Development of a Thermoelectric and Electromagnetic Hybrid Energy Harvester from Water Flow in an Irrigation System

Abstract

1. Introduction

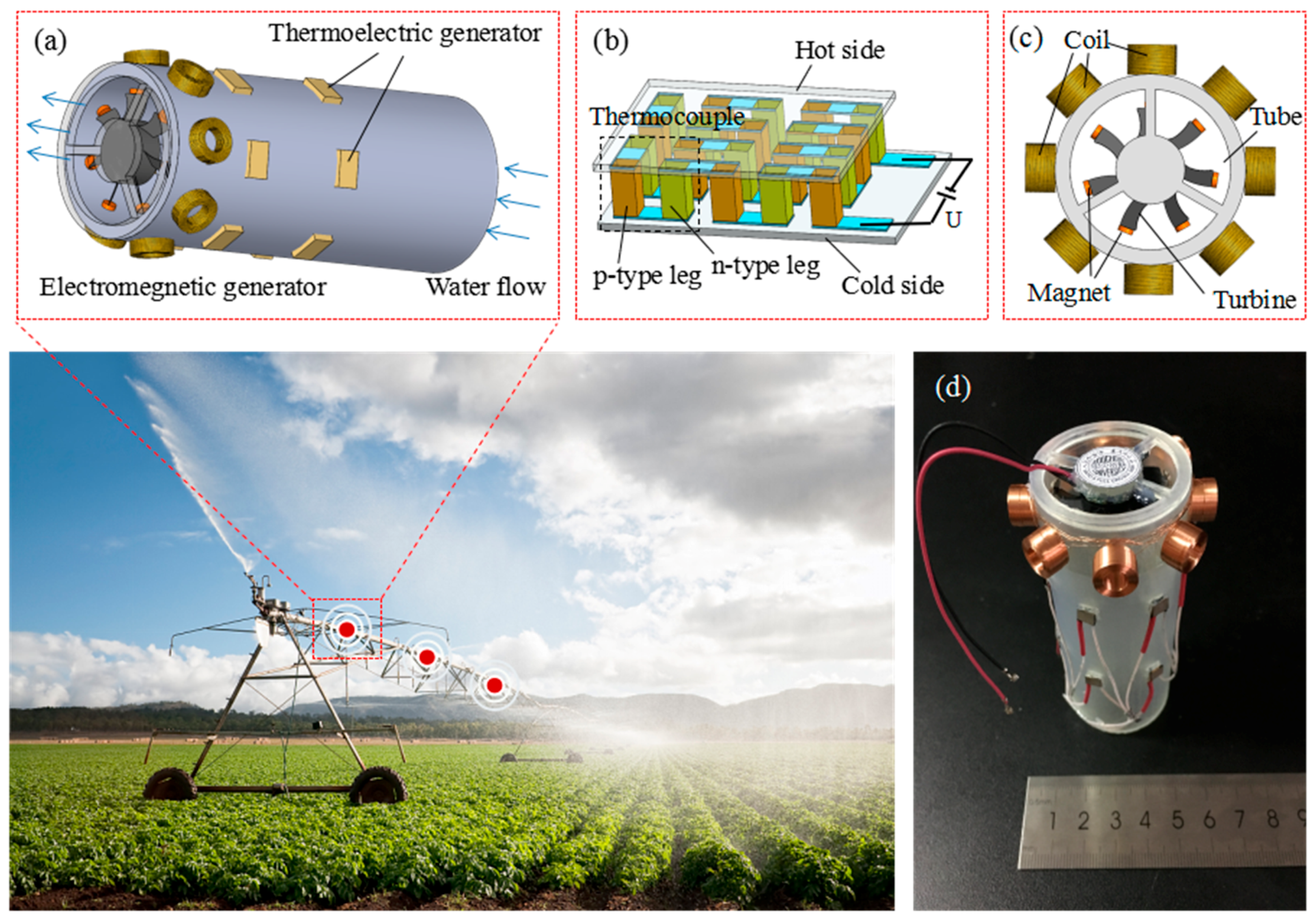

2. Design and Fabrication

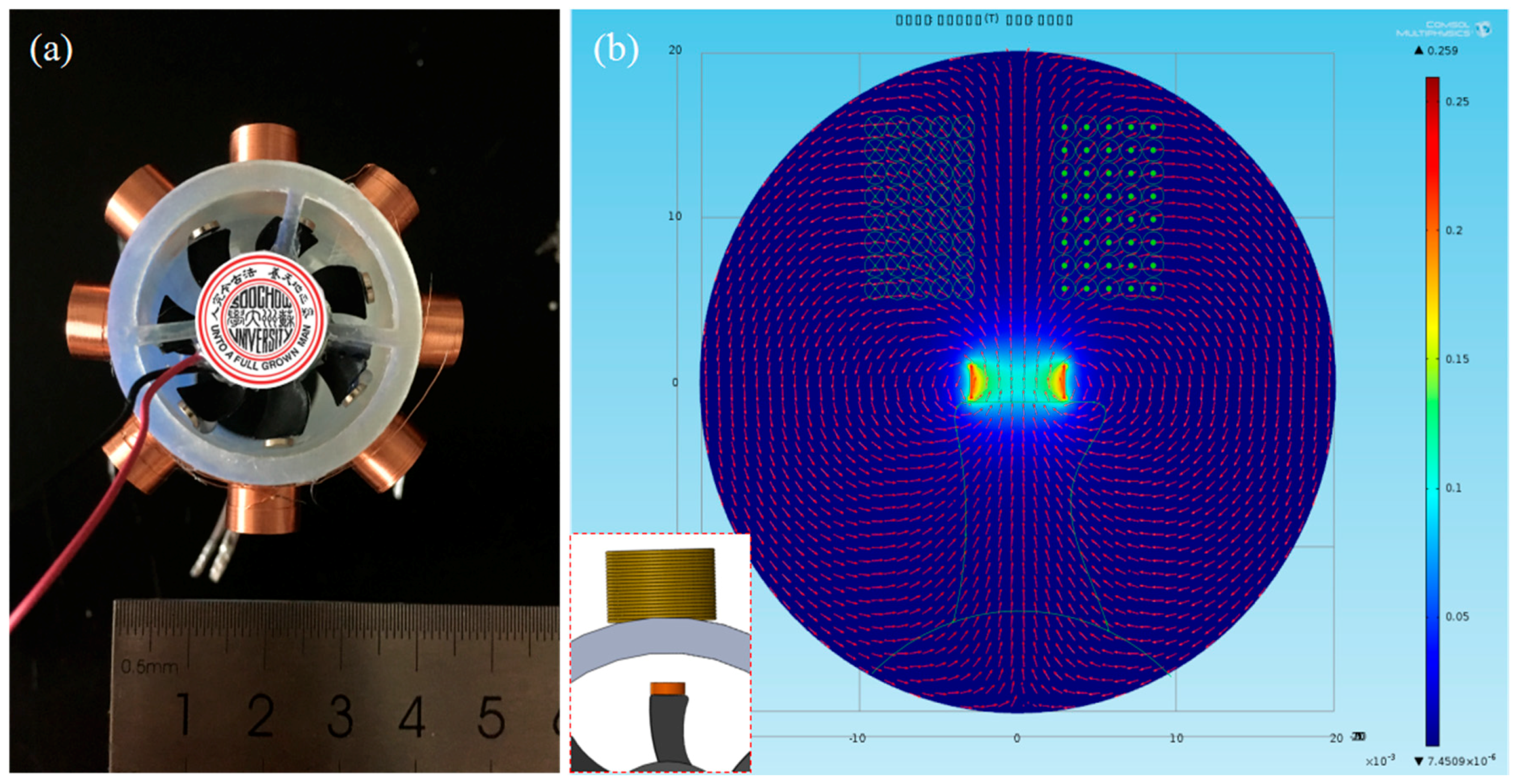

3. Working Principle and Simulation

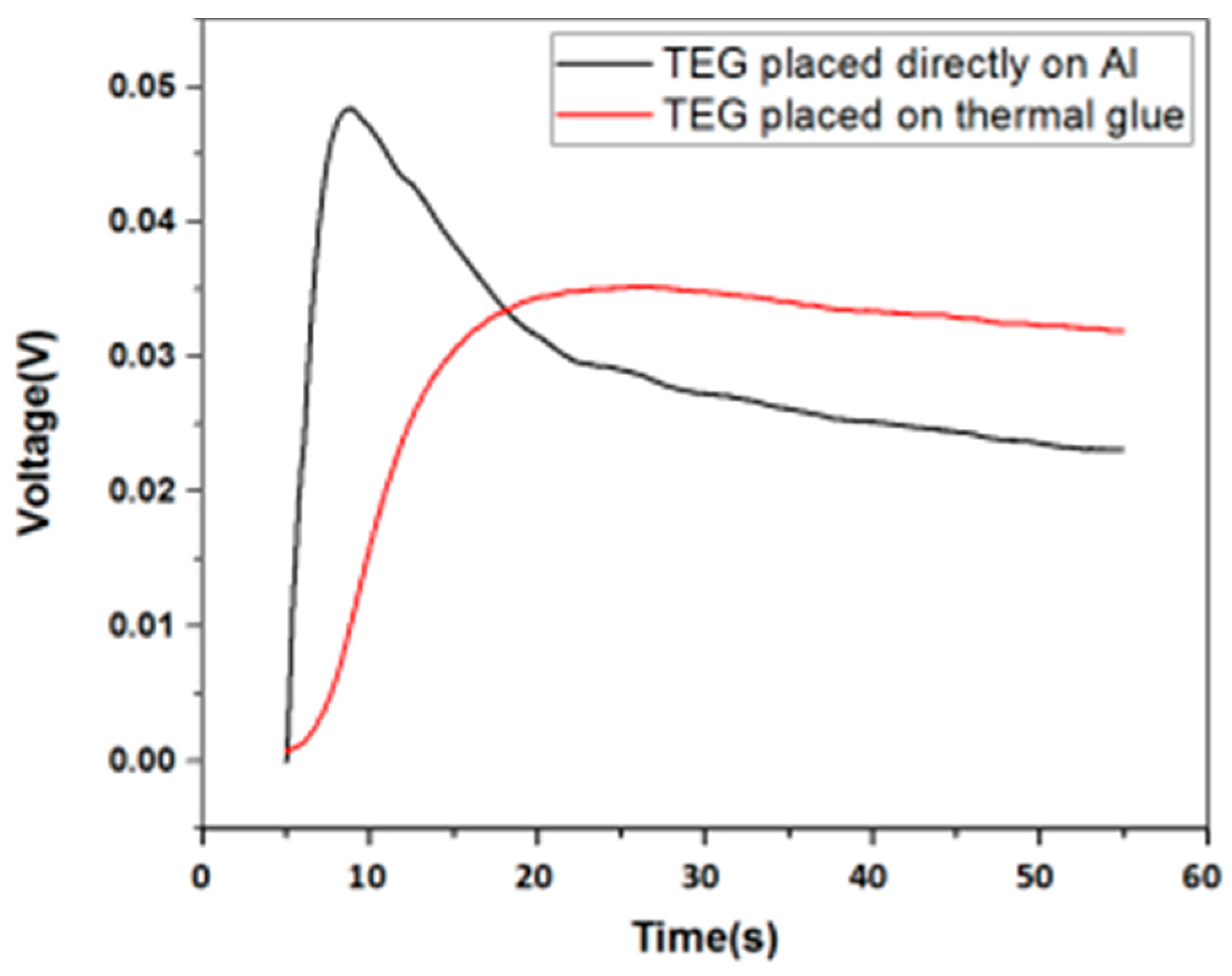

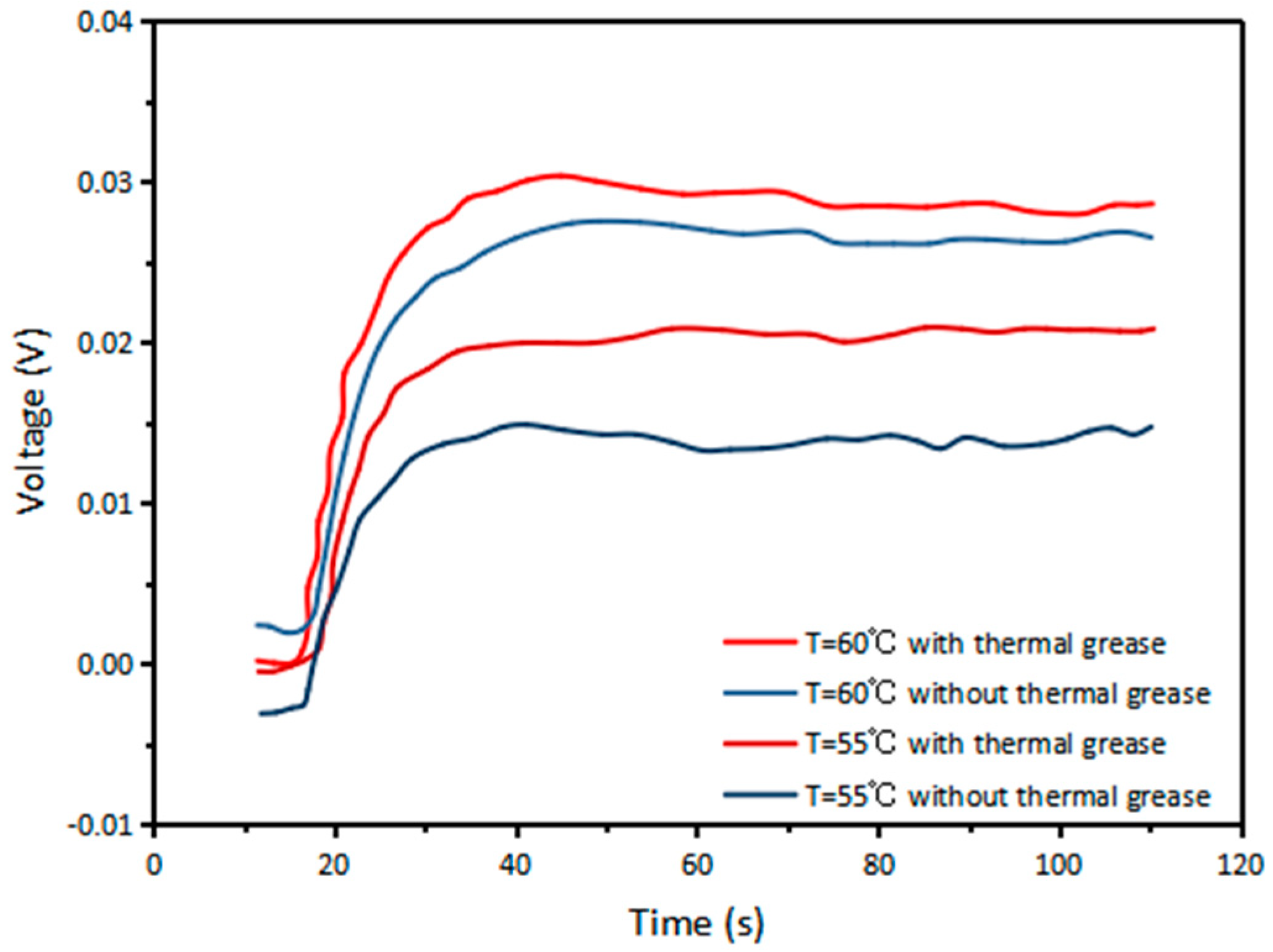

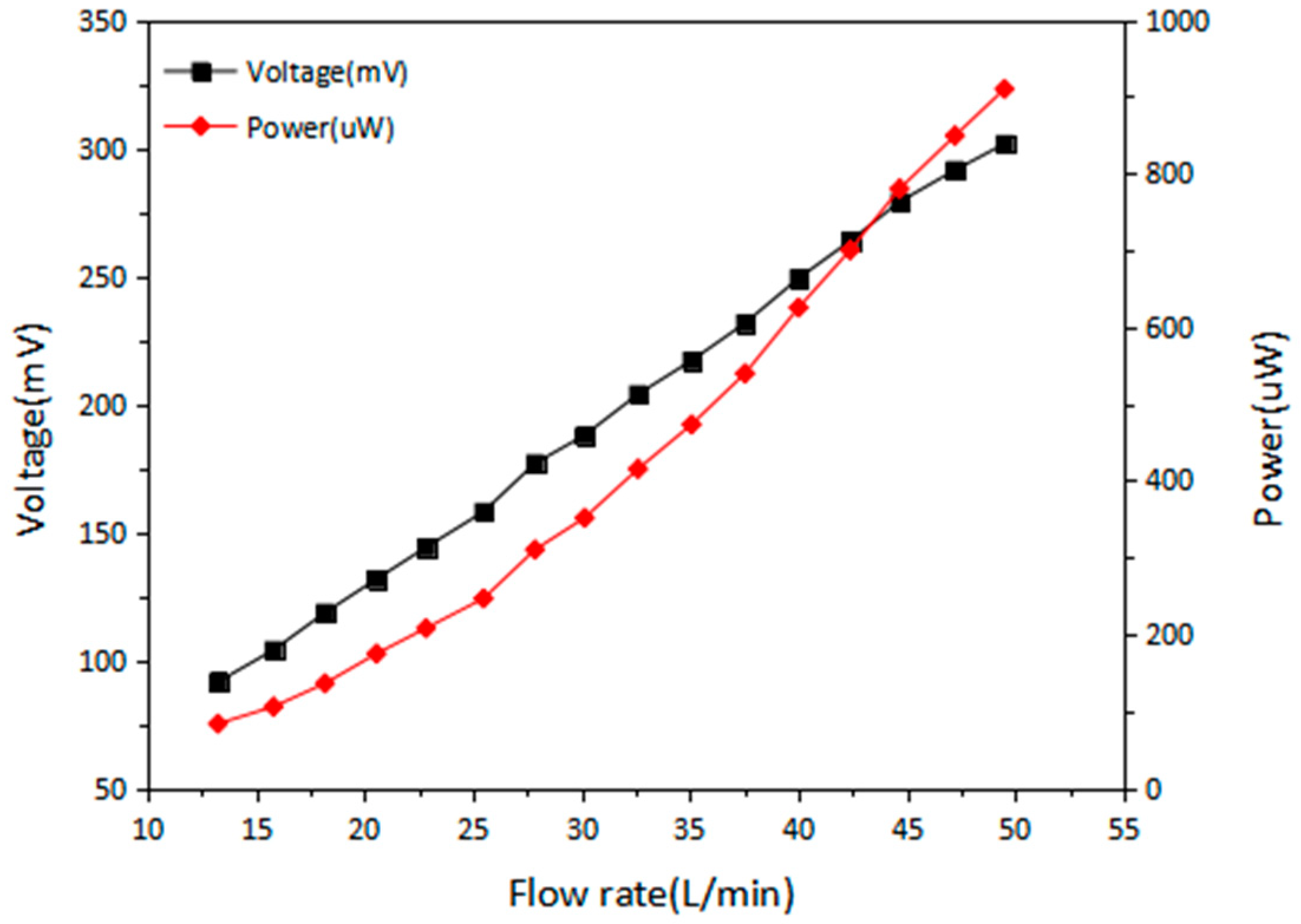

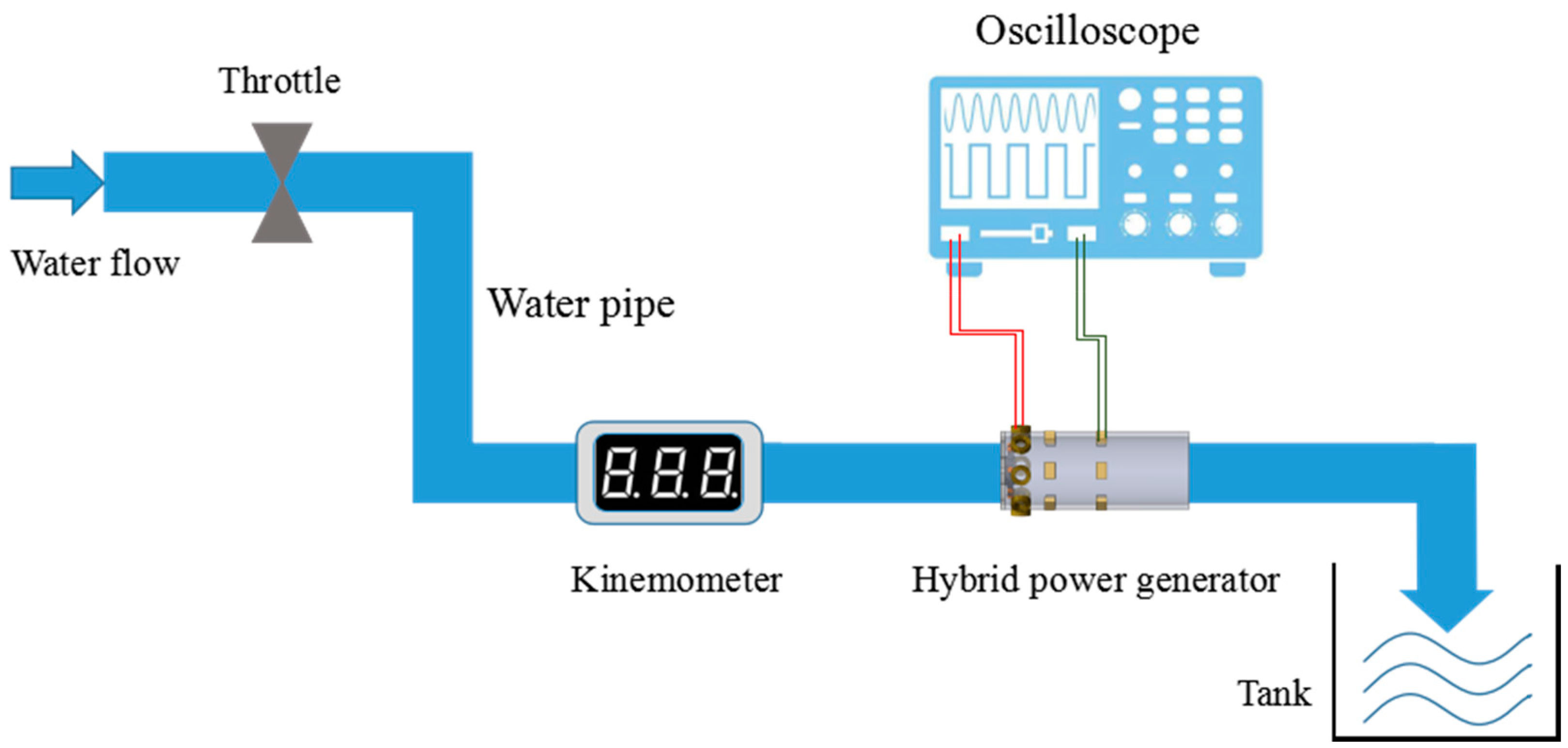

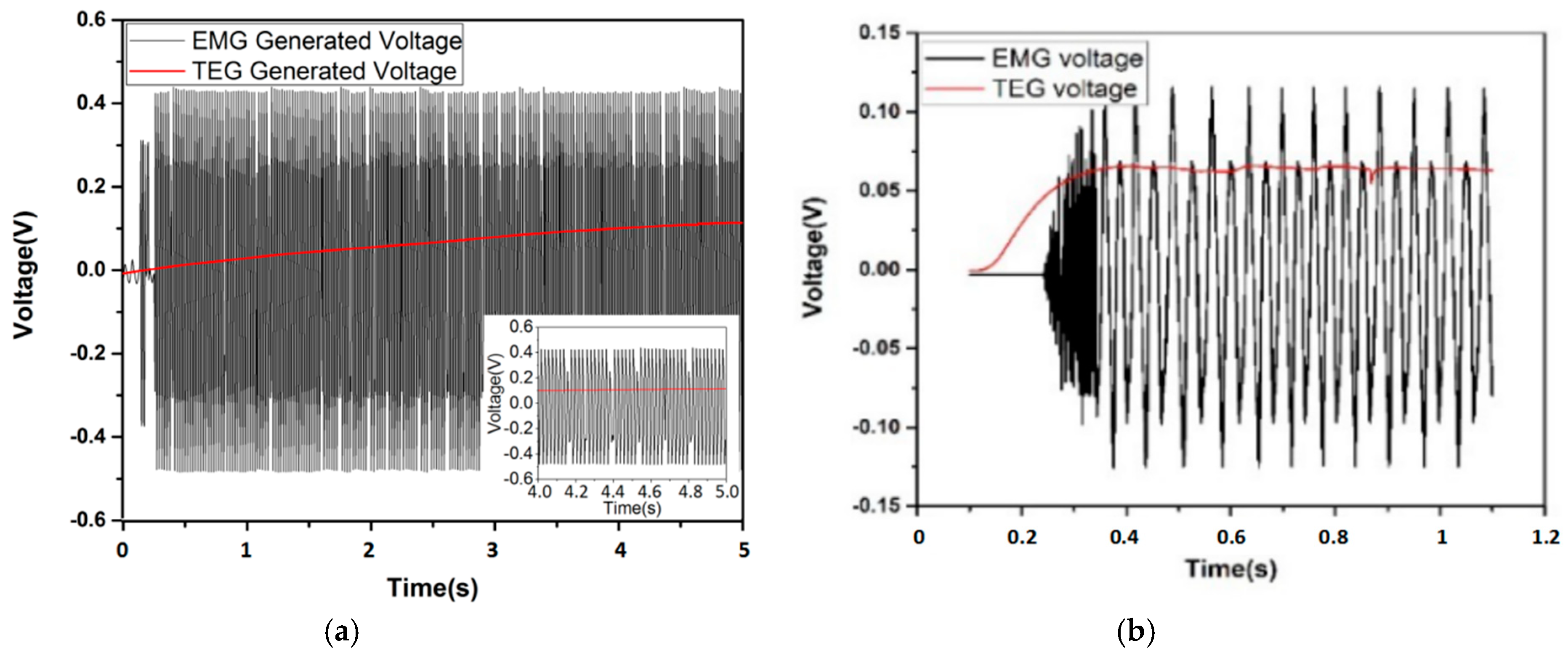

4. Experiment and Optimization

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Li, W. Design of wireless water-saving irrigation system