Production of 1,3-Propanediol from Pure and Crude Glycerol Using Immobilized Clostridium butyricum

Abstract

:1. Introduction

2. Results and Discussion

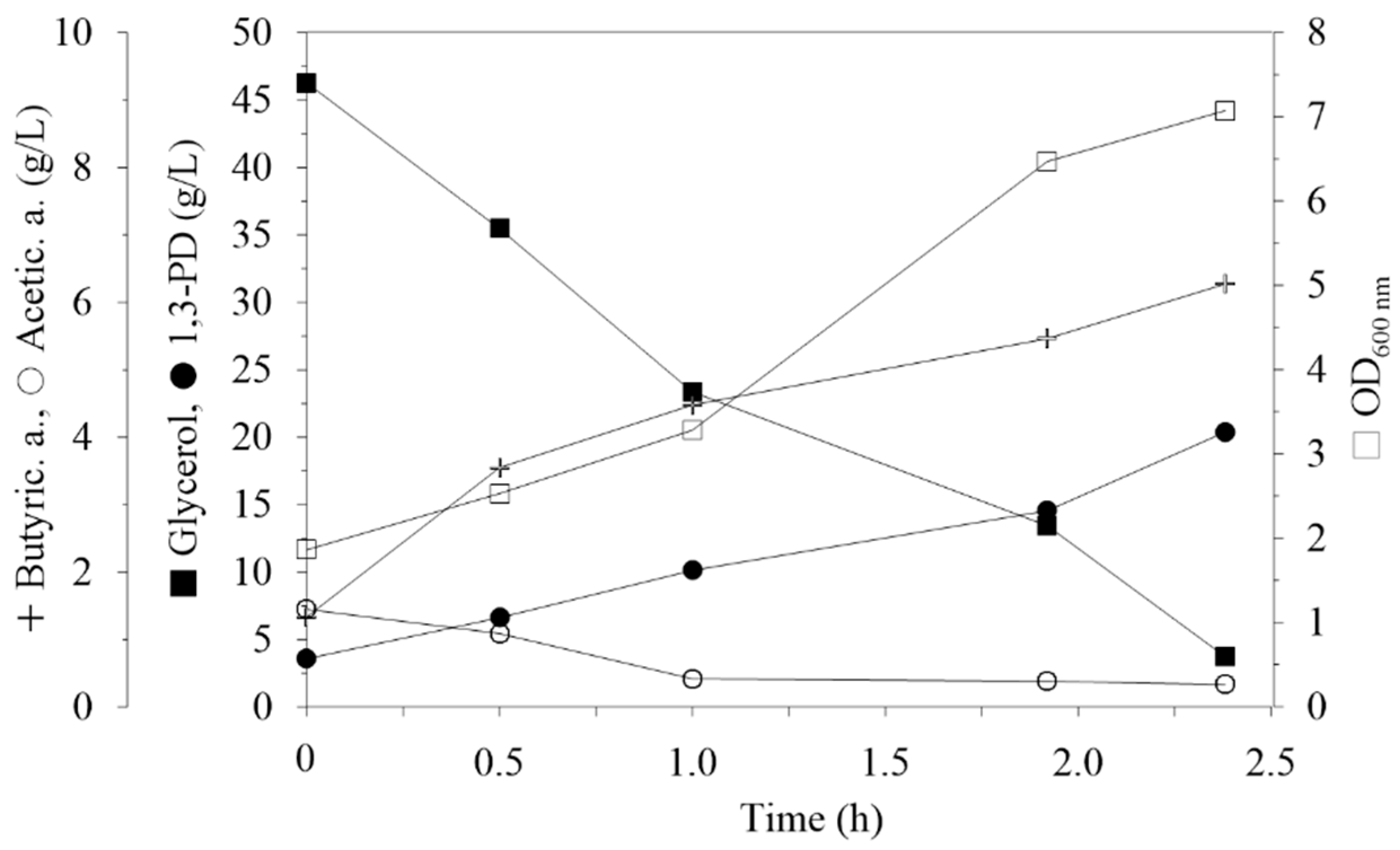

