A Recent Review of Primary Hydrogen Carriers, Hydrogen Production Methods, and Applications

Abstract

1. Introduction

2. Hydrogen Carriers and Production Methods

2.1. Water (H2O)

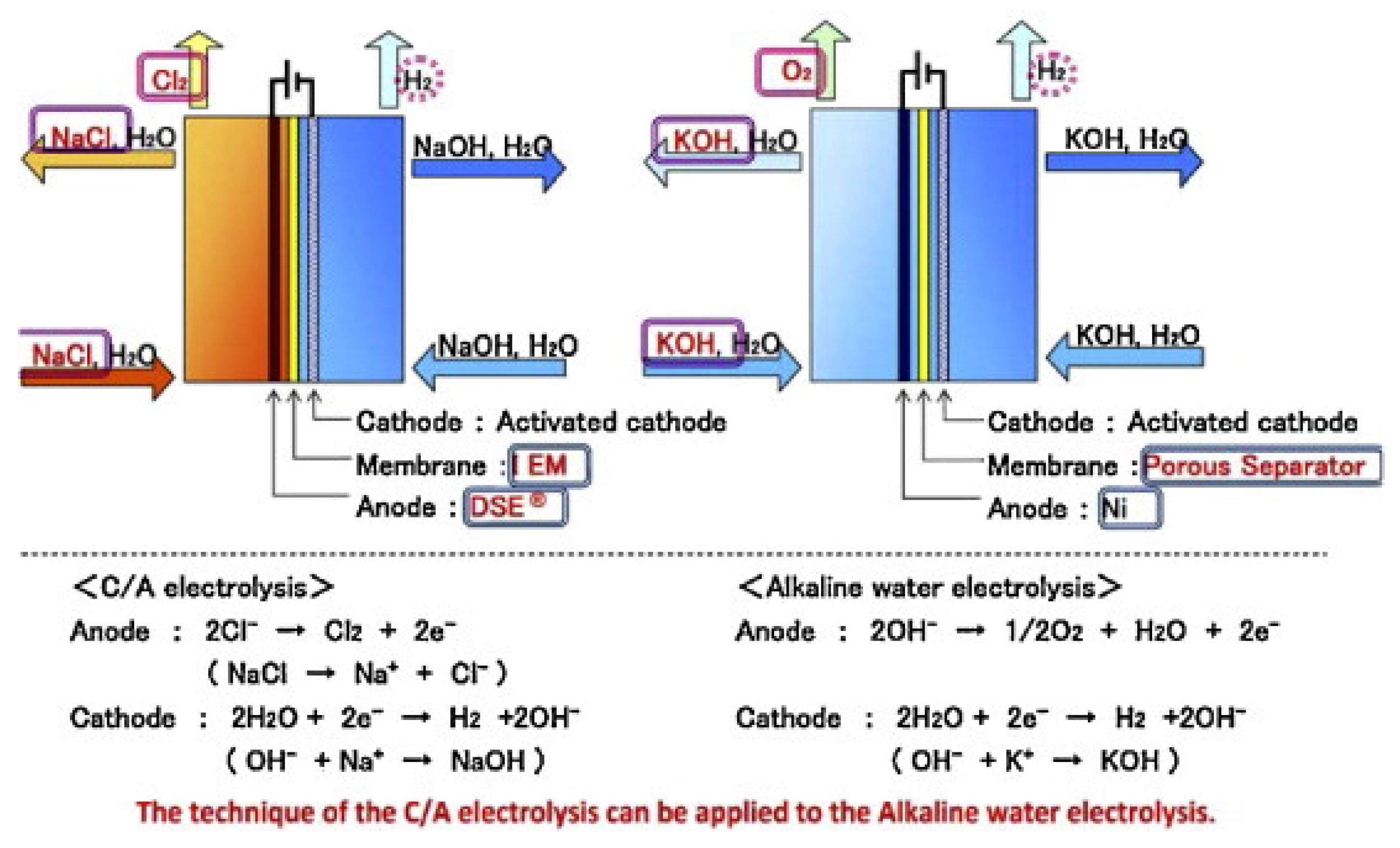

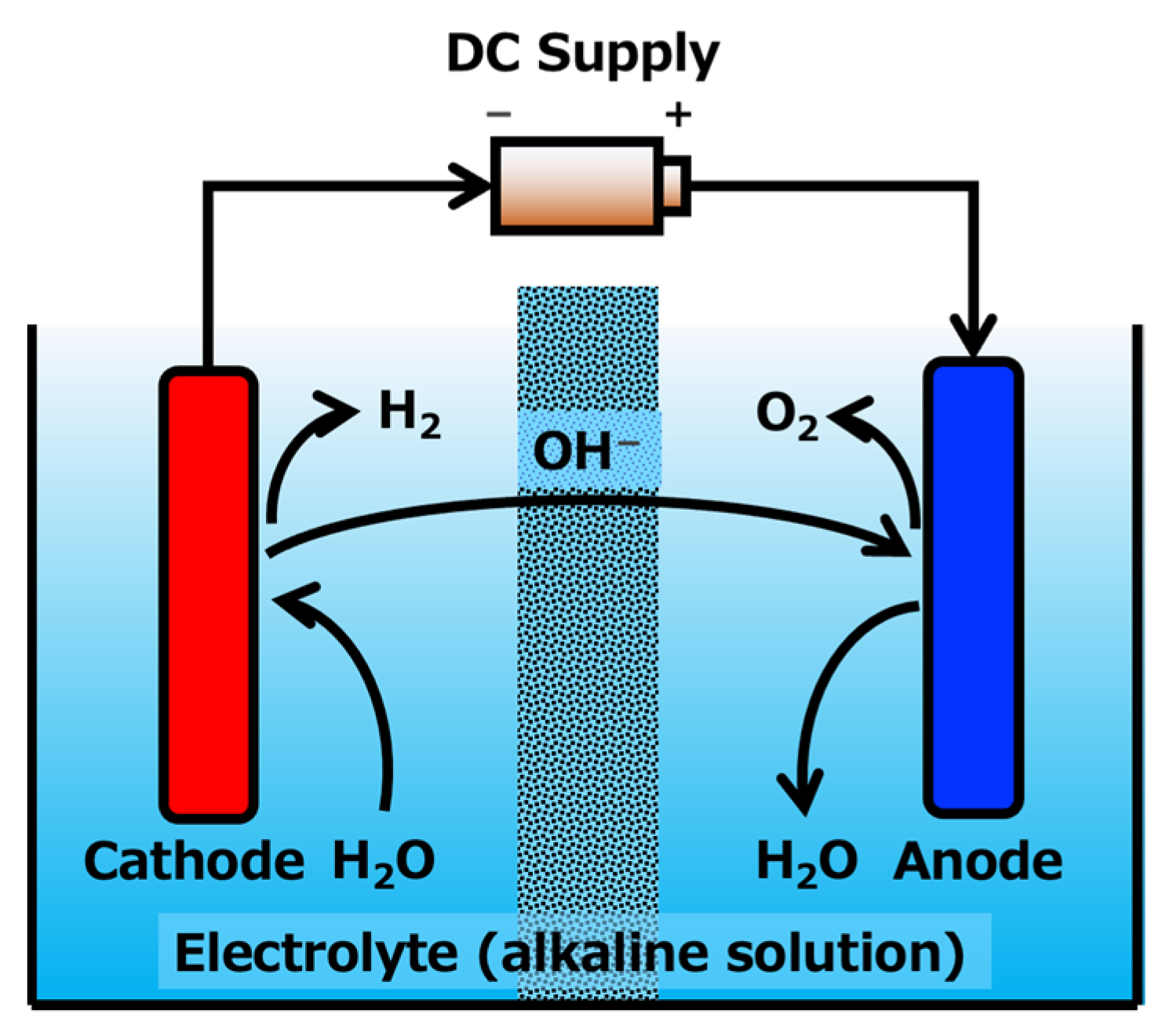

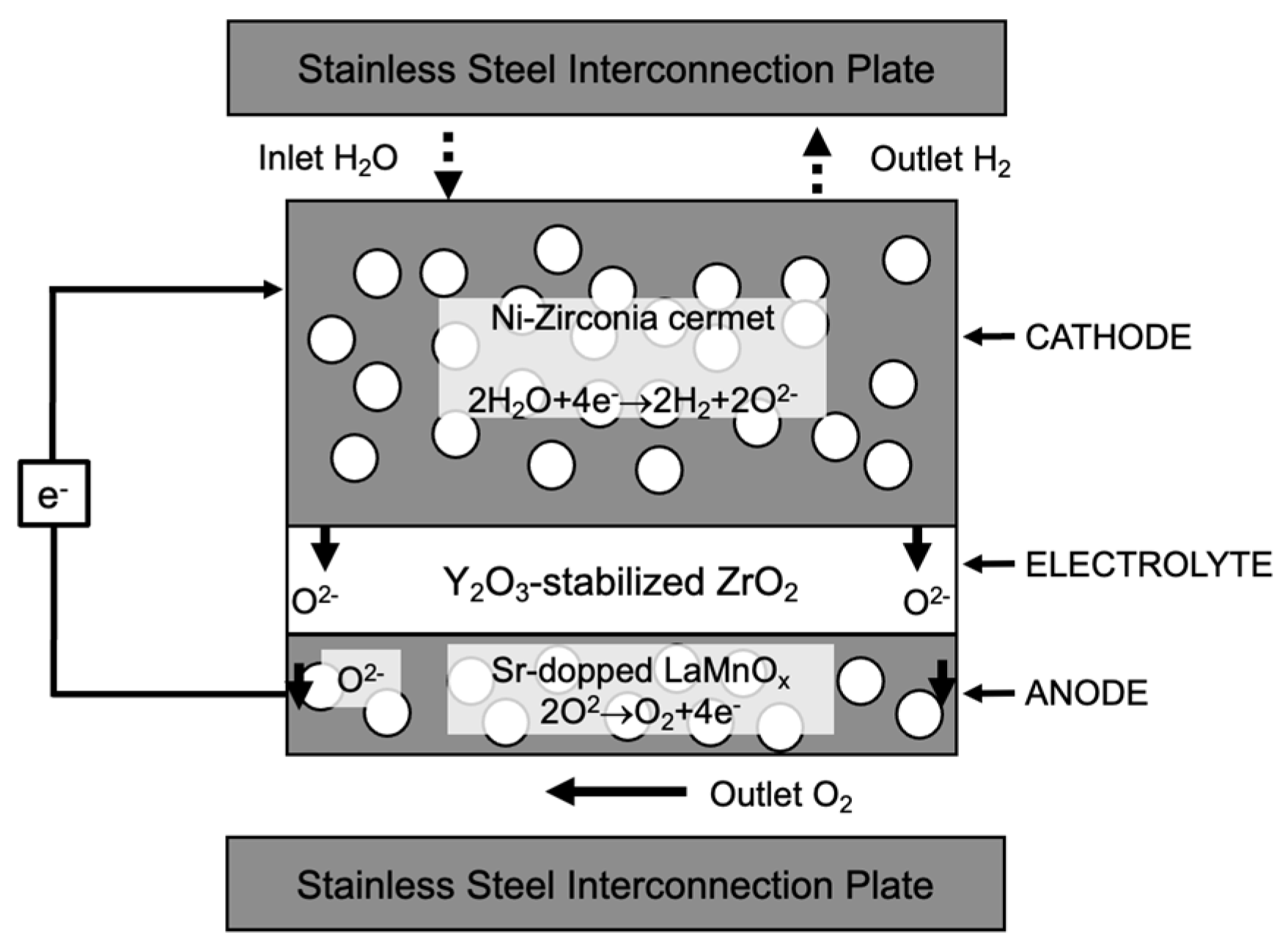

Water Electrolysis

2.2. Methane and Methanol

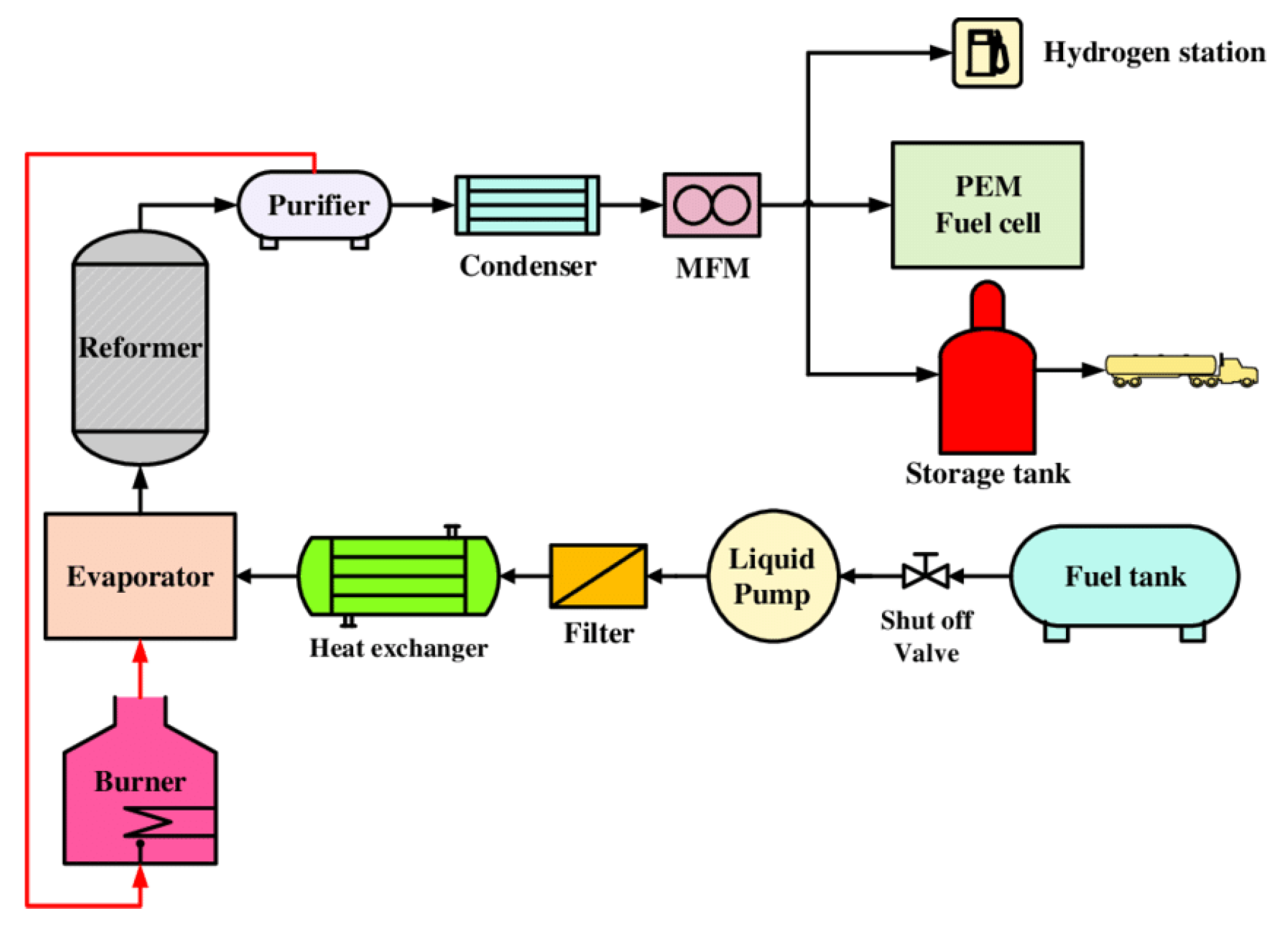

2.2.1. Steam Methane Reforming (SMR)

2.2.2. Methanol Reforming

2.3. Ammonia

Metal-Catalytic Reforming

2.4. Formic Acid

2.4.1. FA Catalytic Decomposition

2.4.2. Homogeneous Catalysts for FADH

2.4.3. Heterogeneous Catalysts for FADH

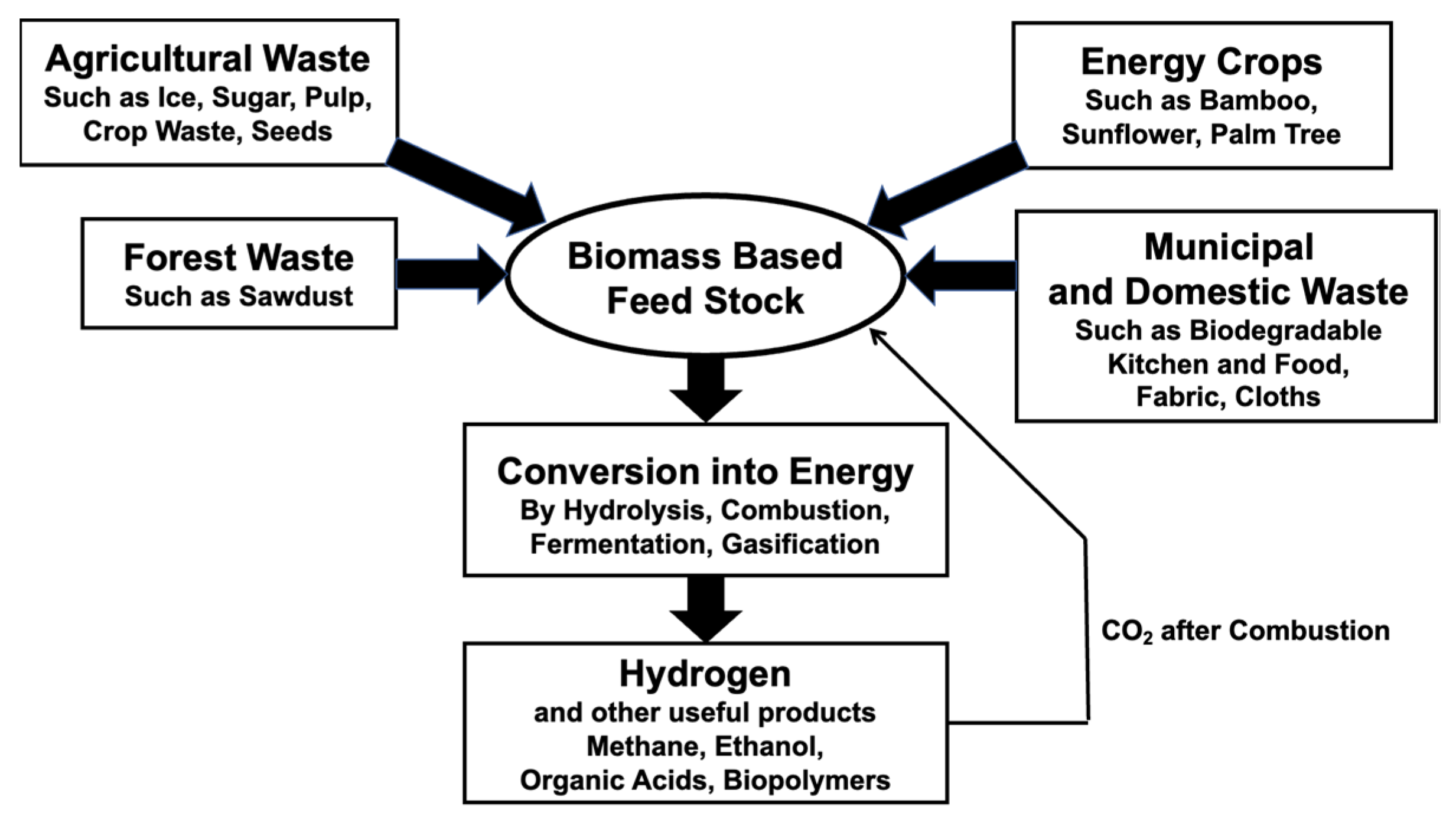

2.5. Biomass

3. Applications of Hydrogen Energy

3.1. Hydrogen Fuel Cell (HFC)

3.2. As a Fuel in an Internal Combustion Engine (Hydrogen Internal Combustion Engine, HICE)

3.3. As a Clean Fuel for the Steel Industry

3.4. Energy Storage System

4. Conclusions and Perspectives

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ashton, T.S. The Industrial Revolution 1760–1830; OUP Catalogue, Oxford University Press: Oxford, UK, 1997. [Google Scholar]

- Ritchie, H.; Roser, M.; Rosado, P. Energy; Our World Data: Oxford, UK, 2022. [Google Scholar]

- Vohra, K.; Vodonos, A.; Schwartz, J.; Marais, E.A.; Sulprizio, M.P.; Mickley, L.J. Global mortality from outdoor fine particle pollution generated by fossil fuel combustion: Results from GEOS-Chem. Environ. Res. 2021, 195, 110754. [Google Scholar] [CrossRef]

