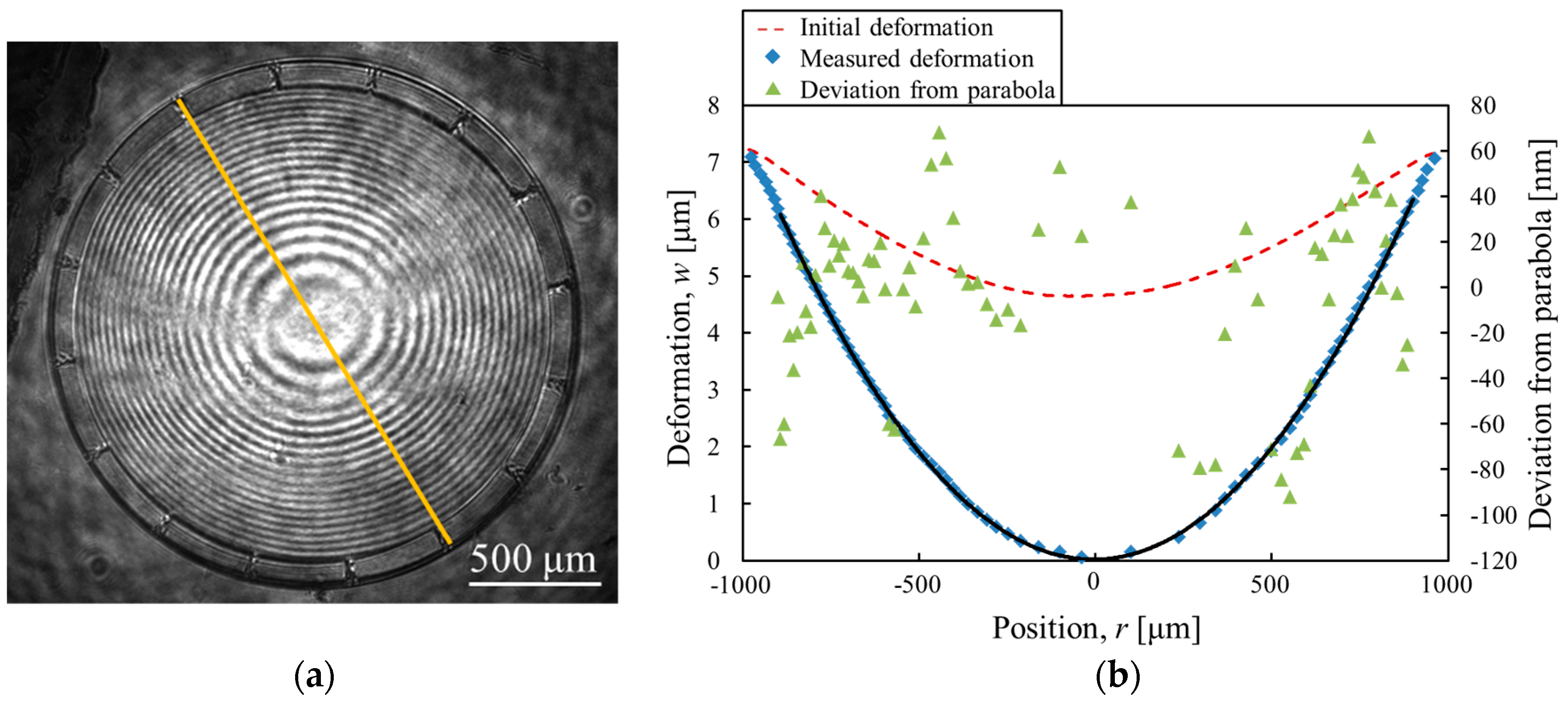

4.2. Mirror Characteristics

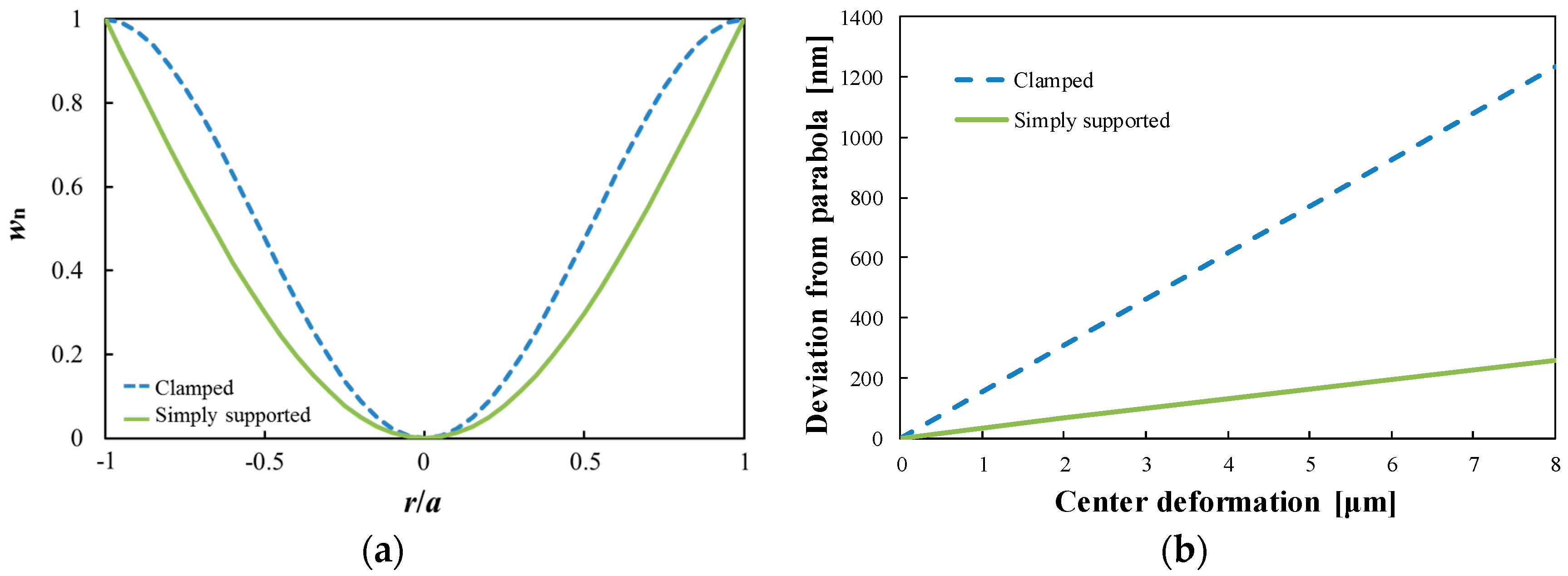

For the optical systems, the high surface precision of the varifocal mirror is required. To estimate the surface precision, the surface profile of the mirror is measured.

Figure 8a shows the interference image from the stroboscopic interferometer at maximum oscillation amplitude at the voltage of 15

VDC + 30

VPP and the frequency of 9.5 kHz. The clear concentric fringes are seen in

Figure 8a. In

Figure 8b, the deformation of the mirror along the line shown in

Figure 8a is plotted. The fitting curve is given by an equation

w = 7.71 × 10

−6r2 + 8.35 × 10

−5r + 1.83 × 10

−2, where

w (in micrometers) is the deformation as a function of the radius

r (in micrometers). The initial deformation of the mirror plate is also measured by a white light interferometer (MSA500, Polytec GmbH, Waldbronn, Germany) as shown in

Figure 8b. The center deformation of the varifocal mirror is 7.3 μm in this condition. The deviation from the fitted parabola in the region |

r| < 0.8

a is also shown in

Figure 8b. The deviation from the parabola is within 150 nm. Considering the He-Ne laser wavelength (λ

He-Ne = 633 nm), the surface precision less than λ

He-Ne/4 is obtained. From the theoretical analysis shown in

Figure 3, the deviation from parabola is within 240 nm at the center deformation of 7.3 μm in the simply supported condition. The mirror surface precision of the experimental results is a little better than the theoretical results since the initial deformation may affects the dynamical surface profile.

