A Novel Method for the Prediction of Erosion Evolution Process Based on Dynamic Mesh and Its Applications

Abstract

:1. Introduction

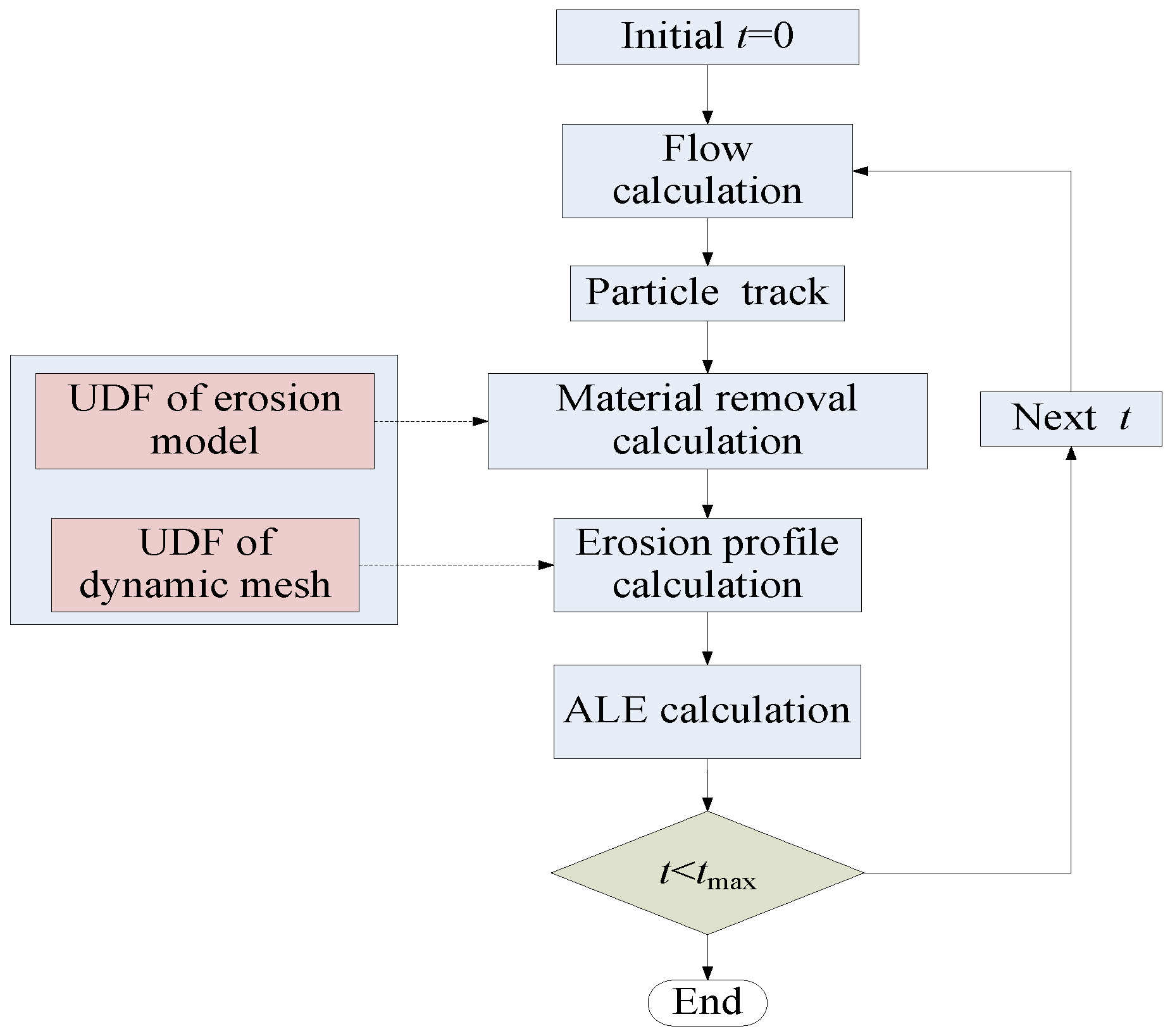

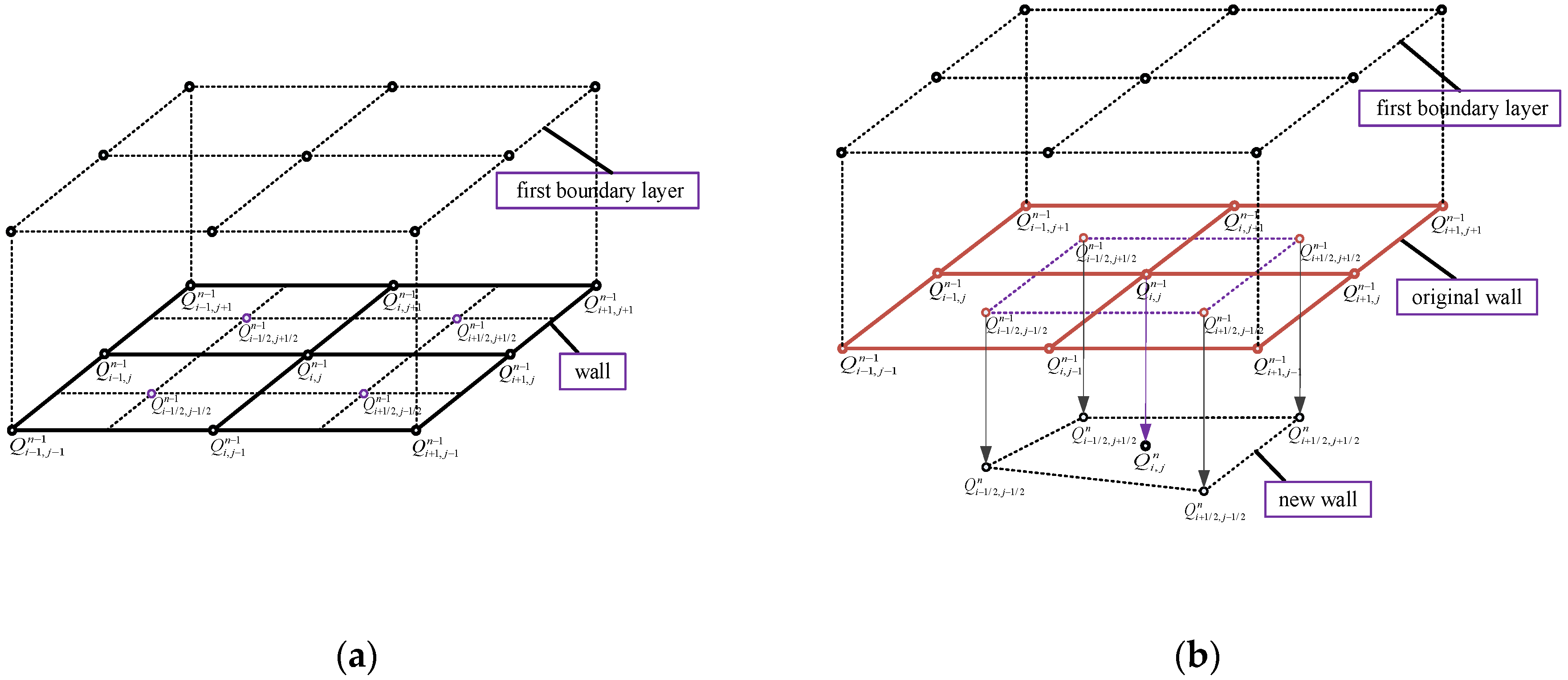

2. Method Description

3. Application

3.1. Mathematical Model

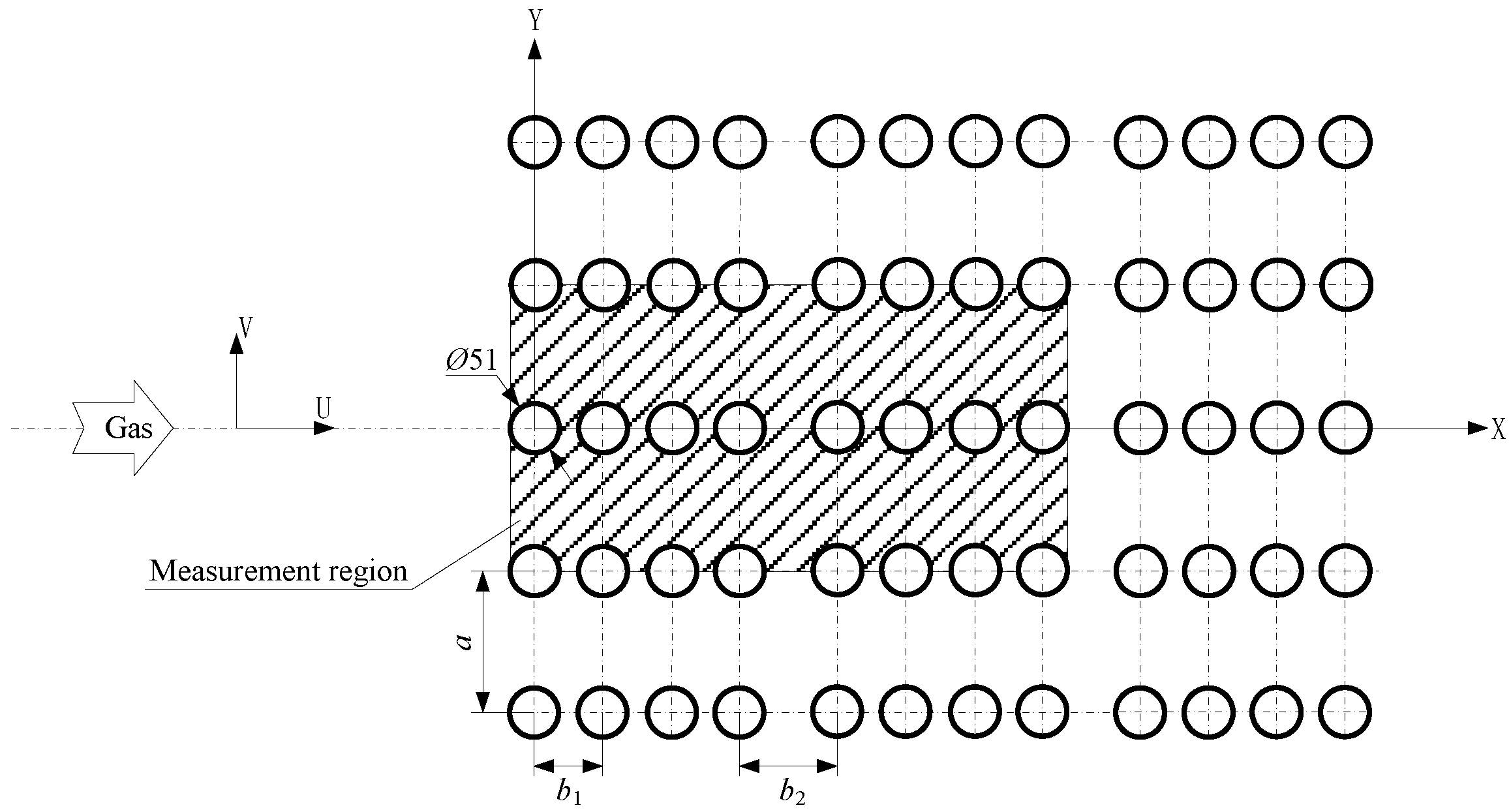

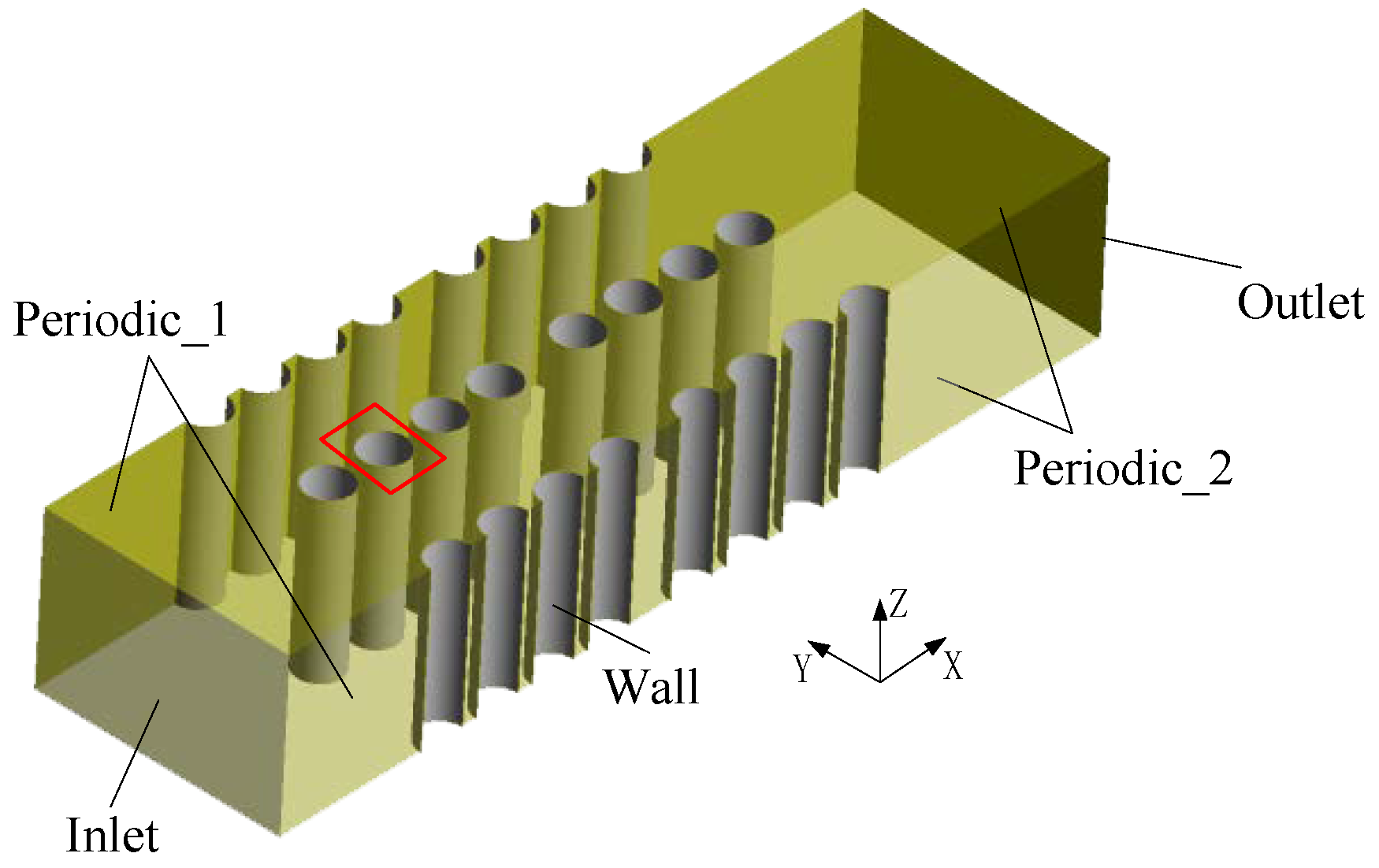