- NASA Global Climate Change. Global Surface Temperature|NASA Global Climate Change. Available online: https://climate.nasa.gov/vital-signs/global-temperature/ (accessed on 17 February 2023).

- IPCC. Global Warming of 1.5 °C: IPCC Special Report on Impacts of Global Warming of 1.5 °C above Pre-Industrial Levels in Context of Strengthening Response to Climate Change, Sustainable Development, and Efforts to Eradicate Poverty, 1st ed.; Cambridge University Press: Cambridge, UK, 2022. [Google Scholar]

- Safari, F.; Dincer, I. A review and comparative evaluation of thermochemical water splitting cycles for hydrogen production. Energy Convers. Manag. 2020, 205, 112182. [Google Scholar] [CrossRef]

- Hydrogen Council. Hydrogen Insights 2021. In Hydrogen Council; Hydrogen Council: Belgium, 2021. [Google Scholar]

- Zoulias, E.; Varkaraki, E.; Lymberopoulos, N.; Christodoulou, C.N.; Karagiorgis, G.N. A Review on Water Electrolysis. Tcjst 2004, 4, 41–71. [Google Scholar]

- Santos, D.M.F.; Sequeira, C.A.C.; Figueiredo, J.L. Hydrogen production by alkaline water electrolysis. Quím. Nova 2013, 36, 1176–1193. [Google Scholar] [CrossRef]

- IEA. Hydrogen. Available online: https://www.iea.org/reports/hydrogen (accessed on 30 December 2022).