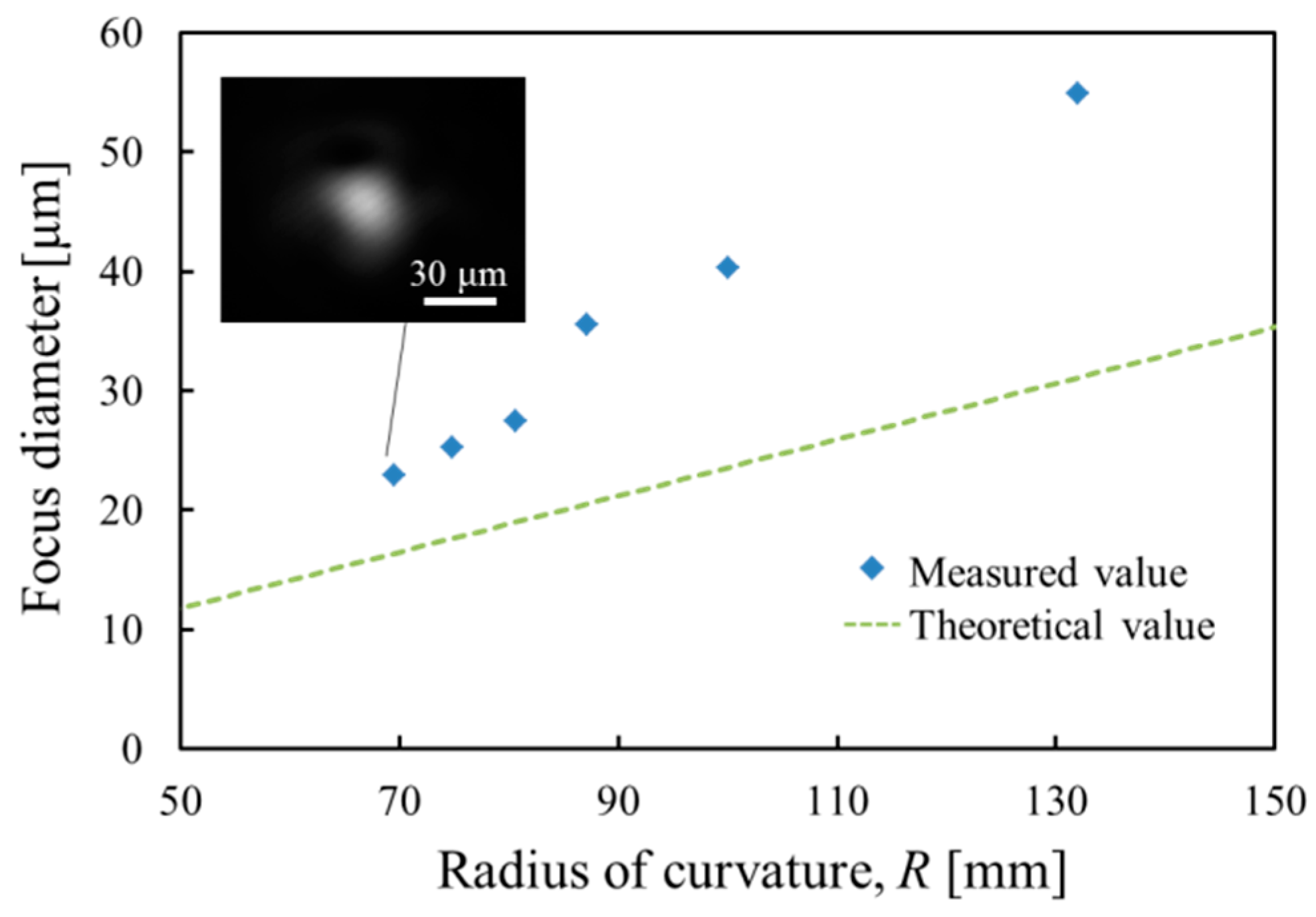

To investigate the focusing function of the varifocal mirror, the focus spot diameter measured as a function of the radius of curvature of the varifocal mirror is shown in

Figure 9. The focus diameter correlates with the image resolution obtained from an instrument using the varifocal mirror. The varifocal mirror is driven at the voltage of 15

VDC + 30

VPP and the frequency of 9.5 kHz. To change the focus, the phase of the laser pulse is changed. The focus spot is obtained by using a charge-coupled device (CCD) camera (UI-2240SE, IDS Imaging Development Systems GmbH, Obersulm, Germany). The intensity distribution of the focus spot is measured using the image analysis software. The theoretical focus diameter