2.1. Fermentation with Free Cells

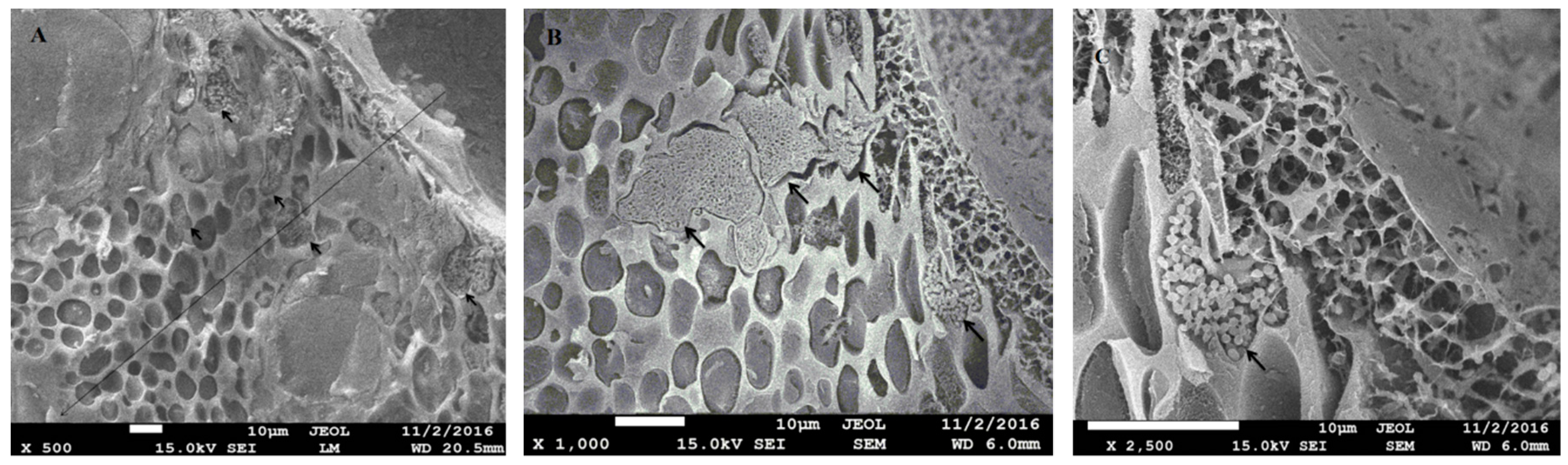

2.2. Immobilization of C. butyricum into PVA by Entrapment

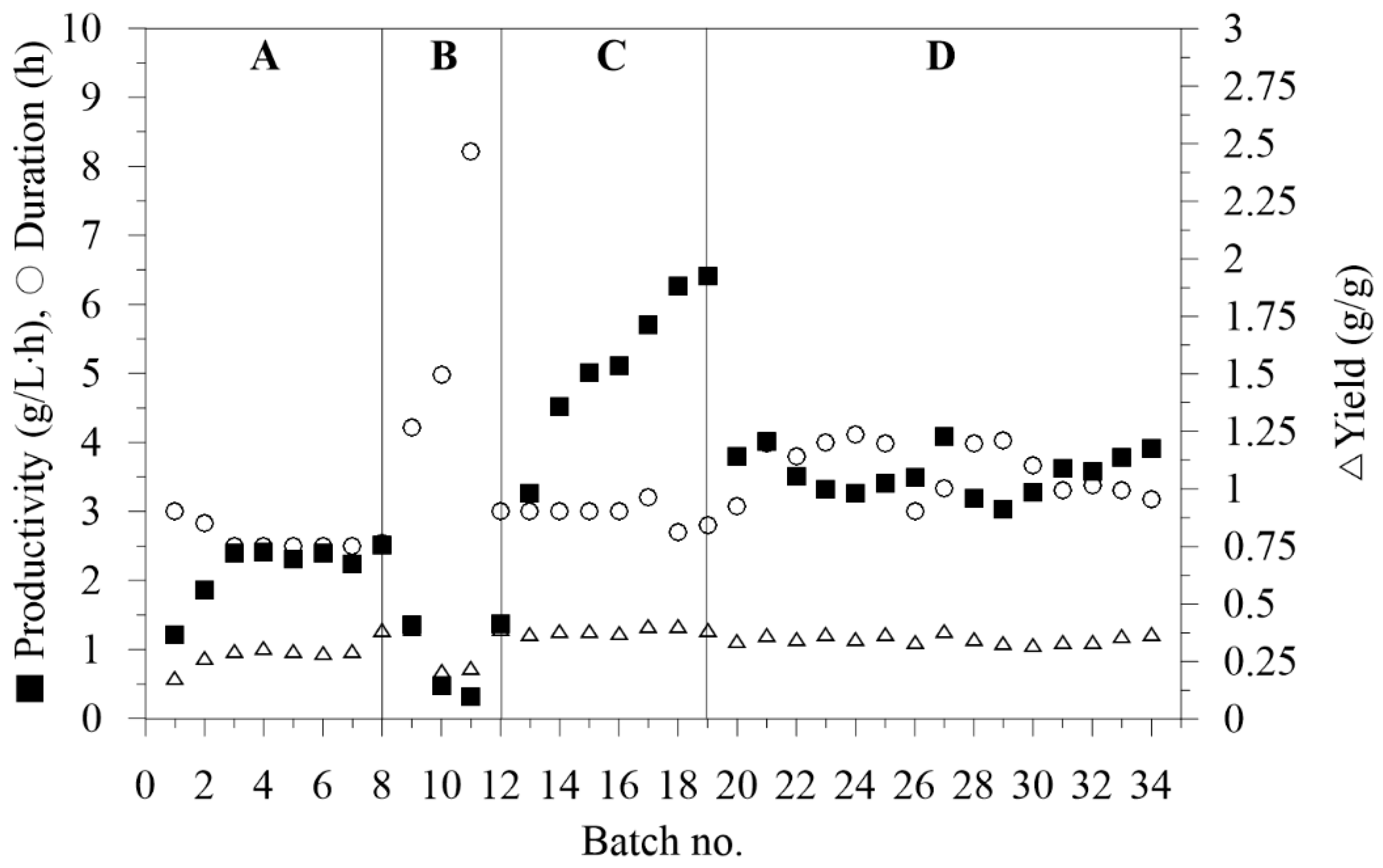

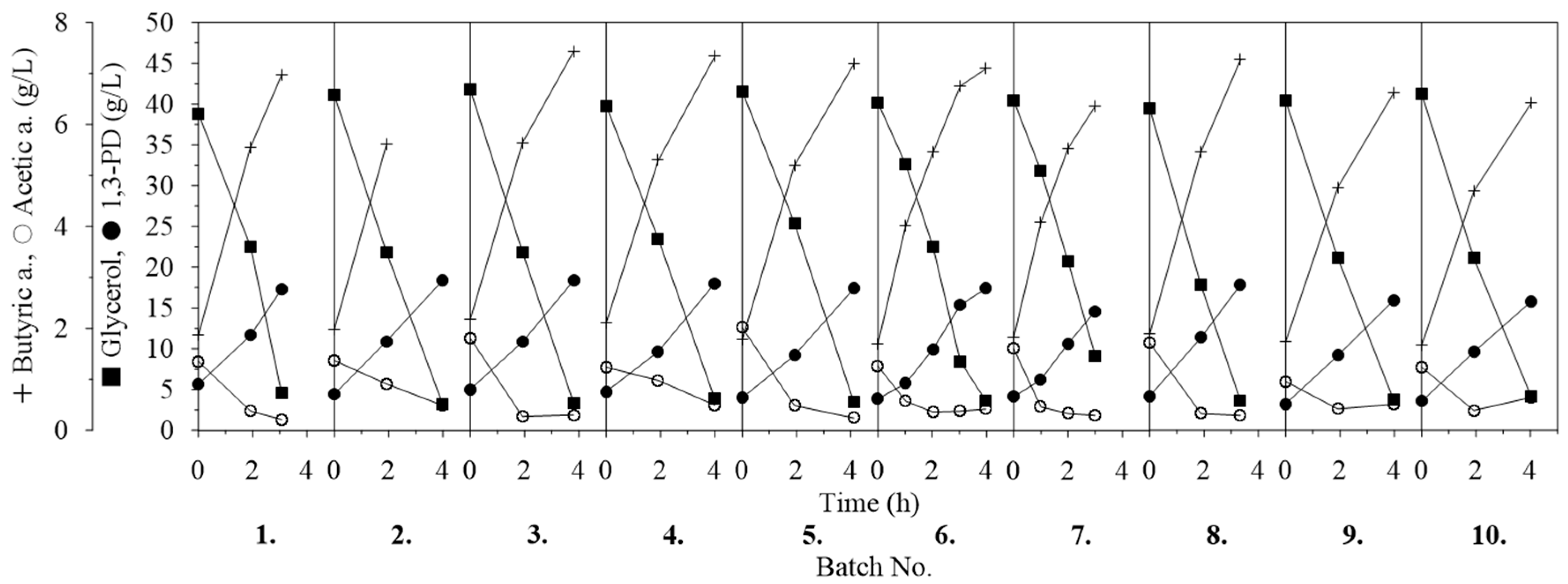

2.3. Propagation of the Immobilised C. butyricum on Pure Glycerol

2.4. Colonisation of the PVA Particles by C. butyricum Originated from the Free-Cell Suspension (Adsorption onto PVA Particles)

