1. Introduction

Creating textiles characterised by long-lasting photocatalytic and antimicrobial properties with strong laundering durability is important from the point of view of environmental pollution and cost and practicality of production. The surface of cotton fabrics from which cotton towels are made contains hydrophilic groups such as hydroxyl groups that absorb moisture, leading to an overgrowth of microorganisms and thus reducing the durability of the fabrics. Therefore, it is essential to carry out a long-lasting photocatalytic and antimicrobial treatment of the cotton fabrics, which extends their durability and—to some extent—their suitability for use as well.

Cotton fabrics modified with nanoparticles have a wide range of applications, e.g., fabrics protecting against UV radiation [

1], antimicrobial [

2] and flame retardant [

3].

The development of new photocatalysts with the use of different experimental systems: TiO

2 coating/doping with various metal nanoparticles (NPS), such as Zn, Cu, Pt, Ag, Cd, Mo and Co, and various kinds of irradiation, for instance, visible light [

4,

5], is becoming more and more popular. Transition metal doping, e.g., Cu of titanium dioxide photocatalysts, is often carried out with the aim of enhancing photocatalytic activity [

6]. Undoubtedly, out of many semi-conductor metal oxides, the most popular photocatalytic compound used in the case of textile applications is TiO

2. The reason for this is its substantial stability, significant photocatalytic activity and nontoxicity [

7,

8]. Lately, an increase in the application of ZnO photocatalysts for textile finishing has been observed in the literature related to the subject [

9]. Nano-TiO

2 is the most often applied of all nanomaterials, and pigment-TiO

2 is a commodity used in the amount of one million tons/year [

10]. The main uses of nano-TiO

2 include UV-absorbers in sunscreens [

11] and photocatalytic coatings [

12]. The incorporation of nano-TiO

2 into textiles increases their UV-protection properties [

13] and has also been proposed as a promoter of antimicrobial activity [

14]. It should be emphasised that both TiO

2 and ZnO photocatalytic NPs have a similar wide band gap that confines their activity in the UV region of light, [

15,

16,

17]. On the other hand, metal/nonmetal doping extends their spectral response to visible light [

9,

16,

17,

18,

19].

Nano titanium dioxide (nano-TiO

2) is an N-type semi-conductor with a rutile type and an anatase type. Under the catalysis of light (especially ultraviolet light), nano-TiO

2 in the water and air system can be decomposed into free-moving negatively charged electrons (e

−) and positively charged holes (h

+), and the final reaction produces highly chemically active hydrogen-oxygen free radicals (HO) and superoxide anion radicals (O

2−) that can attack and degrade the organic compounds in microorganisms [

20]. Experimental studies conducted by Doustkhah et al. (2021) showed that the admixtures of Cl in rutile TiO2 nanosheets with (110) facets (rTiO2-120) produce lower effective charge carrier masses through dispersed band shapes compared to those created by oxygen vacancy. With no external cocatalyst, the material shows state-of-the-art solar-driven photocatalytic activity for H2 production through water splitting [

21]. The main mechanism of photocatalytic antimicrobial reactions under light conditions is based on complex chemical oxidation of the cell wall and cell membranes, mainly including reactions of reactive oxygen species (ROS) with major cell components such as lipids and proteins [

22,

23].

Due to its high safety and good compatibility with human skin, nano ZnO is an appropriate additive for cotton fabrics [

24]. Nano ZnO particles exposure to ultraviolet light release negatively charged electrons (e

−), leaving positively charged holes (h

+), causing the production of (ROS), which oxidise and inhibit the growth of microorganisms. The antimicrobial properties (

S. aureus ATCC 6538,

E. coli ATCC 25922) and durability of cotton fabrics are obtained by synthesising the nano ZnO antimicrobial finishing in an aqueous solution with zinc acetate as a precursor [

25]. Appierot et al. presented a study to explain the effect of ZnO particle size (microscale to nanoscale) on its antimicrobial activity as the result of the ZnO surface reacting with water [

25]. The antimicrobial activity of single ZnO nanoparticles on cotton fabric is weak due to the rapid recombination of holes/electron pairs in nano ZnO. It involves photosensitiser modification of nano ZnO to improve photocatalyst activity and antimicrobial activity [

26].

Both TiO

2 and ZnO nanoparticles have great potential and can be effectively used to impart antimicrobial properties to cotton fabrics, ensuring the long-lasting desired effect. Undoubtedly, the finishing of cotton fabrics with TiO

2 and ZnO nanoparticles brings many valuable benefits in terms of the properties and applications of the final product. Nevertheless, many aspects need to be considered to meet all functional, economic, health, safety, and environmental nature requirements. Generally, there is no research on the synergistic effect following washing cotton fabrics, and there is no information on how lighting affects the photocatalytic/durability effects. The focus should be placed on the durability of the photocatalytic and antimicrobial effects of the modified fabrics after laundering. Previous studies on TiO

2-modified photocatalytically active textiles concerned chitosan or cotton-chitosan and polyester, which showed biological activity against the following bacteria:

E. coli, S. aureus, and

B. cereus [

27,

28]. Chitosan-based adsorbents have also been used to remove pharmaceutical contaminants as micropollutants in water due to their potential ecotoxicity [

29]. The strategy of the in situ growth of nanoparticles was adopted by El-Naggar et al. [

30]. Using urea nitrate as raw material, titanium hydroxide was gelatinised and converted into titanium dioxide nanoparticles on cotton fabric and heated at 130 °C. This method simplifies the process and improves the adhesion of nanoparticles to the fabric so that the antibacterial rate can still achieve 95% after 20 washings. Daoud et al. 2005 found that cotton fabrics coated with TiO

2 NPs showed bactericidal properties against bacteria

Klebsiella pneumoniae and

Staphylococcus aureus even after 20–55 washings [

31].

