Study of Catalysts’ Influence on Photocatalysis/Photodegradation of Olive Oil Mill Wastewater. Determination of the Optimum Working Conditions

Abstract

1. Introduction

2. Results and Discussion

2.1. Analysis of OMW Characterization Parameters

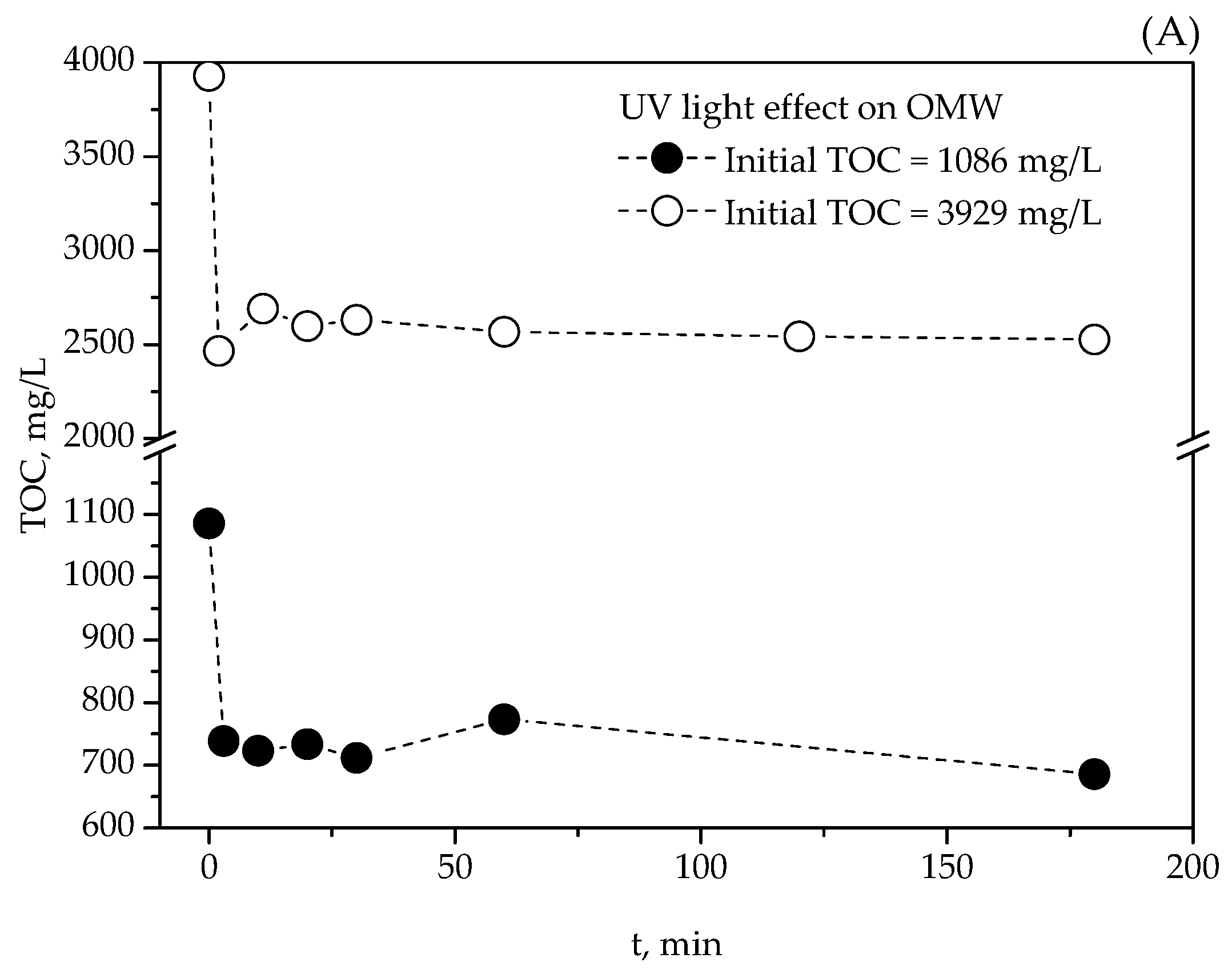

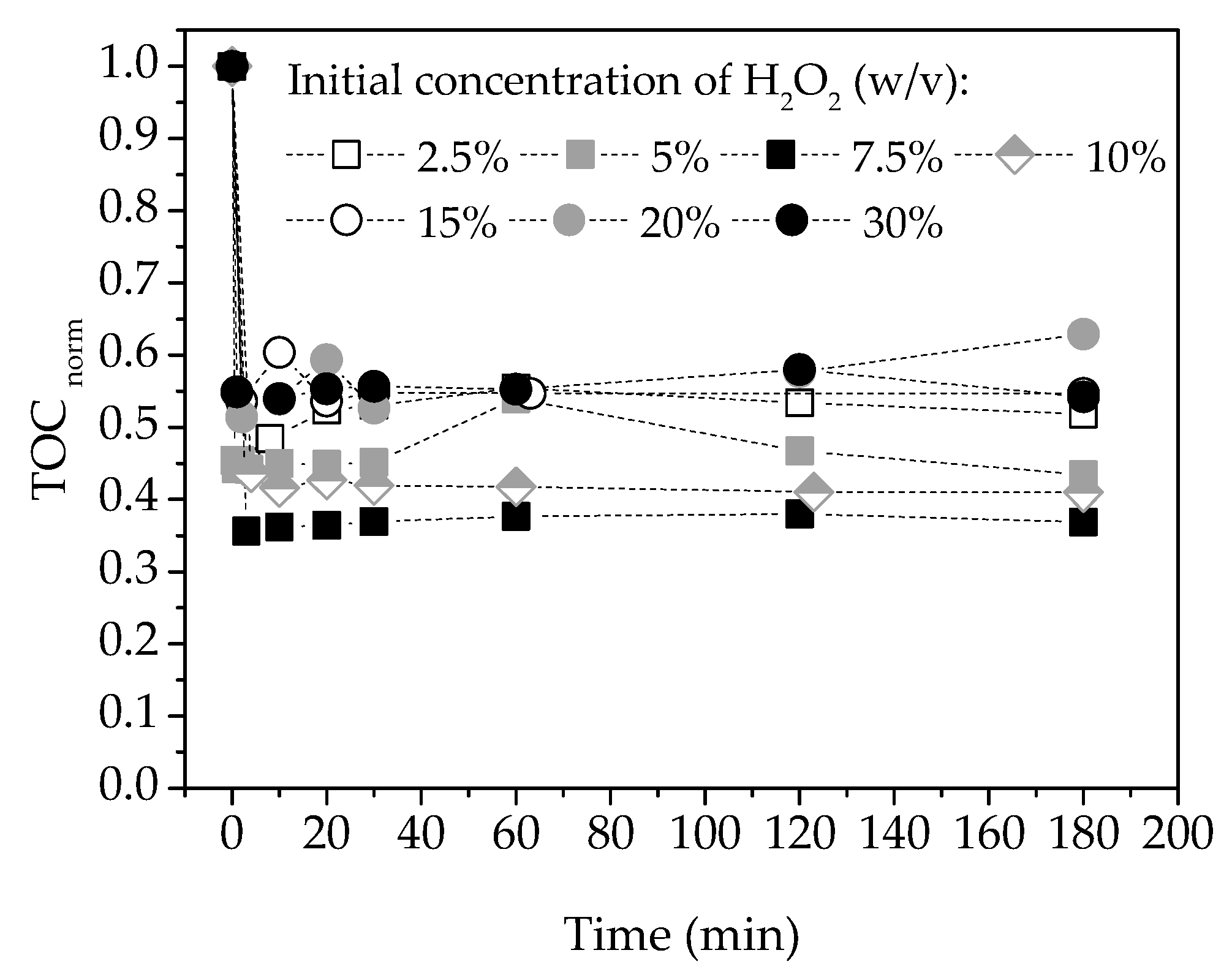

2.2. Effect of Photo-Fenton Reaction on Organic Matter Degradation

Selection of Catalyst

2.3. Kinetic Study

3. Materials and Methods

3.1. Chemicals

3.2. Sampling and Comparative Analysis of OMW

3.3. Methodology

3.4. Analytical Methods

3.5. Calculations and Kinetics

4. Conclusions

5. Patents

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- International Olive Oil Council. Available online: https://www.internationaloliveoil.org/wp-content/uploads/2020/04/HO-W901-29-11-2019-P.pdf (accessed on 15 May 2020).