- Rashid, M.; Al Mesfer, M.; Naseem, H.; Danish, M. Hydrogen Production by Water Electrolysis: A Review of Alkaline Water Electrolysis, PEM Water Electrolysis and High Temperature Water Electrolysis. Int. J. Eng. Adv. Technol. 2015, 4, 2249–8958. [Google Scholar]

- Sapountzi, F.M.; Gracia, J.M.; Weststrate, C.J.; Fredriksson, H.O.A.; Niemantsverdriet, J.W. Electrocatalysts for the generation of hydrogen, oxygen and synthesis gas. Prog. Energy Combust. Sci. 2017, 58, 1–35. [Google Scholar] [CrossRef]

- Hu, X.; Liu, M.; Huang, Y.; Liu, L.; Li, N. Sulfonate-functionalized polybenzimidazole as ion-solvating membrane toward high-performance alkaline water electrolysis. J. Membr. Sci. 2022, 663, 121005. [Google Scholar] [CrossRef]

- Wu, L.; An, L.; Jiao, D.; Xu, Y.; Zhang, G.; Jiao, K. Enhanced oxygen discharge with structured mesh channel in proton exchange membrane electrolysis cell. Appl. Energy 2022, 323, 119651. [Google Scholar] [CrossRef]

- Sun, Y.; Hu, X.; Gao, J.; Han, Y.; Sun, A.; Zheng, N.; Shuai, W.; Xiao, G.; Guo, M.; Ni, M. Solid oxide electrolysis cell under real fluctuating power supply with a focus on thermal stress analysis. Energy 2022, 261, 125096. [Google Scholar] [CrossRef]

- Strmcnik, D.; Uchimura, M.; Wang, C.; Subbaraman, R.; Danilovic, N.; Van Der Vliet, D.; Paulikas, A.P.; Stamenkovic, V.R.; Markovic, N.M. Improving the hydrogen oxidation reaction rate by promotion of hydroxyl adsorption. Nat. Chem. 2013, 5, 300–306. [Google Scholar] [CrossRef]

