Rapid Laser Manufacturing of Microfluidic Devices from Glass Substrates

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Used

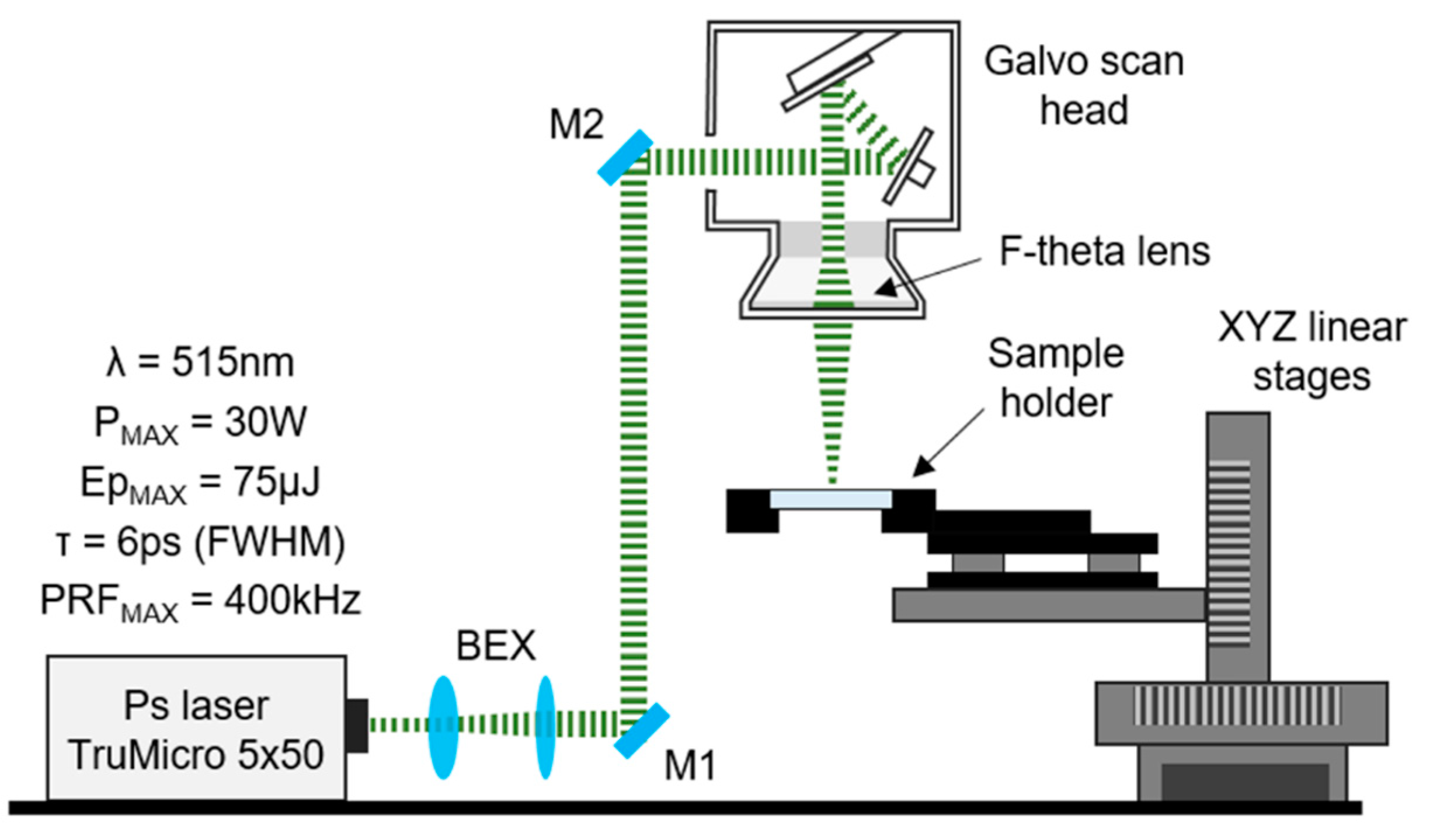

2.2. Laser System

2.3. Laser Micromachining Procedure

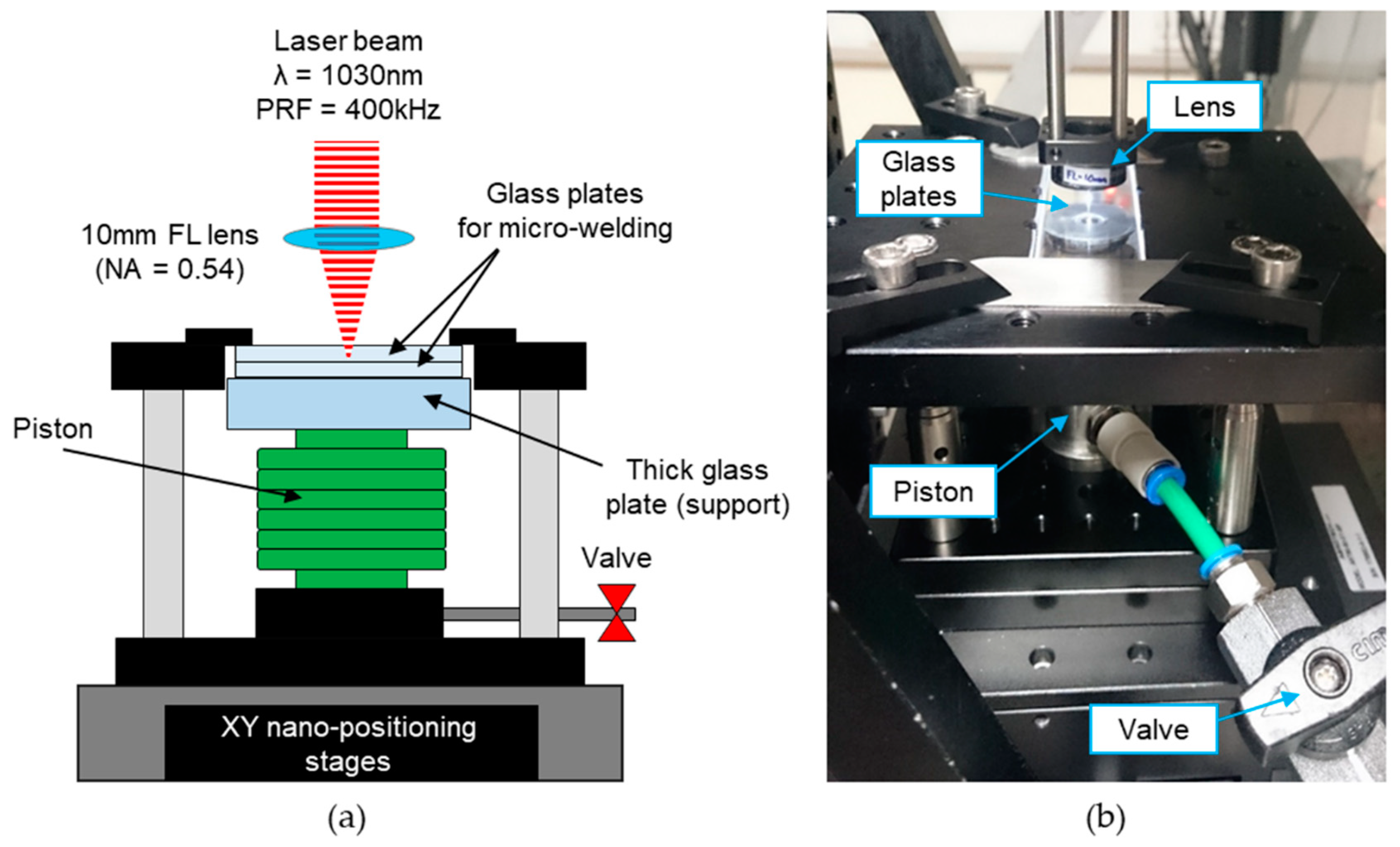

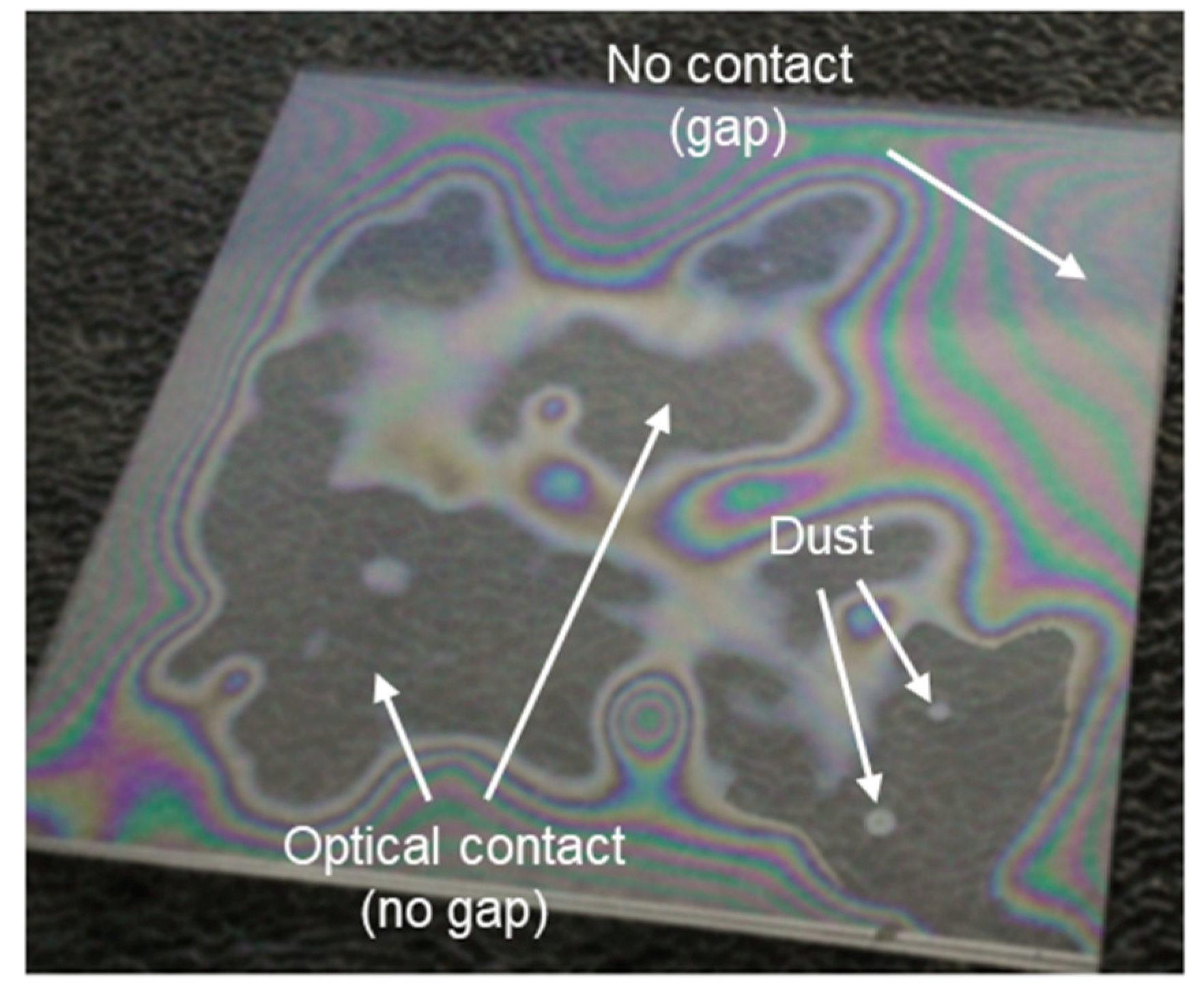

