Effect of Mesostructured Zirconia Support on the Activity and Selectivity of 4,6-Dimethydibenzothiophene Hydrodesulfurization

Abstract

:1. Introduction

2. Results and Discussion

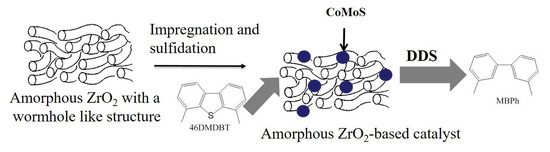

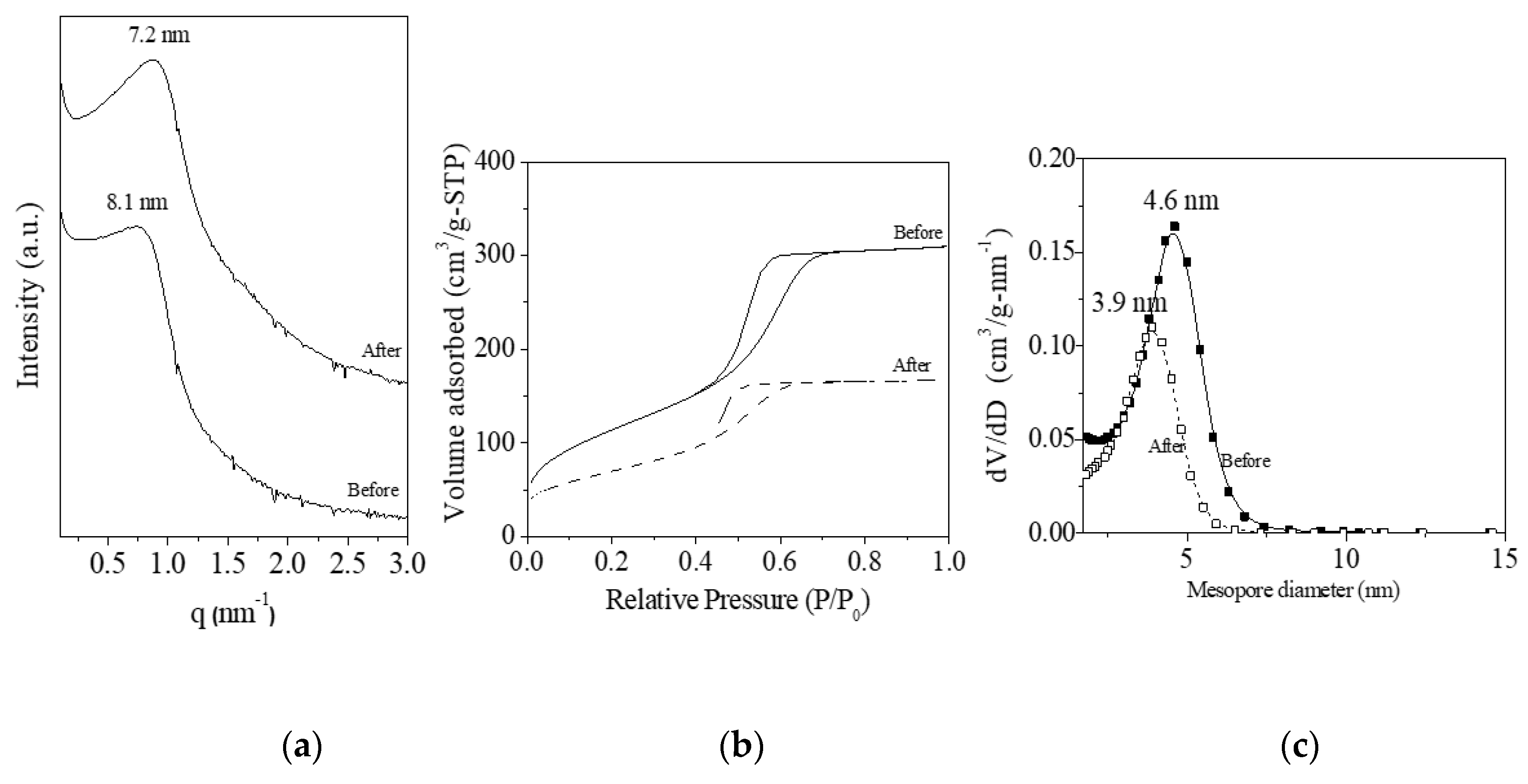

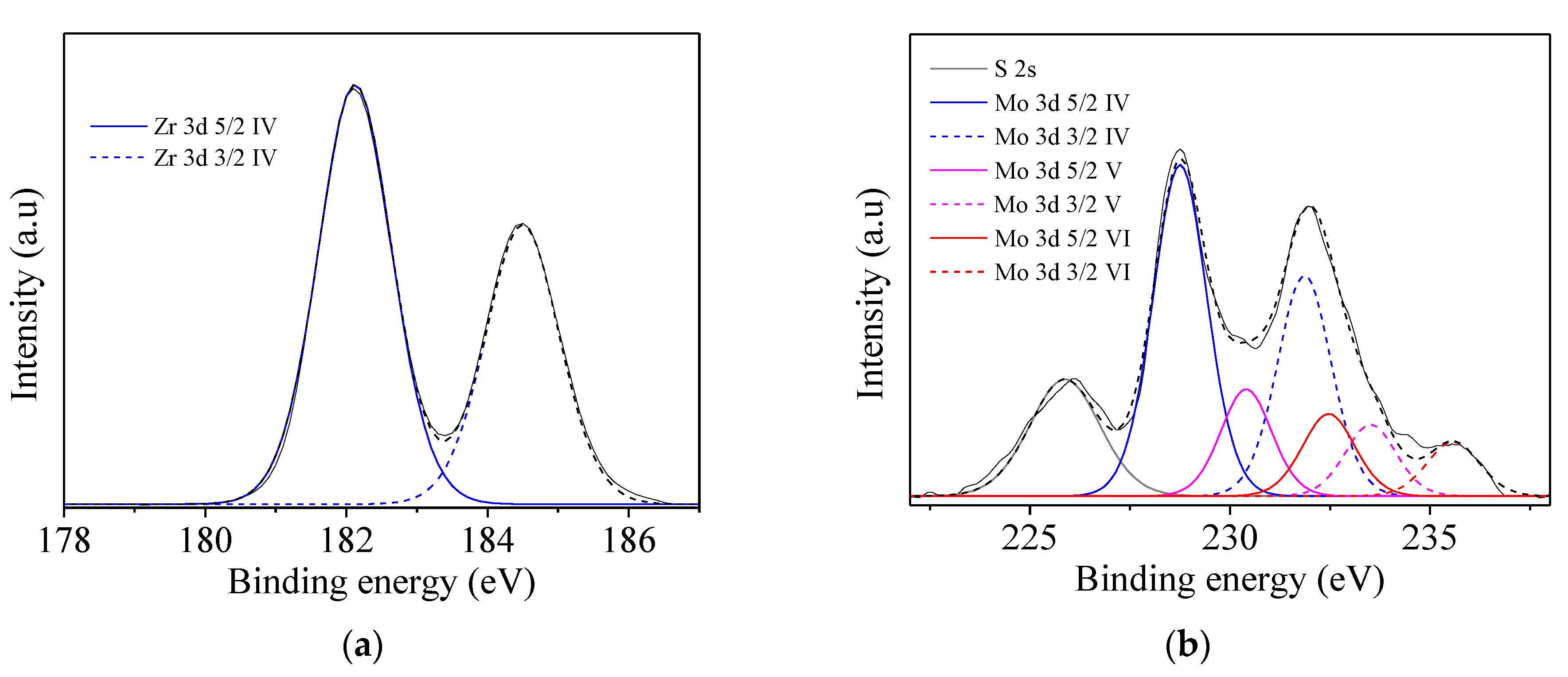

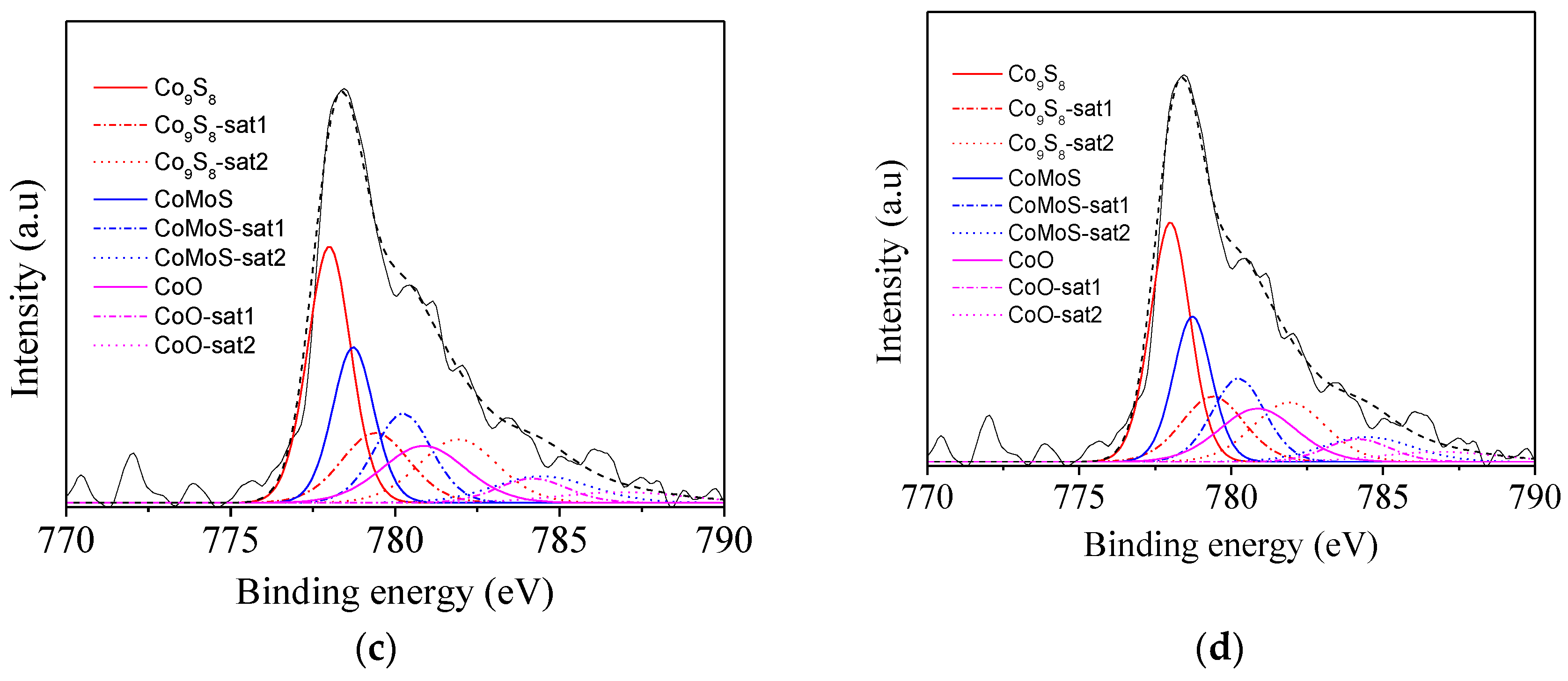

2.1. Characterization of the Mesostructured ZrO2-based Catalyst

