios of {0001} facets. Sci. Rep. 2016, 6, 38474. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Li, N.; Jiu, H.; Qi, G.; Huang, Y. ZnO-reduced graphene oxide nanocomposites as efficient photocatalysts for photocatalytic reduction of CO2. Ceram. Int. 2015, 41, 6256–6262. [Google Scholar] [CrossRef]

- Xu, Q.; Yu, J.; Zhang, J.; Zhang, J.; Liu, G. Cubic anatase TiO2 nanocrystals with enhanced photocatalytic CO2 reduction activity. Chem. Commun. 2015, 51, 7950–7953. [Google Scholar] [CrossRef]

- Sim, L.C.; Leong, K.H.; Saravanan, P.; Ibrahim, S. Rapid thermal reduced graphene oxide/Pt–TiO2 nanotube arrays for enhanced visible-light-driven photocatalytic reduction of CO2. Appl. Surf. Sci. 2015, 358, 122–129. [Google Scholar] [CrossRef]

- Li, Y.; Wang, W.-N.; Zhan, Z.; Woo, M.-H.; Wu, C.-Y.; Biswas, P. Photocatalytic reduction of CO2 with H2O on mesoporous silica supported Cu/TiO2 catalysts. Appl. Catal. B Environ. 2010, 100, 386–392. [Google Scholar] [CrossRef]

- Wang, T.; Meng, X.; Li, P.; Ouyang, S.; Chang, K.; Liu, G.; Mei, Z.; Ye, J. Photoreduction of CO2 over the well-crystallized ordered mesoporous TiO2 with the confined space effect. Nano Energy 2014, 9, 50–60. [Google Scholar] [CrossRef]

- Wang, L.; Sasaki, T. Titanium oxide nanosheets: Graphene analogues with versatile functionalities. Chem. Rev. 2014, 114, 9455–9486. [Google Scholar] [CrossRef]

- Kar, P.; Zeng, S.; Zhang, Y.; Vahidzadeh, E.; Manuel, A.; Kisslinger, R.; Alam, K.M.; Thakur, U.K.; Mahdi, N.; Kumar, P. High rate CO2 photoreduction using flame annealed TiO2 nanotubes. Appl. Catal. B Environ. 2019, 243, 522–536. [Google Scholar] [CrossRef]

- Fang, W.; Khrouz, L.; Zhou, Y.; Shen, B.; Dong, C.; Xing, M.; Mishra, S.; Daniele, S.; Zhang, J. Reduced {001}-TiO2−x photocatalysts: Noble-metal-free CO2 photoreduction for selective CH4 evolution. Phys. Chem. Chem. Phys. 2017, 19, 13875–13881. [Google Scholar] [CrossRef]

- Ijaz, S.; Ehsan, M.F.; Ashiq, M.N.; Karamat, N.; He, T. Preparation of CdS@CeO2 core/shell composite for photocatalytic reduction of CO2 under visible-light irradiation. Appl. Surf. Sci. 2016, 390, 550–559. [Google Scholar] [CrossRef]

- Cho, K.M.; Kim, K.H.; Park, K.; Kim, C.; Kim, S.; Al-Saggaf, A.; Gereige, I.; Jung, H.-T. Amine-functionalized graphene/CdS composite for photocatalytic reduction of CO2. ACS Catal. 2017, 7, 7064–7069. [Google Scholar] [CrossRef]

- Yang, X.; Xin, W.; Yin, X.; Shao, X. Syntheses and evaluations of CdS with various morphologies for photocatalytically reducing CO2. J. Wuhan Univ. Technol. Sci. Ed. 2018, 33, 78–84. [Google Scholar] [CrossRef]

- Wang, J.-C.; Zhang, L.; Fang, W.-X.; Ren, J.; Li, Y.-Y.; Yao, H.-C.; Wang, J.-S.; Li, Z.-J. Enhanced photoreduction CO2 activity over direct Z-scheme α-Fe2O3/Cu2O heterostructures under visible light irradiation. ACS Appl. Mater. Interfaces 2015, 7, 8631–8639. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Jing, H.; Xu, J.; Wu, C.; Peng, H.; Lu, J.; Lu, F. High-efficiency synergistic conversion of CO2 to methanol using Fe2O3 nanotubes modified with double-layer Cu2O spheres. Nanoscale 2014, 6, 11380–11386. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Liu, H.; Xu, Y.; Zhang, X. Preparation of Fe2O3-TiO2 and its photocatalytic reduction of CO2 to methanol. Asian J. Chem. 2014, 26, 3875–3878. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, H.; Wu, Z.; Wang, L. g-C3N4 based composite photocatalysts for photocatalytic CO2 reduction. Catal. Today 2018, 300, 160–172. [Google Scholar] [CrossRef]

- Tang, J.; Zhou, W.; Guo, R.; Huang, C.; Pan, W. Enhancement of photocatalytic performance in CO2 reduction over Mg/g-C3N4 catalysts under visible light irradiation. Catal. Commun. 2018, 107, 92–95. [Google Scholar] [CrossRef]

- Ye, L.; Wu, D.; Chu, K.H.; Wang, B.; Xie, H.; Yip, H.Y.; Wong, P.K. Phosphorylation of g-C3N4 for enhanced photocatalytic CO2 reduction. Chem. Eng. J. 2016, 304, 376–383. [Google Scholar] [CrossRef]