3.1.1. Flow Configuration

3.1.2. Governing Equations

Gas Motion Model

Lagrangian Formulation for Particle Motion Model

Particle-Wall Collision Model

Erosion Model

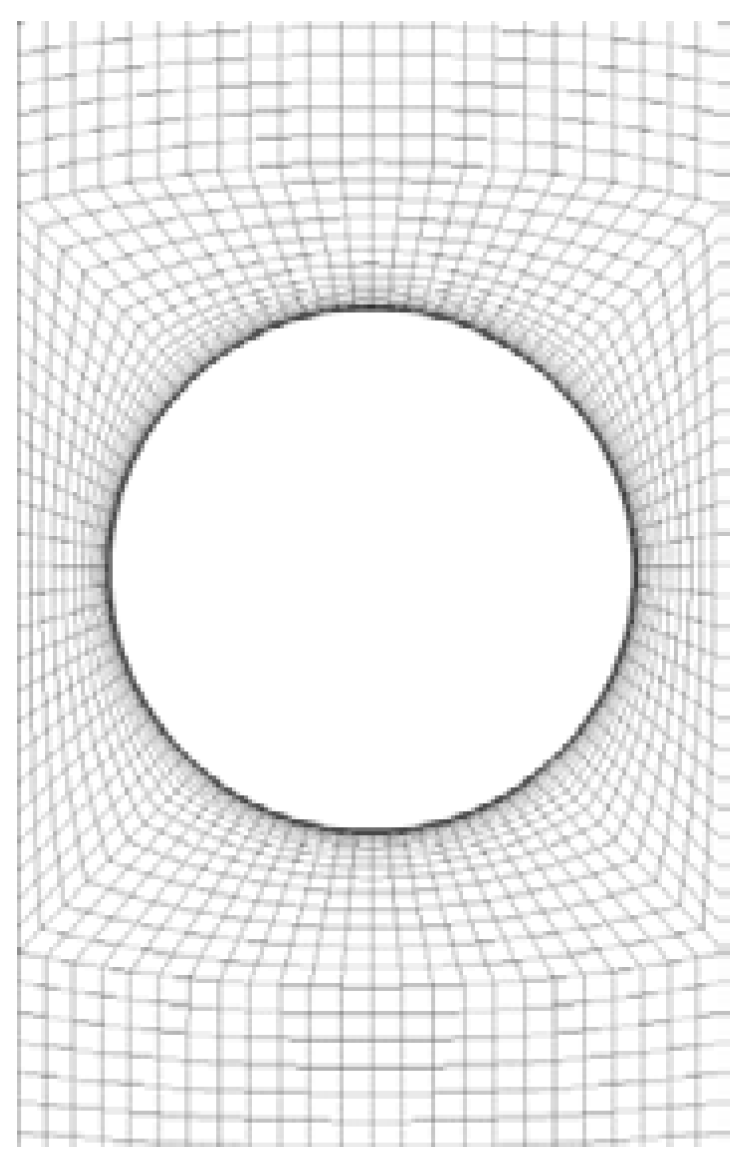

Numerical Procedures

- Step 1: Verification of erosion model on SA210 GrA1(N);

- Step 2: Erosion calculation of economizer unit.