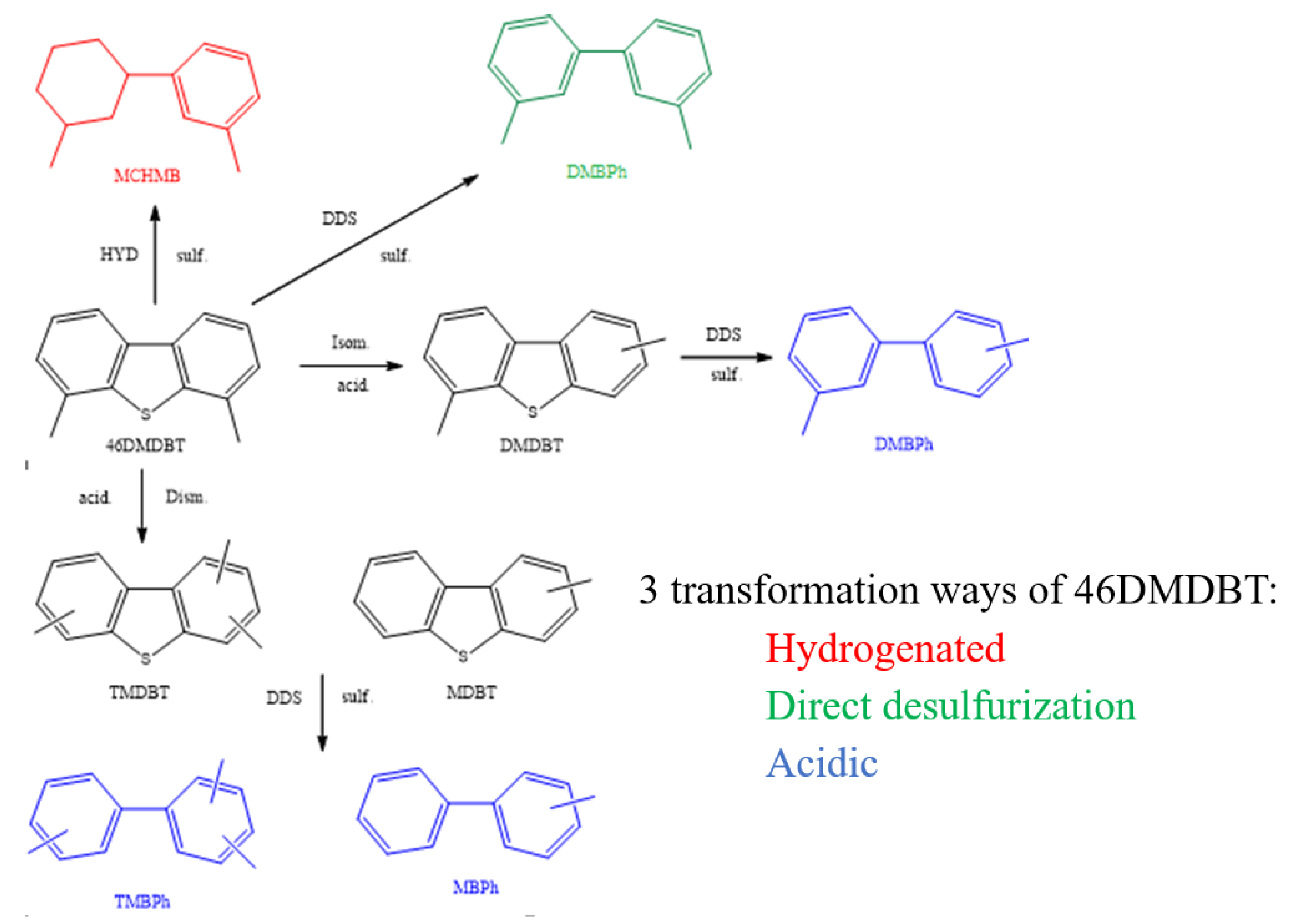

2.2. Catalytic Activity for Hydrodesulfurization of 46DMDBT HDS

3. Materials and Methods

3.1. Materials Preparation

3.2. Characterization

3.3. Catalytic Tests

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- EU: Fuels: Diesel and Gasoline. Available online: https://www.transportpolicy.net/standard/eu-fuels-diesel-and-gasoline (accessed on 24 August 2020).