Since there are no bonding groups on the cotton fabric, the antimicrobial durability of the nanoparticles is limited. Therefore, it is necessary to use crosslinking agents to fix them on the fabric matrixes, which can appropriately improve the washability of nanomaterials and help achieve a long-lasting antimicrobial effect. Therefore, nanoparticles are anchored with the assistance of cyclodextrin, polysiloxane, BTCA—polycarboxylic acids, particularly 1-, 2-, 3-, and 4-butane tetracarboxylic acid, and dopamine adhesion, under electrostatic adsorption [

20].

Prasad et al. (2016) reported durable antimicrobial finishing obtained during the in situ synthesis of nano ZnO onto cotton fabric by the spraying or dipping process. Even after 50 laundering cycles, the antibacterial effect of the cotton fabric only changed slightly [

32].

In the previous studies [

33], the authors assessed the photocatalytic and biological activity of 100% cotton terry towels modified with TiO

2 N-doped nanoparticles and ZnO nanoparticles under model and real conditions. The material obtained was characterised by significant biostatic activity on the surface, where the number of microorganisms (

Enterobacteriaceae, Enterococcus, coli and

E. coli group, as well as

Pseudomonas) has decreased. In addition to this, a statistically significant decrease in the total number of fungi and bacteria was found. Moreover, the high antimicrobial effectiveness of photocatalytically modified TiO

2 and ZnO textile materials under model conditions was revealed. It is also worth mentioning that greater photocatalytic efficiency was noted in natural light than in artificial lighting.

So far in the scientific works, little attention has been paid to application solutions with industrial importance. In this case, photocatalytically modified materials, for example, textiles, should be durable, and the conditions of their use should be fully characterized. This work is devoted to these aspects.

The present study aimed to analyse the durability of the photocatalytic and antimicrobial activity of cotton towels modified with TiO2 and ZnO, as well as to optimise the lighting conditions to improve the photocatalytic effects.

2. Results

The nano-additives amounts (ZnO and TiO2) calculated from squeezing of padding bath are 2.15 g/m2 for cotton terry textiles and 0.73 g/m2 for diagonal cotton wave fabric, respectively. Almost three times more of NPs were deposited on the terry fabric in comparison with diagonal fabric. This may be attributed to the extended surface structure and surface loop system of terry fabric.

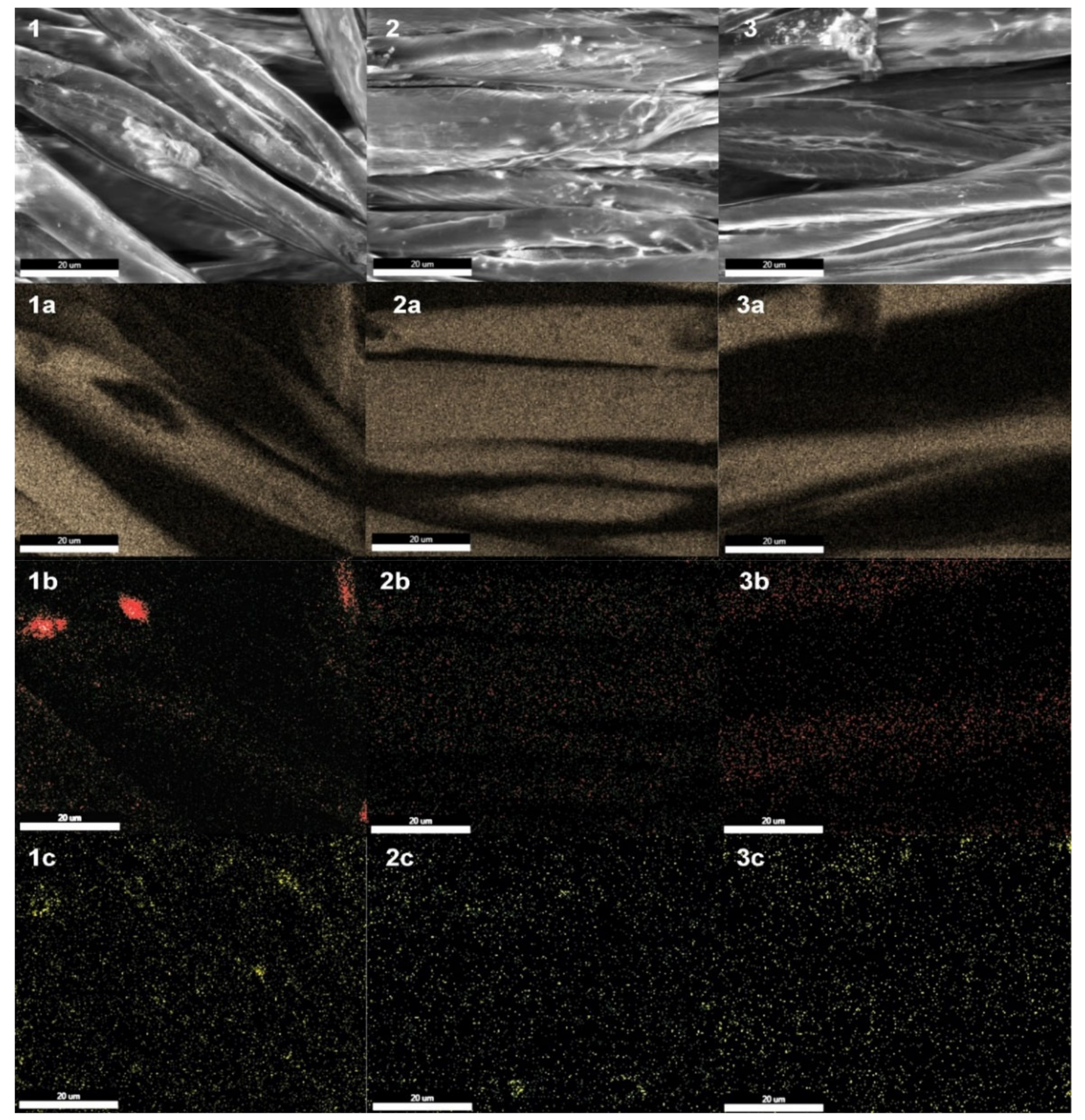

The morphology of ZnO- and TiO

2-modified cotton terry towels before and after the washing process was examined with the scanning electron microscopy (SEM) technique.