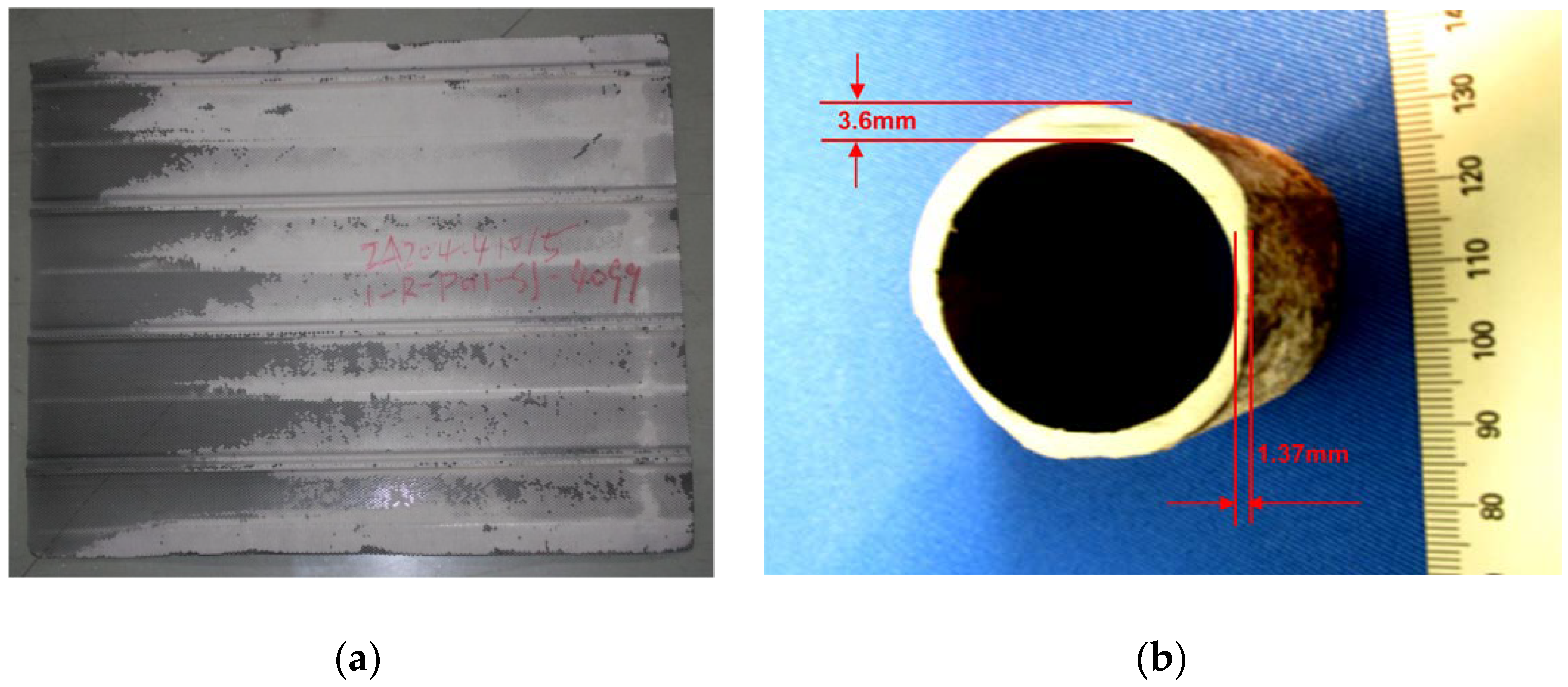

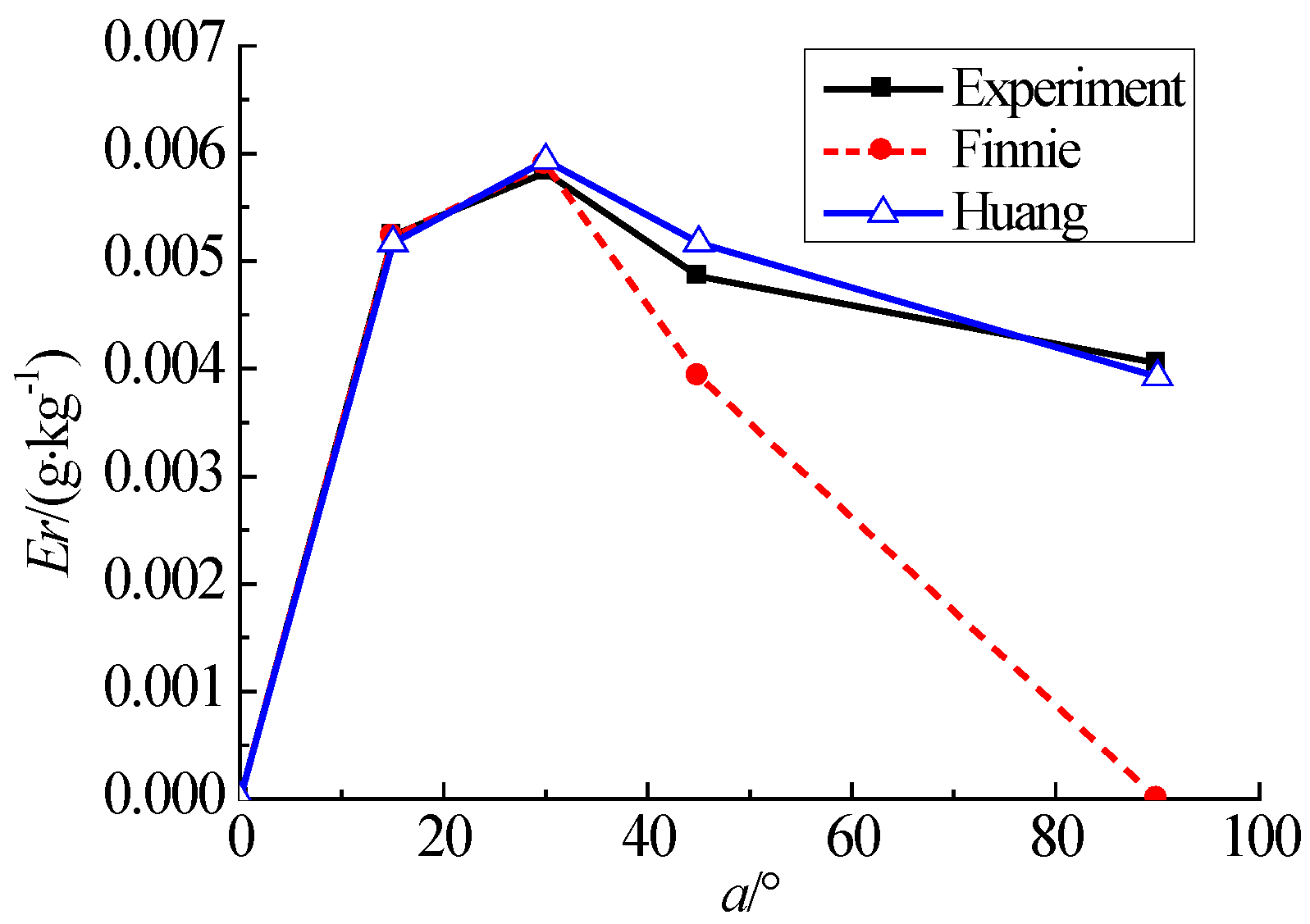

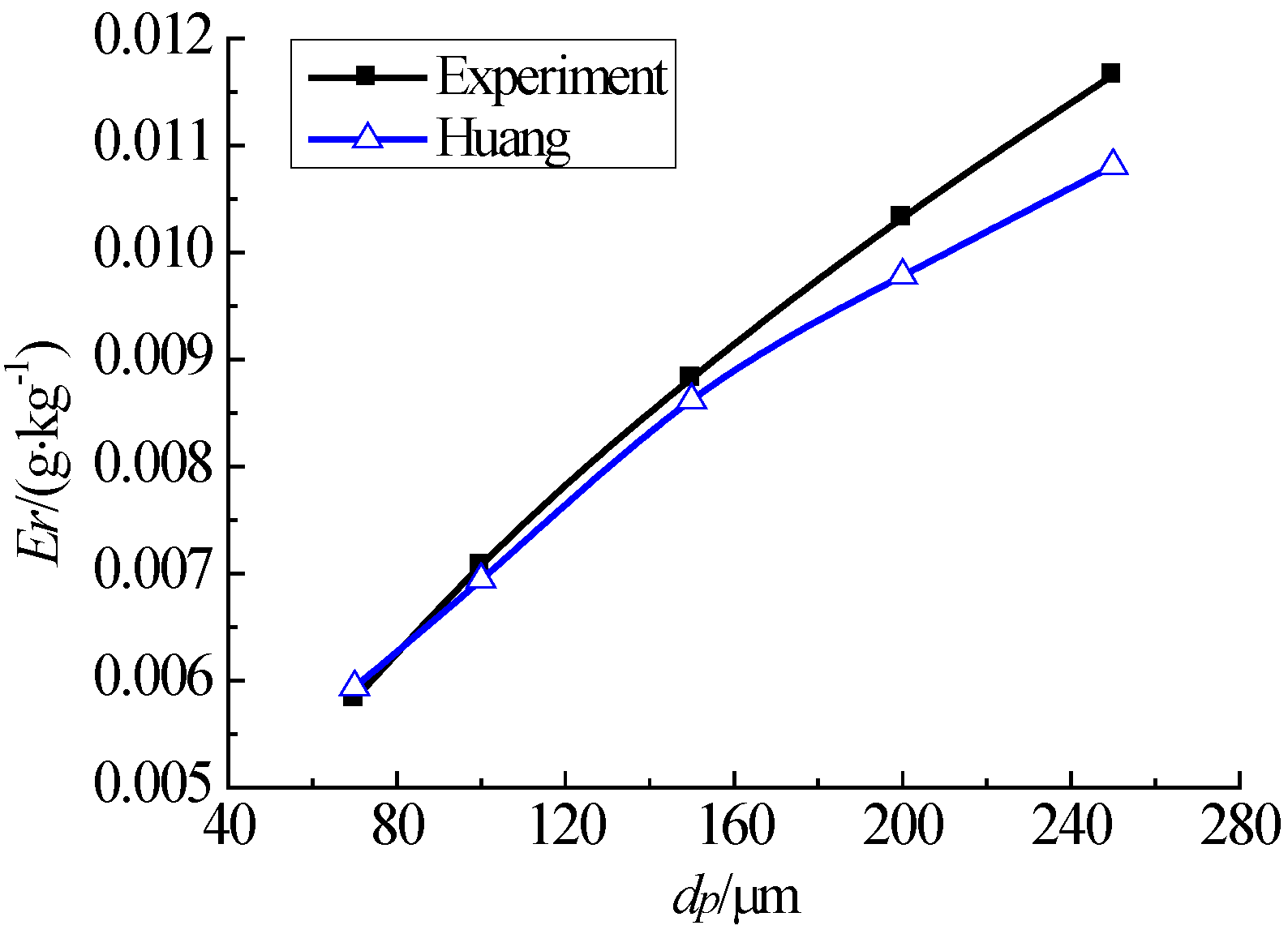

3.2. Verification of Erosion Model

4. Results and Discussion

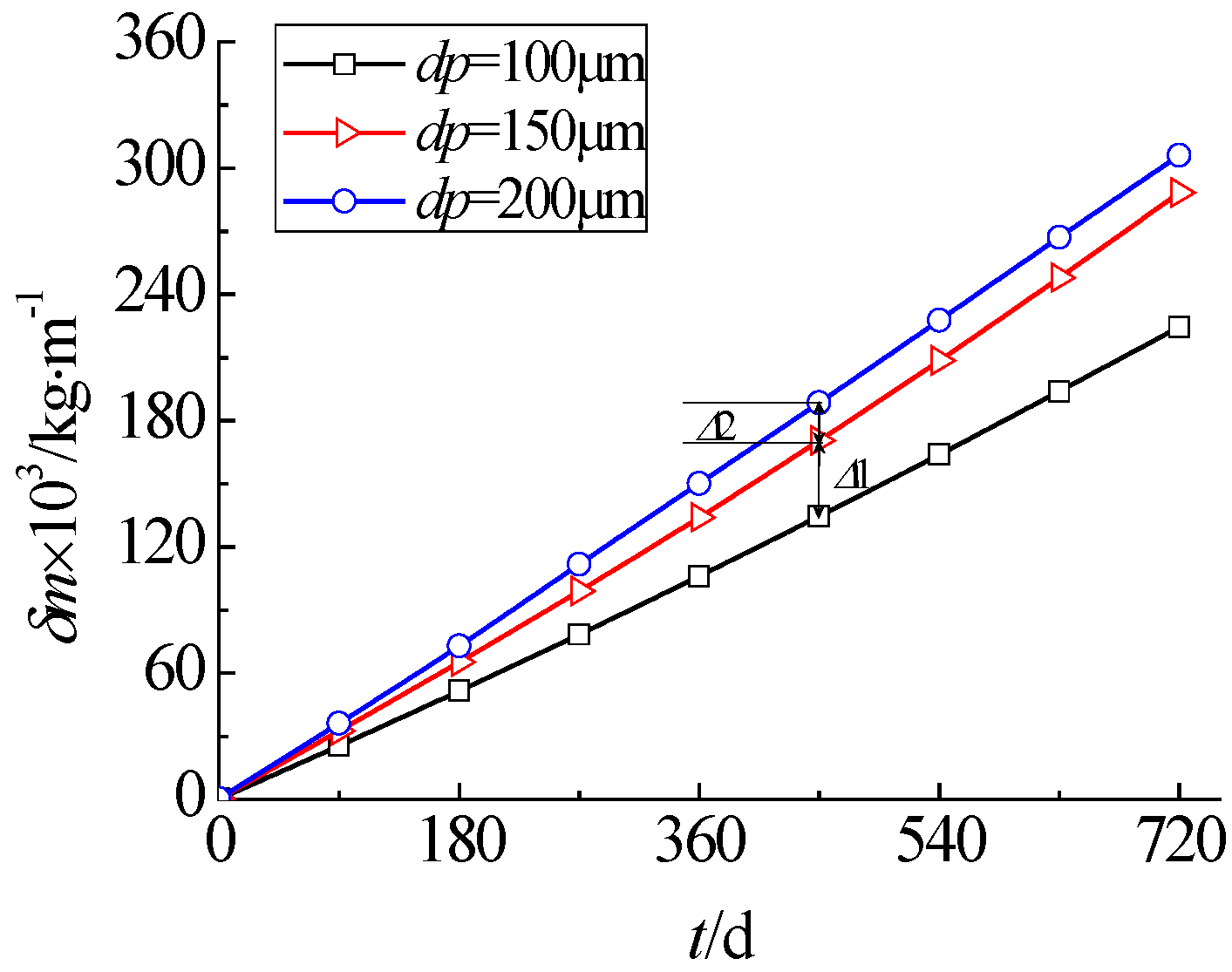

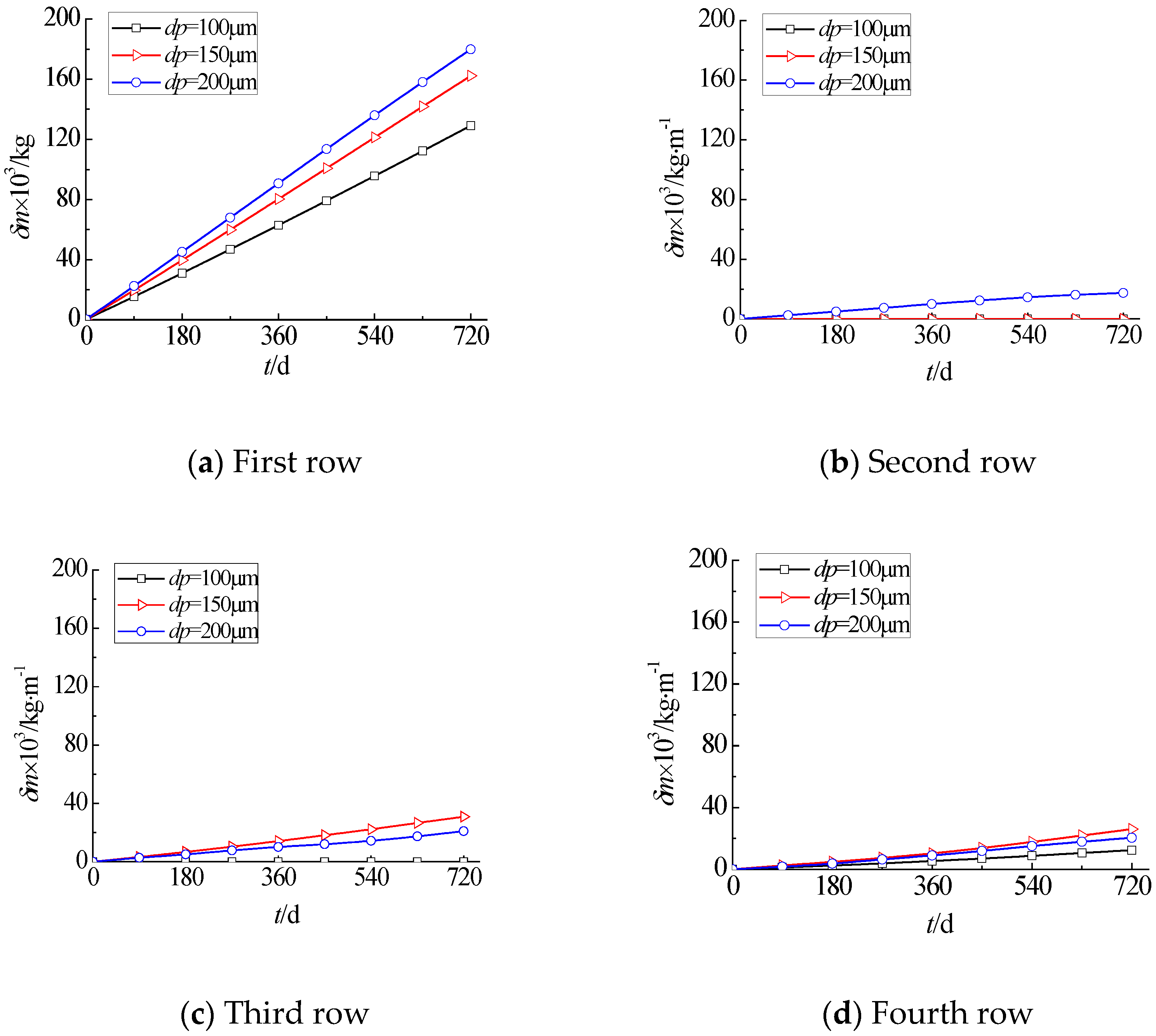

4.1. Erosion Loss

4.1.1. Global Erosion Loss

4.1.2. Local Erosion Loss

4.2. Evolution Process of Erosion

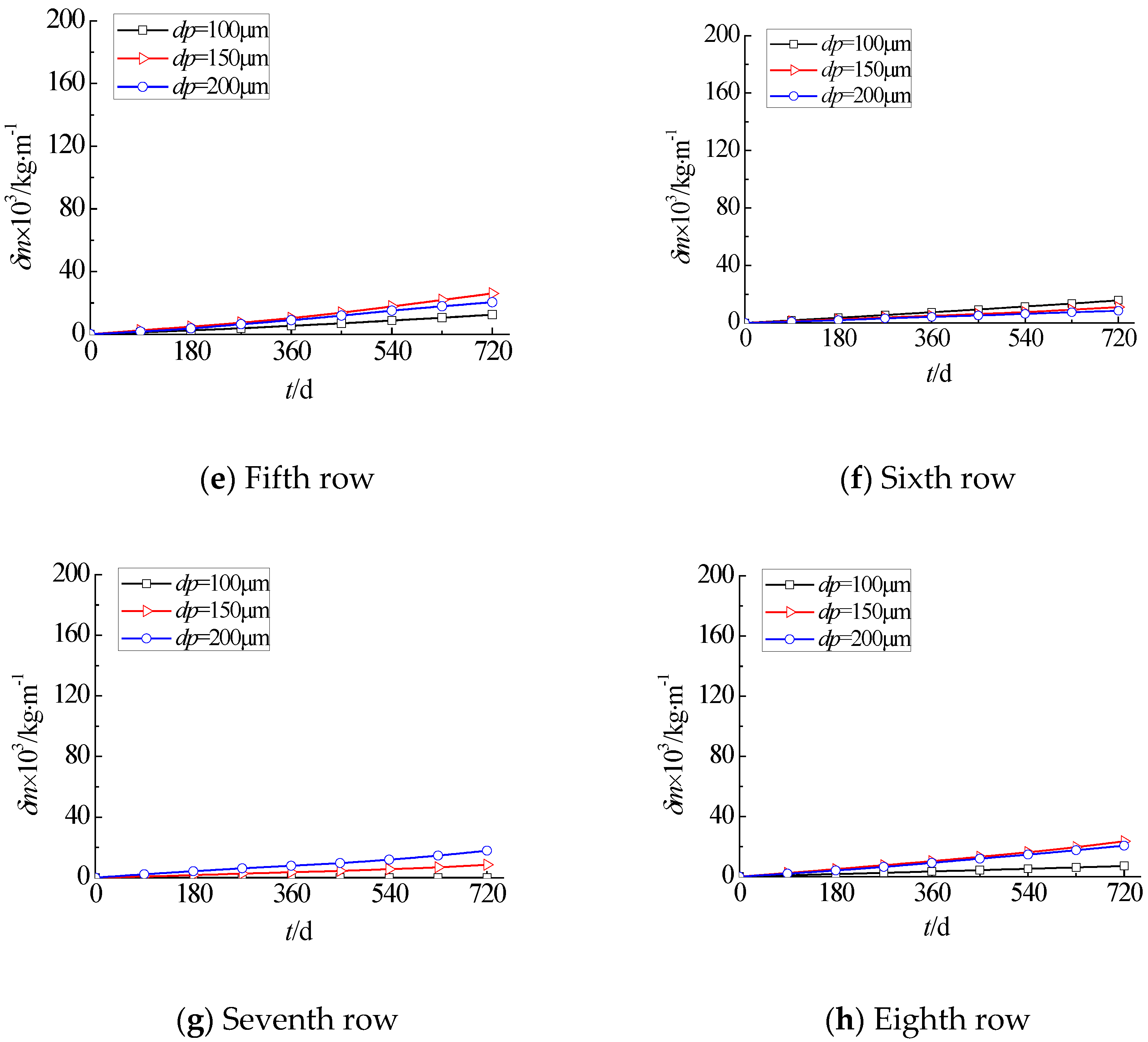

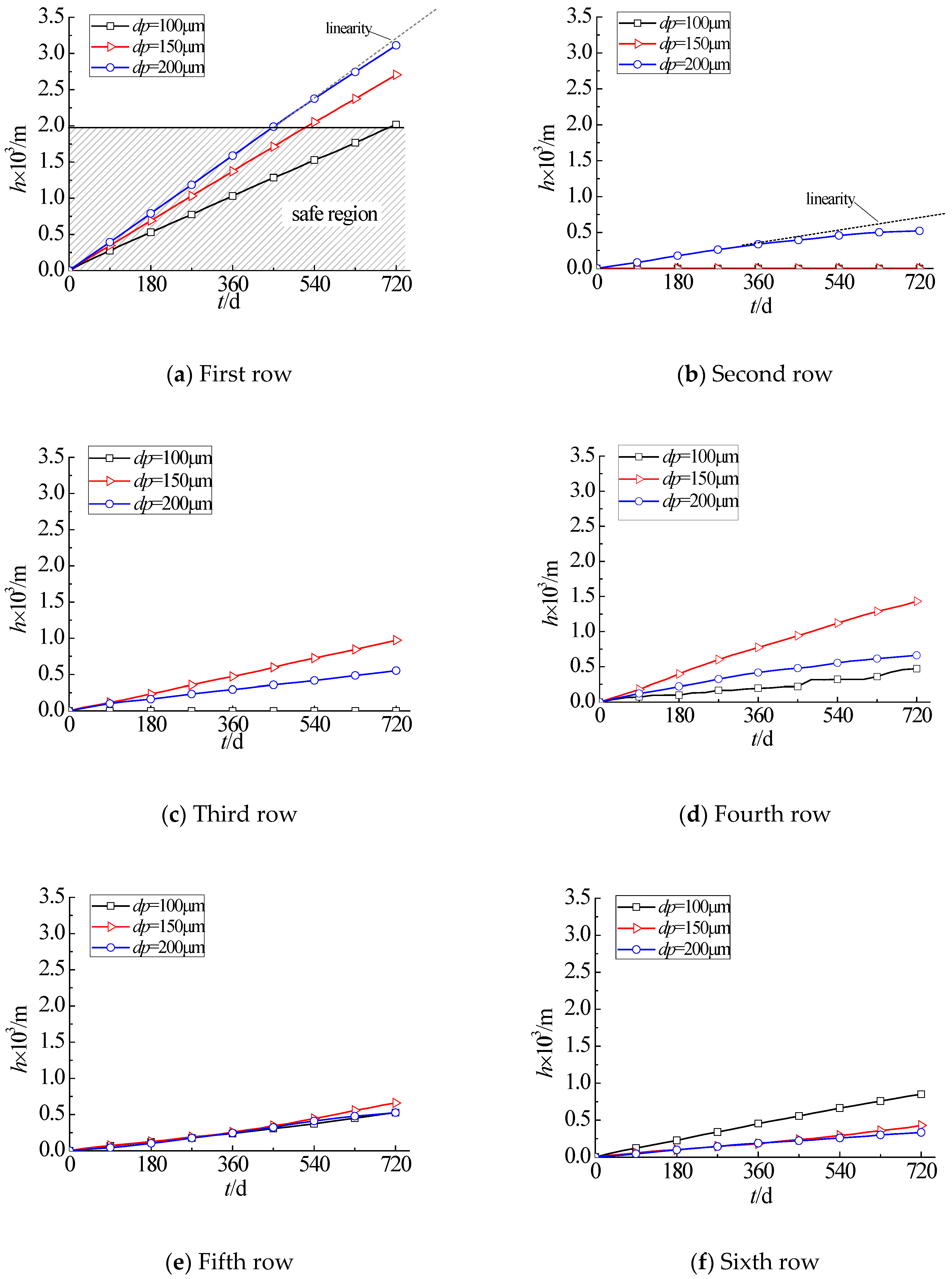

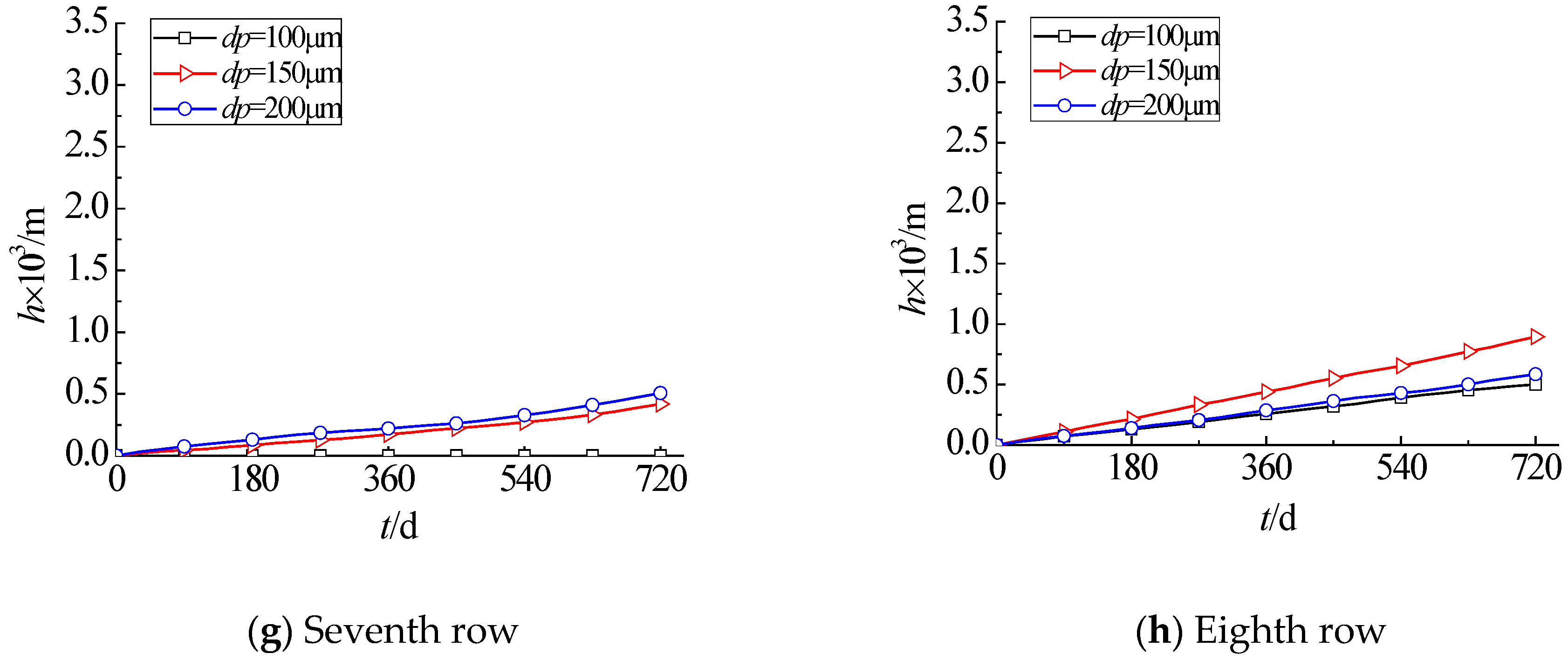

4.2.1. Maximum Erosion Depth

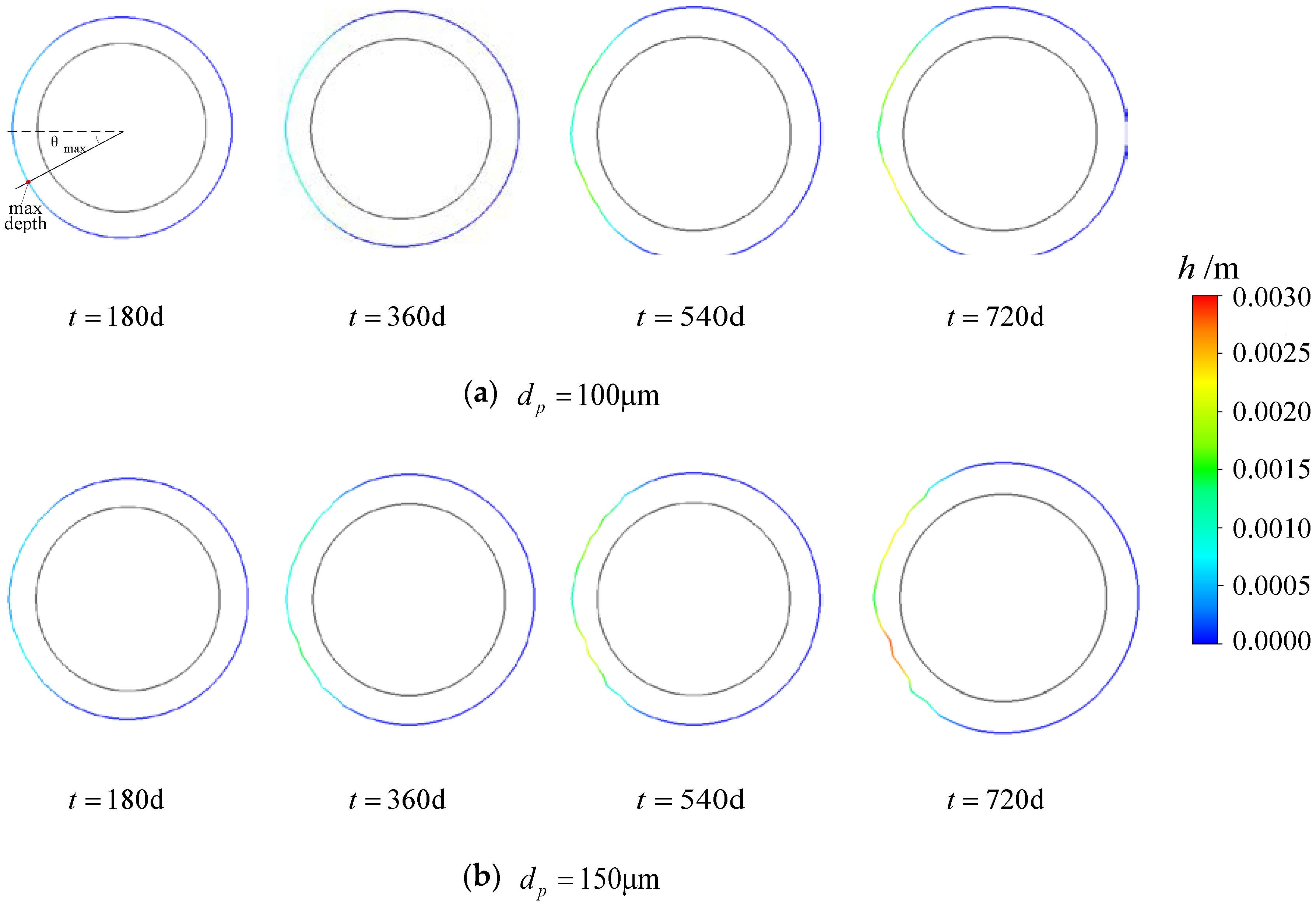

4.2.2. Erosion Profile

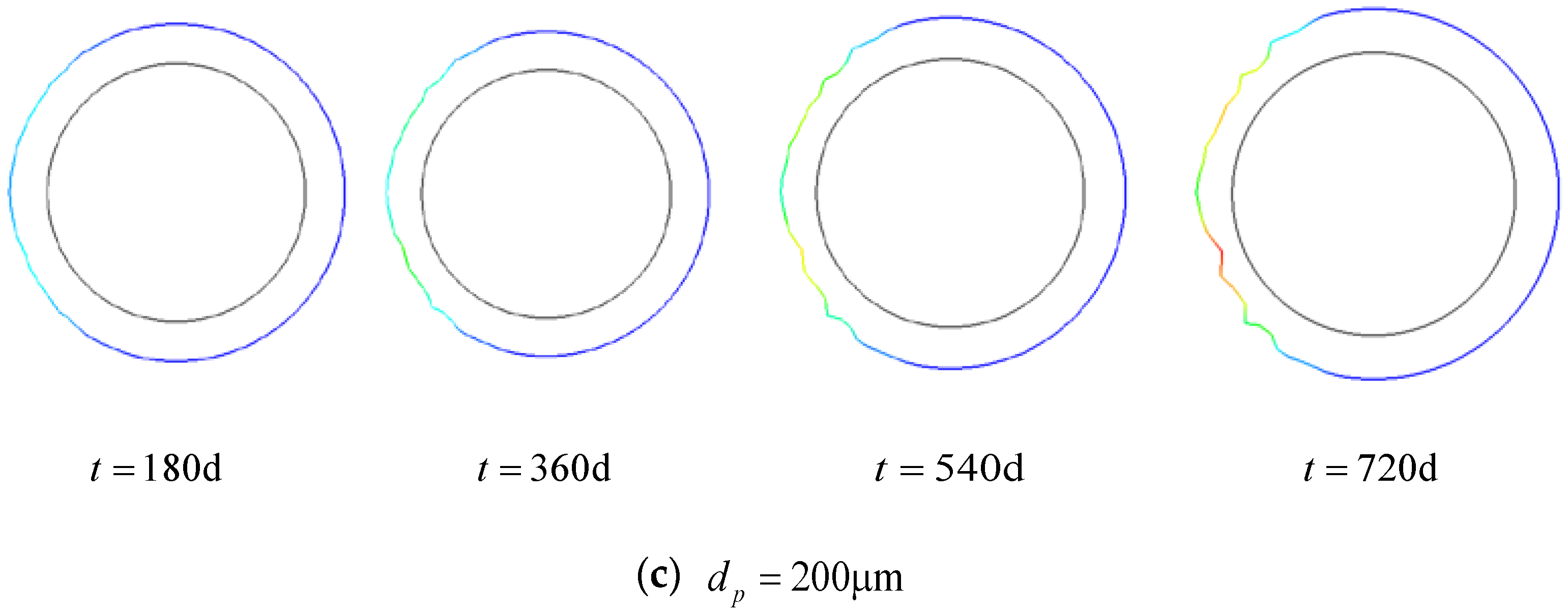

4.3. Evolution Process of Particle Motion

4.4. Expiry Periods

5. Conclusions

- (1)