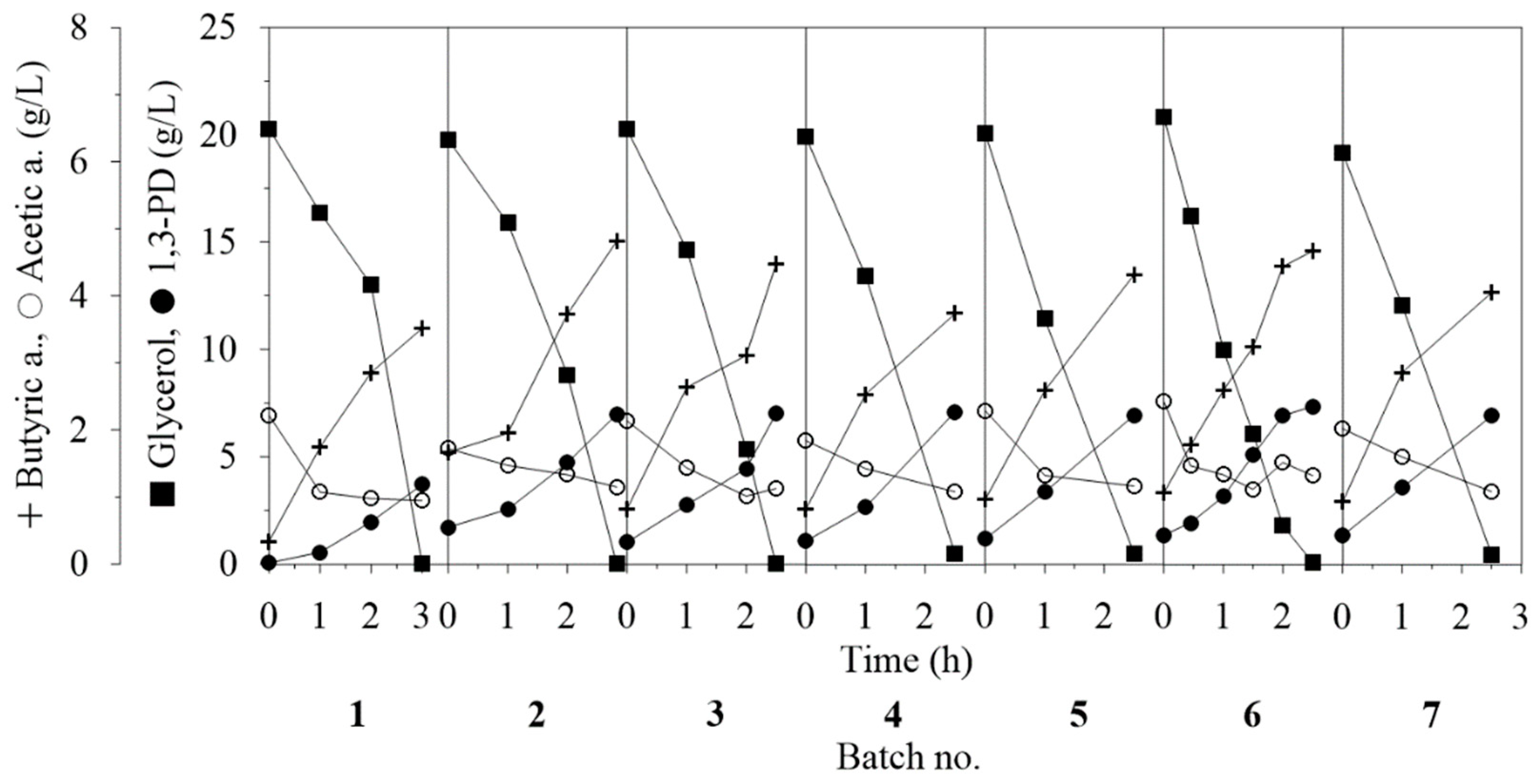

2.5. Crude Glycerol Fermentation by Immobilized C. butyricum

2.6. Crude Glycerol Produced from UCO

2.7. Revitalization Protocol

2.8. Crude Glycerol Produced from RO

3. Materials and Methods

3.1. Strain

3.2. Media

3.3. Biomass Preparation and Fermentation Performance

3.4. Biomass Immobilization

3.5. Analytical Assays

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Zhu, C.; Fang, B. Application of a two-stage temperature control strategy to enhance 1,3-propanediol productivity by clostridium butyricum. J. Chem. Technol. Biotechnol. 2013, 88, 853–857. [Google Scholar] [CrossRef]

- Lee, C.S.; Aroua, M.K.; Daud, W.M.A.W.; Cognet, P.; Pérès-Lucchese, Y.; Fabre, P.L.; Reynes, O.; Latapie, L. A review: Conversion of bioglycerol into 1,3-propanediol via biological and chemical method. Renew. Sustain. Energy Rev. 2015, 42, 963–972. [Google Scholar] [CrossRef]

- Kubiak, P.; Leja, K.; Myszka, K.; Celińska, E.; Spychała, M.; Szymanowska-Powałowska, D.; Czaczyk, K.; Grajek, W. Physiological predisposition of various clostridium species to synthetize 1,3-propanediol from glycerol. Process Biochem. 2012, 47, 1308–1319. [Google Scholar] [CrossRef]

- Kaur, G.; Srivastava, A.K.; Chand, S. Advances in biotechnological production of 1,3-propanediol. Biochem. Eng. J. 2012, 64, 106–118. [Google Scholar] [CrossRef]