Figure 1 shows SEM images of cotton terry towels unmodified (control) and modified with nanoadditives with a magnification of x10,000.

Figure 1a shows SEM image of an untreated sample, while

Figure 1b–d show images of modified samples before and after 15 and 30 washings, respectively.

In

Figure 1b, additional material on modified fibres surface can be observed compared to the surface of the unmodified sample (

Figure 1a). It results from dozen of NPs immobilised in the polymer matrix onto a surface of towels. After subsequent washing cycles (

Figure 1c,d), the damage of the resin can be observed; the greater the damage, the more washing cycles the fabric was subject to. There are randomly distributed NPs and several larger particles on the surface of cotton terry textiles after 15 and 30 washings. Unfortunately, the magnification/resolution of the SEM microscope did not allow us to clearly show the nanoparticles as stated by the DLS analysis in our previous manuscript [

33].

The EDX studies (

Figure 2b–d) compare the presence of Zn and Ti elements on the surface of modified cotton terry towels before and after washings, whereas such elements are not detectable on the surface of the control sample (

Figure 2a).

SEM EDX-mapping of loop yarns taken from modified terry towels before and after washings are presented in

Figure 3. SEM EDS-mapping allows for analysis of the distribution of modifier elements onto the surface of finished fabric. Picture marked as 1 shows SEM images of modified fabric before washings, picture 2 shows SEM images of modified fabric after 15 washings, and picture 3 shows SEM images of modified fabric after 30 washings, while (a), (b) and (c) are images of the distribution of elements: carbon, zinc and titanium on the surface of examined yarns. EDX-mapping confirms the homogenous distribution of modifiers on surface of finished fabric before and after multiple washings. However, some clusters of zinc (

Figure 3(1b)) can be observed on yarns surface before washings. Unfortunately, magnification of SEM microscope did not allow us to clearly show these clusters on SEM images (

Figure 3(1)). EDX-mapping compares the presence of Zn and Ti elements on surface of modified cotton as were stated by EDX spectra.

The results obtained from TGA analysis are shown in

Table 1. The percentage of the residue was calculated to the dry weight of the sample.

Based on the results of the TGA analysis, it can be concluded that, as expected, the padding and unwashed towel sample contains the most NPs of TiO

2 and ZnO. The NPs content in modified fabric before washing amounts to c.a. 1.5% on fabric weight. The amount of NPs decreased c.a. 10 times after 15 washes and c.a. 17 times after 30 washes. To prove that the residue obtained by TGA measurements contained zinc and titanium, the samples were tested by the EDX method (

Figure 4b–d).

The results on the self-cleaning properties of modified materials assessed on diagonal cotton wave fabric are shown in

Table 2. The colour variation of stained samples was assessed using K/S values, colour change (ΔL*, Δa*, and Δb*) and the colour difference ΔE* between irradiated and unirradiated samples. The ΔL* value refers to the difference in lightness from darker (–ΔL*) to lighter (+ΔL*), whereas Δa*and Δb* values refer to red/green differences from greener/less red (−Δa*) to redder/less green (+Δa*) and yellow/blue differences from bluer/less yellow (−Δb*) to yellower/less blue (+Δb*), respectively. The K/S value is linearly related to colourant concentration in the fabric, and ΔE* determines the total colour differences (the higher the ΔE* value, the greater the colour difference).

Based on the results of the self-cleaning experiment (

Table 3), it can be concluded that after irradiation, the colour of all stained samples became lighter. All modified samples with TiO

2/ZnO, before and after washings, are lighter than the unmodified samples. ΔE* indicates easy to perceptible colour change after UV400 light irradiation, both for an untreated and modified sample before and after washings. A more significant colour change was observed for treated samples before and after washings, however. All samples after UV400 light irradiation are less red. Although, the modified sample before and washings are yellower than the control sample. The results indicated decreases in photocatalytic properties in UV400 light after 30 washings. That said, this sample is lighter than the control sample after irradiation. The reduction of K/S for the modified sample ranged from c.a. 27% before washing to c.a. 24% after 30 washings compared to c.a. 16% for untreated sample.

The modified TiO2/ZnO samples are characterised by stronger photocatalytic efficiency in light with a spectrum similar to sunlight (UV1400). Almost 50% reduction in K/S value after UV1400 irradiation was observed for a modified sample before washing compared to a 20% reduction for a control sample. After 15 washings, the K/S reduction increases to c.a. 59%. It may result from removing larger nanoparticles from the fibre surface, causing enhancement of photocatalytic activity. ΔE* indicated significant colour change after UV1400 irradiation for modified samples before and after washings. ΔE* values between irradiated and unirradiated modified samples are from c.a. twice greater before washing to c.a. 1.6 times greater after 30 washings than for control fabric. The colours of all samples became lighter after UV1400 irradiation. ΔL* value between irradiated and unirradiated modified samples are from 2.3 (after 30 washings) to c.a. 4 (after 15 washings) times greater than for control fabric. In addition, significant shade change after UV1400 irradiation can be observed. All fabric (control and modified with TiO2/ZnO) became less red and yellower after irradiation; however, the changes are greater for modified samples. The shade shift from red toward yellow results from photodegradation of the colour compound of the stain, which confirmed the photocatalytic properties of the modified fabric.