- The CFD-DPM approach coupled with the UDF of Huang’s erosion model and the dynamic mesh technology can describe the evolution process of erosion on an economizer bank, especially the erosion profile; by comparing the simulation results with the erosion profile on-site, the correctness is verified for this proposed CFD-DPM approach.

- (2)

- The global/local erosion loss and the maximum erosion depth are linearly related to the working time, but the growth of the maximum erosion depth slows down gradually in the later stage; as the ash size increases, the growth amplification of global erosion loss, local erosion in the first row, and the maximum erosion depth decrease.

- (3)

- With increasing time, the collision point trajectory moves along the increasing direction of the absolute value of θ in the first row, which explains why the growth of the maximum erosion depth slows down in later stages.

- (4)

- The expiry period is shortened as the ash diameter increases; moreover, as the ash size increases, the declining amplification of expiry periods is retarded.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| area of grid element [m2] | model constant | ||

| model constant | fluid thermal conductivity [W/(m·K)] | ||

| model constant | Knudsen number | ||

| model constant | particle mass [kg] | ||

| model constant | gas pressure [pa] | ||

| drag coefficient | Reynolds number | ||

| model constant | turbulence kinetic energy source term [kg/(m·s3)] | ||

| specific heat [J/(kg·K)] | turbulence dissipation rate source term [kg/(m·s4)] | ||

| model constant | gas temperature [K] | ||