- Ong, W.-J.; Tan, L.-L.; Chai, S.-P.; Yong, S.-T.; Mohamed, A.R. Surface charge modification via protonation of graphitic carbon nitride (g-C3N4) for electrostatic self-assembly construction of 2D/2D reduced graphene oxide (rGO)/g-C3N4 nanostructures toward enhanced photocatalytic reduction of carbon dioxide to methane. Nano Energy 2015, 13, 757–770. [Google Scholar] [CrossRef]

- Wang, K.; Li, Q.; Liu, B.; Cheng, B.; Ho, W.; Yu, J. Sulfur-doped g-C3N4 with enhanced photocatalytic CO2-reduction performance. Appl. Catal. B Environ. 2015, 176, 44–52. [Google Scholar] [CrossRef]

- Li, F.; Zhang, L.; Tong, J.; Liu, Y.; Xu, S.; Cao, Y.; Cao, S. Photocatalytic CO2 conversion to methanol by Cu2O/graphene/TNA heterostructure catalyst in a visible-light-driven dual-chamber reactor. Nano Energy 2016, 27, 320–329. [Google Scholar] [CrossRef]

- Xu, H.; Ouyang, S.; Liu, L.; Wang, D.; Kako, T.; Ye, J. Porous-structured Cu2O/TiO2 nanojunction material toward efficient CO2 photoreduction. Nanotechnology 2014, 25, 165402. [Google Scholar] [CrossRef] [PubMed]

- An, X.; Li, K.; Tang, J. Cu2O/reduced graphene oxide composites for the photocatalytic conversion of CO2. ChemSusChem 2014, 7, 1086–1093. [Google Scholar] [CrossRef]

- Murcia-López, S.; Vaiano, V.; Hidalgo, M.C.; Navío, J.A.; Sannino, D. Photocatalytic reduction of CO2 over platinised Bi2WO6-based materials. Photochem. Photobiol. Sci. 2015, 14, 678–685. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Yang, Z.; Liu, H.; Wang, H.; Wu, Z. Visible-light CO2 photocatalytic reduction performance of ball-flower-like Bi2WO6 synthesized without organic precursor: Effect of post-calcination and water vapor. Appl. Surf. Sci. 2014, 315, 360–367. [Google Scholar] [CrossRef]

- Kong, X.Y.; Choo, Y.Y.; Chai, S.-P.; Soh, A.K.; Mohamed, A.R. Oxygen vacancy induced Bi2WO6 for the realization of photocatalytic CO2 reduction over the full solar spectrum: From the UV to the NIR region. Chem. Commun. 2016, 52, 14242–14245. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Yu, J.; Jaroniec, M. Hierarchical photocatalysts. Chem. Soc. Rev. 2016, 45, 2603–2636. [Google Scholar] [CrossRef] [PubMed]

- Zhou, P.; Yu, J.; Jaroniec, M. All-solid-state Z-scheme photocatalytic systems. Adv. Mater. 2014, 26, 4920–4935. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Ouyang, S.; Xi, G.; Kako, T.; Ye, J. The effects of crystal structure and electronic structure on photocatalytic H2 evolution and CO2 reduction over two phases of perovskite-structured NaNbO3. J. Phys. Chem. C 2012, 116, 7621–7628. [Google Scholar] [CrossRef]

- Iizuka, K.; Wato, T.; Miseki, Y.; Saito, K.; Kudo, A. Photocatalytic reduction of carbon dioxide over Ag cocatalyst-loaded ALa4Ti4O15 (A= Ca, Sr, and Ba) using water as a reducing reagent. J. Am. Chem. Soc. 2011, 133, 20863–20868. [Google Scholar] [CrossRef] [PubMed]

- Fang, M.; Dong, G.; Wei, R.; Ho, J.C. Hierarchical nanostructures: Design for sustainable water splitting. Adv. Energy Mater. 2017, 7, 1700559. [Google Scholar] [CrossRef]

- Gao, X.; Li, G.; Xu, Y.; Hong, Z.; Liang, C.; Lin, Z. TiO2 Microboxes with controlled internal porosity for high-performance lithium storage. Angew. Chem. Int. Ed. 2015, 54, 14331–14335. [Google Scholar] [CrossRef]