- Niaounakis, M.; Halvadakis, C.P. Olive Processing Waste Management, Volume 5 Pergamon, 2nd ed.; Elsevier Science: Amsterdam, The Netherlands, 2006; pp. 23–64. [Google Scholar]

- Hodaifa, G.; Sanchez, S.; Martínez, M.E.; Orpez, R. Biomass production of Scenedesmus obliquus from mixtures of urban and olive-oil mill wastewaters used as culture medium. Appl. Energy 2013, 104, 345–352. [Google Scholar] [CrossRef]

- Hodaifa, G.; Martínez, M.E.; Sanchez, S. Use of industrial wastewater from olive-oil extraction for biomass production of Scenedesmus obliquus. Bioresour. Technol. 2008, 99, 1111–1117. [Google Scholar] [CrossRef]

- Hodaifa, G.; Agabo, C.; Moya, A.J.; Pacheco, R.; Mateo, S. Treatment of olive oil mill wastewater by UV-light and UV/H2O2. Int. J. Green Technol. 2015, 1, 46–53. [Google Scholar] [CrossRef]

- Bouknana, D.; Hammouti, B.; Salghi, R.; Jodeh, S.; Zarrouk, A.; Warad, I.; Aouniti, A.; Sbaa, M. Physicochemical characterization of olive oil mill wastewaters in the eastern region of Morocco. J. Mater. Environ. Sci. 2014, 5, 1039–1058. [Google Scholar]

- Borja, R.; Martin, A.; Alonso, V.; Garcia, I.; Banks, C.J. Influence of different aerobic pretreatments on the kinetics of anaerobic digestion of olive mill wastewater. Water Res. 1995, 29, 489–495. [Google Scholar] [CrossRef]

- Caputo, A.C.; Scacchia, F.; Pelagagge, P.M. Disposal of by-products in olive oil industry: Waste-to-energy solutions. Appl. Therm. Eng. 2003, 23, 197–214. [Google Scholar] [CrossRef]

- Nickheslat, A.; Mehdi-Amin, M.; Izanloo, H.; Fatehizadeh, A.; Mousavi, S.M. Phenol photocatalytic degradation by advanced oxidation process under ultraviolet radiation using titanium dioxide. J. Environ. Public Health 2013, 2013, 1–9. [Google Scholar] [CrossRef]

- Spanish Law 22/2011. Wastes and Polluted Soils. Available online: https://www.boe.es/eli/es/l/2011/07/28/22/con (accessed on 16 May 2020).

- Israilides, C.; Vlyssides, A.; Galiatsatou, P.; Iconomou, D.; Arapoglou, D.; Christopoulou, N.; Bocari, M. Methods of integrated management of olive oil mill wastewater (OMW) in the framework of the EU Environmental Quality Standards (EQS). In Proceedings of the VIII International Conference “Protection and Restoration of the Environment”, Chania, Greece, 28 June–1 July 2006; pp. 291–292. [Google Scholar]

- Jarboui, R.; Sellami, F.; Kharroubi, A.; Gharsallah, N.; Ammar, E. Olive mill wastewater stabilization in open-air ponds: Impact on clay–sandy soil. Bioresour. Technol. 2008, 99, 7699–7708. [Google Scholar] [CrossRef]

- Fernández-Santos Ortiz-Yribas, F.X.; Rodríguez Padilla, L.M.; Cárdenas Fernández, J.; Capítulo, V. Sector de Almazaras de Aceitunas. Incidencias Ambientales y Medidas Correctoras en Sectores Agroalimentarios; Junta Andalucía Conserjería de medio Ambiente: Córdoba, Spain, 1997. [Google Scholar]

- Petrovic, M.; Radjenovic, J.; Barcelo, D. Advanced oxidation processes (AOPs) applied for wastewater and drinking water treatment: Elimination of pharmaceuticals. Holist. Approach Environ. 2011, 1, 63–74. [Google Scholar]

