Assessment of a Euro VI Step E Heavy-Duty Vehicle’s Aftertreatment System

Abstract

1. Introduction

2. Results

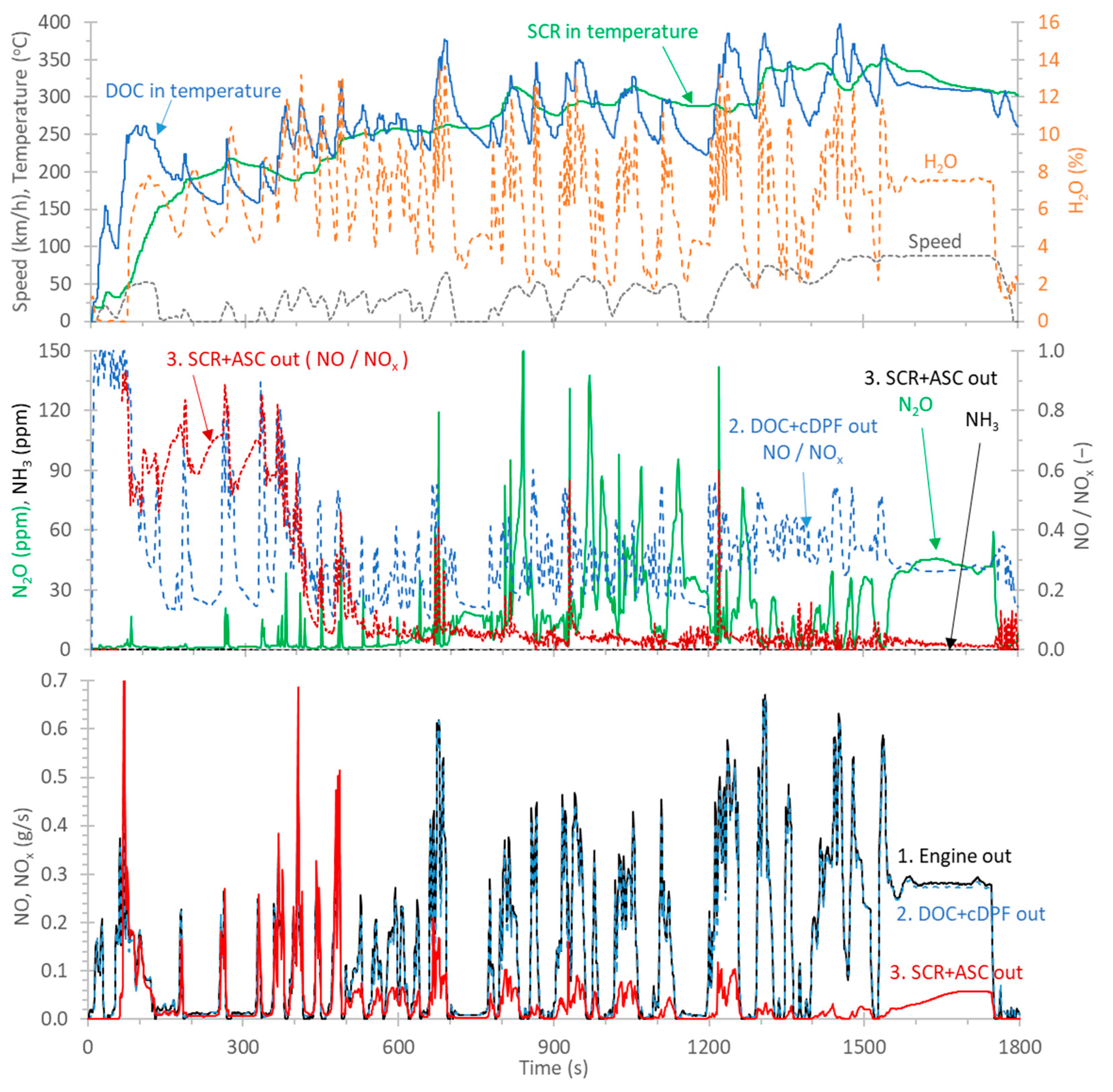

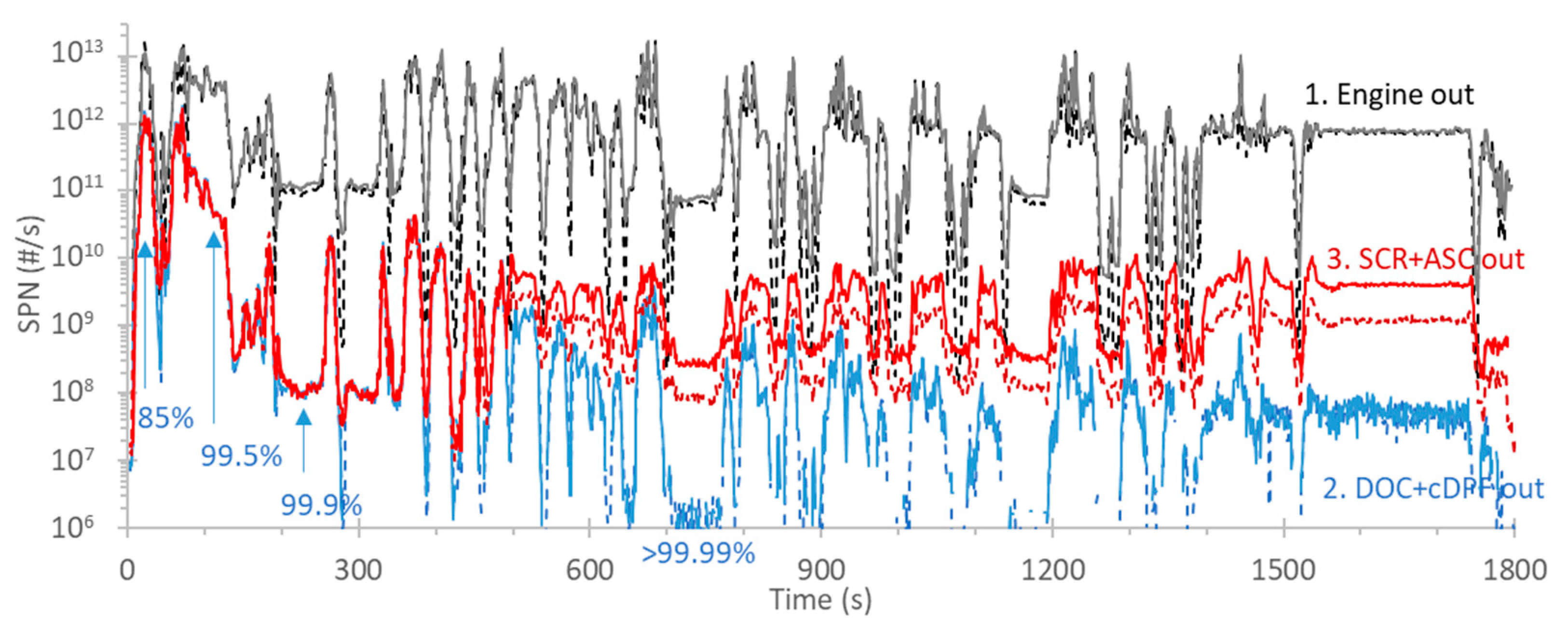

2.1. WHVC (World Harmonized Vehicle Cycle)

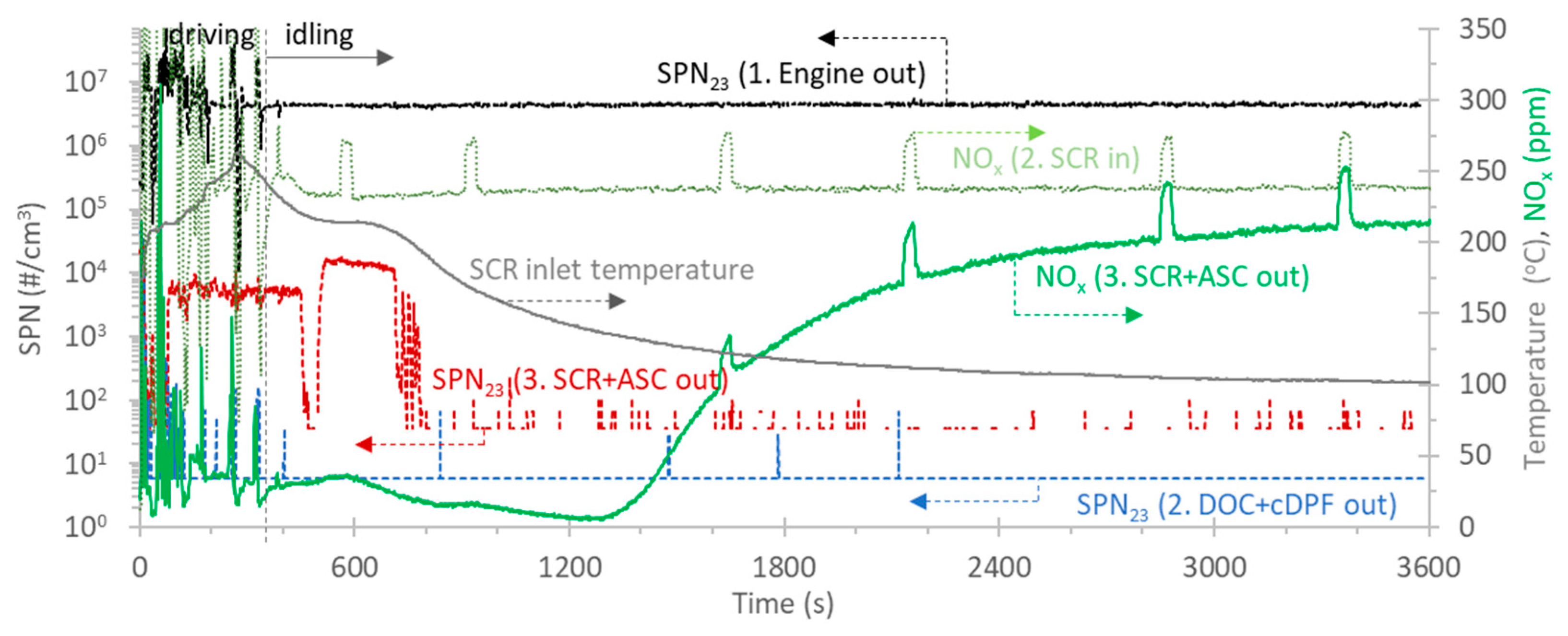

2.2. Idling

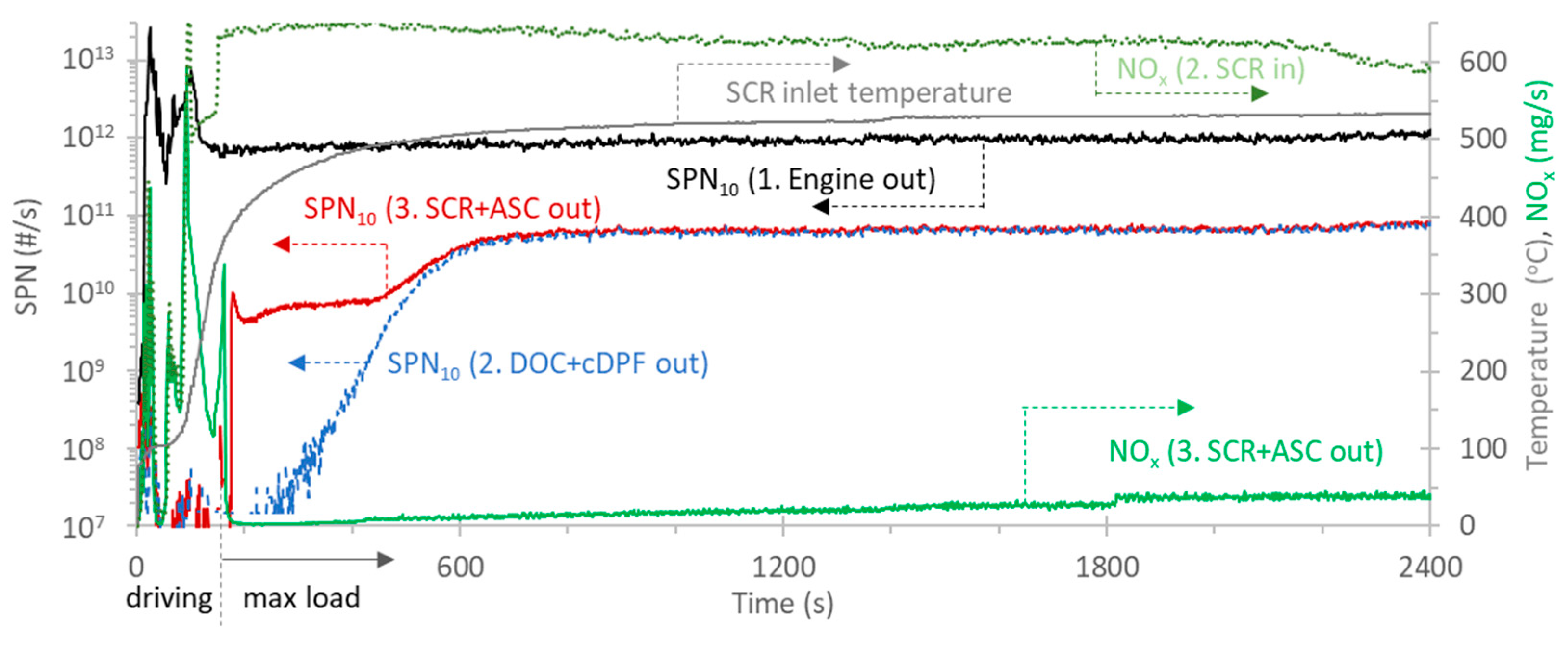

2.3. Maximum Load (Passive Regeneration)

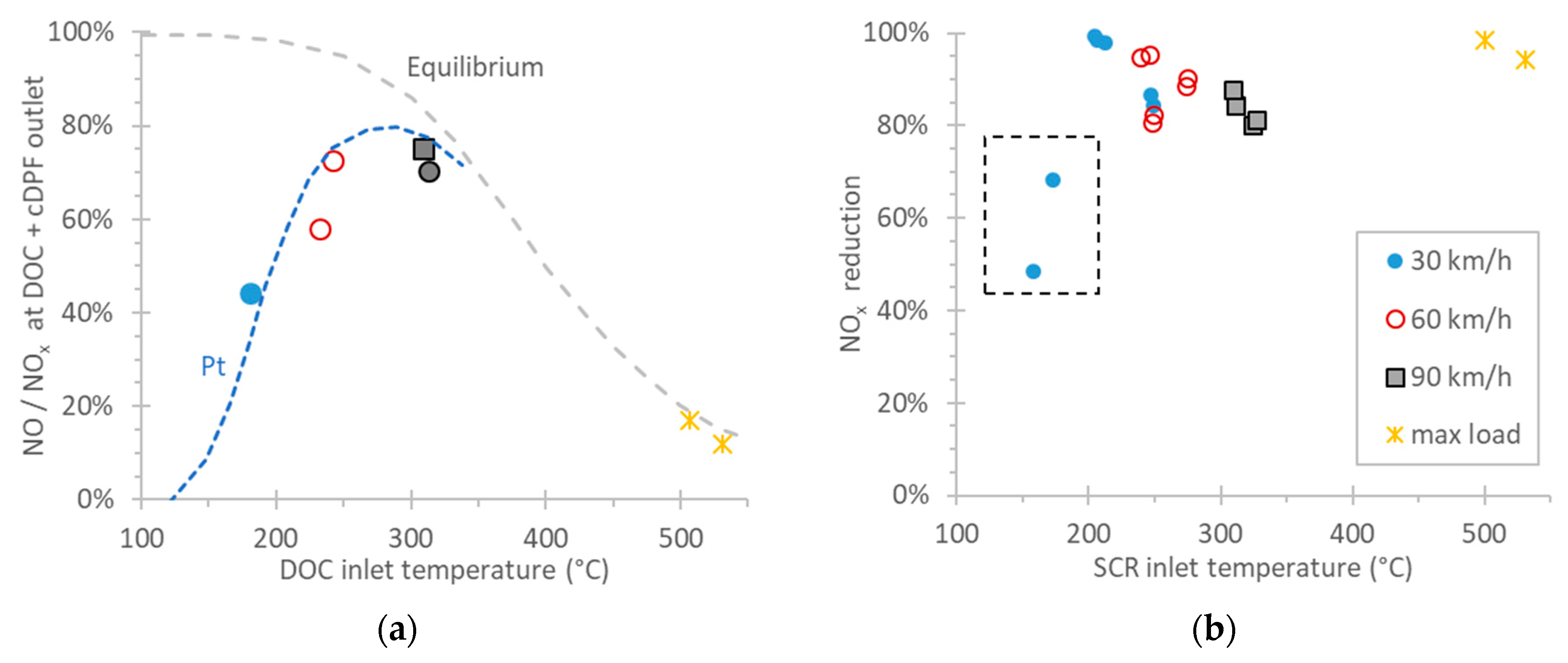

2.4. NOx Conversions

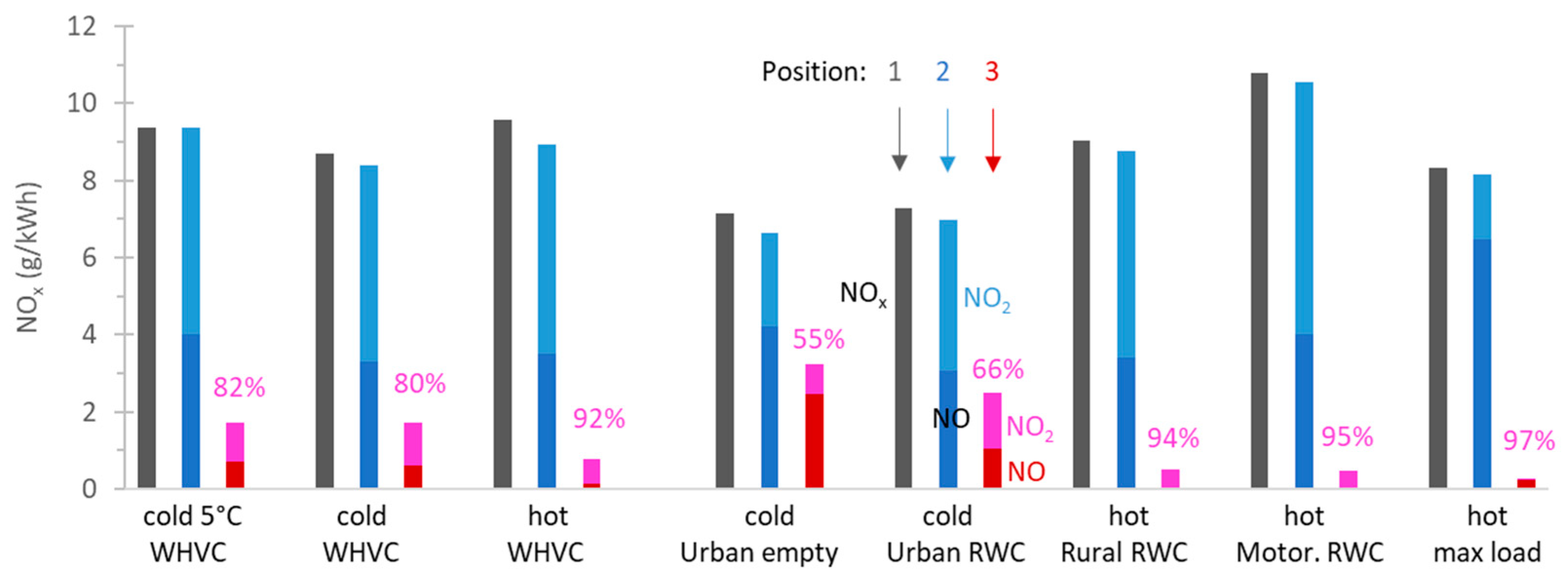

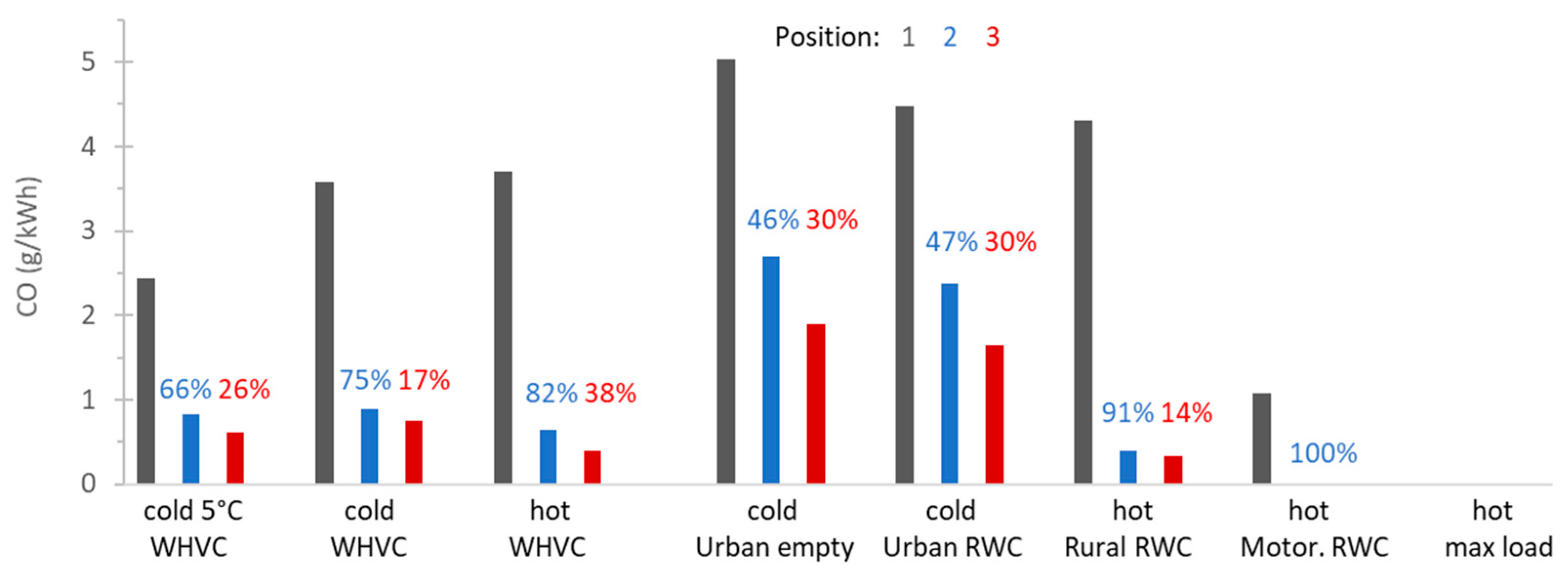

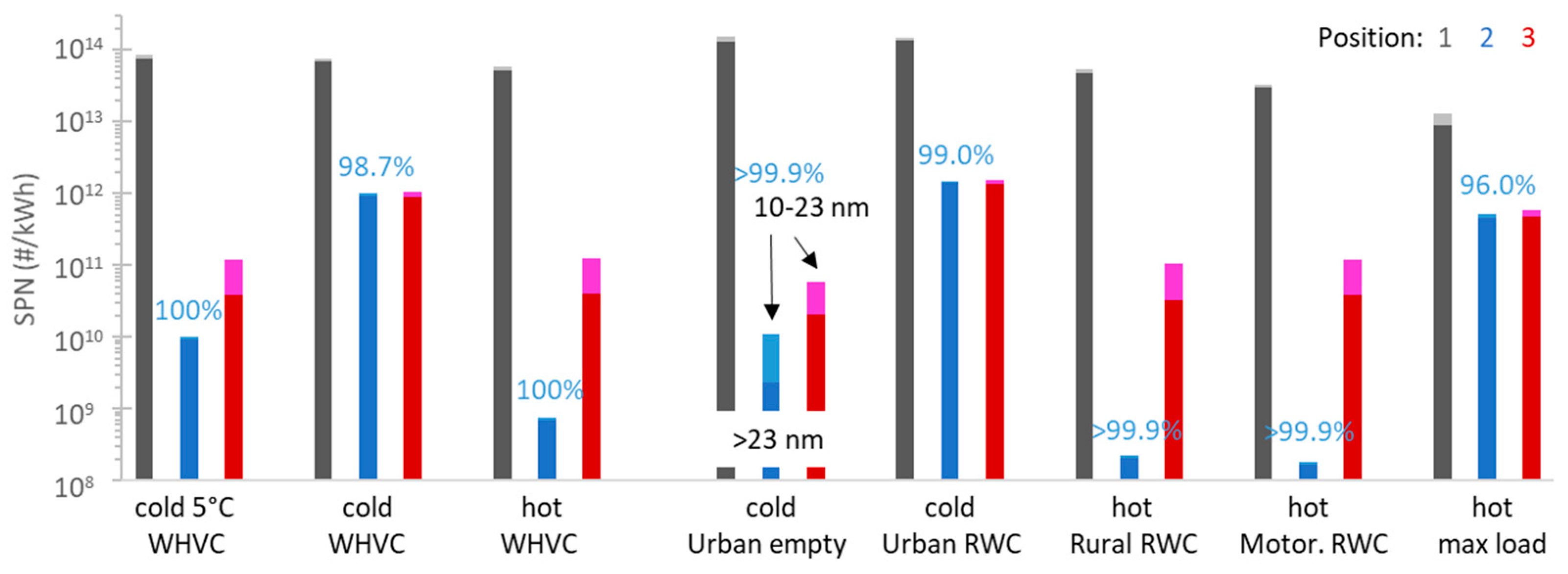

2.5. Emission Factors

2.6. Euro VI and Future

3. Materials and Methods

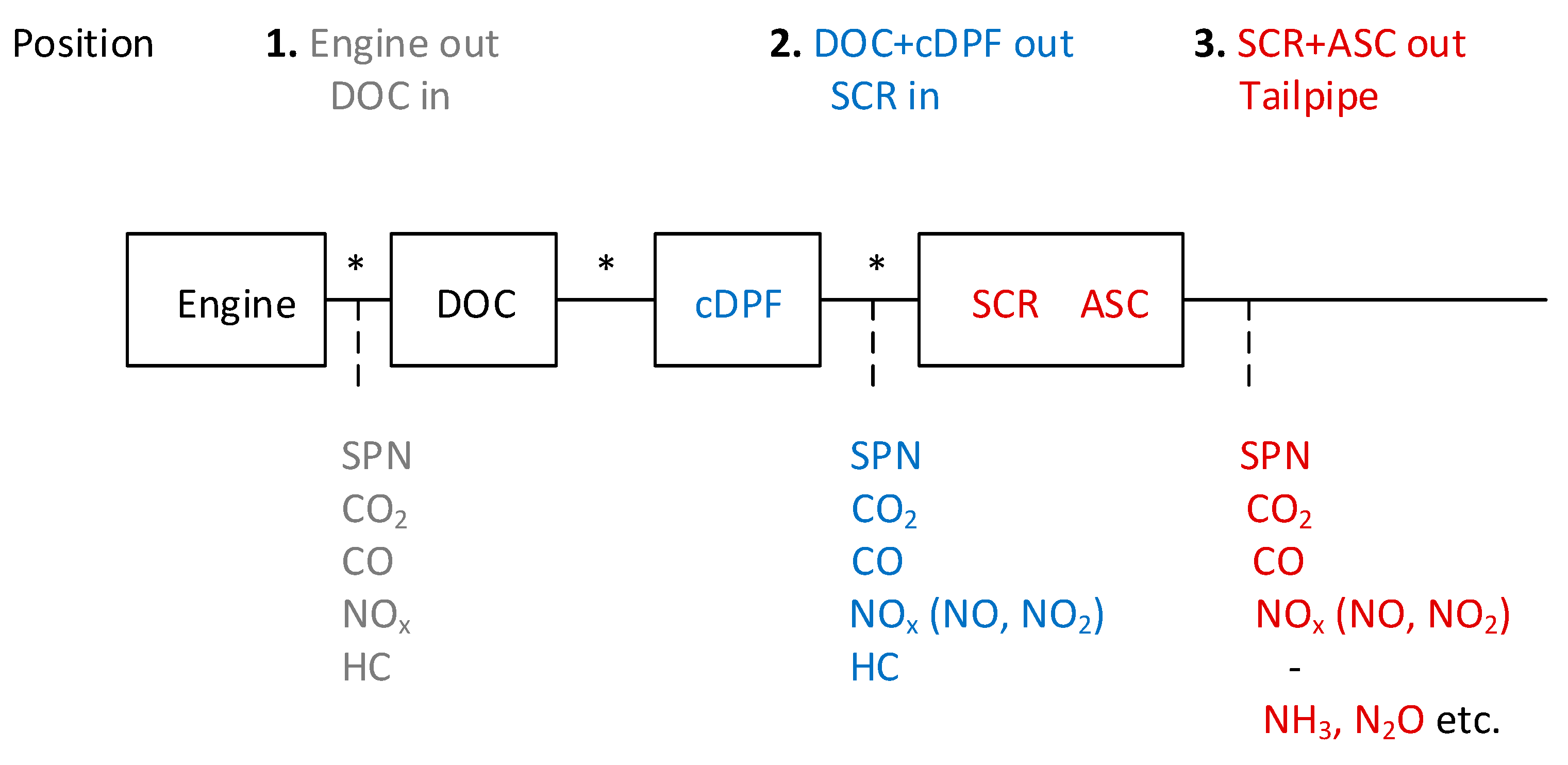

- Engine out (or DOC in);

- DOC + cDPF out (or SCR in);