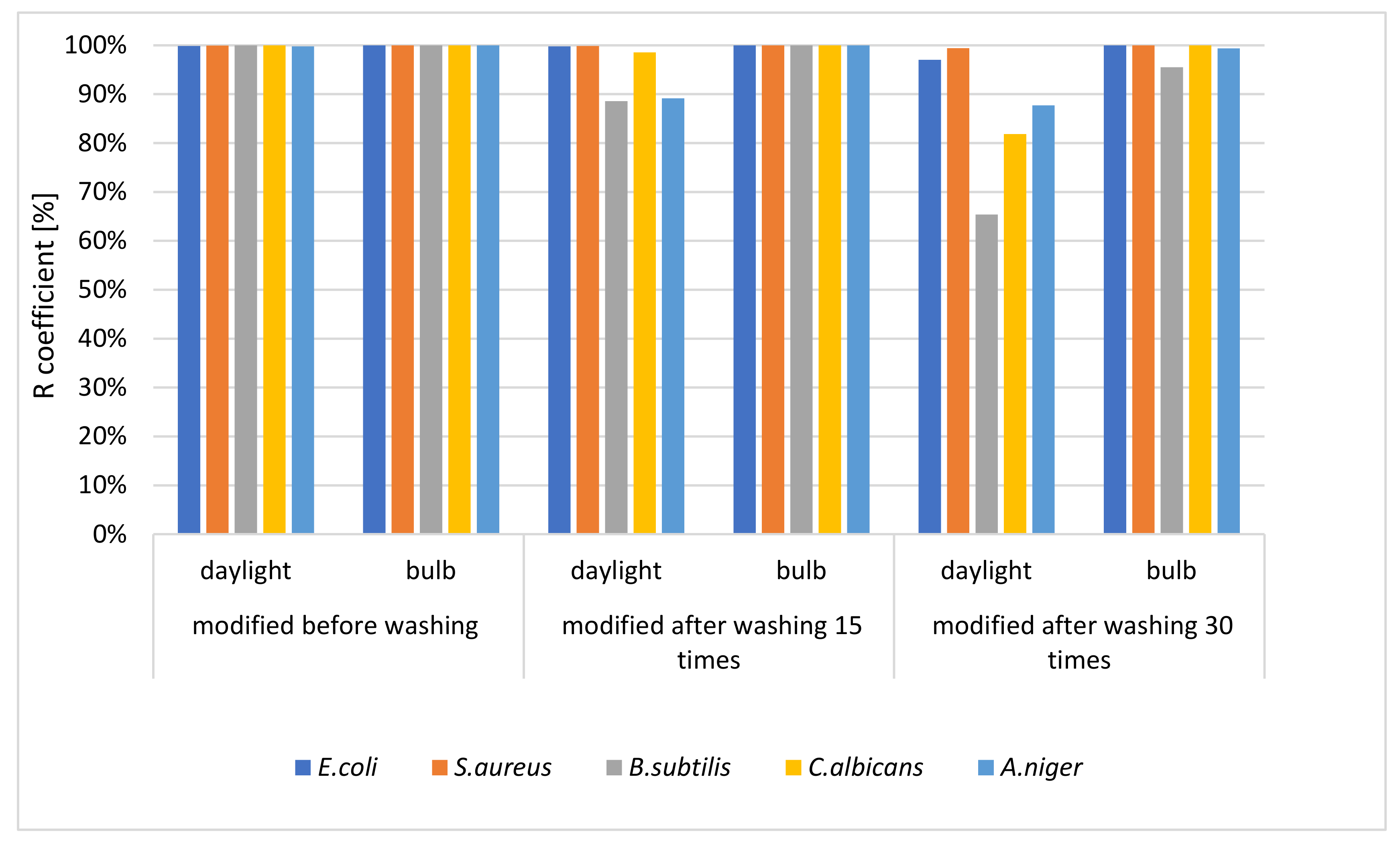

The antimicrobial activity of tested nonwovens results before and after 15 and 30 wash cycles assessed under different lighting conditions (daylight, UVA/B radiation intensity 400 µW/cm

2 and daylight with a bulb during 12 h/day, UVA/B radiation intensity 1400 µW/cm

2) are presented in

Table 3.

A statistically significant reduction in the number of all tested bacteria:

E. coli, S. aureus B. subtilis, yeasts

C. albicans and moulds

A. niger after 24 h of incubation was obtained on all samples of materials modified with TiO

2/ZnO before washing, after 15 and 30 wash cycles in daylight conditions with an additional light bulb (UVA/B radiation intensity 1400 µW/cm

2) (

Table 3).

Similarly, in daylight conditions in a daily cycle (UVA/B radiation intensity 400 µW/cm

2) without additional lighting (bulb), significant differences in the number of microorganisms were observed on the modified samples before washing and after 15 wash cycles. Under these conditions, the number of microorganisms on the fabrics washed 30 cycles decreased significantly for bacteria

E. coli, S. aureus and moulds

A. niger, while no statistical differences were found against spore producing bacteria

B. subtilis and yeast

C. albicans (

Table 4).

The reduction in the number of microorganisms on tested materials is presented in

Figure 5, while the antimicrobial activity is in

Figure 6.