- Carmo, M.; Fritz, D.L.; Mergel, J.; Stolten, D. A comprehensive review on PEM water electrolysis. Int. J. Hydrog. Energy 2013, 38, 4901–4934. [Google Scholar] [CrossRef]

- Phillips, R.; Gannon, W.; Dunnill, C. Alkaline Electrolysers; Royal Society of Chemistry: London, UK, 2019; Chapter 2; pp. 28–58. [Google Scholar] [CrossRef]

- Millet, P.; Andolfatto, F.; Durand, R. Design and performance of a solid polymer electrolyte water electrolyzer. Int. J. Hydrog. Energy 1996, 21, 87–93. [Google Scholar] [CrossRef]

- Manabe, A.; Hashimoto, T.; Kashiwase, M.; Kurosaki, M.; Hayashida, T.; Hirao, K.; Shimomura, I.; Nagashima, I. Basic Study of Alkaline Water Electrolysis. Electrochim. Acta 2013, 100, 249–256. [Google Scholar] [CrossRef]

- Xu, W.; Scott, K. The effects of ionomer content on PEM water electrolyser membrane electrode assembly performance. Int. J. Hydrog. Energy 2010, 35, 12029–12037. [Google Scholar] [CrossRef]

- Coutanceau, C.; Jaubert, T.; Baranton, S.; Lamy, C. Clean Hydrogen Generation through the Electrocatalytic Oxidation of ethanol in a Proton Exchange Membrane Electrolysis Cell (PEMEC): Effect of the nature and structure of the catalytic anode. J. Power Sources 2014, 245, 927. [Google Scholar] [CrossRef]

- Gómez, S.; Hotza, D. Solid Oxide Electrolysers; Keith Scott: Newcastle, UK, 2019; Chapter 5; pp. 136–179. [Google Scholar] [CrossRef]

- Zhang, X.; Song, Y.; Wang, G.; Bao, X. Co-electrolysis of CO2 and H2O in high-temperature solid oxide electrolysis cells: Recent advance in cathodes. J. Energy Chem. 2017, 26, 839–853. [Google Scholar] [CrossRef]

- Laguna-Bercero, M.A. Recent advances in high temperature electrolysis using solid oxide fuel cells: A review. J. Power Sources 2012, 203, 4–16. [Google Scholar] [CrossRef]

- Rashkeev, S.N.; Glazoff, M.V. Atomic-scale mechanisms of oxygen electrode delamination in solid oxide electrolyzer cells. Int. J. Hydrog. Energy 2012, 37, 1280–1291. [Google Scholar] [CrossRef]

- Tietz, F.; Sebold, D.; Brisse, A.; Schefold, J. Degradation phenomena in a solid oxide electrolysis cell after 9000 h of operation. J. Power Sources 2013, 223, 129–135. [Google Scholar] [CrossRef]

- Ebbesen, S.; Høgh, J.; Agersted, K.; Nielsen, J.; Mogensen, M. Durable SOC stacks for production of hydrogen and synthesis gas by high temperature electrolysis. Fuel Energy Abstr. 2011, 36, 7363–7373. [Google Scholar] [CrossRef]

- Liu, Y.L.; Jiao, C. Microstructure degradation of an anode/electrolyte interface in SOFC studied by transmission electron microscopy. Solid State Ion. 2005, 176, 435–442. [Google Scholar] [CrossRef]

- Knibbe, R.; Hauch, A.; Hjelm, J.; Ebbesen, S.; Mogensen, M. Durability of Solid Oxide Cells. Green 2011, 1, 141. [Google Scholar] [CrossRef]

- Makarova, M.; Jirkovský, J.; Klementova, M.; Jirka, I.; Macounová, K.; Krtil, P. The Electrocatalytic Behavior of Ru0.8Co0.2O2−x—The Effect of Particle Shape and Surface Composition. Electrochim. Acta 2008, 53, 2656–2664. [Google Scholar] [CrossRef]

- Lewis, N.; Nocera, D. Powering the Planet: Chemical Challenges in Solar Energy Utilization. Proc. Natl. Acad. Sci. USA 2006, 103, 15729–15735. [Google Scholar] [CrossRef]

- Panwar, N.L.; Kaushik, S.C.; Kothari, S. Role of renewable energy sources in environmental protection: A review. Renew. Sustain. Energy Rev. 2011, 15, 1513–1524. [Google Scholar] [CrossRef]

- Peng, L.; Ling, Z.; Shen, J.; Wei, Z. Self-Assembly- and Preshaping-Assisted Synthesis of Ultrathin Nitrogen-Doped Graphitic Carbon Lamellas Supported Molybdenum Carbide for Hydrogen Evolution Reaction. In Electrochemical Society Meeting Abstracts; The Electrochemical Society, Inc.: Pennington, NJ, USA, 2017; Volume MA2017-02, p. 2219. [Google Scholar] [CrossRef]

- Xu, W.; Chang, J.; Cheng, Y.; Liu, H.; Li, J.; Yongjian, A.; Hu, Z.; Zhang, X.; Wang, Y.; Liang, Q.o.Q.-l.; et al. A multi-step induced strategy to fabricate core-shell Pt-Ni alloy as symmetric electrocatalysts for overall water splitting. Nano Res. 2021, 15, 965–971. [Google Scholar] [CrossRef]

- Liyanage, D.R.; Li, D.; Cheek, Q.B.; Baydoun, H.; Brock, S.L. Synthesis and oxygen evolution reaction (OER) catalytic performance of Ni2−xRuxP nanocrystals: Enhancing activity by dilution of the noble metal. J. Mater. Chem. A 2017, 5, 17609–17618. [Google Scholar] [CrossRef]

- Zhang, J.; Zy, T.; Peng, C. Direct Photo-curing 3D Printing of Nickel-based Electrocatalysts for Highly-efficient Hydrogen Evolution. Nano Energy 2022, 102, 107615. [Google Scholar] [CrossRef]

- Izquierdo, U.; Barrio, V.L.; Cambra, J.; Requies, J.; Güemez, M.B.; Arias, P.L.; Kolb, G.; Zapf, R.; Gutiérrez, A.M.; Arraibi, J.R. Hydrogen production from methane and natural gas steam reforming in conventional and microreactor reaction systems. Int. J. Hydrog. Energy 2012, 37, 7026–7033. [Google Scholar] [CrossRef]

- Collodi, G. Hydrogen production via steam reforming with CO2 capture. Chem. Eng. Trans. 2010, 19, 37–42. [Google Scholar] [CrossRef]

- Branco, D.A.C.; Szklo, A.S.; Schaeffer, R. Co2e emissions abatement costs of reducing natural gas flaring in Brazil by investing in offshore GTL plants producing premium diesel. Energy 2010, 35, 158–167. [Google Scholar] [CrossRef]

- Matsumura, Y.; Nakamori, T. Steam reforming of methane over nickel catalysts at low reaction temperature. Appl. Catal. A Gen. 2004, 258, 107–114. [Google Scholar] [CrossRef]

- Hoshi, N.; Nakamura, M.; Kida, K. Structural effects on the oxidation of formic acid on the high index planes of palladium. Electrochem. Commun. 2007, 9, 279–282. [Google Scholar] [CrossRef]

- Ali, S.; Al-Marri, M.J.; Abdelmoneim, A.G.; Kumar, A.; Khader, M.M. Catalytic evaluation of nickel nanoparticles in methane steam reforming. Int. J. Hydrog. Energy 2016, 41, 22876–22885. [Google Scholar] [CrossRef]

- Evans, S.E.; Staniforth, J.Z.; Darton, R.J.; Ormerod, R.M. A nickel doped perovskite catalyst for reforming methane rich biogas with minimal carbon deposition. Green Chem. 2014, 16, 4587–4594. [Google Scholar] [CrossRef]

- Shin, G.; Yun, J.; Yu, S. Thermal design of methane steam reformer with low-temperature non-reactive heat source for high efficiency engine-hybrid stationary fuel cell system. Int. J. Hydrog. Energy 2017, 42, 14697–14707. [Google Scholar] [CrossRef]