- Sekine, M.; Salehi, Z.; Tokumura, M.; Kawase, Y. Solar photo-Fenton process for the treatment of colored soft drink wastewater: Decolorization, mineralization and COD removal of oolong tea effluent. J. Environ. Sci. Health A 2012, 47, 2181–2189. [Google Scholar] [CrossRef]

- Ebrahiem, E.E.; Al-Maghrabi, M.N.; Mobarki, A.R. Removal of organic pollutants from industrial wastewater by applying photo-Fenton oxidation technology. Arab. J. Chem. 2017, 10, S1674–S1679. [Google Scholar] [CrossRef]

- Khoufi, S.; Aloui, F.; Sayadi, S. Treatment of olive oil mill wastewater by combined process electro-Fenton reaction and anaerobic digestion. Water Res. 2006, 40, 2007–2016. [Google Scholar] [CrossRef] [PubMed]

- Nieto, M.L.; Hodaifa, G.; Rodríguez, S.; Giménez, J.A.; Ochando, J.M. Degradation of organic matter in olive-oil mill wastewater through homogeneous Fenton-like reaction. Chem. Eng. J. 2011, 173, 503–510. [Google Scholar] [CrossRef]

- Chong, M.N.; Sharma, A.K.; Burn, S.; Saint, C.P. Feasibility study on the application of advanced oxidation technologies for decentralised wastewater treatment. J. Clean. Prod. 2012, 35, 230–238. [Google Scholar] [CrossRef]

- Kalajdžic, B.B.; Habuda-stanić, M.; Romić, Ž.; Trossmayer, J.J.; Kuleš, M. Removal of natural organic matter from groundwater using Fenton’s process. Glob. NEST J. 2013, 15, 13–20. [Google Scholar]

- Wang, N.N.; Zheng, T.; Zhang, G.S.; Wang, P. A review on Fenton-like processes for organic wastewater treatment. J. Environ. Chem. Eng. 2016, 4, 762–787. [Google Scholar] [CrossRef]

- Nieto, L.M.; Hodaifa, G.; Vives, S.; Casares, J.A.; Driss, S.B.; Grueso, R. Treatment of olive-mill wastewater from a two-phase process by chemical oxidation on an industrial scale. Water Sci. Technol. 2009, 59, 2017–2027. [Google Scholar] [CrossRef]

- Hodaifa, G.; Ochando, J.M.; Vives, S.R.; Ferez, M.A. Optimization of continuous reactor at pilot scale for olive-oil mill wastewater treatment by Fenton-like process. Chem. Eng. J. 2013, 220, 117–124. [Google Scholar] [CrossRef]

- Huang, C.P.; Dong, C.; Tang, Z. Advanced chemical oxidation: Its present role and potential future in hazardous waste treatment. Waste Mgmt. 1993, 13, 361–377. [Google Scholar] [CrossRef]

- Lu, M.C.; Lin, C.J.; Liao, C.H.; Ting, W.P.; Huang, R.Y. Influence of pH on the dewatering of activated sludge by Fenton’s reagent. Water Sci. Technol. 2001, 44, 327–332. [Google Scholar] [CrossRef]

- Lin, S.H.; Lo, C.C. Fenton process for treatment of desizing wastewater. Water Res. 1997, 31, 2050–2056. [Google Scholar] [CrossRef]

- Agabo-García, C.; Hodaifa, G. Real olive oil mill wastewater treatment by photo-Fenton system using artificial ultraviolet light lamps. J. Clean. Prod. 2017, 162, 743–753. [Google Scholar] [CrossRef]

- García-Ballesteros, S.; Grimalt, J.; Berto, S.; Minella, M.; Laurenti, E.; Vicente, R.; López-Pérez, M.F.; Amat, A.M.; Prevot, A.B.; Arques, A. New route for valorization of oil mill wastes: Isolation of humic-like substances to be employed in solar-driven processes for pollutants removal. ACS Omega 2018, 3, 13073–13080. [Google Scholar] [CrossRef] [PubMed]