based on solar energy. In Proceedings of the 2011 International Conference on Control, Automation and Systems Engineering (CASE), Singapore, 30–31 July 2011. [Google Scholar]

- Mitralexis, G.; Goumopoulos, C. Web based monitoring and irrigation system with energy autonomous wireless sensor network for precision agriculture. In Proceedings of the 2015 European Conference on Ambient Intelligence, Athens, Greek, 11–13 November 2015; pp. 361–370. [Google Scholar]

- Yang, S.M.; Lee, T.; Cong, M. Design and verification of a thermoelectric energy harvester with stacked polysilicon thermocouples by CMOS process. Sens. Actuators A Phys. 2010, 157, 258–266. [Google Scholar] [CrossRef]

- Wan, Q.; Teh, Y.K.; Gao, Y.; Mok, P.K. Analysis and design of a thermoelectric energy harvesting system with reconfigurable array of thermoelectric generators for IoT applications. IEEE Trans. Circuits Sys. I Regul. Pap. 2017, 99, 1–13. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, Y.; Mei, D.; Feng, B.; Chen, Z. Design and fabrication of wearable thermoelectric generator device for heat harvesting. IEEE Robot. Autom. Lett. 2018, 3, 373–378. [Google Scholar] [CrossRef]

- Yun, G.S.; Leong, K.S.; Rahman, M.F.B.A. Development of self-powered thermoelectric based RF transmitter circuit. In