- SCR + ASC out (corresponding to the end of the tailpipe).

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Environment Agency. Air Quality in Europe: 2020 Report; Publications Office: Luxembourg, 2020.

- European Environment Agency. Decarbonising Road Transport: The Role of Vehicles, Fuels and Transport Demand; Publications Office: Luxembourg, 2022.

- Wagner, V.; Rutherford, D. Survey of Best Practices in Emission Control of In-Use Heavy-Duty Diesel Vehicles. In International Council Clean Transportation (ICCT) Report; ICCT: Washington, DC, USA, 2013. [Google Scholar]

- Giechaskiel, B.; Bonnel, P.; Perujo, A.; Dilara, P. Solid Particle Number (SPN) Portable Emissions Measurement Systems (PEMS) in the European Legislation: A Review. Int. J. Environ. Res. Public Health 2019, 16, 4819. [Google Scholar] [CrossRef]

- Bielaczyc, P.; Woodburn, J. On-Road Emissions and Fuel Consumption Testing of Heavy-Duty Vehicles via PEMS—Comparisons of Various Performance Metrics; 2022-01–0571; Society of Automotive Engineers: Warrendale, PA, USA, 2022. [Google Scholar]

- Chen, L.; Wang, Z.; Liu, S.; Qu, L. Using a Chassis Dynamometer to Determine the Influencing Factors for the Emissions of Euro VI Vehicles. Transp. Res. Part D Transp. Environ. 2018, 65, 564–573. [Google Scholar] [CrossRef]

- Järvinen, A.; Timonen, H.; Karjalainen, P.; Bloss, M.; Simonen, P.; Saarikoski, S.; Kuuluvainen, H.; Kalliokoski, J.; Dal Maso, M.; Niemi, J.V.; et al. Particle Emissions of Euro VI, EEV and Retrofitted EEV City Buses in Real Traffic. Environ. Pollut. 2019, 250, 708–716. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Lü, L. Evaluating the Real-World NOx Emission from a China VI Heavy-Duty Diesel Vehicle. Appl. Sci. 2021, 11, 1335. [Google Scholar] [CrossRef]

- Li, X.; Ai, Y.; Ge, Y.; Qi, J.; Feng, Q.; Hu, J.; Porter, W.C.; Miao, Y.; Mao, H.; Jin, T. Integrated Effects of SCR, Velocity, and Air-Fuel Ratio on Gaseous Pollutants and CO2 Emissions from China V and VI Heavy-Duty Diesel Vehicles. Sci. Total Environ. 2022, 811, 152311. [Google Scholar] [CrossRef] [PubMed]

- Grigoratos, T.; Fontaras, G.; Giechaskiel, B.; Zacharof, N. Real World Emissions Performance of Heavy-Duty Euro VI Diesel Vehicles. Atmos. Environ. 2019, 201, 348–359. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Gioria, R.; Carriero, M.; Lähde, T.; Forloni, F.; Perujo, A.; Martini, G.; Bissi, L.M.; Terenghi, R. Emission Factors of a Euro VI Heavy-Duty Diesel Refuse Collection Vehicle. Sustainability 2019, 11, 1067. [Google Scholar] [CrossRef]

- Zheng, F.; Zhang, H.; Yin, H.; Fu, M.; Jiang, H.; Li, J.; Ding, Y. Evaluation of Real-World Emissions of China V Heavy-Duty Vehicles Fueled by Diesel, CNG and LNG on Various Road Types. Chemosphere 2022, 303, 135137. [Google Scholar] [CrossRef] [PubMed]

- Keramydas, C.; Ntziachristos, L.; Tziourtzioumis, C.; Papadopoulos, G.; Lo, T.-S.; Ng, K.-L.; Wong, H.-L.A.; Wong, C.K.-L. Characterization of Real-World Pollutant Emissions and Fuel Consumption of Heavy-Duty Diesel Trucks with Latest Emissions Control. Atmosphere 2019, 10, 535. [Google Scholar] [CrossRef]