- Pignatello, J.J.; Oliveros, E.; MacKay, A. Advanced oxidation processes for organic contaminant destruction based on the Fenton reaction and related Chemistry. Crit. Rev. Environ. Sci. Technol. 2006, 36, 1–84. [Google Scholar] [CrossRef]

- Gallard, H.; De Laat, J. Kinetic modelling of Fe (III)/H2O2 oxidation reactions in dilute aqueous solution using atrazine as a model organic compound. Water Res. 2000, 34, 3107–3116. [Google Scholar] [CrossRef]

- Franch, M.I.; Ayllón, J.A.; Xavier Domènech, J.P. Fe(III) photocatalyzed degradation of low chain carboxylic acids: Implications of the iron salt. Appl. Catal. B Environ. 2004, 50, 89–99. [Google Scholar] [CrossRef]

- Maletzky, P.; Bauer, R. The photo-Fenton method-degradation of nitrogen containing organic compounds. Chemosphere 1998, 37, 899–909. [Google Scholar] [CrossRef]

- Esteves, B.M.; Rodrigues, C.S.D.; Maldonado-Hódar, F.J.; Madeira, L.M. Treatment of high-strength olive mill wastewater by combined Fenton-like oxidation and coagulation/flocculation. J. Environ. Chem. Eng. 2019, 7, 103252. [Google Scholar] [CrossRef]

- Safarzadeh-Amiri, A.; Bolton, J.R.; Cater, S.R. The use of iron in advanced oxidation processes. J. Adv. Oxid. Technol. 1996, 1, 18–26. [Google Scholar] [CrossRef]

- Pignatello, J.J. Dark and photoassisted Fe3+-Catalyzed Degradation of chlorophenoxy herbicides by hydrogen peroxide. Environ. Sci. Technol. 1992, 26, 944–951. [Google Scholar] [CrossRef]

- Faust, B.C.; Hoigne, J. Photolysis of fe (iii)-hydroxy complexes as sources of oh radicals in clouds, fog and rain. Atmos. Environ. 1990, 24A, 79–89. [Google Scholar] [CrossRef]

- Bergendahl, J.A.; Thies, T.P. Fenton’s oxidation of MTBE with zero-valent iron. Water Res. 2004, 38, 327–334. [Google Scholar] [CrossRef] [PubMed]

- Mancinelli, R.L.; McKay, C. The evolution of nitrogen cycling. Orig. Life Evol. Biosph. 1988, 18, 311–325. [Google Scholar]

- Trigo-Rodriguez, J.M.; Raulin, F.; Muller, C.; Nixon, C. The Early Evolution of the Atmospheres of Terrestrial Planets; Springer: New York, NY, USA, 2013. [Google Scholar]

- Hermanson, M.H.; Hites, R.A. Polychlorinated biphenyls in tree bark. Environ. Sci. Technol. 1990, 24, 666–671. [Google Scholar] [CrossRef]

- Bamwenda, G.R.; Sayama, K.; Arakawa, H. The effect of selected reaction parameters on the photoproduction of oxygen and hydrogen from a WO3-Fe2+-Fe3+ aqueous suspension. J. Photochem. Photobiol. A 1999, 122, 175–183. [Google Scholar] [CrossRef]

- Rana, S.; Suresh, S. Comparison of different Coagulants for Reduction of COD from Textile industry wastewater. Mater. Today Proceed 2017, 4, 567–574. [Google Scholar] [CrossRef]

- Dong, Q.; Parker, W.; Dagnew, M. Impact of FeCl3 dosing on AnMBR treatment of municipal wastewater. Water Res. 2015, 80, 281–293. [Google Scholar] [CrossRef]

- Guo, X.; Wei, Z.; Wu, Q.; Li, C.; Qian, T.; Zheng, W. Effect of soil washing with only chelators or combining with ferric chloride on soil heavy metal removal and phytoavailability: Field experiments. Chemosphere 2016, 147, 412–419. [Google Scholar] [CrossRef]

- Balamane-Zizi, O.; Ait-Amara, H. Study of the simultaneous elimination of phosphates and heavy metals contained in dairy wastewater by a physical-chemical and biological mixed process; consequences on the biodegradability. Energy Procedia 2012, 18, 1341–1360. [Google Scholar] [CrossRef][Green Version]