- Whitehurst, D.D.; Isoda, T.; Mochida, I. Present state of the art and future challenges in the hydrodesulfurization of polyaromatic sulfur compounds. Adv. Catal. 1998, 42, 345–471. [Google Scholar]

- Landau, M.V. Deep hydrotreating of middle distillates from crude and shale oils. Catal. Today 1997, 36, 393–429. [Google Scholar] [CrossRef]

- Ma, X.; Sakanishi, K.; Mochida, I. Hydrodesulfurization reactivities of various sulfur compounds in vacuum gas oil. Ind. Eng. Chem. Res. 1996, 35, 2487–2494. [Google Scholar] [CrossRef]

- Bataille, F.; Lemberton, J.L.; Michaud, P.; Pérot, G.; Vrinat, M.; Lemaire, M.; Schulz, E.; Breysse, M.; Kasztelan, S. Alkyldibenzothiophenes hydrodesulfurization-promoter effect, reactivity, and reaction mechanism. J. Catal. 2000, 191, 409–422. [Google Scholar] [CrossRef]

- Bej, S.K.; Maity, S.K.; Turaga, U.T. Search for an efficient 4,6-DMDBT hydrodesulfurization catalyst: A review of recent studies. Energy Fuels 2004, 5, 1227–1237. [Google Scholar] [CrossRef]

- Stanislaus, A.; Marafi, A.; Rana, M.S. Recent advances in the science and technology of ultra low sulfur diesel (ULSD) production. Catal. Today 2010, 153, 1–68. [Google Scholar] [CrossRef]

- Sundaramurthy, V.; Eswaramoorthi, I.; Dalai, A.K.; Adjaye, J. Hydrotreating of gas oil on SBA-15 supported NiMo catalysts. Microporous Mesoporous Mater. 2008, 111, 560–568. [Google Scholar] [CrossRef]

- Klimova, T.; Peña, L.; Lizama, L.; Salcedo, C.; Gutiérrez, O.Y. Modification of activity and selectivity of NiMo/SBA-15 HDS catalysts by grafting of different metal oxides on the support surface. Ind. Eng. Chem. Res. 2009, 48, 1126–1133. [Google Scholar] [CrossRef]

- Duchet, J.C.; Tilliette, M.J.; Cornet, D.; Vivier, L.; Perot, G.; Bekakra, L.; Moreau, C.; Szabo, G. Catalytic properties of nickel molybdenum sulphide supported on zirconia. Catal. Today 1991, 10, 579–592. [Google Scholar] [CrossRef]

- Kumaran, G.M.; Garg, S.; Soni, K.; Prasad, V.V.D.N.; Sharma, L.D.; Murali Dhar, G. Catalytic functionalities of H-β-zeolite-supported molybdenum hydrotreating catalysts. Energy Fuels 2006, 20, 1784–1790. [Google Scholar] [CrossRef]

- Breysse, M.; Afanasiev, P.; Geantet, C.; Vrinat, M. Overview of support effects in hydrotreating catalysts. Catal. Today 2003, 86, 5–16. [Google Scholar] [CrossRef]

- Prabhu, N.; Dalai, A.K.; Adjaye, J. Hydrodesulphurization and hydrodenitrogenation of light gas oil using NiMo catalyst supported on functionalized mesoporous carbon. Appl. Catal. A Gen. 2011, 401, 1–11. [Google Scholar] [CrossRef]

- Ramireza, J.; Macıas, G.; Cedenoa, L.; Gutierrez-Alejandre, A.; Cuevasa, R.; Castillo, P. The role of titania in supported Mo, CoMo, NiMo, and NiW hydrodesulfurization catalysts: Analysis of past and new evidences. Catal. Today 2004, 98, 19–30. [Google Scholar] [CrossRef]

- Platanitisa, P.; Panagiotoua, G.D.; Bourikasb, K.; Kordulisa, C.; Fierrod, J.L.G.; Lycourghiotis, A. Preparation of un-promoted molybdenum HDS catalysts supported on titania by equilibrium deposition filtration: Optimization of the preparative parameters and investigation of the promoting action of titania. J. Mol. Catal. A Chem. 2016, 412, 1–12. [Google Scholar] [CrossRef]