2.4. Laser Microwelding Procedure

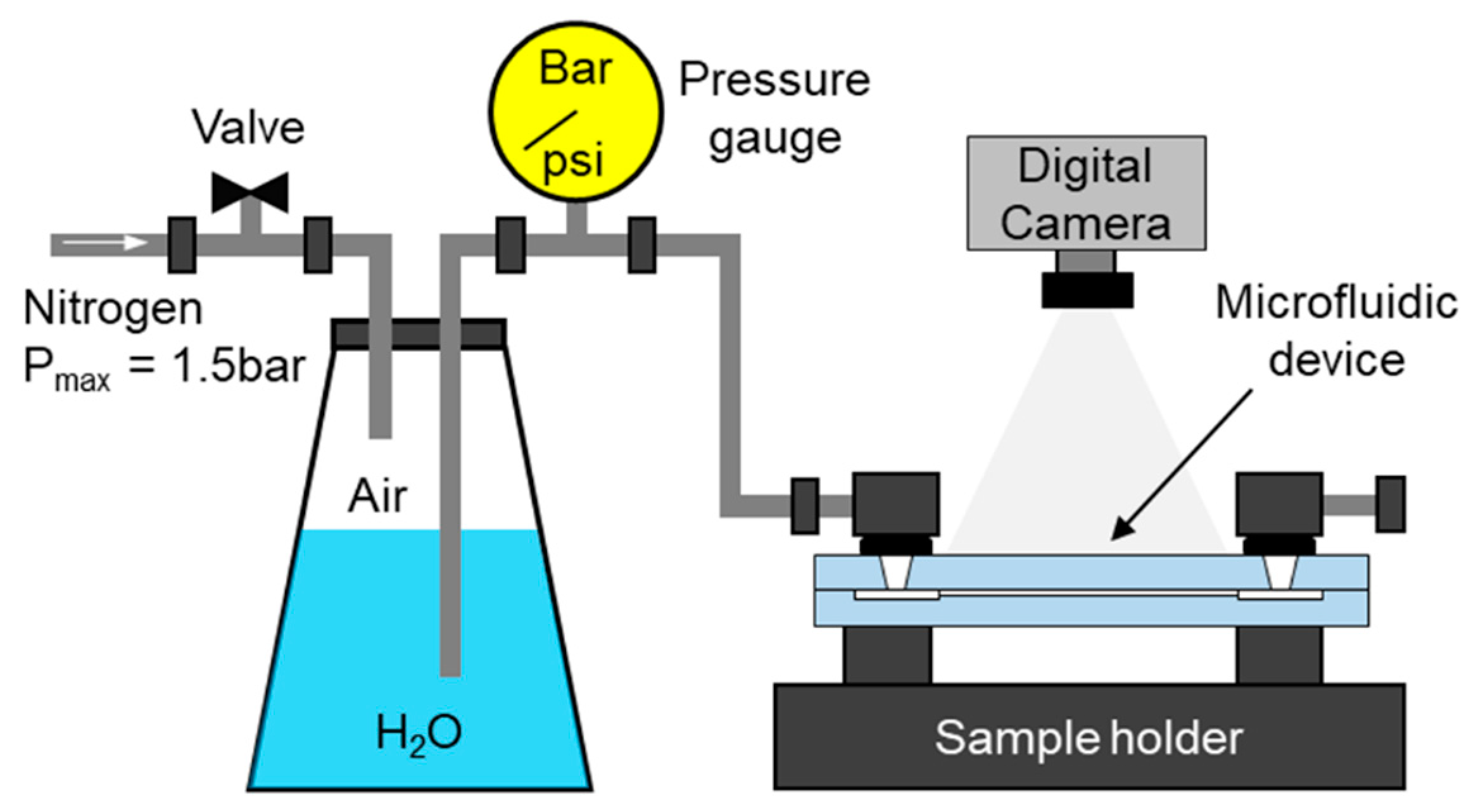

2.5. Testing of the Laser-Manufactured Microfluidic Devices

3. Results and Discussion

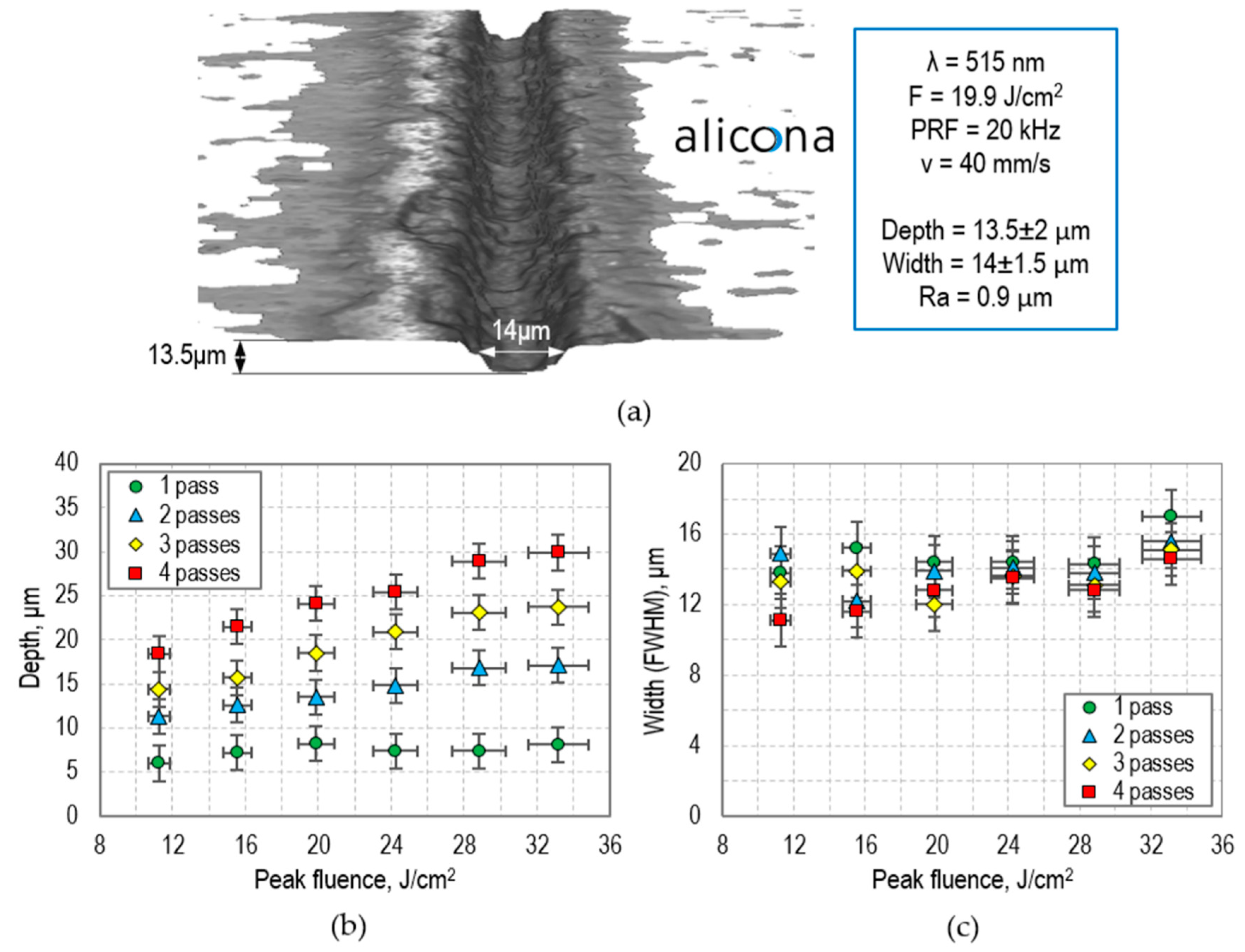

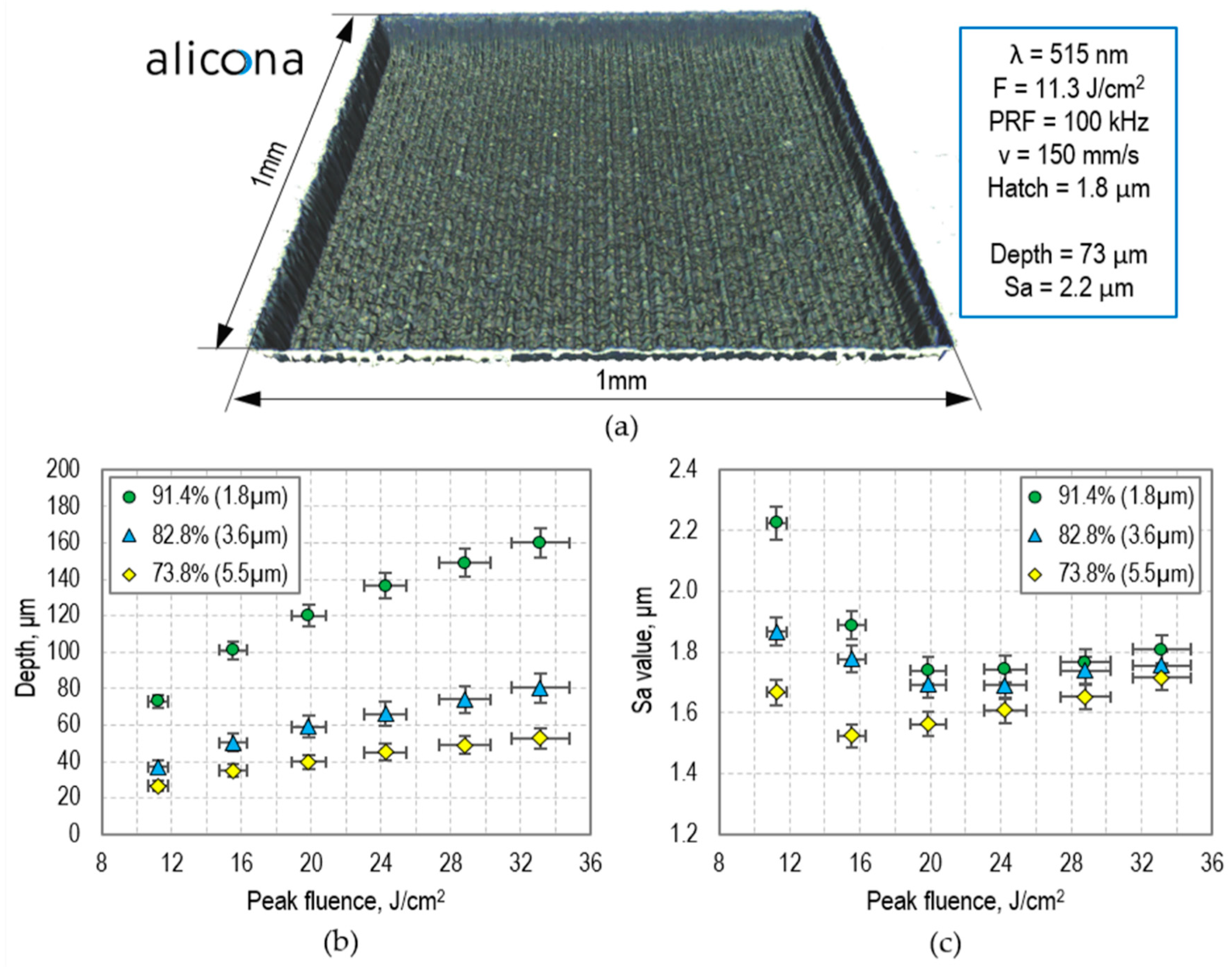

3.1. Calibration of the Laser Micro-Machining Process