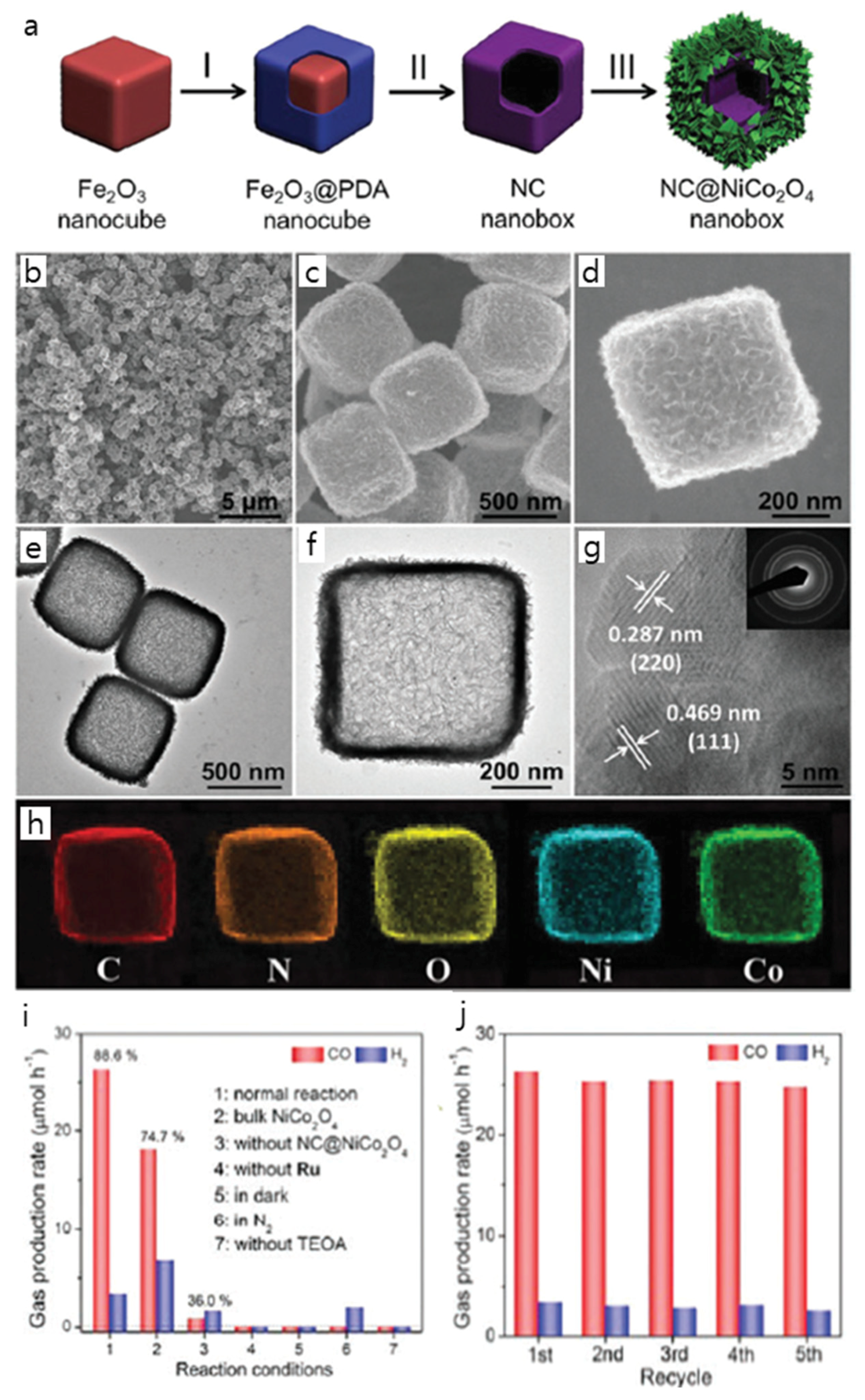

- Wang, S.; Guan, B.Y.; Lou, X.W.D. Rationally designed hierarchical N-doped carbon@NiCo2O4 double-shelled nanoboxes for enhanced visible light CO2 reduction. Energy Environ. Sci. 2018, 11, 306–310. [Google Scholar] [CrossRef]

- Ali, S.; Razzaq, A.; In, S.-I. Development of graphene based photocatalysts for CO2 reduction to C1 chemicals: A brief overview. Catal. Today 2018. [Google Scholar] [CrossRef]

- Jiao, W.; Wang, L.; Liu, G.; Lu, G.Q.; Cheng, H.-M. Hollow anatase TiO2 single crystals and mesocrystals with dominant {101} facets for improved photocatalysis activity and tuned reaction preference. ACS Catal. 2012, 2, 1854–1859. [Google Scholar] [CrossRef]

- Xiao, L.; Lin, R.; Wang, J.; Cui, C.; Wang, J.; Li, Z. A novel hollow-hierarchical structured Bi2WO6 with enhanced photocatalytic activity for CO2 photoreduction. J. Colloid Interface Sci. 2018, 523, 151–158. [Google Scholar] [CrossRef]

- Pan, B.; Zhou, Y.; Su, W.; Wang, X. Self-assembly synthesis of LaPO4 hierarchical hollow spheres with enhanced photocatalytic CO2-reduction performance. Nano Res. 2017, 10, 534–545. [Google Scholar] [CrossRef]

- Fu, J.; Zhu, B.; Jiang, C.; Cheng, B.; You, W.; Yu, J. Hierarchical porous O-doped g-C3N4 with enhanced photocatalytic CO2 reduction activity. Small 2017, 13, 1603938. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Yu, J.C.; Ho, C.; Hou, Y.; Fu, X. Photocatalytic activity of a hierarchically macro/mesoporous titania. Langmuir 2005, 21, 2552–2559. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Zhang, J.; Zhang, M.; Antonietti, M.; Fu, X.; Wang, X. Bioinspired hollow semiconductor nanospheres as photosynthetic nanoparticles. Nat. Commun. 2012, 3, 1139. [Google Scholar] [CrossRef]