- Ko, S.; Park, J.; Kim, H.; Kang, G.; Lee, J.; Kim, J.; Lee, J. NOx Emissions from Euro 5 and Euro 6 Heavy-Duty Diesel Vehicles under Real Driving Conditions. Energies 2020, 13, 218. [Google Scholar] [CrossRef]

- McCaffery, C.; Zhu, H.; Tang, T.; Li, C.; Karavalakis, G.; Cao, S.; Oshinuga, A.; Burnette, A.; Johnson, K.C.; Durbin, T.D. Real-World NOx Emissions from Heavy-Duty Diesel, Natural Gas, and Diesel Hybrid Electric Vehicles of Different Vocations on California Roadways. Sci. Total Environ. 2021, 784, 147224. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Tan, Y.; Yang, J.; Karavalakis, G.; Johnson, K.C.; Yoon, S.; Herner, J.; Durbin, T.D. Understanding Elevated Real-World NOx Emissions: Heavy-Duty Diesel Engine Certification Testing versus in-Use Vehicle Testing. Fuel 2022, 307, 121771. [Google Scholar] [CrossRef]

- Rosero, F.; Fonseca, N.; López, J.-M.; Casanova, J. Real-World Fuel Efficiency and Emissions from an Urban Diesel Bus Engine under Transient Operating Conditions. Appl. Energy 2020, 261, 114442. [Google Scholar] [CrossRef]

- Wang, J.; Wang, R.; Yin, H.; Wang, Y.; Wang, H.; He, C.; Liang, J.; He, D.; Yin, H.; He, K. Assessing Heavy-Duty Vehicles (HDVs) on-Road NOx Emission in China from on-Board Diagnostics (OBD) Remote Report Data. Sci. Total Environ. 2022, 846, 157209. [Google Scholar] [CrossRef] [PubMed]

- Su, S.; Ge, Y.; Hou, P.; Wang, X.; Wang, Y.; Lyu, T.; Luo, W.; Lai, Y.; Ge, Y.; Lyu, L. China VI Heavy-Duty Moving Average Window (MAW) Method: Quantitative Analysis of the Problem, Causes, and Impacts Based on the Real Driving Data. Energy 2021, 225, 120295. [Google Scholar] [CrossRef]

- Giechaskiel, B. Solid Particle Number Emission Factors of Euro VI Heavy-Duty Vehicles on the Road and in the Laboratory. Int. J. Environ. Res. Public Health 2018, 15, 304. [Google Scholar] [CrossRef]

- Su, S.; Ge, Y.; Zhang, Y. NOx Emission from Diesel Vehicle with SCR System Failure Characterized Using Portable Emissions Measurement Systems. Energies 2021, 14, 3989. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Forloni, F.; Carriero, M.; Baldini, G.; Castellano, P.; Vermeulen, R.; Kontses, D.; Fragkiadoulakis, P.; Samaras, Z.; Fontaras, G. Effect of Tampering on On-Road and Off-Road Diesel Vehicle Emissions. Sustainability 2022, 14, 6065. [Google Scholar] [CrossRef]

- Samaras, Z.C.; Kontses, A.; Dimaratos, A.; Kontses, D.; Balazs, A.; Hausberger, S.; Ntziachristos, L.; Andersson, J.; Ligterink, N.; Aakko-Saksa, P.; et al. A European Regulatory Perspective towards a Euro 7 Proposal; 2022-37–0032; Society of Automotive Engineers: Warrendale, PA, USA, 2022. [Google Scholar]

- Ximinis, J.; Massaguer, A.; Massaguer, E. NOx Emissions below the Prospective EURO VII Limit on a Retrofitted Heavy-Duty Vehicle. Appl. Sci. 2022, 12, 1189. [Google Scholar] [CrossRef]

- Selleri, T.; Gioria, R.; Melas, A.D.; Giechaskiel, B.; Forloni, F.; Mendoza Villafuerte, P.; Demuynck, J.; Bosteels, D.; Wilkes, T.; Simons, O.; et al. Measuring Emissions from a Demonstrator Heavy-Duty Diesel Vehicle under Real-World Conditions—Moving Forward to Euro VII. Catalysts 2022, 12, 184. [Google Scholar] [CrossRef]

- Mendoza Villafuerte, P.; Demuynck, J.; Bosteels, D.; Wilkes, T.; Mueller, V.; Recker, P. Future-Proof Heavy-Duty Truck Achieving Ultra-Low Pollutant Emissions with a Close-Coupled Emission Control System Including Active Thermal Management. Transp. Eng. 2022, 9, 100125. [Google Scholar] [CrossRef]

- Clairotte, M.; Suarez-Bertoa, R.; Zardini, A.A.; Giechaskiel, B.; Pavlovic, J.; Valverde, V.; Ciuffo, B.; Astorga, C. Exhaust Emission Factors of Greenhouse Gases (GHGs) from European Road Vehicles. Environ. Sci. Eur. 2020, 32, 125. [Google Scholar] [CrossRef]

- Russell, A.; Epling, W.S. Diesel Oxidation Catalysts. Catal. Rev. 2011, 53, 337–423. [Google Scholar] [CrossRef]

- Selleri, T.; Melas, A.D.; Joshi, A.; Manara, D.; Perujo, A.; Suarez-Bertoa, R. An Overview of Lean Exhaust DeNOx Aftertreatment Technologies and NOx Emission Regulations in the European Union. Catalysts 2021, 11, 404. [Google Scholar] [CrossRef]

- Peng, M.; Xiao, G.; Zou, K.; Chen, Y.; Huang, W. Reality Driving Emission Characteristics of Gaseous Pollutants and Particles of China VI Heavy-Duty Diesel Vehicle; 2022-01–1155; Society of Automotive Engineers: Warrendale, PA, USA, 2022. [Google Scholar]

- Hong, Z.; Wang, Z.; Li, X. Catalytic Oxidation of Nitric Oxide (NO) over Different Catalysts: An Overview. Catal. Sci. Technol. 2017, 7, 3440–3452. [Google Scholar] [CrossRef]

- Ciardelli, C.; Nova, I.; Tronconi, E.; Chatterjee, D.; Bandl-Konrad, B.; Weibel, M.; Krutzsch, B. Reactivity of NO/NO2–NH3 SCR System for Diesel Exhaust Aftertreatment: Identification of the Reaction Network as a Function of Temperature and NO2 Feed Content. Appl. Catal. B Environ. 2007, 70, 80–90. [Google Scholar] [CrossRef]

- Grossale, A.; Nova, I.; Tronconi, E.; Chatterjee, D.; Weibel, M. The Chemistry of the NO/NO2–NH3 “Fast” SCR Reaction over Fe-ZSM5 Investigated by Transient Reaction Analysis. J. Catal. 2008, 256, 312–322. [Google Scholar] [CrossRef]