- Yoo, J.; Park, S.; Song, J.H.; Yoo, S.; Song, I.K. Hydrogen production by steam reforming of natural gas over butyric acid-assisted nickel/alumina catalyst. Int. J. Hydrog. Energy 2017, 42, 28377–28385. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, X.; Shi, R.; Zhao, J.; Yuan, Z.; Zhang, T. Light-Driven Hydrogen Production from Steam Methane Reforming via Bimetallic PdNi Catalysts Derived from Layered Double Hydroxide Nanosheets. Energy Fuels 2022, 36, 11627–11635. [Google Scholar] [CrossRef]

- Andreasen, S.J.; Kær, S.K.; Sahlin, S. Control and experimental characterization of a methanol reformer for a 350 W high temperature polymer electrolyte membrane fuel cell system. Int. J. Hydrog. Energy 2013, 38, 1676–1684. [Google Scholar] [CrossRef]

- Tojira, O.; Tepamatr, P. Catalytic Activity of Ni Based Materials Prepared by Different Methods for Hydrogen Production via the Water Gas Shift Reaction. Catalysts 2023, 13, 176. [Google Scholar] [CrossRef]

- Men, Y.; Kolb, G.; Zapf, R.; Tiemann, D.; Wichert, M.; Hessel, V.; Loewe, H. A complete miniaturized microstructured methanol fuel processor/fuel cell system for low power applications. Int. J. Hydrog. Energy 2008, 33, 1374–1382. [Google Scholar] [CrossRef]

- Huang, P.-H.; Kuo, J.-K.; Tu, W.-C. Investigations into the Evaporation Efficiency and Hydrogen Production Rate of Methanol-Water Fuels in a Steam Reformer Tube. Combust. Sci. Technol. 2019, 192, 1–17. [Google Scholar] [CrossRef]

- Mei, D.; Qiu, X.; Liu, H.; Wu, Q.; Yu, S.; Xu, L.; Zuo, T.; Wang, Y. Progress on methanol reforming technologies for highly efficient hydrogen production and applications. Int. J. Hydrog. Energy 2022, 47, 35757–35777. [Google Scholar] [CrossRef]

- Ye, R.; Xiao, S.; Lai, Q.; Wang, D.; Huang, Y.; Feng, G.; Zhang, R.; Wang, T. Advances in Enhancing the Stability of Cu-Based Catalysts for Methanol Reforming. Catalysts 2022, 12, 747. [Google Scholar] [CrossRef]

- Fornari, A.C.; Menechini Neto, R.; Lenzi, G.G.; dos Santos, O.A.A.; de Matos Jorge, L.M. Utilization of sol-gel CuO-ZnO-Al2O3 catalysts in the methanol steam reforming for hydrogen production. Can. J. Chem. Eng. 2017, 95, 2258–2271. [Google Scholar] [CrossRef]

- Mohtashami, Y.; Taghizadeh, M. Performance of the ZrO2 promoted CuZnO catalyst supported on acetic acid-treated MCM-41 in methanol steam reforming. Int. J. Hydrog. Energy 2019, 44, 5725–5738. [Google Scholar] [CrossRef]

- Palo, D.R.; Dagle, R.A.; Holladay, J.D. Methanol steam reforming for hydrogen production. Chem. Rev. 2007, 107, 3992–4021. [Google Scholar] [CrossRef]

- Shahsavar, H.; Taghizadeh, M.; Kiadehi, A.D. Effects of catalyst preparation route and promoters (Ce and Zr) on catalytic activity of CuZn/CNTs catalysts for hydrogen production from methanol steam reforming. Int. J. Hydrog. Energy 2021, 46, 8906–8921. [Google Scholar] [CrossRef]

- Cheng, Z.; Zhou, W.; Lan, G.; Sun, X.; Wang, X.; Jiang, C.; Li, Y. High-performance Cu/ZnO/Al2O3 catalysts for methanol steam reforming with enhanced Cu-ZnO synergy effect via magnesium assisted strategy. J. Energy Chem. 2021, 63, 550–557. [Google Scholar] [CrossRef]

- Luo, S.; Lin, H.; Wang, Q.; Ren, X.; Hernández-Pinilla, D.; Nagao, T.; Xie, Y.; Yang, G.; Li, S.; Song, H. Triggering water and methanol activation for solar-driven H2 production: Interplay of dual active sites over plasmonic ZnCu alloy. J. Am. Chem. Soc. 2021, 143, 12145–12153. [Google Scholar] [CrossRef]

- Hou, X.; Qing, S.; Liu, Y.; Zhang, L.; Zhang, C.; Feng, G.; Wang, X.; Gao, Z.; Qin, Y. Cu1−xMgxAl3 spinel solid solution as a sustained release catalyst: One-pot green synthesis and catalytic performance in methanol steam reforming. Fuel 2021, 284, 119041. [Google Scholar] [CrossRef]

- Chen, Y.; Li, S.; Lv, S.; Huang, Y. A novel synthetic route for MOF-derived CuO-CeO2 catalyst with remarkable methanol steam reforming performance. Catal. Commun. 2021, 149, 106215. [Google Scholar] [CrossRef]

- Wang, A.; Zhang, Y.; Fu, P.; Zheng, Q.; Fan, Q.; Wei, P.; Zheng, L. Achieving strong thermal stability in catalytic reforming of methanol over in-situ self-activated nano Cu2O/ZnO catalyst with dual-sites of Cu species. J. Environ. Chem. Eng. 2022, 10, 107676. [Google Scholar] [CrossRef]

- Conant, T.; Karim, A.M.; Lebarbier, V.; Wang, Y.; Girgsdies, F.; Schlögl, R.; Datye, A. Stability of bimetallic Pd–Zn catalysts for the steam reforming of methanol. J. Catal. 2008, 257, 64–70. [Google Scholar] [CrossRef]

- Shanmugam, V.; Neuberg, S.; Zapf, R.; Pennemann, H.; Kolb, G. Hydrogen production over highly active Pt based catalyst coatings by steam reforming of methanol: Effect of support and co-support. Int. J. Hydrog. Energy 2020, 45, 1658–1670. [Google Scholar] [CrossRef]

- Liu, L.; Lin, Y.; Hu, Y.; Lin, Z.; Lin, S.; Du, M.; Zhang, L.; Zhang, X.-h.; Lin, J.; Zhang, Z. ZnAl2O4 Spinel-Supported PdZnβ Catalyst with Parts per Million Pd for Methanol Steam Reforming. ACS Catal. 2022, 12, 2714–2721. [Google Scholar] [CrossRef]

- Yan, P.; Tian, P.; Cai, C.; Zhou, S.; Yu, X.; Zhao, S.; Tu, S.-T.; Deng, C.; Sun, Y. Antioxidative and stable PdZn/ZnO/Al2O3 catalyst coatings concerning methanol steam reforming for fuel cell-powered vehicles. Appl. Energy 2020, 268, 115043. [Google Scholar] [CrossRef]

- Ding, Y.; Zhang, T.; Ge, Z.; Li, P.; Shen, Y. High-efficiency steam reforming of methanol on the surface of a recyclable NiO/NaF catalyst for hydrogen production. Compos. Part B Eng. 2022, 243, 110113. [Google Scholar] [CrossRef]

- Davda, R.R.; Shabaker, J.W.; Huber, G.W.; Cortright, R.D.; Dumesic, J.A. A review of catalytic issues and process conditions for renewable hydrogen and alkanes by aqueous-phase reforming of oxygenated hydrocarbons over supported metal catalysts. Appl. Catal. B Environ. 2005, 56, 171–186. [Google Scholar] [CrossRef]

- Pipitone, G.; Zoppi, G.; Pirone, R.; Bensaid, S. A critical review on catalyst design for aqueous phase reforming. Int. J. Hydrog. Energy 2022, 47, 151–180. [Google Scholar] [CrossRef]

- Pitinova, M.; Rinta-Paavola, A.; Karinen, R. Hydrogen production via aqueous-phase reforming of methanol over nickel modified Ce, Zr and La oxide supports. Catal. Today 2017, 304, 143–152. [Google Scholar] [CrossRef]