- Bedia, J.; Monsalvo, V.M.; Rodriguez, J.J.; Mohedano, A.F. Iron catalysts by chemical activation of sewage sludge with FeCl3 for CWPO. Chem. Eng. J. 2017, 318, 224–230. [Google Scholar] [CrossRef]

- Sreeja, P.H.; Sosamony, K.J. A comparative study of homogeneous and heterogeneous photo-Fenton process for textile wastewater treatment. Proc. Technol. 2016, 24, 217–223. [Google Scholar] [CrossRef]

- Lofrano, G.; Meriç, S.; Belgiorno, V.; Napoli, R.M. Fenton’s oxidation of various-based tanning materials. Desalination 2007, 211, 10–21. [Google Scholar] [CrossRef]

- Andreozzi, R.; Longo, G.; Majone, M.; Modesti, G. Integrated treatment of olive oil mill effluents (OME): Study of ozonation coupled with anaerobic digestion. Water Res. 1998, 32, 2357–2364. [Google Scholar] [CrossRef]

- Krýsová, H.; Jirkovský, J.; Krýsa, J.; Mailhot, G.; Bolte, M. Comparative kinetic study of atrazine photodegradation in aqueous Fe (ClO4)3 solutions and TiO2 suspensions. Appl. Catal. B Environ. 2003, 40, 1–12. [Google Scholar] [CrossRef]

- Lagergren, S.Y. Zur Theorie der sogenannten Adsorption gelöster Stoffe. Kungliga Sven. Vetensk. Handl. 1898, 24, 1–39. [Google Scholar]

- Patila, S.; Kumara, N. Sun light transmission through silica optical fibers for lighting: An experimental study. Mater. Today Proc. 2018, 5, 22943–22949. [Google Scholar] [CrossRef]

- DIN 38409-41. German Standard Methods for Examination of Water, Waste Water and Sludge; Summary Action and Material Characteristic Parameters (group H); Determination of the Chemical Oxygen Demand (COD) in the Range over 15 mg/L (H41); German Institute for Standardisation (Deutsches Institut für Normung): Berlin, Germany, 1980. [Google Scholar]

- ISO 8466-1. Water Quality-Calibration and Evaluation of Analytical Methods and Estimation of Performance Characteristics—Part 1: Statistical Evaluation of the Linear Calibration Function; International Organization for Standardization: Genève, Switzerland, 1990. [Google Scholar]

- DIN 38402 A51. German Standard Methods for the Examination of Water, Waste Water and Sludge; General Information (Group A); Calibration of Analytical Methods, Evaluation of Analytical Results and Linear Calibration Functions Used to Determine the Performance Characteristics of Analytical Methods (A 51); German Institute for Standardisation (Deutsches Institut für Normung): Berlin, Germany, 1986. [Google Scholar]

- Dubber, D.; Gray, N.F. Replacement of chemical oxygen demand (COD) with total organic carbon (TOC) for monitoring wastewater treatment performance to minimize disposal of toxic analytical waste. J. Environ. Sci. Health A Tox. Hazard. Subst. Environ. Eng. 2010, 45, 1595–1600. [Google Scholar] [CrossRef]