Reduction of tested microorganisms on the level of 100% was obtained on the fabrics modified with TiO

2/ZnO before washing, after 15 and 30 wash cycles under 1400 µW/cm

2 lighting, excluding

B. subtilis on the sample washed 30 times, where the reduction coefficient was also high and amounted R = 95.5%. In daylight conditions with a UVA/B radiation intensity of 400 µW/cm

2 for all microorganisms, the reduction coefficient was high for materials before washing R = 100%. After 15 wash cycles of fabrics, the reduction coefficients for

E. coli and

S. aureus were still at the level R = 100%, but for other microorganisms, reduction coefficients were lower at the levels R = 88.6–98.5 %. After 30 wash cycles, the reduction coefficients were noted at the following levels: R = 65.4% (

B. subtilis), R = 81.8 –87.7% (

C. albicans, A. niger) and R = 97.1–99.4% (

E. coli and

S. aureus) (

Figure 5).

In most cases, tested modified with nanoparticles TiO

2/ZnO materials inhibited the growth of microorganisms at high (A > 3) and medium (A = 1–3) levels of antimicrobial activity (

Figure 2). Under 1400 µW/cm

2 conditions, a biocidal effect was noted, reduction in the number of the microorganisms was high at a level of A = 3–8, which corresponded to a decrease in the number of microorganisms by 3–8 log units, except for the medium activity against

B. subtilis and

A. niger (A = 1.35–2.88). Low antimicrobial effect was found under 400 µW/cm

2 lighting conditions, after 30 wash cycles for

B. subtilis, A. niger, C. albicans (A = 0.46–0.96) (

Figure 6).

The microorganisms that can be easily removed from the surface of the modified TiO

2/ZnO materials even after 30 washes in daylight conditions were bacteria

E. coli, S. aureus and yeasts

C. albicans, and the microorganisms less sensitive to the photocatalytic effect under the tested conditions were moulds

A. niger and spore-forming bacteria

B. subtilis (

Figure 6).

3. Discussion

The objective of this study was to evaluate the durability of the photocatalytic and biological activities of ZnO- and TiO

2-modified 100% cotton terry textiles. Cotton terry towels were surface-modified using commercial dispersions of ZnO and TiO

2 NPs using the padding-squeezing method. The crystal structure of NPs in dispersion are as follows: ZnO zincite crystal structure and TiO

2 rutile crystal structure, as were indicated in our earlier studies [

33]. Rutile form is a stable phase of TiO

2 [

34], and zincite form of ZnO is stable in a neutral medium at temperatures up to 1100 °C [

35]. We consider that drying of modified samples for 3 min. at 150 °C during finishing process as well as washing processes, does not affect the crystal structure of NPs used.

The analysis of SEM micrographs confirmed the presence of a dozen NPs randomly immobilised in the polymer matrix onto fabric surface before washing. The damage of resin was observed after subsequent washings; the damage was greater with more washes. This may result in the washing out of larger NPs from fabric surface after 15 and 30 washings. Unlikely, a magnification/resolution of SEM microscope did not allow one to clearly show the NPs on fabric surface after washings. However, the presence of Zn and Ti atoms on the fabric surface was confirmed by the EDX analysis in all modified samples (unwashed and washed samples).

Although the combination of chemical and spectrophotometric methods is quite precise for quantifying the content of some compounds, it should be emphasised that these methods are relatively complicated and time-consuming [

10]. Since both titanium dioxide and zinc oxide are inorganic compounds with relatively high thermal stability, it was decided to use the thermogravimetric analysis (TGA) technique to assess the content of these compounds in the towels. The technique is a very precise measuring method that uses samples weighing only a few milligrams. After 15 washes, the amount of NPs in the towel decreases by about 10 times, and after a further 15 washes, only by about 1.6 times. These results suggest that during the first few washes, the largest NPs are removed from the samples and those that are not bonded tightly enough to the fibre structure. Apparently, only those NPs that have penetrated deep enough into the porous structure of cotton fibres remain. These NPs are very difficult to remove even after several dozen washes. In addition, the elemental composition of residue after TGA was characterised by EDX spectroscopy. The results obtained on the basis of EDX elemental analysis of TGA residues showed that both ZnO and TiO

2 remain on the fabric surface even after 30 washings.

The photodegradation of blackcurrant juice staining on the under surface of modified fabric was confirmed. However, a stronger photocatalytic efficiency in light with a greater proportion of UVA/B radiation was observed. However, the self-cleaning properties were achieved after 30 washings. The relations between light and self-cleaning properties of semiconductor finished textiles, affected by UV light and light intensity and irradiation time, were described in the studies [

36,

37]. The results of self-cleaning experiments showed that increasing UVA/B radiation intensity from 400 to 1400 µW/cm

2 significantly increased the self-cleaning properties of the modified sample. It should be mentioned that self-cleaning experiments were determined using diagonally woven fabric (without loop cover) and surface mass twice lower than terry fabric. According to our raw estimations, on the surface of the diagonal fabric, almost three times less NPs are deposited, thus self-cleaning properties of terry textiles can be better. Unfortunately, the presence of a loop pile on the surface of towels makes colour measurements impossible.

The obtained results show that the tested textile materials modified with TiO2/ZnO nanoparticles have long-lasting antimicrobial activity, which lasted up to 30 wash cycles.

Earlier authors’ studies showed that the tested materials modified with TiO

2/ZnO nanoparticles in real conditions in bathrooms (lighting time 1.5 and 7 h/day, air humidity RH = 36–67%, light intensity, 81–167 lux) showed biostatic activity, and the number of microorganisms decreased by 1–5 log to the level of 0–5 CFU/cm

2 [

33]. The present study in the conditions of supporting natural lighting with a light bulb (lighting time 12 h/day, air humidity RH = 39%, UVA/B radiation intensity 1400 µW/cm

2) showed an increase in antimicrobial activity, and the number of microorganisms decreased by 5–8 log to the level of 0 CFU/cm

2. The increase in photocatalytic activity in the present study may be due to higher light intensity and longer lighting time, which means that lighting plays a key role in inducing photocatalysis of textiles modified with metals nanoparticles.