- Zoppi, G.; Pipitone, G.; Gruber, H.; Weber, G.; Reichhold, A.; Pirone, R.; Bensaid, S. Aqueous phase reforming of pilot-scale Fischer-Tropsch water effluent for sustainable hydrogen production. Catal. Today 2020, 367, 239–247. [Google Scholar] [CrossRef]

- Ren, X.; Wilson, M.; Gottesfeld, S. High Performance Direct Methanol Polymer Electrolyte Fuel Cell. J. Electrochem. Soc. 1996, 143, L12–L15. [Google Scholar] [CrossRef]

- Zuo, Y.; Sheng, W.; Tao, W.; Li, Z. Direct methanol fuel cells system–A review of dual-role electrocatalysts for oxygen reduction and methanol oxidation. J. Mater. Sci. Technol. 2022, 114, 29–41. [Google Scholar] [CrossRef]

- Alia, S.; Zhang, G.; Kisailus, D.; Li, D.; Gu, S.; Jensen, K.; Yan, Y. Porous Platinum Nanotubes for Oxygen Reduction and Methanol Oxidation Reactions. Adv. Funct. Mater. 2010, 20, 3742–3746. [Google Scholar] [CrossRef]

- Sharma, C.; Awasthi, R.; Singh, R.; Sinha, A. Graphene-Manganite-Pd Hybrids as Highly Active and Stable Electrocatalysts for Methanol Oxidation and Oxygen Reduction. Electrochim. Acta 2014, 136, 166–175. [Google Scholar] [CrossRef]

- Ghosh, S.; Sahu, R.; Raj, C.R. Shape-regulated high yield synthesis of electrocatalytically active branched Pt nanostructures for oxygen reduction and methanol oxidation reactions. J. Mater. Chem. 2011, 21, 11973–11980. [Google Scholar] [CrossRef]

- Du, Y.; Lv, K.; Su, B.; Zhang, N.; Wang, C. Electro-reduction of oxygen and electro-oxidation of methanol at Pd monolayer-modified macroporous Pt electrode. J. Appl. Electrochem. 2009, 39, 2409–2414. [Google Scholar] [CrossRef]

- Shi, Q.; Zhu, C.; Bi, C.; Xia, H.; Engelhard, M.; Du, D.; Lin, Y. Intermetallic Pd3Pb Nanowire Networks Boost Ethanol Oxidation and Oxygen Reduction Reaction with Significantly Improved Methanol Tolerance. J. Mater. Chem. A 2017, 5, 23952–23959. [Google Scholar] [CrossRef]

- Uribe, J.; García-Montalvo, V.; Jiménez-Sandoval, O. A novel Rh–Ir electrocatalyst for the oxygen reduction reaction and the hydrogen and methanol oxidation reactions. Int. J. Hydrog. Energy 2014, 39, 9121–9127. [Google Scholar] [CrossRef]

- Cao, J.; Du, Y.; Dong, M.; Chen, Z.; Xu, J. Template-free synthesis of chain-like PtCu nanowires and their superior performance for oxygen reduction and methanol oxidation reaction. J. Alloy. Compd. 2018, 747, 258–264. [Google Scholar] [CrossRef]

- Hodnik, N.; Bele, M.; Hocevar, S. New Pt-skin electrocatalysts for oxygen reduction and methanol oxidation reactions. Electrochem. Commun. 2012, 23, 125. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, L.; Gong, H.; Zhu, Y.; Zhao, H.; Fu, Y. Dealloyed PtAuCu electrocatalyst to improve the activity and stability towards both oxygen reduction and methanol oxidation reactions. Electrochim. Acta 2016, 212, 277–285. [Google Scholar] [CrossRef]

- Luo, l.; Zhang, R.-H.; Chen, d.; Hu, q.; Zhou, X.-W. Synthesis of 3D Thornbush-like Trimetallic CoAuPd Nanocatalysts and Electrochemical Dealloying for Methanol Oxidation and Oxygen Reduction Reaction. ACS Appl. Energy Mater. 2018, 1, 2619–2629. [Google Scholar] [CrossRef]

- Yan, H.; Meng, M.; Wang, L.; Wu, A.; Tian, C.; Zhao, l.; Fu, H. Small-sized tungsten nitride anchoring into a 3D CNT-rGO framework as a superior bifunctional catalyst for the methanol oxidation and oxygen reduction reactions. Nano Res. 2015, 9, 329–343. [Google Scholar] [CrossRef]

- Kulprathipanja, A.; Falconer, J. Partial oxidation of methanol for hydrogen production using ITO/Al2O3 nanoparticle catalysts. Appl. Catal. A Gen. 2004, 261, 77–86. [Google Scholar] [CrossRef]

- Ahmed, S.; Krumpelt, M. Hydrogen from hydrocarbon fuels for fuel cells. Int. J. Hydrog. Energy 2001, 26, 291–301. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Hohn, K.L.; Stagg-Williams, S.M. Hydrogen generation from methanol oxidation on supported Cu and Pt catalysts: Effects of active phases and supports. Appl. Catal. A Gen. 2007, 327, 164–172. [Google Scholar] [CrossRef]

- Herdem, M.S.; Sinaki, M.Y.; Farhad, S.; Hamdullahpur, F. An overview of the methanol reforming process: Comparison of fuels, catalysts, reformers, and systems. Int. J. Energy Res. 2019, 43, 5076–5105. [Google Scholar] [CrossRef]

- Chih, Y.-K.; Su, Y.-Q.; Chen, W.-H.; Lin, B.-J.; Kuo, J.-K.; You, S.; Lin, H.-P. Optimization for hydrogen production from methanol partial oxidation over Ni–Cu/Al2O3 catalyst under sprays. Int. J. Hydrog. Energy 2022, 47, 40559–40572. [Google Scholar] [CrossRef]

- Faheem, H.H.; Tanveer, H.U.; Abbas, S.Z.; Maqbool, F. Comparative study of conventional steam-methane-reforming (SMR) and auto-thermal-reforming (ATR) with their hybrid sorption enhanced (SE-SMR & SE-ATR) and environmentally benign process models for the hydrogen production. Fuel 2021, 297, 120769. [Google Scholar]

- Richards, N.; Erickson, P. An investigation of a stratified catalyst bed for small-scale hydrogen production from methanol autothermal reforming. Int. J. Hydrog. Energy 2014, 39, 18077–18083. [Google Scholar] [CrossRef]

- Mu, X.; Pan, L.; Liu, N.; Zhang, C.; Li, S.; Sun, G.; Wang, S. Autothermal reforming of methanol in a mini-reactor for a miniature fuel cell. Int. J. Hydrog. Energy 2007, 32, 3327–3334. [Google Scholar] [CrossRef]

- Ghavam, S.; Vahdati, M.; Wilson, I.A.G.; Styring, P. Sustainable Ammonia Production Processes. Front. Energy Res. 2021, 9, 580808. [Google Scholar] [CrossRef]

- Ganley, J.C.; Thomas, F.; Seebauer, E.; Masel, R.I. A priori catalytic activity correlations: The difficult case of hydrogen production from ammonia. Catal. Lett. 2004, 96, 117–122. [Google Scholar] [CrossRef]

- Rasmussen, S.B.; Perez-Ferreras, S.; Bañares, M.A.; Bazin, P.; Daturi, M. Does pelletizing catalysts influence the efficiency number of activity measurements? Spectrochemical engineering considerations for an accurate operando study. ACS Catal. 2013, 3, 86–94. [Google Scholar] [CrossRef]

- Cha, J.; Park, Y.; Brigljević, B.; Lee, B.; Lim, D.; Lee, T.; Jeong, H.; Kim, Y.; Sohn, H.; Mikulčić, H. An efficient process for sustainable and scalable hydrogen production from green ammonia. Renew. Sustain. Energy Rev. 2021, 152, 111562. [Google Scholar] [CrossRef]

- Qiu, Y.; Fu, E.; Gong, F.; Xiao, R. Catalyst support effect on ammonia decomposition over Ni/MgAl2O4 towards hydrogen production. Int. J. Hydrog. Energy 2022, 47, 5044–5052. [Google Scholar] [CrossRef]