| model constant | gas velocity vector [m/s] | ||

| model constant | gas velocity of i-direction [m/s] | ||

| deformation tensor | particle velocity vector [m/s] | ||

| particle diameter [m] | the coordinate of i-direction [m] | ||

| model constant | particle velocity magnitude [m/s] | ||

| total energy [J/kg] | gas velocity magnitude [m/s] | ||

| normal coefficient of velocity restitution | contribution of the fluctuating dilatation in compressible turbulence to the overall dissipation rate [kg/(m·s3)] | ||

| tangential coefficient of velocity restitution | incidence angle | ||

| ratio of abrasion loss and particle mass [g/kg] | gas density [kg/m3] | ||

| drag force [N] | density of economizer material [kg/m3] | ||

| gravity [N] | particle density [kg/m3] | ||

| thermophoretic force [N] | Gas stress tensor [pa] | ||

| Saffman lift force [N] | Kronecker tensor | ||

| acceleration of gravity [m/s2] | erosion loss [kg/m] | ||

| generation of turbulence kinetic energy due to buoyancy [kg/(m·s3)] | time interval [s] | ||

| generation of turbulence kinetic energy due to the velocity gradients [kg/(m·s3)] | gas viscosity [pa·s] | ||

| h | erosion depth [mm] | gas second viscosity [pa·s] | |

| hi,j | erosion depth of grid element [mm] | turbulent Prandtl number for k | |

| particle thermal conductivity [W/(m·K)] | turbulent Prandtl number for ε |

References

- Arabnejad, H.; Mansouri, A.; Shirazi, S.A.; McLaury, B.S. Abrasion erosion modeling in particulate flow. Wear 2017, 376–377, 1194–1199. [Google Scholar] [CrossRef]