- Hailili, R.; Jacobs, D.L.; Zang, L.; Wang, C. Morphology controlled synthesis of CeTiO4 using molten salts and enhanced photocatalytic activity for CO2 reduction. Appl. Surf. Sci. 2018, 456, 360–368. [Google Scholar] [CrossRef]

- Zhang, S.; Li, L.; Zhao, S.; Sun, Z.; Hong, M.; Luo, J. Hierarchical metal-organic framework nanoflowers for effective CO2 transformation driven by visible light. J. Mater. Chem. A 2015, 3, 15764–15768. [Google Scholar] [CrossRef]

- Dai, W.; Yu, J.; Xu, H.; Hu, X.; Luo, X.; Yang, L.; Tu, X. Synthesis of hierarchical flower-like Bi2MoO6 microspheres as efficient photocatalyst for photoreduction of CO2 into solar fuels under visible light. CrystEngComm 2016, 18, 3472–3480. [Google Scholar] [CrossRef]

- Dai, W.; Hu, X.; Wang, T.; Xiong, W.; Luo, X.; Zou, J. Hierarchical CeO2/Bi2MoO6 heterostructured nanocomposites for photoreduction of CO2 into hydrocarbons under visible light irradiation. Appl. Surf. Sci. 2018, 434, 481–491. [Google Scholar] [CrossRef]

- Zhou, H.; Guo, J.; Li, P.; Fan, T.; Zhang, D.; Ye, J. Leaf-architectured 3D hierarchical artificial photosynthetic system of perovskite titanates towards CO2 photoreduction into hydrocarbon fuels. Sci. Rep. 2013, 3, 1667. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Wang, S.; Guan, B.Y.; Lou, X.W.D. Fabrication of CdS hierarchical multi-cavity hollow particles for efficient visible light CO2 reduction. Energy Environ. Sci. 2019, 12, 164–168. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, L.; Zhang, X.; Zhang, Z.; Tong, Y.; Li, F.; Wu, J.C.-S.; Wang, X. Openmouthed β-SiC hollow-sphere with highly photocatalytic activity for reduction of CO2 with H2O. Appl. Catal. B Environ. 2017, 206, 158–167. [Google Scholar] [CrossRef]

- Fang, B.; Bonakdarpour, A.; Reilly, K.; Xing, Y.; Taghipour, F.; Wilkinson, D.P. Large-scale synthesis of TiO2 microspheres with hierarchical nanostructure for highly efficient photodriven reduction of CO2 to CH4. ACS Appl. Mater. Interfaces 2014, 6, 15488–15498. [Google Scholar] [CrossRef] [PubMed]

- Di, T.; Zhang, J.; Cheng, B.; Yu, J.; Xu, J. Hierarchically nanostructured porous TiO2(B) with superior photocatalytic CO2 reduction activity. Sci. China Chem. 2018, 61, 344–350. [Google Scholar] [CrossRef]

- Jin, J.; Yu, J.; Guo, D.; Cui, C.; Ho, W. A Hierarchical Z-scheme CdS–WO3 photocatalyst with enhanced CO2 reduction activity. Small 2015, 11, 5262–5271. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.; Sun, X.; Qin, B.; Yu, T. Improving the photocatalytic reduction of CO2 to CO for TiO2 hollow spheres through hybridization with a cobalt complex. RSC Adv. 2018, 8, 20543–20548. [Google Scholar] [CrossRef]

- Wu, H.; Kong, D.; Ruan, Z.; Hsu, P.-C.; Wang, S.; Yu, Z.; Carney, T.J.; Hu, L.; Fan, S.; Cui, Y. A transparent electrode based on a metal nanotrough network. Nat. Nanotechnol. 2013, 8, 421–425. [Google Scholar] [CrossRef] [PubMed]

- Le, V.T.; Kim, H.; Ghosh, A.; Kim, J.; Chang, J.; Vu, Q.A.; Pham, D.T.; Lee, J.-H.; Kim, S.-W.; Lee, Y.H. Coaxial fiber supercapacitor using all-carbon material electrodes. ACS Nano 2013, 7, 5940–5947. [Google Scholar] [CrossRef]

- Reñones, P.; Moya, A.; Fresno, F.; Collado, L.; Vilatela, J.J.; Víctor, A. Hierarchical TiO2 nanofibres as photocatalyst for CO2 reduction: Influence of morphology and phase composition on catalytic activity. J. CO2 Util. 2016, 15, 24–31. [Google Scholar] [CrossRef]

- Xu, F.; Zhang, J.; Zhu, B.; Yu, J.; Xu, J. CuInS2 sensitized TiO2 hybrid nanofibers for improved photocatalytic CO2 reduction. Appl. Catal. B Environ. 2018, 230, 194–202. [Google Scholar] [CrossRef]