- Vivek, N.; Pandey, A.; Binod, P. Production and applications of 1,3-propanediol. In Current Developments in Biotechnology and Bioengineering; Elsevier: Amsterdam, The Netherlands, 2017; pp. 719–738. [Google Scholar]

- Tsuji, Y.; Huh, K.T.; Watanabe, Y. Ruthenium-complex-catalyzed n-heterocyclization. Syntheses of quinolines and indole derivatives from aminoarenes and 1,3-propanediol of glycols. J. Org. Chem. 1987, 52, 1673–1680. [Google Scholar] [CrossRef]

- Monrad, R.N.; Madsen, R. Ruthenium-catalysed synthesis of 2- and 3-substituted quinolines from anilines and 1,3-diols. Org. Biomol. Chem. 2011, 9, 610–615. [Google Scholar] [CrossRef]

- Aramoto, H.; Obora, Y.; Ishii, Y. N-heterocyclization of naphthylamines with 1,2- and 1,3-diols catalyzed by an iridium chloride/binap system. J. Org. Chem. 2009, 74, 628–633. [Google Scholar] [CrossRef] [PubMed]

- Labed, A.; Jiang, F.; Labed, I.; Lator, A.; Peters, M.; Achard, M.; Kabouche, A.; Kabouche, Z.; Sharma, G.V.M.; Bruneau, C. Iridium-catalyzed sustainable access to functionalized julolidines through hydrogen autotransfer. ChemCatChem 2015, 7, 1090–1096. [Google Scholar] [CrossRef]

- Huh, K.-T.; Shim, S.C.; Doh, C.H. Ruthenium complex catalyzed syntehesis of diamino compounds from -diols and secondary amines. Bull. Korean Chem. Soc. 1990, 11, 49. [Google Scholar]

- Maeda, K.; Obora, Y.; Sakaguchi, S.; Ishii, Y. Synthesis of diketones and ω-hydroxy ketones from methyl ketones and α,ω-diols by an [ircl(cod)]2/pph3/koh system. Bull. Chem. Soc. Jpn. 2008, 81, 689–696. [Google Scholar] [CrossRef]