Df is also plotted in

Figure 9, which is defined by full-width-at-half-maximum intensity and expressed as follows [

15],

here, λ is the wavelength of the laser light for measurement,

Rc is the radius of mirror curvature,

Din is the diameter of the incident collimated beam. The value of

Df corresponds to the diffraction limited value. In

Figure 9, the dotted line shows the diffraction limit obtained by Equation (11). The deviation of the measured value from the theoretical value is considered to be caused by the non-parabolic surface profile and the measurement error by laser pulse width. The finite pulse width of the laser irradiation generates the error of measured spot size. For example, because the mirror velocity is nearly zero at the radius of the radius of the curvature of 70 mm, the measurement error by the mirror velocity is negligible as mentioned in

Section 3. The laser spot size enlargement due to the non-parabolic surface profile is estimated to be 30%. At the radius of the curvature of 130 mm, the spot size enlargement is 43%. Because the mirror velocity is not zero, the spot size is enlarged by not only the non-parabolic surface profile but also the measurement error by laser pulse width. The latter is calculated to be 28% and the former is estimated to be 15%.

4.3. Focus Sensor Signal

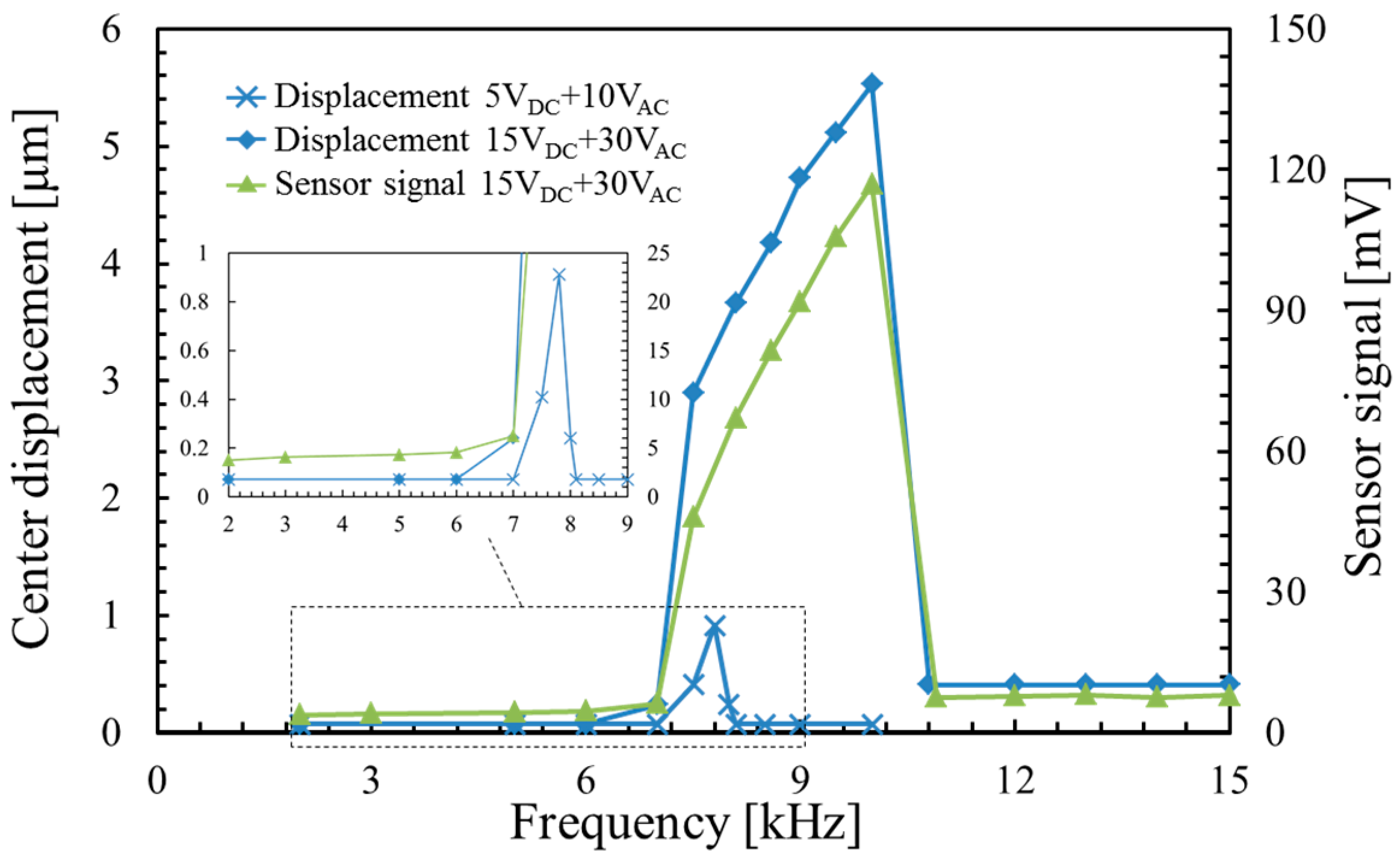

Figure 10 shows the frequency responses of the center displacement of the varifocal mirror and the piezoresistor signal voltage. The sensor signal voltage is given by the peak-to-peak value. The varifocal mirror is driven at the voltage of 15

VDC + 30

VPP and 5

VDC + 10

VPP. The Wheatstone bridge is driven at the voltage of 1.5 V. At the voltage of 5

VDC + 10

VPP, the resonant frequency is 7.8 kHz and the quality factor is 22. In our measurements, the distribution of the resonant frequency for each device is about 1 kHz in the same wafer. The time constant is decided by the focusing, which is approximately 0.1 μs. The resonant frequency is smaller than that obtained by FEM analysis (11.1 kHz). The difference between the measured and the calculated resonant frequency can be attributed to a compressive stress acting on the mirror plate. The deposited aluminum film and the anodic bonding may generate the compressive stress. At the voltage of 15

VDC + 30

VPP, the mirror amplitude increases in the frequency range between 7.5 and 10 kHz. The center displacement at a frequency of 10 kHz is 92 times larger than that in frequency range from 2 to 6 kHz. The piezoresistor signal agrees well with the center displacement of the varifocal mirror. The nonlinear phenomenon is described as follows. At a small voltage of 5

VDC + 10