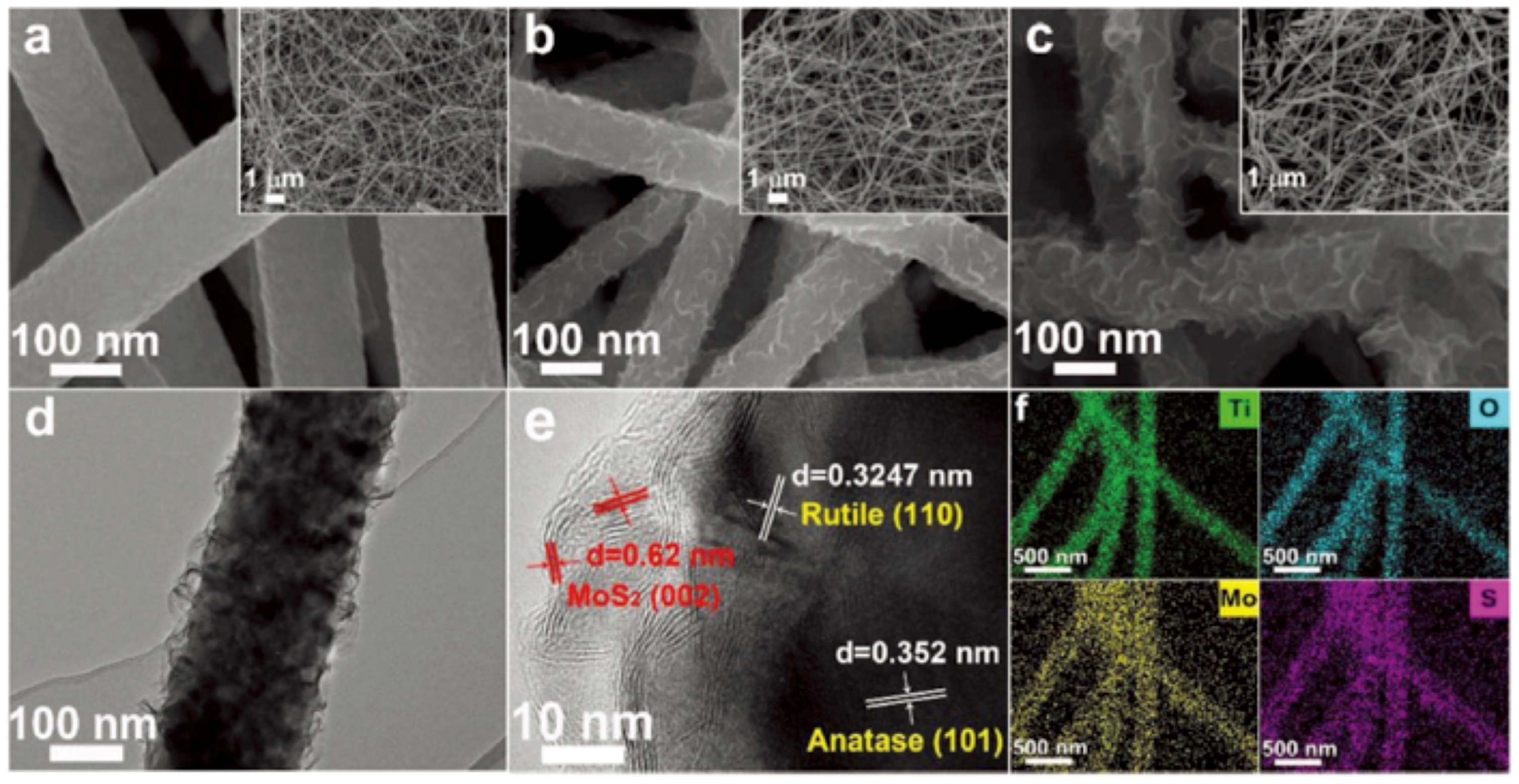

- Xu, F.; Zhu, B.; Cheng, B.; Yu, J.; Xu, J. 1D/2D TiO2/MoS2 hybrid nanostructures for enhanced photocatalytic CO2 reduction. Adv. Opt. Mater. 2018, 6, 1800911. [Google Scholar] [CrossRef]