- Andrushko, N.; Andrushko, V.; Roose, P.; Moonen, K.; Börner, A. Amination of aliphatic alcohols and diols with an iridium pincer catalyst. ChemCatChem 2010, 2, 640–643. [Google Scholar] [CrossRef]

- Gao, X.; Han, H.; Krische, M.J. Direct generation of acyclic polypropionate stereopolyads via double diastereo- and enantioselective iridium-catalyzed crotylation of 1,3-diols: Beyond stepwise carbonyl addition in polyketide construction. J. Am. Chem. Soc. 2011, 133, 12795–12800. [Google Scholar] [CrossRef]

- Han, S.B.; Hassan, A.; Kim, I.S.; Krische, M.J. Total synthesis of (+)-roxaticin via c−c bond forming transfer hydrogenation: A departure from stoichiometric chiral reagents, auxiliaries, and premetalated nucleophiles in polyketide construction. J. Am. Chem. Soc. 2010, 132, 15559–15561. [Google Scholar] [CrossRef]

- Lu, Y.; Kim, I.S.; Hassan, A.; Del Valle, D.J.; Krische, M.J. 1,n-glycols as dialdehyde equivalents in iridium-catalyzed enantioselective carbonyl allylation and iterative two-directional assembly of 1,3-polyols. Angew. Chem. Int. Ed. 2009, 48, 5018–5021. [Google Scholar] [CrossRef] [PubMed]

- Lacroix, S.D.; Pennycook, A.; Liu, S.; Eisenhart, T.T.; Marr, A.C. Amination and dehydration of 1,3-propanediol by hydrogen transfer: Reactions of a bio-renewable platform chemical. Catal. Sci. Technol. 2012, 2, 288–290. [Google Scholar] [CrossRef]

- Liu, S.; Rebros, M.; Stephens, G.; Marr, A.C. Adding value to renewables: A one pot process combining microbial cells and hydrogen transfer catalysis to utilise waste glycerol from biodiesel production. Chem. Commun. 2009, 2308–2310. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.-M.; Lorenzini, F.; Rebros, M.; Saunders, G.C.; Marr, A.C. Combining bio- and chemo-catalysis for the conversion of bio-renewable alcohols: Homogeneous iridium catalysed hydrogen transfer initiated dehydration of 1,3-propanediol to aldehydes. Green Chem. 2016, 18, 1751–1761. [Google Scholar] [CrossRef]

- Chatzifragkou, A.; Papanikolaou, S.; Dietz, D.; Doulgeraki, A.I.; Nychas, G.-J.E.; Zeng, A.-P. Production of 1,3-propanediol by clostridium butyricum growing on biodiesel-derived crude glycerol through a non-sterilized fermentation process. Appl. Microbiol. Biotechnol. 2011, 91, 101–112. [Google Scholar] [CrossRef]

- Cho, M.-H.; Joen, S.I.; Pyo, S.-H.; Mun, S.; Kim, J.-H. A novel separation and purification process for 1,3-propanediol. Process Biochem. 2006, 41, 739–744. [Google Scholar] [CrossRef]

- Martin, A.; Armbruster, U.; Gandarias, I.; Arias, P.L. Glycerol hydrogenolysis into propanediols using in situ generated hydrogen—A critical review. Eur. J. Lipid Sci. Technol. 2013, 115, 9–27. [Google Scholar] [CrossRef]

- Drozdzynska, A.; Leja, K.; Czaczyk, K. Biotechnological production of 1,3-propanediol from crude glycerol. Biotechnol. J. Biotechnol. Comput. Biol. Bionanotechnol. 2011, 92, 92–100. [Google Scholar]

- Papanikolaou, S.; Ruiz-Sanchez, P.; Pariset, B.; Blanchard, F.; Fick, M. High production of 1,3-propanediol from industrial glycerol by a newly isolated clostridium butyricum strain. J. Biotechnol. 2000, 77, 191–208. [Google Scholar] [CrossRef]

- Willke, T.; Vorlop, K. Biotransformation of glycerol into 1,3-propanediol. Eur. J. Lipid Sci. Technol. 2008, 110, 831–840. [Google Scholar] [CrossRef]

- Casali, S.; Gungormusler, M.; Bertin, L.; Fava, F.; Azbar, N. Development of a biofilm technology for the production of 1,3-propanediol (1,3-pdo) from crude glycerol. Biochem. Eng. J. 2012, 64, 84–90. [Google Scholar] [CrossRef]