VAC, although the oscillation curve is slightly asymmetric, it has a peak at 7.8 kHz and does not have the sudden transition observed at the higher voltage as shown in the inset of

Figure 10. Therefore, spring hardening effect is small under the condition. Increasing the applied voltage, the frequency at the peak of the oscillation curve shifts with the increase of the amplitude. The resonant frequency at the voltage of 15

VDC + 30

VAC is larger by a factor of 6 than that at the voltage of 5

VDC + 10

VAC. However, the sudden transition from the peak at the frequency of 10 kHz to the amplitude of 0.41 μm (1/11 of the peak value) is observed at the high voltage. The sudden transition has a hysteresis when the applied voltage is decreased. This phenomenon is explained by the oscillation curve of the spring hardening effect [

16]. The resonant frequency which is corresponding to the frequency at the peak increases because the stress caused by the elongation of the mirror plate increases the stiffness varifocal mirror. Therefore, the resonant frequency of the varifocal mirror depends on the displacement.

In order to estimate the spring hardening effect, a doubly clamped beam is considered as a model of the varifocal mirror for simplicity. For the beam analysis, only longitudinal stress is considered. On the other hand, for the circular plate analysis, the circumferential stress σ

t and the radial stress σ

r are considered. In case of

r = 0,

a/2 and

a, the ratio σ

r/σ

t are equal to 1, 0.5 and 3, respectively [

17]. When the circumferential stress is ignored, the circular plate can be assumed to be the beam. The difference of the stress caused by the spring hardening effect between the circular plate and the beam is estimated to be a few hundred percent by the ratio σ

r/σ

t. Therefore, the doubly-clamped beam can estimate in the same digit. The spring constant of the doubly clamped beam

kN is expressed as follows when a compressive or tensile stress is applied [

18,

19]:

here, σ

N and

b are the stress and the width of the beam, respectively. Here,

j0 is given by:

On the other hand, the resonant frequency

fr of the clamped beam is given by:

where

m is the mass of beam. Using Equations (12)–(14), the stress σ

N of the spring hardening effect can be roughly estimated. The value of the resonant frequency in the small amplitude is obtained from the peak value of the frequency response at 5

VDC + 10

VPP in

Figure 10 to be 7.8 kHz. Similarly, the value of the resonant frequency in large amplitude is estimated from the peak value at 15

VDC + 30

VPP in

Figure 10 to be 10 kHz. The frequency increase from 7.8 to 10 kHz is considered to be changed the stress σ

N of the spring hardening effect. The stress sift is roughly estimated to be 1.7 MPa.