- Birkhold, F.; Meingast, U.; Wassermann, P.; Deutschmann, O. Modeling and Simulation of the Injection of Urea-Water-Solution for Automotive SCR DeNOx-Systems. Appl. Catal. B Environ. 2007, 70, 119–127. [Google Scholar] [CrossRef]

- Gramigni, F.; Selleri, T.; Nova, I.; Tronconi, E.; Dieterich, S.; Weibel, M.; Schmeisser, V. Analysis of AdSCR Systems for NOx Removal During the Cold-Start Period of Diesel Engines. Top. Catal. 2019, 62, 3–9. [Google Scholar] [CrossRef]

- Selleri, T.; Gramigni, F.; Nova, I.; Tronconi, E.; Dieterich, S.; Weibel, M.; Schmeisser, V. A PGM-Free NOx Adsorber + Selective Catalytic Reduction Catalyst System (AdSCR) for Trapping and Reducing NOx in Lean Exhaust Streams at Low Temperature. Catal. Sci. Technol. 2018, 8, 2467–2476. [Google Scholar] [CrossRef]

- Schmeisser, V.; Weibel, M.; Sebastian Hernando, L.; Nova, I.; Tronconi, E.; Ruggeri, M.P. Cold Start Effect Phenomena over Zeolite SCR Catalysts for Exhaust Gas Aftertreatment. SAE Int. J. Commer. Veh. 2013, 6, 190–199. [Google Scholar] [CrossRef]

- Lukas, D.; Michael, M.; Gert, B.; Andreas, K. Analysis of the NOx Storage Behaviour during Cold Start of Modern SCR Flow-through Substrates and SCR on-Filter Substrates. Automot. Engine Technol. 2022, 7, 81–96. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Zardini, A.A.; Clairotte, M. Exhaust Gas Condensation during Engine Cold Start and Application of the Dry-Wet Correction Factor. Appl. Sci. 2019, 9, 2263. [Google Scholar] [CrossRef]

- Colombo, M.; Nova, I.; Tronconi, E. A Comparative Study of the NH3-SCR Reactions over a Cu-Zeolite and a Fe-Zeolite Catalyst. Catal. Today 2010, 151, 223–230. [Google Scholar] [CrossRef]

- Grossale, A.; Nova, I.; Tronconi, E.; Chatterjee, D.; Weibel, M. NH3–NO/NO2 SCR for Diesel Exhausts Aftertreatment: Reactivity, Mechanism and Kinetic Modelling of Commercial Fe- and Cu-Promoted Zeolite Catalysts. Top. Catal. 2009, 52, 1837–1841. [Google Scholar] [CrossRef]

- Mamakos, A.; Schwelberger, M.; Fierz, M.; Giechaskiel, B. Effect of Selective Catalytic Reduction on Exhaust Nonvolatile Particle Emissions of Euro VI Heavy-Duty Compression Ignition Vehicles. Aerosol Sci. Technol. 2019, 53, 898–910. [Google Scholar] [CrossRef]

- Melas, A.; Selleri, T.; Suarez-Bertoa, R.; Giechaskiel, B. Evaluation of Measurement Procedures for Solid Particle Number (SPN) Measurements during the Periodic Technical Inspection (PTI) of Vehicles. Int. J. Environ. Res. Public Health 2022, 19, 7602. [Google Scholar] [CrossRef] [PubMed]

- Metkar, P.S.; Balakotaiah, V.; Harold, M.P. Experimental Study of Mass Transfer Limitations in Fe- and Cu-Zeolite-Based NH3-SCR Monolithic Catalysts. Chem. Eng. Sci. 2011, 66, 5192–5203. [Google Scholar] [CrossRef]

- Salman, A.U.R.; Enger, B.C.; Auvray, X.; Lødeng, R.; Menon, M.; Waller, D.; Rønning, M. Catalytic Oxidation of NO to NO2 for Nitric Acid Production over a Pt/Al2O3 Catalyst. Appl. Catal. A Gen. 2018, 564, 142–146. [Google Scholar] [CrossRef]

- Wang, X.; Song, G.; Wu, Y.; Yu, L.; Zhai, Z. A NOx Emission Model Incorporating Temperature for Heavy-Duty Diesel Vehicles with Urea-SCR Systems Based on Field Operating Modes. Atmosphere 2019, 10, 337. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Lähde, T.; Schwelberger, M.; Kleinbach, T.; Roske, H.; Teti, E.; van den Bos, T.; Neils, P.; Delacroix, C.; Jakobsson, T.; et al. Particle Number Measurements Directly from the Tailpipe for Type Approval of Heavy-Duty Engines. Appl. Sci. 2019, 9, 4418. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Schwelberger, M.; Kronlund, L.; Delacroix, C.; Locke, L.A.; Khan, M.Y.; Jakobsson, T.; Otsuki, Y.; Gandi, S.; Keller, S.; et al. Towards Tailpipe Sub-23 Nm Solid Particle Number Measurements for Heavy-Duty Vehicles Regulations. Transp. Eng. 2022, 9, 100137. [Google Scholar] [CrossRef]

- Ravishankara, A.R.; Daniel, J.S.; Portmann, R.W. Nitrous Oxide (N2O): The Dominant Ozone-Depleting Substance Emitted in the 21st Century. Science 2009, 326, 123–125. [Google Scholar] [CrossRef] [PubMed]

- Hausberger, S.; Weller, K.; Ehrly, M. Supplements to the Scenarios for HDVs. Available online: https://circabc.europa.eu/sd/a/e0063651-4e84-4b95-aac4-edb85a719764/AGVES-2021-04-27-HDV_Exhaust-v6b.pdf (accessed on 12 October 2022).

- Boger, T.; Rose, D.; He, S.; Joshi, A. Developments for Future EU7 Regulations and the Path to Zero Impact Emissions—A Catalyst Substrate and Filter Supplier’s Perspective. Transp. Eng. 2022, 10, 100129. [Google Scholar] [CrossRef]

- Mamakos, A.; Rose, D.; Besch, M.C.; He, S.; Gioria, R.; Melas, A.; Suarez-Bertoa, R.; Giechaskiel, B. Evaluation of Advanced Diesel Particulate Filter Concepts for Post Euro VI Heavy-Duty Diesel Applications. Atmosphere 2022, 13. [Google Scholar]

- Guan, B.; Zhan, R.; Lin, H.; Huang, Z. Review of State of the Art Technologies of Selective Catalytic Reduction of NOx from Diesel Engine Exhaust. Appl. Therm. Eng. 2014, 66, 395–414. [Google Scholar] [CrossRef]

- Kamasamudram, K.; Henry, C.; Currier, N.; Yezerets, A. N2O Formation and Mitigation in Diesel Aftertreatment Systems. SAE Int. J. Engines 2012, 5, 688–698. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Cresnoverh, M.; Jörgl, H.; Bergmann, A. Calibration and Accuracy of a Particle Number Measurement System. Meas. Sci. Technol. 2010, 21, 045102. [Google Scholar] [CrossRef]