- Barbirato, F.; Himmi, E.H.; Conte, T.; Bories, A. 1,3-propanediol production by fermentation: An interesting way to valorize glycerin from the ester and ethanol industries. Ind. Crop. Prod. 1998, 7, 281–289. [Google Scholar] [CrossRef]

- González-Pajuelo, M.; Andrade, J.C.; Vasconcelos, I. Production of 1,3-propanediol by clostridium butyricum vpi 3266 in continuous cultures with high yield and productivity. J. Ind. Microbiol. Biotechnol. 2005, 32, 391–396. [Google Scholar] [CrossRef]

- Sarma, S.J.; Brar, S.K.; Sydney, E.B.; Le Bihan, Y.; Buelna, G.; Soccol, C.R. Microbial hydrogen production by bioconversion of crude glycerol: A review. Int. J. Hydrog. Energy 2012, 37, 6473–6490. [Google Scholar] [CrossRef]

- Moslemy, P.; Neufeld, R.J.; Guiot, S.R. Biodegradation of gasoline by gellan gum-encapsulated bacterial cells. Biotechnol. Bioeng. 2002, 80, 175–184. [Google Scholar] [CrossRef] [PubMed]

- Schlieker, M.; Vorlop, K.-D. A novel immobilization method for entrapment: Lentikats®. In Immobilization of Enzymes and Cells; Guisan, J.M., Ed.; Humana Press: Totowa, NJ, USA, 2006; pp. 333–343. [Google Scholar]

- Dolejš, I.; Krasňan, V.; Stloukal, R.; Rosenberg, M.; Rebroš, M. Butanol production by immobilised clostridium acetobutylicum in repeated batch, fed-batch, and continuous modes of fermentation. Bioresour. Technol. 2014, 169, 723–730. [Google Scholar] [CrossRef]

- Rebroš, M.; Dolejš, I.; Rosenberg, M. Method for Preparation of Immobilisates of clostridium sp. to Polyvinyl Alcohol Gel for Production of Organic Acids and Chemicals. Patent application SK288469, 2 June 2017. [Google Scholar]

- Biebl, H.; Marten, S.; Hippe, H.; Deckwer, W.-D. Glycerol conversion to 1,3-propanediol by newly isolated clostridia. Appl. Microbiol. Biotechnol. 1992, 36, 592–597. [Google Scholar] [CrossRef]

- De Vasconcelos, J.N.; Lopes, C.E.; De França, F.P. Continuous ethanol production using yeast immobilized on sugar-cane stalks. Braz. J. Chem. Eng. 2004, 21, 357–365. [Google Scholar] [CrossRef]

- Sarchami, T.; Munch, G.; Johnson, E.; Kießlich, S.; Rehmann, L. A review of process-design challenges for industrial fermentation of butanol from crude glycerol by non-biphasic clostridium pasteurianum. Fermentation 2016, 2, 13. [Google Scholar] [CrossRef]

- Rebroš, M.; Dolejš, I.; Stloukal, R.; Rosenberg, M. Butyric acid production with clostridium tyrobutyricum immobilised to pva gel. Process Biochem. 2016, 51, 704–708. [Google Scholar] [CrossRef]

- Dolejš, I.; Rebroš, M.; Rosenberg, M. Immobilisation of clostridium spp. For production of solvents and organic acids. Chem. Pap. 2014, 68, 1–14. [Google Scholar] [CrossRef]

- Huang, W.-C.; Chen, S.-J.; Chen, T.-L. Production of hyaluronic acid by repeated batch fermentation. Biochem. Eng. J. 2008, 40, 460–464. [Google Scholar] [CrossRef]

- Sanda, T.; Hasunuma, T.; Matsuda, F.; Kondo, A. Repeated-batch fermentation of lignocellulosic hydrolysate to ethanol using a hybrid saccharomyces cerevisiae strain metabolically engineered for tolerance to acetic and formic acids. Bioresour. Technol. 2011, 102, 7917–7924. [Google Scholar] [CrossRef]

- Rebroš, M.; Rosenberg, M.; Stloukal, R.; Krištofíková, L. High efficiency ethanol fermentation by entrapment of zymomonas mobilis into lentikats®. Lett. Appl. Microbiol. 2005, 41, 412–416. [Google Scholar] [CrossRef] [PubMed]