- Castillo-Villalón, P.; Ramírez, J.; Cuevas, R.; Vázquez, P.; Castañeda, R. Influence of the support on the catalytic performance of Mo, CoMo, and NiMo catalysts supported on Al2O3 and TiO2 during the HDS of thiophene, dibenzothiophene, or 4,6-dimethyldibenzothiophene. Catal. Today 2016, 259, 140–149. [Google Scholar] [CrossRef]

- Shimada, H.; Sato, T.; Yoshimura, Y.; Hiraishi, J.; Nishijima, A. Support effect on the catalytic activity and properties of sulfided molybdenum catalysts. J. Catal. 1988, 110, 275–284. [Google Scholar] [CrossRef]

- Shimada, H. Morphology and orientation of MoS2 clusters on Al3 and TiO2 supports and their effect on catalytic performance. Catal. Today 2003, 86, 17–29. [Google Scholar] [CrossRef]

- Wang, D.; Qian, W.; Ishihara, A.; Kabe, T. Elucidation of Sulfidation State and Hydrodesulfurization Mechanism on TiO2 Catalysts Using 35S Radioisotope Tracer Methods. J. Catal. 2001, 203, 322–328. [Google Scholar] [CrossRef]

- Roy, T.; Rousseau, J.; Daudin, A.; Pirngruber, G.; Lebeau, B.; Blin, J.L.; Brunet, S. Deep hydrodesulfurization of 4,6-dimethydibenzothiophene over CoMoS/TiO2 catalysts: Impact of the TiO2 treatment. Catal. Today 2020. [Google Scholar] [CrossRef]

- Mazurelle, J.; Lamonier, C.; Lancelot, C.; Payen, E.; Pichon, C.; Guillaume, D. Use of the cobalt salt of the heteropolyanion [Co2Mo10O38H4]6− for the preparation of CoMo HDS catalysts supported on Al2O3, TiO2 and ZrO2. Catal. Today 2008, 130, 41–49. [Google Scholar] [CrossRef]

- Orozco, E.O.; Vrinat, M. Kinetics of dibenzothiophene hydrodesulfurization over MoS2 supported catalysts: Modelization of the H2S partial pressure effect. Appl. Catal. A Gen. 1998, 170, 195–206. [Google Scholar] [CrossRef]

- Ji, Y.; Afanasiev, P.; Vrinat, M.; Li, W.; Li, C. Promoting effects in hydrogenation and hydrodesulfurization reactions on the zirconia and titania supported catalysts. Appl. Catal. A Gen. 2004, 257, 157–164. [Google Scholar] [CrossRef]

- Breysse, M.; Portefaix, J.L.; Vrinat, M. Support effects on hydrotreating catalysts. Catal. Today 1991, 10, 489–505. [Google Scholar] [CrossRef]

- Hamon, D.; Vrinat, M.; Breysse, M.; Durand, B.; Beauchesne, F.; Des Courieres, T. Surface structure and catalytic activities of Mo/ZrO2-Y2O3 catalysts. Bull. Soc. Chim. Belg. 1991, 100, 933–943. [Google Scholar] [CrossRef]

- Grange, P.; Vanhaeren, X. Hydrotreating catalysts, an old story with new challenges. Catal. Today 1997, 4, 375–391. [Google Scholar] [CrossRef]

- Ancheyta, J.; Speight, J.G. Hydroprocessing of Heavy Oil and Residua; CRC Press; Taylor and Francis Group: Boca Raton, FL, USA, 2007. [Google Scholar]

- Furimsky, E. Catalyst for Upgrading Heavy Petroleum Feeds. Stud. Surf. Sci. Catal. 2007, 169, 1–387. [Google Scholar]

- Lebeau, B.; Naboulsi, I.; Michelin, L.; Marichal, C.; Rigolet, S.; Carteret, C.; Brunet, S.; Bonne, M.; Blin, J.L. Amorphous Mesostructured Zirconia with High (Hydro)Thermal Stability. Rsc Adv. 2020, 10, 26165–26176. [Google Scholar] [CrossRef]