- El-Shafie, M.; Kambara, S.; Hayakawa, Y. Development of zeolite-based catalyst for enhancement hydrogen production from ammonia decomposition. Catal. Today 2022, 397, 103–112. [Google Scholar] [CrossRef]

- Guo, J.; Chen, P. Interplay of Alkali, Transition Metals, Nitrogen, and Hydrogen in Ammonia Synthesis and Decomposition Reactions. Acc. Chem. Res. 2021, 54, 2434–2444. [Google Scholar] [CrossRef]

- Guo, J.; Chen, Z.; Wu, A.; Fei, C.; Peikun, W.; Hu, D.; Wu, G.; Xiong, Z.; Yu, P.; Chen, P. Electronic promoter or reacting species? The role of LiNH2 on Ru in catalyzing NH3 decomposition. Chem. Commun. 2015, 51, 15161–15164. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Fei, C.; Peikun, W.; Hu, D.; Yu, P.; Wu, G.; Xiong, Z.; Chen, P. Highly Active MnN–Li 2 NH Composite Catalyst for Producing CO x -Free Hydrogen. ACS Catal. 2015, 5, 2708–2713. [Google Scholar] [CrossRef]

- Coffey, R. The decomposition of formic acid catalysed by soluble metal complexes. Chem. Commun. 1967, 18, 923–924. [Google Scholar] [CrossRef]

- Puddephatt, R.; Yap, G.A. An efficient binuclear catalyst for decomposition of formic acid. Chem. Commun. 1998, 21, 2365–2366. [Google Scholar]

- Gao, Y.; Kuncheria, J.K.; Jenkins, H.A.; Puddephatt, R.J.; Yap, G.P. The interconversion of formic acid and hydrogen/carbon dioxide using a binuclear ruthenium complex catalyst. J. Chem. Soc. Dalton Trans. 2000, 18, 3212–3217. [Google Scholar] [CrossRef]

- Mellmann, D.; Sponholz, P.; Junge, H.; Beller, M. Formic acid as a hydrogen storage material—Development of homogeneous catalysts for selective hydrogen release. Chem. Soc. Rev. 2016, 45, 3954–3988. [Google Scholar] [CrossRef]

- Sordakis, K.; Dalebrook, A.F.; Laurenczy, G. A viable hydrogen storage and release system based on cesium formate and bicarbonate salts: Mechanistic insights into the hydrogen release step. ChemCatChem 2015, 7, 2332–2339. [Google Scholar] [CrossRef]

- Sponholz, P.; Mellmann, D.; Junge, H.; Beller, M. Towards a practical setup for hydrogen production from formic acid. ChemSusChem 2013, 6, 1172–1176. [Google Scholar] [CrossRef]

- Hull, J.F.; Himeda, Y.; Wang, W.-H.; Hashiguchi, B.; Periana, R.; Szalda, D.J.; Muckerman, J.T.; Fujita, E. Reversible hydrogen storage using CO2 and a proton-switchable iridium catalyst in aqueous media under mild temperatures and pressures. Nat. Chem. 2012, 4, 383–388. [Google Scholar] [CrossRef]

- Wang, W.H.; Hull, J.F.; Muckerman, J.T.; Fujita, E.; Hirose, T.; Himeda, Y. Highly efficient D2 generation by dehydrogenation of formic acid in D2O through H+/D+ exchange on an iridium catalyst: Application to the synthesis of deuterated compounds by transfer deuterogenation. Chem. A Eur. J. 2012, 18, 9397–9404. [Google Scholar] [CrossRef]

- Lentz, N.; Albrecht, M. A Low-Coordinate Iridium Complex with a Donor-Flexible O, N-Ligand for Highly Efficient Formic Acid Dehydrogenation. ACS Catal. 2022, 12, 12627–12631. [Google Scholar] [CrossRef]

- Li, R.; Kodaira, T.; Kawanami, H. In situ formic acid dehydrogenation observation using a UV-vis-diffuse-reflectance spectroscopy system. Chem. Commun. 2022, 58, 11079–11082. [Google Scholar] [CrossRef] [PubMed]

- Fellay, C.; Yan, N.; Dyson, P.; Laurenczy, G. Selective Formic Acid Decomposition for High-Pressure Hydrogen Generation: A Mechanistic Study. Chem. Eur. J. 2009, 15, 3752–3760. [Google Scholar] [CrossRef] [PubMed]

- Iguchi, M.; Himeda, Y.; Manaka, Y.; Matsuoka, K.; Kawanami, H. Simple Continuous High-Pressure Hydrogen Production and Separation System from Formic Acid under Mild Temperatures. ChemCatChem 2015, 8, 886–889. [Google Scholar] [CrossRef]

- Kawanami, H.; Himeda, Y.; Laurenczy, G. Formic Acid as a Hydrogen Carrier for Fuel Cells Toward a Sustainable Energy System. In Advances in Inorganic Chemistry; Academic Press: Cambridge, MA, USA, 2017. [Google Scholar] [CrossRef]

- Iguchi, M.; Guan, C.; Huang, K.-W.; Kawanami, H. Solvent effects on high-pressure hydrogen gas generation by dehydrogenation of formic acid using ruthenium complexes. Int. J. Hydrog. Energy 2019, 44, 28507–28513. [Google Scholar] [CrossRef]

- Kawanami, H.; Iguchi, M.; Himeda, Y. Ligand Design for Catalytic Dehydrogenation of Formic Acid to Produce High-pressure Hydrogen Gas under Base-free Conditions. Inorg. Chem. 2020, 59, 4191–4199. [Google Scholar] [CrossRef]

- Boddien, A.; Gärtner, F.; Jackstell, R.; Junge, H.; Spannenberg, A.; Baumann, W.; Ludwig, R.; Beller, M. Ortho-metalation of iron (0) tribenzylphosphine complexes: Homogeneous catalysts for the generation of hydrogen from formic acid. Angew. Chem. Int. Ed. 2010, 49, 8993–8996. [Google Scholar] [CrossRef]

- Enthaler, S.; Brück, A.; Kammer, A.; Junge, H.; Irran, E.; Gülak, S. Exploring the reactivity of nickel pincer complexes in the decomposition of formic acid to CO2/H2 and the hydrogenation of NaHCO3 to HCOONa. ChemCatChem 2015, 7, 65–69. [Google Scholar] [CrossRef]

- Neary, M.; Parkin, G. Nickel-catalyzed release of H2 from formic acid and a new method for the synthesis of zerovalent Ni(PMe3)4. Dalton Trans. 2016, 45, 14645–14650. [Google Scholar] [CrossRef]

- Boddien, A.; Loges, B.; Gärtner, F.; Torborg, C.; Fumino, K.; Junge, H.; Ludwig, R.; Beller, M. Iron-catalyzed hydrogen production from formic acid. J. Am. Chem. Soc. 2010, 132, 8924–8934. [Google Scholar] [CrossRef]

- Nakajima, T.; Kamiryo, Y.; Kishimoto, M.; Imai, K.; Nakamae, K.; Ura, Y.; Tanase, T. Synergistic Cu2 catalysts for formic acid dehydrogenation. J. Am. Chem. Soc. 2019, 141, 8732–8736. [Google Scholar] [CrossRef] [PubMed]

- Wei, D.; Sang, R.; Sponholz, P.; Junge, H.; Beller, M. Reversible hydrogenation of carbon dioxide to formic acid using a Mn-pincer complex in the presence of lysine. Nat. Energy 2022, 7, 438–447. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, B.; Hangkong, Y.; Sun, Y.; Yang, D.; Cui, X.; Shi, F. Catalytic Dehydrogenation of Ethanol by Heterogeneous Catalysts. Catal. Sci. Technol. 2021, 11, 1652–1664. [Google Scholar] [CrossRef]

- Gambo, Y.; Adamu, S.; Abdulrasheed, A.A.; Lucky, R.A.; Ba-Shammakh, M.S.; Hossain, M.M. Catalyst design and tuning for oxidative dehydrogenation of propane–A review. Appl. Catal. A Gen. 2021, 609, 117914. [Google Scholar] [CrossRef]