Proceedings of the 2016 IEEE International Conference on Power and Energy (PECon), Melaka, Malaysia, 28–29 November 2016; pp. 439–443. [Google Scholar]

- Saida, M.; Zaibi, G.; Samet, M.; Kachouri, A. A new design of thermoelectric generator for health monitoring. In Proceedings of the 2017 International Conference on Smart, Monitored and Controlled Cities (SM2C), Sfax, Tunisia, 17–19 February 2017; pp. 59–63. [Google Scholar]

- Xiong, B.; Chen, L.; Meng, F.; Sun, F. Modeling and performance analysis of a two-stage thermoelectric energy harvesting system from blast furnace slag water waste heat. Energy 2014, 77, 562–569. [Google Scholar] [CrossRef]

- He, W.; Su, Y.; Wang, Y.Q.; Riffat, S.B.; Ji, J. A study on incorporation of thermoelectric modules with evacuated-tube heat-pipe solar collectors. Renew. Energy 2012, 1, 142–149. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, Y.; Cao, Z. Modeling of piezoelectric energy harvesting from freely oscillating cylinders in water flow. Math. Probl. Eng. 2014, 2014, 1–13. [Google Scholar] [CrossRef]

- Molino-Minero-Re, E.; Carbonell-Ventura, M.; Fisac-Fuentes, C.; Mànuel-Làzaro, A.; Toma, D.M. Piezoelectric energy harvesting from induced vortex in water flow. In Proceedings of the 2012 Instrumentation and Measurement Technology Conference, Graz, Austria, 13–16 May 2012; pp. 624–627. [Google Scholar]

- Karami, M.A.; Farmer, J.R.; Inman, D.J. Parametrically excited nonlinear piezoelectric compact wind turbine. Renew. Energy 2013, 50, 977–987. [Google Scholar] [CrossRef]

- Chen, T.; Xia, Y.; Liu, W.; Liu, H.; Sun, L.; Lee, C. A hybrid flapping-blade wind energy harvester based on vortex shedding effect. J. Microelectromech. Syst. 2016, 25, 845–847. [Google Scholar] [CrossRef]

- Boisseau, S.; Duret, A.B.; Perez, M.; Jallas, E.; Jallas, E. Water flow energy harvesters for autonomous flowmeters. J. Phys. Conf. Ser. 2016, 773, 012019. [Google Scholar] [CrossRef]