The present study found that the effectiveness of microbial growth inhibition on textile materials modified with TiO

2/ZnO nanoparticles depends on the UVA/B radiation intensity (400 and 1400 µW/cm

2), the type of microorganisms and the number of wash cycles (15 and 30 times). In earlier research in the photocatalytically modified textiles model conditions, low and medium antimicrobial activity (A = 0.40–1.62) was observed towards the tested microorganisms:

E. coli, S. aureus., B. subtilis, C. albicans, and

A. niger [

33]. In the present study, for the same microorganisms, higher antimicrobial activity was observed, mainly medium and high (A = 1.3–8.0) with the exception of low biostatic effect under conditions of lower light intensity 400 µW/cm

2 for

B. subtilis, A. niger, and

C. albicans (A = 0.46–0.96). It has also been confirmed in the present study that

A. niger moulds are the most resistant to photocatalysis, which is consistent with other studies [

33,

38].

Relations between microclimate parameters and lighting in the rooms and photocatalytic processes in the air were described in the studies using different photocatalytic arrays, which were significantly affected by air humidity, lighting type and lighting time [

39,

40]. The obtained results prove that the increase in UVA/B radiation intensity from 400 to 1400 µW/cm

2 significantly induces photocatalysis of modified textiles and increases their antimicrobial activity. At the radiation intensity of 1400 µW/cm

2 (simulation of conditions in the summer season), a biocidal effect (R = 100%) against all tested microorganisms (

E. coli, S. aureus. B. subtilis, C. albicans, and

A. niger) was observed on the surface of materials modified TiO

2/ZnO.

The lower light intensity (UV400) and 30 wash cycles of material modified with TiO2/ZnO significantly reduce the effectiveness of inhibiting the growth of microorganisms compared to 1400 µW/cm2 lighting, regardless of the wash cycles. At a light intensity of 400 µW/cm2 and after 30 washes, a low antimicrobial effect was observed for B. subtilis, C. albicans, and A. niger (A = 0.46–0.96).

In the studies by El-Naggar et al. (2016), it was found that on nano-TiO

2-modified cotton after washing, the reduction of bacteria

E. coli and

S. aureus changed from levels R = 96.1–97.6% after 5 wash cycles, R = 94.2–95.5% after 10 wash cycles, to the level R = 89.4–92.9% after 20 wash cycles. The present study confirms the decrease in the antimicrobial effect of materials modified with TiO

2/ZnO nanoparticles after 15 wash cycles from the levels of R = 88.6–100% (at UV400) and R = 100% (at UV1400) to R = 65.4–99.4% (at UV400) and R = 95.5–100% (at UV1400) after 30 wash cycles. However, in the present study, the washing process was performed at a higher temperature (60 °C) than in the study by El-Naggar et al. (room temperature), which may have a significant impact on the obtained results. Moreover, the durability of the antimicrobial activity of materials modified with metal nanoparticles depends on the physical linkages between the hydroxyl and carboxyl groups of cotton and nanoparticles on the fabric surfaces [

25]. Studies showed that washing of fabrics with TiO

2 released small amounts of NPs, mainly depending on the type of fabric and how the particles are attached or deposited on the fabric surface [

10]. The addition of NPs in a stage of the finishing process resulting in only weak binding to the surface, while adding in the polymer matrix causes strong bonding [

41]. In the present study, nanoparticles were bonded onto fabric surface in a polymer matrix, as was stated by the SEM micrograph.

Tests performed for commercial textiles (sun-protection clothes) showed low washout amounts of Ti (from 0.01 to 0.06 wt% of total Ti) in one wash cycle. The results indicated that functional textiles release some TiO

2 particles but that the amounts are relatively low and mostly not in the nanoparticulate range [

10], which is important because it does not burden the natural environment. We did not research the toxicity of the water solutions after rinsing TiO2 and ZnO from modified textiles due to NPs low concentration and negligible toxicity risk. The literature indicates the toxicity associated mainly with inhalation exposure to nano-TiO2. However, the extensive industrial use of TiO2 and ZnO NPs and the properties of the nanoparticles (their larger surface area and reactivity) indicate that more attention should be paid to TiO2 and ZnO nanoparticles exposure.

4. Materials and Methods

4.1. Textiles

A 100% cotton double-side terry woven fabric with three-weft assembled weave and declared surface mass of 400 g/m2 made by ZWOLTEX Sp. z o.o., Poland. Self-cleaning experiments were determined using 100% cotton diagonal woven fabric (without loop cover) and declared surface mass of 200 g/m2 made by ZWOLTEX Sp. z o.o., Poland. Fabric pretreatment and bleaching.

Prior to modification, the fabric was pretreated and chemically bleached under industrial conditions using periodic finishing methods in rope form. The fabric pretreatment and bleaching processes (without dyeing) were described in detail by Gutarowska et al. (2020). The pretreatment and bleaching processes were carried out in ZWOLTEX Sp. z o.o., Poland. Fabric modification using nanoparticles (NPs) with photocatalytic properties.