- Amanatidis, S.; Ntziachristos, L.; Giechaskiel, B.; Katsaounis, D.; Samaras, Z.; Bergmann, A. Evaluation of an Oxidation Catalyst (“Catalytic Stripper”) in Eliminating Volatile Material from Combustion Aerosol. J. Aerosol Sci. 2013, 57, 144–155. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Melas, A.D.; Lähde, T.; Martini, G. Non-Volatile Particle Number Emission Measurements with Catalytic Strippers: A Review. Vehicles 2020, 2, 342–364. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Wang, X.; Horn, H.-G.; Spielvogel, J.; Gerhart, C.; Southgate, J.; Jing, L.; Kasper, M.; Drossinos, Y.; Krasenbrink, A. Calibration of Condensation Particle Counters for Legislated Vehicle Number Emission Measurements. Aerosol Sci. Technol. 2009, 43, 1164–1173. [Google Scholar] [CrossRef]

- Takegawa, N.; Sakurai, H. Laboratory Evaluation of a TSI Condensation Particle Counter (Model 3771) under Airborne Measurement Conditions. Aerosol Sci. Technol. 2011, 45, 272–283. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Clairotte, M. Fourier Transform Infrared (FTIR) Spectroscopy for Measurements of Vehicle Exhaust Emissions: A Review. Appl. Sci. 2021, 11, 7416. [Google Scholar] [CrossRef]

| Pollutant | WHVC Cold 5 °C | WHVC Cold | WHVC Hot | Urban Cold | Urban RWC Cold | Rural RWC Hot | Motor RWC Hot | Max Load Hot |

|---|---|---|---|---|---|---|---|---|

| CO2 (g/kWh) | 710.3 | 654.4 | 649.7 | 716.4 | 727.9 | 650.1 | 640.8 | 614.7 |

| N2O (mg/kWh) | 82.2 | 161.3 | 176.3 | 52.8 | 91.8 | 196.4 | 196.3 | 63.9 |

| CH4 (mg/kWh) | 4.9 | 3.0 | 2.9 | 13.0 | 6.6 | 1.9 | 1.0 | 0.1 |

| Pollutant | Cold | Hot | Weighted 1 | Limit |

|---|---|---|---|---|

| NOx (g/kWh) | 1.71 | 0.79 | 0.92 | 0.46 |

| CO (g/kWh) | 0.75 | 0.40 | 0.45 | 4.00 |

| SPN23 × 1011 (#/kWh) | 8.94 | 0.40 | 1.59 | 6.00 |

| Pollutant | Cold | Hot (90th) | Weighted 1 | On-Road 2 |

|---|---|---|---|---|

| NOx (-) | 3.56 | 1.87 | 2.11 | 1.50 |

| CO (-) | 0.31 | 0.21 | 0.22 | 1.50 |

| SPN23 × 1011 (-) | 0.84 | 0.07 | 0.18 | 1.63 |

| Pollutant | 100th | Limit 100th | 90th | Limit 90th |

|---|---|---|---|---|

| NOx (g/kWh) | 1.67 | 0.18–0.35 | 1.02 | 0.09 |

| CO (g/kWh) | 1.13 | 1.5–3.5 | 1.08 | 0.20 |

| SPN10 × 1011 (#/kWh) 1 | 8.7 | 5.0 | 1.3 | 1.0 |

| N2O (g/kWh) | 0.22 | 0.16 | 0.21 | 0.06 |

| Cycle | Duration (s) | D (km) | Speed (km/h) | W/D (kWh/km) | Tamb (°C) | Tcoolant (°C) | DPF 1 (%) |

|---|---|---|---|---|---|---|---|

| WHVC cold | 1800 | 20.2 | 40.4 | 1.52 | 24 | 29 | 11.8/11.8 |

| WHVC hot | 1800 | 20.2 | 40.5 | 1.40 | 25 | 79 | 11.8/11.8 |

| Max load | 1300 | 27.1 | 75.1 | 3.26 | 25 | 84 | 11.8/9.8 |

| RWC urban | 2085 | 15.7 | 27.2 | 1.24 | 23 | 23 | 9.8/9.8 |

| RWC rural | 2190 | 28.1 | 46.2 | 1.34 | 23 | 80 | 9.8/25.8 |

| RWC motorway | 3150 | 71.3 | 81.5 | 1.00 | 24 | 80 | 25.8/26.7 |

| Idling | 3150 | 0.0 | 0.0 | - | 25 | 80 | 26.7/26.7 |

| Max load | 2745 | 58.4 | 76.6 | 3.33 | 25 | 79 | 26.7/11.0 |

| WHVC cold | 1800 | 20.2 | 40.3 | 1.44 | 22 | 21 | 11.0/11.0 |

| WHVC hot | 1800 | 20.1 | 40.2 | 1.40 | 21 | 81 | 11.0/11.0 |

| Urban empty | 2745 | 13.2 | 17.3 | 0.99 | 22 | 26 | 11.0/13.7 |

| WHVC hot | 1800 | 20.1 | 40.3 | 1.34 | 22 | 79 | 13.7/13.7 |

| WHVC cold | 1800 | 20.2 | 40.4 | 1.43 | 4 | 6 | 13.7/13.7 |

| 30–60–90 km/h | 1800 | 25.5 | 30.0 | 0.87 | 24 | 55 | 13.7/13.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giechaskiel, B.; Selleri, T.; Gioria, R.; Melas, A.D.; Franzetti, J.; Ferrarese, C.; Suarez-Bertoa, R. Assessment of a Euro VI Step E Heavy-Duty Vehicle’s Aftertreatment System. Catalysts 2022, 12, 1230. https://doi.org/10.3390/catal12101230

Giechaskiel B, Selleri T, Gioria R, Melas AD, Franzetti J, Ferrarese C, Suarez-Bertoa R. Assessment of a Euro VI Step E Heavy-Duty Vehicle’s Aftertreatment System. Catalysts. 2022; 12(10):1230. https://doi.org/10.3390/catal12101230

Chicago/Turabian StyleGiechaskiel, Barouch, Tommaso Selleri, Roberto Gioria, Anastasios D. Melas, Jacopo Franzetti, Christian Ferrarese, and Ricardo Suarez-Bertoa. 2022. "Assessment of a Euro VI Step E Heavy-Duty Vehicle’s Aftertreatment System" Catalysts 12, no. 10: 1230. https://doi.org/10.3390/catal12101230

APA StyleGiechaskiel, B., Selleri, T., Gioria, R., Melas, A. D., Franzetti, J., Ferrarese, C., & Suarez-Bertoa, R. (2022). Assessment of a Euro VI Step E Heavy-Duty Vehicle’s Aftertreatment System. Catalysts, 12(10), 1230. https://doi.org/10.3390/catal12101230