- Bagshaw, S.A.; Prouzet, E.; Pinnavaia, T.J. Templating of mesoporous molecular sieves by nonionic polyethylene oxide surfactants. Science 1995, 269, 1242–1244. [Google Scholar] [CrossRef]

- Sing, K.S.W.; Everett, D.H.; Haul, R.A.W.; Moscou, L.; Pierotti, R.A.; Rouquerol, J.; Siemieniewska, T. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (Recommendations 1984), IUPAC. Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Lavalley, J.C.; Anquetil, R.; Czyziewska, J.; Ziolek, M. Use of pyridine as a probe for the determination, by IR spectroscopy, of the Brønsted acid strength of MIHNaY zeolites. J. Chem. Soc. Trans. 1996, 92, 1263–1266. [Google Scholar] [CrossRef]

- Soni, K.K.; Mouli, K.C.; Dalai, A.K.; Adjaye, J. Effect of Ti loading on the HDS and HDN activity of KLGO on NiMo/TiSBA-15 catalysts. Microporous Mesoporous Mater. 2012, 152, 224–234. [Google Scholar] [CrossRef]

- Du, P.; Zheng, P.; Song, S.; Wang, X.; Zhang, M.; Chi, K.; Xu, C.; Duan, A.; Zhao, Z. Synthesis of a novel micro/mesoporous composite material Beta-FDU-12 and its hydro-upgrading performance for FCC gasoline. RSC Adv. 2016, 6, 1018–1026. [Google Scholar] [CrossRef]

- Zakharova, M.V.; Kleitz, F.; Fontaine, F.G. Lewis acidity quantification and catalytic activity of Ti, Zr and Al-supported mesoporous silica. Dalton Trans. 2017, 46, 3864–3876. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Marakatti, V.; Marappa, S.; Gaigneaux, E.M. Sulfated zirconia: An efficient catalyst for the Friedel-Crafts monoalkylation of resorcinol with methyl tertiary butyl ether to 4-tertiary butylresorcinol. N. J. Chem. 2019, 43, 7733–7742. [Google Scholar] [CrossRef]

- Bui, V.N.; Laurenti, D.; Delichère, P.; Geantet, C. Hydrodeoxygenation of guaiacol Part II: Support effect for CoMoS catalysts on HDO activity and selectivity. Appl. Catal. B 2011, 101, 246–255. [Google Scholar] [CrossRef]

- Han, W.; Yuan, P.; Fan, Y.; Shi, G.; Liu, H.; Bai, D.; Bao, X. Preparation of supported hydrodesulfurization catalysts with enhanced performance using Mo-based inorganic–organic hybrid nanocrystals as a superior precursor. J. Mater. Chem. 2012, 22, 25340–25353. [Google Scholar] [CrossRef]

- Farag, H.; Mochida, I.; Sakanishi, K. Fundamental comparison studies on hydrodesulfurization of dibenzothiophenes over CoMo-based carbon and alumina catalysts. Appl. Catal. A Gen. 2000, 194–195, 147–157. [Google Scholar] [CrossRef]

- Zhou, W.; Zhou, Y.; Wei, Q.; DU, L.; Ding, S.; Jiang, S.; Zhang, Y.; Zhang, Q. Gallium modified HUSY zeolite as an effective co-support for NiMo hydrodesulfurization catalyst and the catalyst’s high isomerization selectivity. Chem. Eur. J. 2017, 23, 9369–9382. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Yang, C.; Wei, W.; Li, W.H.; Sun, Y.H. Surface properties and CO adsorption on zirconia polymorphs. J. Mol. Catal. A Chem. 2005, 227, 119–124. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, W.; Zhang, M.; Tao, K. A comparison of surface acidic features between tetragonal and monoclinic nanostructured zirconia. Catal. Commun. 2002, 3, 239–245. [Google Scholar] [CrossRef]

- Liu, C.; Wang, W.; Xu, Y.; Li, Z.; Wang, B.; Ma, X. Effect of zirconia morphology on sulfur-resistant methanation performance of MoO3/ZrO2 catalyst. Appl. Surf. Sci. 2018, 441, 482–490. [Google Scholar] [CrossRef]