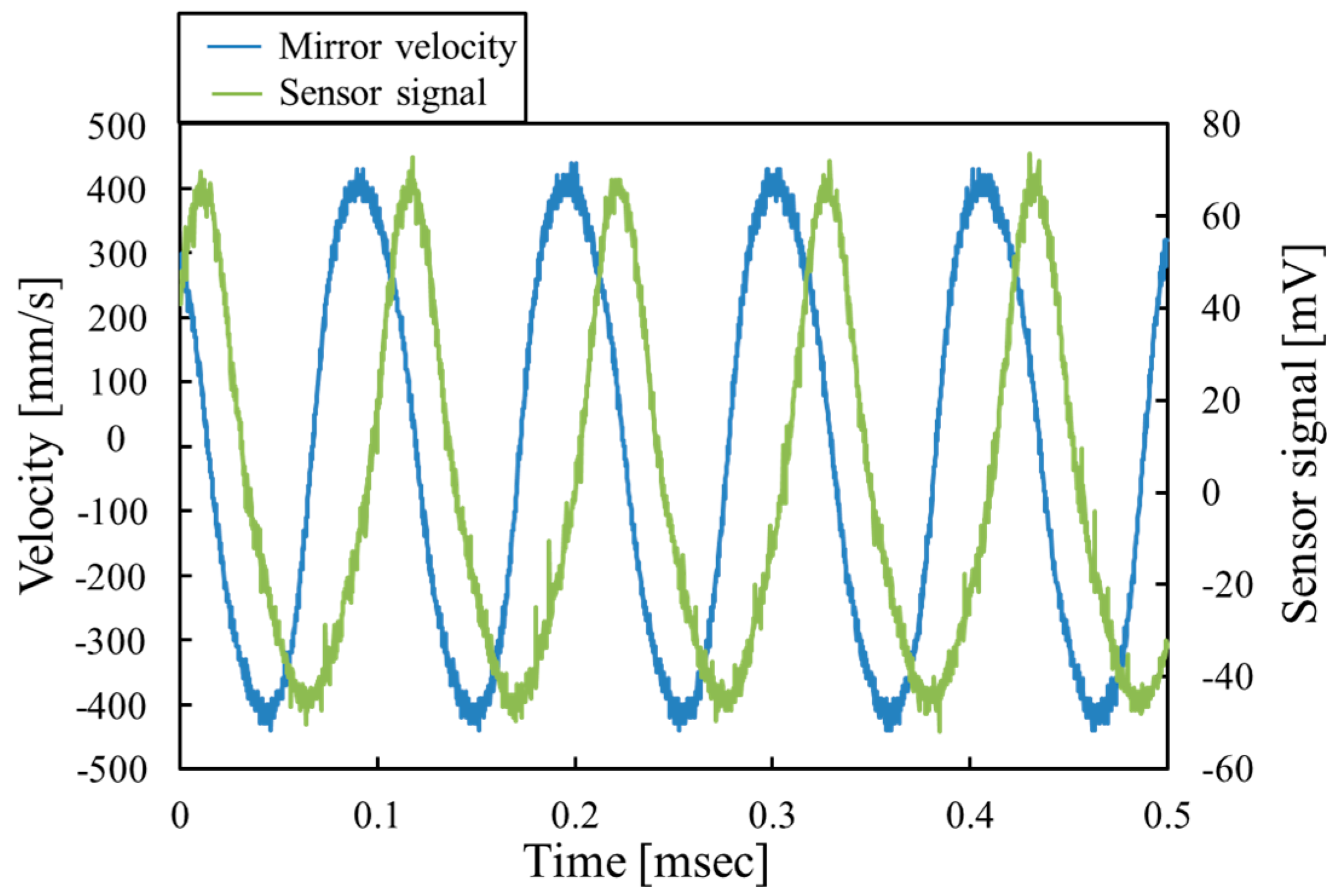

Figure 11 shows the time dependence of the mirror velocity at the center of mirror and the piezoresistor signal at the applied voltage of 15