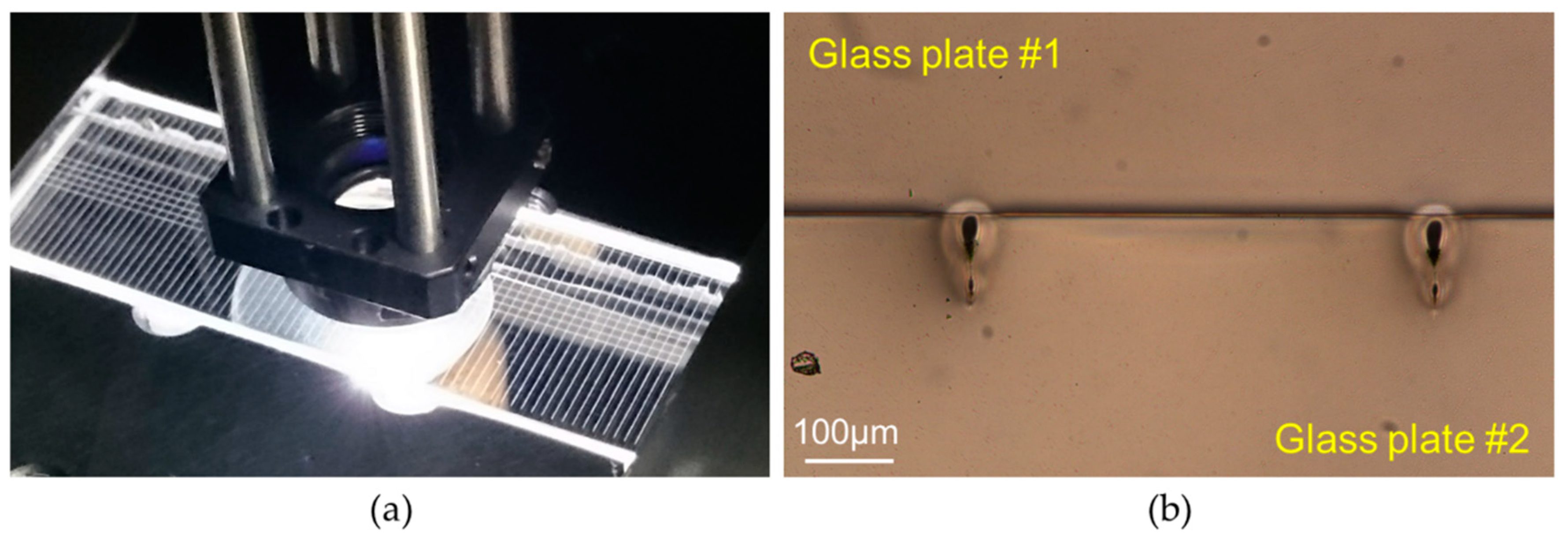

3.2. Calibration of the Laser Microwelding Process

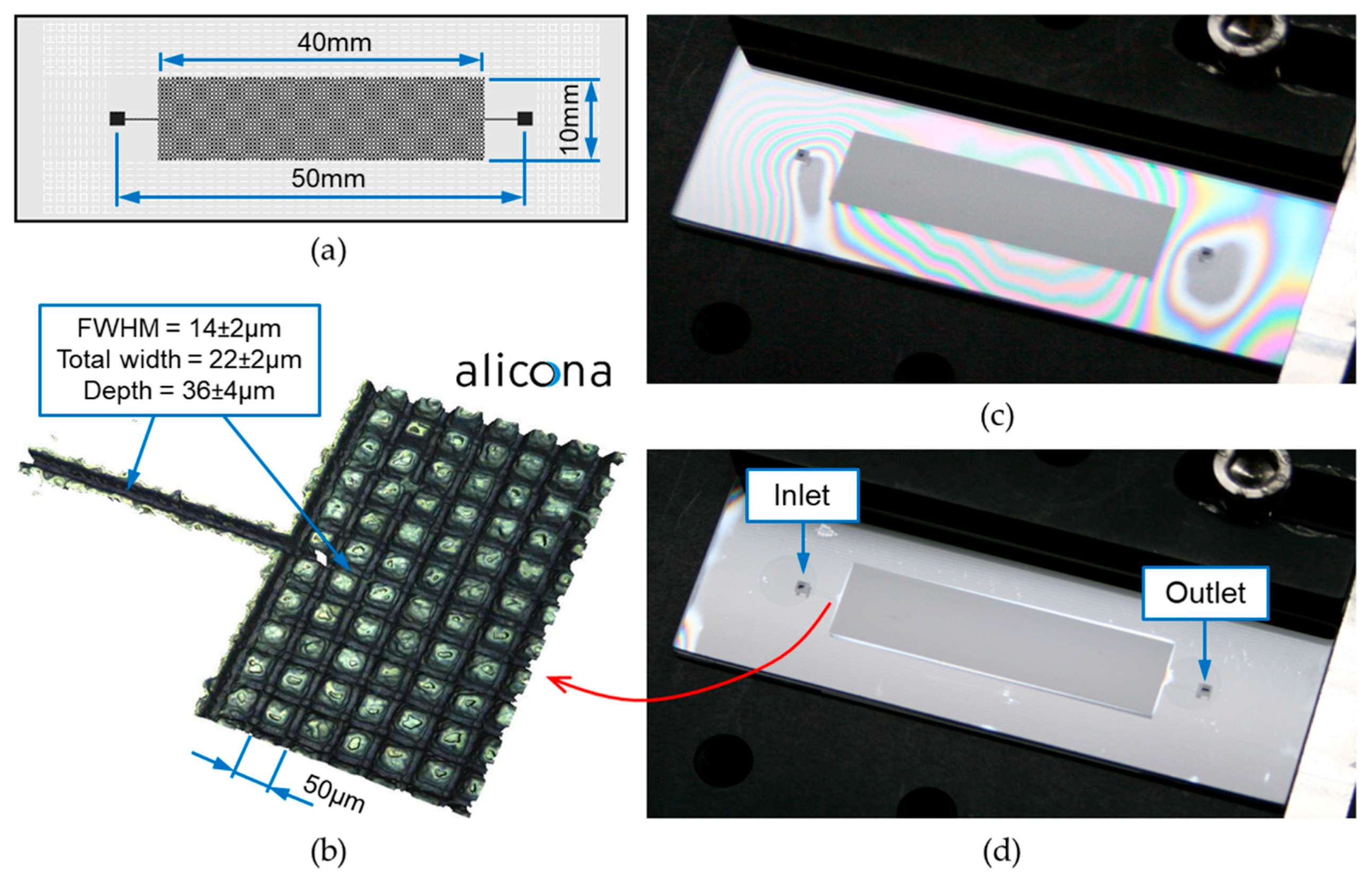

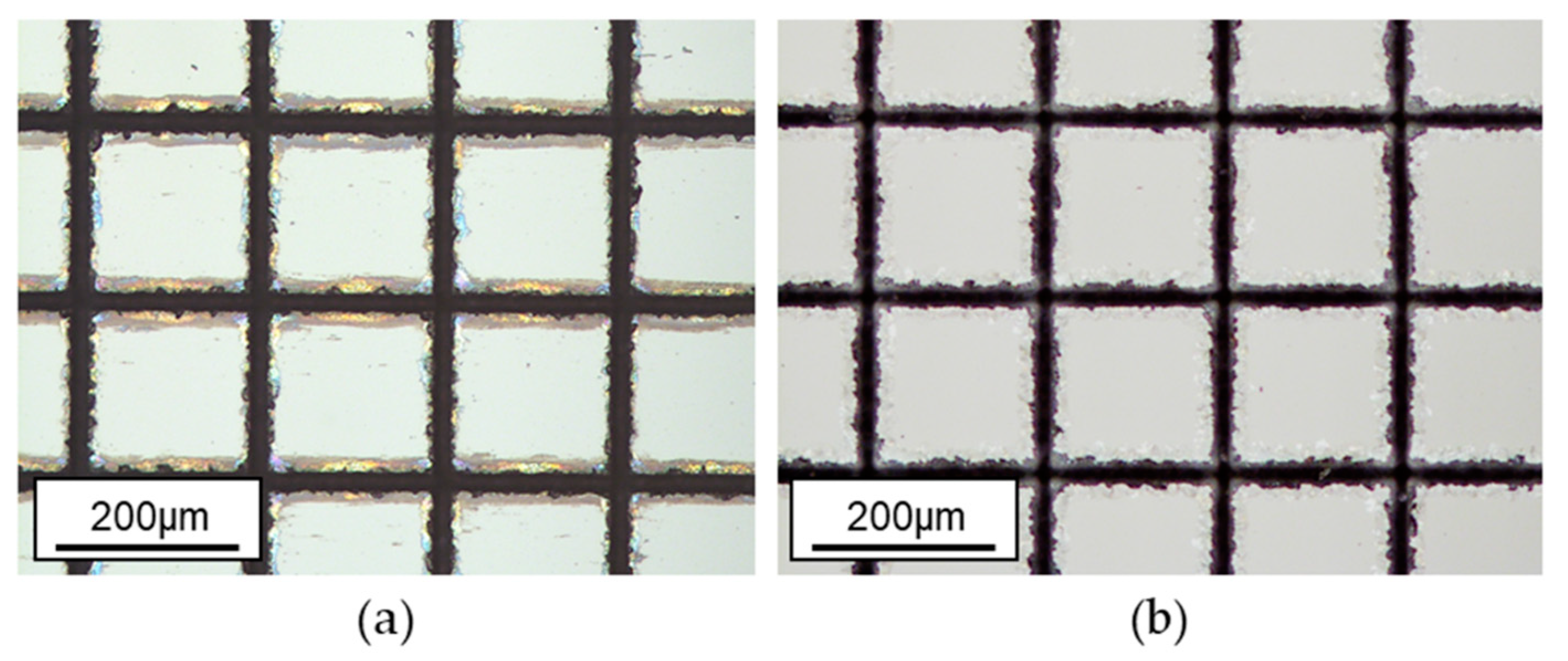

3.3. Manufacturing of Microfluidic Devices

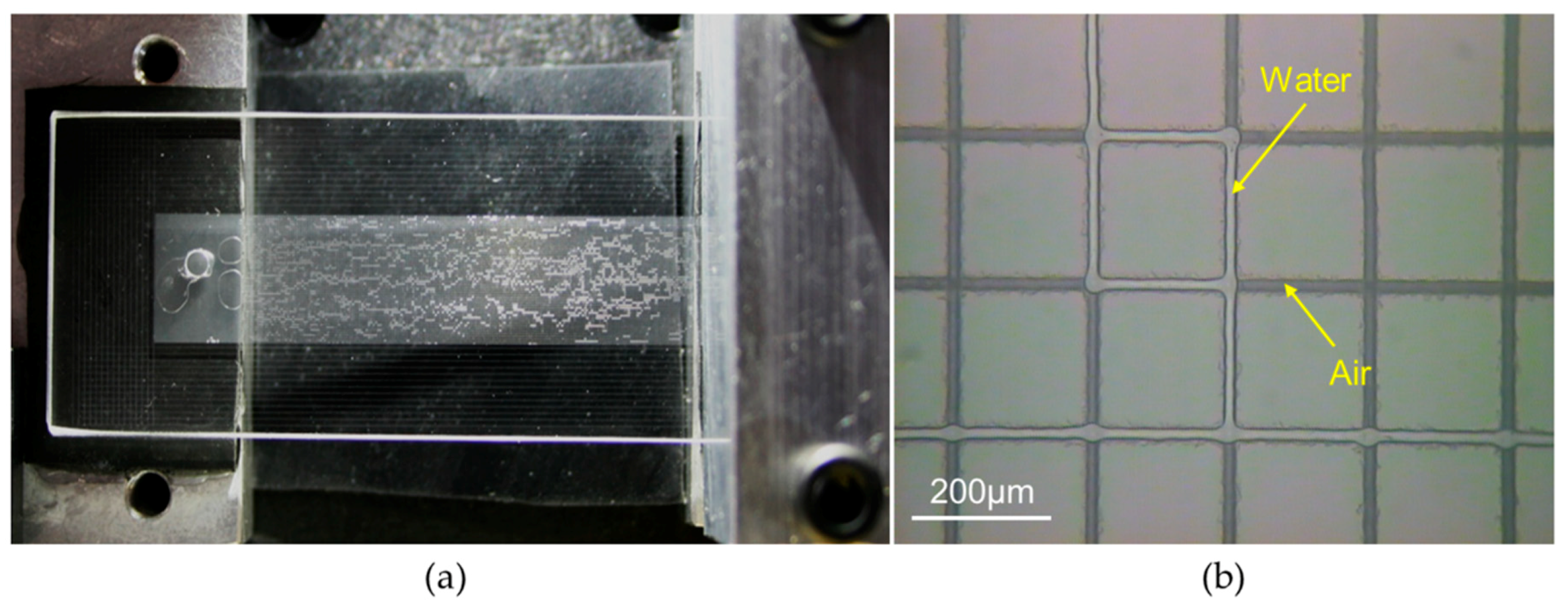

3.4. Fluid Flow Test

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Whitesides, G.M. The origins and the future of microfluidics. Nature 2006, 442, 368–373. [Google Scholar] [CrossRef] [PubMed]

- Sackmann, E.K.; Fulton, A.L.; Beebe, D.J. The present and future role of microfluidics in biomedical research. Nature 2014, 507, 181–189. [Google Scholar] [CrossRef] [PubMed]

- Watanabe, T.; Sassa, F.; Yoshizumi, Y.; Suzuki, H. Review of microfluidic devices for on-chip chemical sensing. Electron. Commun. Jpn. 2017, 100, 25–32. [Google Scholar] [CrossRef]

- Weibel, D.B.; Whitesides, G.M. Applications of microfluidics in chemical biology. Curr. Opin. Chem. Biol. 2006, 10, 584–591. [Google Scholar] [CrossRef] [PubMed]

- Riahi, R.; Tamayol, A.; Shaegh, S.A.M.; Ghaemmaghami, A.M.; Dokmeci, M.R.; Khademshosseini, A. Microfluidics for advanced drug delivery systems. Curr. Opin. Chem. Eng. 2015, 7, 101–112. [Google Scholar] [CrossRef]