- Alam, T.; Farhat, Z.N. Slurry erosion surface damage under normal impact for pipeline steels. Eng. Fail. Anal. 2018, 90, 116–128. [Google Scholar] [CrossRef]

- Eichner, D.; Schlieter, A.; Leyens, C.; Shang, L.; Shayestehaminzadeh, S.; Schneider, J.M. Solid particle erosion behavior of nanolaminated Cr2AlC films. Wear 2018, 402–403, 187–195. [Google Scholar] [CrossRef]

- Ji, X.; Wu, J.; Pi, J.; Cheng, J.; Shan, Y.; Zhang, Y. Slurry erosion induced surface nanocrystallization of bulk metallic glass. Appl. Surf. Sci. 2018, 440, 1204–1210. [Google Scholar] [CrossRef]

- William, L. Failure analysis on the economisers of a biomass fuel boiler. Eng. Fail. Anal. 2013, 31, 101–117. [Google Scholar] [CrossRef]

- Finnie, I. Erosion of surfaces. Wear 1960, 3, 87–103. [Google Scholar] [CrossRef]

- Finnie, I. Some reflections on the past and future of erosion. Wear 1995, 186–187, 1–10. [Google Scholar] [CrossRef]

- Bitter, J. A study of erosion phenomena Part I. Wear 1963, 6, 5–21. [Google Scholar] [CrossRef]

- Bitter, J. A study of erosion phenomena Part II. Wear 1963, 6, 169–190. [Google Scholar] [CrossRef]

- Huang, C.; Chiovelli, S.; Minev, P.; Luo, J.; Nandakumar, K. A comprehensive phenomenological model for erosion of materials in jet flow. Powder Technol. 2008, 187, 273–279. [Google Scholar] [CrossRef]

- Grant, G.; Tabakoff, W. An Experimental Investigation of the Erosion Characteristics of 2024 Aluminum Alloy; Report; Cincinnati University: Cincinnati, OH, USA, 1973; p. 49. [Google Scholar]

- Oka, Y.I.; Okamura, K.; Yoshida, T. Practical estimation of erosion damage caused by solid particle impact: Part 1: Effects of impact parameters on a predictive equation. Wear 2005, 259, 95–101. [Google Scholar] [CrossRef]

- Oka, Y.I.; Yoshida, T. Practical estimation of erosion damage caused by solid particle impact: Part 2: Mechanical properties of materials directly associated with erosion damage. Wear 2005, 259, 102–109. [Google Scholar] [CrossRef]

- Haugen, K.; Kvernvold, O.; Ronold, A.; Sandberg, R. Sand erosion of wear-resistant materials: Erosion in choke valves. Wear 1995, 186–187, 179–188. [Google Scholar] [CrossRef]

- Ahlert, K. Effects of Particle Impingement Angle and Surface Wetting on Solid Particle Erosion of AISI 1018 Steel. Master’s. Thesis, The University of Tulsa, Tulsa, OK, USA, 1994. [Google Scholar]

- McLaury, B.S. Predicting Solid Particle Erosion Resulting from Turbulent Fluctuations in Oilfield Geometries. Ph.D. Thesis, The University of Tulsa, Tulsa, OK, USA, 1996. [Google Scholar]

- Zhang, Y.; Reuterfors, E.P.; McLaury, B.S.; Shirazi, S.A.; Rybicki, E.F. Comparison of computed and measured particle velocities and erosion in water and air flows. Wear 2007, 263, 330–338. [Google Scholar] [CrossRef]

- Shamshirband, S.; Malvandi, A.; Karimipour, A.; Goodarzi, M.; Afrand, M.; Petković, D.; Dahari, M.; Mahmoodian, N. Performance investigation of micro- and nano-sized particle erosion in a 90° elbow using an ANFIS model. Powder Technol. 2015, 284, 336–343. [Google Scholar] [CrossRef]

- Moakhar, R.S.; Mehdipour, M.; Ghorbani, M.; Mohebali, M.; Koohbor, B. Investigations of the failure in boilers economizer tubes used in power plants. J. Mater. Eng. Perform. 2013, 22, 2691–2697. [Google Scholar] [CrossRef]

- Ding, Q.; Tang, X.F.; Yang, Z.G. Failure analysis on abnormal corrosion of economizer tubes in a waste heat boiler. Eng. Fail. Anal. 2017, 73, 129–138. [Google Scholar] [CrossRef]

- Yang, L. One-fluid formulation for fluid–structure interaction with free surface. Comput. Methods Appl. Mech. Eng. 2018, 332, 102–135. [Google Scholar] [CrossRef]

- Joshson, A.A. Dynamic-mesh CFD and its application to flapping-wing micro-air vehicles. In Proceedings of the 25th Army Science Conference, Orlando, FL, USA, 27–30 November 2006; ANSI: Orlando, FL, USA, 2006. [Google Scholar]

- Savidis, S.A.; Aubram, D.; Rackwitz, F. Arbitrary Lagrangian-eulerian finite element formulation for geotechnical construction processes. J. Theor. Appl. Mech. 2008, 38, 165–194. [Google Scholar]

- Li, J.; Hesse, M.; Ziegler, J.; Woods, A.W. An arbitrary Lagrangian Eulerian method for moving-boundary problems and its application to jumping over water. J. Comput. Phys. 2005, 208, 289–314. [Google Scholar] [CrossRef]

- Yuping, C. Boiler Instruction Manual of DAIHAI in China; Shang Boiler Works, Ltd.: Shanghai, China, 2006. [Google Scholar]

- Versteeg, H.; Malalasekera, W. An Introduction to Computational Fluid Dynamics: The Finite Volume Method; Prentice Hall: London, UK, 1995. [Google Scholar]

- Gao, W.; Li, Y.; Kong, L. Numerical investigation of erosion of tube sheet and tubes of a shell and tube heat exchanger. Comput. Chem. Eng. 2017, 96, 115–127. [Google Scholar] [CrossRef]

- Launder, B.E.; Spalding, D.B. The numerical computation of turbulent flows. Comput. Methods Appl. Mech. Eng. 1974, 3, 269–289. [Google Scholar] [CrossRef]

- ANSYS. Ansys Fluent User’s Guide; Ansys Inc.: Canonsburg, PA, USA, 2015. [Google Scholar]

- Grant, G.; Tabakoff, W. Erosion Prediction in Turbomachinery Resulting from environmental solid particles. J. Aircr. 1975, 12, 471–478. [Google Scholar] [CrossRef]

- ASTM. Standard test method for conducting erosion tests by solid particle impingement. ASTM Int. 2013. [Google Scholar] [CrossRef]

- Sagayaraj, T.A.D.; Suresh, S.; Chandrasekar, M. Experimental studies on the erosion rate of different heat treated carbon steel economizer tubes of power boilers by fly ash particles. Int. J. Miner. Metall. Mater. 2009, 16, 534–539. [Google Scholar] [CrossRef]

| Material | Rows | Diameter/mm | Transversal Pitch a/mm | Longitudinal Pitch b1/mm | Longitudinal Pitch b2/mm |

|---|---|---|---|---|---|

| SA 210 GrA1(N) | 135 | Φ51×6 | 144 | 102 | 69 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, Y.; Qiao, Z.; Si, F.; Zhang, B.; Yu, C.; Jiang, X. A Novel Method for the Prediction of Erosion Evolution Process Based on Dynamic Mesh and Its Applications. Catalysts 2018, 8, 432. https://doi.org/10.3390/catal8100432

Dong Y, Qiao Z, Si F, Zhang B, Yu C, Jiang X. A Novel Method for the Prediction of Erosion Evolution Process Based on Dynamic Mesh and Its Applications. Catalysts. 2018; 8(10):432. https://doi.org/10.3390/catal8100432

Chicago/Turabian StyleDong, Yunshan, Zongliang Qiao, Fengqi Si, Bo Zhang, Cong Yu, and Xiaoming Jiang. 2018. "A Novel Method for the Prediction of Erosion Evolution Process Based on Dynamic Mesh and Its Applications" Catalysts 8, no. 10: 432. https://doi.org/10.3390/catal8100432

APA StyleDong, Y., Qiao, Z., Si, F., Zhang, B., Yu, C., & Jiang, X. (2018). A Novel Method for the Prediction of Erosion Evolution Process Based on Dynamic Mesh and Its Applications. Catalysts, 8(10), 432. https://doi.org/10.3390/catal8100432