| Parameters | Seville 1 | Seville 2 | Seville 3 | Seville 4 |

|---|---|---|---|---|

| pH | 8.6 | 7.04 | 8.6 | 8.63 |

| Electric Conductivity (mS/cm) | 30.7 | 1.51 | 116 | 142 |

| Turbidity (FTU) | 149 | 134 | 997 | 724 |

| Total Solids (%, w/w) | 2.32 | 0.0935 | 11.4 | 26.2 |

| Suspended Solids (%, w/w) | 0.518 | 0.0625 | - | 25.06 |

| Organic matter (%, w/w) | 0.316 | 0.0501 | 1.90 | 0.177 |

| Ash (%, w/w) | 2.01 | 0.0434 | 9.56 | 25.9 |

| Chemical oxygen demand, COD, (mg O2/L) | 6187 | 511 | 18,981 | 38,139 |

| Total phenolic compounds, TPCs, (mg/L) | 20.0 | 7.2 | 189.6 | 84.9 |

| Total carbon, TC, (mg/L) | 3710 | 207 | 14,212 | 29,981 |

| Total organic carbon, TOC, (mg/L) | 2903 | 177 | 11,684 | 25,006 |

| Inorganic carbon, IC, (mg/L) | 807 | 119 | 2528 | 4875 |

| Total nitrogen, TN, (mg/L) | 87 | 12.6 | 391.7 | 928 |

| Total iron (mg/L) | 48.2 | 9.0 | 42.3 | 107.6 |

| Chloride (mg/L) | 8756 | - | 11,544 | 10,637 |

| Sulfates (mg/L) | 545 | 631 | 1299 | 21,270 |

| Parameter | Value ± Standard Deviation |

|---|---|

| pH | 9.0 ± 0.4 |

| Electric conductivity (mS/cm) | 37 ± 3 |

| COD (mg O2/L) | 6454 ± 307 |

| TOC (mg/L) | 3245 ± 683 |

| TC (mg/L) | 4060 ± 718 |

| IC (mg/L) | 814 ± 113 |

| TN (mg/L) | 104 ± 12 |

| Turbidity (FTU) | 278 ± 220 |

| Total Phenolic compounds (mg/L) | 30 ± 9 |

| Total iron, (mg/L) | 39 ± 55 |

| SO42−, (mg/L) | 441 ± 219 |

| Chlorine, mg/L | 10,295 ± 1907 |

| Parameter | %H2O2 (w/v) | FeCl3 | Fe2(SO4)3·H2O | FeSO4·7H2O | Fe(ClO4)3·H2O |

|---|---|---|---|---|---|

| %TC | 2.5 | 61.8 | 65.3 | 65.0 | 59.1 |

| 5 | 61.2 | 69.3 | 72.1 | 70.8 | |

| 7.5 | 70.1 | 69.9 | 57.9 | 69.5 | |

| 10 | 71.8 | 72.5 | 71.1 | 52.0 | |

| 15 | 52.5 | 40.0 | 32.4 | 48.8 | |

| 20 | 52.0 | 44.2 | 51.0 | 49.5 | |

| 30 | 53.4 | 54.0 | 53.4 | 52.5 | |

| %TOC | 2.5 | 46.4 | 55.1 | 66.4 | 51.6 |

| 5 | 54.2 | 54.7 | 69.2 | 56.8 | |

| 7.5 | 63.2 | 62.7 | 57.9 | 63.3 | |

| 10 | 57.9 | 52.0 | 68.3 | 44.5 | |

| 15 | 45.5 | 26.5 | 38.6 | 38.1 | |

| 20 | 46.1 | 34.2 | 55.8 | 41.6 | |

| 30 | 43.9 | 46.1 | 55.0 | 47.8 | |

| %TN | 2.5 | 57.6 | 60.6 | 63.8 | 60.5 |

| 5.0 | 59.1 | 69.5 | 50.9 | 52.5 | |

| 7.5 | 51.5 | 44.5 | 59.4 | 46.9 | |

| 10 | 67.9 | 65.1 | 69.4 | 46.0 | |

| 15 | 57.6 | 50.5 | 61.0 | 58.6 | |

| 20 | 98.7 | 52.8 | 60.0 | 59.3 | |

| 30 | 65.0 | 62.3 | 59.5 | 62.2 | |

| %COD | 2.5 | 30.8 | 40.9 | 54.0 | 48.5 |

| 5 | 56.5 | 66.0 | 52.7 | 70.0 | |

| 7.5 | 60.3 | 57.0 | 58.0 | 38.3 | |

| 10 | 74.3 | 64.2 | 61.4 | 25.8 | |

| 15 | 36.7 | 47.6 | 41.8 | 21.4 | |

| 20 | 20.0 | 14.6 | 23.4 | 16.1 | |

| 30 | 40.0 | 17.6 | 14.9 | 17.6 | |

| %TPCs | 2.5 | 55.3 | 39.7 | 25.7 | 56.8 |

| 5 | 68.3 | 48.7 | 36.1 | 44.8 | |

| 7.5 | 88.4 | 56.3 | 52.2 | - | |