Water dispersion of ZnO NPs (zincite crystal structure, NP mean size 86 nm and specific surface area 100 ± 10 m

2/g) and TiO

2 NPs (rutile crystal structure, N-doped crystal lattice, NP mean size 30 nm and specific surface area > 60 m

2/g) were purchased from Bochemie (Czech Republic) and Cinkarna (Slovenia), respectively. Bleached woven terry fabric was submitted to the functionalisation process under laboratory conditions. The fabric was padded using a laboratory padding-squeezing machine (E. Benz, Switzerland) in a bath containing 2.5 g/dm

3 ZnO NPs, 2.5 g/dm

3 N-doped TiO

2 NPs, 40 g/dm

3 softening agent Persoftal Hydrosoft (Tanatex Chemicals B.V., Ede, The Netherlands), 46 g/dm

3 binder Silpure FBR-5 Part B (Thomson Research Associates, Toronto, ON, Canada) and 0.6 g/dm

3 wetting and deaerate agent Newalol PFN (Zchimmer and Schwarz Chemie GmbH, Lahnstein, Germany). The pressure of padding-squeezing rolls was 40 kG/cm (squeezing degree 86%). Subsequently, the fabric was dried at 150 °C for 5 min in open-width form using a laboratory stenter drying-curing machine (E. Benz, Switzerland). For self-cleaning experiments, the 100% cotton woven fabric with a diagonal wave and surface mass of 200 g/m

2 was submitted to the functionalisation process with the same condition as terry textiles. The amount of nanoadditives deposited on the surface was estimated on the basis of the amount of padding bath applied to the sample during the padding processes:

where

Characteristics of tested cotton materials are presented in

Table 4.

4.2. Textile Material Characterisation

Morphological observation of ZnO and TiO2 modified textiles was carried out using scanning electron microscope (SEM) VEGA3-SBU. The elemental analysis of modified textiles was performed by energy-dispersive X-ray spectroscopy (EDX) using Bruker Nano XFlash Detector 410M (Bruker GmbH, Berlin, Germany). Before the SEM-EDX investigation, the samples were placed on carbon plasters and coated with gold using Cressington Sputter Coater 108 auto (Cressington Scientific Instruments UK, Watford, England). The distribution of the elements on the surface of modified fabric was carried out using SEM FEI Quanda 250 FEG equipped with EDAX detector. EDX maps were recorded on yarn taken from towels loops of modified terry fabric before and after 15 and 30 washings.

Thermogravimetric analysis (TGA) was performed using a TA Instruments TGA 5500 device (USA). Measurements were carried out under nitrogen atmosphere in the range of temperatures from 20 to 900 °C with a heating speed of 20°/min. Towel samples weighing 3–4 mg were taken from the towel loops.

The ability of a cotton surface modified with photocatalytic compounds to decompose staining particles was tested. Self-cleaning properties were determined using 100% cotton woven fabric (made with bleached cotton yarn) of diagonal wave weave and declared surface mass of 200 g/m, reduced and modified under laboratory conditions. Padding with the same condition as in the scope of terry textiles was applied (squeezing degree 73%). The procedure of self-cleaning properties determination was described in detail by Gutarowska et al. (2020). The stained with 25% blackcurrant juice cotton samples were irradiated at different conditions:

8 h irradiation using 160 W mercury lamp (Solar Glo PT2193, Exo Terra, Montreal, QC, Canada), the distance between the bulb and sample 75 cm, UVA/B radiation intensity 420 ± 27 µW/cm2, marked as UV400,

8 h irradiation using 160 W mercury lamp (Solar Glo PT2193, Exo Terra, Montreal, QC, Canada), the distance between the bulb and sample 30 cm, UVA/B radiation intensity 1385 ± 26.0 µW/cm2, marked as UV1400.

The samples were exposed to light with a spectrum similar to sunlight (UV/VIS) with different UVA/B radiation intensity c.a. 400 and c.a. 1400 µW/cm2. The samples exposed to different conditions simulate different parameters depending on the season: 1. room conditions in winter (400 µW/cm2) and 2. room conditions in summer (1400 µW/cm2). The UVA/B radiation intensity was monitored by means of a UV-AB ST513 SENTRY radiation meter (Sentry Optronics Corp., Taipei, Taiwan). The irradiated samples were sprayed with distilled water before and after each hour of irradiation.

The stained samples (irradiated and unirradiated) were subjected to colour measurements using the Spectraflash 300 colourimeter (DataColor, Rotkreuz, Switzerland). Prior to measurement, the instrument was calibrated according to the manufacturer’s instructions. The light reflectance was measured in the range of 400–700 nm. The self-cleaning action was monitored by comparing the K/S values, the colour differences (ΔE*), and colour change (ΔL*, Δa*, Δb*) between irradiated and unirradiated stained samples.

4.3. Washing

The washing process was carried out using a home laundering machine (Indesit, Italy) with a load capacity of 5 kg, typical washing powder for coloured fabrics from a reputable company, widely available on the market. Our recommended washing temperature for coloured towels is 60 °C. The process of a single washing operation was as follows:

before starting washing, 5 g/L of washing powder was introduced into the powder dispenser in an automatic washing machine,

process according to the automatic 60 °C cotton washing machine program with a duration of 30 min,

after the washing process, pause, drain and automatic programmer of the washing machine’s multiple rinsing, ending with 1000 rpm spin,

towels dried in the open air by hanging them to dry. Dry towels were recharged for the next wash.

4.4. Microorganisms

In the model experiment, five microorganisms from the American Type Culture Collection (ATCC) and the National Collection of Agricultural and Industrial Microorganisms (NCAIM): Staphylococcus aureus ATCC 6538, Escherichia coli ATCC 10536, Candida albicans ATCC 10231, Aspergillus niger ATCC 16404 and Bacillus subtilis NCAIM 01644 were used. The selected microorganisms represent different morphology, physiology and sensitivity to disinfection.

4.5. Model Study—Conditions Description

The cotton samples with microorganisms were incubated at different conditions:

24 h daily cycle with daylight, temperature 25.6 ± 1.1 °C, relative air humidity RH = 39.6 ± 4.6%, UVA/B radiation intensity 441 ± 28 µW/cm2;

24 h daily cycle supported by an additional light source—Sanlux bulb, time 12 h, the distance between the bulb and the samples 30 cm; temperature 26.1 ± 0.8 °C, relative air humidity RH = 39.7 ± 1.7%, UVA/B radiation intensity 1387 ± 17 µW/cm2.