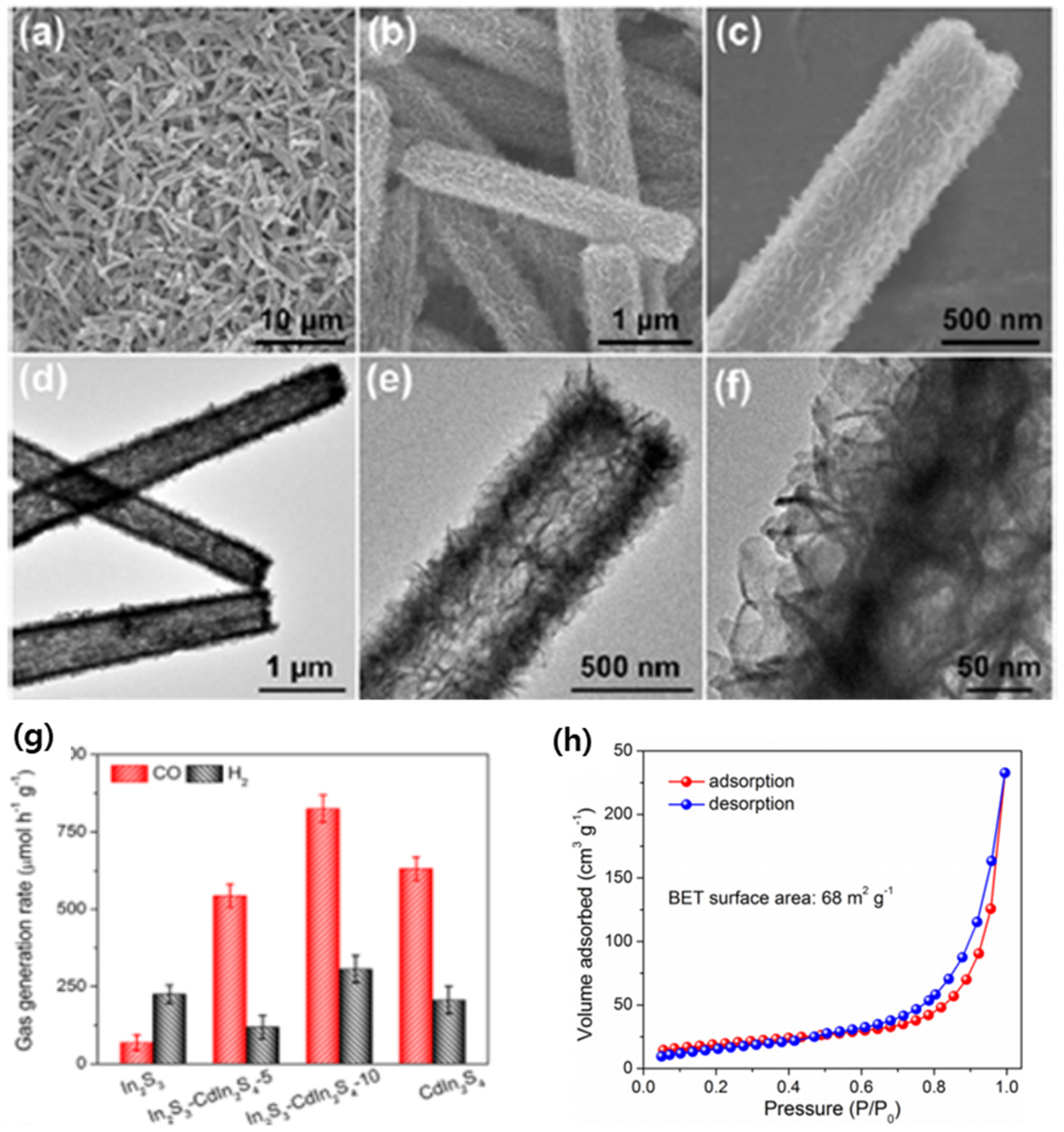

- Wang, S.; Guan, B.Y.; Lu, Y.; Lou, X.W. Formation of hierarchical In2S3–CdIn2S4 heterostructured nanotubes for efficient and stable visible light CO2 reduction. J. Am. Chem. Soc. 2017, 139, 17305–17308. [Google Scholar] [CrossRef]