- Adamski, K.; Adamski, J.; Dziuban, J.A.; Walczak, R. Inkjet 3D printed miniature water turbine as flow meter and energy harvester for wireless sensor system. In Proceedings of the 21st International Conference on Miniaturized Systems for Chemistry and Life Sciences, Savannah, GA, USA, 22–26 October 2017. [Google Scholar]

- Hoffmann, D.; Willmann, A.; Göpfert, R.; Becker, P.; Folkmer, B.; Manoli, Y. Energy harvesting from fluid flow in water pipelines for smart metering applications. J. Phys. Conf. Ser. 2013, 476, 012104. [Google Scholar] [CrossRef]

- Liao, L.D.; Chao, P.C.P.; Chen, J.T.; Chen, W.D.; Hsu, W.H.; Chiu, C.W.; Lin, C.T. A miniaturized electromagnetic generator with planar coils and its energy harvest circuit. IEEE Trans. Magn. 2009, 45, 4621–4627. [Google Scholar] [CrossRef]

- Bansal, A.; Howey, D.A.; Holmes, A.S. Cm-scale air turbine and generator for energy harvesting from low-speed flows. In Proceedings of the 2009 International Solid-State Sensors, Actuators and Microsystems Conference, Denver, CO, USA, 21–25 June 2009; pp. 529–532. [Google Scholar]

- Ahmed, A.; Saadatnia, Z.; Hassan, I.; Zi, Y.; Xi, Y.; He, X.; Zu, J.; Wang, Z. Self-powered wireless sensor node enabled by a duck-shaped triboelectric nanogenerator for harvesting water wave energy. Adv. Energy Mater. 2016, 7, 1601705. [Google Scholar] [CrossRef]

- Xie, Y.; Wang, S.; Lin, L.; Jing, Q.; Lin, Z.H.; Niu, S.; Wu, Z.; Wang, Z. Rotary triboelectric nanogenerator based on a hybridized mechanism for harvesting wind energy. ACS Nano 2013, 7, 7119–7125. [Google Scholar] [CrossRef] [PubMed]

- Cho, J.Y.; Choi, J.Y.; Jeong, S.W.; Ahn, J.H.; Hwang, W.S.; Yoo, H.H.; Sung, T.H. Design of hydro electromagnetic and piezoelectric energy harvesters for a smart water meter system. Sens. Actuators A Phys. 2017, 261, 261–267. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, Y. Design, analysis, and evaluation of a compact electromagnetic energy harvester from water flow for remote sensors. Energies 2018, 11, 1424. [Google Scholar] [CrossRef]

- Alammri, A.S.; Ridah, S. Smart irrigation system using wireless sensor network. Int. J. Eng. Res. Technol. 2014, 3, 2278. [Google Scholar]

- Futagawa, M.; Iwasaki, T.; Murata, H.; Ishida, M.; Sawada, K. A miniature integrated multimodal sensor for measuring pH, EC and temperature for precision agriculture. Sensors 2012, 12, 8338–8354. [Google Scholar] [CrossRef] [PubMed]

- Awu, J.I.; Mbajiorgu, C.C.; Michael, O.; James, D.D.; Anyaeji, F.O.; Willoughby, F.A.; Eneh, C.K. Development of a low cost digital turbine water flow meter for irrigation farm. Int. J. Basic Appl. Sci. 2017, 6, 92–97. [Google Scholar]

- Ihring, A.; Kessler, E.; Dillner, U.; Schinkel, U.; Kunze, M.; Billat, S. A planar thin-film peltier cooler for the thermal management of a dew-point sensor system. J. Microelectromechan. Syst. 2015, 24, 990–996. [Google Scholar] [CrossRef]

- Su, J.; Vullers, R.J.; Goedbloed, M.; van Andel, Y.; Leonov, V.; Wang, Z. Thermoelectric energy harvester fabricated by stepper. Microelectron. Eng. 2010, 87, 1242–1244. [Google Scholar] [CrossRef]

- Kwon, S.D.; Park, J.; Law, K. Electromagnetic energy harvester with repulsively stacked multilayer magnets for low frequency vibrations. Smart Mater. Struct. 2013, 22, 055007. [Google Scholar] [CrossRef]

- Liu, H.; Xia, Y.; Chen, T.; Yang, Z.; Liu, W.; Wang, P.; Sun, L. Study of a hybrid generator based on triboelectric and electromagnetic mechanisms. IEEE Sens. J. 2017, 17, 3853–3860. [Google Scholar] [CrossRef]