- Nan, L.; Jiang, Z.; Wei, X. Emerging microfluidic devices for cell lysis: A review. Lab Chip 2014, 14, 1060–1073. [Google Scholar] [CrossRef] [PubMed]

- Faustino, V.; Catarino, S.O.; Lima, R.; Minas, G. Biomedical microfluidic devices by using low-cost fabrication techniques: A review. J. Biomech. 2016, 49, 2280–2292. [Google Scholar] [CrossRef] [PubMed]

- Bruijns, B.; van Asten, A.; Tiggelaar, R.; Gardeniers, H. Microfluidic devices for forensic DNA analysis: A review. Biosensors 2016, 6, 41. [Google Scholar] [CrossRef] [PubMed]

- Sajeesh, P.; Sen, A.K. Particle separation and sorting in microfluidic devices: A review. Microfluid. Nanofluid. 2014, 17, 1–52. [Google Scholar] [CrossRef]

- Karadimitriou, N.K.; Hassanizadeh, S.M. A review of micromodels and their use in two-phase flow studies. Vadose Zone J. 2012, 11. [Google Scholar] [CrossRef]

- Tsakiroglou, C.; Vizika-Kavvadias, O.; Lenormand, R. Use of Micromodels to Study Multiphase Flow in Porous Media. Available online: http://www.jgmaas.com/SCA/2013/SCA2013-038.pdf (accessed on 15 August 2018).

- Riazi, M.; Sohrabi, M.; Bernstone, C.; Jamiolahmady, M.; Ireland, S. Visualisation of mechanisms involved in CO2 injection and storage in hydrocarbon reservoirsand water-bearing aquifers. Chem. Eng. Res. Des. 2011, 89, 1827–1840. [Google Scholar] [CrossRef]

- Hu, R.; Wan, J.; Kim, Y.; Tokunaga, T.K. Wettability effects on supercritical CO2–brine immiscible displacement during drainage: Pore-scale observation and 3D simulation. Int. J. Greenh. Gas Contorl 2017, 60, 129–139. [Google Scholar] [CrossRef]

- Kim, Y.; Wan, J.; Kneafsey, T.J.; Tokunaga, T.K. Dewetting of silica surfaces upon reactions with supercritical CO2 and brine: Pore-scale studies in micromodels. Environ. Sci. Technol. 2012, 46, 4228–4235. [Google Scholar] [CrossRef] [PubMed]

- Bahralolom, I.M.; Bretz, R.E.; Orr, F.M. Experimental investigation of the interaction of phase behavior with microscopic heterogeneity in a CO2 flood. SPE Reserv. Eng. 1988, 3, 662–672. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, C.; Wei, N.; Oostrom, M.; Wietsma, T.W.; Li, X.; Bonneville, A. Experimental study of crossover from capillary to viscous fingering for supercritical CO2–water displacement in a homogeneous pore network. Environ. Sci. Technol. 2013, 47, 212–218. [Google Scholar] [CrossRef] [PubMed]

- Campbell, B.T.; Orr, F.M. Flow visualization for CO2/crude-oil displacements. Soc. Pet. Eng. J. 1985, 25, 665–678. [Google Scholar] [CrossRef]

- Van Dijke, M.I.J.; Sorbie, K.S.; Sohrabi, M.; Danesh, A. Simulation of WAG floods in an oil-wet micromodel using a 2-D pore-scale network model. J. Pet. Sci. Eng. 2006, 52, 71–86. [Google Scholar] [CrossRef]

- Sohrabi, M.; Danesh, A.; Tehrani, D.H.; Jamiolahmady, M. Microscopic mechanisms of oil recovery by near-miscible gas injection. Transp. Porous Media 2008, 72, 351–367. [Google Scholar] [CrossRef]

- Sohrabi, M.; Danesh, A.; Jamiolahmady, M. Visualisation of residual oil recovery by near-miscible gas and SWAG injection using high-pressure micromodels. Transp. Porous Media 2008, 74, 239–257. [Google Scholar] [CrossRef]

- Oostrom, M.; Mehmani, Y.; Romero-Gomez, P.; Tang, Y.; Liu, H.; Yoon, H.; Kang, Q.; Joekar-Niasar, V.; Balhoff, M.T.; Dewers, T.; et al. Pore-scale and continuum simulations of solute transport micromodel benchmark experiments. Comput. Geosci. 2016, 20, 857–879. [Google Scholar] [CrossRef]

- Goldenberg, L.C.; Hutcheon, I.; Wardlaw, N. Experiments on transport of hydrophobic particles and gas bubbles in porous media. Transp. Porous Media 1989, 4, 129–145. [Google Scholar] [CrossRef]

- Leester-Schädel, M.; Lorenz, T.; Jürgens, F.; Richter, C. Fabrication of microfluidic devices. In Microsystems for Pharmatechnology; Dietzel, A., Ed.; Springer: New York, NY, USA, 2016; pp. 23–57. [Google Scholar]

- Iliescu, C.; Taylor, H.; Avram, M.; Miao, J.; Franssila, S. A practical guide for the fabrication of microfluidic devices using glass and silicon. Biomicrofluidics 2012, 6, 016505. [Google Scholar] [CrossRef] [PubMed]

- Queste, S.; Salut, R.; Clatot, S.; Rauch, J.-Y.; Khan Malek, C.G. Manufacture of microfluidic glass chips by deep plasma etching, femtosecond laser ablation, and anodic bonding. Microsyst. Technol. 2010, 16, 1485–1493. [Google Scholar] [CrossRef]

- Khan Malek, C.G. Laser processing for bio-microfluidics applications (part I). Anal. Bioanal. Chem. 2006, 385, 1351–1361. [Google Scholar] [CrossRef] [PubMed]

- Khan Malek, C.G. Laser processing for bio-microfluidics applications (part II). Anal. Bioanal. Chem. 2006, 385, 1362–1369. [Google Scholar] [CrossRef] [PubMed]

- Yen, M.-H.; Cheng, J.-Y.; Wei, C.-W.; Chuang, Y.-C.; Young, T.-H. Rapid cell-patterning and microfluidic chip fabrication by crack-free CO2 laser ablation on glass. J. Micromech. Microeng. 2006, 16, 1143–1153. [Google Scholar] [CrossRef]