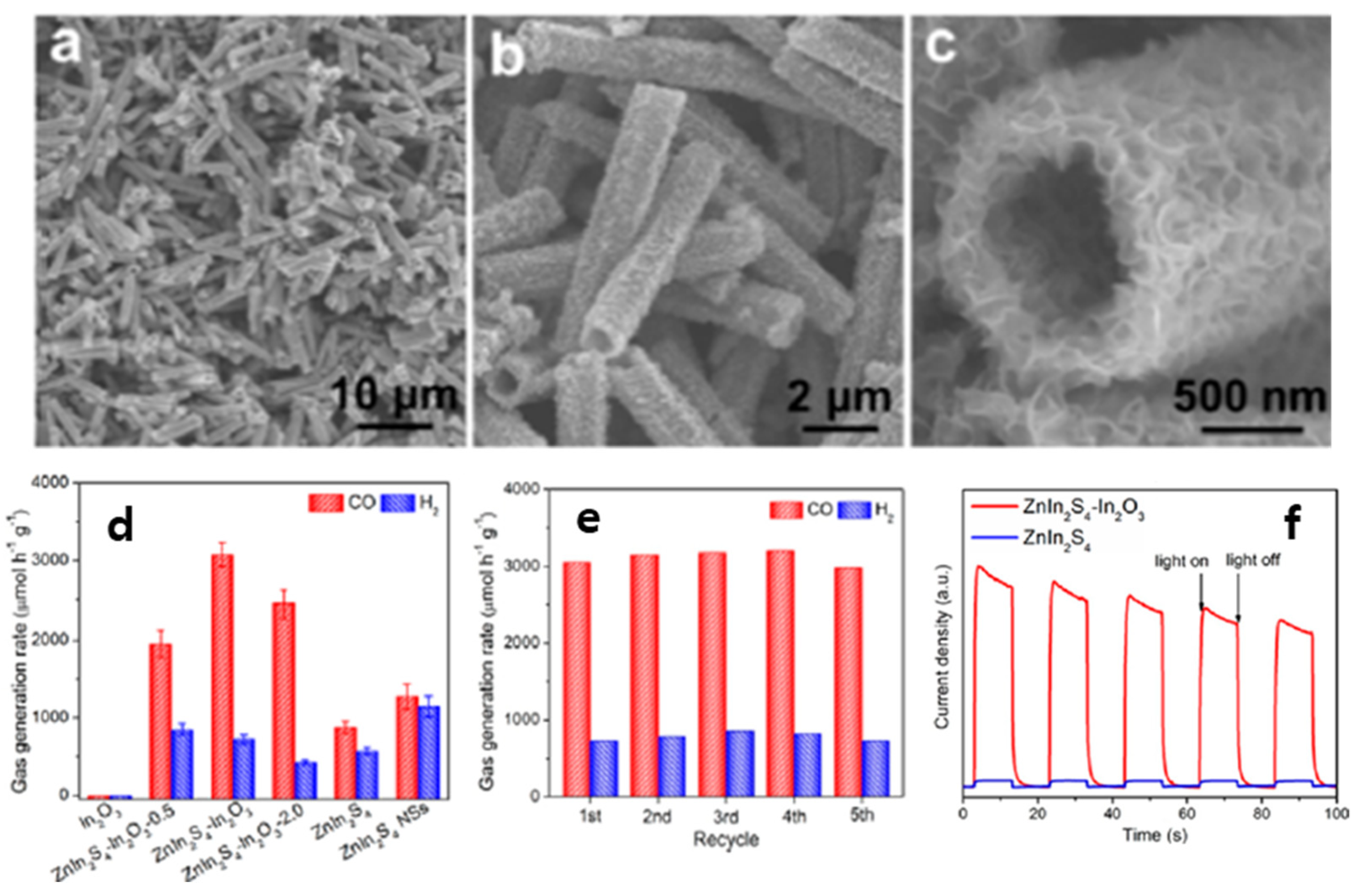

- Wang, S.; Guan, B.Y.; Lou, X.W.D. Construction of ZnIn2S4–In2O3 hierarchical tubular heterostructures for efficient CO2 photoreduction. J. Am. Chem. Soc. 2018, 140, 5037–5040. [Google Scholar] [CrossRef]

- Bafaqeer, A.; Tahir, M.; Amin, N.A.S. Synthesis of hierarchical ZnV2O6 nanosheets with enhanced activity and stability for visible light driven CO2 reduction to solar fuels. Appl. Surf. Sci. 2018, 435, 953–962. [Google Scholar] [CrossRef]

- Jung, H.; Cho, K.M.; Kim, K.H.; Yoo, H.-W.; Al-Saggaf, A.; Gereige, I.; Jung, H.-T. Highly efficient and stable CO2 reduction photocatalyst with a hierarchical structure of mesoporous TiO2 on 3D graphene with few-layered MoS2. ACS Sustain. Chem. Eng. 2018, 6, 5718–5724. [Google Scholar] [CrossRef]

- Qiu, B.; Zhu, Q.; Du, M.; Fan, L.; Xing, M.; Zhang, J. Efficient solar light harvesting CdS/Co9S8 hollow cubes for Z-Scheme photocatalytic water splitting. Angew. Chem. Int. Ed. 2017, 56, 2684–2688. [Google Scholar] [CrossRef]

- Sakimoto, K.K.; Wong, A.B.; Yang, P. Self-photosensitization of nonphotosynthetic bacteria for solar-to-chemical production. Science 2016, 351, 74–77. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Z.; Sun, H.; Wang, T.; Wang, B.; Wei, W.; Li, H.; Yuan, S.; An, T.; Zhao, H.; Yu, J. Nature-based catalyst for visible-light-driven photocatalytic CO2 reduction. Energy Environ. Sci. 2018, 11, 2382–2389. [Google Scholar] [CrossRef]

| Reaction | Product | E°redox | Equation |

|---|---|---|---|

| CO2 + e− → CO2• − | CO2• − anion radical | −1.90 V | (1) |

| CO2 + 2H+ + 2e− → HCOOH | Formic acid | −0.61 V | (2) |

| CO2 + 2H+ + 2e− → CO + H2O | Carbon monoxide | −0.53 V | (3) |

| CO2 + 4H+ + 4e− → HCHO + H2O | Formaldehyde | −0.48 V | (4) |

| CO2 + 6H+ + 6e− → CH3OH + H2O | Methanol | −0.38 V | (5) |

| CO2 + 8H+ + 8e− → CH4 + 2H2O | Methane | −0.24 V | (6) |

| 2H+ + 2e− → H2 | Hydrogen | −0.41 V | (7) |

| Hierarchical Morphology | Photocatalyst | Light Source and Reactor Type | CO2 Photoreduction Results; Yield and AQY | Ref. |

|---|---|---|---|---|

| Flower-, leaf- and fruit-like structures | Ru-MOF | A 500 W Xe lamp, liquid phase, in a 100 mL Schlenk tube (triethanolamine as a sacrificial agent) | HCOO−, 24.7 µmol g−1 (8 h), AQY 0.67% | [89] |

| Bi2MoO6 | A 300 W Xe arc lamp, liquid phase, in closed vessel | CH3OH, 24.8 and C2H5OH, 18.8 µmol g−1 (4 h) | [90] | |

| CeO2@Bi2MoO6 | A 300 W Xe arc lamp (PLS-SXE300) with a 420 nm, a closed 200 mL quartz glass reactor containing 50 mL of ultrapure water | CH3OH and C2H5OH, 58.4 µmol g−1 (4 h) | [91] | |