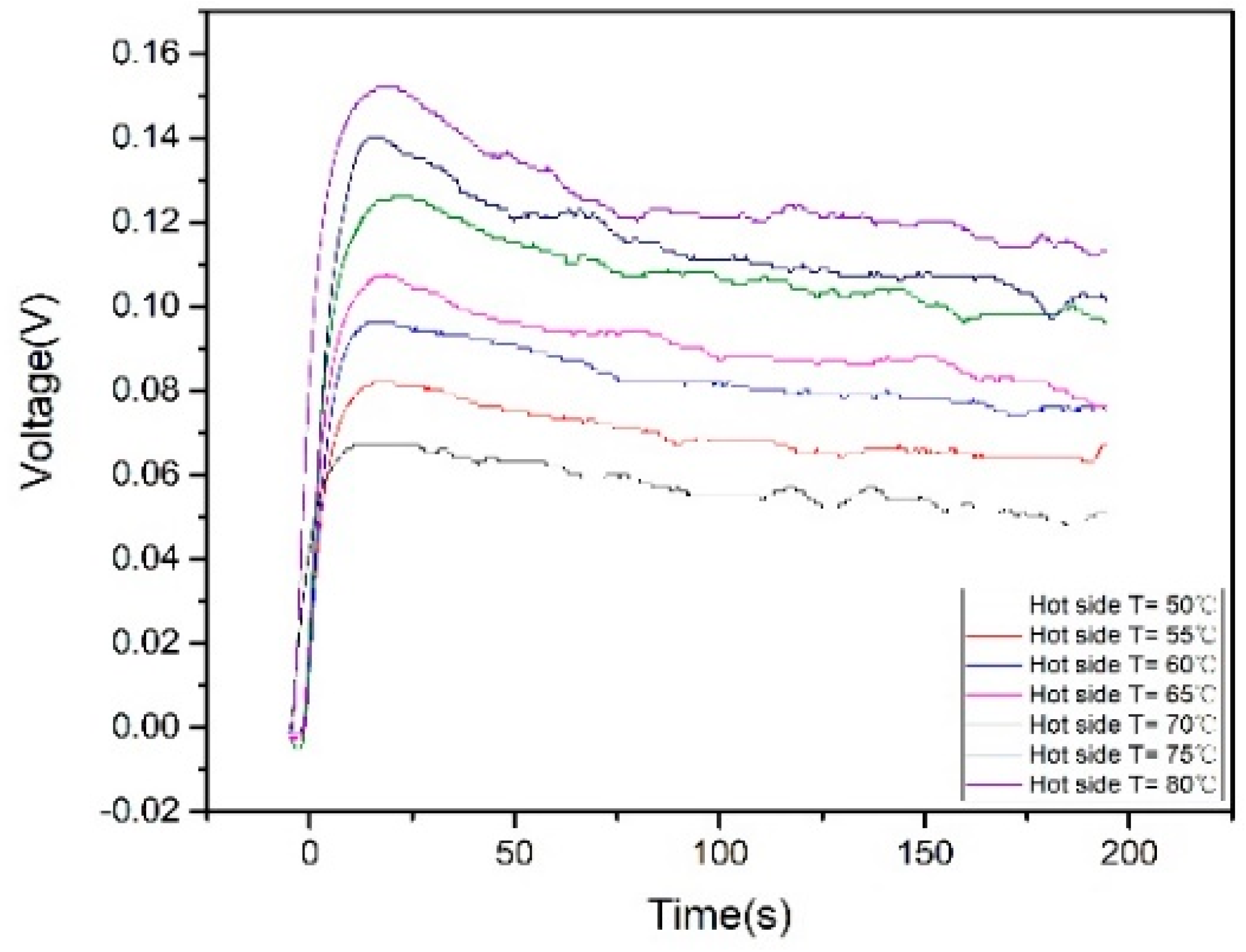

| Hot Side Temperature (°C) | Maximum Open Circuit Voltage (mV) | Voltage after 200 s (mV) | Percentage |

|---|---|---|---|

| 80 | 155 | 114.025 | 73.56% |

| 75 | 147 | 109.225 | 74.30% |

| 70 | 131 | 102.275 | 78.07% |

| 65 | 110 | 83.15 | 75.59% |

| 60 | 97 | 77.375 | 79.77% |

| 55 | 86 | 69.025 | 80.20% |

| 50 | 69 | 53.75 | 77.90% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Zhang, J.; Shi, Q.; He, T.; Chen, T.; Sun, L.; Dziuban, J.A.; Lee, C. Development of a Thermoelectric and Electromagnetic Hybrid Energy Harvester from Water Flow in an Irrigation System. Micromachines 2018, 9, 395. https://doi.org/10.3390/mi9080395

Liu H, Zhang J, Shi Q, He T, Chen T, Sun L, Dziuban JA, Lee C. Development of a Thermoelectric and Electromagnetic Hybrid Energy Harvester from Water Flow in an Irrigation System. Micromachines. 2018; 9(8):395. https://doi.org/10.3390/mi9080395

Chicago/Turabian StyleLiu, Huicong, Jiankang Zhang, Qiongfeng Shi, Tianyiyi He, Tao Chen, Lining Sun, Jan A Dziuban, and Chengkuo Lee. 2018. "Development of a Thermoelectric and Electromagnetic Hybrid Energy Harvester from Water Flow in an Irrigation System" Micromachines 9, no. 8: 395. https://doi.org/10.3390/mi9080395

APA StyleLiu, H., Zhang, J., Shi, Q., He, T., Chen, T., Sun, L., Dziuban, J. A., & Lee, C. (2018). Development of a Thermoelectric and Electromagnetic Hybrid Energy Harvester from Water Flow in an Irrigation System. Micromachines, 9(8), 395. https://doi.org/10.3390/mi9080395