- Rosenberg, M.; Rebroš, M.; Krištofíková, L.; Malátová, K. High temperature lactic acid production by bacillus coagulans immobilized in lentikats. Biotechnol. Lett. 2005, 27, 1943–1947. [Google Scholar] [CrossRef]

- González-Pajuelo, M.; Andrade, J.C.; Vasconcelos, I. Production of 1,3-propanediol by clostridium butyricum vpi 3266 using a synthetic medium and raw glycerol. J. Ind. Microbiol. Biotechnol. 2004, 31, 442–446. [Google Scholar] [CrossRef]

- Marmesat, S.; Rodrigues, E.; Velasco, J.; Dobarganes, C. Quality of used frying fats and oils: Comparison of rapid tests based on chemical and physical oil properties. Int. J. Food Sci. Technol. 2007, 42, 601–608. [Google Scholar] [CrossRef]

- Mandolesi de Araújo, C.D.; de Andrade, C.C.; de Souza e Silva, E.; Dupas, F.A. Biodiesel production from used cooking oil: A review. Renew. Sustain. Energy Rev. 2013, 27, 445–452. [Google Scholar] [CrossRef]

- Enweremadu, C.C.; Mbarawa, M.M. Technical aspects of production and analysis of biodiesel from used cooking oil—A review. Renew. Sustain. Energy Rev. 2009, 13, 2205–2224. [Google Scholar] [CrossRef]

- Chatzifragkou, A.; Dietz, D.; Komaitis, M.; Zeng, A.-P.; Papanikolaou, S. Effect of biodiesel-derived waste glycerol impurities on biomass and 1,3-propanediol production of clostridium butyricum vpi 1718. Biotechnol. Bioeng. 2010, 107, 76–84. [Google Scholar] [CrossRef] [PubMed]

- Papanikolaou, S.; Fick, M.; Aggelis, G. The effect of raw glycerol concentration on the production of 1,3-propanediol by clostridium butyricum. J. Chem. Technol. Biotechnol. 2004, 79, 1189–1196. [Google Scholar] [CrossRef]

- Liu, X.H.; Rebroš, M.; Dolejš, I.; Marr, A.C. Designing ionic liquids for the extraction of alcohols from fermentation broth: Phosphonium alkanesulfonates, solvents for diol extraction. ACS Sustain. Chem. Eng. 2017, 5, 8260–8268. [Google Scholar] [CrossRef]

- Stloukal, R.; Rosenberg, M.; Rebros, M. A Method for Industrial Production of Biocatalysts in the form of Enzymes or Microorganisms Immobilized in Polyvinyl Alcohol Gel, Their Use and Devices for Their Production. Patent Application No. WO2007104268, 20 September 2007. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dolejš, I.; Líšková, M.; Krasňan, V.; Markošová, K.; Rosenberg, M.; Lorenzini, F.; Marr, A.C.; Rebroš, M. Production of 1,3-Propanediol from Pure and Crude Glycerol Using Immobilized Clostridium butyricum. Catalysts 2019, 9, 317. https://doi.org/10.3390/catal9040317

Dolejš I, Líšková M, Krasňan V, Markošová K, Rosenberg M, Lorenzini F, Marr AC, Rebroš M. Production of 1,3-Propanediol from Pure and Crude Glycerol Using Immobilized Clostridium butyricum. Catalysts. 2019; 9(4):317. https://doi.org/10.3390/catal9040317

Chicago/Turabian StyleDolejš, Igor, Monika Líšková, Vladimír Krasňan, Kristína Markošová, Michal Rosenberg, Fabio Lorenzini, Andrew C. Marr, and Martin Rebroš. 2019. "Production of 1,3-Propanediol from Pure and Crude Glycerol Using Immobilized Clostridium butyricum" Catalysts 9, no. 4: 317. https://doi.org/10.3390/catal9040317

APA StyleDolejš, I., Líšková, M., Krasňan, V., Markošová, K., Rosenberg, M., Lorenzini, F., Marr, A. C., & Rebroš, M. (2019). Production of 1,3-Propanediol from Pure and Crude Glycerol Using Immobilized Clostridium butyricum. Catalysts, 9(4), 317. https://doi.org/10.3390/catal9040317