VDC + 30

VPP and the frequency of 9.5 kHz. The velocity of the varifocal mirror is measured by the laser Doppler vibrometer (MSA500, Polytec GmbH). The surface profile of the mirror plate is concave when the piezoresistor signal voltage is negative.

Figure 11 shows that the varifocal mirror deforms sinusoidally. The signal of the piezoresistor is also periodical and the frequency agrees with that of the mirror velocity. However, the piezoresistor signal varies from −45 to 65 mV and is not completely a pure sinusoidal curve. These facts may be caused by the stress σ

bN causing the spring hardening effect. The stress from the bending σ

b is calculated to be 24.7 MPa by Equation (10). The stress σ

bN causing the nonlinear effect is estimated to be 1.7 MPa from the resonant frequency shift as described above. The stress σ

bN affects the piezoresistor signal because the ratio σ

bN/σ

b is 0.07. A compressive stress σ

b is always applied to the piezoresistor when the mirror shape is concave. In addition, the tensile stress σ

bN caused by the spring hardening effect also acts on the piezoresistor, which compensates the compressive stress σ

b. Similarly, when mirror shape is convex, the tensile stress σ

b caused by the bending of mirror and the tensile stress σ

bN by the spring hardening effect are applied to the piezoresistor. Therefore, the amplitude of the piezoresistor signal voltage decreases when the mirror shape is concave, and, the amplitude increases when the mirror shape is convex. The above discussion can explain the waveform of the sensor signal shown in

Figure 11.

For the actual use, it is important to know the relationship between the curvature of the varifocal mirror and the piezoresistor signal voltage. The curvature as a function of the piezoresistor signal voltage is shown in

Figure 12. The varifocal mirror is driven at the voltage of 15

VDC + 30

VPP and the frequency of 9.5 kHz. The curvature is measured by the two methods. One is by a focal length measurement from the spot size and the other is the measurement of the mirror velocity shown in

Figure 11. The cross mark in

Figure 12 shows the result of the focal length measurement and the solid curve shows the result obtained from

Figure 11. In the focal length measurement, the minimum spot position is measured by changing the distance of the image sensor. In the case of the focal length measurement, the curvature is measured only from 9 to 14 m

−1 due to the limitation of the measurement setup. In the case of the mirror velocity measurement, the mirror velocity is assumed to be sinusoidal and the velocity signal is integrated to obtain the displacement of the varifocal mirror at the center position. Then, the displacement is converted to the curvature assuming the deformed shape is parabolic. The curvature of the varifocal mirror obtained from piezoresistor is in the range from −12.2 to 14.4 m

−1, which correspond to the focal lengths from −41 to 35 mm. The result obtained from the mirror velocity agrees with that of the focal length measurement as shown in

Figure 12. In

Figure 12, the curvature as a function of the piezoresistor signal voltage is not linear as described in the explanation of the waveform in

Figure 11. The nonlinear dependence can be compensated by software when the varifocal mirror is used in application systems. For actual use of the varifocal mirror, the focal length is obtained by the curvature as a function of the piezoresistor signal voltage as shown in

Figure 12. Since the focal length is the inverse of the curvature, the piezoresistor signal can be used as a signal of the focus sensor. From

Figure 12, in the signal region higher than −5 mV, the curvature is negative and the mirror is convex. In this region, the parallel beam is reflected by the mirror and diverges from the mirror. At the sensor voltage of −5 mV, the beam is reflected as it is since the curvature is zero. At the sensor voltage of 65 mV, the laser beam diverges from a virtual image focus at a focal length of −41 mm. In the sensor signal region lower than −5 mV, the curvature is positive and mirror is concave. The parallel laser beam converges on a real focus. At the sensor voltage of −45 mV, the curvature is 14.4 m

−1, which is equal to the real focal length of 35 mm.