- Nikumb, S.; Chen, Q.; Li, C.; Reshef, H.; Zheng, H.Y.; Qiu, H.; Low, D. Precision glass machining, drilling and profile cutting by short pulse lasers. Thin Solid Films 2005, 477, 216–221. [Google Scholar] [CrossRef]

- Darvishi, S.; Cubaud, T.; Longtin, J.P. Ultrafast laser machining of tapered microchannels in glass and PDMS. Opt. Laser. Eng. 2012, 50, 210–214. [Google Scholar] [CrossRef]

- Fu, L.-M.; Ju, W.-J.; Yang, R.-J.; Wang, Y.-N. Rapid prototyping of glass-based microfluidic chips utilizing two-pass defocused CO2 laser beam method. Microfluid. Nanofluid. 2013, 14, 479–487. [Google Scholar] [CrossRef]

- Gomez, D.; Goenaga, I.; Lizuain, I.; Ozaita, M. Femtosecond laser ablation for microfluidics. Opt. Eng. 2005, 44, 051105. [Google Scholar] [CrossRef]

- Sugioka, K.; Cheng, Y. Fabrication of 3D microfluidic structures inside glass by femtosecond laser micromachining. Appl. Phys. A 2014, 114, 215–221. [Google Scholar] [CrossRef]

- Serhatlioglu, M.; Ortaç, B.; Elbuken, C.; Biyikli, N.; Solmaz, M.E. CO2 laser polishing of microfluidic channels fabricated by femtosecond laser assisted carving. J. Micromech. Microeng. 2016, 26, 115011. [Google Scholar] [CrossRef]

- Bellouard, Y.; Said, A.; Dugan, M.; Bado, P. Fabrication of high-aspect ratio, micro-fluidic channels and tunnels using femtosecond laser pulses and chemical etching. Opt. Express 2004, 12, 2120–2129. [Google Scholar] [CrossRef] [PubMed]

- Matsuo, S.; Sumi, H.; Kiyama, S.; Tomita, T.; Hashimoto, S. Femtosecond laser-assisted etching of Pyrex glass with aqueous solution of KOH. Appl. Surf. Sci. 2009, 255, 9758–9760. [Google Scholar] [CrossRef]

- Gottmann, J.; Hermans, M.; Ortmann, J. Digital photonic production of micro structures in glass by in-volume selective laser-induced etching using a high speed micro scanner. Phys. Procedia 2012, 39, 534–541. [Google Scholar] [CrossRef]

- Gottmann, J.; Hermans, M.; Repiev, N.; Ortmann, J. Selective laser-induced etching of 3D precision quartz glass components for microfluidic applications—Up-scaling of complexity and speed. Micromachines 2017, 8. [Google Scholar] [CrossRef]

- Wlodarczyk, K.L.; MacPherson, W.M.; Hand, D.P. Laser Processing of Borofloat®33 Glass. Available online: https://researchportal.hw.ac.uk/en/publications/laser-processing-of-borofloat33-glass (accessed on 15 August 2018).

- Wlodarczyk, K.L.; Brunton, A.; Rumsby, P.; Hand, D.P. Picosecond laser cutting and drilling of thin flex glass. Opt. Lasers Eng. 2016, 78, 64–74. [Google Scholar] [CrossRef]

- Carter, R.M.; Chen, J.; Shephard, J.D.; Thomson, R.R.; Hand, D.P. Picosecond laser welding of similar and dissimilar materials. Appl. Opt. 2014, 53, 4233–4238. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Carter, R.M.; Thomson, R.R.; Hand, D.P. Avoiding the requirement for pre-existing optical contact during picosecond laser glass-to-glass welding. Opt. Express 2015, 23, 18645–18657. [Google Scholar] [CrossRef] [PubMed]

- Borofloat®33—Borosilicate Glass. Available online: https://www.schott.com/borofloat/english/ (accessed on 11 Jun 2018).

- Rabbani, H.S.; Or, D.; Liu, Y.; Lai, C.-Y.; Lu, N.B.; Datta, S.S.; Stone, H.A.; Shokri, N. Suppressing viscous fingering in structured porous media. Proc. Natl. Acad. Sci. USA 2018, 115, 4833–4838. [Google Scholar] [CrossRef] [PubMed]

| Wavelength (nm) | P (W) | Ep (μJ) | 2 ω0 (μm) | M2 (value) | F (J/cm2) 1 |

|---|---|---|---|---|---|

| 1030 | 50 | 125 | 35 ± 1 | 1.3 ± 0.1 | 26.0 ± 1.5 |

| 515 | 30 | 75 | 21 ± 1 | 1.4 ± 0.1 | 36.3 ± 3.5 |

| 343 | 18 | 45 | 20 ± 1 | 2.1 ± 0.1 | 28.9 ± 2.9 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wlodarczyk, K.L.; Carter, R.M.; Jahanbakhsh, A.; Lopes, A.A.; Mackenzie, M.D.; Maier, R.R.J.; Hand, D.P.; Maroto-Valer, M.M. Rapid Laser Manufacturing of Microfluidic Devices from Glass Substrates. Micromachines 2018, 9, 409. https://doi.org/10.3390/mi9080409

Wlodarczyk KL, Carter RM, Jahanbakhsh A, Lopes AA, Mackenzie MD, Maier RRJ, Hand DP, Maroto-Valer MM. Rapid Laser Manufacturing of Microfluidic Devices from Glass Substrates. Micromachines. 2018; 9(8):409. https://doi.org/10.3390/mi9080409

Chicago/Turabian StyleWlodarczyk, Krystian L., Richard M. Carter, Amir Jahanbakhsh, Amiel A. Lopes, Mark D. Mackenzie, Robert R. J. Maier, Duncan P. Hand, and M. Mercedes Maroto-Valer. 2018. "Rapid Laser Manufacturing of Microfluidic Devices from Glass Substrates" Micromachines 9, no. 8: 409. https://doi.org/10.3390/mi9080409

APA StyleWlodarczyk, K. L., Carter, R. M., Jahanbakhsh, A., Lopes, A. A., Mackenzie, M. D., Maier, R. R. J., Hand, D. P., & Maroto-Valer, M. M. (2018). Rapid Laser Manufacturing of Microfluidic Devices from Glass Substrates. Micromachines, 9(8), 409. https://doi.org/10.3390/mi9080409