- Ninh, T.K.T.; Laurenti, D.; Leclerc, E.; Vrinat, M. Support effect for CoMoS and CoNiMoS hydrodesulfurization catalysts prepared by controlled method. Appl. Catal. A Gen. 2014, 487, 210–218. [Google Scholar] [CrossRef]

| Oxide | Mo Distribution (at.%) | Co Distribution (at.%) | S Distribution (at.%) | |||||

|---|---|---|---|---|---|---|---|---|

| MoS2 | Mo5+ | MoO3 | CoMoS | Co9S8 | CoO | Sulfur | Sulfates | |

| ZrO2 | 65 | 20 | 16 | 33.0 | 48.7 | 18.3 | 90.7 | 9.3 |

| Al2O3 * | 70 | 15 | 15 | 25.7 | 52.3 | 22 | 100 | 0 |

| Oxide | TSMo (%) | TSG (%) | PR (%) | S/Mo | Co/Mo | (Co/Mo)slabs |

|---|---|---|---|---|---|---|

| ZrO2 | 65 | 56 | 33 | 1.6 | 0.6 | 0.3 |

| Al2O3 * | 70 | 53 | 26 | 1.5 | 0.3 | 0.1 |

| Materials | Atotal | Aacid | AHYD | Atotal DDS | AHYD/ADDS |

|---|---|---|---|---|---|

| CoMoS/Al2O3 | 0.73 | 0.00 | 0.55(75%) | 0.18(25%) | 3.1 |

| CoMoS/ZrO2 | 0.61 | 0.17 | 0.18(41%) | 0.26(59%) | 0.7 |

| Materials | Atotal | Aacid | AHYD | Atotal DDS | ||||

|---|---|---|---|---|---|---|---|---|

| (a) | (b) | (a) | (b) | (a) | (b) | (a) | (b) | |

| CoMoS/Al2O3 | 6 | 2 | 0 | 0 | 4.5 | 0.5 | 1.5 | 0.5 |

| CoMoS/ZrO2 | 2.5 | 0.9 | 0.68 | 0.3 | 0.72 | 0.2 | 1.1 | 0.4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brunet, S.; Lebeau, B.; Naboulsi, I.; Michelin, L.; Comparot, J.D.; Marichal, C.; Rigolet, S.; Bonne, M.; Blin, J.-L. Effect of Mesostructured Zirconia Support on the Activity and Selectivity of 4,6-Dimethydibenzothiophene Hydrodesulfurization. Catalysts 2020, 10, 1162. https://doi.org/10.3390/catal10101162

Brunet S, Lebeau B, Naboulsi I, Michelin L, Comparot JD, Marichal C, Rigolet S, Bonne M, Blin J-L. Effect of Mesostructured Zirconia Support on the Activity and Selectivity of 4,6-Dimethydibenzothiophene Hydrodesulfurization. Catalysts. 2020; 10(10):1162. https://doi.org/10.3390/catal10101162

Chicago/Turabian StyleBrunet, Sylvette, Bénédicte Lebeau, Issam Naboulsi, Laure Michelin, Jean Dominique Comparot, Claire Marichal, Séverinne Rigolet, Magali Bonne, and Jean-Luc Blin. 2020. "Effect of Mesostructured Zirconia Support on the Activity and Selectivity of 4,6-Dimethydibenzothiophene Hydrodesulfurization" Catalysts 10, no. 10: 1162. https://doi.org/10.3390/catal10101162

APA StyleBrunet, S., Lebeau, B., Naboulsi, I., Michelin, L., Comparot, J. D., Marichal, C., Rigolet, S., Bonne, M., & Blin, J.-L. (2020). Effect of Mesostructured Zirconia Support on the Activity and Selectivity of 4,6-Dimethydibenzothiophene Hydrodesulfurization. Catalysts, 10(10), 1162. https://doi.org/10.3390/catal10101162