| 10 | 72.1 | 34.1 | 46.1 | 45.1 | |

| 15 | 68.3 | 33.4 | - | 51.0 | |

| 20 | 63.5 | 31.7 | 51.2 | 20.0 | |

| 30 | 41.6 | 24.6 | 46.0 | 24.6 | |

| %Turbidity | 2.5 | 80.8 | 91.8 | 87.5 | 87.5 |

| 5 | 87.8 | 90.9 | 92.9 | 75.0 | |

| 7.5 | 94.8 | 99.9 | 81.8 | 52.9 | |

| 10 | 83.1 | 80.2 | 81.2 | 51.7 | |

| 15 | 90.0 | 99.8 | 95.7 | 65.4 | |

| 20 | 92.8 | 94.2 | 90.9 | 79.2 | |

| 30 | 94.4 | 90.0 | 94.4 | 66.0 |

| Catalyst | Oxidation State | Price/Supplier | Applications |

|---|---|---|---|

| FeCl3 | Fe+3 | 38.9 €/kg Sigma-Aldrich | Wastewater coagulation [42]; reduces membrane fouling in MBRs [43]; removes heavy metals in soils [44]; removes phosphates and heavy metals in water [45]; advanced immobilized oxidation [46]. |

| Fe2(SO4)3·H2O | Fe+3 | 176.3 €/kg Honeywell Fluka | Homo and heterogeneous catalysis of wastewater oxidation [47]. |

| FeSO4·7H2O | Fe+2 | 60 €/kg Sigma-Aldrich | Advanced chemical oxidation [48]; coagulant [42]. |

| Fe(ClO4)3·H2O | Fe+3 | 394 €/kg Sigma-Aldrich | Advanced chemical oxidation in OMWs [49]. Synthesis of furans and indoles by photodegradation [50]. |

| Catalyst | %H2O2 | XTOC, max | k (min−1) | RSS * | R2 |

|---|---|---|---|---|---|

| FeCl3 | 7.5 | 0.632 | 3.00 | 4.17 × 10−4 | 0.999 |

| FeCl3 | 10 | 0.583 | 0.841 | 2.01 × 10−4 | 0.999 |

| Fe2(SO4)3·H2O | 5 | 0.549 | 2.00 | 7.92 × 10−4 | 0.996 |

| Fe2(SO4)3·H2O | 7.5 | 0.628 | 1.13 | 3.61 × 10−5 | 0.999 |

| FeSO4·7H2O | 5 | 0.693 | 2.00 | 1.16 × 10−3 | 0.997 |

| FeSO4·7H2O | 10 | 0.687 | 1.50 | 2.36 × 10−3 | 0.993 |

| Fe(ClO4)3·H2O | 5 | 0.578 | 1.00 | 4.55 × 10−3 | 0.983 |

| Fe(ClO4)3·H2O | 7.5 | 0.636 | 1.20 | 4.33 × 10−3 | 0.985 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hodaifa, G.; Agabo García, C.; Borja, R. Study of Catalysts’ Influence on Photocatalysis/Photodegradation of Olive Oil Mill Wastewater. Determination of the Optimum Working Conditions. Catalysts 2020, 10, 554. https://doi.org/10.3390/catal10050554

Hodaifa G, Agabo García C, Borja R. Study of Catalysts’ Influence on Photocatalysis/Photodegradation of Olive Oil Mill Wastewater. Determination of the Optimum Working Conditions. Catalysts. 2020; 10(5):554. https://doi.org/10.3390/catal10050554

Chicago/Turabian StyleHodaifa, Gassan, Cristina Agabo García, and Rafael Borja. 2020. "Study of Catalysts’ Influence on Photocatalysis/Photodegradation of Olive Oil Mill Wastewater. Determination of the Optimum Working Conditions" Catalysts 10, no. 5: 554. https://doi.org/10.3390/catal10050554

APA StyleHodaifa, G., Agabo García, C., & Borja, R. (2020). Study of Catalysts’ Influence on Photocatalysis/Photodegradation of Olive Oil Mill Wastewater. Determination of the Optimum Working Conditions. Catalysts, 10(5), 554. https://doi.org/10.3390/catal10050554