| Perovskite Titanates | A 300 W Xe arc lamp, A gas closed circulation system with an upside window with λ > 420 nm cut-off-filter | CO, 349 and CH4, 231 nmol g−1 h−1 | [94] | |

| Au@CdS HMCHPs (Au, 0.25%) | A 300 W Xe lamp with long-pass cutoff filter, a gas-closed glass reactor (80 mL) | CO, 3758 µmol g−1 h−1, AQY, 0.61% | [95] | |

| Spheres (nano/micro) | Pt doped TiO2 spheres | A 40 W Hg UV lamp, a batch reactor (diameter of 39 mm and depth of 9 mm) | CO, 19 and CH4, 3.5 µmol g−1 h−1, AQY, CO, 1.632% CH4, 1.315% | [97] |

| Porous TiO2 | A 300 W Xe lamp, homemade Pyrex reactor (200 mL) | CH4, 0.23 μmol h−1 and CH3OH, 0.08 μmol h−1 | [98] | |

| LaPO4 | A 125-W high-pressure Hg lamp, Inner-irradiation quartz reactor (200-mL), Liquid phase | CH4, 10.5 μmol, AQY of 0.54% | [86] | |

| CdS-WO3 | A 300 W Xe arc lamp with a UV cut-off- filter (λ ≥ 420 nm), home-made Pyrex reactor (200 mL) | CH4, 1.02 µmol g−1 h−1 | [99] | |

| Hollow TiO2 | A non-focused 6 W UV lights (Hitachi F6T5, 365nm), Schlenk flask (80 mL) | CO, 16.8 and H2, 6.6 µmol (2h), AQY, 0.66% | [100] | |

| Nanofibers | Mesoporous TiO2 | A 6 W UV lamp (λmax = 365 nm), gas-phase stainless steel photoreactor (190 mL) | CO, 203.91, CH4, 26.88, CH3OH, 5.04 and H2, 398.84 µmol g−1 AQY, 0.030% | [103] |

| TiO2/Ni(OH)2 | A 350 W Xe lamp (40 mW cm−2), self-designed reactor | CH4, 2.20, CO, 0.71 and CH3OH, 0.11 µmol g−1 h−1 | [26] | |

| 2.5% CuInS2/ TiO2 | A 50 W Xe lamp, home-made Pyrex reactor (200 mL) | CH4, 2.5 and CH3OH, 0.86 μmol g–1 h–1 | [104] | |

| 10% MoS2/TiO2 | A 350 W Xe lamp, home-made reactor | CH4, 2.86 and CH3OH, 2.55 μmol g–1 h–1, AQY, 0.16% | [105] | |

| Nanotubes | O-g-C3N4 | A 350 W Xe lamp along with a 420 nm cut-off-filter, Double-neck cylindrical home-made flask (200 mL) | CH3OH, 0.88 μmol g–1 h–1 | [87] |

| In2S3-CdIn2S4 | A 300 W Xe lamp (400 nm cut-off-filter), An 80 mL reactor | CO, 825 μmol h−1 g−1 | [106] | |

| ZnIn2S4-In2O3 | A 300 W Xe lamp along with a 400 nm cut-off-filter, A 80 mL glass reactor (with gas-closed) | CO, 3075 μmol h−1 g−1 | [107] | |

| Bi2WO6 | A 300 W Xe lamp, A 100 mL quartz reactor | CH4, 2.6 μmol g−1 h−1 | [85] | |

| Sheets (and platelets) | ZnV2O6 | A 35 W HID Xe lamp, A slurry type photoreactor with quartz glass | CH3OH, 3253.84, HCOOH, 2886.9 and CH3COOH, 530.1 μmol g−1 | [108] |

| TiO2-graphene-MoS2 | A 300 W Xe lamp, stainless-steel reactor | 2.33 μmol g−1 h−1 | [109] | |

| Nanoboxes | N-carbon@NiCO2O4 | A 300W Xe lamp (420 nm cut-off-filter), 80 mL glass reactor | 26.2 μmol h−1 | [82] |

| Nature based materials | ||||

| Oval | Treated rape pollen | 300 W Xenon lamp, closed gas system | CO, 488.4 μmol h−1 g−1, Quantum Efficiency (QE), 6.7% | [112] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hiragond, C.; Ali, S.; Sorcar, S.; In, S.-I. Hierarchical Nanostructured Photocatalysts for CO2 Photoreduction. Catalysts 2019, 9, 370. https://doi.org/10.3390/catal9040370

Hiragond C, Ali S, Sorcar S, In S-I. Hierarchical Nanostructured Photocatalysts for CO2 Photoreduction. Catalysts. 2019; 9(4):370. https://doi.org/10.3390/catal9040370

Chicago/Turabian StyleHiragond, Chaitanya, Shahzad Ali, Saurav Sorcar, and Su-Il In. 2019. "Hierarchical Nanostructured Photocatalysts for CO2 Photoreduction" Catalysts 9, no. 4: 370. https://doi.org/10.3390/catal9040370

APA StyleHiragond, C., Ali, S., Sorcar, S., & In, S.-I. (2019). Hierarchical Nanostructured Photocatalysts for CO2 Photoreduction. Catalysts, 9(4), 370. https://doi.org/10.3390/catal9040370