The parameters were measured using an HL-1D hygrometer (temperature and relative air humidity) and UV-AB ST513 SENTRY (radiation intensity). The fabric samples were moistened every hour by adding sterile water in the volume of 0.1 mL in order to maintain the appropriate moisture content of the material (at the level of approximately 70–80%).

4.6. Antimicrobial Activity of Textiles

The antimicrobial activity of textiles under model conditions was determined by the AATCC Test Method 100-2004 [

28], according to previous studies (Gutarowska et al., 2020). The densities of inoculums were established by the culture method. The densities for the tested microorganisms were: 2.5 × 10

8 CFU/mL (

E. coli), 2.2 × 10

8 CFU/mL (

S. aureus), 1.7 × 10

9 CFU/mL (

B. subtilis), 2.0 × 10

6 CFU/mL (

C. albicans), 7.0 × 10

6 CFU/mL (

A. niger). The suspension of microorganisms (0.1 mL) was inoculated on the surface of the modified, modified and washed and control samples (area 4 cm

2).

Samples were collected after time t = 0 h and 24 h, transferred into saline (50 mL sterile 0.85%) and shaken (5 min). Then, the method of serial dilutions in saline (from 10−2 to 10−6) and the culture method were performed. The microorganisms were cultured in the following conditions: MEA medium (malt extract agar, Merck, Germany), temperature 27 ± 2 °C, 48–72 h (number of fungi); and TSA medium (tryptic soy agar, Merck, Germany), temperature 30 ± 2 °C, 24–48 h (number of bacteria). After incubation, the colonies were counted, and the result was given as colony-forming units per 4 cm2 of a sample (CFU/sample). The tests were performed in three independent replicates for each variant.

The microorganism’s reduction coefficient on modified cotton towels before and after washing (15 and 30 cycles) under the daylight and additional lighting conditions and the biostatic activity were determined. Microorganisms’ reduction coefficient (R) on cotton towels after 24 h of incubation determines the number of microorganisms (%) on the modified towel samples were inhibited compared to the control sample incubated in the same conditions, and the R coefficient was calculated according to the Equation (2):

where:

Nc—number of microorganisms on textile material (CFU/sample) after 24 h incubation on the control textile material (in following conditions: 24 h daily cycle with daylight/24 h daily cycle supported by an additional light source)

Nm—number of microorganisms on textile material (CFU/sample) after 24 h incubation on the modified textile material, before and after 15 and 30 wash cycles (in following conditions: 24 h daily cycle with daylight/24 h daily cycle supported by an additional light source).

Antimicrobial activity was determined using Equation (3):

where:

NC—number of microorganisms on textile material (CFU/sample) after incubation on the control textile material;

Nm—number of microorganisms on textile material (CFU/sample) after incubation on modified/washed textile material.

The results of antimicrobial activity were compared to criteria using normative findings in order to determine the biostatic effect of disinfectants against microorganisms (PN-EN 1276). The activity below 1 was considered low, activity at the level of 1–3 was considered medium, and above 3, it was high, assuming that the value of 1 means a decrease in the number of microorganisms by one logarithmic scale.

Statistical differences in the number of microorganisms on textiles between the control sample at t = 0 h and the samples modified with different lighting parameters after t = 24 h were analysed using one-way variance analysis (ANOVA test), with the significance level p < 0.05. Statistical analysis was performed using the Origin 6.1 computer program (OriginLab, Northampton, MA, USA).

5. Conclusions

The study results have demonstrated that deposition of ZnO and TiO2 nanoparticles in a polymeric matrix using the padding-squeezing method is a simple way to achieve photocatalytic and antimicrobial properties of cotton terry fabric.

SEM-EDX analysis revealed that ZnO and TiO2 nanoparticles can be found on terry fabric surface after several washing cycles. TGA also confirmed the long-lasting durability of the washing processes. Moreover, the EDX study of TGA residues is a simple way for elementary analysis of thermal resistant metal oxide nanoparticles present in ash after cotton fabric pyrolysis.

Long-lasting self-cleaning properties characterise tested fabric in light with different intensity of UVA/B radiation; however, stronger photocatalytic efficiency is observed in light with a larger intensity of UVA/B radiation. The efficiency of self-cleaning properties depends on UV intensity. Increasing UVA/B radiation intensity from 400 to 1400 µW/cm2 significantly increased the self-cleaning properties of the modified sample.

Tested fabrics modified with TiO2/ZnO nanoparticles have long-lasting antimicrobial activity, which lasted up to 30 wash cycles. The effectiveness of microbial growth inhibition on tested materials depends on the light intensity (UV 400 and 1400), the type of microorganisms and the number of wash cycles (15 and 30 times). Light intensity plays a key role in inducing photocatalysis of textiles modified with metals nanoparticles. The increase in light intensity from 400 to 1400 µW/cm2 significantly increases the effectiveness of photocatalysis. At the light intensity of 1400 µW/cm2, a biocidal effect (R = 100%) against all tested microorganisms (E. coli, S. aureus. B. subtilis, C. albicans, and A. niger) was observed on the surface of materials. The lower UVA/B intensity (UV400) and 30 wash cycles reduce the antimicrobial activity of the material (R = 65.4–99.4%). At a light with UVA/B radiation intensity of 400 µW/cm2 and after 30 washes, a low antimicrobial effect was observed for B. subtilis, C. albicans, and A. niger. The antimicrobial activity of washed materials modified with TiO2/ZnO nanoparticles can be gained by intensifying UV irradiation.