- Yaacoub, L.; Dutta, I.; Werghi, B.; Chen, B.W.J.; Zhang, J.; Hamad, E.A.; Ling Ang, E.P.; Pump, E.; Sedjerari, A.B.; Huang, K.-W.; et al. Formic Acid Dehydrogenation via an Active Ruthenium Pincer Catalyst Immobilized on Tetra-Coordinated Aluminum Hydride Species Supported on Fibrous Silica Nanospheres. ACS Catal. 2022, 12, 14408–14417. [Google Scholar] [CrossRef]

- Yu, Z.; Yang, Y.; Yang, S.; Zheng, J.; Hao, X.; Wei, G.; Bai, H.; Abudula, A.; Guan, G. Selective dehydrogenation of aqueous formic acid over multifunctional γ-Mo2N catalysts at a temperature lower than 100 °C. Appl. Catal. B Environ. 2022, 313, 121445. [Google Scholar] [CrossRef]

- Ding, Y.; Peng, W.; Zhang, L.; Xia, J.; Feng, G.; Lu, Z.-H. Chromic hydroxide-decorated palladium nanoparticles confined by amine-functionalized mesoporous silica for rapid dehydrogenation of formic acid. J. Colloid Interface Sci. 2023, 630, 879–887. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, G.; Yao, Q.; Li, H.; Feng, G.; Lu, Z.-H. Amine-Functionalized Carbon Bowl-Supported Pd-La(OH)3 for Formic Acid Dehydrogenation. Inorg. Chem. 2022, 61, 18102–18111. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.-L.; Yan, J.-M.; Ping, Y.; Wang, H.-L.; Zheng, W.-T.; Jiang, Q. An Efficient CoAuPd/C Catalyst for Hydrogen Generation from Formic Acid at Room Temperature. Angew. Chem. 2013, 125, 4502–4505. [Google Scholar] [CrossRef]

- Liu, D.-X.; Zhou, Y.-T.; Zhu, Y.-F.; Chen, Z.-Y.; Yan, J.-M.; Jiang, Q. Tri-metallic AuPdIr nanoalloy towards efficient hydrogen generation from formic acid. Appl. Catal. B Environ. 2022, 309, 121228. [Google Scholar] [CrossRef]

- Kumar, G.; Banu, R.; Xia, A.; Sivagurunathan, P.; Saratale, G. A critical review on anaerobic digestion of microalgae and macroalgae and co-digestion of biomass for enhanced methane generation. Bioresour. Technol. 2018, 262, 319–332. [Google Scholar] [CrossRef]

- Ayodele, B.; bin Tuan Abdullah, T.A.R.; Ali Alsaffar, M.; Mustapa, S.; Salleh, S. Recent advances in renewable hydrogen production by thermo-catalytic conversion of biomass-derived glycerol: Overview of prospects and challenges. Int. J. Hydrog. Energy 2019, 45, 18160–18185. [Google Scholar] [CrossRef]

- Gautam, P.; Neha; Upadhyay, S.; Dubey, S. Bio-methanol as a renewable fuel from waste biomass: Current trends and future perspective. Fuel 2020, 273, 117783. [Google Scholar] [CrossRef]

- Manochio, C.; Andrade, B.R.; Rodriguez, R.; Moraes, B. Ethanol from biomass: A comparative overview. Renew. Sustain. Energy Rev. 2017, 80, 743–755. [Google Scholar] [CrossRef]

- Pal, D.B.; Singh, A.; Bhatnagar, A. A review on biomass based hydrogen production technologies. Int. J. Hydrog. Energy 2022, 47, 1461–1480. [Google Scholar] [CrossRef]

- Dincer, I.; Acar, C. Review and Evaluation of Hydrogen Production Methods for Better Sustainability. Altern. Energy Ecol. (ISJAEE) 2016, 11, 14–36. [Google Scholar] [CrossRef]

- Zhao, L.; Wu, K.-K.; Chen, C.; Ren, H.-Y.; Wang, Z.-H.; Nan, J.; Yang, S.; Cao, G.; Ren, N.-Q. Role of residue cornstalk derived biochar for the enhanced bio-hydrogen production via simultaneous saccharification and fermentation of cornstalk. Bioresour. Technol. 2021, 330, 125006. [Google Scholar] [CrossRef]

- Fahmy, T.; Fahmy, Y.; Mobarak, F.; El-Sakhawy, M.; Abouzeid, R. Biomass pyrolysis: Past, present, and future. Environ. Dev. Sustain. 2020, 22, 17–32. [Google Scholar] [CrossRef]

- Pokorna, E.; Postelmans, N.; Jenicek, P.; Schreurs, S.; Carleer, R.; Yperman, J. Study of bio-oils and solids from flash pyrolysis of sewage sludges. Fuel 2009, 88, 1344–1350. [Google Scholar] [CrossRef]

- Valle, B.; Aramburu, B.; Benito, P.; Bilbao, J.; Gayubo, A. Biomass to hydrogen-rich gas via steam reforming of raw bio-oil over Ni/La2O3-αAl2O3 catalyst: Effect of space-time and steam-to-carbon ratio. Fuel 2018, 216, 445–455. [Google Scholar] [CrossRef]

- Demirbas, M. Hydrogen from Various Biomass Species via Pyrolysis and Steam Gasification Processes. Energy Sources 2006, 28, 245–252. [Google Scholar] [CrossRef]

- Florin, N.; Harris, A. Enhanced hydrogen production from biomass with in situ carbon dioxide capture using calcium oxide sorbents. Chem. Eng. Sci. 2008, 63, 287–316. [Google Scholar] [CrossRef]

- Manoharan, Y.; Hosseini, S.E.; Butler, B.; Alzhahrani, H.; Senior, B.T.F.; Ashuri, T.; Krohn, J. Hydrogen fuel cell vehicles; current status and future prospect. Appl. Sci. 2019, 9, 2296. [Google Scholar] [CrossRef]

- Youon Technology Co., Ltd. Available online: https://www.youonbikeshare.com/ (accessed on 22 February 2022).

- Wróbel, K.; Wróbel, J.; Tokarz, W.; Lach, J.; Podsadni, K.; Czerwiński, A. Hydrogen Internal Combustion Engine Vehicles: A Review. Energies 2022, 15, 8937. [Google Scholar] [CrossRef]

- Wakayama, N.; Morimoto, K.; Kashiwagi, A.; Saito, T. Development of Hydrogen Rotary Engine Vehicle. In Proceedings of the 16th World Hydrogen Energy Conference, Lyon, France, 13–16 June 2006. [Google Scholar]

- Liu, W.; Zuo, H.; Wang, J.; Xue, Q.; Ren, B.; Yang, F. The production and application of hydrogen in steel industry. Int. J. Hydrog. Energy 2021, 46, 10548–10569. [Google Scholar] [CrossRef]

- DATAZERO. Available online: https://www.irit.fr/datazero/index.php/en/ (accessed on 10 February 2023).

- Sun.Storage Underground. Final Report. Available online: https://www.underground-sun-storage.at/en/public-relations-/-publications/publications-1.html (accessed on 10 February 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, R.; Kawanami, H. A Recent Review of Primary Hydrogen Carriers, Hydrogen Production Methods, and Applications. Catalysts 2023, 13, 562. https://doi.org/10.3390/catal13030562

Li R, Kawanami H. A Recent Review of Primary Hydrogen Carriers, Hydrogen Production Methods, and Applications. Catalysts. 2023; 13(3):562. https://doi.org/10.3390/catal13030562

Chicago/Turabian StyleLi, Risheng, and Hajime Kawanami. 2023. "A Recent Review of Primary Hydrogen Carriers, Hydrogen Production Methods, and Applications" Catalysts 13, no. 3: 562. https://doi.org/10.3390/catal13030562

APA StyleLi, R., & Kawanami, H. (2023). A Recent Review of Primary Hydrogen Carriers, Hydrogen Production Methods, and Applications. Catalysts, 13(3), 562. https://doi.org/10.3390/catal13030562